WarmlyYours WHCA2080100, WHCA1200043, WHMA1200215, WHCA2400128 Installation Manual

Installation Manual for

Snow Melting Systems

24/7 Installation Support • Free Design Service • www.WarmlyYours.com • (800) 875-5285

Contents

1.0 Product Specications ...................................................................................................... 1

2.0 Selection of the Heating System ......................................................................................... 2

3.0 Important Instructions before Installing the System............................................................ 2

4.0 Installation for Snow Melting .............................................................................................. 3

4.1 Control of Snow Melting System .............................................................................. 3

4.2 Electrical Provisions for the System .......................................................................... 3

4.3 Installation under Asphalt .......................................................................................... 4

4.4 Installation under Concrete ....................................................................................... 5

4.5 Installation in mortar under Pavers ............................................................................ 6

4.6 Installation of Snow Melting Mat ............................................................................... 7

5.0. Testing the Mats and Cable ................................................................................................ 8

5.1 Test One: Insulation Resistance ................................................................................ 8

5.2 Test Two: Total Cable Resistance .............................................................................. 8

6.0 Warranty .............................................................................................................................. 8

7.0 Appendix

Appendix A: WarmlyYours Snow Melting Mats and cable charts .............................................. 9-10

Appendix B: Cross-Section of Snow Melting Cable in Asphalt ................................................. 11

Appendix C: Cross-Section of Snow Melting Cable in Concrete ............................................... 12

Appendix D: Cross-Section of Snow Melting Cable in Mortar Under Pavers ............................ 13

Appendix E: Cross-Section of Snow Melting Cable in Stairs ..................................................... 14

Appendix F: WarmlyYours Snow Melting System Diagram Premium 240V ............................... 15

Appendix G: WarmlyYours Snow Melting System Diagram Premium 277V .............................. 16

Appendix H: WarmlyYours Snow Melting System Diagram Premium 208V............................... 17

Appendix I: WarmlyYours Snow Melting System Diagram SCA-120-SS ................................... 18

Appendix J: WarmlyYours Snow Melting System Diagram Economy 240V .............................. 19

Appendix K: WarmlyYours Snow Melting System Diagram Economy 277V .............................. 20

Appendix L: WarmlyYours Snow Melting System Diagram Economy 208V .............................. 21

Appendix M: WarmlyYours Snow Melting System Diagram Manual 240V................................. 22

Appendix N: WarmlyYours Snow Melting System Diagram Manual 277V ................................. 23

Appendix O: WarmlyYours Snow Melting System Diagram Manual 208V ................................. 24

Appendix P: WarmlyYours Snow Melting System Diagram SCA-DUAL 240V ........................... 25

Appendix Q: WarmlyYours Snow Melting System Diagram SCA-DUAL 277V ........................... 26

Appendix R: WarmlyYours Snow Melting System Diagram SCA-DUAL 208V ........................... 27

Appendix S WarmlyYours Snow Melting System Diagram SCA-DUAL No Relay 240V ............ 28

Appendix T: WarmlyYours Snow Melting System Diagram SCA-DUAL No Relay 208V ............ 29

Appendix U: WarmlyYours Snow Melting System Diagram SCA-DUAL w/Relay 240V ............. 30

Appendix V: WarmlyYours Snow Melting System Diagram SCA-DUAL w/Relay 277V ............. 31

Appendix W: WarmlyYours Snow Melting System Diagram SCA-DUAL w/Relay 208V ............ 32

Appendix X Expansion and Control Joint Cross Section ........................................................... 33

Appendix Y: Junction Box Mounting .......................................................................................... 34

8.0 Troubleshooting ................................................................................................................... 35

1.0 Product Specications

WarmlyYours Heating Cable is designed for outdoor driveways, walkways, stairs and

patios. It is well suited for large areas like driveways.

The Heating Cable is comprised of a dual, multistrand heating element with a primary

insulation of Fluoropolymer. The insulated core is then protected with a woven metal

braid and an outer jacket of PVC, EPR or Zero Halogen Polyolen based compound

to make it sturdier and to provide corrosion protection. These cables are terminated

with 20’ (6.1m) for 120V/240V or 50’ (15.2m) for 208V/277V long standard cold leads.

The hot and cold junction is uniquely designed to make it 100% fool proof.

The Snow Melting Mat is a cable in mat (1.25” x 1.25” mesh openings) construction

which consists of the Heating Cable taped on a Polypropylene (PP) mat. The Heating

Cable is laid in a serpentine fashion so that it is equally spaced and distributed on

the (PP) mat.

Available in a wide range of capacities and sizes to suit your requirements, the Snow

Melting Mats and Heating Cables are identied as indicated below.

Item Number: AAAA-BBB-CCCC

Ex: Item Number: WHMA-240-0250

(product type) (voltage) (width & length = 2’x50’)

• AAAA = WHMA for Snow Melting Mat, WHCA for Snow Melting Cable

• BBB = Operating Voltage available in 120V, 208V, 240V and 277V

• CCCC = Mat width in ft. (rst two digits) and Mat length in ft. (third and fourth

digits) for Snow Melting Mat, Cable length in ft. for Snow Melting Cable

The available sizes of Snow Melting Mats are shown in Appendix A. The available

lengths of Snow Melting Cables are shown in Appendix B. Both Appendices include

the following attributes for each Item Number.

• Product Type

• Operating Voltage

• Cable Length

• Mat Width and Length

• Total Ohms

• Total Watts

• Watts/Ft for Cable or Watts/Sq Ft for Mats

• Amps

9.0 Warranty Registration .......................................................................................................... 37

1

2.0 Selection of the Heating System

Selection of your Heating System will depend on the application. The following can

be taken as a general guide:

Install Chart

6. Do not install the Heating Cable below 5˚ F (-15˚ C) ambient temperature.

7. Minimum bending radius of the Heating Cable shall not be less than 10 times

its diameter.

8. Minimum spacing of Cables is 3” (76 mm) and maximum spacing of Cables is 3.5”

(89 mm). As spacing distance of wire increases, watts per square foot decrease.

Application

Outdoor Snow Melting

Watts per Sq.Ft. (per Sq.M.)

- Cable spacing inches (mm)

45 to 55 W/ft2 (484 to 592 W/m2)

Recommended spacing 3” (76mm).

