Page 1

Automatic Snow/Ice Melting System Control Panel

MODEL SCP-120 (APS-3C) SNOW SWITCH

Installation and Operation Manual

24/7 Installation Support • Lifetime Technical Assistance • Free Design Service • www.WarmlyYours.com • (800) 875-5285

Page 2

Safety

Make all electrical connections in compliance with the National Electric Code (NFPA 70)

and local electrical code. If you have questions concerning the installation or application, contact

Customer Service.

General

Introduction

The SCP-120 Series Snow Switch Control Panels, when used with compatible sensors, automatically controls snow and ice melting systems, ensuring complete snow and ice melting at minimum

operating costs. Typical applications include pavement, sidewalk, loading dock, roof, gutter and down

spout snow/ice melting.

The SCP-120 provides a relay closure interface for use with energy management computers (EMC). This feature can also be used for general purpose remote control annunciation and other

advanced applications. Simple remote control features are also provided by the RCO Remote Control

for the SCP-120.

All sensor and communications wiring is NEC Class 2 (high voltage). This simplifi es installation while

enhancing fi re and shock safety.

Environmental Interfaces

The SCP-120 determines when to start heater operation by monitoring the signals produced

by up to six customer supplied environmental sensors paralleled together using a three-wire bus.

Available sensors include:

• AIR-SS Aerial Snow and Ice Sensor

When used either alone or in combination, these sensors accurately determine whether or

not snow and ice melting is required. This data is communicated back to SCP-120.

Sensors measure ambient temperature and detect moisture, in any form. Snow, sleet, freezing rain, etc. is assumed if moisture is present at temperatures below 38°F (3.33°C). Beginning heater

operation at temperatures slightly above freezing is essential to meeting customer expectations. It

takes a long time for snow to melt at 34°F.

Sensors employ a heated interdigitated grid for moisture detection. Heat melts frozen precipitation to form water which is a better conductor of electricity. Circuits detect water as a change in

resistance between the fi ngers of the interdigitated grid. The temperature of the moisture sensor is

regulated electronically.

Each sensor has its own microcontroller for signal processing, logic and control. This enables the use of a simple 3-wire bus to connect sensors with the control. Extension wire function and

colors follow:

• Supply(Red)

• Signal(White)

• Ground(Black)

The supply voltage is nominally 24 VAC. The signal is inverted. That is, snow produces a

ground and its absence produces 24 VAC rectifi ed. Sensors are wired together in parallel in a “wired

OR” confi guration. That is, red to red, white to white and black to black. When several sensors are

connected in parallel, any sensor asserting a ground on the signal conductor enables snow melting

heater operation. No ground on the signal line indicates the absence of snow. The SCP-120 includes

a temperature sensor for measuring pavement slab or ambient air temperature. Its signal is used to

provide an adjustable high limit temperature function.

Page 3

High Limit Sensor

The calibrated 40°F to 90°F (4°C to 32°C) high limit sensor prevents excessive temperatures

when using constant wattage and MI heaters. It also permits safe testing at outdoor temperatures too

high for continuous heater operation. The temperature sensor is included.

There are two DIP switch confi gurable operation modes for the high limit thermostat. The factory default operation mode uses the high limit thermostat as a slab temperature regulator, preventing

heater operation at temperatures above the set HIGH TEMPERATURE LIMIT. The optional operation

mode uses the high limit thermostat as an ambient air sensor, preventing heater operation at temperatures above the set HIGH TEMPERATURE LIMIT until the temperature comes back within limits.

The details of operation in each mode are as follows:

Slab Regulating Thermostat Mode

• High temperature causes unit to turn off heaters, if running, and to ignore any call for heater

operation from the panel, RCO or EMC.

• High temperature continues any hold-on cycle that was initiated before the high temperature

condition. If the slab temperature drops within limits during the hold-on time the heater will be turned

back on.

• The HEATER CYCLE functions normally.

Ambient Temperature Sensor Mode

• High temperature causes unit to turn off heaters, if running, and to ignore any call for heater

operation from the panel, RCO (RCU) or EMC.

• High temperature cancels any hold-on cycle that was initiated before the high temperature

condition.

• If the HEATER CYCLE switch is operated in a high temperature condition the heater(s) will be

turned on for a maximum of 30 seconds. A new HEATER CYCLE can not be initiated for another two

minutes after that.

Page 4

Initial Settings

When fi rst placing the system in service, the hold-on time should be set to an initial value.

