WarmlyYours WSHM24015095, WSHM12015056 Installation Manual

Installation Manual for

Slab Heating Systems

24/7 Installation Support • Lifetime Technical Assistance • Free Design Service • www.WarmlyYours.com • (800) 875-5285

CONTENTS PAGE

1.0 Product Specications ............................................................................. 1

2.0 Selection of the Heating System ................................................................ 2

3.0 Important Instructions before Installing the System................................... 2

4.0 Installation for Slab Heating ....................................................................... 3

4.1 Thermostat & Sensor.......................................................................... 3

4.2 Electrical Provisions for the System ................................................... 3

4.3 Pre-Installation Preparations .............................................................. 4

4.4 Installation for Concrete Embedded Applications .............................. 4

4.5 Operating Tips .................................................................................... 5

4.6 Installation under Concrete ................................................................ 6

4.7 Installation of Slab Heating Mat ......................................................... 6

1.0 PRODUCT SPECIFICATIONS

WarmlyYours Heating Cable is designed for new concrete slab oors. It is well suited

for large areas like basements, garages and additions.

The Heating Cable is comprised of a dual, multistrand heating element with a primary

insulation of Fluoropolymer. The insulated core is then protected with a woven metal

braid and an outer jacket of PVC, EPR or Zero Halogen Polyolen based compound

to make it sturdier and to provide corrosion protection. These cables are terminated

with 20’ (6.1m) long standard cold leads. The hot and cold junction is uniquely

designed to make it durable and exible.

Available in a wide range of lengths and sizes to suit your requirements, the Slab

Heating Mats and Heating Cables are identied as indicated below.

Item Number: AAAA-BBB-CCCC

5.0. Testing the Mats and Cable ....................................................................... 7

5.1 Test One: Total Cable Resistance ....................................................... 7

5.2 Test Two & Three: Insulation Resistance ............................................ 7

6.0 Warranty ..................................................................................................... 7

7.0 Appendix

Appendix A: Slab Heating Mats ............................................................... 8

Appendix B: Slab Heating Cables ............................................................ 8

Appendix C: Cross-section of indoor slab Heating Cable in concrete

(With NO oor covering) ........................................................................... 9

Appendix D: Cross-section of indoor slab Heating Cable in concrete

(With oor covering) ................................................................................. 9

8.0 Troublshooting ............................................................................................ 12

9.0 Warranty ..................................................................................................... 14

Warranty Registration ............................................................................... 15

Ex: Item Number: WSHM-240-0250

• AAAA = WSHM for Slab Heating Mat, WSHC for Slab Heating Cable

• BBB = Operating Voltage available in 120V and 240V

• CCCC = Mat width in ft. (rst two digits) and Mat length in ft. (third and fourth

The available lengths of Slab Heating Mats are shown in Appendix A. The available

lengths of Slab Heating Cables are shown in Appendix B. Both Appendices include

the following attributes for each Item Number.

• Product Type • Watts/Ft for Cable or Watts/Sq Ft for Mats

• Operating Voltage • Amps

• Cable Length

• Mat Width and Length

• Total Ohms

• Total Watts

(product type) (voltage) (width & length = 2’x50’)

digits) for Slab Heating Mat, Cable length in ft. for Slab Heat Cable

1

2.0 SELECTION OF THE HEATING SYSTEM

Wrong

Wrong

Selection of your Heating System will depend on the application. The following can

be taken as a general guide:

INSTALL CHART

Application

Indoor Slab Heating

Watts per Sq.Ft. (per Sq.M.)

- Cable spacing inches (mm)

20 W/ft2 (161 to 215 W/m2)

Recommended spacing 3” to 3.5” (76

to 89mm).

Formula: Area of Application x Multiplier at given cable spacing = Heated Cable

Length required

Example 1 (English): 100 sq.ft of Slab Heating x 4.0 at 3” spacing = 400 feet of

Heated Cable required

Example 2 (Metric): 9.3 sq.m of Slab Heating x 4.0 at 76mm spacing = 122m of

Heated Cable required

Note: For normal plain bare slabs, stained or stamped use 3” spacing. For

application when the slab also has a oor covering like tile or wood, use 5” spacing

for a maximum of 15w/sq ft. to meet code requirements.

Please note the above-indicated values are meant as a general guide. Your values

may vary depending on a number of factors. Please consult your Account Manager

for assistance.

