Warmington TF 1200, TF 1000, TF 800 Installation Instructions Manual

16 December 2014

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm……….Copyright

1

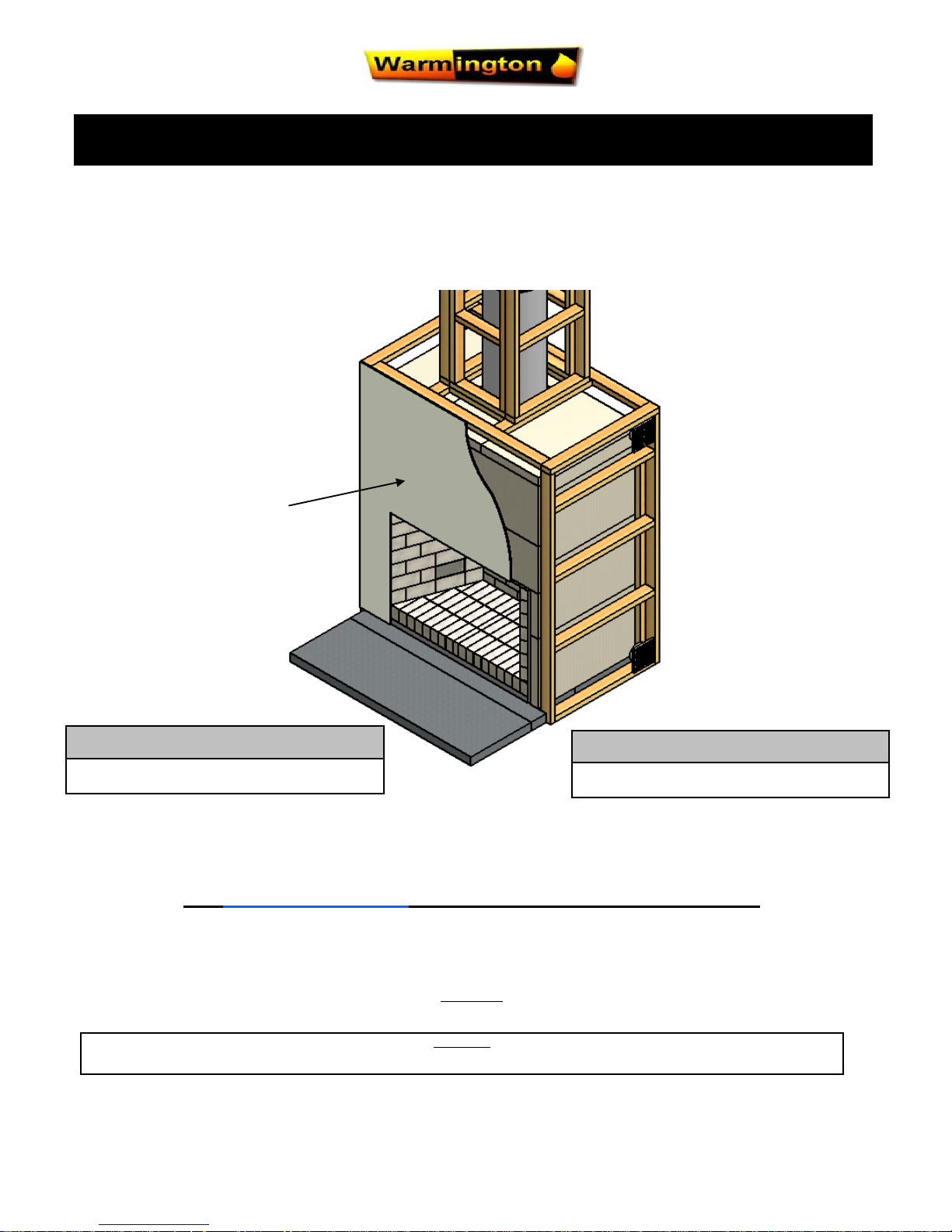

Solid Fuel Burner, Traditional Brick Built Open Fire.

