Warmington Studio Oven Installation Instructions Manual

21 February 2017

All Dimension are in mm………….Copyright ©

1

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

Studio Oven—Clean Air 2016

Visit www.warmington.co.nz for Spec’s, DWG’s and PDF uploads of Fires

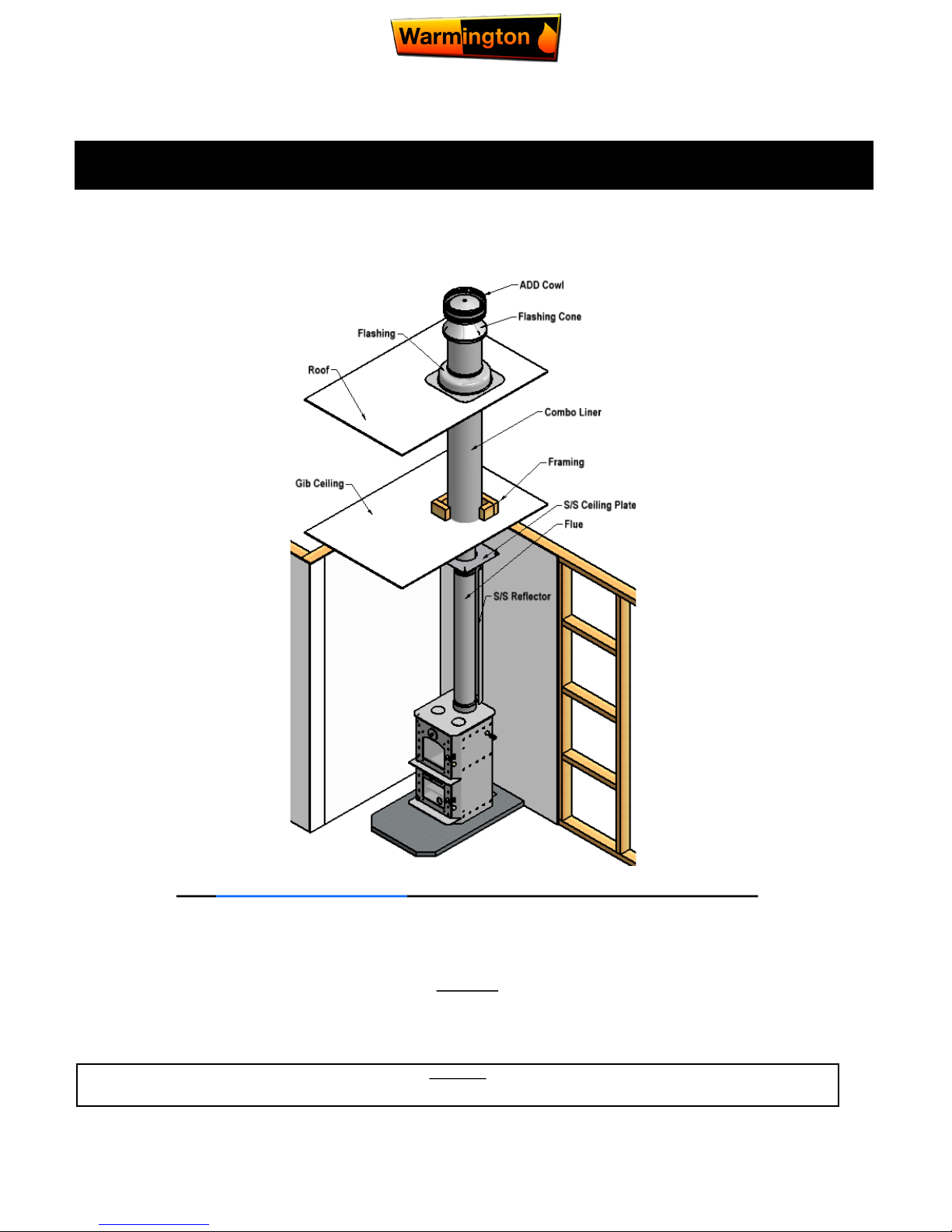

Fire, Flue System and Instructions to Comply with ASNZS 2918:2001

Keep these Instructions for further reference……Ensure that you have the correct and current Installation details for the Warmington Fire

Installation

The Warmington unit is to be Installed by a Certified Warmington Installer or an Approved NZHHA Installation Technician .

