Warmup DWS300, DWS400, DWS600, DWS800 Installation Manual

TECHNICAL HELPLINE

0845 345 2288

IMPORTANT

Read this manual before attempting to

install your undertile heate r.

Incorrect installation could damage the

heater and will invalidate your warranty.

by filling in your Guarantee

information online at

warmup.com

Installation Manual:

Undertile Heating

Loose Wire System

3

4

5

6

8

9

10

11

12

14

15

16

19

Do’s and don’ts

Heater information

Making electric provision

Subfloor preparation

Wiring configuration

Installing multiple heaters

Installation step 1

Installation step 2

Installation step 3

Installation step 4

Installation step 5

Guarantees

Sizing guide table

If these instructions are followed you should have no problems.

However, if you do require help at any stage, please call our FREE helpline:

Warmup Technical Helpline 0845 345 2288

You can also find a copy of this manual, wiring instructions, a list of frequently asked

questions and more helpful information on our website:

www.warmup.co.uk

Your Warmup®Undertile Heater

has been designed so that

installation is quick and straight

forward, but as with all electrical

systems, certain procedures

must be strictly followed.

Please check the sizing guide

at the back of this manual

to ensure that you have the

correct heater(s) for the area

you wish to heat.

Warmup plc, the manufacturer of the Warmup®Undertile

Heating System, accepts no liability, expressed or implied,

for any loss or consequential damage suffered as a result

of installations which in any way contravene the instructions

that follow.

Contents

2

DO carefully read this installation manual before commencing installation.

DO ensure the floor surface is smooth, clean and dry before priming the floor with

Warmup

®

primer.

DO ensure good ventilation during application and drying of the primer.

DO lay the wires whilst the primer is still “tacky” to ensure the greatest level of adhesion.

DO plan the heater layout and installation so that any drilling after tiling (e.g. for fixing

sanitary ware) will not damage the wiring.

DO maintain a gap between heating wire runs of at least 50mm (2 inches) at all times.

DO make sure that ALL heating wire, including joints, are positioned under the tiles in the

installation.

DO protect the heating wire with cardboard or hardboard between installation and tiling.

DO use ceramic tile adhesives and grouts suitable for use with underfloor heating.

DO check that the heater is working immediately before commencing tiling.

DO take particular care when tiling not to dislodge or damage the heating wire.

DO ensure that each tile is solidly bedded in tile adhesive, with no gaps or voids beneath.

DO ensure that the heating elements are installed at least 50mm from conductive parts

of the building, such as water pipes.

DON’T install the Warmup

®

Undertile Heating System heater under any floor other than

ceramic, quarry or natural stone tiles.

DON’T commence installation on a concrete floor that has not been fully dried.

DON’T allow traffic over the primed floor or the installed heating wire before tiling.

DON’T cut or shorten the heating wire at any time.

DON’T allow the heating wires to cross over or touch each other at any point.

DON’T store tiles, sharp or heavy objects on any of the wiring whilst tiling.

DON’T commence tiling before testing the Warmup

®

Undertile Heating System.

DON’T switch on the installed heating system until tile adhesive has fully dried (7 days

minimum).

DON’T install the heating wire on stairways or up the walls.

DON’T install the mat in temperatures less than +5°C.

DON’T bend the heating cable under a 25mm radius.

The heating must be separated from other heat sources such as luminaires and chimneys.

WARNING

During the course of the installation care must be taken to ensure that no damage is caused by, for

example, falling objects, sharp objects, walking on the heating element. Once the heating wire has been

installed avoid all traffic over the wire until the floor has been tiled and the adhesive has set. Do not install

the heating wire until the floor is ready to be tiled. If the floor is not being tiled immediately, all heating

wires must be protected with two layers of cardboard or hardboard to prevent damage. Immediately prior

to tiling, test the heating wires as specified on page 14 to check it has not been damaged. If you are in

any doubt call the Warmup

®

Undertile Heating helpline on 0845 345 2288.

Do’s and don’ts

3

The heaters consist of a fixed length of heating wire terminated at one end by a sealed joint

and the other end by a 3m power supply cable (cold tail).

The cores and earth braid are spliced in a waterproof joint assembly to the supply conductors

and the earth conductor of the cold tail.