Installation Instructions

Traditional 800-1000-1200 Open Fire

Visit www.warmington.co.nz for Spec’s, DWG’s and PDF uploads of fires

Fire, flue system and instructions to comply with ASNZS 2918:2001 & Building Code C/AS1 7.5 Open Fires

Keep these Instructions for further reference……Ensure that you have the correct and current installation details for the Warmington Fire

Installation

The Warmington unit is to be installed by a certified Warmington installer or an Approved NZHHA Installation Technician.

IMPORTANT

Read all the instructions carefully before commencing the Installation. Failure to follow these instructions may result in a fire hazard and void the warranty

NOTE ON TRAD. FIRES :

Like the Traditional Brick

Back Fire of yesteryear, the

Warmington Traditional Fire

is built with the experience

and techniques of the past ....

These make a grand

statement in the home and

with the introduction of the

Gas Log Lighter for ease of

lighting are simple to

operate, however they can

lack in efficiency.

Note : Not Included—see page 2:

Bricks and Bricklaying

Log Lighter

Grate

Hearth and Plinth

Installation

NOTE : Non-Combustible

Cladding eg :

10mm Promina Board ,

10mm Supalux ,

Latex Plaster .

(Not Supplied)

NOTE : Traditional Open fires are the least efficient fires available and can lack in Heat output.

Note: FLUE SYSTEMS Casing….

Flue system may require to be Doubled lined to comply.

Ref ASNZS:2918:2001 4.3 Flue pipe casing

Note: BRICK OUT GUIDE Details….

When purchasing the fire bricks the bricking guide will

come with the bricks.