Multiplier at

given spacing

4 at 3” (76mm)

3.5 at 3.5” (89mm)

3 at 4” (102mm)

2.4 at 5” (127mm)

over cable. Duct tape the ends of shovels. Do NOT saw expansion joints, without

having lines marked o clearly with spray paint, where installer has veried that

Heating Cables will not be cut. Do NOT damage Cables with heavy equipment,

machinery or vehicles.

6. Heating Cables should be separated from other heat sources such as luminaries,

and replaces.

7. Do not install the Heating Cable below 5˚ F (-15˚ C) ambient temperature.

8. Minimum bending radius of the Heating Cable shall not be less than 10 times its

diameter.

9. Minimum spacing of Cables is 3” (76 mm) and maximum spacing of Cables is 5”

(127mm).

10. Twin Conductor Heating Cable has a ground braid (metal sheath) to be connected

to ground and 2 conductors which are to be connected to the power supply.

11. Double check the voltage and wattage of the Heating Cable received against

the project specications on your custom installation plan. These are marked on

the CSA label of the product. A qualied electrician should connect the Heating

System.

12. Check the conductor, resistance and insulation resistance of the Heating Cable

before installing and also after installing. Resistance value should match the value

shown in Appendix A and Appendix B. A tolerance of -5% to +10% is allowed.

Insulation resistance must be innite (500 VDC megger meter required to test).

13. Keep high voltage power wires in a separate conduit from the low voltage sensor

wire.

14. Allow sucient drying or curing period of the slab after installing the Heating

System before energizing the Heating System. (7 day minimum)

15. For easy reference, x a label at the power distribution board indicating the

location of the heating units installed.

