Warmington SG SN 1500, EG SN 1500, EG SN 1250, SG SN 1250, SG-EG 600 Twin Installation Manual

...

14 June 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm

1

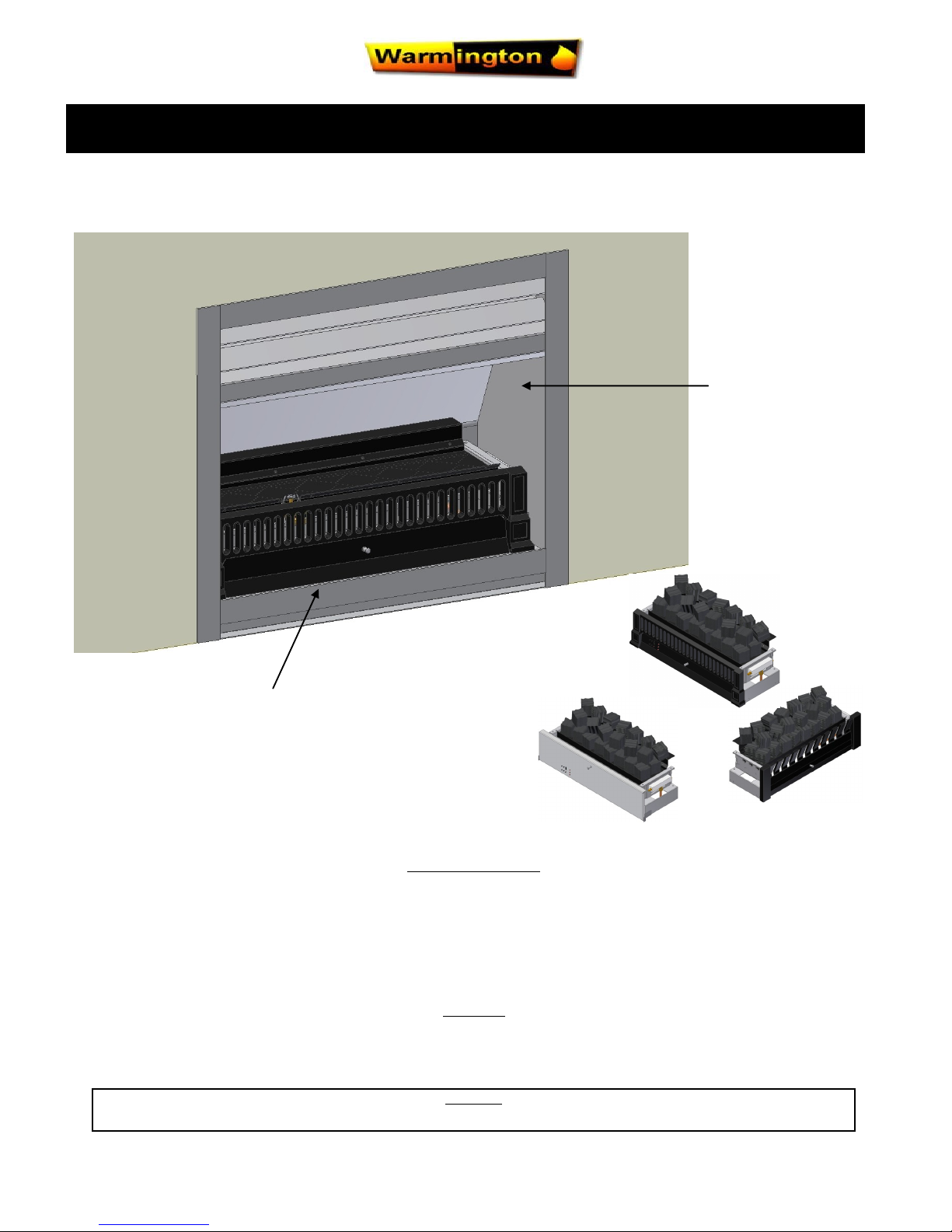

SG Gas Burner into a Warmington SI Wood Open Fire

Installation Guide Only

SG 700-780-900-1100 Burner Only

Traditional Grate

& Burner

Pure Grate

& Burner

Classic

Grate

Warmington SG

Gas Burner.

Warmington

SI Open

Wood Firebox.

The fireplace is constructed and tested to comply with NZS 4558(int):2013 “Decorative gas log and other fuel effect appliances”.

Keep these instructions for further reference. Ensure that you have the correct and current installation details for the Warmington fireplace.

Installation

The Warmington unit is to be installed by a certified Warmington installer or an approved NZHHA installation technician.