16 December 2014

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm……….Copyright

2

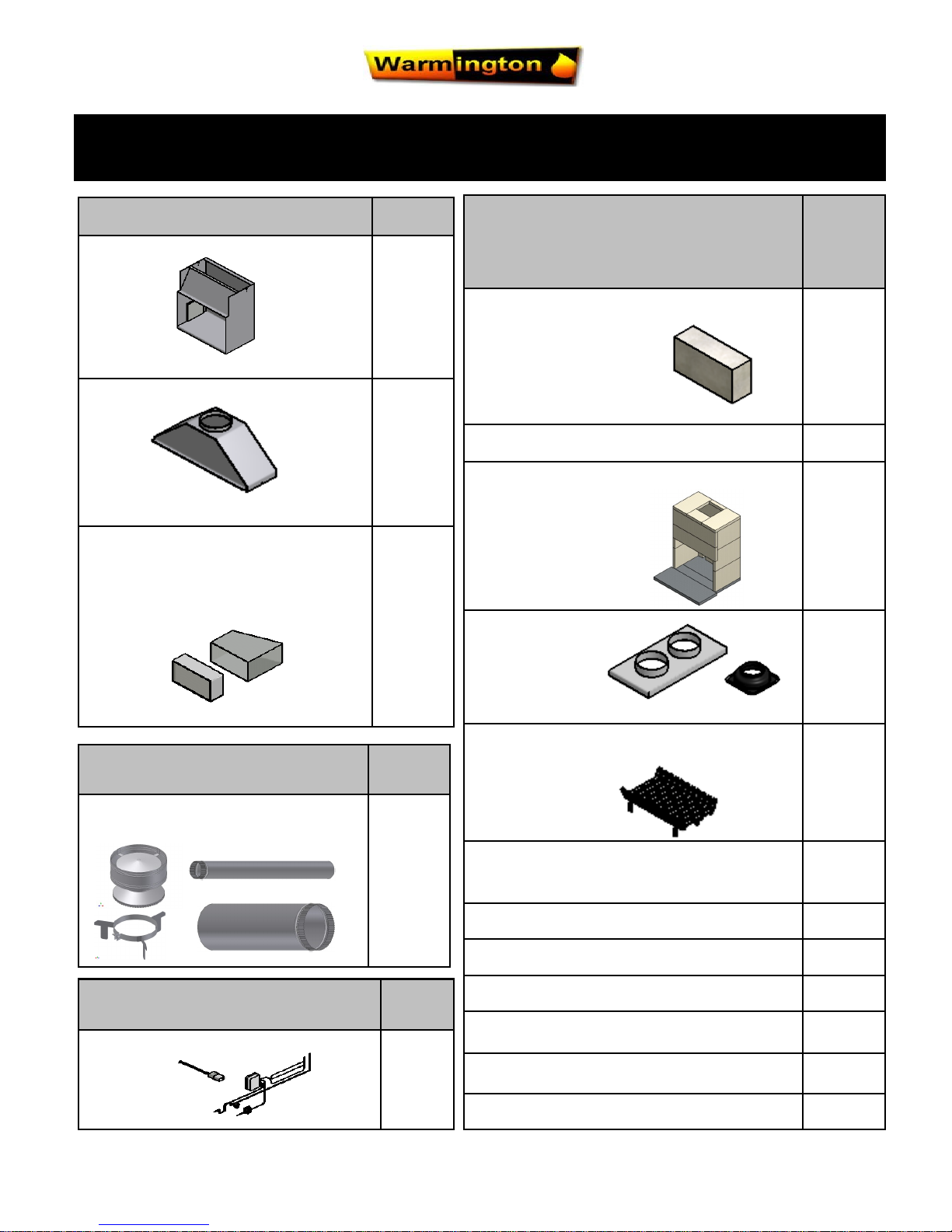

Supplied as Trad. Fire Box No:

Traditional Firebox .

1

Traditional Firebox Adaptor .

1

Caitec Venting System .

*Caitec Steel Brick .

*Caitec Perf. Extension .

2

Supplied

Priced depending on Requirements

No:

Warmington Fluekit

1

NOT Supplied

(Optional extra)

No:

Log Lighter & Control Box .

1

NOT Supplied

Components are required for

Install

Priced depending on Requirements

No:

Fire Bricks (H40) 75X115X230mm .

Other Sizes Available

Varied

Fire Brick Refractite Mortar .

1

Autoclaved Aerated Concrete (AAC) Heat cell

Constructed on Site

1

Flashing System

1

Traditional Fire Grate .

Size to Order

After Bricklaying

1

Non Combustible Cladding

(Promat-Superlux-Brick-Stone etc)

10:1 Fill /Crush (vermiculite etc) .

1

Aluminium Tape . 3M Scotch Brand

1

Gas & Electrical Work Onsite .

1

Installation :

Fire / Flue kit / Flashing .

Installation . Brickwork .

Council Permit .

Components Required for Construction

(SUPPLIED SEPERATELY)

16 December 2014

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm……….Copyright

3

POINTS TO CONSIDER PRIOR TO INSTALLATION

Prior to Construction and Installation Important Notes:

Install to AS/NZS 2918:2001.

Install to manufacture’s specifications.

All new installations require a permit.

For special requirements concerning materials (timber mantle and surrounds) within close proximity of Warmington products, please contact your

local Warmington Technical Consultant or designated Installer.

Stage 1: Frame Construction Procedure by Builder.

Mark out Flue Centre on Floor.

Mark out Heat Cell Clearance requirements.

Construct Plinth only, to required height. *

Stage 2: Install Procedure by Certified “Warmington Installer” or see www.homeheat.co.nz go to ”members” & follow Instructions .

For an NZHHA Cerified SFAIT Installer .

Fit Fire to Plinth.

Fit Adaptor to Firebox.

Construct Autoclaved Aerated Concrete (AAC) Enclosure around Traditional Firebox.

Fit Flue System.

Fit Cowl and Flashing System

Stage 3: Finishing Procedure by Builder. NOTE : Bricklaying of Firebricks can be carried out by clients Bricklayer at a Convenient time.

