Warmington Debonaire DUPLO 1200, Debonaire DUPLO 2000, Debonaire DUPLO 2400, Debonaire DUPLO 2800, Debonaire DUPLO 1600 Installation Instructions Manual

12 September 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm………….Copyright ©

1

Debonaire DUPLO 1200-1600-2000-2400-2800

Custom Fire DUPLO — Gas Burner

Installation Instructions

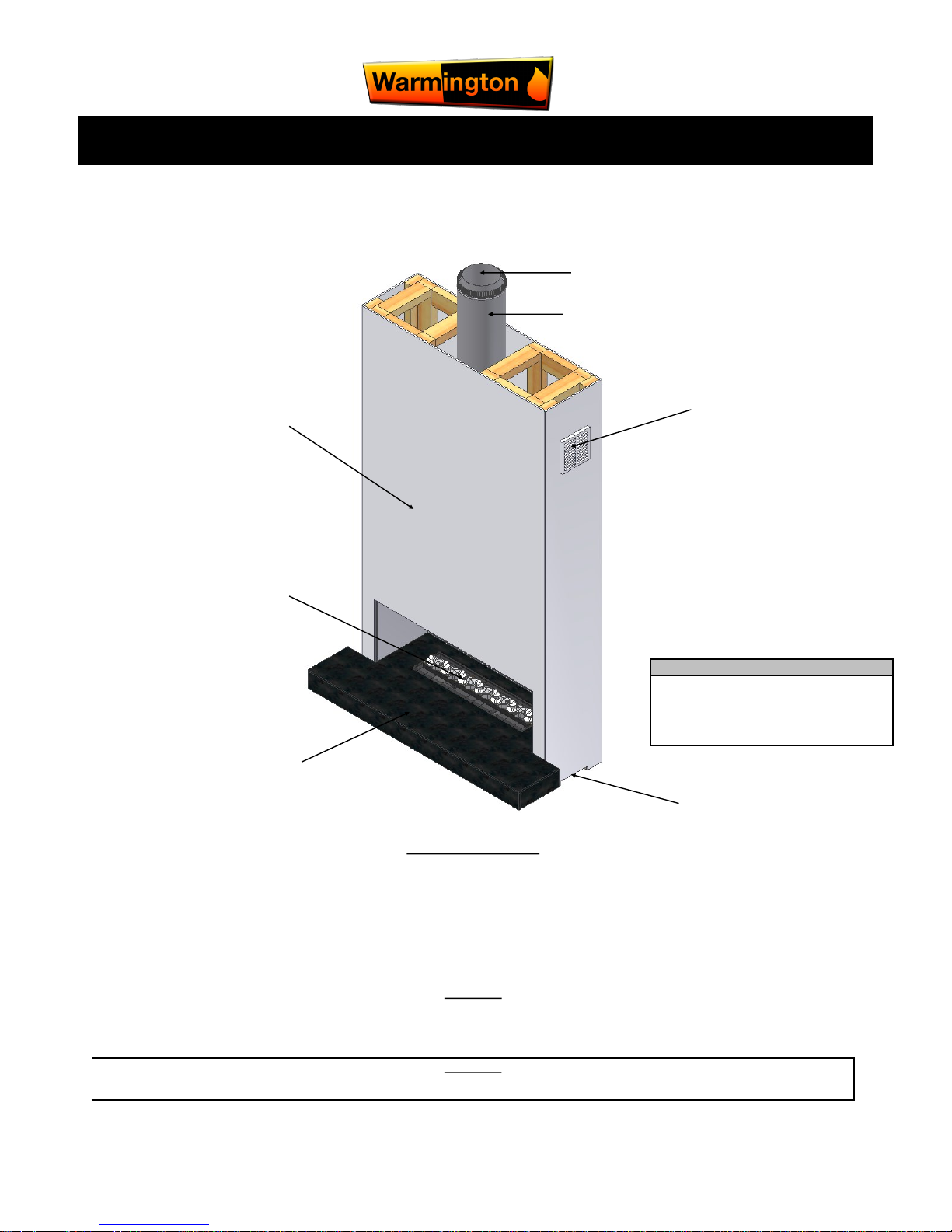

Flue

Liner

Firebox

Venting

Promina Board

Cladding

Non-Combustible

Burner

Hearth

Venting Base Burner

NOTE: T.V. Option Available

Additional Costing for T.V Above Fire-

Consult your nearest Warmington Agent

Visit: www.warmington.co.nz

For Specification

The fireplace is constructed and tested to comply with NZS 4558(int):2013 “Decorative gas log and other fuel effect appliances”.

Keep these instructions for further reference. Ensure that you have the correct and current installation details for the Warmington fireplace.

Installation

The Warmington unit is to be installed by a certified Warmington installer or an approved NZHHA installation technician.

See www.homeheat.co.nz/members for a certified NZHHA SFAIT Installer in your area.

A licenced certified gas fitter and licenced electrician are required to run power and gas supplies as required to the unit and any commissioning as part of the installation

process.The heater must be installed according to these instructions and in compliance with all relevant building, gas fitting, electrical and other statutory regulations.

IMPORTANT

Read all the instructions carefully before commencing the Installation. Failure to follow these instructions may result in a fire hazard and void the warranty

Related documents

Fire and flue system installation, and instructions to comply with NZS 5601.1:2013,

3645.1(Int):2010, 3645.2(Int):2010, 5266:2014, 2918:2001.

12 September 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm………….Copyright ©

2

POINTS TO CONSIDER PRIOR TO INSTALLATION

INSTALLATION ORDER OF OPERATIONS

Prior to Construction and Installation Important Notes:

1. Consult a licenced certified gas fitter for correct gas installation.

2. Install to current standards.

3. Install to manufacture’s specifications.

4. All new installations require a permit.

