WarmlyYours AIRSS Installation Manual

Pavement-Mounted Snow and Ice Sensor

SNOW SWITCH

®

MODEL SIT–6E

For Use With any APS series

or EUR–5A Control Panel

Installation and Operation Manual

The Snow Switch® Model SIT–6E Pavement-Mounted Snow and Ice Sensor reliably detects snow and ice conditions on pavement

surfaces when used with any APS series or EUR–5A Control Panel. This ensures that deicing heaters operate only while needed which

minimizes energy costs without sacrificing snow melting effectiveness. As part of a snow melting system, an SIT–6E sensor will

signal for snow and ice melting at pavement temperatures below 38°F (3.3° C) while moisture in any form—including water, snow,

sleet or ice—is present. Operation in the 32° to 38°F (0° to 3.3°C) temperature range speeds the process, eliminating otherwise

slow melting. A built-in hold-on timer keeps heaters operating for an hour after snow stops to help ensure complete snow melting.

The SIT–6E sensor accurately measures pavement temperature by compensating for its internal heating. This eliminates the

cost and complexity of a separate pavement temperature sensor. For improved efficiency, products mount close t o the deicing

heaters to ensure that pavement and sensor become dry at about the same time.

Packing List

Item description

SIT–6E Assembly (with 60' leads)

Installation Manual (this document)

Duct Seal, 1 lb.

Screw, Set, Hex Socket, 3/8-16, 0.25" L (Qty 3)

Screw, Machine, S-BH-SS, #8-32, 0.375 L (Qty. 3)

Hex L-Key, 3/16

NOTE: The SIT–6E Sensor requires Pavement Sensor Housing with its

accompanying installation sheet .

MANUAL

Sensor

Housing

General Guidelines

1. For the greatest installation flexibility, use extra pavement sensor housing

units per paved slab. NOTE: not all pavement sensor housing units will

contain an actual sensor.

2. Prior to paving, make sure the sensor housing units are clear of the heating

coil. Do not locate a sensor housing box on top of any portion of the actual

heating coil.

3. Because there are two ports on the bottom of each sensor housing unit,

dig a little trench slightly deeper underneath each of the housing units to

accommodate those ports.

