Page 1

16-1/2" x 5" Shoe Brake

#1305-2 Brake, Complete Pair

P-1384

819-0116

Installation Instructions

Page 2

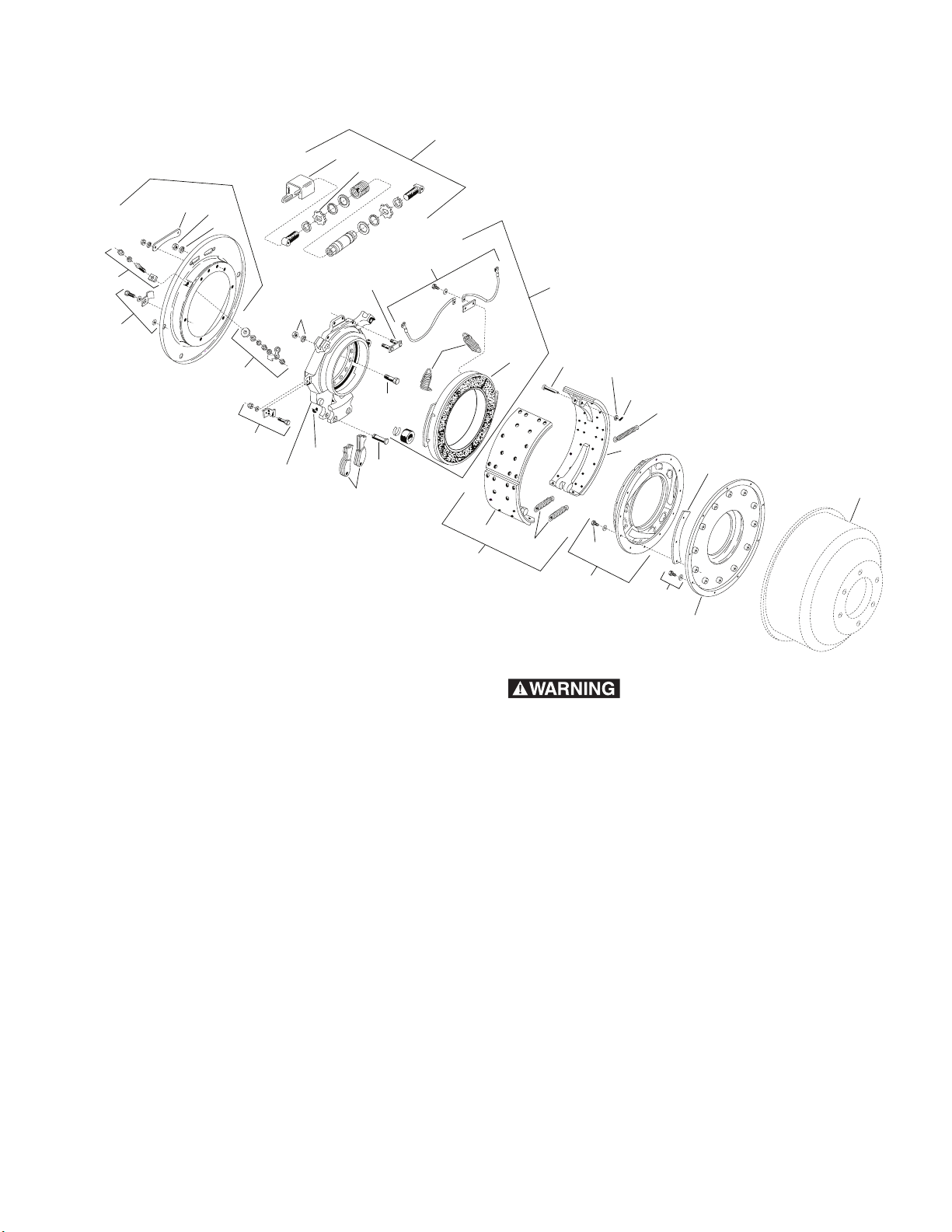

Service Parts and Kits

14

11

11

12

13

14-3

7-1

7-2

7

14-1

14-2

12-4

13

12-3

12-1

12-2

13

10-1

10-3

10-2

9

14-5

14-6

14-4

6

6-1

6-2

6-3

6-1

5

5-1

3

4

2

31

12

7-0

Kit No. 1305-2

Complete Axle Kit

Kit consists of:

1-R.H. Brake Assembly

1-L.H. Brake Assembly

1 - Armature R.H.

1-Armature L.H.

2-Armature Adapter Assemblies

with Grease Guard

1-Brake Mounting Accessory

1-Adapter Mounting Accessory

1-Armature Mounting Accessory

Warner Electric • 800-825-9050 P-1384 • 819-0116

2

instructions may result in product damage,

equipment damage, and serious or fatal injury

to personnel.

General Note

It is suggested that, because of the size and weight of

the components of this brake, the complete assembly

be removed from the vehicle to facilitate handling

while replacing parts.