Construct Hearth to required thickness. *

Finish Autoclaved Aerated Concrete (AAC) enclosure and Hearth to Customers requirements (e.g. paint / tiles ).

Close in Autoclaved Aerated Concrete (AAC) enclose and chimney chase . ( If in timber Alcove ).

* Note: A Certified Installer can Install Hearth and Plinth also.

Ensure that the Warmington and flue system is swept annually or more frequently if required.

To Sweep Flue and Firebox:

Cover front of fire with sheets.

Remove cowl from top of chimney.

Sweep from the top, down the flue.

Remove all soot and ash.

Ensure cowl and bird protection is clean and replaced.

Visually inspect fireplace and flue system.

INSTALLATION ORDER OF OPERATIONS Installation is not provided

Location of the Fire. Open fires are better located at one end of a room or area, as they project the heat away from their opening.

The Topography of the land .

The slope and position of the land in relation to the home has a bearing on how the wind will interact with the fire and flue system. Care needs to be taken to ensure that the flue

termination is in the correct position to maximise performance.

The Prevailing Wind.

Care needs to be taken to ensure that the flue termination is in the correct position as wind and gusts that hits the flue and cowl system may overcome the cowl and draft back down

the flue into the home. This can be a combination of down draft and high pressure.

Hearth and Plinth:

The Height of the Hearth off the Floor. The Finis hing that is to be used on the Hearth is to be allowed for at the design stage.

Note : Ensure Air Intake at Base of Firebox is not b locked or restricted .

Positioning of the Flue System:

There is a maximum distance that an offset flue can be Installed . Reference to AS/NZS 2918:2001 .

Flue And Fire Clearance:

To be maintained to the Manufactures Instructions &/or Comply with appropriate Standards & Building Codes .

Pressure Differential, Venting & External Air into the Building :

All fires need air to burn and draw correctly, Kitchen Fans, Air Conditioning units, High Wind Zones, Nat urally forming Draft spaces, can all have an effect on the pressure difference

from inside the building to the outside. A lower pressure in the building may induce a draft down the flue system and back into the building causing the fire to smoke or spill into the

building. Care needs to be taken at the design and installation stage to adequately vent the building, or some mechanical system to ens ure that there is always a neutral or

positive pressure at the fireplace and a negative press ure at the flue outlet. This will ensure that the draft in the flue system is always to the outside.

“CAITEC AIR” the limits and requirements. See details in these Spec’s

Wind Noise:

You may encounter wind noise in some installations. It is recommended to use an enclosed chase with a chimney pot to help reduce noise.

There will always be some noise from the flue systems of all fireplaces.

Traditional Open fires are the least efficient fires available and can lack in Heat output.

Installation Notes:

Due to the expansion and contraction of metal fireplaces a 3mm gap between the flange and the finished surround should be mai ntained.

