Page 1

®

INSTALLATION INSTRUCTIONS

THERMAL INSULATING & SOUND CONTROL UNDERLAYMENT

BONDING MATERIAL

CeraZorb can be bonded to the sub fl oor with Mapei Ultracontact or UltracontactRS bond coat adhesive or equivalent (recommended,

but not sold through WarmlyYours). Use a 1/8” x 1/8” x 1/16” V-Notched trowel. Apply only enough adhesive as can be covered by a 2’ x

4’ sheet. Clean up any extra adhesive before the adhesive skins over. Mapei Ultracontact or UltracontactRS and the sub fl oor must be at

65ºF (18ºC).

INSTALL CERAZORB

Set the CeraZorb into the adhesive while it is still wet. Do not allow adhesive to skin over. Lift a corner periodically to see if the adhesive is

transferring 100 percent. If adhesive is not transferring, apply additional adhesive. Flat trowel the CeraZorb sheets, making sure to install

with edges butted tight to each other and ensure that you do not overlap seams. After fi rst row is completed, roll the mat with a 35 lb.

roller. Install the second row with staggered seams to the fi rst row and repeat steps above. It is recommended to wait 8-12 hours before

installing tile or stone on top of the CeraZorb.

INSTALLATION OF TILE, STONE, OR MARBLE

Before installation of the fl ooring, you may choose to install CeraZorb 1” wide by 4’ lengths cut off the sheet to act as perimeter strips around

your room (optional). To install, fasten the perimeter strips to the wall of the entire sub fl oor using Mapei Ultracontact or UltracontactRS or

equivalent. Make sure to follow applicable ANSI A. 108/A. 118/A. 136 for proper installation of ceramic tile.

When applying tiles to CeraZorb, always use a polymer-modifi ed mortar meeting ANSI A118.4 or A118.11 standard. It is recommended to

key-in/burn-in a thin layer of thin set into the surface of CeraZorb as a fi rst step to tiling.

After fi nished fl oor is installed and grouted, trim the excess perimeter isolation strip fl ush with the fl oor. Prior to installation of the cove or

base molding, seal isolation foam with any waterproof acrylic caulk. Adhere the base or cove to the wall. The baseboard must not touch

the fl oor to avoid sound/vibration to fl ank through the walls.

PRODUCT INFORMATION

Item Number Quantity

CZRG-SH5MM-4848 CeraZorb Regular, 5 mm. (3/16”) 24” x 48”

10226 6/09

10233-A 8/2011

24/7 Installation Support • Lifetime Technical Assistance • Free Design Service • www.WarmlyYours.com • (800) 875-5285

