Warner ERS VAR10 SZ 2500 Service & Installation Manual

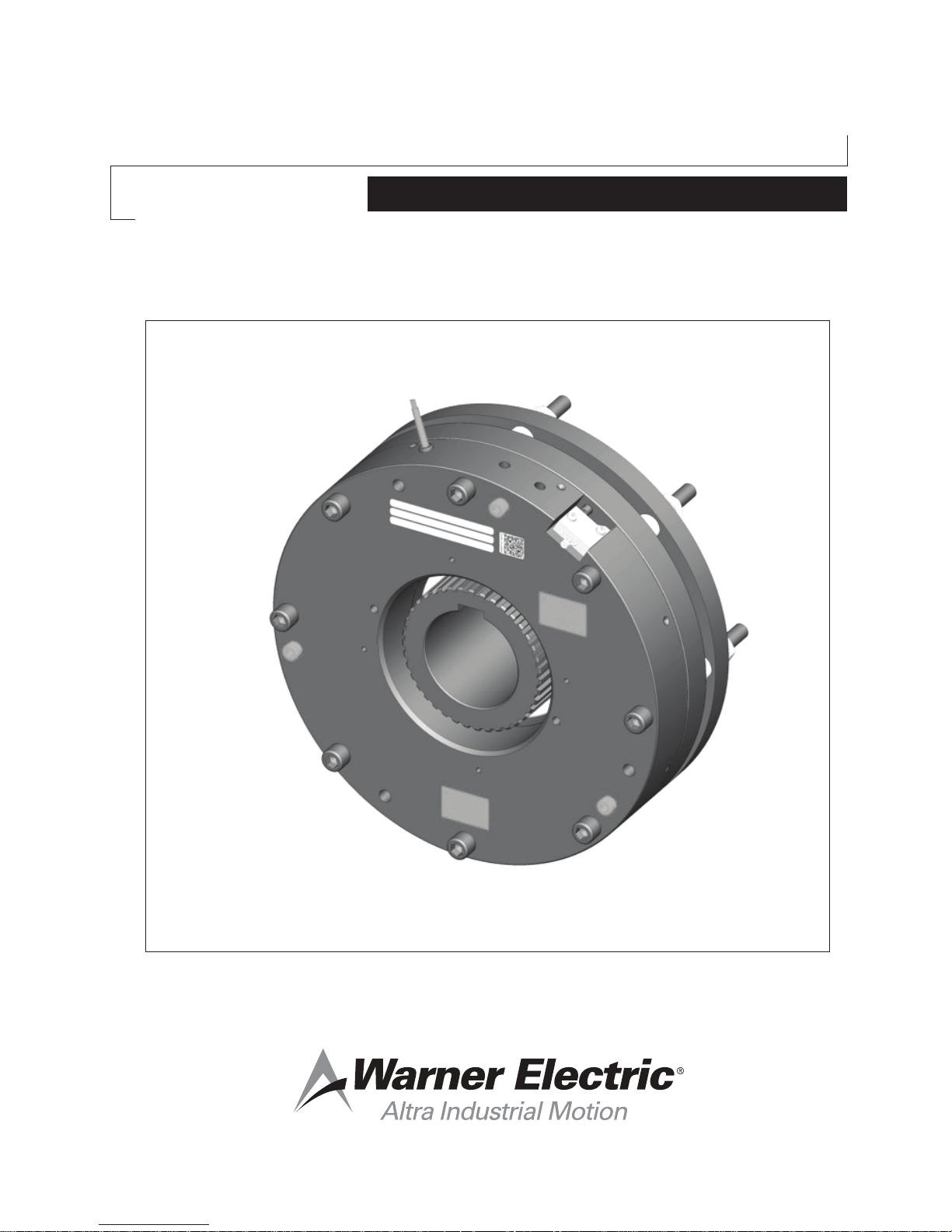

Electrically Released Brake

ERS VAR10 SZ 2500

Service & Installation Instructions

P-2107-WE-A4

SM477GB

WARNER!ELECTRIC!EUROPE!-!Rue!Champfleur,!B.P.!20095,!F!-!49182!St!Barthélemy!d’Anjou!Cedex! SM477gb!-!rev!04/16! 2/15!

!

CONTENTS&

1-! EU&DECLARATION&OF&CONFORMITY& ____________________________________&3!

2-! PRECAUTIONS&AND&SAFETY&MEASURES& _________________________________&3!

2.1!-! SYMBOLS!USED!IN!THIS!MANUAL! _____________________________________________________________! 3!

2.2!-! SAFETY!PRECAUTIONS!FOR!INSTALLATION!AND!MAINTENANCE! _________________________________________! 4!

2.3!-! PRECAUTIONS!FOR!HANDLING!_______________________________________________________________! 5!

2.4!-! PRECAUTIONS!ON!USE! ____________________________________________________________________! 5!

2.5!-! RESTRICTIONS!ON!USE! ____________________________________________________________________! 6!