Three to fi ve hours is suggested as a starting point. If the heaters turn off before the snow is completely cleared and the melt water evaporated, increase the hold-on time by an hour or two. If the

heaters operate for several hours after the pavement is clear and dry, decrease the hold-on time by

an hour. Continue this process until satisfactory performance is achieved.

The small amount of energy wasted by a slightly excessive hold-on time is secondary to complete snow clearing and melt water evaporation. Incomplete operation is not desirable since

this can result in re-freezing melt water which creates a slippery ice fi lm.

If The System Turns Off Too Soon

If the system turns off before the pavement is clear and dry, toggle the heaters on for the holdon using the HOLD-ON switch on the front panel of the control. Repeat as many times as is necessary until the pavement is clear and dry. If the heaters remain operating after the pavement is clear

and dry, terminate the hold- on cycle with the HOLD-ON switch. Normal operation resumes if it starts

snowing during hold-on.

Energy Management Computer (EMC) Interface

The SCP-120 interfaces an EMC via relays. Inputs from the EMC include OVERRIDE ON

which causes heater operation and OVERRIDE OFF which inhibits heater operation. These functions

are independent of weather conditions and the status of the hold-on timer. The interface provides fi ve

system status contact closures for the EMC including SUPPLY, SNOW, HEATER, ALARM and TEMPERATURE LIMIT.

Absent signals from the EMC, the SCP-120 control panel controls the heaters based on environmental conditions. Automatic snow melting control is the default condition of the system.

SCP-120 Front Panel

The SCP-120 has indicators, adjustments and a switch for local control of the snow melting

system. Indicators include LED lights for SUPPLY, SNOW, HEAT, EMC, TEMP LIMIT and GFEP.

Adjustments provided allow for the calibrated adjustment of system HOLD-ON time from zero to ten

hours (or off) and TEMP LIMIT for the high-limit temperature adjustment with a range of 40° to 90°F

(4° to 32°C). The HEATER TOGGLE switch allows for the starting and stopping of a manual HEATER

CYCLE.

Figure 2 shows the SCP-120 front panel layout.

Page 5

Figure 2: SCP-120 front

panel detail

RCO Remote Control Unit

The RCO Remote Control Unit is used with the SCP-120. It adds remote control and status

display to the SCP-120 control at a location convenient to personnel capable of observing snow

melting system operation.

Snow, slush or ice, either alone or in combination, must contact at least one sensor to start

melting. Heater operation continues until all sensors are dry. Depending on the rate of fall, snow

density, wind velocity, and other factors, heater operation must continue for a period of time after the

last sensor dries off. Slush tracked by vehicle and pedestrian traffi c along with blowing and drifting

snow are problems that are hard to predict.

The cycle timer in the SCP-120 begins when the last sensor dries off and continues for an

adjustable period of up to 10 hours to keep the heaters operational until the pavement is completely

dry. Otherwise, residual water could re-freeze and create a hazardous condition.

The RCO provides a two, four, six or eight hour CYCLE TIME adjustment that is independent of the

cycle time in the SCP-120. This allows treatment of the condition requiring an additional heater cycle

as the exception rather than the rule in order to minimize energy use.

Page 6

Operating the HEATER CYCLE switch operates heaters for the CYCLE TIME which is normally set to 2 hours. Operating the HEATER CYCLE switch during the cycle time stops the timer. If

the pavement or ambient temperature exceeds the SCP-120 HIGH LIMIT TEMPERATURE setting,

the heater duty cycle is reduced or disabled to prevent overheating.

Status indicators include SUPPLY and HEAT. These perform the same functions as those on

the SCP-120 front panel.

Figure 5 shows the RCO layout.

SPECIFICATIONS

All Specifi cations apply to SCP-120

General

Area of use

Approvals

Enclosure

Protection

Cover attachment

Entries

Material

Mounting

Nonhazardous locations

NEMA 3R

Hinged polycarbonate cover, lockable

SCM120: 3 × 1-1/16" entries (120 VAC Single Phase ONLY

Polycarbonate

Wall mounted

Figure 5: RCO

Page 7

Control

Supply

Load

Contact type

Maximum Ratings

Heater hold-on timer

System test

Snow/Ice Sensors

Sensor type

Circuit type

Lead length

High Limit Sensor

Adjustment range

Dead band

Sensor type

Circuit type

Lead type

SCP-120: ETI PN 22470: 120 VAC, 50/60 Hz, 35 VA

SCP-120: ETI PN 22470: 120 VAC, 24 amp max. inductive

ETI PN 22471: 208-240 VAC, 24 amp max. inductive

SCP-120: Form C

SCP-120: Voltage: 120VAC

Current: 24 amps

0 to 10 hours; actuated by snow stopping or toggle switch

Switch toggles the heater contact on and off. If temperature

exceeds high limit, heater cycles to prevent damage.

