Warner TCS-200-1, TCS-200-1H Service & Installation Manual

P-2003-2-WE

819-0420

TCS-200-1 and TCS-200-1H

Tension Controls

Service & Installation Instructions

An Altra Industrial Motion Company

Contents

Introduction ............................2

Theory of Operation ......................3

Technical Specifications ..................3

Installation

Control Mounting .....................4

External Sensor Mounting...............5

System Wiring ..........................5

System Start-Up and Adjustment ..........11

Voltage Tables .........................19

System Troubleshooting .................20

Component Parts List

Coupling, MCS-605-1 284-8000-003

Roll Pin (Drive) for Sensor Coupling 679-8001-067

TCS-200-1 Tension Control 6910-448-086

TCS-200-1H Tension Control 6910-448-087

Ultrasonic Sensor 4-40in 7600-448-001

List of Illustrations and Figures

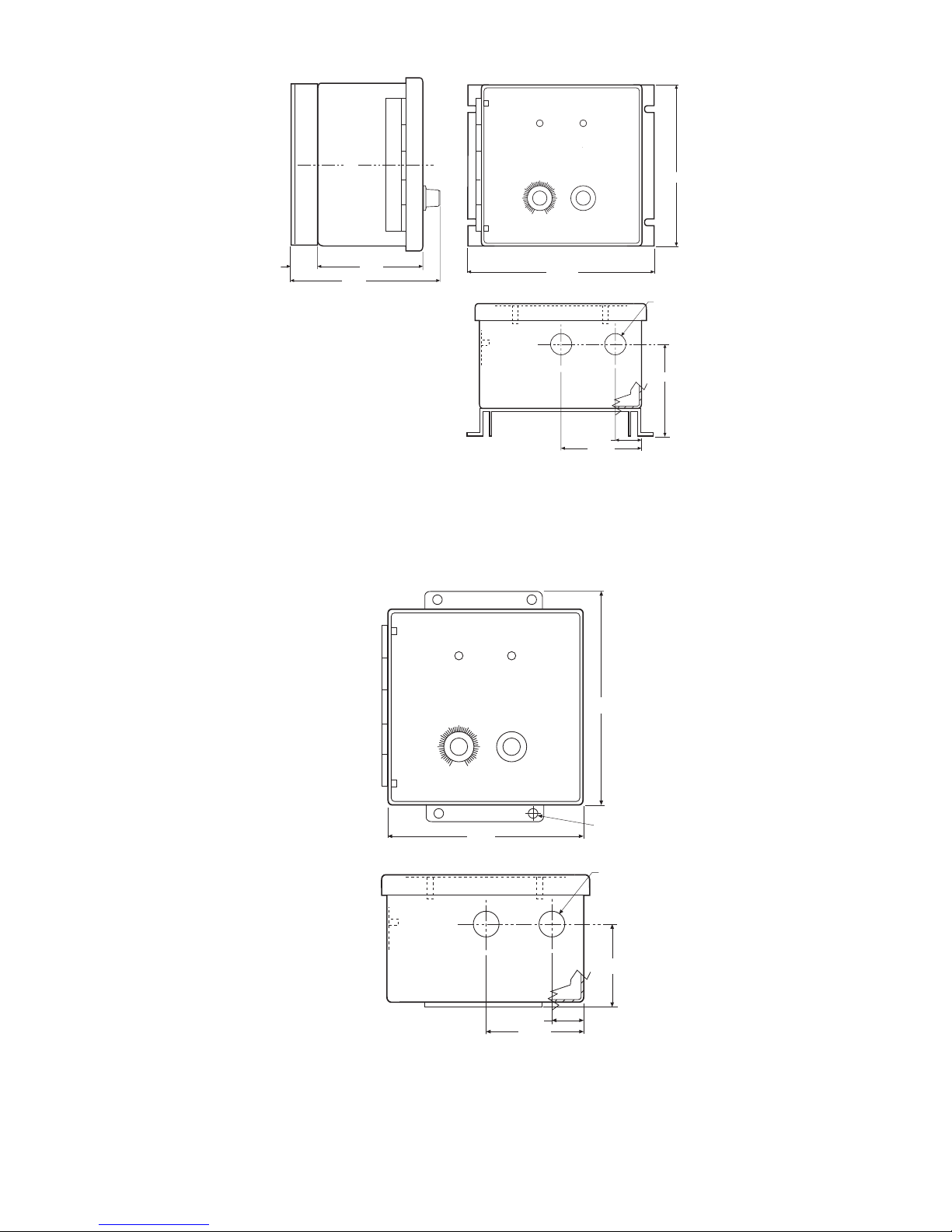

Figure 1 Dimensional Data, Mounting ....... 6

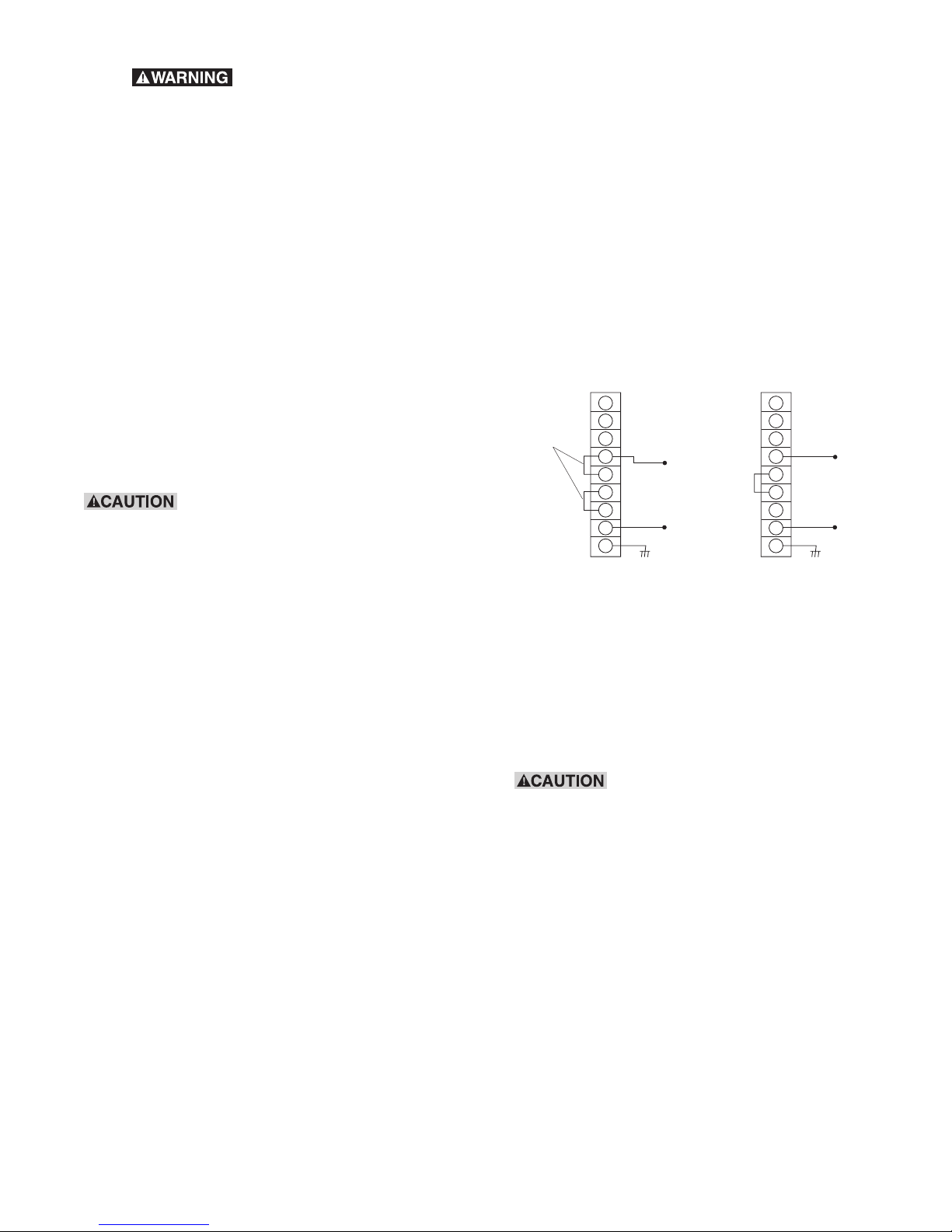

Figure 2 Power Connections .............. 7

Figure 3 Brake Connections ..............8

Figure 4 Remote Torque and Roll

Follower Connections ............. 9

Figure 5 Remote Switch, Analog Input and

Analog Input Isolation Connections . 10

Tables 1,2,3 Voltage/Current Tables .......... 19

Templates TCS-200-1H Template ........... 21

TCS-200-1 Template ............ 21

Introduction

The Warner Electric Tension Control system is

comprised of a tension brake, control module, and

optional external sensor input.

This manual has been designed to cover installation,