3-! STORAGE&__________________________________________________________&6!

4-! TECHNICAL&SPECIFICATION& ___________________________________________&7!

4.1!-! BRAKE!DESCRIPTION!______________________________________________________________________! 7!

4.2!-! TECHNICAL!DATA!________________________________________________________________________! 7!

4.3!-! LABELING!DETAILS!_______________________________________________________________________! 8!

5-! INSTALLATION&______________________________________________________&9!

5.1!-! CUSTOMER!INTERFACE!SPECIFICATION! _________________________________________________________! 9!

5.2!-! BRAKE!MOUNTING! ______________________________________________________________________! 9!

6-! ELECTRICAL&CONNECTION& ___________________________________________&10!

6.1!-! MICROSWITCH!TECHNICAL!DATA!____________________________________________________________! 10!

7-! MAINTENANCE&____________________________________________________&11!

7.1!-! AIR!GAP!CHECKING!_____________________________________________________________________!11!

7.2!-! DISCS!EXCHANGE!_______________________________________________________________________! 12!

7.3!-! DETECTION!CHECKING!___________________________________________________________________!12!

7.4!-! DETECTION!SETTING!_____________________________________________________________________! 13!

7.5!-! MICROSWITCH!EXCHAN G E ! ________________________________________________________________!13!

8-! SPARE&PARTS&______________________________________________________&14!

9-! TOOLING&_________________________________________________________&14!

10-! TROUBLESHOOTING&________________________________________________&15!

11-! CONTACT&_________________________________________________________&15!

&

! &

WARNER!ELECTRIC!EUROPE!-!Rue!Champfleur,!B.P.!20095,!F!-!49182!St!Barthélemy!d’Anjou!Cedex! SM477gb!-!rev!04/16! 3/15!

!

1- EU&Declaration&of&conformity&

The!Product!described!in!this!manual!is!in!conformity!with!the!relevant!EU!harmonized!legislation:!

Directive&2014/33/EU! Ensuring!lift!safety!

Directive&2014/35/EU! Electrical!safety:!Low-voltage!electrical!equipment!

Directive&2006/42/EC! Machinery!safety!

Evidence!of!conformity!to!the!Directives!is!assured!through!the!application!of!the!following!standards:!!

EN&81-1+A3:2009! Safety!rules!for!the!construction!and!installation!of!lifts!–!Part!1:!Electric!lifts!(end! of!the!

period!of!applicability:!31!August!2017).!

EN&81-20:2014! Safety! rules! for! the! construction! and! installation! of! lifts! –! Lifts! for! the! transport! of!

persons!and!goods!–!Parts!20:!Passenger!and!goods!passenger!lifts.!

EN&81-50:2014! Safety!rules!for!the! construction! and!installation!of!lifts!– !Examinations!and!tests!–!Parts!

50:!Design!rules,!calculations,!examination!and!tests!of!lift!components.!

DIN&VDE&0580:2011!! Electromagnetic!devices!and!components,!General!requirements.!

EN&ISO&12100:2010! Safety!of!machinery!–!General!principles!for!design!–!Risk!assessment!and!risk!reduction.!

2- Precautions&And&Safety&Measures&

&

Precautions&and&safety&measures&must&be&read&before&any&installation&or&maintenance&of&the&brake.&

Compliance& with& the& instructions& and& values& given& by& the& documentation& and& marking& of& the& unit& is&

imperative&in&orde r&t o &e n su r e &a &p r o per&functioning&of&the&brake.&

!

!

2.1&- Symbols&used&in&this&manual&

!

Action!that!might!damage!the!brake.!

!

Action!that!might!be!dangerous!to!human!safety.!

!

Electrical!action!that!might!be!dangerous!to!human!safety.!

!

Handling!of!loads!that!might!be!dangerous!to!human!safety.!

!

Surface!temperature!that!might!be!dangerous!to!human!safety.!

!

WARNER!ELECTRIC!EUROPE!-!Rue!Champfleur,!B.P.!20095,!F!-!49182!St!Barthélemy!d’Anjou!Cedex! SM477gb!-!rev!04/16! 4/15!

!

2.2&- Safety&precautions&for&installation&and&maintenance&

!

During! maintenance,!make! sure! that!the!driving!mechanism!is!stopped!and! that!there!is!no! risk! of!

accidental!starting.!The!intervention!must!be!signaled!and!the!work!area!delimited.!

!

All!intervention!must! be! done! by!authorized! and! qualified! personnel,!having!read! and! understood!

this! manual,! using! adapted! procedures! an d ! profe ssion al! too ls.! All! interven tion! m u st! be! d on e!

according!the!regulation!of!the!country!of!the!installation.!

!

All!works!on!the!electrical!connections!must!be!done!with!power!off.!

!

Magnetic!field!generated!by! the!magnet,! can!create!dysfunctions!on! near!machine! or!device.!Users!

must!also!be!careful!about!attractions!of!tools!or!other!devices!during!interventions.!

!