Up to 6 sensors from the AIR-SS product family

NEC Class 2

Up to 500’ (152m) using 18 AWG 2-wire jacketed cable Up to

1,000’ (304m) using 12 AWG 2-wire jacketed cable

40°F to 90°F (4°C to 32°C)

1°F (0.6°C)

Thermistor network

NEC Class 2

Up to 500’ (152m) using 18 AWG 2-wire jacketed cable Up to

1,000’ (304m) using 12 AWG 2-wire jacketed cable

Energy Management Computer

(EMC) Interface

Inputs

Outputs

Environmental

Operating temperature

Storage temperature

OVERRIDE ON (10 ma dry switch contact)

OVERRIDE OFF (10 ma dry switch contact)

SUPPLY (10 ma dry switch contact) SNOW (10 ma dry switch

contact) HEAT (10 ma dry switch contact) HIGH TEMP (10 ma

dry switch contact) ALARM (10 ma dry switch contact)

–40°F to 160°F (–40°C to 71°C)

–50°F to 180°F (–45°C to 82°C)

Page 8

OPERATION

SCP-120

The snow melting system can be monitored and controlled either locally from the SCP-120 itself

or from two remote locations including:

• RCO Remote Control Unit

• BEMC

Local Control from the SCP-120

Indicators:

• SUPPLY (green) shows that power is present.

• SNOW (yellow) shows that there is a snow/ice signal originating from at least one of the sensors attached to the system.

• HEAT (yellow) shows that there is a call for heat. This happens during snow and for the holdon time thereafter or when the heater cycle switch is operated.

• EMC (yellow) shows that the interfaced Energy Management Computer is presently overriding

local system control.

• TEMP LIMIT (red) shows that either the pavement temperature is above the set HIGH TEMPERATURE LIMIT and there is a call for HEAT or the ambient air temperature is above the set HIGH

TEMPERATURE LIMIT. The SCP-120 can be confi gured to monitor slab temperature or ambient air

temperature but not both.

Adjustments:

• HOLD-ON TIME adjustment sets the time that heaters operate after snow stops. Doing this is

necessary to make certain the pavement dries before heating ceases. This prevents refreezing. Try

an initial setting of 3-5 hours. Increase, if necessary. Reduce with care since energy savings are being traded for an increased likelihood of refreezing.

• HIGH-LIMIT TEMPERATURE adjustment sets the maximum deicing temperature.

Switches:

• HEATER CYCLE switch momentarily toggled down will start a manual heater cycle for the set

HOLD-ON TIME or restart the HEATER CYCLE if on was already in progress. Momentarily toggled

up will cancel a heater cycle if one is in progress.

Remote Control from the RCO

Indicators:

• SUPPLY (green) shows that power is present.

• HEAT (yellow) shows that there is a call for heat. This happens during snow and for the holdon time thereafter or when the heater cycle switch is operated.

Adjustments:

• CYCLE TIME adjustment sets the time heaters will operate when HEATER CYCLE switch is

momentarily depressed at the RCO.

Page 9

Switches:

• HEATER CYCLE switch momentarily depressed will start a manual heater cycle for the set

CYCLE TIME. Momentarily depressed while heaters are being operated by a hold-on timer or during manual heater cycle will end the heater cycle. Heater operation during snow conditions cannot be

canceled in this manner.

Remote Control from the EMC Interface

Please see the EMC section of the manual for interface details.

Energy Management Computer (EMC) Interface

The SCP-120 Series provides an EMC interface to communicate with the EMC of building automation systems. The EMC interface provides 10 mA dry switch contacts for communicating status to

the EMC or starting or stopping the system from the EMC.

EMC interface outputs:

• Output Common

• HEAT indicates that there is a call for heat. This happens during snow and for the hold-on time

thereafter or when the heater cycle switch is operated.

• SNOW indicates that there is a snow/ice signal originating from AIR-SS sensor attached to the

system.

• ALARM

• SUPPLY indicates that power is present.

• TEMP LIMIT indicates that either the pavement temperature is above

the set HIGH TEMPERATURE LIMIT and there is a call for HEAT or the ambient air temperature is

above the set HIGH TEMERATURE LIMIT. An SCP-120 Series control can be confi gured to monitor

slab temperature or ambient air temperature but not both.

