Page 1

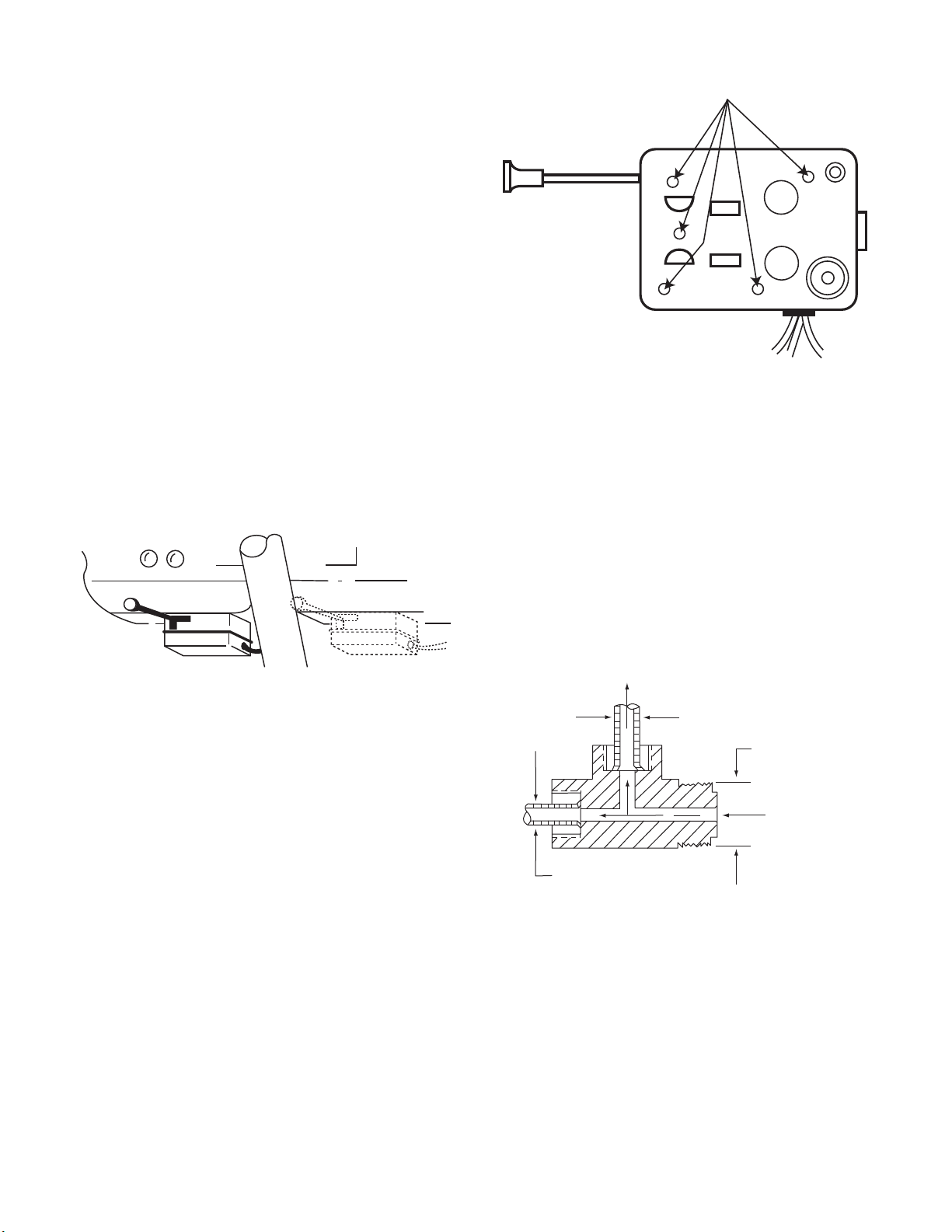

12 Volt Utility Controller

for 4, 6, or 8 Brakes No. 1300-76

P-1396

819-0301

Installation Instructions

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mounting Under Instrument Panel . . . . . . . . . . . 3

Hydraulic Connection . . . . . . . . . . . . . . . . . . . . . 3

Electrical Connection . . . . . . . . . . . . . . . . . . . . . 5

Sensitivity Adjustment . . . . . . . . . . . . . . . . . . . . 6

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . 7

Warranty . . . . . . . . . . . . . . . . . . . . . . . back cover

Introduction

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal injury

to personnel.