Multiplier at

given spacing

4.0 at 3” (76mm)

Formula: Area of Application x Multiplier at given cable spacing = Heated Cable

Length required

Example 1 (English): 100 sq.ft of Outdoor Snow Melting x 4.0 at 3” spacing = 400

feet of Heated Cable required

Example 2 (Metric): 9.3 sq.m of Outdoor Snow Melting x 4.0 at 76mm spacing =

122m of Heated Cable required

Please note the above-indicated values are meant as a general guide. Your values

may vary depending on a number of factors. Please consult your Account Manager

for assistance.

3.0 Important Instructions before

Installing the System

1. Heating Cable must not cross or overlap itself at any point. This could cause the

Cable to overheat, requiring replacement.

2. The Heating Cable length should not be cut or altered under any circumstances. This

may cause over-heating resulting in damage to the Cable.

9. Twin Conductor Heating Cable has a ground braid (metal sheath) to be connected to

ground and 2 conductors which are to be connected to the power supply.

10. Double check the voltage and wattage of the Heating Cable received against the

project specications on your custom installation plan. These are marked on the

packing box of the product. A qualied electrician should connect the Heating

System.

11. A digital Ohm meter and a Megohmmeter (Insulation Tester) will be needed

to properly install the system. Check the continuity, resistance and insulation

resistance of the Heating Cable before installing and also after installing. Resistance

value should match the value shown in Appendix A on page 9 & 10. A tolerance of

-5% to +10% is allowed. Insulation resistance should be innity.

12. Keep high voltage power wires in a separate conduit from low voltage wires.

13. Allow sucient drying or curing period of the concrete / asphalt after installing the

Heating System and before energizing the Heating System.

14. For easy reference, ax a label at the power distribution board indicating the

location of the heating units installed.

15. The National Electric code requires that the heating cables be installed over a base

of at least 2” of substantial masonry or asphalt, and have at least 1.5” of the same

installed over the cable. Our recommendations are based on these NEC standards.

WARNING

16. The Cable must NOT be shortened or cut in any manner or subjected to strain at

the splice joint.

3. The cold lead can be cut or extended with a conventional splice, inside of an

accessible junction box (weatherproof if outdoors).

4. Take precautions to avoid damage to Heating Cable during installation. Do not drive

over cable. Duct tape the ends of shovels. Do NOT saw expansion joints, without

having lines marked o clearly with spray paint, where installer has veried that

Heating Cables will not be cut. Do NOT damage Cables with heavy equipment,

machinery or vehicles. Do not walk on splices, do not bend splices.

5. Heating Cables should be separated from other heat sources such as luminaries

and chimneys.

17. NEVER power-up Heating Cables prior to being buried in concrete, asphalt or

in mortar (even for testing purposes). This will prevent premature failure of the

Heating Cable.

Heating Cable must not cross or overlap itself at any point.

This could cause the Cable to overheat, requiring replacement.

2

Heating Conductor (Solid/Multistrand)

20’ (610cm)

Cold Lead

SENSOR

HEATING

CABLE

FLOOR

HEATING SYSTEM

THERMOSTAT

110V / 230V AC SUPPLY

in (15 cm) apart

and 6 in (15 cm)

from slab edge

installed on

slab edge

bunched

Control joint

Concrete

Heating cable secured to

rebar with plastic tie wraps

Steel bar

3”

3”

Topping 2 in (5.0 cm)

minimum to 3 in (7.5 cm)

maximum thickness

Dimension B must not

exceed 6 in (15 cm)

Dimension A must not

exceed 3 in (7.5 cm)

If dimension C exceeds 3

in(10 cm) an additional run

of cable must be used

B

Wrong

Wrong

C

A

3”

3”

4.0 Installation for Snow Melting

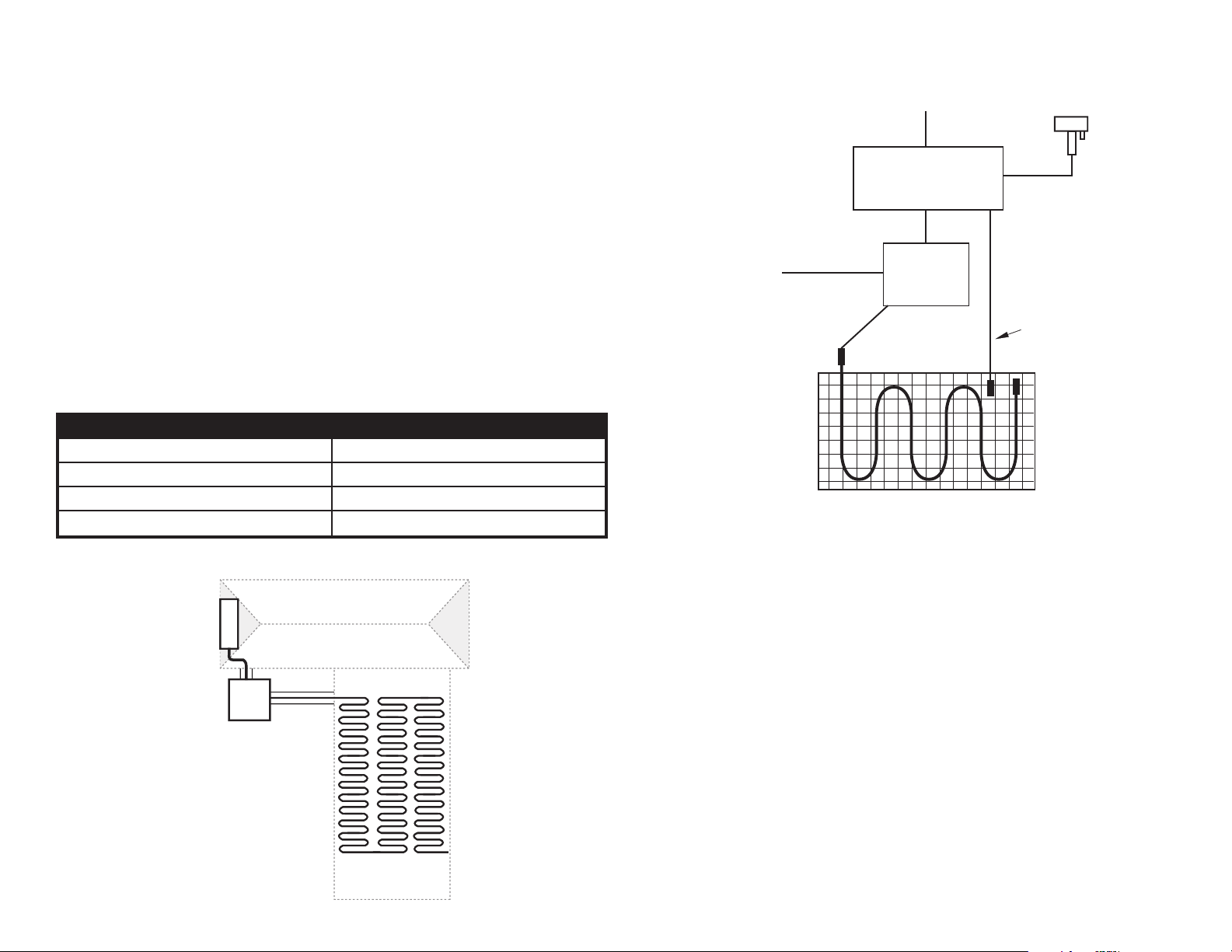

4.1 Control of Snow Melting System

A control suitable for Snow Melting systems with pavement mounted or aerial

mounted sensor should be used for Snow Melting applications, when not using a

Timer.