16 December 2014

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm……….Copyright

4

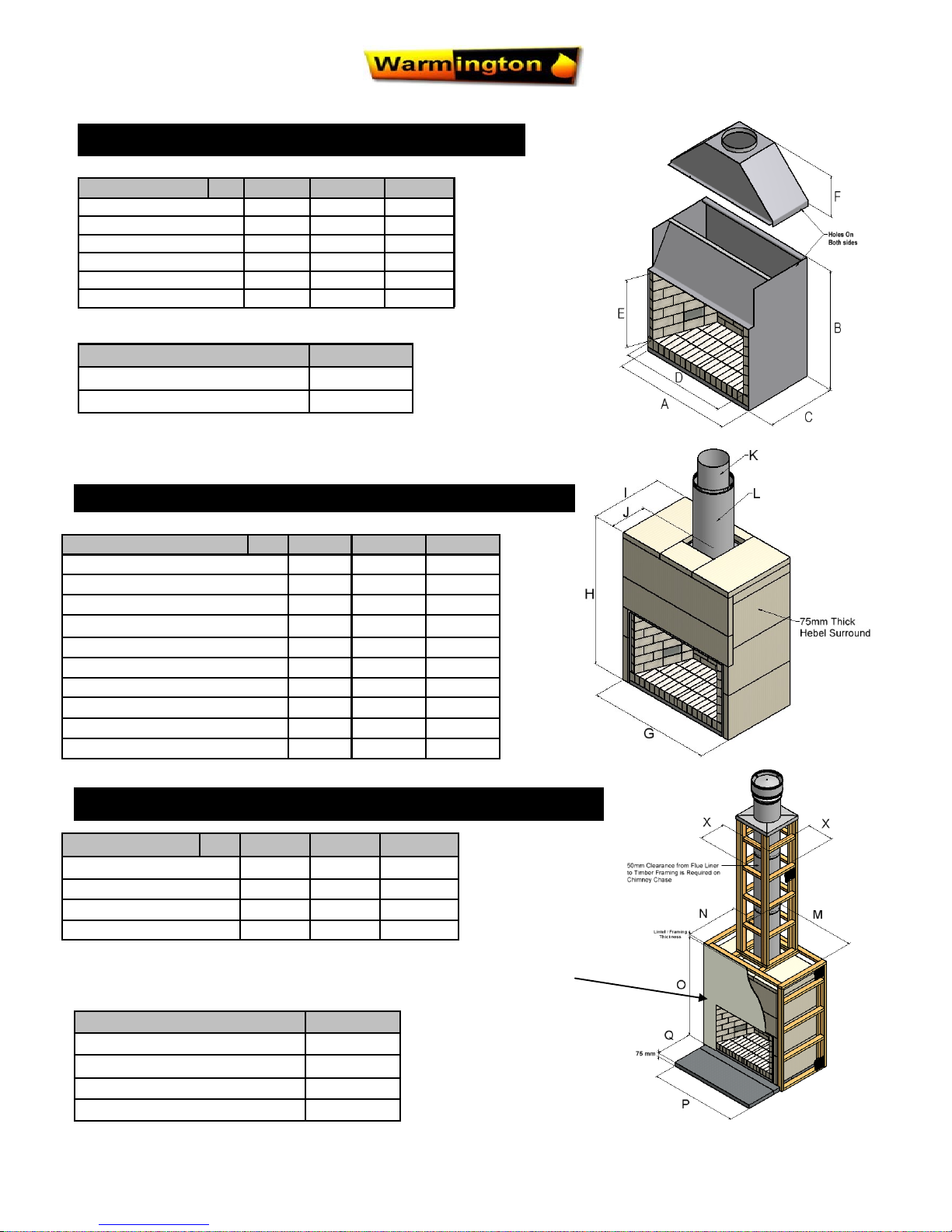

Description

TF 800 TF 1000 TF 1200

Firebox Width A 1050 1240 1440

Firebox Height B 1315 1315 1415

Firebox Depth C 740 735 835

Flange Width D 800 1000 1200

Flange Height E 704 700 800

Adaptor Height F 405 405 480

WARMINGTON TRADITIONAL FIREBOX DIMENSIONS

Autoclaved Aerated Concrete (AAC) HEAT CELL DETAILS DIMENSIONS

Description

TF 800 TF 1000 TF 1200

Heat Cell Width

G

1240 1440 1640

Heat Cell Height

H

1820 1820 1995

Heat Cell Depth

I

865 865 965

To Centre of Flue

J

539 538 589

Flue Diameter

K

300 300 350

Liner Diameter

L

400 400 450