3.0 IMPORTANT INSTRUCTIONS BEFORE INSTALLING THE SYSTEM

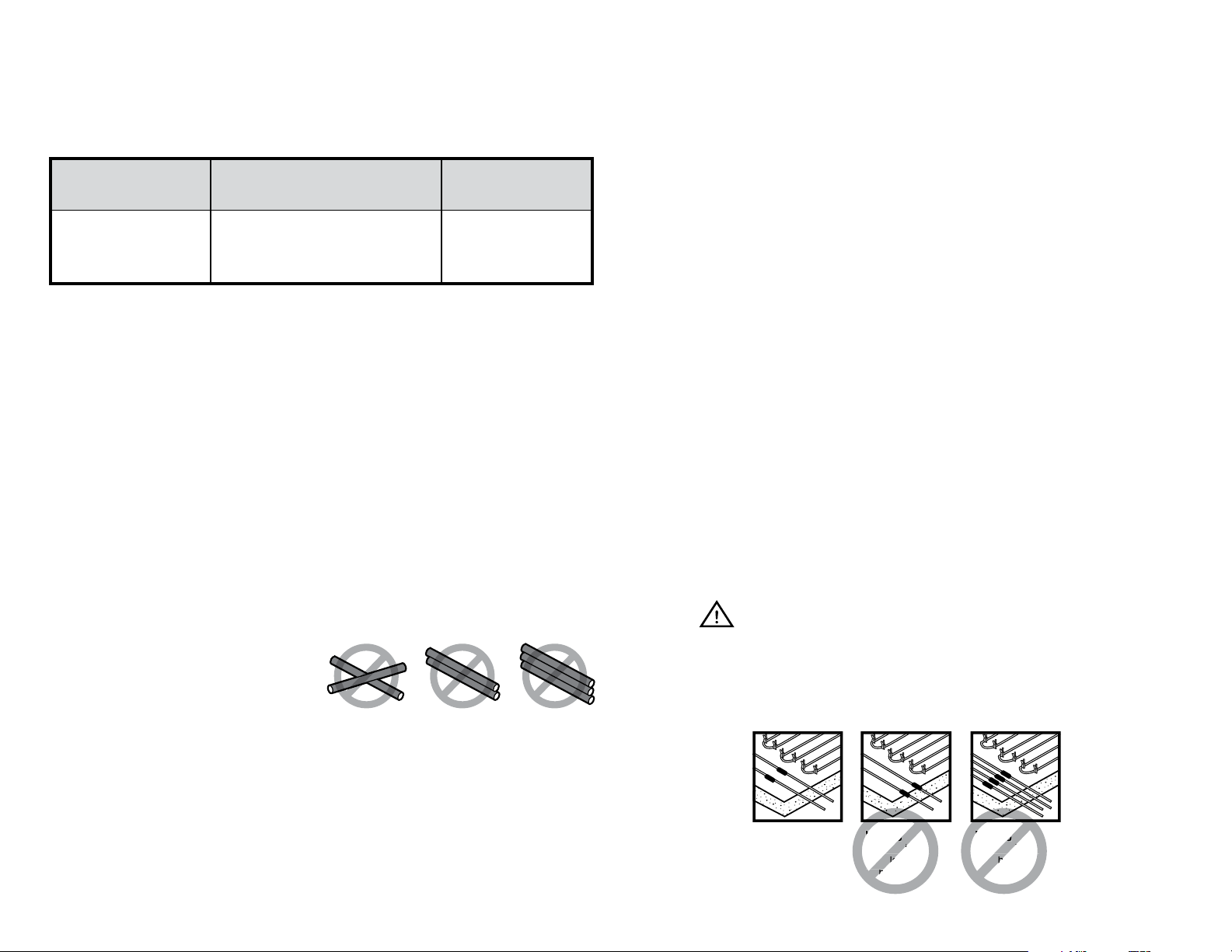

1. Heating Cable must not cross or

overlap itself at any point. Do not

install cable runs any closer than 3”

on center. This could cause the Cable

to overheat, requiring replacement.

2. The Heating Cable length should not

be cut or altered under any circumstances. This may cause over heating resulting in

damage to the Cable.

3. All heated portion (blue) and factory splice must end up buried completely in the

concrete. Ensure none of the heated portion (blue) or the splice (look for heatshrink)

enter into any conduit.

4. The cold lead can be cut /extended with a conventional splice, inside of an

accessible junction box (weatherproof if outdoors).

5. Take precautions to avoid damage to Heating Cable during installation. Do not drive

WARNING

16. The Cable must NOT be shortened or cut in any manner or subjected to strain at

the factory splice joint.

17. NEVER power up Heating Cables prior to being buried in concrete, (even for

testing purposes). This will prevent premature failure of the Heating Cable.

Right

hot/cold joints 3

in (7.6 cm) apart

and 6 in (15 cm)

from slab edge

Wrong

hot/cold joints

installed on

slab edge

Wrong

hot/cold joints

bunched

2

4.0 INSTALLATION FOR INDOOR SLAB HEATING

2’ (61cm)

or

3’ (91cm)

Length 5’ (152cm) min 50’ (1524cm) max

20’ (610cm) Cold Lead

Metal Sheath (Copper/Galvanised Steel/Cladded Steel)

Primary Insulation (Fluoropolymer)

Heating Conductor (Solid/Multistrand)

10"

(251mm)

3"

(8cm)

2’ (61cm)

or

3’ (91cm)

Length 5’ (152cm) min 50’ (1524cm) max

10"

(251mm)

3"

(8cm)

20’ (610cm)

Cold Lead

110V / 230V AC SUPPLY

4.1 TEMPERATURE CONTROLLER & SENSOR

We recommend a standard Programmable Thermostat with a temperature sensor

specially designed for control of the Heating System.

The sensor normally comes with a 2 conductor lead wire of 15 feet (4.5m) in

length. Thermostat sensor location shall be centered between two adjacent runs of

Heating Cable within metal pipe or conduit to allow for replacement. Do not position

Thermostat sensor closer than 1.5 inch (38 mm) to Heating Cable. Sensor cable shall

be routed to the Thermostat located in the wall at suitable operating height. Do not

allow any other Heating Cable to overlap with the sensor cable.

WARNING

In case the GFCI in our thermostat trips during normal operation, and cannot be

reset, there is likely a fault in the Cable. No attempt should be made to re-energize

the system. The GFCI must not be bypassed under any circumstances. Consult a

qualied electrician.