Page 2

INSTALLATION INSTRUCTIONS

THERMAL INSULATING & SOUND CONTROL UNDERLAYMENT

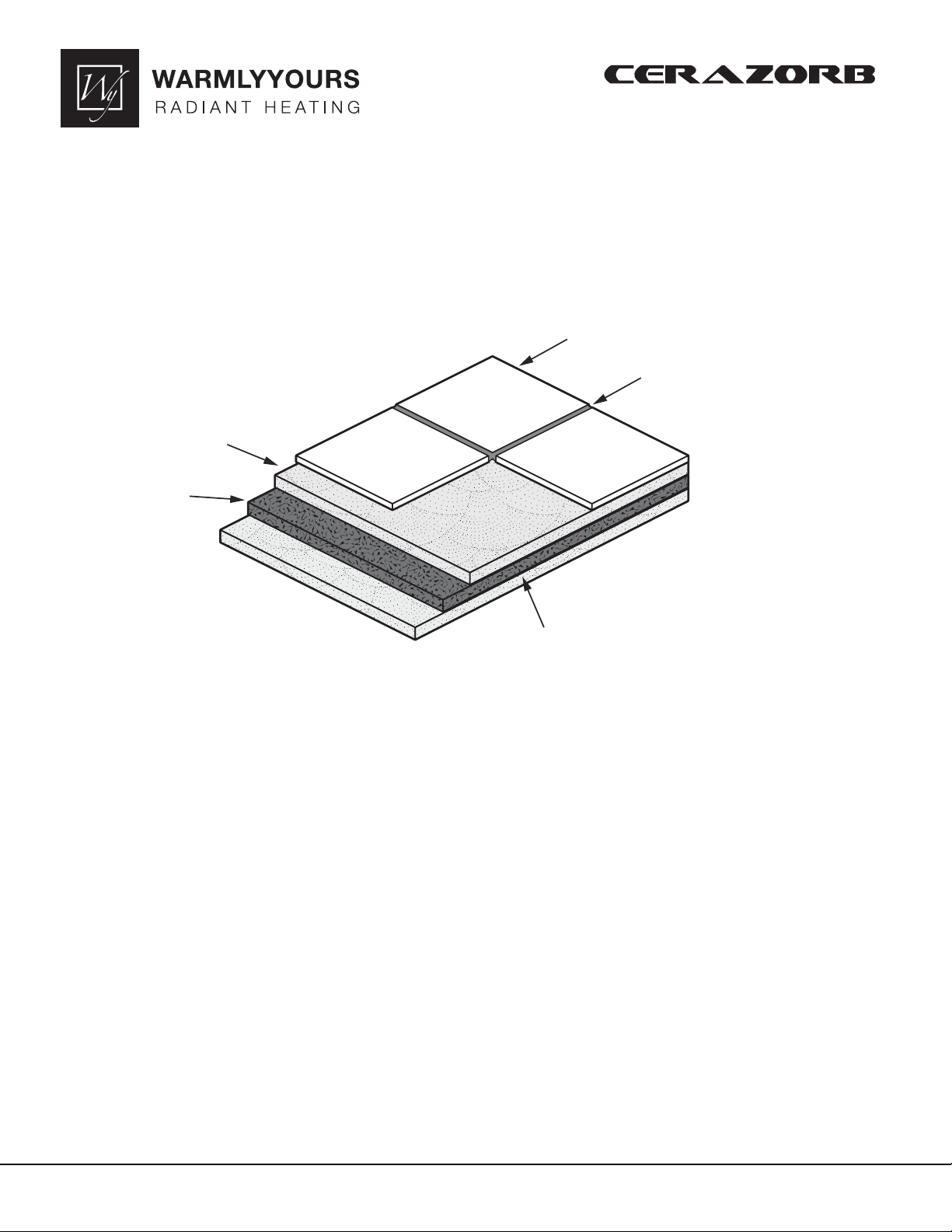

CERAMIC TILE

GROUT

POLYMER-MODIFIED

THIN SET MORTER

CERAZORB

®

MAPEI ULTRACONTACT® or ULTRACONTACT RS

or equivalent BOND COAT ADHESIVE

SURFACE PREPARATION

Surface must be structurally sound, clean, dry, and free from dirt, oil sealers or any contaminants that would prevent a good bond.

CeraZorb must acclimatize in their sealed packaging for 48 hours at a temperature of 65ºF (18ºC).

CONCRETE SLAB

Inspect concrete sub fl oor for any open cracks and fi ll with a high-grade patch. Remove any excess concrete lumps or residue that

may interfere with the installation of CeraZorb. The concrete slab should be fully cured, dry, smooth, fl at, and accept water penetration.

Concrete must be free of effl orescence and not subject to hydrostatic pressure. A good quality concrete waterproof sealer may be

required if moisture in the slab is above 10 percent.

GYPSUM SUBSTRATES

Gypsum substrates must have a PSI greater than 2000 and must fi rst be primed or sealed per manufacturer’s instructions.

WOOD SUBSTRATES

The sub fl oor should be permanently dry, smooth, fl at, and clean – free from dirt, grease, wax, paint, oil, or anything that would hinder a

good bond. Plywood sub fl ooring should be of a good grade. Variations in fl oor level over 1/8” within a 3-ft. span should be leveled before

installing underlayment. Any nails or other protrusions should be pounded fl at or removed. Sub fl oor should have L360 for defl ection.

24/7 Installation Support • Lifetime Technical Assistance • Free Design Service • www.WarmlyYours.com • (800) 875-5285

Loading...

Loading...