start-up, adjustment, and maintenance of your

tension control system and covers the control system

only. Further information on brake sizing and selection

can be found in catalogs P-1234 or P-771.

Power Source

The TCS-200-1 series Tension Controls operates

from a power source of 115 or 230 VAC, 50/60 Hz

input. Primary voltage is determined by the

customer’s input voltage source. The control is

factory set to accept 115 VAC input. Refer to the

wiring section for 230 VAC input connections.

Control

The TCS-200-1 series controls are selectable

voltage or current controlled power supply designed

to power up to a 16 magnet Electro Disc tension

brake system, Electromagnetic Particle Brakes,

TB series brakes or Advanced Technology tension

brakes. This control can be operated manually from

the front panel or remotely via an analog voltage

input, a current input, a remote pot, or a roll follower.

External inputs are also provided for remote brake

“off”, “run”, and “stop” functions, as well as front

panel control of these functions.

The analog voltage and current inputs are

electrically isolated from the main power circuitry of

the control when 15-35 VDC supply is provided to

maintain full isolation. If isolation is not needed, an on

board 15 VDC supply is jumpered to act as a default.

Sensors

When the TCS-200-1 series controls are operated

in a remote torque adjust mode, a 1,000 ohm

potentiometer is required. This should be a linear type

potentiometer with a rating of .5 watts, 10 percent

tolerance, and a .5 percent linearity.