The Warner Electric hydraulic/manual Utility

Controller combines manual and automatic

(hydraulic) actuation for the operation of 4, 6,

or 8 twelve volt electric wheel brakes. Some

of the features of this controller are:

• Can be installed to operate automatically

and/or manually.

• Permits manual over-ride of automatic

operation.

Adjustment Knob

• Brake pedal operated when connected into

towing vehicle hydraulic system.

• Highly sensitive for accurate brake control.

• Wide range of adjustability to compensate for

varying loads and changing road conditions.

• Rated at 30 amperes.

• Low hydraulic fluid displacement – less than

.02 cu. in.

Control Lever

Cover Retaining Screw

Hydraulic Connection

Connection Wires

Warner Electric • 800-825-9050 P-1396 • 819-0301

2

Page 3

Installation

Master Cylinder

Tubing "A" O.D.

Inverted Flare Tube Nut Tee Fittings

For Warner Controllers

Hydraulic Supply

For Rear Brakes

Master Cylinder

Thread Size "B"

3/16 O.D. Tubing Supplied

with Controller

To Controller

F

These instructions provide for ease of

installation. Please follow them carefully.

The basic installation steps are:

1. Mount the controller inside the towing vehicle.

2. Connect the controller into the towing

vehicle’s hydraulic system.

3. Connect the controller electrically.

4. Adjust the controller for synchronized braking.

Mounting Holes

Mounting Under Instrument Panel

1. Position the controller under the instrument

panel to the left or right of the steering

column, based on available space and

driver preference.

Mount on Either Side

Figure 1

2. While sitting in a normal driving position,

place the controller so its handle is within

easy reach.

3. Remove the controller cover and, while

holding the controller in place, select at least

two holes through the case which best mount

the controller. Mark the underside of the

instrument panel through these holes.

Figure 2

Hydraulic Connection

1. To provide for automatic actuation of the

controller, a branch tee must be installed in

the hydraulic brake system. Tees are not

furnished with the controller kit because

requirements vary with different makes and

models of towing vehicles. To determine tee

size, measure A and B dimensions from the

towing vehicle’s master cylinder as illustrated

in Figure 3.

4. Drill 3/16" diameter holes where marked,

being careful not to damage anything under

the instrument panel.

5. Attach the controller with 3/16" bolts, nuts

and lock washers, and tighten securely. Bolt

heads are to be inside the controller.

Warner Electric • 800-825-9050 P-1396 • 819-0301

Figure 3

3

Page 4

2. On towing vehicles with dual brake systems

Master

Cylinder

Fire Wall

Controller

Grommet

and Tape

Tee Fitting

(Connection Made on

Output Side of Booster)

Series

Power

Brake

Typical Installation in Series Type Power Brake System

To Front

Brakes

To Rear Brakes

Grommet

or Sealant

Utility

Controller

Fire Wall

Master Cylinder

Adapter

Tee

Typical hydraulic connection arrangement

showing controller, tubing and tee fitting.

(built since 1966) the controller must be

connected to the rear brake portions of

the system.

Note: The rear portion of a master cylinder

does not always control the rear brakes.

Trace the hydraulic tubing to be sure

connections are made in the rear brake

system.

3. Controller Installation in Series Type Power

Brake System. When installing a controller

in a series type power brake system (typically

used in trucks), the connection must be made

on the output side (high pressure side) of the

booster as shown in the figure below.

Determine the correct Tow Craft tee fitting

size by measurement of mating connections.