See www.homeheat.co.nz/members for a Certified NZHHA SFAIT Installer in your area .

CLEARANCES TO COMBUSTIBLE SURFACES UNLESS STATED

IMPORTANT

Read all the Instructions carefully before commencing the Installation. Failure to follow these Instructions may result in a Fire Hazard and void the warranty

Studio Oven - Wood Burner

Installation Instructions

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

21 February 2017

All Dimension are in mm………….Copyright ©

2

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

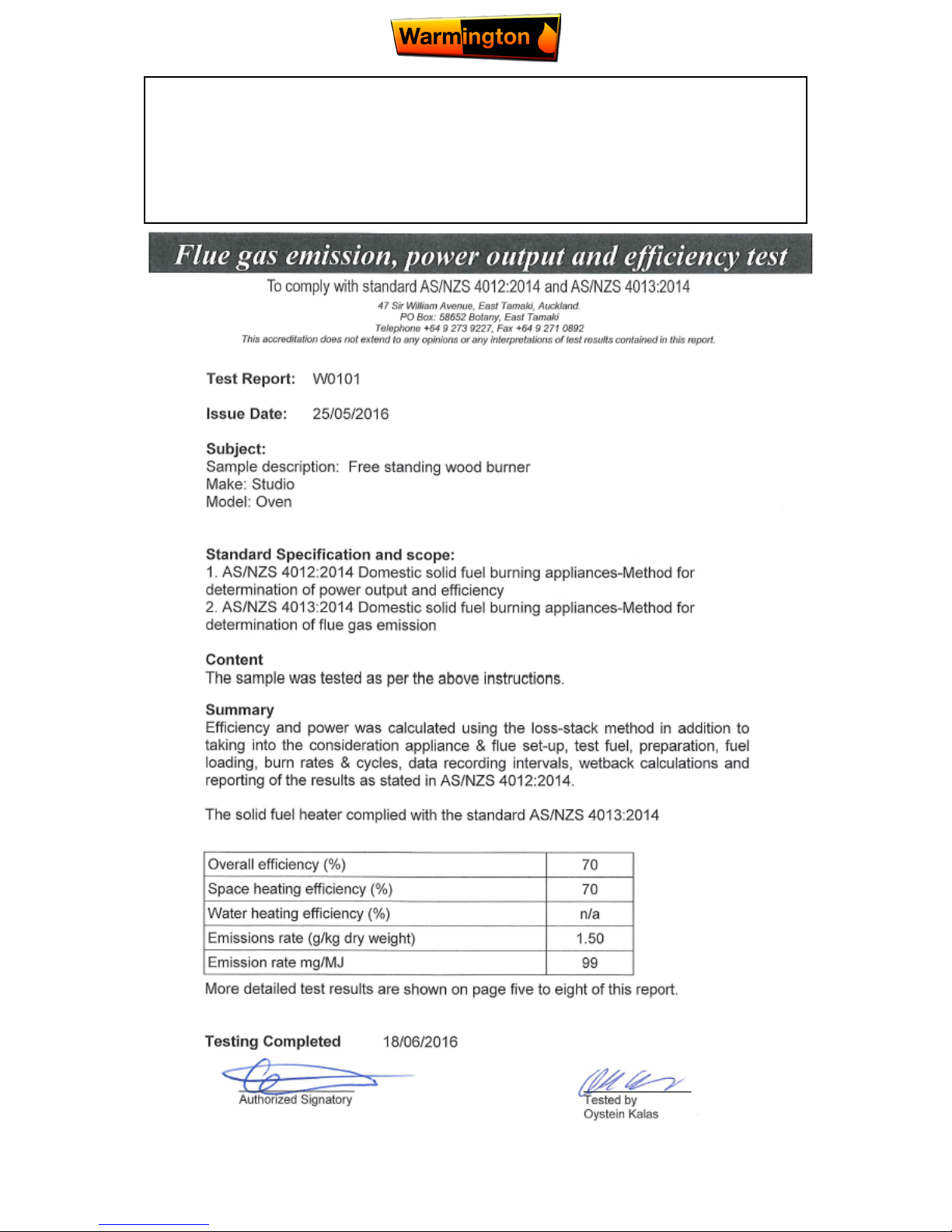

Model: Studio Oven

