Page 1

12 Volt Load Control for Electric

Brake Systems No. 1300-78

P-1385

819-0128

Installation Instructions

Page 2

The Warner Electric Load Control provides the

Mount on either side

12v

Battery

Stoplight

switch

Utility controller

mounted on dash

Fuse

Red

Blue

Socket

to Stoplight

Starter

Black

10 Gauge Wire

recommended

Load control

1300-78

(Optional)

Typical Wiring Diagram

Warner Load Control 1300-78

capability to properly proportion the braking

power of the trailer brakes to the trailer weight.

The Load Control is a variable resistor which

allows the operator to reduce current flow to the

trailer brakes by turning the control knob.

Depending on road conditions and trailer load,

the knob can be set at any position between

“MIN BRAKE” and “MAX BRAKE”. The Load

Control provides a broad range of adjustment to

suit a wide variety of operating conditions.

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Specifications

Resistance Rating: 0-5 ohms

Voltage: 12 volts DC

(use only with 12 volt system)

Brake Coil: Designed for 2-4 brakes wired in

parallel, each with 3.0-3.5 ohms coil resistance.

Installation

Mounting the Control

The Load Control should be mounted under

or behind the towing vehicle’s instrument panel

to the left or right of the steering column,

depending on available space and driver

preference.

For under-dash mounting proceed as follows:

1. While holding the Load Control case in

position, mark the underside of the

instrument panel through the two mounting

holes in the case.

2. Drill two 13/64" diameter holes where

marked, being careful not to damage

anything under the instrument panel.

For behind instrument panel mounting proceed

as follows:

1. Position the face of the Load Control shaft

hole and the washer projection hole.

2. Drill a 13/32" diameter hole for the Load

Control shaft and a 3/16" diameter hole for

the washer projection, where marked. Be

careful not to damage anything under the

instrument panel.