Heater information

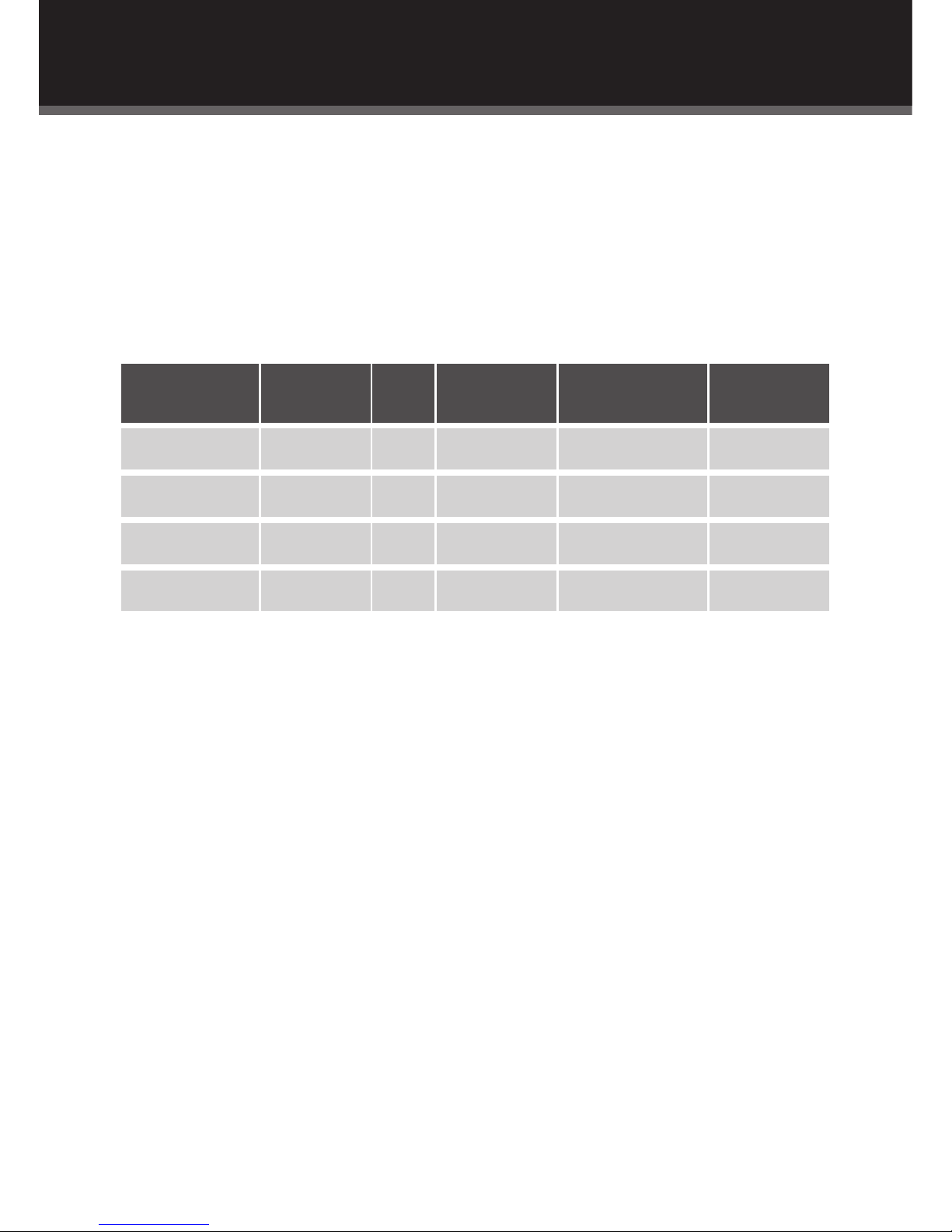

Heater Model Wire Colour kW Wire Length Amps Resistive Resistance

(m) (@230 volts) (ohms-cold)

DWS300 BLUE 0.300 22 1.3 176.0

DWS400 SILVER 0.400 34 1.7 136.0

DWS600 GREY 0.600 44 2.6 88.0

DWS800 RED 0.800 64 3.6 64.0

As with all electrical projects which are subject to Part P Building Regulations, all electrical work should be

carried out by a certified/qualified electrician. All work must conform to BS 7671:2008 and the current IEE

Wiring Regulations.

4

Install the RCD

The electrician must install a dedicated RCD or use an existing RCD. The electrician may wish

to use a combination ‘double pole switched’ fused-spur/RCD. No more than 4.8kW of

heating may be connected to each 30 milliamp RCD. For larger loads, use multiple RCD’s.