Serial No: SO - ……………………

TESTED TO AS/NZS : 2918

TEST REPORT : JOHN YOLLAND & ASSOCIATES LTD

TEST REPORT NO : 98/17

Date of installation: _____/_____/20_____

21 February 2017

All Dimension are in mm………….Copyright ©

3

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

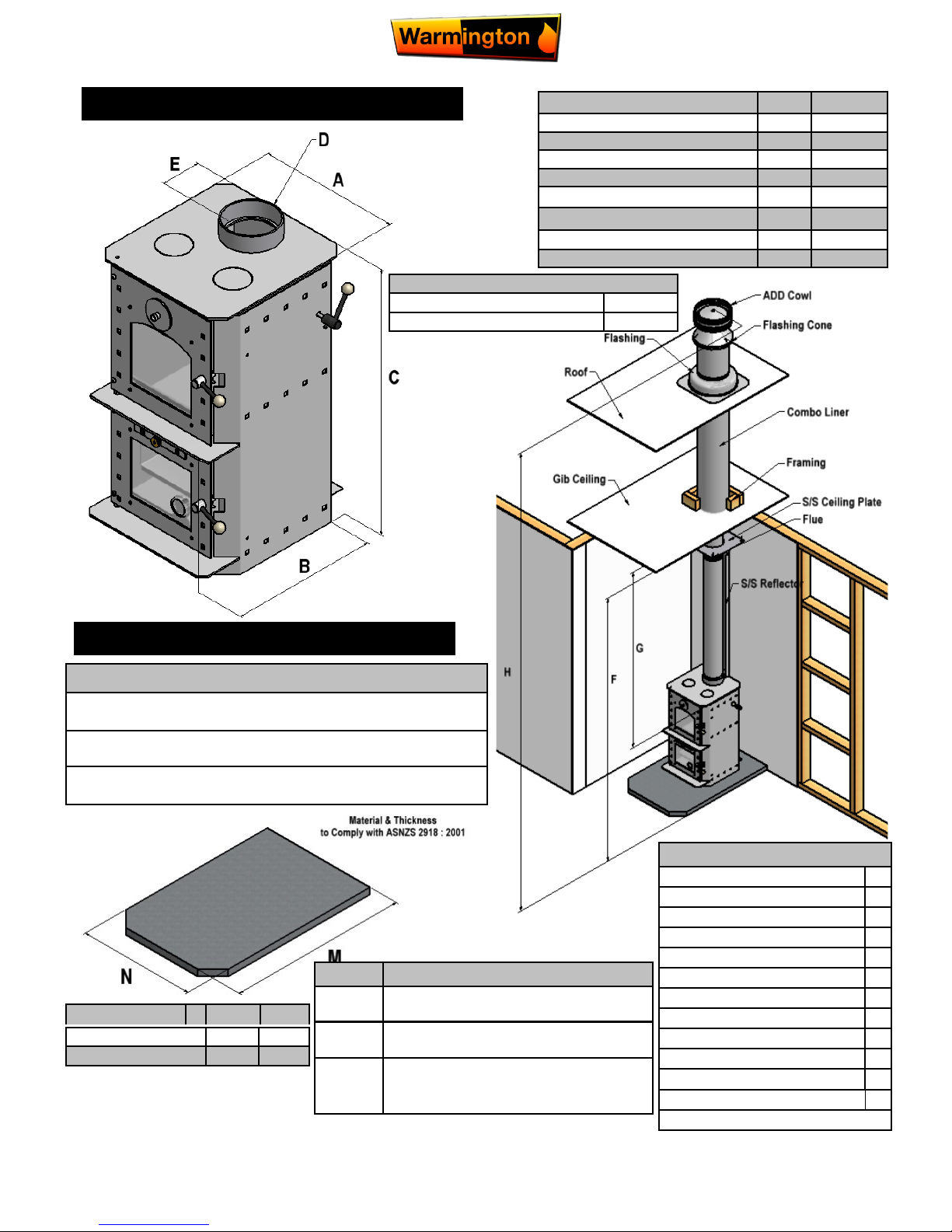

Description

Cabinet Width A 436

Cabinet Depth B 509

Cabinet Height C 820

Flue Diameter D 150

To Flue Centre E 123

Ceiling Height F 2400

Minimum from fire to Ceiling G 1500

Height from Floor Protector H 4600

Check List

Fit Baffle (If Required)