4.2 Electrical Provisions for the Systems

The National Electric Code requires that the heating cables and mats must be

supplied power by a GFEP (30mA) protected circuit.

The Snow Melting system installation wiring shall be in accordance with the National

Electric Code and prevailing local codes.

The snow / moisture sensor cable and the Heating Cable cold leads shall be routed

to the power connection box in separate conduits.

Breaker Size (Amps) Max Design Load (Amps)

40 32

30 24

20 16

15 12

120 VAC

240 VAC

277 VAC

SUPPLY

120 VAC SUPPLY

CONTROL

PANEL

RELAY

PANEL

SLAB TEMP HIGH

LIMIT SENSOR

(IF APPLICABLE)

SNOW MELT MAT AND CABLE

SNOW

SENSOR

RELAY

J-BOX

HOUSE

DRIVEWAY

3

4.3 Installation under Asphalt

1. Ensure that the paving contractor has a solid base of 4” to 8” (102 mm to 203

mm) of crushed rock aggregate tamped down and ready to receive the asphalt.

2. It is extremely important that the paving installer does NOT use any heavy

equipment, machinery, or vehicles over the exposed Heating Cable. Any tracked

mechanical spreaders or dump trucks must be prohibited from running over

exposed Heating Cable.

3. During this process of laying asphalt, installing the heating product, and

laying more asphalt, it is the responsibility of the electrician to use a 500 VDC

megohmmeter and a multi-meter to continuously check the Heating Cables that

are being worked on top of, to ensure they have not been damaged.

4a. The paving installer should lay down the binder / base coat of asphalt and roller it

smooth. The paving installer must decide if this binder coat of asphalt is allowed

to cool before nishing with the top coat of asphalt. This should be coordinated

with the installer of the Heating Cable or Mats. When working on top of hot

asphalt, please consider pre-making “wire mesh heating Mats”. This means

rolling out the reinforcing wire mesh (provided by electrician) and pre-attaching

the Heating Cable to it using wire ties (like rebar wire ties) that will not melt from

the hot asphalt. These “wire mesh heating Mats” could be left in the yard next

to the driveway while the rst binder coat is poured. While the asphalt is still hot,

two people could carry / drag each “wire mesh heating mat” over the hot asphalt,

have it ipped over so that it is wire-side-down / mesh-side-up, and then staked

down to the hot binder coat (stakes provided by electrician).

4b. If the paving installer decides to let the binder / base coat of asphalt cool prior

to nishing with the top coat, then wire mesh is only needed for free-form type

Heating Cable installations. WarmlyYours Snow Melting Mats may be staked

down to the binder coat without using any wire mesh (stakes may only pierce the

black plastic mesh, and should never make direct contact with the Heating Cable

itself). Again, it’s recommended that the Snow Melting Mat be laid down so it

is wire-side-down / mesh-side-up, to help protect it from damage by shovels.

When installing free-form type Heating Cable, stake wire mesh down to the

binder / base coat rst, and then attach the Heating Cable to it using wire ties.

This means it is wire-side-up / mesh-side-down, so extra care must be taken by

the paving installer to avoid damaging the Heating Cables with shovels or rakes

used to spread the top coat of asphalt.

4c. When the binder coat is in place, it is sometimes easier (especially when installing

tire track coverage) to have one person hold the roll of heating mat (wire side

down) as hot asphalt is shoveled over it. as the area is covered the installer

slowly unrolls the product until the remaining area is completed.

5. Once the heater cables are in place, the electrician must route the cold lead(s),

(20’ (6.1m) for 120V/240V or 50’ (15.2m) for 208V and 277V provided per each

Mat/Cable) through rigid metal conduit(s) or other approved means, to get back

to an accessible weatherproof junction box(s). The electrician may supply

junction boxes which can be accessed from above, so the rest of the box is

buried to avoid damage by lawn mowers and/or vehicles. Care must be taken by

the electrician so that none of the heated section of Cable enters the conduit(s).

If a slab-mounted snow sensor will be used, this is the best time for placement.

It should be located in an open area, away from trees or bushes, so that snow

will easily fall directly on it. Separate conduit should be used to protect the low

voltage sensor wire and must NOT be shared with any high voltage cold lead from

the Heating Cables / Mats.

6. Once the Heating Cables and conduits are in place, and are attached by the

methods listed, above the nal top coat of asphalt may be poured. At least 2”

(51mm) of material must cover the Heating Cable. The paving installer will be

required to spread this around evenly with shovels and rakes. Shovels should be

duct taped so the blade ends are less sharp. Again, the topping coat should be

spread manually to avoid use of heavy machinery. The only time it is acceptable

to use a mechanical asphalt spreader would be when it can straddle tire track

coverage used for longer sloped driveways. Tire track coverage allows the

spreader machine to be used without it ever making any direct contact with the

Heating Cables.

7. Once the top coat of asphalt is spread over the Heating Cables evenly with at least

2” (51 mm) thick coverage, it may be rolled over with the steam roller to nish /

atten the driveway. Again, each Heating Cable / Mat must be tested with a multimeter and 500 VDC megohmmeter to verify that they have not been damaged,

and to ensure they will be ready for activation (nal test) after the asphalt has

cured. These values should be recorded on the warranty card on page 35.

4

4.4 Installation under Concrete

1. Ensure that the concrete contractor has installed a solid base of 4” to 8” (102 mm

to 203mm) of crushed rock aggregate base and that it is tamped down and ready

for the concrete pour. The dimensions of the openings in the snow melt rolls are 1

1/4” x 1 1/4”. Use 3/4” or smaller aggregate in concrete when pouring over snow

melt rolls.