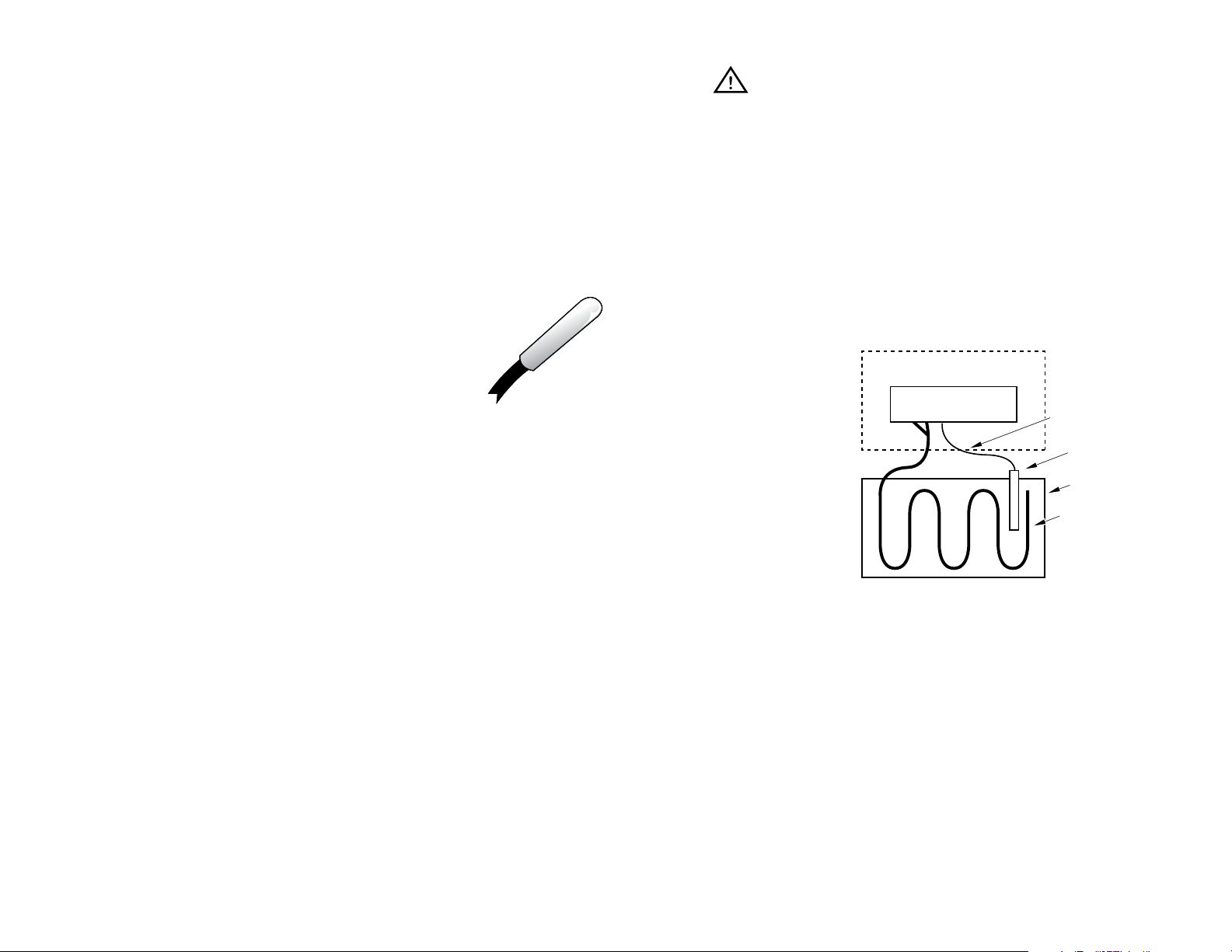

DIAGRAM A

The details of the thermostats and installation guidelines are given in

the instruction manual provided with the Thermostat.

Probe type sensor at the

end of 15’ 2 conductor

4.2 ELECTRICAL PROVISIONS FOR THE SYSTEMS

20AWG wire.

The Heating System installation wiring shall be in accordance with the National Electric

Code and any applicable local codes. Controls and accessories recommended for

use along with the Heating Cables are listed below:

• Floor Sensing Temperature controller / Thermostat

• Relay Panel(s) for amp loads greater than 15 amps

• Dedicated Circuit Breaker(s) for all heater circuits. GFCI (5mA trip) or GFPE (30mA

trip) may be required - check local and national code.

• Plastic zip ties, 2” thick polystyrene insulation (provided by installer)

The location of the Thermostat junction box shall be about 4’ (1.2m) high from the

oor for easy access. The oor sensor wire and the Heating Cable cold leads shall be

routed to the Thermostat / power connection box in separate conduits.