Fit Bricks (If Required)

Fit Bottom Ash Pan

Fit Top Plate Inspection Discs

Fit Oven Trays

Fit Thermometer

Holding Down Brackets

Check Door Seals

Check Door Dampers

Check Flue Damper & Handle

Serial Number Check

Loading Badge

Packed By :

Minimum Flue Height

Flue Height 3600

Measured From Top of Cabinet C + 3600

FIREBOX DETAILS

FLOOR PROTECTOR

Hearth Depth M 1128 903

Hearth Width N 660 660

Description 1. 2.

Note: Floor Protection

Floor Protectors are normally designed to suit each individual

“setting”.

The Studio Oven requires an “Insulating” Floor Protector of

75mm Thickness or more .

The Insulating Floor Protector is to Comply with

ASNZS 2918 : 2001

Situation

1. Combustible Surface without Flue

Shield.

2. Combustible Surface with stainless steel

reflective Flue Shield*

* Construction of Flue Shield must be in

accordance with ASNZS 2918 (minimum

Flue Shield height is 1200mm)

21 February 2017

All Dimension are in mm………….Copyright ©

4

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

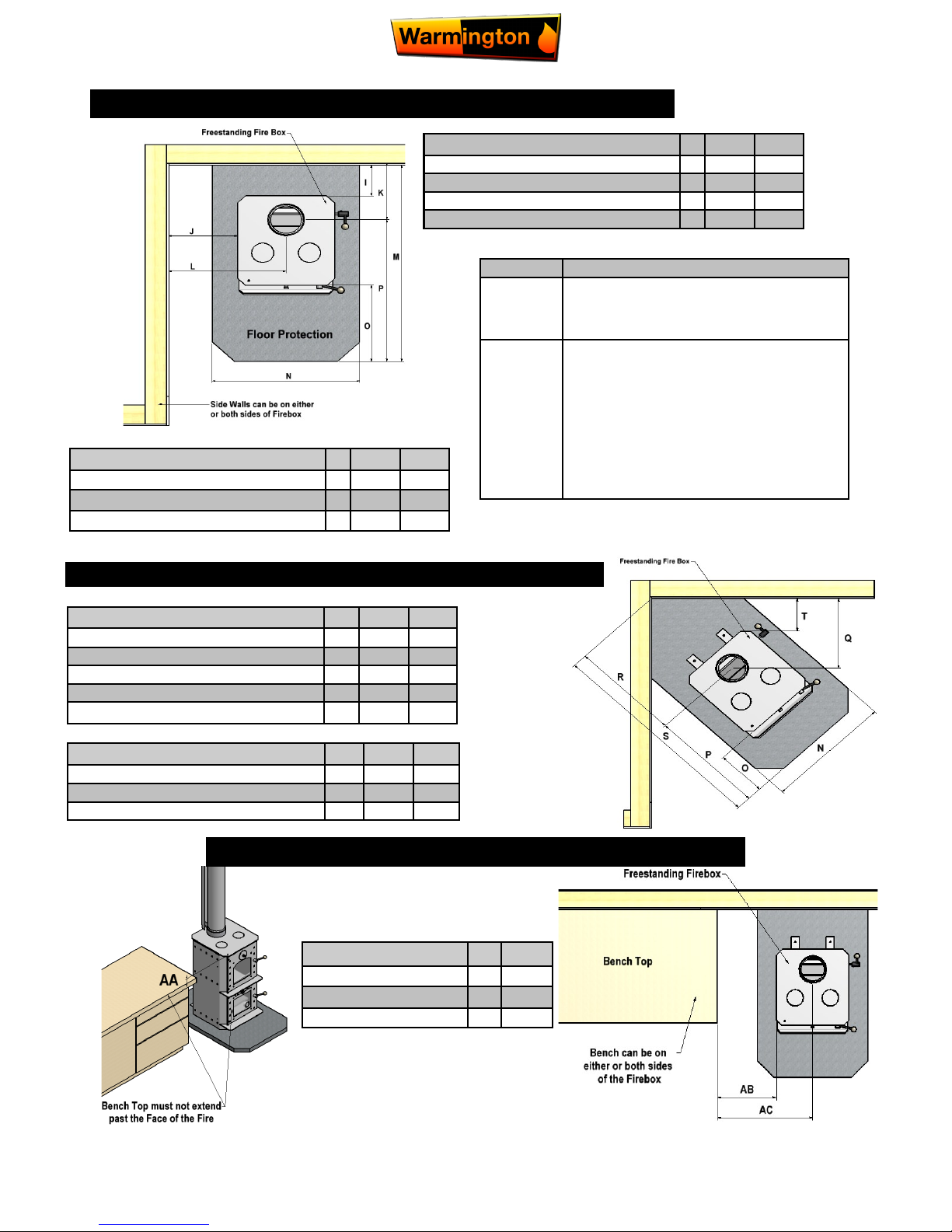

Description 1. 2.

To Wall Behind I 175 100

To Wall Side J 305 100

To Flue Centre (Back) K 298 223

To Flue Centre (Side) L 523 300

*Measurement taken from front ash lip