EMC interface inputs:

• OVERRIDE ON can be used to override an attached SCP-120 control in order to turn heaters

on. A normal contact closure will turn on heaters until operation is cancelled. If the EMC cycles the

OVERIDE ON relay on and off again within more than 32 milliseconds but less than 300 milliseconds

the attached APS “C” Series control will begin a manual heater cycle and run for the HOLD-ON TIME

set at the panel.

• OVERRIDE OFF can be used to override an attached SCP-120 control in order to turn heaters off. A normal contact closure will turn off heaters. If the EMC cycles the OVERIDE OFF relay on

and off again within more than 32 milliseconds but less than 300 milliseconds the attached SCP-120

control will end a manual heater cycle.

Page 10

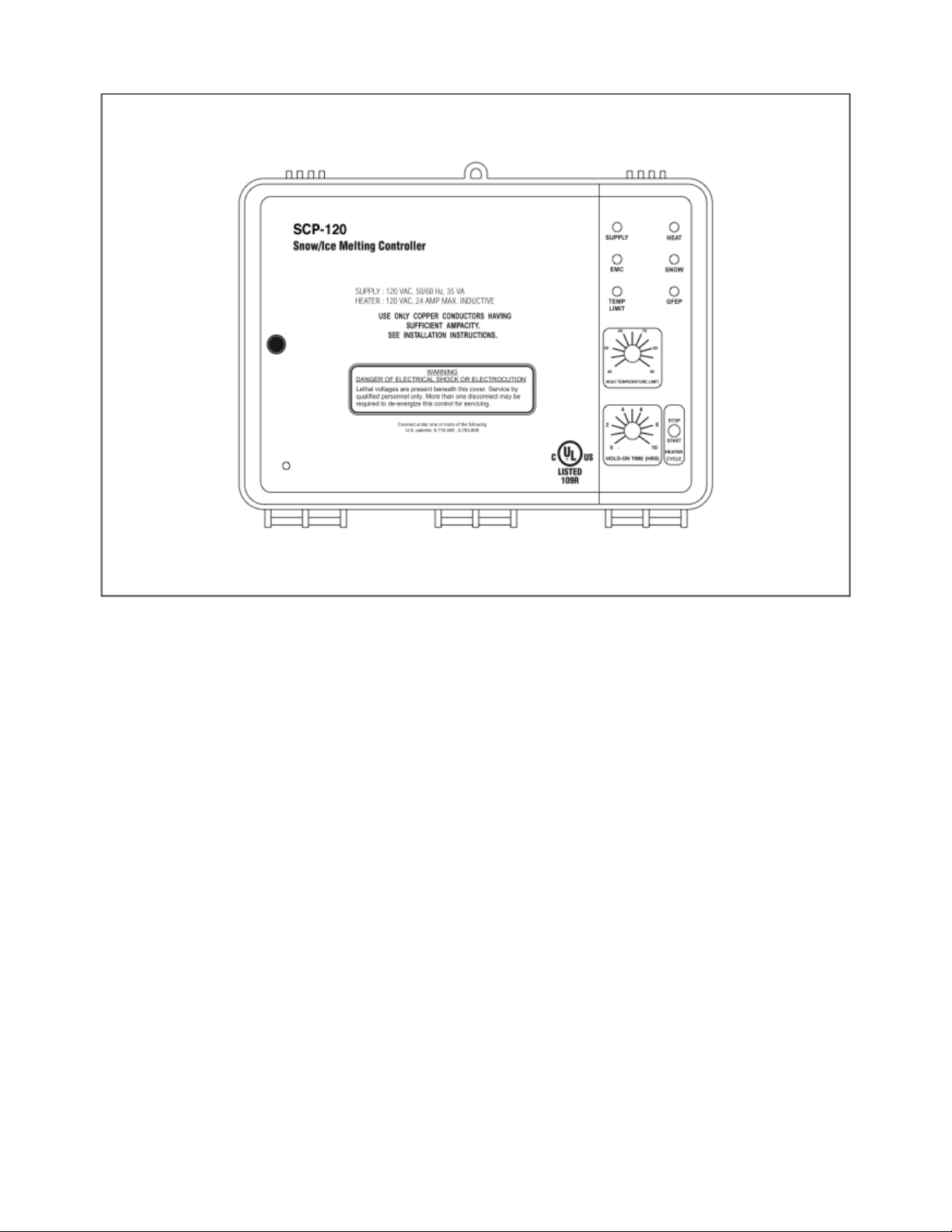

DIP Switch Settings HLT

GF disabled

Figure 8: DIP Switch Setting

for High Limit Sensor

Installation

Confi guring the High Limit Sensor

Dip Switch pin 3 is used to set the high limit sensor op-

eration to one of two possible operational modes:

• OFF sets the high limit sensor as a slab regulating temperature sensor.