See www.homeheat.co.nz/members for a certified NZHHA SFAIT Installer in your area.

A licenced certified gas fitter and licenced electrician are required to run power and gas supplies as required to the unit and any commissioning as part of the

installation process.The heater must be installed according to these instructions and in compliance with all relevant building, gas fitting, electrical and other

statutory regulations.

IMPORTANT

Read all the instructions carefully before commencing the Installation. Failure to follow these instructions may result in a fire hazard and void the warranty

Related documents

Fire and flue system installation, and instructions to comply with NZS 5601.1:2013,

3645.1(Int):2010, 3645.2(Int):2010, 5266:2014, 2918:2001.

14 June 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm

2

POINTS TO CONSIDER PRIOR TO INSTALLATION

INSTALLATION ORDER OF OPERATIONS

Location of the Fire. Open Fires are better located at one end of a room or area, as they project the heat away from their opening .

Venting to the Cavity.

This air is to allow the Cavity to Vent the Warm Air. This Warm Air helps keep the Fire and Flue System form getting to Cold . If the Flue and Fire get to Cold the System may soot often and require

cleaning. Each Fire has different ways of venting the cavity .

The Topography of the Land .

The slope and position of the Land in relation to the Home has a bearing on how the wind will interact with the Fire and Flue System. Care needs to be taken to ensure that the Flue Termination is in the

correct position to maximise performance .

The Prevailing Wind.

Care needs to be taken to ensure that the Flue Termination is in the correct position as wind and gusts that hits the Flue and Cowl System may overcome the Cowl and draft back down the Flue into the

Home. This can be a combination of down draft and high pressure.

Hearth and Plinth:

The height of the Hearth off the Floor. The Finishing that is to be used on the hearth is to be allowed for at the de sign stage.

Positioning of the Flue System:

There is a maximum distance that an Offset Flue can be Installed. Reference to relevant standards.

Flue and Fire Clearance:

To be maintained to the Manufactures Instructions.

Pressure Differential, Venting & External Air into the Building :

All fires need air to burn and draw correctly, Kitchen Fans, Air Conditioning units, High Wind Zones, Naturally formi ng Draft spaces, can all have an effect on the pressure difference from inside the

building to the outside. A lower pressure in the building may induce a draft down the flue system and back into the building causing the fire to smoke or spill into the building. Care needs to be taken at

the design and installation stage to adequately vent the building, or some mechanical system to ensure that there is always a neutral or positive pressure at the fireplace and a negative

pressure at the flue outlet. This will ensure that the draft in the flue system is always to the outside.

“CAITEC AIR” the limits and requirements. See details in these Specs, on www.warmington.co.nz or contact your local Agent.

Wind Noise:

You may encounter wind noise in some installations. It is recommended to use an enclosed chase with a chimney pot to help reduce noise. There will always be some noise from the flue systems of all

fireplaces.

Prior to Construction and Installation Important Notes:

1. Consult a licenced certified gas fitter for correct gas installation.

2. Install to current standards.

3. Install to manufacture’s specifications.

4. All new Installations require a Local Council Consent No/Permit Application to be done .

5. Allow for Gas & Power supply to Cavity.

6. For special requirements concerning Materials (Timber Mantle and Surrounds) within close proximity of Warmington products, please contact your

local Warmington Technical Consultant.

Install Procedure by Certified Gasfitter or approved “Warmington Installer”, see “www.homeheat.co.nz” go to Members & follow

steps to get a Certified NZHHA SFAIT Fire Installer in you Region. Installation to comply with current standards.

Ensure that the gas appliance is fitted and installed to the appropriate gas code

and standard, and that all checks and test have been correctly carried out.

Maintenance:

Visually Inspect Fireplace and Flue System. Ensure that the Firebox is operating according to Manufacture’s Instructions, Fire & Burner may

Require to be serviced by Certified Gasfitter annually.