If the Heating System has a load below 1,750W at 120V or 3,500W at 240V based

on thermostat power rating, it may be connected directly to an electronic thermostat

as shown in Diagram A which gives a typical scheme of the electrical system. If the

Heating System has a load more than the thermostat power rating, consult your

WarmlyYours Account Manager. (you’ll likely need a relay panel)

120V / 240V VAC SUPPLY

THERMOSTAT

SLAB HEATING SYSTEM

SENSOR WIRE

CAPPED

CONDUIT

FLOOR

HEATING

CABLE

3

4.3 PRE-INSTALLATION PREPARATIONS

2’ (61cm)

or

3’ (91cm)

Length 5’ (152cm) min 50’ (1524cm) max

20’ (610cm) Cold Lead

Polyester Sheath

Metal Sheath (Copper/Galvanised Steel/Cladded Steel)

Primary Insulation (Fluoropolymer)

Heating Conductor (Solid/Multistrand)

10"

(251mm)

20’ (610cm)

Cold Lead

HEATING

CABLE

FLOOR

SENSOR WIRE

CAPPED

CONDUIT

HEATING SYSTEM

THERMOSTAT

110V / 230V AC SUPPLY

1. Review the custom installation plan for the area requiring the Heating System and

verify dimensions listed against your actual eld dimensions to ensure they match.

2. Conrm the location of the power supply box/Thermostat and sensor against the

plan.

3. Select Heating Cable(s) and ensure that the procured Cable is correct according to

the requirements in the following section.

4. Check the Slab Heating Cable in the box visually and make sure that it is not

damaged. Check voltage, wattage, resistance values from the factory test record

and verify that they match the required specications.

5. Check resistance of the conductor and its insulation resistance with a multimeter/

megohmmeter as soon as it is removed from its packing. Resistance value of

the Heating Cable shall match to the value shown in Appendix A or Appendix B.

A tolerance of -5% to +10% is allowed. Insulation resistance should be innite.

Record it on the warranty card located on page 13 of this manual.

6. The Heating Cable is now ready for installation.

4.4 INSTALLATION FOR INDOOR CONCRETE SLAB APPLICATION

1. 2” thick polystyrene insulation (or better) should be installed below slab and around

perimeter edges.

8. Heating Cable should be laid so that the Cables are equally spaced. The distance

between two Heating Cable passes should be according to the spacing calculation

determined by WarmlyYours (3” to 5” range).

9. Route the power leads through a conduit from the oor to the connection box. If

multiple cables are being used, route all power leads through a conduit from the

oor to the connection box in the wall. Ensure hot section and factory splice do

NOT get into the conduit

10. Check the resistance and insulation resistance value after laying out Cables.

Check to see if these values are consistent with the pre-install values. Record

values in the warranty card on page 13.

11. At this point, the concrete can be poured.

12. Pour the concrete and spread evenly on the reinforcement mesh / grid. The

concrete oor or slab thickness shall be about 2” (51 mm) on top of the Heating

Cable. Typical 4” to 6” slabs will have cable located in middle (2” to 3” from

nished surface).