Failure to follow these

Page 3

Section A – Replacement of Shoe and

Lining Assembly/Kit #1305-100-024 Item 6

NOTE: Two different types of friction material (brake

lining) are used in each half of the shoe and lining

assembly of this size brake. It is important to install

the assembly with the arrow on the trailing shoe and

lining pointing in the direction of forward drum

rotation.

1. Remove drum (31).

2. Remove magnet (7-0).

3. Remove shoe return springs (6-2).

4. Loosen and remove centralizer place nuts (12-1).

5. Lift off old shoe and lining assembly (6-1).

6. Remove bracket (14-1) from adjuster assembly

(14) and remove adjuster spring (6-3), adjusting

nut and screw assembly (14) from shoe

assembly.

7. Clean all brake parts.

Section B – Replacement of Magnet/

Magnet Kit #1305-100-010 (12V) - Item 7

1. Remove drum (31).

2. Remove centralizer plate bolt assembly (14-3).

3. Remove shoe return springs (6-2). See Section

C.

4. Loosen magnet return springs (7-2) from Magnet

Only.

5. Remove magnet lead wires (7-1) from terminal

blocks (13).

6. Loosen and remove magnet hold down brackets

(8) and lift magnet (7-0) off the assembly.

7. Remove magnet lead wires (7-1) from magnet by

opening lead wire hold down clips carefully to

free wires.

8. Clean inside of magnet mounting surfaces.

9. Install new magnet (7-0) on pilot ring and replace

hold down brackets (8). Torque nuts to 10 to 12

ft. lbs.

8. Reinstall adjuster spring (6-3), adjuster assembly

(14), and attaching parts to new shoes and

linings (6-1) with new cotter pins and washers.

9. Place adjuster bracket (14-1) over adjuster (14).

10. Install complete assembly back on brake by

installing centralizer plate (14-3). Do not tighten

centralizer nuts completely yet…allow centralizer

to float.

11. Reinstall magnet (7-0).

12. Reinstall shoe return springs (6-2).

13. Reinstall brake and drum on axle per running

gear manufacturer’s specifications.

14. Remove adjusting cover (12-3) and turn either

adjusting nut (14-2) until brake shoes (6-1) are

expanded tight against drum (31).

15. Tighten centralizer plate nuts (12-1) against

lockwashers (12-2). Torque to 18 to 20 ft. lbs.

16. Back off adjuster (14-2) until drum turns freely

(approximately 5 or 6 notches).

10. Reconnect magnet leads (7-1) to magnet and

terminal blocks (13). Torque nuts (8) to 59 to 65

in. lbs. Torque screws (13) to 15 to 17 in. lbs.

11. Connect magnet return springs (7-2) to new

magnet.

12. Reconnect shoe return springs (6-2) per

instructions in Section C.

13. Reinstall centralizer plate (14-3) and adjust per

instructions in Section A.

14. Replace drum (31) and reassemble running gear

per manufacturer’s specifications.

Replacement of Magnet Lead Wires only:

Kit #1305-100-012 - Item 7-1

1. Remove magnet (7-0) from brake.

2. Spread lead wire hold down clips on magnets

carefully to free wires.

3. Loosen terminal screws (13) and remove lead

wires (7-1) from terminal.

17. Replace adjusting opening cover (12-3). Torque

nuts 68 to 76 in. lbs.

Warner Electric • 800-825-9050 P-1384 • 819-0116

4. Install new lead wires (7-1) on terminal. Torque

screws (13) to 15 to 17 in. lbs.

5. Close magnet lead wire hold down clips securely

over the new leads (7-1).

6. Replace magnet (7-0) on brake.

3

Page 4

Section C – Replacement of Springs

Shoe Return Spring Kit #1305-100-018 - Item 6-2

1 – Adjuster Spring

2 – Shoe Return Springs

Magnet Return Spring Kit #1302-100-009 - Item 7-2

1 – Magnet Return Spring R.H.

1 – Magnet Return Spring L.H.

Replacement of Adjuster Spring Item 6-2

1. Remove cotter pins (14-4) and washers

(14-6).

2. Grasp one end of spring (6-3) with pliers and

remove from shoe pin (14-5).

3. Remove spring from other shoe pin.

Replacement of Shoe Return Springs

1. Remove drum (31).

2. Grasp one end of return spring (6-2) loop using

commercial spring pliers. Anchor other jaw of the

pliers in nearest brake lining rivet hole. By

squeezing pliers closed, the loop end can be

released from the brake shoe hole.

3. After one end of spring has been released the

other loop can be easily removed.

To Install New Shoe Return Springs

1. Insert one loop of return spring (6-2) in a shoe hole

with hook pointing toward center of brake.

2. Grasp other loop with spring pliers. Place other

jaw of spring pliers in nearest brake lining rivet

hole.

3. Squeeze pliers to close, extending spring loop to

the other shoe end hole for anchoring.

4. Replace drum and readjust brake per steps 13, 14,

15, 16 and 17 of Section A.