• ON sets the high limit sensor as an ambient air sensor.

OFF is the factory default.

Index 8 shows how to confi gure the high limit sensor mode at

the DIP switch.

Factory Use Only

DIP switch pin 4 is for factory use only. The use of pin 4

except by authorized personnel may lead to improper operation

of the SCP-120

Bypassing the High Limit Temperature Sensor

If, for any reason, you need to operate the system without the High Limit Temperature Sensor (for trouble shooting or

while waiting for a replacement sensor) you can temporarily replace the sensor with a 470K resistor. The resistor will allow the

system to run as if the sensed temperature was 40°F (4.4°C).

Refer to Figure 23 for placement of resistor.

Page 11

Supply

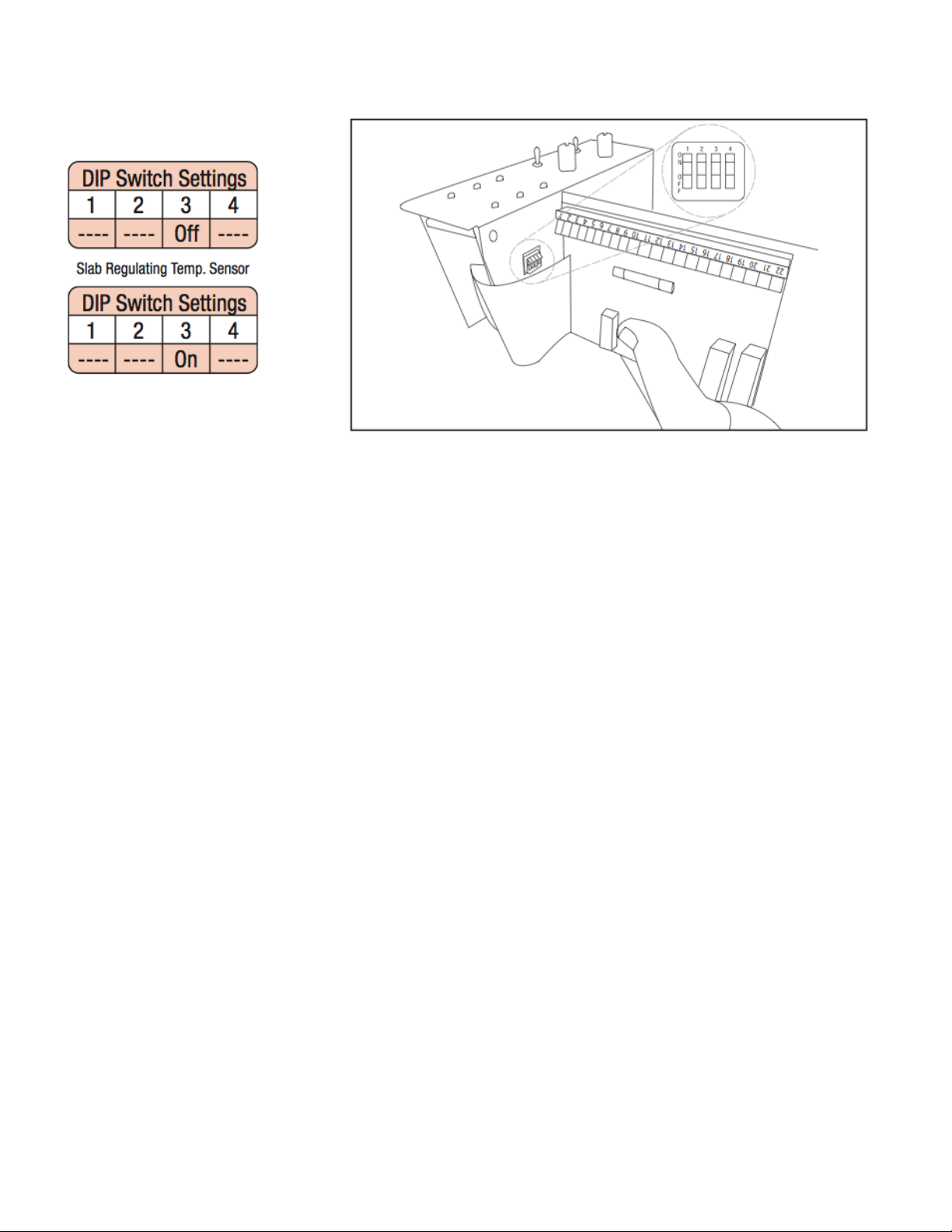

Figure 10: 120 VAC SCP-120 Operating two electrically held contactors

Page 12

22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

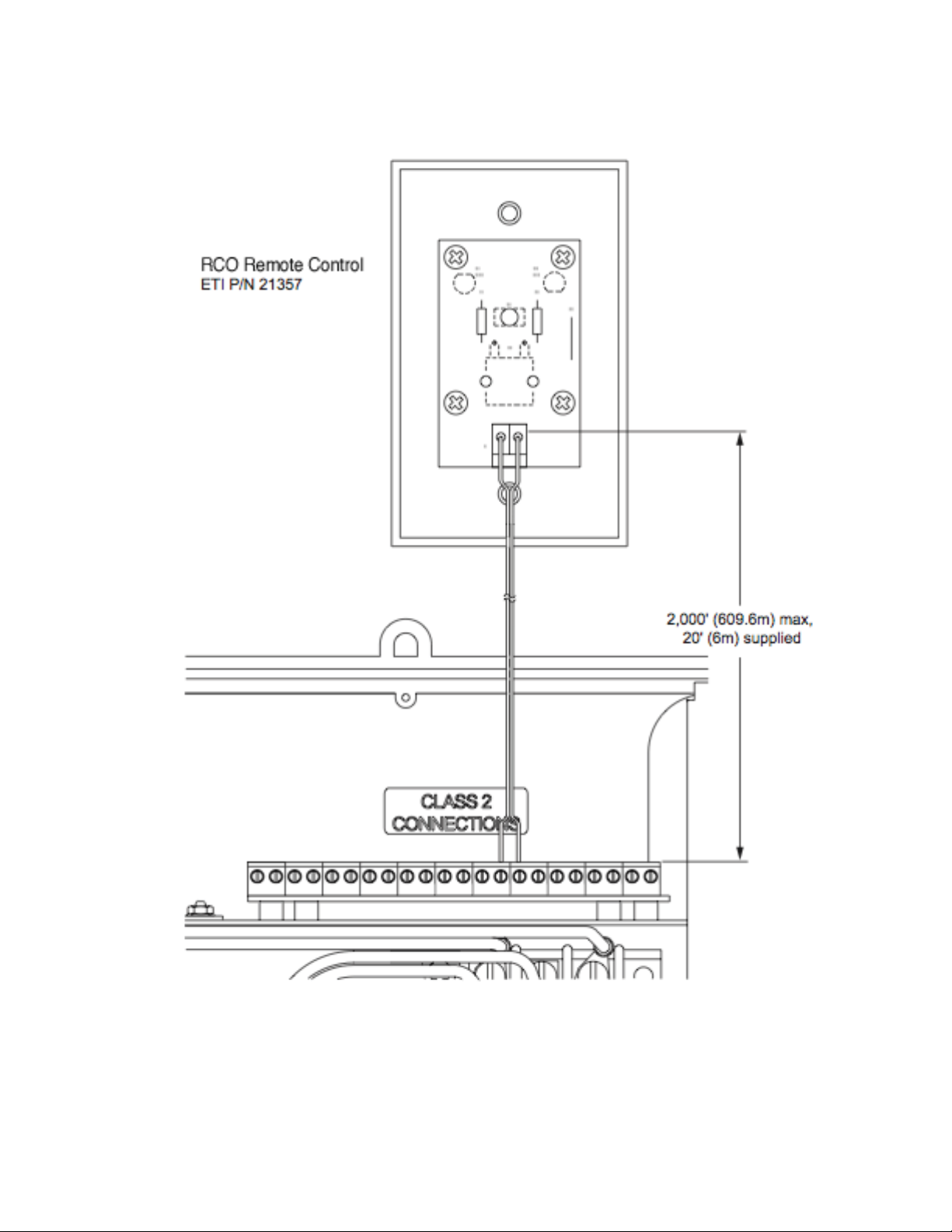

Figure 16: SCP-120 & RCO remote connection

Page 13

Red

Black

White

AIR-SS

Red

Black

White

22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

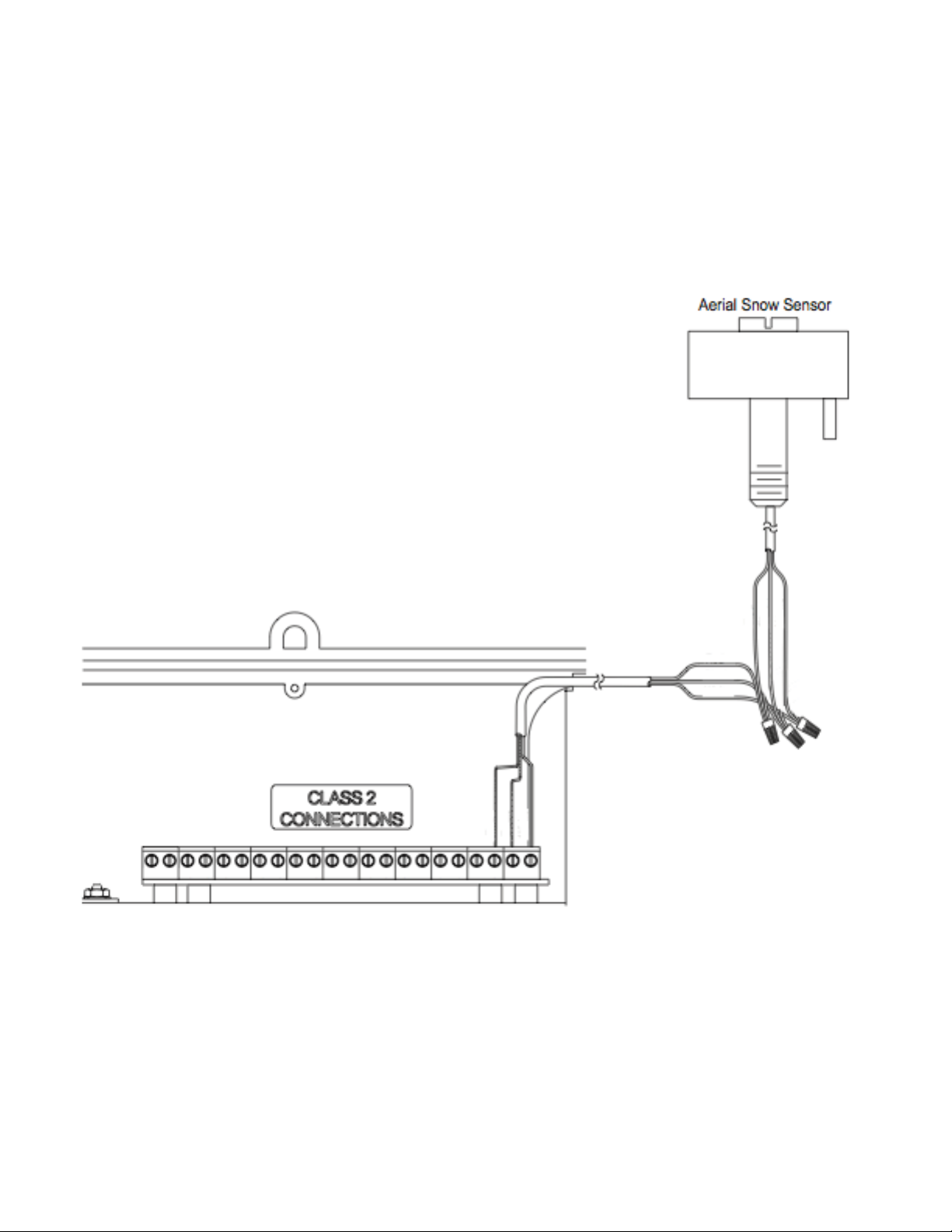

Figure 19: SCP-120 Sensor Connections

Page 14

Figure 20: SCP-120 EMC connections

Page 15

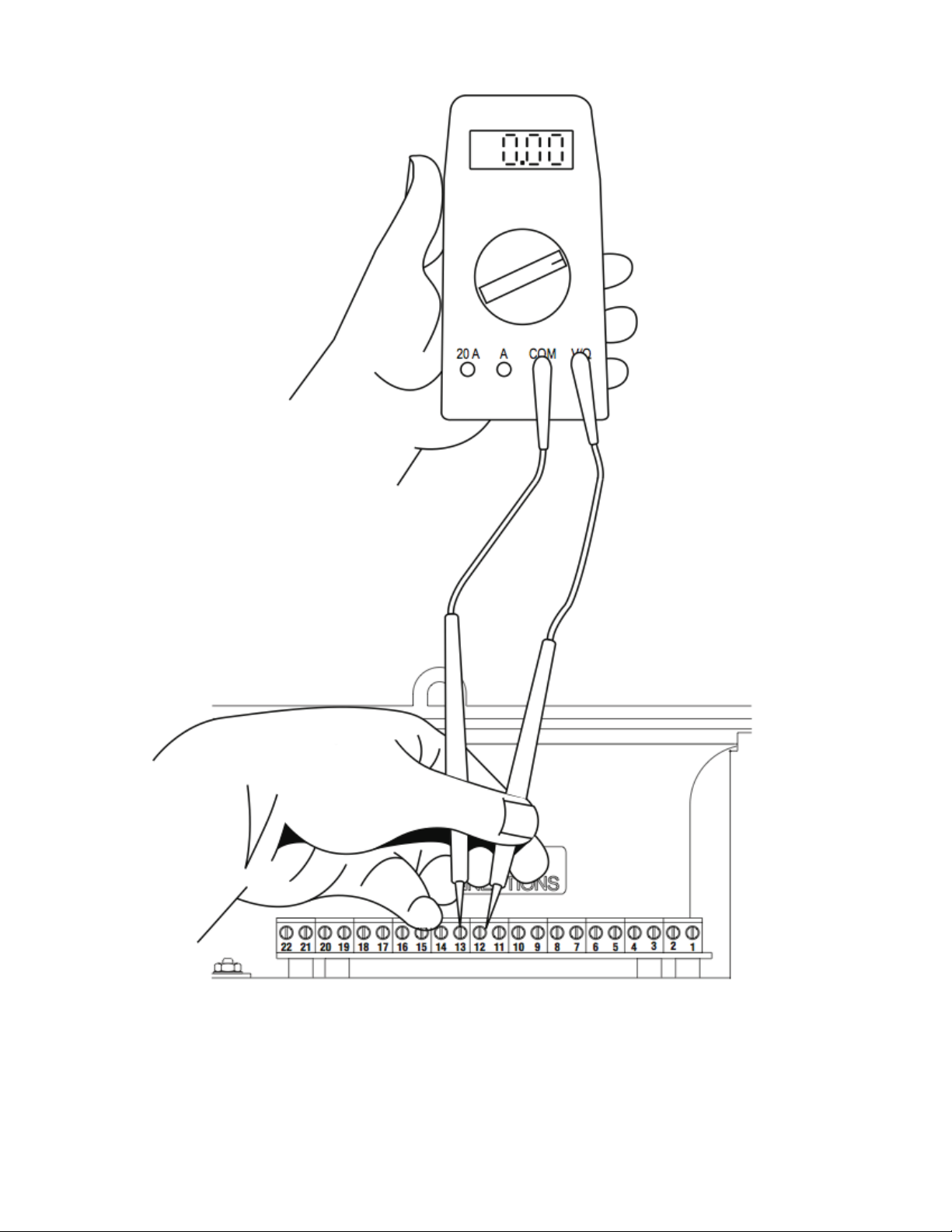

Figure 21: SCP-120 Electrician’s DVM

Page 16

Figure 22: SCP-120 (Slab or Ambient High Limit Sensor)

95-107 ohms (on 200k scale of ohms meter) Thermistor connections