5. Allow for gas supply to heat cell at the rear, and power supply to the rear if required.

6. For special requirements concerning materials (timber mantle and surrounds) within close proximity of Warmington products,

please contact your local Warmington Technical Consultant.

Stage 1: Frame Construction Procedure by Builder.

1. Mark out flue centre.

2. Mark out heat cell clearance requirements.

3. Build timber framing to heat cell clearances and chimney chase clearance requirements.

4. Ensure that front face of heat cell clearance alcove is left open and unframed to enable installation of the firebox. The chimney

chase is left unlined for installation of the flue.

5. Construct plinth only, to required height. *

Stage 2: Install Procedure by Certified “Warmington Installer” or Certified Person (Gas Fitter / Plumber)

1. Fit fire to plinth.(Ensure gas supply line is fed through firebox.)

2. Fit flue system.

3. Fit cowl and flashing system.

4. Fit vents to heat cell alcove and chimney chase, to cool the heat cell and ensure efficiency of CAITEC Technology.

Stage 3: Finishing Procedure by Builder.

1. Construct hearth to required thickness. *

2. Finish framing of heat cell alcove.

3. Close in heat cell alcove and chimney chase.

4. Finish heat cell alcove and hearth to customer’s requirements (e.g. paint / tiles).

5. * Note: Certified installer can install hearth and plinth.

Maintenance.

Visually inspect fireplace and flue system.

Ensure that firebox is operated according to manufacture’s instructions.

Location of the fire. Open fires are better located at one end of a room or area, as the y project the heat away from their opening.

Venting to the cavity.

This air is to allow the cavity to vent the warm air. This warm air helps keep the fire and flue system form getting to cold.

If the flue and fire get to cold the system may soot and require cleaning. Each fire has different ways of venting the cavity .

The Topography of the land .

The slope and position of the land in relation to the home has a bearing on how the wind will interact with the fire and flue system.

Care needs to be taken to ensure that the flue termination is in the correct position to maximise performance.

The Prevailing Wind.