Replacement of Magnet Return Springs Item 7-2

NOTE: These springs must be installed on the proper

side of the magnet; i.e., either right or left when

facing the magnet. Before removing old springs, look

closely at the location of the larger hook end of the

spring. Install new springs in the same manner.

4. Place hook of new adjuster spring (6-3) on one

pin (14-5), extend spring, and connect to other

shoe pin.

5. Replace washer (14-6) and cotter pins

(14-4).

Section D – Replacement of Terminal

Block and Studs, Dust Covers, Cams Items 12 and 13

Replacement of Terminal Block and

Studs/ Kit #1305-100-013 - Item 13

1. Remove drum (31).

2. Remove shoe return springs (6-2) and expand

shoes (6-1) by hand.

3. Loosen and remove all nuts (13) from terminals

(13). Push terminals out of brake

4. Install new terminal blocks (13) and studs (13)

and replace the nuts (13) in order shown in exploded view. Torque nuts to 59 to 65 in. lbs.

5. Reinstall shoe return springs (6-2) and drum (31)

per procedure in Section C.

Replacement of Dust Cover/

Kit #1305-100-022 - Item 12

1. Remove brake assembly from axle flange.

2. Remove shoe return springs (6-2) and open

shoes (6-1) by hand.

1. Remove drum (31).

1a. Locate magnet (7-0).

2. Using pliers, remove return spring (7-2) from

magnet clips.

3. Disengage other hook from brackets on

spider (9).

4. Install new spring in proper location; i.e., right or

left side of magnet.

5. Replace drum (31) and reassemble running gear

per manufacturer’s specifications.

Warner Electric • 800-825-9050 P-1384 • 819-0116

4

3. Remove terminal blocks and studs per above

procedure.

4. Invert brake and remove (6)-5/16" cap screws

(12-4), holding dust cover.

5. Install new dust cover and replace cap screws

(12-4). Torque to 125 to 139 in. lbs.

6. Reinstall terminal blocks and studs per above

procedure.

7. Reposition shoes (6-1) and reinstall shoe return

springs (6-2) per procedure in Section C.

Page 5

Replacement of Cams/Kit #1305-100-020

- Item 10

1. Remove drum (31).

2. Remove shoe return springs (6-2) and spread

shoes (6-1) by hand.

3. Remove retaining rings (10-1) from cam pins

(10-2) on spider (9).

4. Push out pins (10-2) and remove cams (10-3).

5. Install new pins (10-2) and cams (10-3) in order

shown on exploded view. Lock assembly with

retaining rings (10-1).

6. Reposition shoes (6-1) and shoe return springs

(6-2).

7. Replace drum (31) and reinstall running gear per

manufacturer’s specifications.

B. Being careful not to compress the clay, bolt

the armature into the drum.

C. Install the drum on the axle, so there is no

free play.

D. Remove the drum from the axle.

E. Remove the armature from the drum.

F. Measure the thickness of the clay. It should

be about 1/8”. If it is greater than 1/8”, add

shims between the armature and the drum,

and repeat steps A through E.

…this should be between 1/8" and 3/16".

Correct, if necessary, using shims (4) or

hardened spacer rings between armature

and grease guard.

7. Inspect magnet (7-0) to determine if it should be

refaced or replaced.

Section E – Replacement of Armature/

Armature Kits #1305-100-015 R.H.;

#1305-100-016 L.H. - Item 5

NOTE: Warner Electric armatures for this size brake

are designed for use on either the right-hand side

or left-hand side of the trailer when looking toward

the towing vehicle. The armatures are not

interchangeable and must be installed on the

correct side of the trailer. The armatures have a

designating “R” or “L” on the mounting ring.

1. Remove hub, wheel, and drum (31) from trailer.

2. Remove twelve armature mounting screws (5-1)

from grease guard/adapter (2).

3. Lift out old armature (5) and any shims (4) that

may be installed. Clean armature mounting

surface on grease guard (2).

4. Remove and clean grease guard/adapter (2) by

loosening nine screws (3) holding guard on drum.

5. Reinstall grease guard/adapter (2) in drum.

Torque screws to 69-75 in. lbs. Install new

armature (5) on grease guard using twelve

armature mounting screws. Torque screws to

69 to 75 in. lbs.

8. Reassemble running gear per manufacturer’s

specifications.

Important Notice to Purchaser: Since

neither the manufacturer nor the seller of this

product can control the manner in which it is

installed or used, or the suitability of components

used in conjunction with it, the installer and

ultimate user assume all risks and liabilities

appurtenant to installation and conjunctive use.

Therefore, appropriate steps should be taken in

advance by every purchaser and user to insure that

the product is assembled properly with suitable

component elements, and is used in compliance

with generally accepted industry practice, in

accordance with the instruction manual and as

supplemented by other information contained

herein.

6. Check armature depression by following these

steps:

A. Place a 1/4” ball of modeling clay between

each armature tab, and the mounting plate.

Warner Electric • 800-825-9050 P-1384 • 819-0116

5

Page 6

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you at

your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights

and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-1384 • 819-0116 6/12 Printed in USA

Loading...

Loading...