Note: It is possible to run the heater(s) from an existing circuit. The electrician will be able to determine whether or

not the circuit can handle the load and if it is RCD protected.

Install electrical boxes and trunking

You will require a deep (35mm) back box for the Warmup

®

Thermostat. If you are installing

more than two heaters, a junction box will also be necessary. The wiring to the thermostat

should be chased into the wall and protected by conduit or plastic trunking.

Connecting the Warmup

®

Thermostat

The thermostat should be connected to the main electrical supply via a fuse or circuit

breaker, ‘double pole isolator’ in accordance with the wiring regulations.

The thermostat should be installed within the rooms or area to be heated. In the case

of bathroom installations, electrical regulations prohibit the installation of the thermostat

within the bathroom itself. In such cases, the thermostat should be fitted to the outside

of an internal wall of the bathroom, as close to the undertile heating as possible, for example

in an adjacent airing cupboard.

Note: The floor probe wire can be

extended up to 50m.

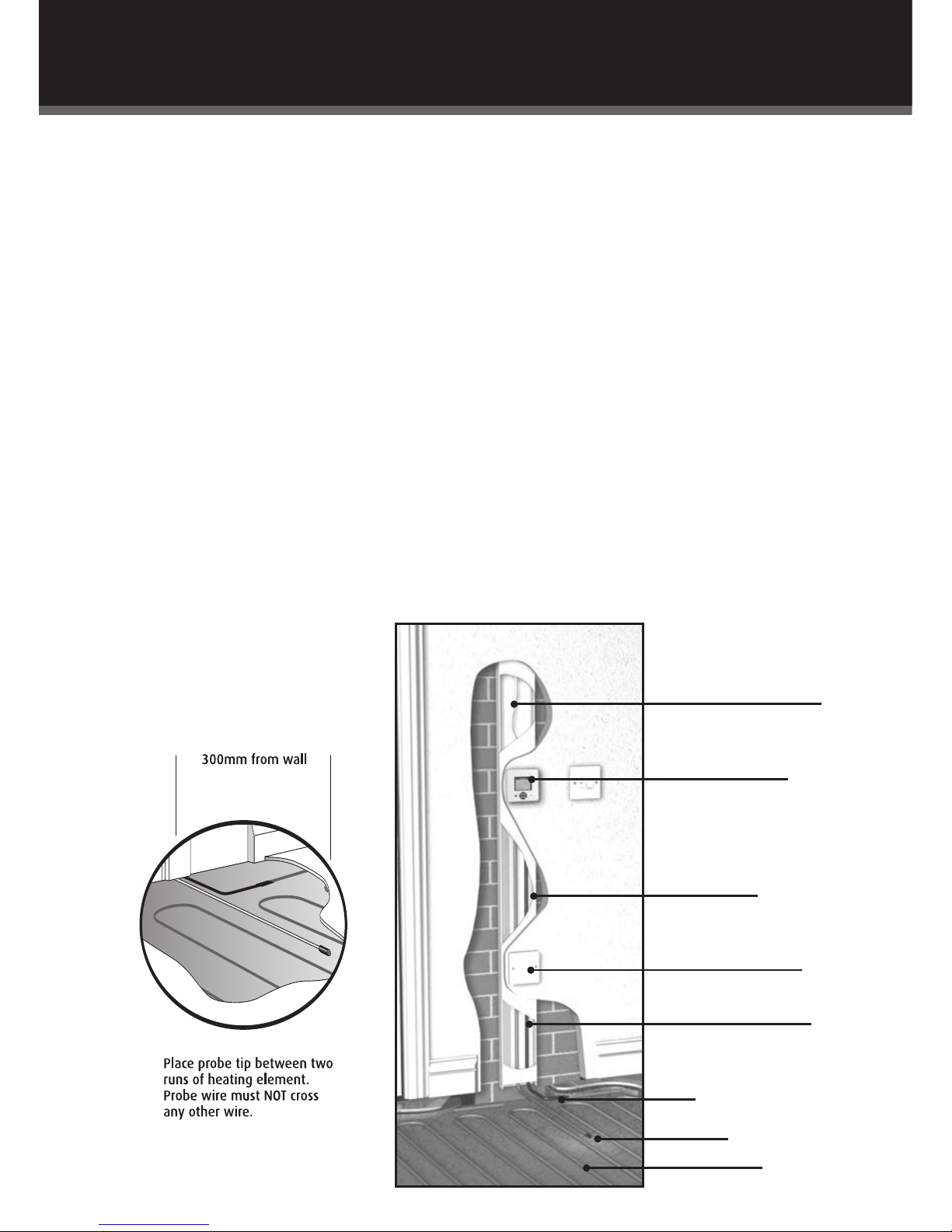

Making electrical provision for the heater

Mains supply via RCD.