Care needs to be taken to ensure that the flue termination is in the correct position as wind and gusts that hits the flue and cowl

system may overcome the cowl and draft back down the flue into the home. This can be a combination of down draft and high

pressure.

Hearth and plinth:

The height of the hearth off the floor. The finishing that is to be used on the hearth is to be allowed for at the design stage.

Positioning of the Flue system:

Flue Systems are to comply with the appropriate standard.

Flue And Fire Clearance:

To be maintained to the manufactures Instructions. Reference the appropriate standard.

Pressure Differential, Venting & External Air into the Building :

All fires need air to burn and draw correctly, Kitchen Fans, Air Conditioning units, High W ind Zones, Naturally forming Draft spaces, can all have an effect on the pressure

difference from inside the building to the outside. A lower pressure in the building may induce a draft down the flue system and back into the building causing the fire to

smoke or spill into the building. Care needs to be taken at the design and installation stage to adequately vent the building, or some mechanical system to ensure

that there is always a neutral or positive pressure at the fireplace and a negative pressure at the flue outlet. Th is will en sure th at t he dr aft in the flu e sy st em is

always to the outside.

“CAITEC AIR” th e li m it s and req ui rem ents. See det ails in th ese Spec ’s , on w ww .war min gt on .co.nz or co ntact you r l ocal Ag ent .

Wind Noise:

You may encounter wind noise in some installations. It is recommended to use an enclosed chase with a chimney pot to help reduce noise. There will always be some

noise from the flue systems of all fireplaces.