Electrical Connection

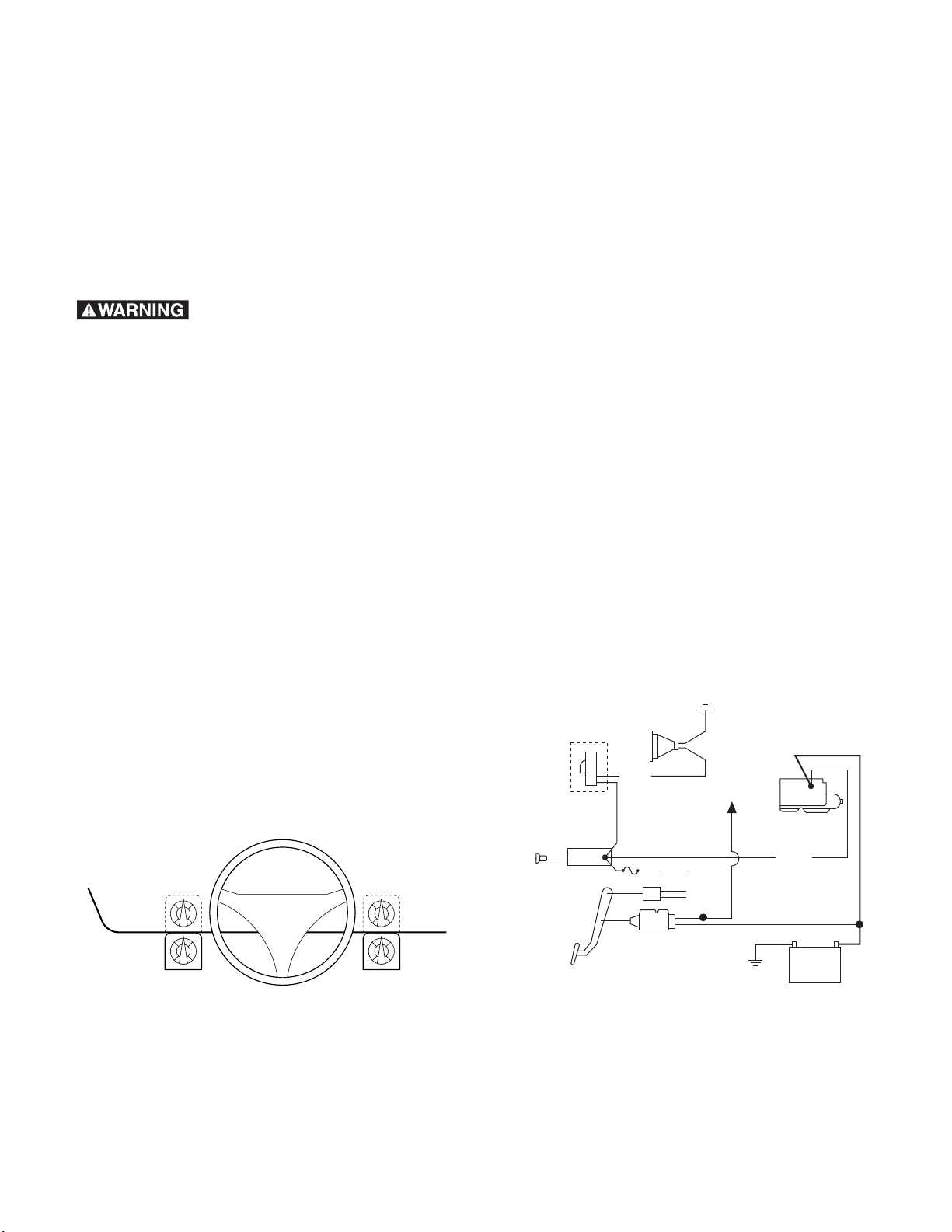

The Load Control is to be wired in series with

the electric brake controller and the trailer

brakes. Refer to the “Typical Wiring Diagram”

to connect the Load Control into the brake

system. (See Figure 2)

To mount the Load Control, sit in a normal

driving position and place the Control case so

its knob is within easy reach. (See Figure 1)

2

Warner Electric • 800-825-9050 P-1385 • 819-0128

Figure 1

Figure 2

Page 3

NOTE: Use only 10 or 12 gauge wire meeting SAE

Specification J558a for connecting the Load

Control.

Strip the insulation back about 1/4" from each cut

end. Insert one stripped end into each of the two

insulated ring terminals provided. After inserting

the full length of bared wire, crimp the terminal

using AMP hand tool 59239-4 (G9150-7 for

thinwall insulation) or equivalent. Assemble the

wired terminals to the Load Control, but do not

tighten. One lead is to be attached to the center

terminal, the other to the left hand (heavy

resistance wire side of the resistor) terminal when

facing the rear of the resistor. (See Figure 3)

Figure 3

Under Instrument Panel Installation

Mount the case under the instrument panel,

inserting the tapping screws (with heads inside the

control case) provided through the newly-drilled

holes and tightening securely to the speednuts

included with your Load Control.

Remove the jam nut from the Load Control shaft

and insert the shaft and the washer projection into

the holes provided in the front portion of the case.

Place the Load Control into the case so the

washer projection protrudes through the case

front. Position the dial face on the case and

tighten the jam nut securely with the washer

locating tab projecting through its locator hole.

Assemble the hand knob to the control shaft,

positioning it so the knob screw opposite the

pointer sets against the control shaft flat. Tighten

the setscrews securely. Tighten both electrical

terminal connections, carefully positioning the

lead wires so the ring terminals will not contact

the sides of the case.

Behind Instrument Panel Installation

Remove the jam nut from the Load Control shaft

and insert the shaft and the washer projection

into the holes provided in the front portion of

the case.

Insert the Load Control into its case so the

washer locating tab protrudes through the case

front. Insert the control shaft and locating tab

into the holes provided in the instrument panel.

Position the dial face on the control shaft and

tighten the jam nut securely with the washer

locating tab projecting through the case

instrument panel, and dial face. Assemble the

hand knob to the control shaft, positioning it

so the knob setscrew opposite the pointer sets

against the control shaft flat. Tighten the

setscrew securely. Tighten both electrical

terminal connections, carefully positioning the

lead wires so the ring terminals will not contact

the sides of the case.

Since the Load Control can

become very warm during normal operation,

the case must be used with the control

whether it is mounted under or behind the

instrument panel. When installing the Load

Control, take care to assure that all electrical

wires and other underdash components are

securely fastened to prevent accidental

contact with the resistor winding.

Adjustment

Your Warner Electric Load Control will help

compensate for trailer load variations by limiting

the maximum torque output of the brakes by

adding dropping resistance in the electrical

control line. When towing a trailer loaded to

brake rated capacity, the Load Control must be

set at maximum braking. When pulling an empty

or partially loaded trailer, the Load Control must

be set between maximum and minimum braking

at a position just before the point at which trailer

tire skidding occurs when actuating the hand

control fully on. Failure to use the Warner Electric

Load Control properly can result in excessive

brake torque when stopping a trailer loaded to

less than brake capacity.

Warner Electric • 800-825-9050 P-1385 • 819-0128

3

Page 4

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within a

period of one (1) year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may

be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner

Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you will

be notified and, with your consent, the item will be repaired or replaced and returned to you at your

expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any defective

product. Warner Electric LLC neither assumes nor authorizes any other person to give any other

warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished without

charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-1385 • 819-0128 6/12 Printed in USA

Loading...

Loading...