Page 17

Contactor Connections

Contactor Connection

Number

1 Sensor Connection (White Wire)

2 Sensor Connection (Black Wire)

3 Sensor Connection (Red wire)

4 Satellite Panel Connection

5 Satellite Panel Connection

6 Satellite Panel Connection

7 Satellite Panel Connection

8 RCO Connection

9 RCO Connection

10 Thermistor Connection

11 Thermistor Connection

12 Electrician’s DVM

13 Electrician’s DVM

14 Output Common

15 Heat

16 Snow

17 Alarm

18 Supply

19 High Temperature Limit

20 Override On

21 Override Off

22 Close Override On/Off Circuit

Page 18

24/7 Installation Support • Lifetime Technical Assistance • Free Design Service • www.WarmlyYours.com • (800) 875-5285

APS-3C AUTOMATIC CONTROLLER

WIRING TO RELAY (120V)

LNR (Relay Panel) with

2-Pole relays (120V Coils)

APS-3C Automatic Snow Controller (120V)

L

N

Inputs for 120V

Hot Leg

Neutral

Neutral

120V

15 Amp

Breaker

Hot (L1)

Page 19

APS-3C AUTOMATIC CONTROLLER

WIRING TO SENSORS & RCU

(CLASS 2 CONNECTIONS)

Thermistor probe type

sensor (mounts in metal

conduit within the slab

between two passes of

heater cable)

Optional Device

RCU-3 Unit

CIT-1 Aerial Snow Sensor

Red

Black

White

2

19

20 1821

17

16

15

14

1213

1011

89

6

7

5

3

4

1

APS-3C Automatic Controller Panel

10272-A 1/11

24/7 Installation Support • Lifetime Technical Assistance • Free Design Service • www.WarmlyYours.com • (800) 875-5285

Loading...

Loading...