For roll follower input applications, a 1,000 ohm

potentiometer with a rating of .5 watts, 10 percent

tolerance, and .5 percent linearity is required for best

performance.

Brakes

All 24 VDC tension brakes that Warner Electric offers,

to a maximum of 4.25 amps, can be used with the

TCS-200-1 tension control. For all 24 VDC tension

brakes that require greater current capability from the

control (not to exceed 5.8 amps), use a TCS-2001H. The brake converts electrical current supplied by

the control into torque, which retards material flow,

maintaining the desired web tension.

2 Warner Electric • 800-825-9050 P-2003-2 • 819-0420

Theory of Operation

When in operation, the control is powered by a

standard 115/230 VAC line. The control has a

transformer that converts that voltage to a level

suitable for any 24 VDC brake system. The signal is

rectified to DC and pulse width modulated (PWM) to

the desired brake current via the TENSION ADJUST

knob.

The front panel TENSION ADJUST feeds a small

voltage to a comparator, which compares this signal

to a triangular wave. This is where the PWM pulse is

generated. This pulse is then inverted and used to

drive a power circuit. The main brakes and a sense

brake are then energized by the power circuit at

regular intervals. From the sense brake, a growth and

decay signal is converted to a voltage that can be

added to the signal by setting a jumper on the inside

of the cover. This signal, when selected, is used to

maintain constant current to the brake. The signal

must not be selected when no sense brake is

connected.