5. Uncoil the tubing provided. Avoid sharp

bending which could cause kinks. Leave one

or more loops of tubing on the engine side of

the firewall to absorb vibration. To insure that

the tubing remains clean, place a rag over the

exposed end. Feed the tubing through a hole

in the firewall, positioning it to avoid hot

engine members or any surface which

could damage it.

6. Connect the tubing to the branch junction

of the tee and tighten the tubing nut (to

approximately 150 in. lbs.).

Figure 4

4. Disconnect the rear supply line at the master

cylinder (except where adapter fitting is used

or when installation is made in a series type

power brake system – see Figure 5) and

install the tee fitting according to the towing

vehicle manufacturer’s recommendations.

over-tightening at all connections.

Avoid cross-threading and

Figure 5

7. Connect the other end, with male tubing nut,

to the female fitting on the controller cylinder,

but do not hand tighten completely. Take care

not to deform the female thread of the fitting,

which has been pre-tightened during

assembly of the controller.

8. To bleed the hydraulic system, wrap a rag

around this connection and depress the brake

pedal slowly and often enough to fill the

tubing with fluid. All air must be bled from

this line. When hydraulic fluid appears on

the rag, remove it and tighten the tubing nut

securely to stop all leakage (correct torque

approximately 150 in. lbs.), while the pedal is

depressed. The factory installed controller

fitting should not be retightened.

When the tubing nut is

tightened, use a wrench to hold female

fitting. Rocking the female fitting will

cause leakage at the threads.

Warner Electric • 800-825-9050 P-1396 • 819-0301

4

Page 5

Figure 6

9. To test for sponginess and leaks, pump the

brake pedal and hold it depressed for

approximately one minute. If sponginess

exists, the entire system should be bled at

the wheel cylinders. Refill the master cylinder

fluid reservoir as required.

Electrical Connection

1. Electrical connection is required for all

installations. Approximately 25 ft. of

automotive-type multistranded 12 gauge or

heavier single wire with tough, thermoplastic

insulation meeting SAE standard J558a is

required.

4. Remove a knock-out plug or cut a hole in the

firewall near the mounted controller.

5. Cut the wire to a proper length for reaching

the controller. Strip the wire and feed it

through the firewall hole.

6. Connect this wire to the blue brake lead wire

extending from the back of the controller.

Note: Solder or crimp clamp connections

will be required when connecting all three

controller lead wires. Wrap electrician’s

tape around all bare wire joints. Do NOT

use twist-type connectors.

7. Making a chassis ground connection is the

next installation step. Strip one end of the

remaining length of hook-up wire and connect

it securely to the ground terminal of the

socket at the rear of the towing vehicle.

8. Feed the wire under the towing vehicle to a

convenient chassis ground, such as a body

or chassis nut and bolt, battery ground-post,

etc. Cut and strip the wire and attach it

securely to this ground. A good ground

connection is essential for proper

operation.

Note: When towing a trailer which will carry

variable loads, or which is light weight when

compared with its brake capacity, a Warner

Electric Load Control part No. 1300-78, may

be required to properly proportion braking

force between the trailer and the towing

vehicle. See Optional Equipment.

9. Two Utility Controllers leads are still to be

connected. The red lead actuates the

stoplights when the controller is operated

manually. An interrupted stoplight circuit for

turn signals is used on most towing vehicles.

Connect the controller’s red lead to the output

side of the towing vehicle stoplight switch.

(This switch could be a pressure switch

2. An electrical socket which mates with the

trailer power cable is to be installed in the

rear of the towing vehicle. Strip one end of

the hook-up wire and connect it to the brake

terminal of this socket.

3. Secure a single length of wire from the brake

connection of the socket to the underside of

the towing vehicle and lead it to the engine

firewall. Position the wire to insure maximum

protection from scraping on the road surface

located in the brake line or a limit switch

activated by the brake pedal.) Connect an

inline fuse in series between the red lead and

the stoplight switch. This fuse should be the

same type and rating as recommended for

the tow vehicle’s existing stoplight circuit.

