Warmington Studio Stove, Studio OH-AH 14 Installation Instructions Manual

17 October 2014

All Dimension are in mm………….Copyright ©

1

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

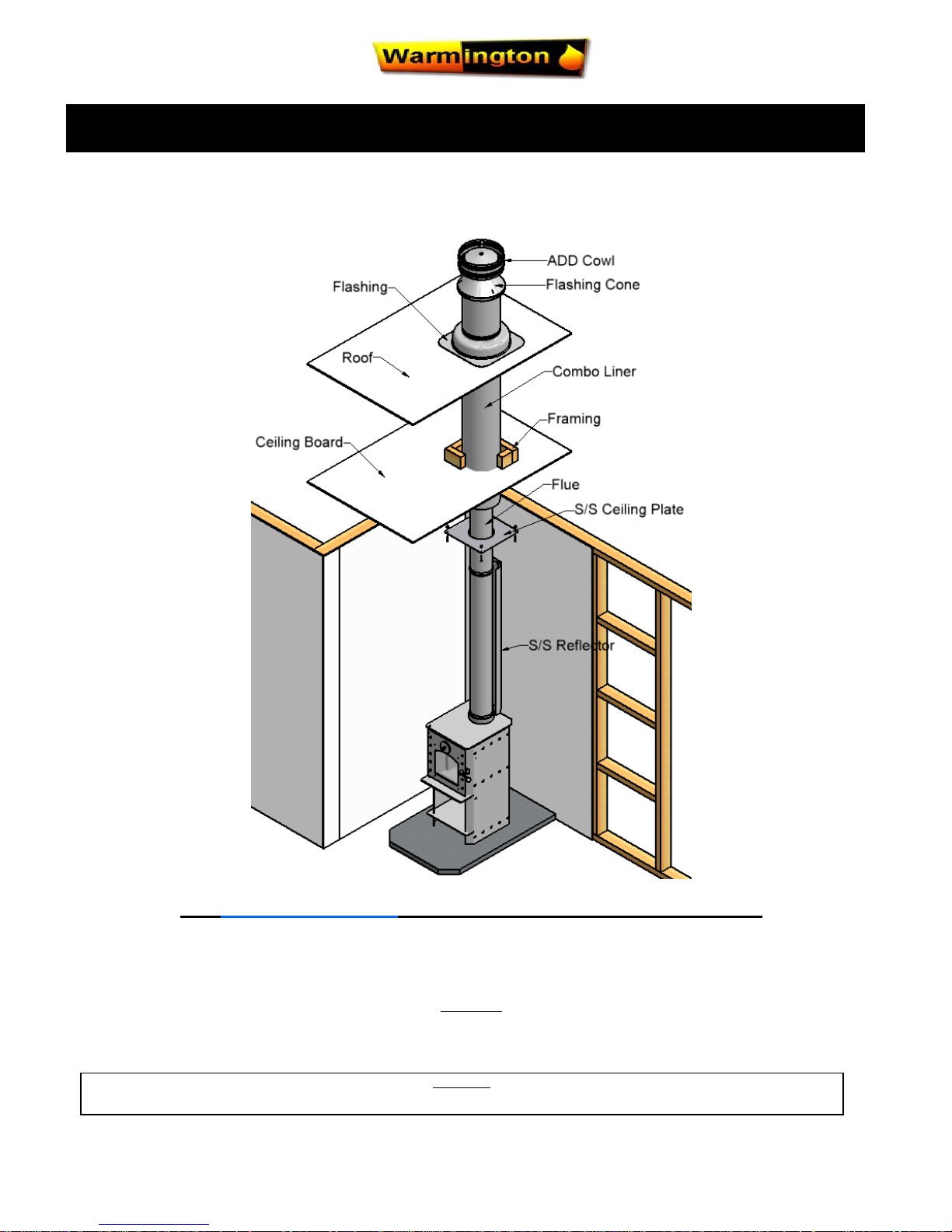

Studio Stove

Visit www.warmington.co.nz for Spec’s, DWG’s and PDF uploads of Fires

Fire, Flue System and instructions to comply with ASNZS 2918:2001

Keep these Instructions for future reference……Ensure that you have the correct and current Installation details for the Warmington Fire

Installation

The Warmington unit is to be Installed by a Certified Warmington Installer or an Approved NZHHA Installation Technician .