The control has several options that allow for

external/remote tension adjust in addition to the

tension adjust pot on the front of the panel. Two such

options are the remote pot or a roll follower. Another

is the option for an analog input of voltage or current

from a PLC or ultrasonic sensor. A special feature of

the analog inputs is that they are optically isolated

from the rest of the control circuitry if an external

power source is used to power the isolated circuits.

The isolation is needed when using a PLC or an

external power supply for the ultrasonic sensor. An

internal power source is also available and jumpered

in as default if isolation is not necessary. The tension

adjust pot on the front of the panel becomes a span

adjust when any of the external control options are

connected.

The two indicators on the front of the panel are

green for “power on” and red to indicate a short

circuit. When a short occurs in the brake, the control

disables the power circuits to prevent damage. Turn

the switch to “off” to reset the short circuit indicator.

Because this is a basic tension control, no anti-residual

circuits, zero adjust circuits, or other complex control

circuits (found in other Warner Electric tension control

systems) are included in the TCS-200-1 series controls.

Technical Specifications

TCS200-1 and TCS200-1H

Input Power

115/230 VAC 50/60 Hz

Output TCS-200-1

Adjustable 0-24 VDC. Maximum of 4.25 amps

continuous. Can be used with any 24 VDC

tension brake with or without the need for a

sense coil.

Output TCS-200-1H

Adjustable 0-24 VDC. Maximum of 5.8 amps

continuous. Can be used with any 24 VDC

tension brake with or without the need for a

sense coil.

Ambient Temperature

-20° to 125° F (-29° to 51° C)

Fuse

2.5 Amp, 250 VAC, Slow-Blow

Protection

Internal short-circuit protection on driver output

stage

Sensor Inputs

• Remote Torque Adjust 1,000Ω

The control also has the capability to duplicate the

front panel selector switch at a remote location.

Brake “off” mode overrides the tension adjustment

and provides for resetting the short circuit indicator.

In the “run” mode, output operation is normal and is

controlled by any of the front panel or remote tension

adjust features discussed above. The brake “stop”

mode provides for full output current to the brake.

Warner Electric • 800-825-9050 P-2003-2 • 819-0420 3

• Roll Follower 1,000Ω

• Analog voltage input, 0-10 VDC (Optically isolated

when 15-35 VDC supplied from external source)

• Analog current input, 4-20mA (Optically isolated

when 15-35 VDC supplied from external source)

Auxiliary Inputs

• Brake Stop – Applies full voltage to the

connected brakes. Active high input.

o 1. If you are using a PLC or an

external power supply with this control, you must

enable the isolation of the control.

• Brake Run – Voltage to the brake is controlled by

any of the sensor inputs and/or the front panel

tension adjust. Active high input.

• Brake Off – Removes output current to the brake.

Puts the brake at zero current level. Active high

input.

Note 1: The remote input signal for these functions

requires a minimum contact rating of 20 VDC at .01

amps and a maximum of state leakage current less

than 100 micro-amps.

Note 2: The remote switch input overrides the front

panel switch.

Front Panel

• Tension Adjust – Provides current adjust to the

brake from 0 to 100%. In the remote and

analog input mode, provides for maximum output

level set to the brake.

• Brake Mode Switch –

Modes: “stop”-brake full on

“run” -normal operation

o 2. The TCS-200-1 cannot operate a single brake

or brakes that require more than 4.25 amps

continuous.

o 3. The TCS-200-1H cannot operate a single

brake or brakes that require more than 5.8 amps

continuous.

This Installation and Operation Manual has been

arranged for the systematic installation and start-up

of your tension control system. To achieve the best

possible results, we recommend checking off each

completed step in the space provided before

proceeding to the next step.

Sample

o Attach the TCS-200 control chassis to the

mounting surface and secure with mounting

hardware.

Check box after completing each step.