Heat Cell Clearance Width

M

1290 1490 1690

Heat Cell Clearance Depth

N

990 990 990

Heat Cell Clearance Height

O

2150 2150 2150

Chimney Chase Clearance

X

500 500 550

Minimum Flue Height

Flue Height 3600

Measured From Top of Adaptor B + F + 3600

Check List

Firebox

2 x Air Brick and CAITEC covers

Adaptor & Bolts

Packed by

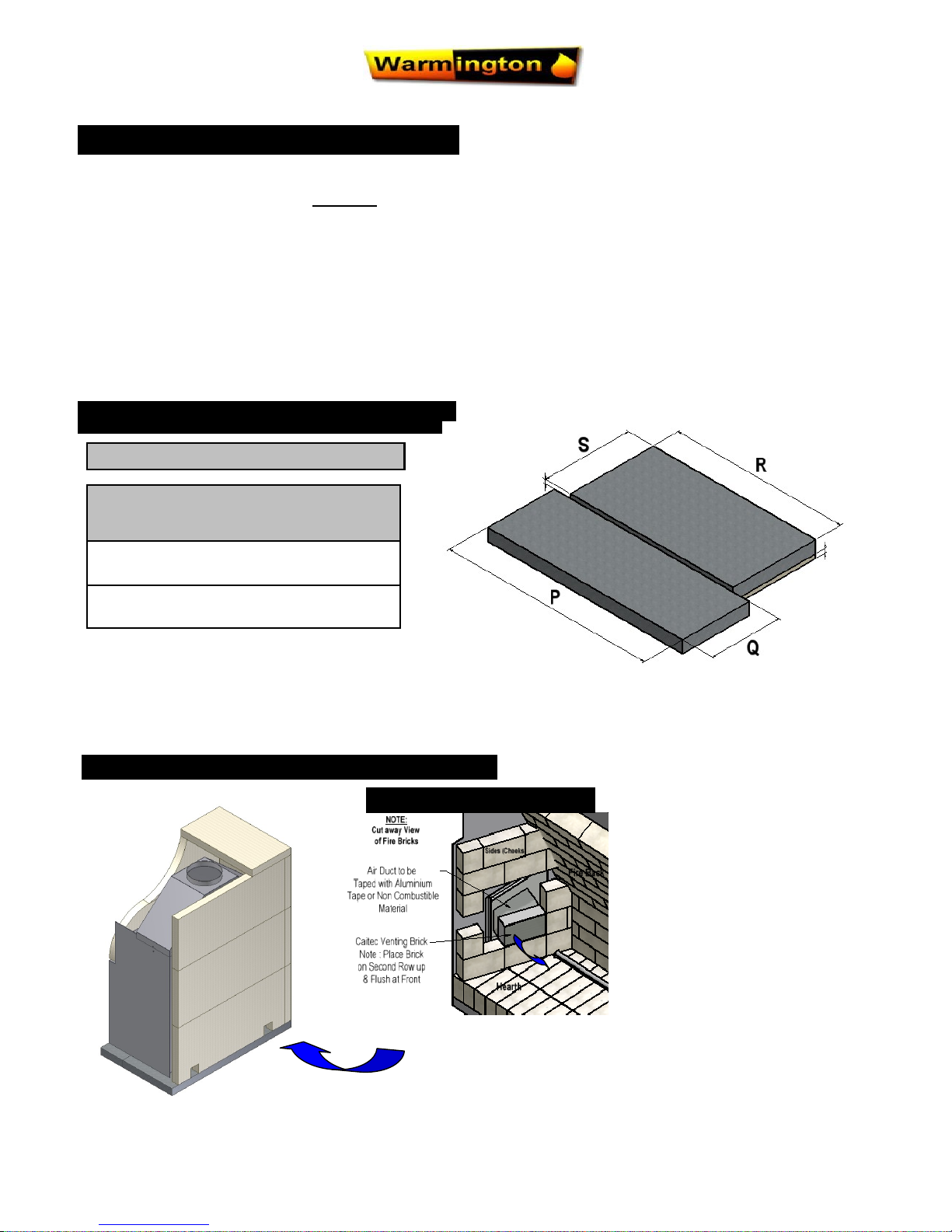

Description

TF 800 TF 1000 TF 1200

Hearth Width

P

1350 1550 1800

Hearth Projection

Q

500 600 750

Plinth Width

R

1240 1440 1640

Plinth Depth

S

865 865 965

Autoclaved Aerated Concrete (AAC) HEARTH & PLINTH DIMENSIONS

NOTE : Non-

Combustible

Cladding eg :

10mm Promina Board ,

10mm Supalux ,

Latex Plaster .