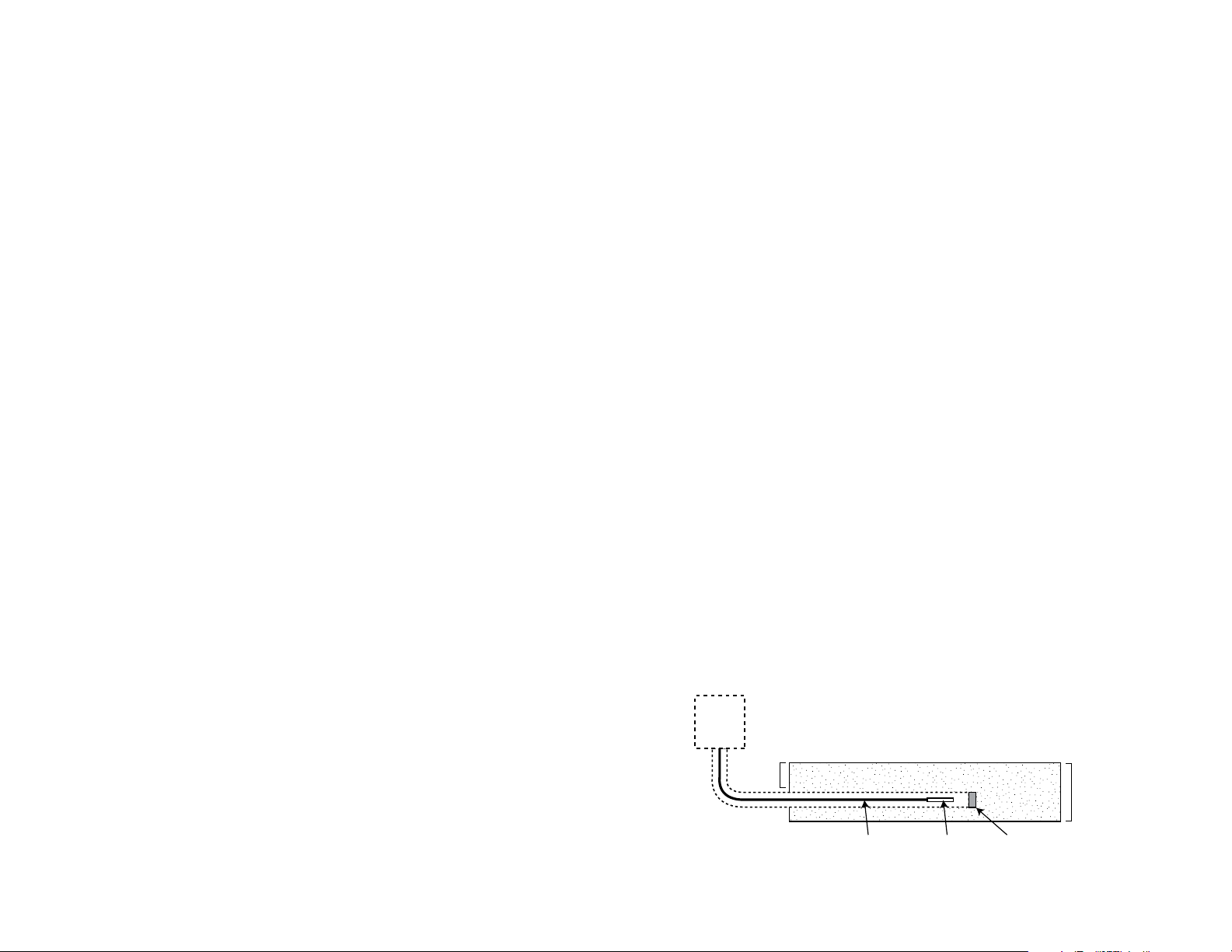

13. Ensure the entire Heating Cable, factory splices and thermostat sensor (in metal

conduit) are embedded in the cement mortar. The choice and application of building

materials should be in accordance with the building material manufacturer’s

instructions. (see diagram B)

14. Ensure the correct curing time for drying of construction materials is followed

before powering ON the Heating Cables (7 day minimum).

2. Reinforcement mesh on the oor or slab should be strong enough to walk on and

not sag or bend.

3. Reinforcement mesh should be properly positioned and supported so that it does

not get disturbed during the concrete pour. Ensure the Heating Cable is on the

reinforcement mesh a minimum of 2” (51mm) below the nished concrete/slab

surface.

4. Surface preparation of the oor is very important. The oor must be completely free

of all debris including all nails, sharp metallic objects, wood and construction debris.

Make absolutely sure that there are no objects on the oor that might damage the

Heating Cable.

5. Start installing Heating Cable from the location of power connection box.

6. Roll out the Heating Cable. Secure it to the reinforcement mesh or grid using plastic

zip ties (supplied by installer).

7. Heating Cable should be laid 3” (76mm) away from the wall perimeter.

15. Check the continuity, resistance and insulation resistance values after the concrete

or mortar is poured. They should be consistent with the values recorded previously.

Record values on the warranty card on page 13 of this manual.

16. Never use 500 VAC megger while personal are standing in, or touching the wet

cement. Wait until personal are out of the wet concrete.

DIAGRAM B

T-Stat

2-3”

4

CONCRETE SLAB

SENSOR WIRE SENSOR

SLAB

4-6”

CAPPED 3/4”

METAL CONDUIT

Loading...

Loading...