2 . It is extremely important that the concrete installer does NOT use any heavy

equipment, machinery, or vehicles over the exposed Heating Cable. During

concrete pours, it is recommended that care be taken to avoid stepping on the

transition portion of cable, where the hot section (green) meets the cold section

(black). This is the location of the factory splice. During this process of installing

the heating product and pouring concrete, it is the responsibility of the electrician

to use a 500 VDC megohmmeter and a multi-meter to keep checking on the

Heating Cables that are currently being worked on top of, to ensure they have not

been damaged, and will be ready for action once the concrete slab has cured.

3. For installations in stairs and ramps that will include hand rails, it is strongly

recommended that the concrete installer pre-sleeve for the posts to avoid any

and all drilling of the concrete. The Heating Cable must be routed around these

sleeves or posts to avoid any direct contact with them. Heating Cables or Mats

must not be allowed to pass thru expansion joint locations. It is recommended

that lines are spray painted on the nished concrete surface by the electrician to

mark o exactly where expansion joints may be located. It is the responsibility of

the electrician and the concrete installer to coordinate their eorts so they avoid

saw-cutting or drilling thru Heating Cables that are no longer visible beneath the

concrete. Following the proposed installation plan from WarmlyYours will help to

ensure this process goes smoothly.

4a. For Two-Pour Installations: The concrete installer pours the rst 2” to 3” (51mm

to 76mm) of concrete. While this rst pour is still wet, rebar or wire-mesh should

be placed on top of the rst pour. The Snow Melting Mats / Cables should be

attached to the rebar / mesh with plastic zip ties, using 3” to 4” (76mm to 102mm)

spacing for free-form type cable. At this time, the electrician must route the cold

lead(s) thru rigid metal conduit(s) or other approved means, to get back to an

accessible weatherproof junction box(es). Care must be taken by the electrician

so that none of the heated section enters any conduit. If a slab-mounted snow

sensor will be used, this is the best time for placement. It should be located in

an open area away from trees or bushes so that snow will easily fall directly on

it. Separate conduit should be used to protect the low voltage sensor wire and

must NOT be shared with any high voltage cold lead from the Heating Cables /

Mats. Once conduits & sensor(s) are placed, the topping pour of concrete can

be nished. Again, the concrete installer(s) must take care not to walk on the

hot-cold splice point, and to avoid damaging the Heating Cables with shovels

and rakes. Taping up the shovel blades helps make them less sharp. Like with

asphalt, it’s recommended that Mats be placed so the mesh faces up, keeping

the wire-side-down to help protect it from shovels.

4b. For Single-Pour Installations: The wire mesh or rebar is rst placed by the

concrete installer or electrician. The electrician then must attach the Heating

Cable to the rebar / mesh with plastic zip ties using 3” to 4” (51mm to 76mm)

spacing for free-form type cable. Then the rebar / mesh must be propped up

with concrete rubble, wire chairs, or brick pavers to the appropriate depth so that

Heating Cable / Mat ends up 2” to 3” (51mm to 76mm) from nished surface and

no deeper. Once rebar / mesh / Heating Cable is all propped up, the electrician

must route the cold leads(s) thru rigid metal conduit(s) or other approved means,

to get back to an accessible weatherproof junction box (es). Care must be taken

so that none of heated section enters any conduit. If a slab-mounted snow

sensor will be used, this is the best time for placement. It should be located in

an open area, away from trees or bushes, so that snow will easily fall directly on

it. Separate conduit should be used to protect the low voltage sensor wire and

must NOT be shared with any high voltage cold lead from the Heating Cables

/ Mats. Once conduits & sensor(s) are placed, the pour of the concrete can be

nished in one step. The concrete installer(s) must take care not to walk on the

hot-cold splice and to avoid damaging the Heating Cables with shovels and

rakes. Mats should be placed mesh facing up, keeping the wire-side-down, to

help protect it from the shovels and rakes.

5. The electrician needs to complete nal testing of all the Heating Cables / Mats

with a multi-meter and a megohmmeter to verify and record that each Heating

Cable has survived the pour of concrete and is ready for action once the concrete

is cured. These values must be recorded on the warranty card on page 35.

5

4.5 Installation under Pavers (Stone or Brick)

1. Ensure that there is a solid base of 4” to 8” (102mm to 203mm) of crushed rock

aggregate base and that it is tamped down and ready to receive the mortar pour.

2. It is extremely important that the paver installer does NOT use any heavy

equipment, machinery, or vehicles over the exposed Heating Cable. During

the paver installation process, it is recommended that care be taken to avoid

stepping on the hot-cold factory splice portion of cable (green meets black).

It is the responsibility of the electrician to use a 500 VDC megohmmeter and

a multi-meter to continuously check on the Heating Cables that are currently

being worked on top of, to ensure they have not been damaged, and will be

ready for action once the mortar pour has cured.

7. The paver installer(s) must take care not to walk on the hot-cold factory splice

and to avoid damaging the Heating Cables with shovels or rakes. Mats should

be placed mesh facing up, keeping the wire-side-down, to help protect them

from shovels.

8. The electrician needs to complete nal testing of all the Heating Cables / Mats

with a multi-meter and a megohmmeter to verify and record that each Heating

Cable has survived the pour of mortar, and is ready for action once the mortar is

cured. These values must be recorded on the warranty card on page 35.

9. If sand or limestone screenings are used instead of mortar, avoid dropping

pavers onto the surface, as doing so may damage the heating cables.

3. For installations in stairs and ramps that will include hand rails, it is strongly

recommended that the paver installer pre-sleeve for the posts to avoid any and

all drilling of the mortar. The Heating Cable must be routed around these sleeves

or posts to avoid any direct contact with them. It is the responsibility of the

electrician and the paver installer to coordinate their eorts so they avoid sawcutting or drilling thru Heating Cables that are no longer visible beneath the

mortar.

4. The paver installer or electrician should place wire mesh (like would be used

in concrete) down on top of the crushed rock aggregate. The mesh should be

staked down rmly to the crushed rock so it remains at. Next, the Heating Cable

or Mats should be attached to the mesh using wire ties to maintain proper depth

and spacing, 3” (76mm) for free-form type Cable. Reference the WarmlyYours

custom installation plan provided with quotation so that this process goes

smoothly.