Due!to!the!magnetic!field!generated!by!the! ma gnet,!the!bearers!of!a!heart!pace-maker!or!an!

implant!must!avoid!th e !p ro ximity!of!the!unit.!

!

During!operation!the!brake!surface!can!reach! temperatures!higher!than!80°C.!Users!must!be!

careful!during!contact!with!the!unit.!

!

!

Respiratory&protection&

Inhalation!of!large!am o u n t s!o f!dust!can!cause!coughs!and!difficulty!in!bre a th in g .!

Respirator!must!be!worn!if!exposed!to!friction!material!dust.![Dust!mask!FFP2].!

Move!to!fresh!air!in!case!of!accidental!inhalation!of!dusts.!

In!the!event!of!persiste n t!s ymptoms!receive!medical!treatment.!

In!case!of!ingestion!of!f rict io n !material!dust,!consult!a!doctor.!

!

Provide!appropriate!exhaust!ventilation!at!places!where!friction!material!dust!can!be!generated.!

Do!not!use! brushes,! pressurized!air!or! hazardous! agents!to!clean!the! brake.! The! use! of! a! vacuum!

cleaner!is!recommended.!

!

Hand&protection&

Protective!and!dust-resistant!gloves.!

!

Eyes&protection&

Friction!material!dust!particles,!like!other!inert!materials,!may!be!mechanically!irritating!the!eyes.!

Safety!goggles!with!side!protection.!

In!case!of!contact!with !e y es ,!ca re fu lly !rin s e!with!plenty!of!water.!

In!the!event!of!persiste n t!s ymptoms!seek!medical!treatment.!

!

Skin&protection&

Prolonged!skin!contact!may!cause!mechanical!irritation.!

Dust!resistant!protective!clothing.!

In!case!of!contact!with !s kin ,!wash!with!soap!and!water!as!a!precaution.!

Consult!a!doctor!if!skin!irritation!persists.&

!

Feet&protection&

Safety!shoes!must!be!worn.!

!

! &

WARNER!ELECTRIC!EUROPE!-!Rue!Champfleur,!B.P.!20095,!F!-!49182!St!Barthélemy!d’Anjou!Cedex! SM477gb!-!rev!04/16! 5/15!

!

Helmet&protection&

Safety!helmet!must!be!worn.!

!

Protective&and&hygiene&measures&

Do!not!breathe!friction!material!dust.!

Wash!hands!before!breaks!and!at!the!end!of!workday.!

During!maintenance,!do!not!eat,!drink!or!smoke.!

Handle!in!accordance!with!the!general!hygienic!rules.!

Remove!and!wash!contaminated!clothes!before!re-use.!

!

!

2.3&- Precautions&for&handling&

!

Avoid!any!impact!or!damage!to!the!brake!during!handling.!

!

To! avoid!risk!of! injury! (see! mass! of! the! units!in!the!service! manual! of! the! brake),!use!an!adapted!

device,!hoist!or!crane,!for!the!handling!of!the!unit.!

!

When!handling,!use!the!handling!holes!intended!for!this!purpose.!

Never!lift!the!brake!using!the!coil!cables.!

!

!

2.4&- Precautions&on&use&

!

Customer&is&responsible& of& brake&qualification& with&his&interface& in& order&to& guaranty& that& brake&

performances&are¬&reduced.&

The!use!of!the!2!circuits!in!redundancy!is!mandatory.!

This!brake!is! designed!to!work! in!clean!conditions.!Friction!faces! must!be! kept! completely!clean!of!

any!oil,!water,!grease!or!abrasive!dust.!

The!friction!flange,!on!customer!side,!must!be,!also,!carefully!cleaned!and!degreased.!

!

The!friction!faces!must!be!protected,!with!adapted!devices!(cover,!heating!devices,!etc…):!

!

• To!avoid!pollution!and!rusting!during!the!lifetime!of!the!unit.!

• To!avoid!condensation,!resulting!in!freezing!conditions,!in!low!temperature/high!humidity,!or!

sticking!of!the!disc.!

!

This!brake!is!designed!to!work!in!ambient!temperature!between!0°C!and!40°C.!

!

This! brake! is! designed! to! work! with!duty!cycle!of!50%!(Insulation!class:!155°C).!The!temperature!of!

customer!friction!flange!must!not!exceed!90°C.!

!

This!brake!can!only!be!used!on!«!horizontal!»!position.!

!

When! switching! on! DC-side! the! coil! must! be! protected! against! voltage! peaks,! according!!!!!!!!!!!!!!!!!!!

DIN!VDE0580.!

!

Make!sure!the!rated!supply!voltage!is!set!within!the!tolerances,!an!under-voltage!supply,!generates!a!

reduction!of!the!maximum!air!gap .!

!

An!over-voltage! su pply!generates!additional!heat!on!the!surface!of!the!brake,! with!risks!

of!injury!by!burning!and!possible!damage!to!the!coil.!

!

!

Loading...

Loading...