PLAN VIEW OF CLEARANCES TO COMBUSTIBLE S—STRAIGHT WALL INSTALL

Description 1. 2.

Hearth Projection O 300* 300*

Hearth Projection from Centre of Flue P 614 614

To Flue Centre – Corner Q 366 303

To Flue Centre – Corner R 518 429

To Wall Side – Corner T 150 100

Description

2. 3.

Hearth Depth M 903 837

Hearth Width N 660 660

Hearth Projection from Centre of Flue P 614 614

PLAN VIEW OF CLEARANCES TO COMBUSTIBLES—CORNER INSTALL

Description 1. 2.

Hearth Depth S 1123 1043

Hearth Width N 660 660

Hearth Projection from Centre of Flue P 614 614

CLEARANCES TO BENCH TOP FOR STUDIO OVEN

Description

mm

Bench Top Clearance AA 50

To Bench Top Side AB 352

To Flue Centre (Side) AC 570

Situation

1.

Combustible Surface with stainless steel reflective Flue Shield. Construction of Flue Shield

must be in accordance with ASNZS 2918

(minimum Flue Shield height is 1200mm)

2.

Non Combustible Surface and including walls

without Flue Shield , eg Concrete/Block/Brick/

ACC Block.

Re Clearance to a Non Combustible materials, walls or surfaces Ref to

ASNZS:2918:2001 3.2.1.

The clearance to a Non Combustible surface

and including wall can be less that 100mm if

a wet back is not fitted and no requirement

for maintenance.