5. At this time, the electrician must route the cold lead(s) thru rigid metal conduit(s)

or other approved means, to get back to an accessible weatherproof junction

box(es). Care must be taken by the electrician so that none of the heated section

(green) enters any conduit. For this type of application, we recommend using

an aerial mounted snow sensor to avoid having to cut around a circular slab

mounted sensor (this could cause a trip hazard or premature paver crumble).

Once the conduit(s) is in place, the product is ready to receive the mortar pour

or sand, or limestone screenings.

WARNING

1. Brick and Stone Pavers must NOT be any thicker than 2.5” (63.5mm).

2. We do not recommend tire track coverage when using pavers

6. Care must be taken by the paver installer so the mortar covers the Heating Cables

/ Mats and they will not make direct contact with the pavers. We recommend

that at least 1” (25mm) thick mortar is poured over the Heating Cables / Mats,

but no more than 1.5”(38mm). If using sand or limestone screenings, cover to an

uncompacted depth of 1.5” (38mm), leveled to grade.

6

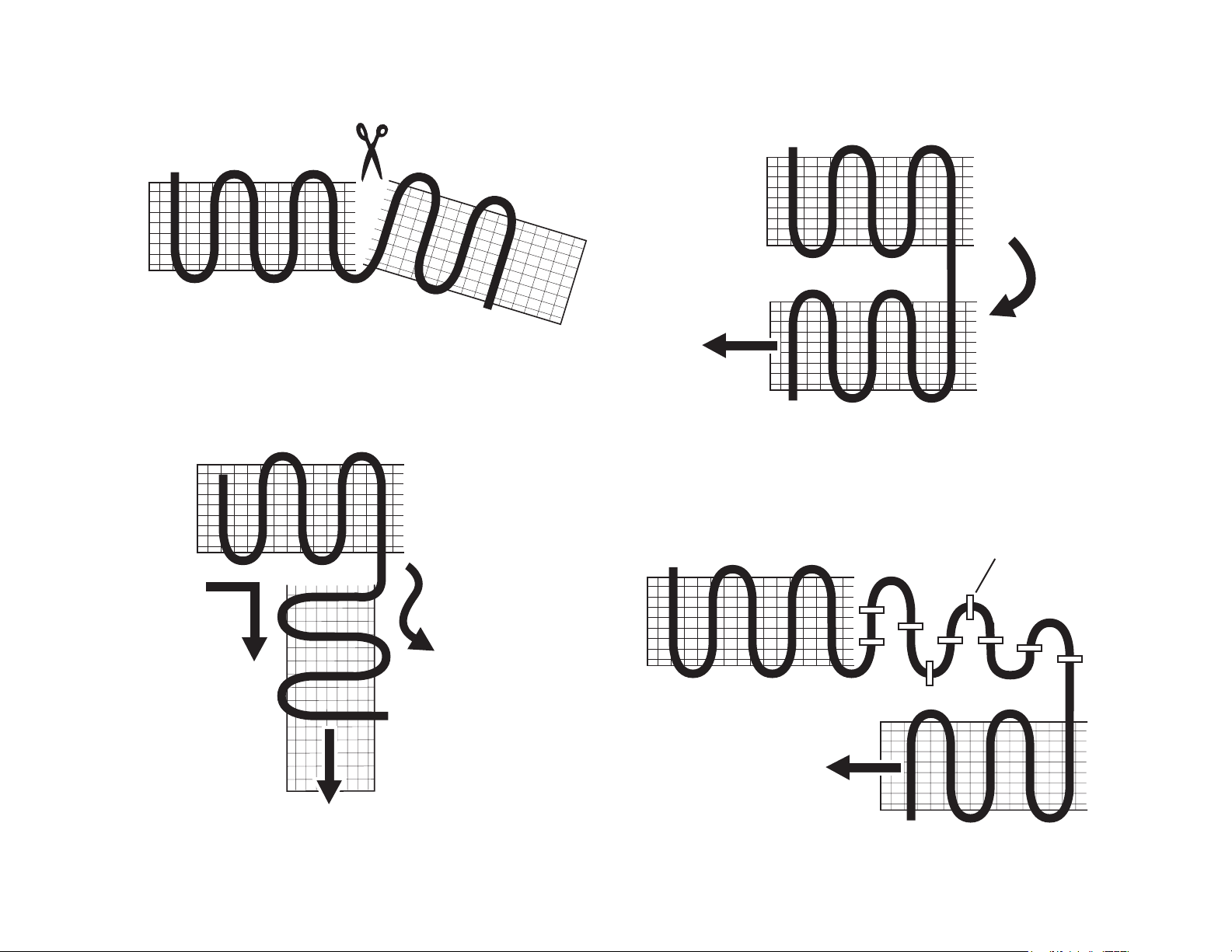

4.6 Installation of Snow Melting Mat

Use scissors to cut the Mat. NEVER cut the Heating Cable

Flip / Turn the Mat

For 90 Degree Turn

For 180 Degree Turn

Turn the Mat

180˚

For other shapes, detach Cable from Mat to required

length and lay only Cable.

Means of attachment may vary

project to project.

90˚

Flip the

Mat Reverse

7

5.0 Testing the Mats and Cable

6.0 Warranty

5.1 Test One: Insulation Resistance

(Megohmmeter Required)

1. Connect one meter clamp to the cold lead (pigtail) inner conductors and the

other meter clamp to the metal cable braided sheath (ground) of the Heating

Cable.

2. Test in accordance with the meter manufacturer’s instructions. Recommended

meter is a 500 VDC megohmmeter.

3. Megohmmeter reading should read innity.

4. Record measured values on the warranty card on page 36. Perform this test

before, during and after installation of the Heating Cables.

5.2 Test Two: Total Cable Resistance

(Multi-Meter Required)

1. Connect one meter clamp to one cold lead (pigtail) inner conductor and the other

meter clamp to the other cold lead (pigtail) inner conductor.

2. Test in accordance with the meter manufacturer’s instructions and record this

ohm value on the warranty card on page 36.

WarmlyYours provides a warranty for the Heating Cables for a period of 10 years

from date of purchase, covering the materials and workmanship under normal

operating conditions.

In case of defective material, WarmlyYours obligation will be limited to the repair or

supply of new material, free of charge to the customer.

The warranty does not cover installations made by unqualied persons or faults

caused by incorrect design by others / misuse / damage caused by others /

damage in transit / incorrect installation and any other subsequent damage that

may occur. Costs related to repair / replacement will be fully chargeable to the

customer if the damage is due to of any of the above reasons.

WarmlyYours is under no circumstances liable for consequential damages or losses

including without limitations the loss or prot arising from any cause whatsoever.