See www.homeheat.co.nz/members for a Certified NZHHA SFAIT Installer in your area .

CLEARANCES TO COMBUSTIBLE SURFACES UNLESS STATED

IMPORTANT

Read all the Instructions carefully before commencing the Installation. Failure to follow these Instructions may result in a Fire Hazard and void the warranty

Studio Stove—Clean Air Approved Wood Burner

Installation Instructions

17 October 2014

All Dimension are in mm………….Copyright ©

2

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

Manufactured by: Warmington Industries Ltd - PO Box 58652 Botany 2163, Auckland NZ

Model: ……Studio Stove

Serial No: S - ……………………

Emission Report No: 05/1196 Applied Research Services LTD

TESTED TO AS/NZS 4013.

BURN ONLY UNTREATED WOOD WITH A MOISTURE CONTENT LESS THAN 25% (DRY BASIS)

AVERAGE PARTICULATE EMMISSION FACTOR BURNING SOFTWOOD – 0.95g/kg

MAXIUM AVERAGE HEAT OUTPUT BURNING SOFTWOOD – 8.9KW

OVERALL AVERAGE EFFICIENCY BURNING SOFTWOOD - 69.9%

When Tested in Accordance with AS/NZS 4012

Council Authorization No: Expiry date:

ECan 071226 01 Jan 9999

NCC 071226 N/A

Performance may vary from tested values depending on actual operating conditions.

Date of installation: _____/_____/20_____

Free down load of operating instructions from the website .