Control Mounting

“off” -brake off

Indicators (Front Panel)

• Green LED indicates AC power has been applied

to the control.

• Red LED indicates there is a short on the output.

Turn the front panel switch “off” to reset the short

circuit.

General

The control chassis must be considered NEMA 1

and should be kept clear of areas where foreign

material, dust, grease, or oil might affect control

operation.

Potentiometers (supplied by the customer)

• Remote Torque Adjust

1,000 ohms, 10% tolerance, .5% linearity,

.5 watts, linear taper

• Roll Follower – 1,000 ohms, 10% tolerance, .5%

linearity, .5 watts, linear taper

o 1. Determine a suitable location for the control to

be mounted. Consideration should be given to

whether the front panel adjustments will require

access by the operator.

o 2. Using the dimensional data supplied in Figure

1a and Figure 1b, drill four mounting holes using

a #16 drill if #8 through-bolts are used. For #8

capscrew mounting, use a #29 drill and tap holes

for #8 screws. Templates for hole drilling are

found on page 21.

o 3. Attach the TCS-200-1 or TCS-200-1H control

chassis to the mounting surface and secure with

mounting hardware.

Note: The control chassis has been designed to

accommodate two half-inch conduits for wiring when

the control is mounted to the machine frame.

4 Warner Electric • 800-825-9050 P-2003-2 • 819-0420

o 4. Attach conduit or seal tight connectors.

The control is now ready to be wired. Refer to the

wiring section of this manual for proper system wiring.

Brake Installation

Refer to the brake manual that is appropriate for the

brake selected for its installation procedures.

External Sensor Mounting (Optional)

Options for four types of external sensor inputs are

available. These consist of either an external torque

adjust, roll follower input that provides a signal

directly proportional to the diameter of the roll to be

processed, analog voltage, or analog current input.

Determine which type of external sensor will be

used and proceed to the appropriate section of this

manual.

Remote Torque Adjust Potentiometer (Optional)

Note: If angular rotation is not adequate, insufficient

output from the control is possible. In this case, a

timing belt drive between the roll follower pivot-point

and the sensor potentiometer may be necessary to

obtain adequate angular rotation.

o 2. Secure the roll follower potentiometer. This

completes the mounting for a roll follower

potentiometer. Refer to the wiring section of this

manual for proper control wiring.

Analog Input (Optional)

o 1. Select an appropriate mounting location for the

PLC or ultrasonic sensor.

o 2. Mount and secure the PLC or ultrasonic

sensor according to the specifications for those

products.

This completes the mounting. Refer to the wiring

section of this manual for proper control wiring.

o 1. Select an appropriate mounting location for the

external torque-adjust potentiometer.

Note: In determining this mounting location, take

into consideration the routing of the wires necessary

to connect the control, access for the operator,

and space required by the physical size of the

potentiometer.

o 2. Drill a mounting hole based on the bushing

diameter of the potentiometer selected.

o 3. Mount and secure the potentiometer.

This completes the mounting for an external remote

torque adjust potentiometer. Refer to the wiring

section of this manual for proper control wiring.

Roll Follower Adjust Potentiometer (Optional)

o 1. Mount the roll follower potentiometer and

determine the amount of angular rotation at the

potentiometer shaft.

System Wiring

System Wiring Precautions

The following wiring precautions will help you

properly wire and install a trouble free system.

o 1. Use a proper gauge wire for all wiring.

o 2. Insure that wires are cut and stripped so that

no excess bare wire is exposed.

o 3. Segregate AC input power from control

switching and external sensor wiring (if used).

o 4. Do not run AC power lines with DC power,

input sensor wiring, or switching wiring. Noise

transients can be easily transferred, causing

erratic control operation.

o 5. Use shielded cable when possible for

connecting the TCS-200-1 to external switches,

the sensor potentiometer, PLC’s, and ultrasonic

sensor.