The guarantee is a material warranty only and does not cover eld labor.

The warranty is void if there is any payment default and if data is not lled in on

attached warranty card.

3. Total nominal cable resistance information is found on the CSA label, the bill

of materials and Appendix A, or can be obtained by calling your WarmlyYours

Account Manager. Actual reading should be within -5% - +10% of the cable

resistance.

4. Record measured values on the warranty card on page 36. Perform this test

before, during and after installation of the Heating Cables.

5. Please be sure that you write in the full part number of the Cable or Mat next to

your results.

8

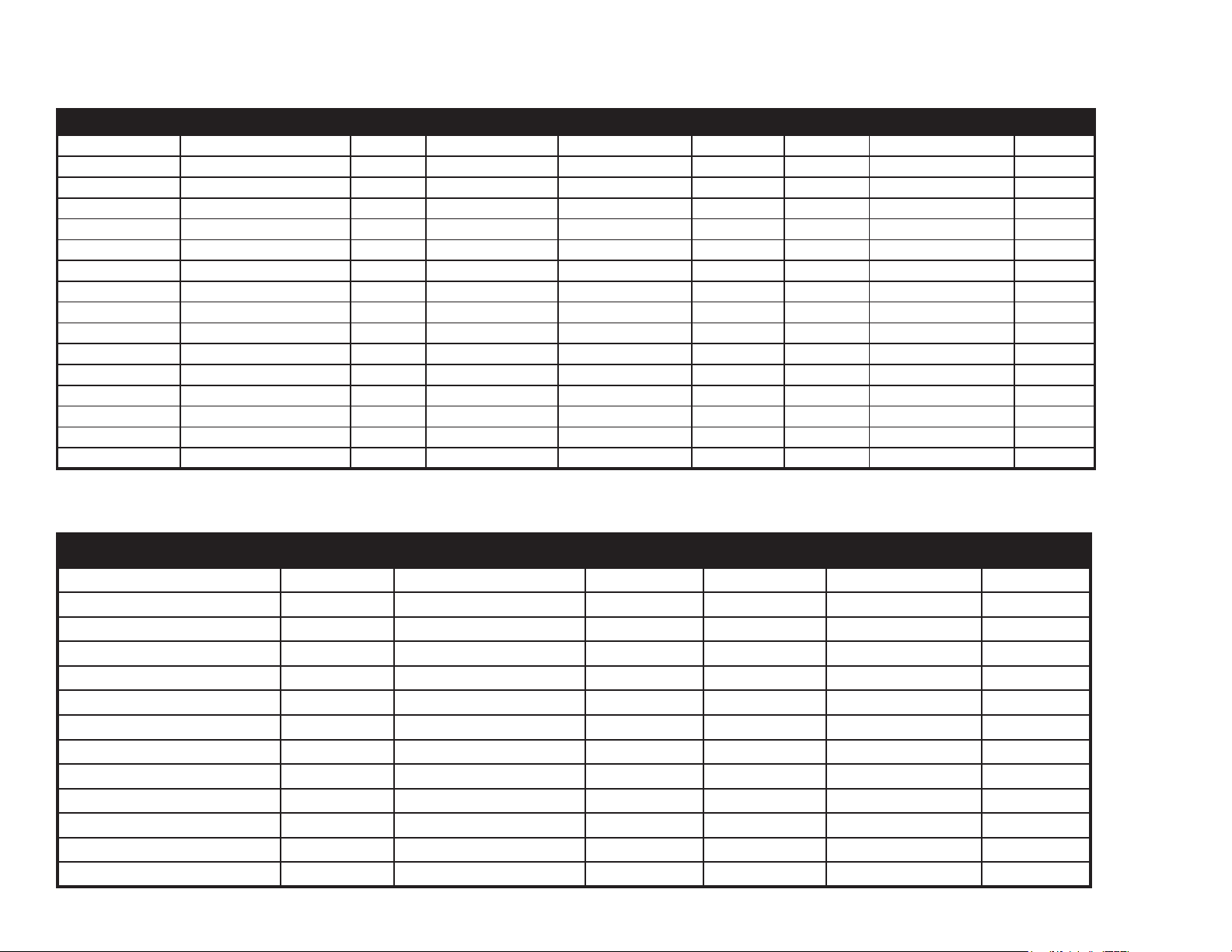

7.0 APPENDIX A:

WARMLYYOURS SNOW MELTING MATS (SUITABLE FOR ASPHALT, CEMENT AND UNDER PAVERS)

Part # Size (ft/m) Voltage Area (ft2/m2) Cable Length (ft/m) Total Ohms Total Watts Watts/ft2 (W/m2) Amps

WHMA-120-0205 2’ x 5’ (0.61 x 1.52m) 120 10.0 (.93m2) 42.77 (13.04m) 28.80 500 50.00 (538W/m2) 4.17

WHMA-120-0305 3’ x 5’ (0.91 x 1.52m) 120 15.0 (1.39m2) 62.78 (19.14m) 19.20 750 50.00 (538W/m2) 6.25

WHMA-120-0210 2’ x 10’ (0.61 x 3.05m) 120 20.0 (1.86m2) 85.54 (26.07m) 14.40 1,000 50.00 (538W/m2) 8.33

WHMA-120-0310 3’ x 10’ (0.91 x 3.05m) 120 30.0 (2.79m2) 125.56 (38.27m) 9.60 1,500 50.00 (538W/m2) 12.50

WHMA-120-0215 2’ x 15’ (0.61 x 4.57m) 120 30.0 (2.79m2) 128.31 (39.11m) 9.60 1,500 50.00 (538W/m2) 12.50

WHMA-120-0315 3’ x 15’ (0.91 x 4.57m) 120 45.0 (4.18m2) 188.34 (57.41m) 6.40 2,250 50.00 (538W/m2) 18.75

WHMA-240-0210 2’ x 10’ (0.61 x 3.05m) 240 20.0 (1.86m2) 85.54 (26.07m) 57.60 1,000 50.00 (538W/m2) 4.17

WHMA-240-0215 2’ x 15’ (0.61 x 4.57m) 240 30.0 (2.79m2) 128.31 (39.11m) 38.40 1,500 50.00 (538W/m2) 6.25

WHMA-240-0220 2’ x 20’ (0.61 x 6.10m) 240 40.0 (3.72m2) 171.08 (52.15m) 28.80 2,000 50.00 (538W/m2) 8.33