See next Page 5 for Plinth & Hearth details

16 December 2014

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm……….Copyright

5

FIREBOX INSTALLATION

This is a general installation guide only – Contact a “NZHHA Installer” for Installation Advice or go to

www..homeheat.co.nz then select Members & follow Instructions , to find a Certified NZHHA SFAIT Installer .

1. All the dimensions are minimums

2. Fit the Plinth into position in the Cavity. If onto a wooden floor ensure that an insulating plinth is fitted as per the specifications.

Ensure that the plinth is elevated to allow for finishing on the hearth. (See Hearth and plinth details)

3. Fit the firebox into the Cavity. Bolt the fire box to the plinth or through to the floor with the bolting point provided on t he Left and

Right hand sides of the fire box or drill holes through base for Bolts (seismic restraints bolts not provided).

4. Fit the Adaptor to the Fire box. Ensure that exhaust sealant is used between the fire and Adaptor. Bolt into position with the bolt

in the Left and right hand sides of the Fire box.

5. Install the flue system. Ensure that the Flue system comply to ASNZS 2918

6. Fit the Autoclaved Aerated Concrete (AAC) Heat cell around the fire. A general minimum lay out is shown in this

Specification.

Note: Hearth and Plinth Construction.

For combustible flooring an insulating hearth and plinth of

75mm Hebel is required.

Plinth to be off set above hearth by the hearth finishing’s

( e.g. tiles / granite / plaster / etc )

Visit the Warmington Web Site for “Autoclaved Aerated Concrete

(AAC) ” instruction (PDF Download).. www.warmington.co.nz

IMPORTANT NOTE :

*Note: If Solid Plastering the Heat Cell structure, it is

recommended to use a fibreglass mesh with a latex

plaster to minimise the chance of the plaster cracking. (See

your plasterer for correct materials and applications).

HEARTH & PLINTH CONSTRUCTION DETAILS

CAITEC Air Venting System

Caitec" draws air from an external air

source to ensure that the open fire has

pre-heated combustion air maximising

efficiency while maintaining the home at

constant pressure equilibrium, reducing

the risk of back drafting .

Ensure that the cavity is vented to

Outside Fresh Air and the Warmington

Fire will take care of the rest. 2 x

100mm Diameter vent are required (Or

equivalent to that.)

Builder to supply external air to the

Cavity and the “Warmington Fire”

takes care of the rest.

“CAITEC” TECHNOLOGY—ROOM AIR REPLACEMENT

External Air Supply for “Caitec Air” and Cooling

Rear View of Autoclaved Aerated Concrete (AAC) Heat cell and fire box.