4. Read all enclosed product information sheets for additional information.

Height

Adjustment

Ring Cap

Adjustment

Pavement Sensor

Housing Unit

Height

Ring

Pavement Sensor

Housing Unit: Height

Adjustment Ring cap

removed for sensor

mounting

Two ports at bottom

of Pavement Sensor

Housing Unit

Installation Support • (800) 875-5285 • www.WarmlyYours.com

Snow Switch Model SIT–6E

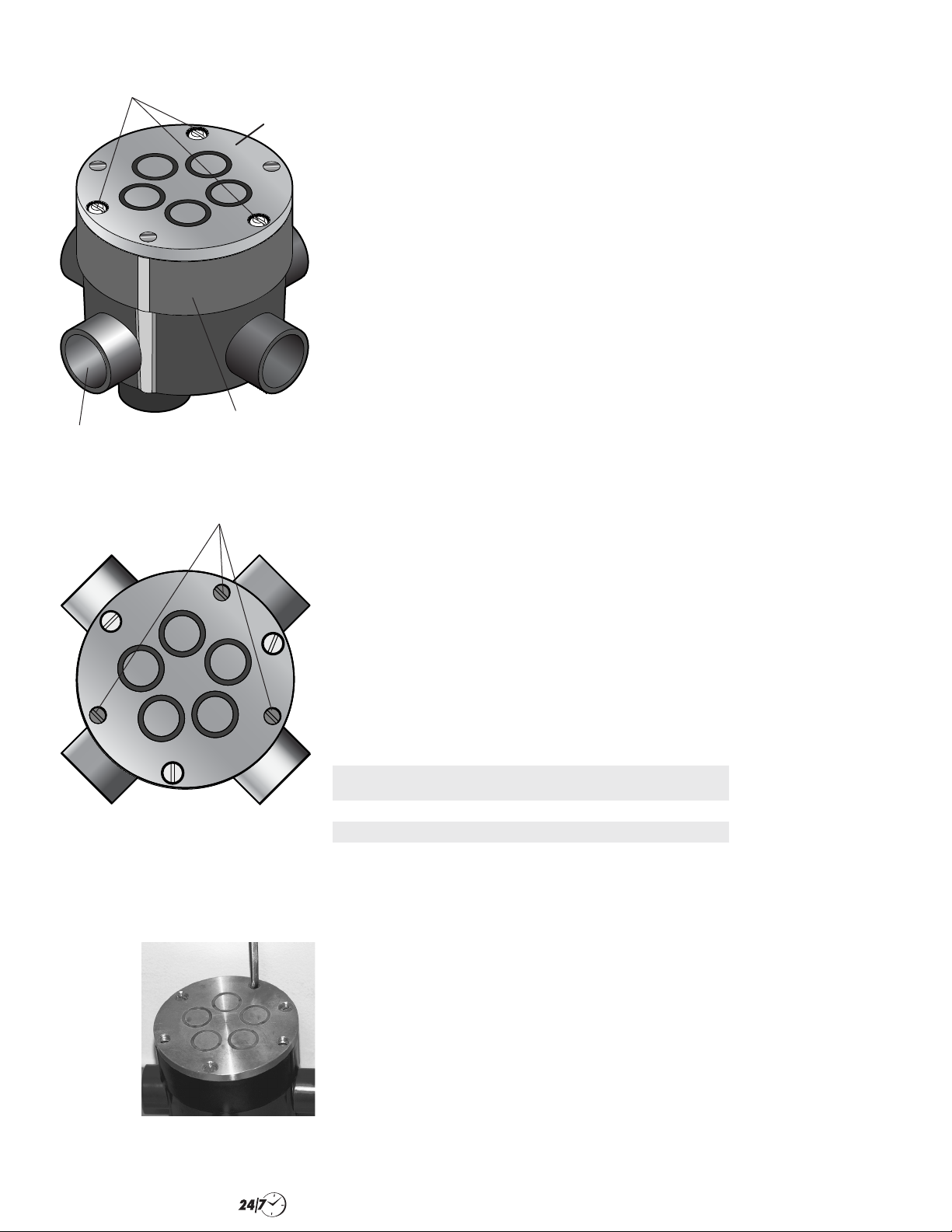

Sensor Retaining

Screws (3)

Knockout Port

(6 locations)

Height Adjustment Screws (3 Places)

(shown with protective Allen-head set

Height

Adjustment

Ring

screws removed)

Sensor

Installation Instructions

1. Lay out the sensor housing units or floor boxes according to your plan for the size and

shape of the pavement area and traffic overflow area.

2. Using a screwdriver or similar tool, remove the desired knock-out seal(s) from the floor

boxes. (Not all are used.) Knock out one of the two bottom seals in each floor box as

well for greater stability as described in step 6 below.

3. With the cap off, rotate each of the three height adjustment screws to the left to raise

the height adjustment ring between 1/8 and 1/4 of an inch. Refer to Figure 1.

4. Once the adjustment ring has been raised, apply a layer of grease to the outside of

the sensor housing body underneath the height adjustment ring. Also apply grease to

the adjustment ring itself. Applying plenty of grease ensures the continued and proper

operation of the height adjustment ring after the pavement sets up and cures.

5. Rotate each of the three height adjustment screws to the right to lower the height

adjustment ring to lowest setting. Put caps back on housing units using the three

retaining screws from the accessory kit.

6. Run PVC conduit between the floor box ports opened in step 2, as well as one for the

control box wiring. Use PVC glue to secure the PVC conduit in place inside each housing

unit port. If not being used for wiring – and unless prohibited by a high water table – ETI

recommends using one of the two bottom ports as a drain with a short piece of

conduit extending down past the concrete into sand or gravel to promote draining

and to provide greater stability for each floor box.

7. As the paving material is poured and sets up, make sure the caps of all of the housing

units are flush with the pavement. There must be no paving material on the caps

of the housing units. Adjust the height flush with the pavement by using the height

adjustment ring.

8. To install a sensor into a housing unit, first select the sensor housing unit to be fitted

with the sensor. If more than one housing unit has been placed as part of the installation,

it is best to select the one it is believed will be closest to the center of the traffic or

snow build-up pattern(s).

9. Remove the sensor housing cap from the housing unit by removing the three screws

securing it in place. Make sure to retain the cap someplace at the facility in case the

location of the sensor needs to be changed in the future and the current housing has

to be closed and covered up again.

10. Connect the wires from the power cable inside the conduit to the sensor. Once the

sensor is wired, apply duct sealant to protect the installation inside the housing, leaving

room for the sensor to be placed down inside the housing. Refer to wiring table below

for connections.

Figure 1.

Sensor Housing Adjustment Points

Rotate Height

Adjustment

Screws

to the left to

raise the ring

or to the right

to lower it

Figure 2.

Rotate Height Adjustment Screws

Table 1. CABLING CONNECTIONS

CABLE LEAD

DESIGNATION

Sensor 24V Red Red

Sensor Ground Black Black

Sensor Signal White Blue

11. Once the wires are connected, place the sensor down into the housing with the sensor

top resting on the top of the housing. Verify that the top of the sensor is flush with the

pavement around it. The top of the sensor has three protective set screws, under which

are located three access holes to reach the height adjustment screws. As needed, rotate

the three adjustment screws (Figure 2) to the left to raise the height adjusting ring or to

the right to lower the ring, and then replace the three Allen-head protective set screws

(Figure 3). Install retaining screws into the sensor to secure it to the housing.

WIRE COLOR

WAS

NOTE: Any designation to sensor white lead applies now to the sensor blue lead.

CURRENT WIRE

COLOR IS

Conduit

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor

cable, taking care to ensure that all embedded or outdoor couplings and terminations

are made watertight. Do not share conduit with other wiring. Do not route conduit across

pavement expansion or control joints. For sensors embedded in slab on grade, conduit

should be depressed under these joints, as necessary.

Installation Support • (800) 875-5285 • www.WarmlyYours.com

Loading...

Loading...