WHMA-240-0230 2’ x 30’ (0.61 x 9.14m) 240 60.0 (5.57m2) 256.63 (78.22m) 19.20 3,000 50.00 (538W/m2) 12.50

WHMA-240-0240 2’ x 40’ (0.61 x 12.19m) 240 80.0 (7.43m2) 342.17 (104.29m) 14.40 4,000 50.00 (538W/m2) 16.67

WHMA-240-0250 2’ x 50’ (0.61 x 15.24m) 240 100.0 (9.29m2) 427.71 (130.37m) 11.50 5,000 50.00 (538W/m2) 20.87

WHMA-240-0310 3’ x 10’ (0.91 x 3.05m) 240 30.0 (2.79m2) 125.56 (38.27m) 38.40 1,500 50.00 (538W/m2) 6.25

WHMA-240-0315 3’ x 15’ (0.91 x 4.57m) 240 45.0 (4.18m2) 188.34 (57.41m) 25.60 2,250 50.00 (538W/m2) 9.38

WHMA-240-0320 3’ x 20’ (0.91 x 6.10m) 240 60.0 (5.57m2) 251.12 (76.54m) 19.20 3,000 50.00 (538W/m2) 12.50

WHMA-240-0330 3’ x 30’ (0.91 x 9.14m) 240 90.0 (8.36m2) 376.68 (114.81m) 12.80 4,500 50.00 (538W/m2) 18.75

WARMLYYOURS SNOW MELTING CABLES (SUITABLE FOR ASPHALT, CEMENT AND UNDER PAVERS)

Part # Voltage Cable Length Total Ohms Total Watts Watts/Ft Amps

WHCA-120-0043 120 42.77’ (13.04m) 28.80 500

WHCA-120-0063 120 62.78’ (19.14m) 19.20 750

WHCA-120-0086 120 85.54’ (26.07m) 14.40 1,000

WHCA-120-0126 120 125.56’ (38.27m) 9.60 1,500

WHCA-120-0188 120 188.34’ (57.41m) 6.40 2,250

WHCA-240-0086 240 85.54’ (26.07m) 57.60 1,000

WHCA-240-0128 240 128.31’ (39.11m) 38.40 1,500

WHCA-240-0171 240 171.08’ (52.15m) 28.80 2,000

WHCA-240-0188 240 188.34’ (57.41m) 25.60 2,250

WHCA-240-0251 240 251.12’ (76.54m) 19.20 3,000

WHCA-240-0342 240 342.17’ (104.29m) 14.40 4,000

WHCA-240-0377 240 376.68’ (114.81m) 12.80 4,500

WHCA-240-0428 240 427.71’ (130.37m) 11.50 5,000

11.69 (38W/m)

11.95 (39W/m)

11.69 (38W/m)

11.95 (39W/m)

11.95 (39W/m)

11.69 (38W/m)

11.69 (38W/m)

11.69 (38W/m)

11.95 (39W/m)

11.95 (39W/m)

11.70 (38W/m)

11.95 (39W/m)

11.69 (38W/m)

9 10

4.17

6.25

8.33

12.50

18.75

4.17

6.25

8.33

9.38

12.50

16.67

18.75

20.87

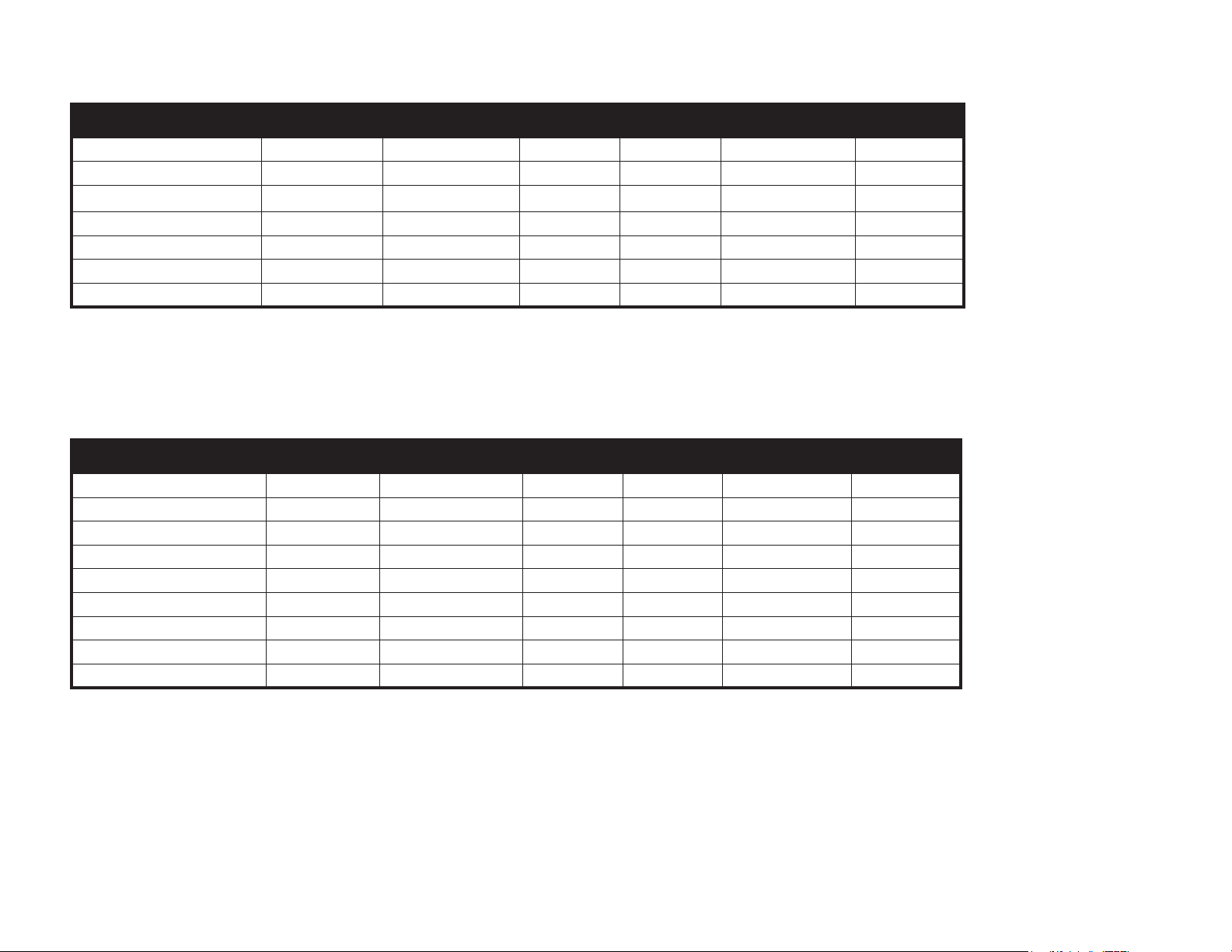

WARMLYYOURS SNOW MELTING CABLES 208V (SUITABLE FOR ASPHALT, CEMENT AND UNDER PAVERS)