14 June 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm

3

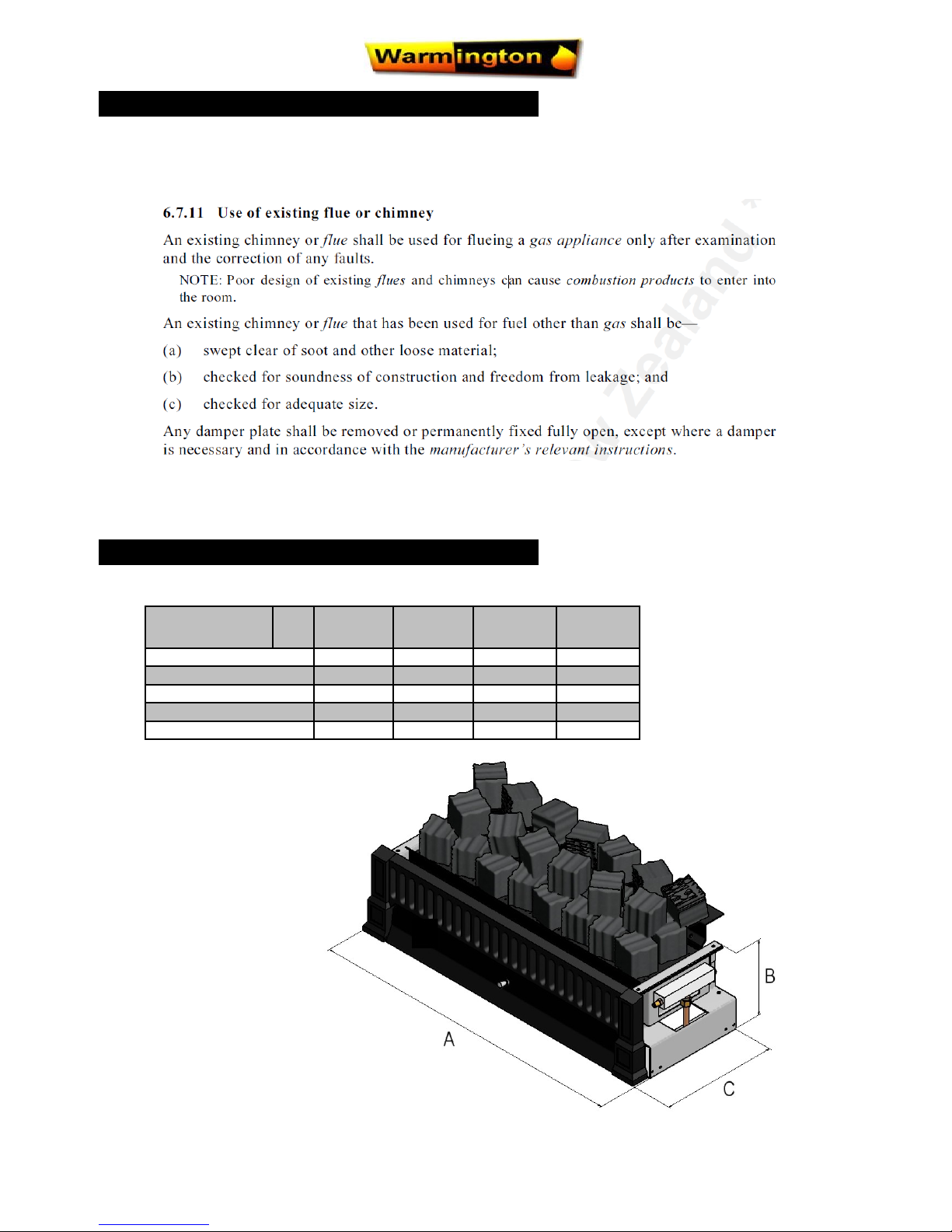

Burner SG

700

SG

780

SG

900

SG

1100

Burner Width A 674 754 874 1074

Burner Height B 205 205 205 205

Burner Depth C 272 272 272 272

Flue Diameter Min J 200 200 250 250

Flue CSA mm K 31 416 31 416 49 087 49 087

WARMINGTON BURNERS

NOTE: IMPORTANT INFORMATION FROM THE STANDARD

Installation to comply with current standards. When installing a fitted open gas fire with an existing chimney section 6.7.11 in

NZS 5601 is particularly relevant, see quote below:

14 June 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm

4

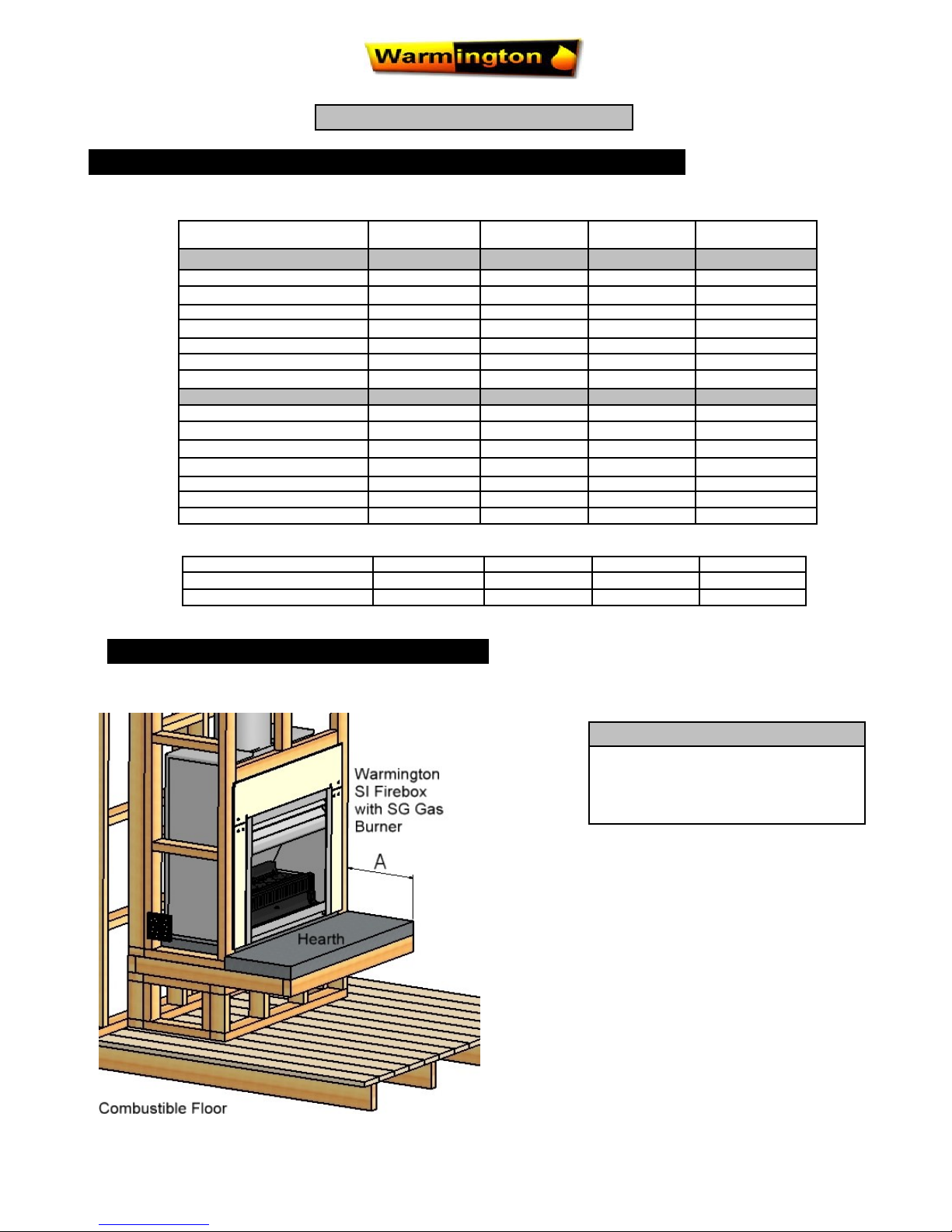

HEARTH CLEARANCES

Note: For Combustible Floors

Minimum Hearth of 300mm (A) must be

maintained at any given height.

* Inlet Pressure not to exceed 4.0KPa

GAS SPECIFICATIONS Tested to current gas standards

NOTE : All Test Pressures are tested by a Independent Test Lab

MODLE SG 700 SG 780 SG 900 SG 1100

LPG

Nominal Pressure kPa

2.75 kPa 2.75 kPa 2.75 kPa 2.75 kPa

Nominal Injector Size mm

2 X 1.1mm 2 X 1.2mm 2 X 1.3mm 2 X 1.4mm

Burner Pressure High kPa

2.5 2.5 2.5 2.5

Burner Pressure Low kPa

0.75 0.75 0.75 0.75

MJ/h

29 38 42 50

Flame Effect Output Only

Effect Effect Effect Effect

Supply Pipe Size dia—min

3/8” 3/8” 1/2” 1/2”

Natural Gas

Nominal Pressure kPa

1.5 kPa 1.5 kPa 1.5 kPa 1.5 kPa

Nominal Injector Size mm

2 X 1.8mm 2 X 2mm 2 X 2.2mm 2 X 2.4mm

Burner Pressure High kPa

1.0 1.0 1.0 1.0

Burner Pressure Low kPa

0.3 0.3 0.3 0.3

MJ/h

35 41 48 60

Flame Effect Output Only

Effect Effect Effect Effect

Supply Pipe Size dia—min

3/8” 1/2” 1/2” 1/2”

IMPORTANT NOTES :

Lab. Test No

GL 923 GL 900 GL 834 GL 876

Lab. Test Dates

20/04/2010 26/02/10 26/06/09 24/12/09

ESS Declaration No: 1149420106 1149520106 1149720106 1149820106

Loading...

Loading...