Offset

Offset for

Hearth

Finishing

Hearth

Plinth

16 December 2014

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm……….Copyright

6

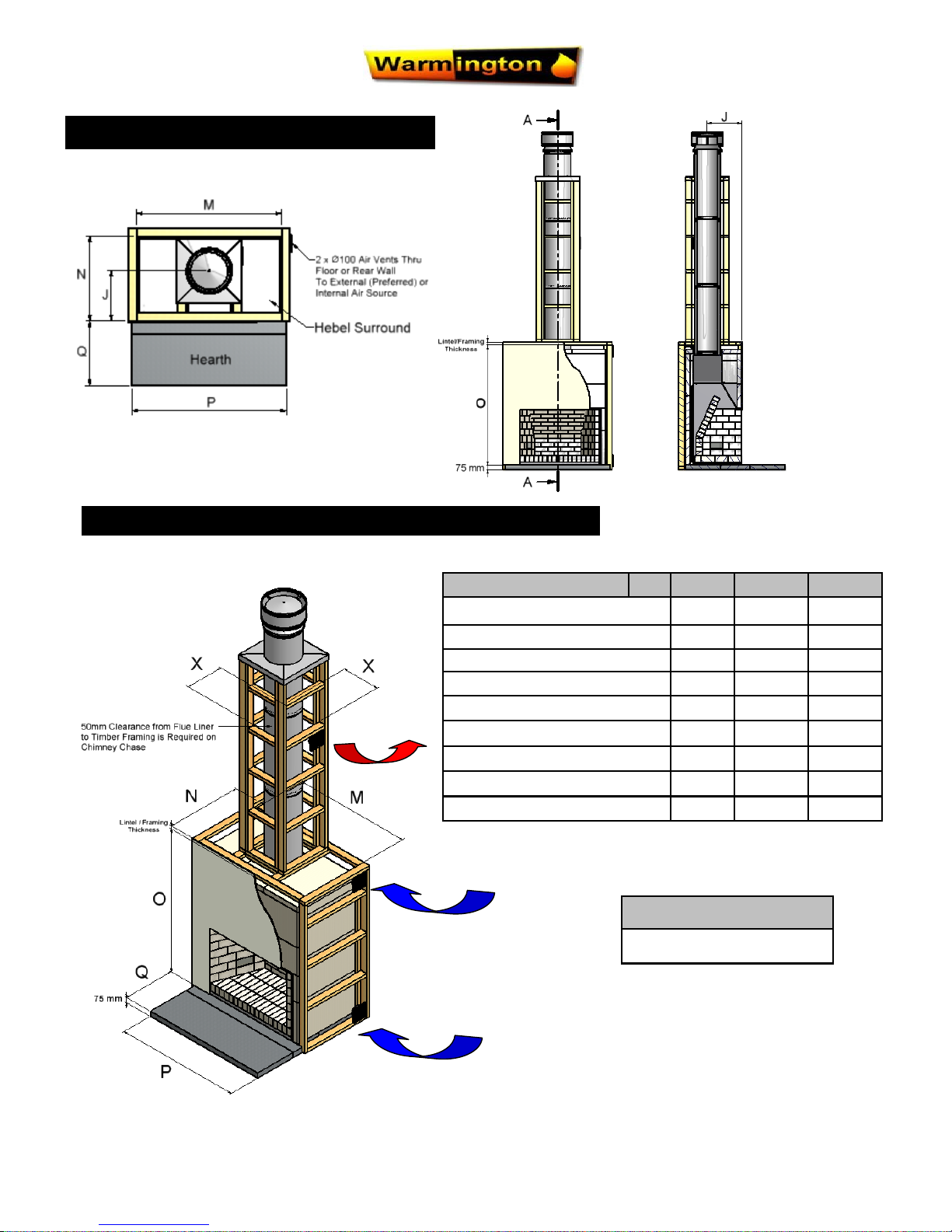

TIMBER FRAMING & TRIM OUT DETAILS—Heat Cell Clearance

PLAN, FRONT ELEVATION & CROSS SECTION

Description

TF 800 TF 1000 TF 1200

To Centre of Flue

J

539 538 589

Flue Diameter

K

300 300 350

Liner Diameter

L

400 400 450

Heat Cell Clearance Width

M

1290 1490 1690

Heat Cell Clearance Depth

N

990 990 990

Heat Cell Clearance Height

O

2150 2150 2150

Hearth Width

p

1350 1550 1800

Hearth Projection

Q

500 600 750

Chimney Chase Clearance

X

500 500 550

External Air Supply for “Caitec Air” and Cooling Air

Warm Air

Vent

Note:

Centre Line of Flue is `NOT’ in Centre

of Alcove

NOTE : NonCombustible

Cladding eg :

10mm Promina

Board , 10mm

Supalux ,

Latex Plaster .

(Not Supplied)

NOTE : 50mm

Clearance from the

Flue Liner to Timber

is required

Loading...

Loading...