Part # Voltage Cable Length (feet) Total Ohms Total Watts Watts/ft Amps

WHCA-208-0100 208 100' 36.05 1,200 12 5.8

WHCA-208-0128 208 128' 28.28 1,530 11.9 7.4

WHCA-208-0171 208 171' 21.63 2,000 11.6 9.7

WHCA-208-0200 208 200' 18.03 2,400 12 11.6

WHCA-208-0251 208 251' 14.42 3,000 11.9 14.5

WHCA-208-0342 208 342' 10.82 4,000 11.6 19.3

WHCA-208-0377 208

377' 9.61

4,500

119 21.7

WARMLYYOURS SNOW MELTING CABLES 277V (SUITABLE FOR ASPHALT, CEMENT AND UNDER PAVERS)

Part # Voltage Cable Length (feet) Total Ohms Total Watts Watts/ft Amps

WHCA-277-0100 277 100' 63.94 1,200 12 4.4

WHCA-277-0128 277 128' 50.15 1,530 11.9 5.6

WHCA-277-0171 277 171' 38.36 2,000 11.6 7.3

WHCA-277-0200 277 200' 31.97 2,400 12 8.7

WHCA-277-0251 277 251' 25.58 3,000 11.9 10.9

WHCA-277-0342 277 342' 19.18 4,000 11.6 14.5

WHCA-277-0377 277 377' 17.05 4,500 11.9 16.3

WHCA-277-0428 277 428' 15.35 5,000 11.6 18.1

WHCA-277-0502 277 502' 12.79 6,000 11.9 21.7

10

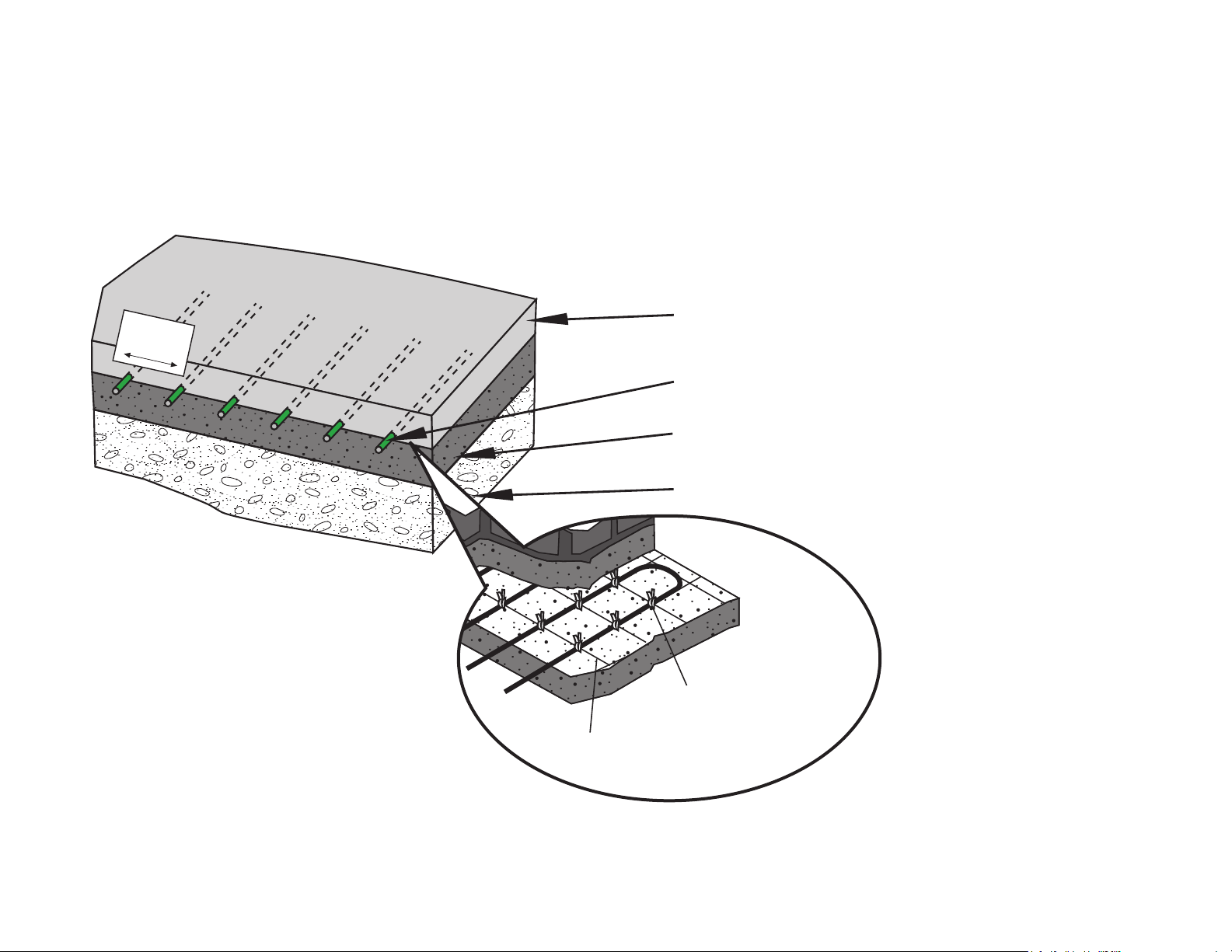

Outdoor Asphalt Snow Melt Application

Recommended Products: Snow Melt Rolls

APPENDIX B:

Plastic tie wrap

4 in (10) or 6 in (15) square 10

gauge wire mesh

CROSS-SECTION OF SNOW MELTING CABLE IN ASPHALT

3” (76mm)

Spacing

2” to 3” (51mm to 76mm) of nished asphalt

Snow Melting Mat

1.5” to 2”(38mm to 51mm) of base/primer asphalt

4” to 8” (102mm to 203mm) of crushed rock aggregate base

Note: Cables may be tied to reinforcement type mesh and then the mesh should be staked down to the base/primer pour.

11

Loading...

Loading...