Fused isolator switch

must be fitted.

Warmup

®

Thermostat

mounted on the wall.

Wires recessed into

blockwork in metal

or plastic trunking.

Junction box.

(if more than 2 heaters)

Black power supply cable.

Temperature sensing

floor probe.

Heating element.

Joint.

5

To fully utilise the long-term durability of ceramic tiling, whether heated or not, it is important

that the design, construction and preparation of the subfloor is carried out correctly.

It is essential that the subfloor be sufficiently rigid to support the ultimate weight that

it will have to bear without movement or deflection.

The choice of products for subfloor preparation and tile will vary depending on the existing

subfloor, preferred tiling system and choice of tile. This document is only intended to

be an outline guide to laying ceramic floor tiles. Further help regarding floor preparation

and tile application is available from the tile adhesive manufacturers.

Comprehensive information can be found in the following British Standards with which

all installations should comply:

BS 7671: "The IEE Wiring Regulations" (latest edition)

BS 8204: "Concrete bases and screed to receive in-situ flooring" 1987

BS 5385: "Wall and floor tiling" Part3: 1989 and Part 4: 1992

BS 8000: "Workmanship" Section 11.1:1989 and section 11.2:1990

Copies can be obtained from: British Standards Institute, 389 Chiswick High Road, London,

W4 4AL Or for a token fee, may be viewed at most Public Libraries. Ensure the most

up-to-date versions are seen. Alternatively, you may wish to seek professional advice;

e.g. an architect.

Subfloor Preparation

Prior to installation, it is important that the subfloor is properly prepared.

Timber subfloor: boards must be overboarded by a suitable tile-backer board or overboarded

with WBP plywood (18mm thickness minimum) screwed down at 200mm centres.

Insulated concrete floor: This must be completely dry (can take 8 weeks), smooth and level.

Subfloor previously covered in vinyl, cork or carpeting: all old flooring and adhesive must

be removed.

If bitumen asphalt is present as adhesive residues it must be removed. If the bitumen is a

damp proofing layer, it must be covered with a minimum 50mm of sand/cement screed,

taking care not to puncture the bitumen coating. The screed must be fully dry (6 weeks)

before priming.

If using other damp proofing or tanking systems, contact the manufacturer for advice.

Note: Chipboard, M.D.F. and O.S.B. boards (flake boards) are not suitable bases for ceramic floor tiling.

Technical notes

6

Preparation of timber or concrete subfloor

Using WBP plywood

Ensure adequate underfloor ventilation.

Securely fix existing floorboards and if

necessary, pre-level with a latex/cement

self-levelling compound to give a flush fit

for the subsequently applied WBP plywood.

Refer to BS 5385: Part 3, clause 14.4

regarding sealing the backs and edges

of the WB plywood before fixing.

Fixing ply directly to the joists will not

provide a sufficiently stable floor finish

to accept tiles; fitting tongue and groove

flooring and then over-boarding with ply

or a tile backer board is recommended.

A rigid base is essential.

The above recommendations apply to floors

of small areas as advised in clause 14.4 of

BS 5385: Part 3: 1999.

Using insulated tile backer board

Fix the tile backer board as per

manufacturer’s instructions.

For best results and for ease of installation,

Warmup recommends the use of an

extruded polystyrene building or insulated

tile backer board with a cement-based

facing, such as Warmup

®

Insulation Board.

After attaching the board to the subfloor, the

Warmup®Undertile Heating System may

be laid directly on top of the tile backer/

building board, and then tiled over. It is

important to ensure that the tile adhesive

and grout used are flexible and that the tile

backer/building board has been fitted as per

the manufacturer’s instructions. High quality,

cement-based adhesives with their flexible

additives are most suitable.

NOTE: Do not use the green Warmup

®

primer

when installing on insulated tile backer board.

Tiles Flexible tile adhesive

Heating wire Primer

18mm WBP plywood or Warmup

®

Insulation Board

Tiles Flexible tile adhesive

Heating wire Warmup

®

Insulation board

Insulation board adhesive

Subfloor

(concrete or timber)

1

2

3

4

5

1

2

3

4

5

6

2

1 2

3 4

5

1

3

4

5

6

7

Loading...

Loading...