21 February 2017

All Dimension are in mm………….Copyright ©

5

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

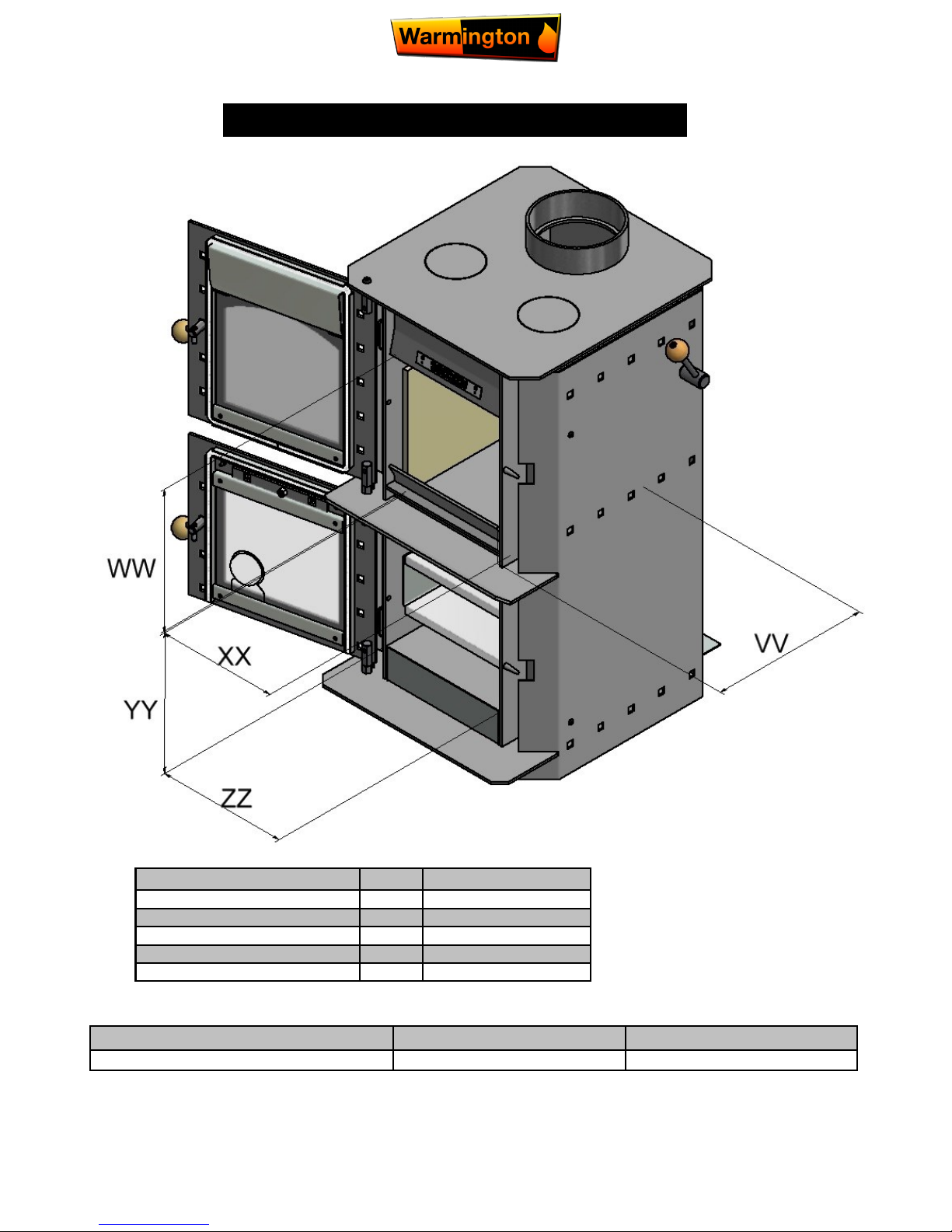

STUDIO OVEN INTERNAL MEASUREMENTS

Description

STUDIO OVEN

Internal Depth VV 295

Firebox Internal Height WW 205

Firebox Internal Width XX 241

Cooker Internal Height YY 281

Cooker Internal Width ZZ 260

Tested Fuel Load (Softwood)

Kg Fire Box Litres : Approx.