12 September 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm………….Copyright ©

3

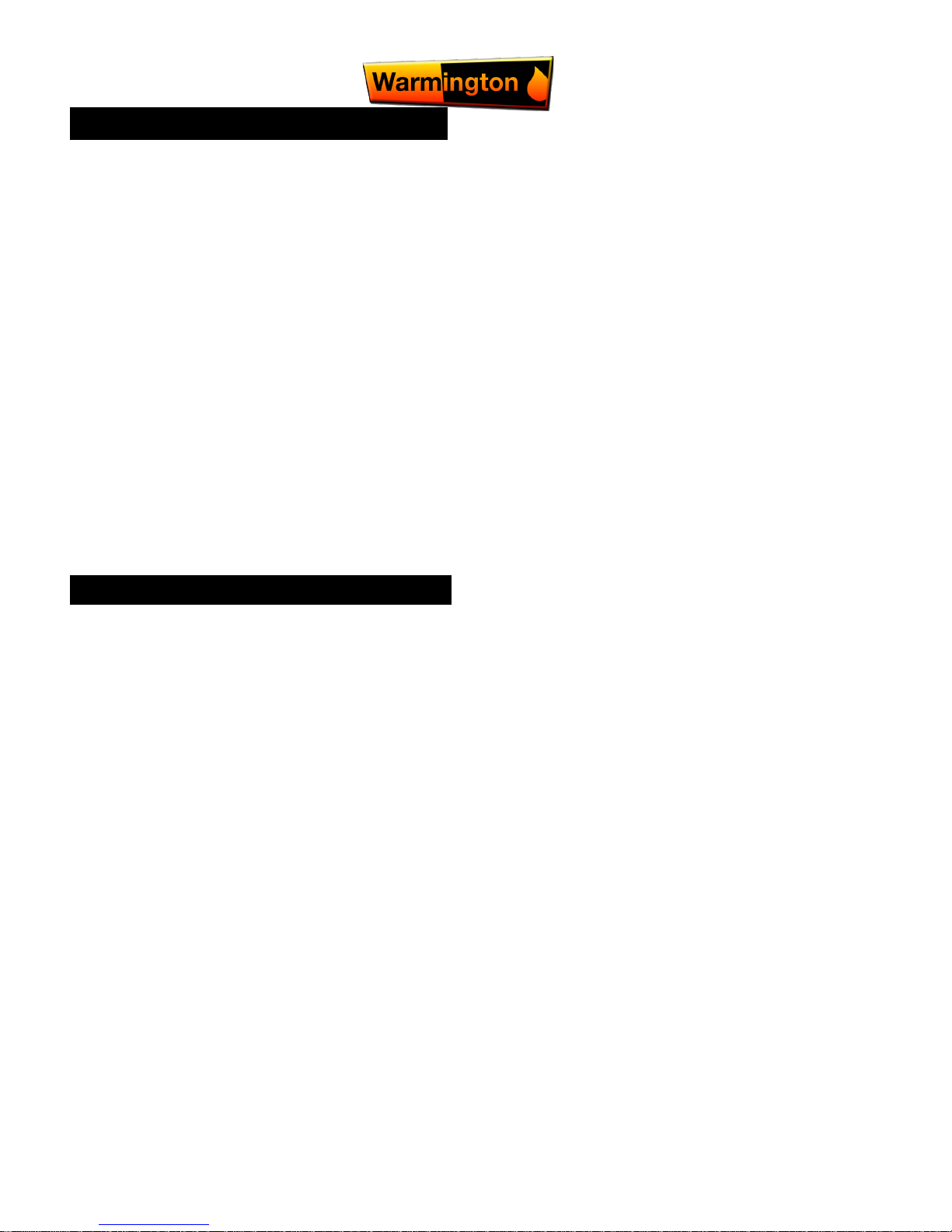

CUSTOM GAS FIREBOX DIMENSIONS

Minimum Flue Height

Flue Height 3600

Measured From Top of Adaptor 3600

HEARTH REQUIREMENTS

TO BE PLACED ON MASONARY FLOOR

Seismic restraint

Secure firebox through

anchor points provided

TOP

FIREBOXBASE

Description 1200 1600 2000 2400 2800

Firebox Overall Width A 1200 1600 2000 2400 2800

Firebox Overall Height B 1800 1800 1800 1800 1800

Firebox Overall Depth C 390 390 390 390 390

Window Width D 1130 1530 1930 2330 2730

Window Height E 400 400 400 400 400

Height from Base F 400 400 400 400 400

Convection Vent Dia G 100 100 100 100 100

Flue Dia. H 200 275 2 x 200 2 x 250 2 x 250

Flue Liner Dia. 250 325 2 x 250 2 x 300 2 x 300

Seismic restraint