Warner Electric • 800-825-9050 P-2003-2 • 819-0420 5

o 6. Under no circumstances should auxiliary

accessories be operated from the TCS-200-1

control.

WA RNER ELECTRIC

®

TCS-200-1H

POWER SHORT

TENSION

ADJUSTMENT

BRAKE MODE

.875 DIA. 2 PLCS.

FOR 1/2 CONDUIT

3.75

1.25

3.00

C

L

4.00

6.82

6.00

5.75

POWER SHORT

BRAKE MODE

®

6.00

.875 DIA. 2 PLCS.

FOR 1/2 CONDUIT

3.75

WA RNER ELECTRIC

TCS-200-1H

C

L

1.00

4.00

5.75

TENSION

ADJUSTMENT

6.82

TCS-200-1H with Heat Sink

Figure 1a

POWER SHORT

WA RNER ELECTRIC

TCS-200-1

TENSION

ADJUSTMENT

6.00

®

BRAKE MODE

1.25

3.00

7.50

.31 Dia.

6 Warner Electric • 800-825-9050 P-2003-2 • 819-0420

CS-200-1

Figure 1b

1.25

3.00

.875 DIA. 2 PLCS.

2.87

o 7. Do not attempt to incorporate

TB2

TB2

GNDGND

external switching schemes between two or

more brakes and the TCS-200-1 output. This will

damage the control and void the warranty.

o 8. Do not attempt to wire two or more controls in

parallel.

TCS-200-1 Series Controls Wiring

Refer to Figure 2 for actual wiring connections.

o 1. Unlatch the front cover of the TCS-200-1.

o 2. Connect one of the jumpers to terminals 5

and 6 of terminal block TB2 and discard the

spare jumper.

o 3. Connect the 230 VAC power to terminals 4

& 8 of terminal block TB2. Secure the terminal

screws.

o 4. Connect an earth ground wire between

terminal 9 of terminal block TB2 and an

unpainted metal surface of the control panel to

ensure a good ground connection. Secure the

terminal screw. Make sure the panel itself is

properly grounded.

Power

Determine if 115 VAC or 230 VAC will be used to

power the control and proceed to that section of this

manual.

Insure power is off and disconnects

open on the control panel before connecting the AC

input. Failure to do so can result in damage to

equipment and injury or even death to personnel.

115 VAC

Refer to Figure 2a for 115 VAC power input

connections.

o 1. Connect the 115 VAC power to terminals 4

& 8 of terminal block TB2 located in the base of

the TCS-200-1 enclosure. Secure the terminal

screws.

o 2. Connect an earth ground wire between

terminal 9 of terminal block TB2 and an

unpainted metal surface of the control panel to

ensure a good ground connection. Secure the

terminal screw. Make sure the control panel itself

is properly grounded.

FACTORY

INSTALLED

JUMPERS

1

2

3

NEUTRAL

4

5

6

7

8

9

115 VAC

HOT

INSTALL

JUMPER

1

2

3

NEUTRAL

4

5

6

7

8

9

230 VAC

HOT

a. 115 AC Power Wiring b: 230 VAC Power Wiring

Figure 2

Note: Do not apply power to the system at this point.

Brake

Determine the type of brake to be used with this

control and proceed to that section of this manual.

Insure connections are tightly secured.

Intermittent connection will cause the control to shut

down and output current to the brake will be

removed.

Electro Disc Tension Brake

230 VAC Input

Refer to Figure 2b for 230 VAC power input

connection.

o 1. Remove the factory installed jumpers from

terminals 4 & 5 and 6 & 7 of terminal block TB2

located in the base of the TCS-200-1 enclosure.

Warner Electric • 800-825-9050 P-2003-2 • 819-0420 7

Refer to Figure 3a for the Electro Disc Tension Brake

wiring connections.

o 1. Connect the red wire from one brake

magnet to terminal 1 of terminal block TB2 of the

TCS-200-1. This becomes the sense magnet.

Loading...

Loading...