www.warmington.co.nz

17 October 2014

All Dimension are in mm………….Copyright ©

3

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

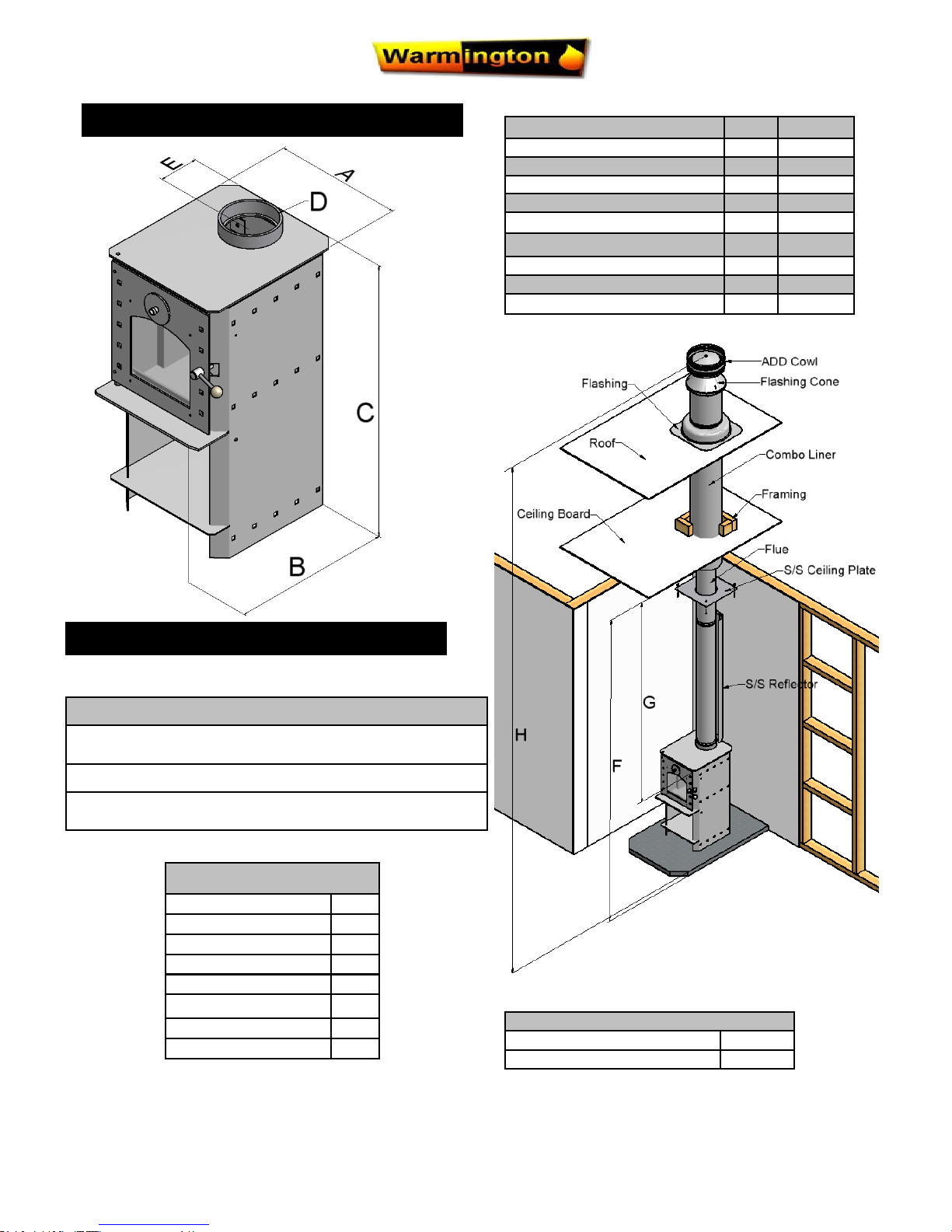

Description

Cabinet Width A 400

Cabinet Depth B 520

Cabinet Height C 820

Flue Diameter D 150

To Flue Centre E 123

Minimum Ceiling Height F 2400

Minimum from fire to Ceiling G 1500

Height from Floor Protector H 4600

Emissions levels (g/kg) 0.95g/kg

Check List

Baffle

Holding Down Brackets

Check Door Seal

Check Damper

Bricks (If Required)

Serial Number Check

Loading Badge

Packed By

Minimum Flue Height

Flue Height 3600

Measured From Top of Cabinet C + 3600

FIREBOX DETAILS

FLOOR PROTECTOR

Note: Floor Protection

Floor Protectors are normally designed to suit each individual

“setting”.