Secure firebox through anchor positions through

Base & through bracket at Top of Fire

Builder to supply

Non-Combustible

Base Compressed

sheet To Act as

Seal to Base

12 September 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm………….Copyright ©

4

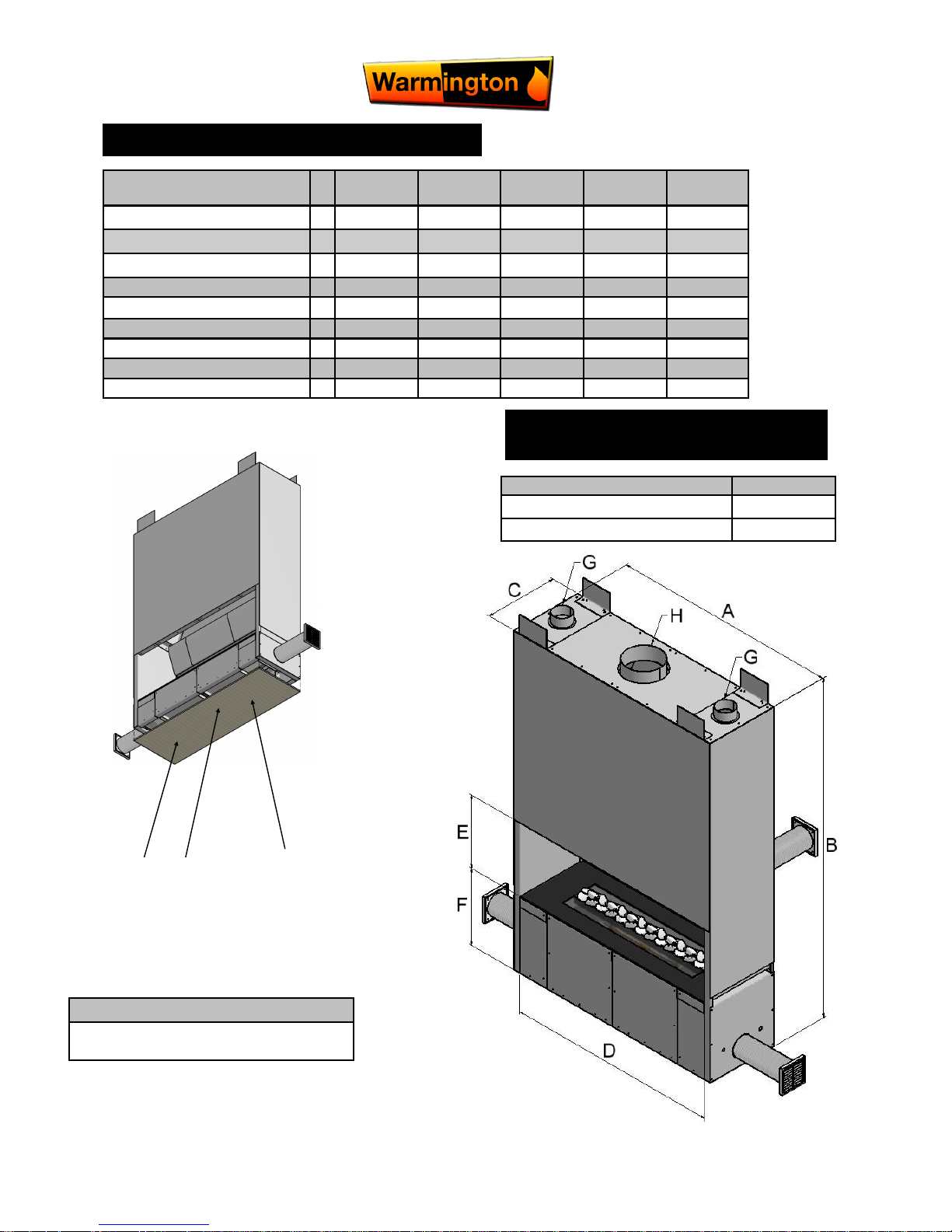

MINIMUM ALCOVE CLEARANCES

FRAMEOUT DETAIL

Description 1200 1600 2000 2400 2800

Overall Timber Width I 1317 1717 2117 2517 2917

Overall Timber Height J 2400 2400 2400 2400 2400

Overall Timber Depth K 390 390 390 390 390

Hearth Width L 1530 1930 2330 2730 3130

Hearth Depth M 300 300 300 300 300

Flue Cavity Depth N 350 425 950 1400 1800

Timber Opening

Opening Height V 1850 1850 1850 1850 1850

Opening Width W 1223 1623 2023 2423 2823

Room Air for

Burner Base

Clad With Promat or other Non-Combustible material

Warm Air

Return to

Room

(Optional

Caitec)