STUDIO OVEN up to 2.9 kg 29 Liters

21 February 2017

All Dimension are in mm………….Copyright ©

6

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

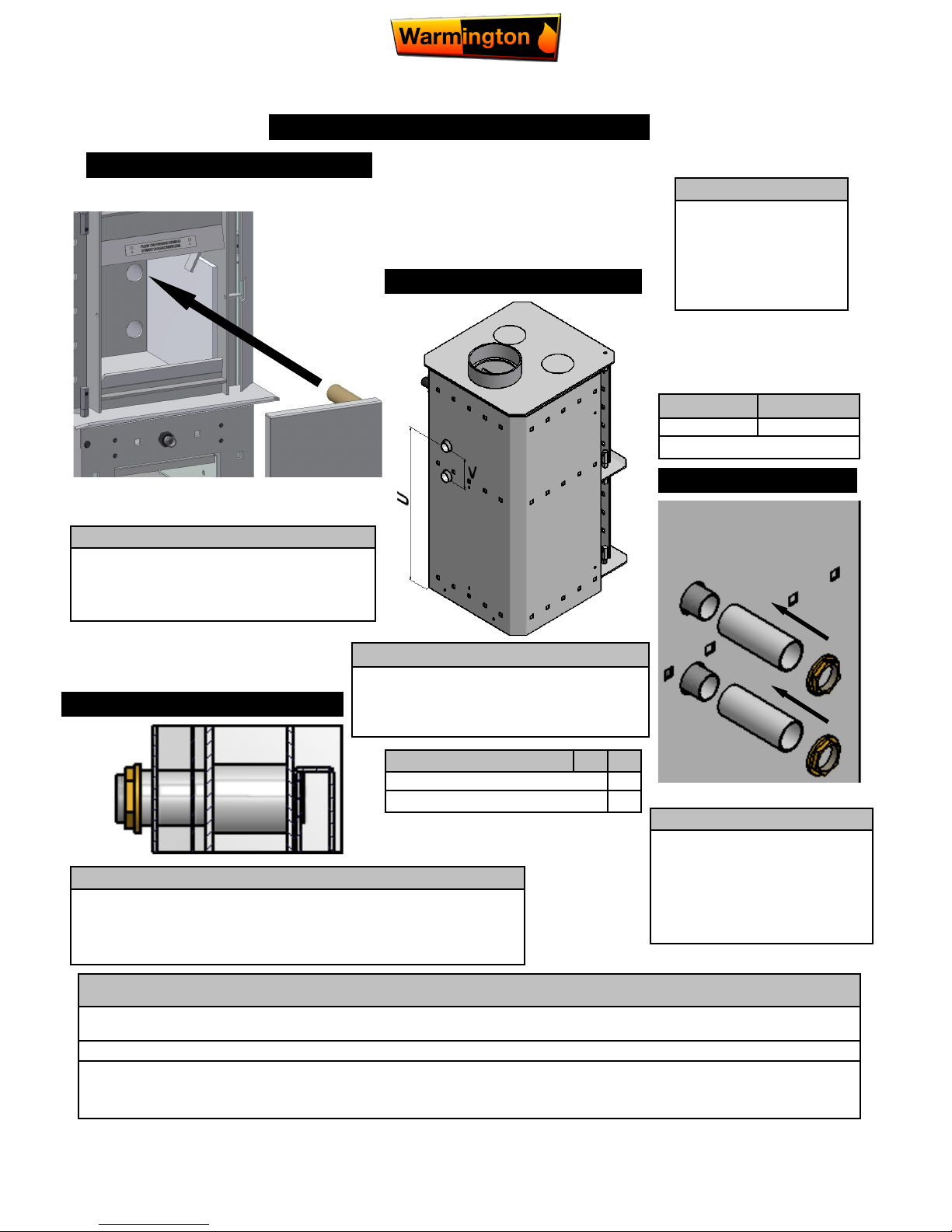

Note:

Cut Excess BSP pipe

off wet back to

length…..By Plumber.

Description

Height from Bottom of Unit U 560

Distance Between Outlets V 110

Power Out KW*

Wetback 2 Kw

*Value is approx.

WETBACK POSITION

STEP 1

STEP 2

Step1 :

Remove 2X Wetback Plugs & Fit Wetback

(as per Diagram above) into 2X Holes inside

Firebox .

Step 2 :

Once Wetback is in Place , the 2 BSP

Pipes should extrude out the back & past

the Fires Main Outer Wrap .

STEP 3

Step 3 :

With the 2X 100mm Galv Spacer Pipes supplied Slide over

BSP Pipe off the Wetback &

then secure with 2X Brass BSP

Nuts supplied .

STEP 4

BSP Brass Nut

100mmGalv

Spacer

Step 4 :

Once the Wetback is secured in place , ensure that

Water is in the Wetback before Operating the Fire .

Damage will result if the Wetback is dry .

Note:

Consult your plumber for wet back system configurations and operation.

Wet back is to be fitted to an internal heat-sync (e.g. Hot water cylinder / Radiator / Under floor heating etc…

Ensure that Water is in the Wetback before Operating the Fire . Damage will result if the

Wetback is dry .

Loading...

Loading...