The Studio Stove requires a “Ash Hearth” Floor Protector

The Floor Protector is to Comply with

ASNZS 2918 : 2001

17 October 2014

All Dimension are in mm………….Copyright ©

4

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

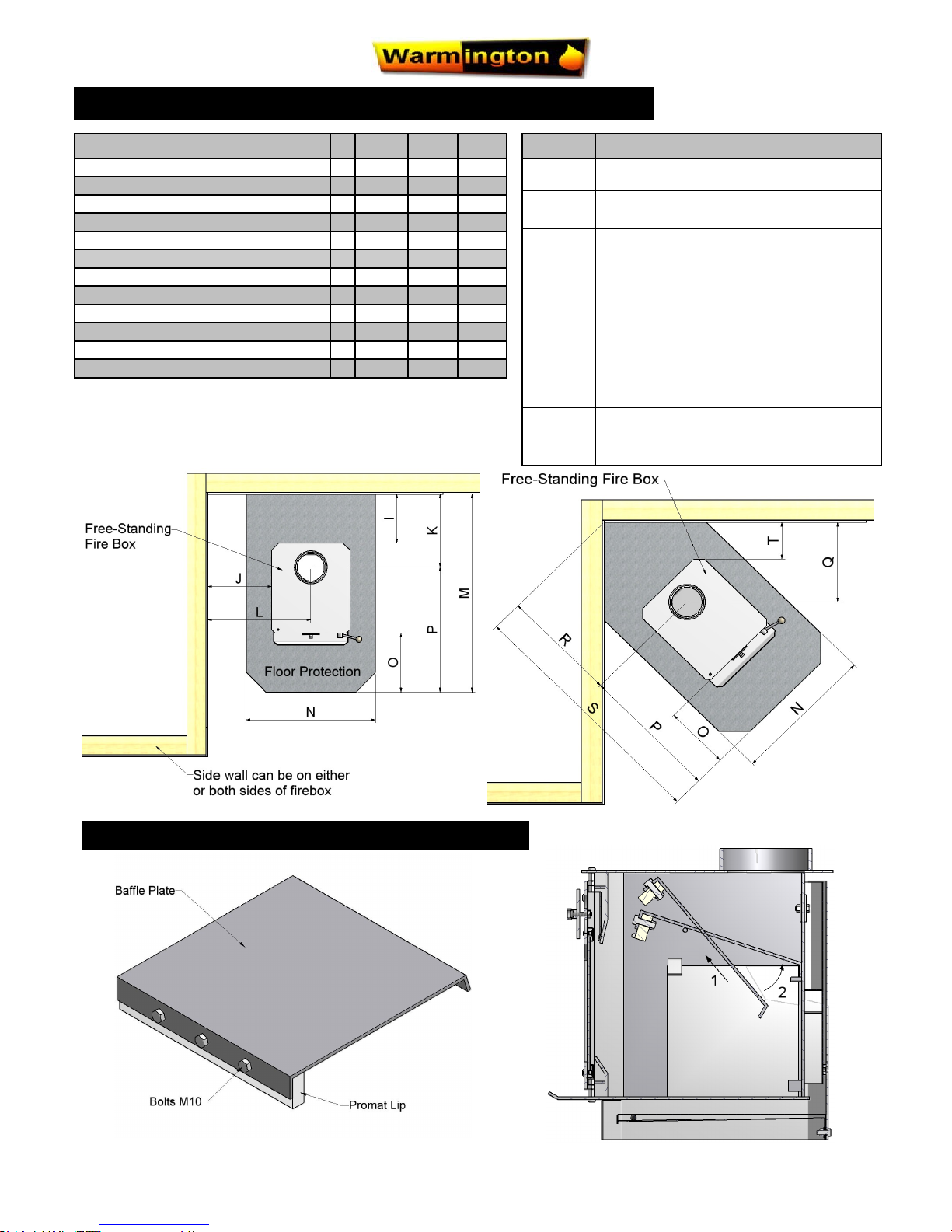

Description

1. 2. 3.

To Wall Behind I 325 250 100

To Wall Side J 325 325 100

To Flue Centre (Back) K 448 373 223

To Flue Centre (Side) L 525 525 300

Hearth Depth M 1062 987 837

Hearth Width N 660 660 600

Hearth Projection O 300* 300* 300*

Hearth Projection from Centre of Flue P 614 614 614

To Flue Centre -Corner Q 453 378 303

To Flue Centre -Corner R 641 535 429

Hearth depth -Corner S 1255 1149 1039

To Wall Side - Corner T 250 175 100

*Measurement taken from front ash lip

Situation

1. Combustible Surface without Flue Shield.

2. Combustible Surface with stainless steel

reflective Flue Shield*

3. Non Combustible Surface and including

walls without Flue Shield , eg Concrete/

Block/Brick/ACC Block.

Re Clearance to a Non Combustible

materials, walls or surfaces Ref to

ASNZS:2918:2001 3.2.1.

The clearance to a Non Combustible

surface and including wall can be less

that 100mm if a wet back is not fitted

and no requirement for maintenance.