Splice a short length of hook-up wire to the

red lead to reach the stoplight switch output.

If your towing vehicle has some other system,

consult your automotive dealer.

in rough terrain, flying stones, spray, etc. Also

avoid attaching wires near mufflers and

exhaust pipes. Wires should be clamped at

frequent intervals.

Warner Electric • 800-825-9050 P-1396 • 819-0301

5

Page 6

BLUE

SOCKET

TO STOPLIGHT

10 GAU GE W IR E

RECOMMENDED

LOAD CONTROL

1300-78

OPTIONAL

UTILITY CONTROLLER

MOUNTED ON DASH

MECHANICAL

STOPLIGHT

SIGNAL

STOPLIGHT

SWITCH

RED

FUSE

BATT ERY

BLACK

10 GAU GE W IR E

RECOMMENDED

STAR TE R

Figure 7

10. The black or power lead of the controller is

last to be connected. Enough hook-up wire

should remain to make this connection.

Strip one end of this hook-up wire and feed

it through a hole in the firewall from the

engine side. Solder or crimp clamp this

wire to the black controller lead.

11. Detach one of the power cables from the

towing vehicle battery to prevent arcing.

12. Cut the hook-up wire to the proper length

to attach it to the live terminal of the starter

solenoid or relay, strip the wire and

complete the connection. Attaching this

lead completes your electrical connection.

Re-connect the towing vehicle battery

cable.

13. Tape together wires leading from the

controller and secure them to the steering

column or underside of the dash. Plug all

holes in the fire wall with sealant or rubber

grommets to prevent exhaust gases from

6

entering through the holes and to protect

the wires from abrasion.

Warner Electric • 800-825-9050 P-1396 • 819-0301

Sensitivity Adjustment

After the entire controller system is installed and

operating, the controller sensitivity must be

adjusted to synchronize the towing vehicle and

trailer braking systems. Proper adjustment of

your controller/braking system is important

for safe automatic operation.

Warner Electric’s Utility Controller has an

adjustment knob to control trailer brake

sensitivity. This adjustment does not affect

maximum braking capacity of the trailer brakes.

Because of the wide variety of towing vehicles

encountered, balancing towing vehicle brakes

and trailer brakes is necessary for smooth,

synchronized stops. To achieve this, the

controller adjustment should be hand set to

provide a slight lead in trailer braking over towing vehicle braking. Setting the adjustment in the

“MORE” brake direction will increase the trailer

brake rate of application, while setting in the

“LESS” direction will decrease the trailer brake

rate of application. When proper adjustment has

been achieved, there should be no sensation of

the trailer pushing or pulling the towing vehicle

during a stop. When this setting has been

reached, no further adjustment should be

required. For operating with varying load

weights, read the following section on “Optional

Equipment.”

Page 7

Optional Equipment

When the trailer load is variable or less than

trailer brake capacity, a Warner Electric Load

Control, part no. 1300-78 should be added in

series with the brake circuit. The Load Control

provides the capability to properly proportion the

braking power of the trailer brakes to the trailer

weight. The Load Control is connected into the

trailer brake wire connected to the blue lead

from the controller. Its position is shown in the

wiring diagram under “Electrical Connection.”

The illustration shows the simplicity of adjusting

this resistor to increase or decrease trailer brake

torque. Contact your Warner Electric distributor

or the factory if you require additional

information.

Warner Electric • 800-825-9050 P-1396 • 819-0301

7

Page 8

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within a

period of one (1) year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner

Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges

prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by

writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit,

Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made, without

charge, together with a refund for transportation costs. If found not to be defective, you will be notified and,

with your consent, the item will be repaired or replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not

apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any defective

product. Warner Electric LLC neither assumes nor authorizes any other person to give any other warranty

or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice.

Weights do not include weight of boxing for shipment. Certified prints will be furnished without charge on

request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-0301 • 819-1396 6/12 Printed in USA

Loading...

Loading...