Vent Grill

NOT

Provided

12 September 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm………….Copyright ©

5

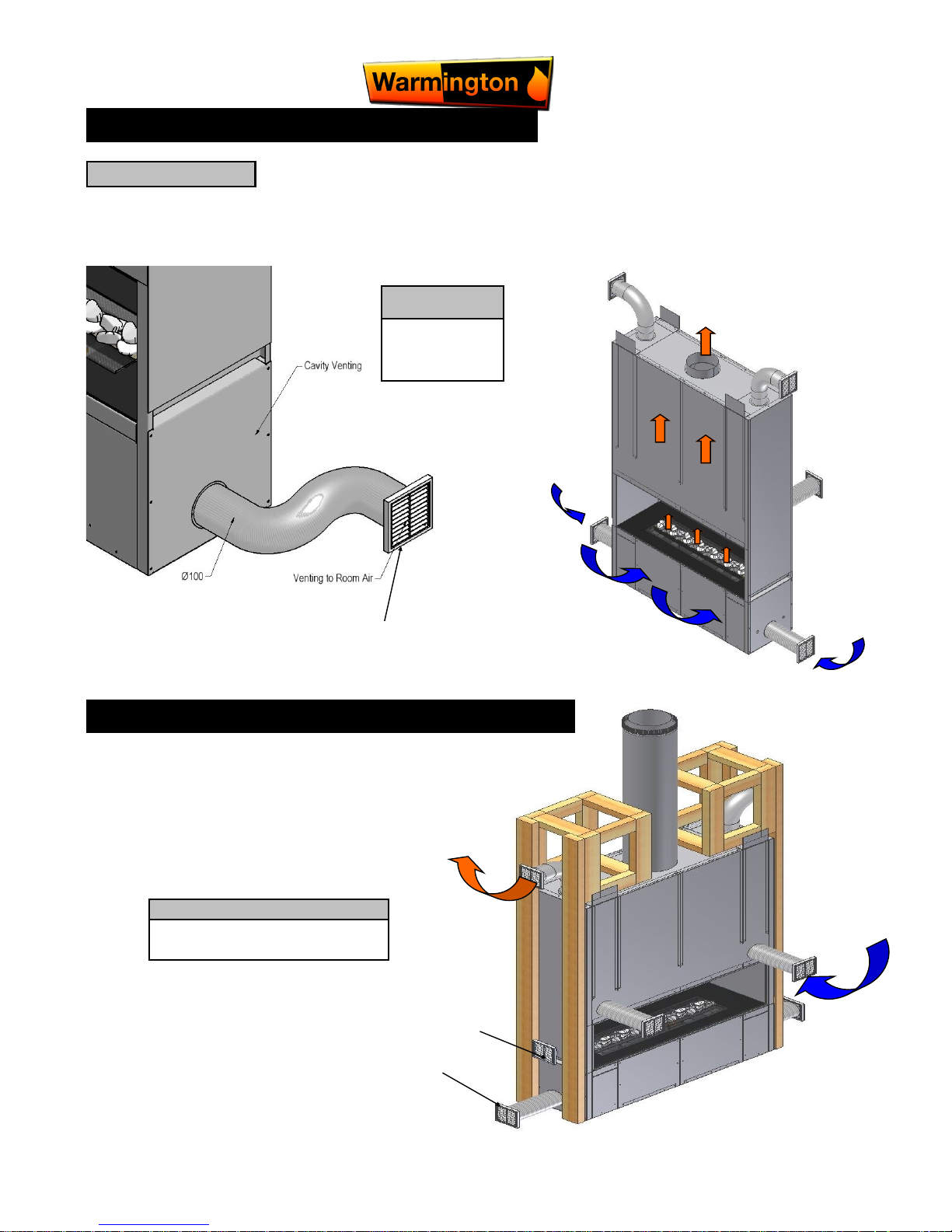

VENTING THE BURNER CAVITY ONLY - General

IMPORTANT NOTE

The Burner and the Burner Base are to be Vented into the same air space. E.G. the

Room that the Burner is taking its air from must be the same as the position of the Vent

for the Burner Base.

The Burner Base must be Vented separately to the Alcove and Flue System

- This is to Avoid the Flames and Heat being drawn from the Fire, Down into the Burner

NOTE

Must be Vented

Separately to the

Cavity

From the Room that the Burner takes its Air from.

The Cavity Venting will allow the Air to

move through the Heat exchanger

Returning Warm Air to the Room.