* Construction of Flue Shield must be in

accordance with ASNZS 2918 (minimum

Flue Shield height is 1200mm)

PLAN VIEW OF CLEARANCES TO COMBUSTIBLES - STRAIGHT & CORNER

BAFFLE POSITION

17 October 2014

All Dimension are in mm………….Copyright ©

5

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

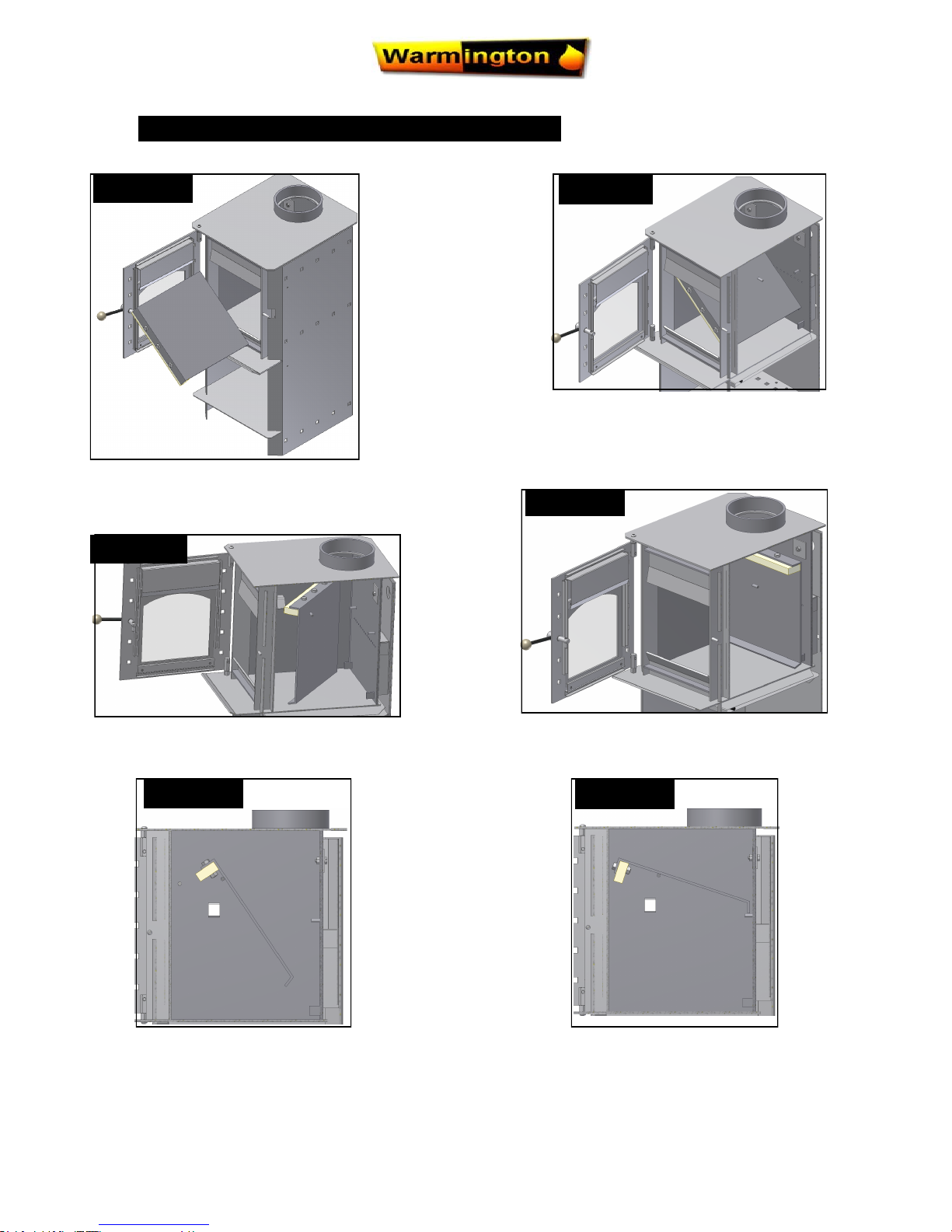

STEP : 1

FITMENT & REMOVAL OF BAFFLE

STEP : 2

STEP : 3

STEP : 4

STEP : 5

STEP : 6

Remove Ash & Studio Bricks

Push Baffle right to the Back of Firebox

Tilt Studio Baffle on an Angle & Slide in

through Door Frame

Move Baffle forward to sit on Pins

Move the Back of the Baffle up to sit

on the Pins at the Back of the Firebox

Rotate Baffle 90 degrees

Loading...

Loading...