NOTE

This Cavity Air Must Not be Vented to the

Burner Cavity

Cavity Venting Only

Burner Base Venting Only

Burnt Gases Travel up

Flue System

Burnt Gases

Main Burner Air from Room

Burner Base Air

Supply

Burner Base Air

Supply

VENTING THE CAVITY & VENTS FOR CONVECTION AIR - General

12 September 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm………….Copyright ©

6

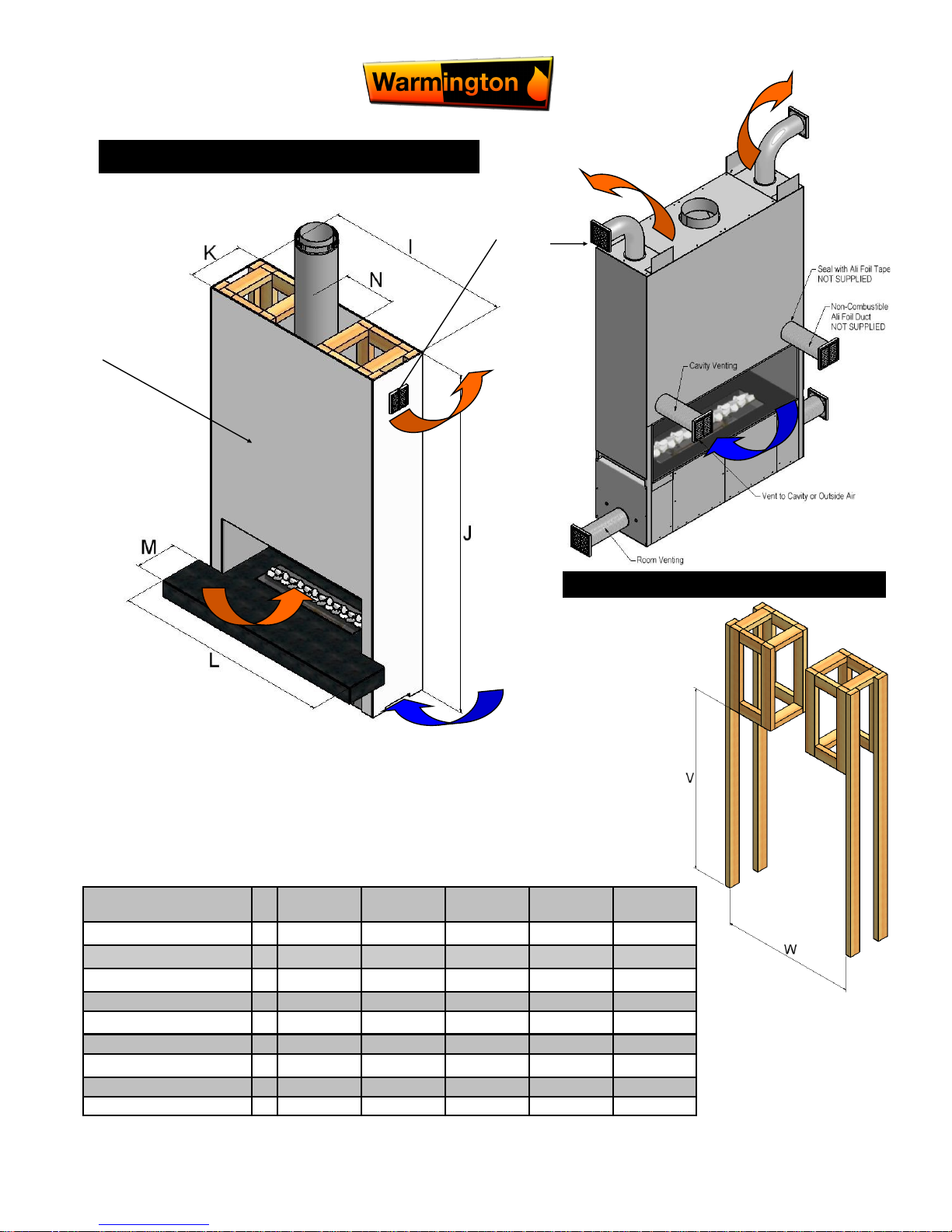

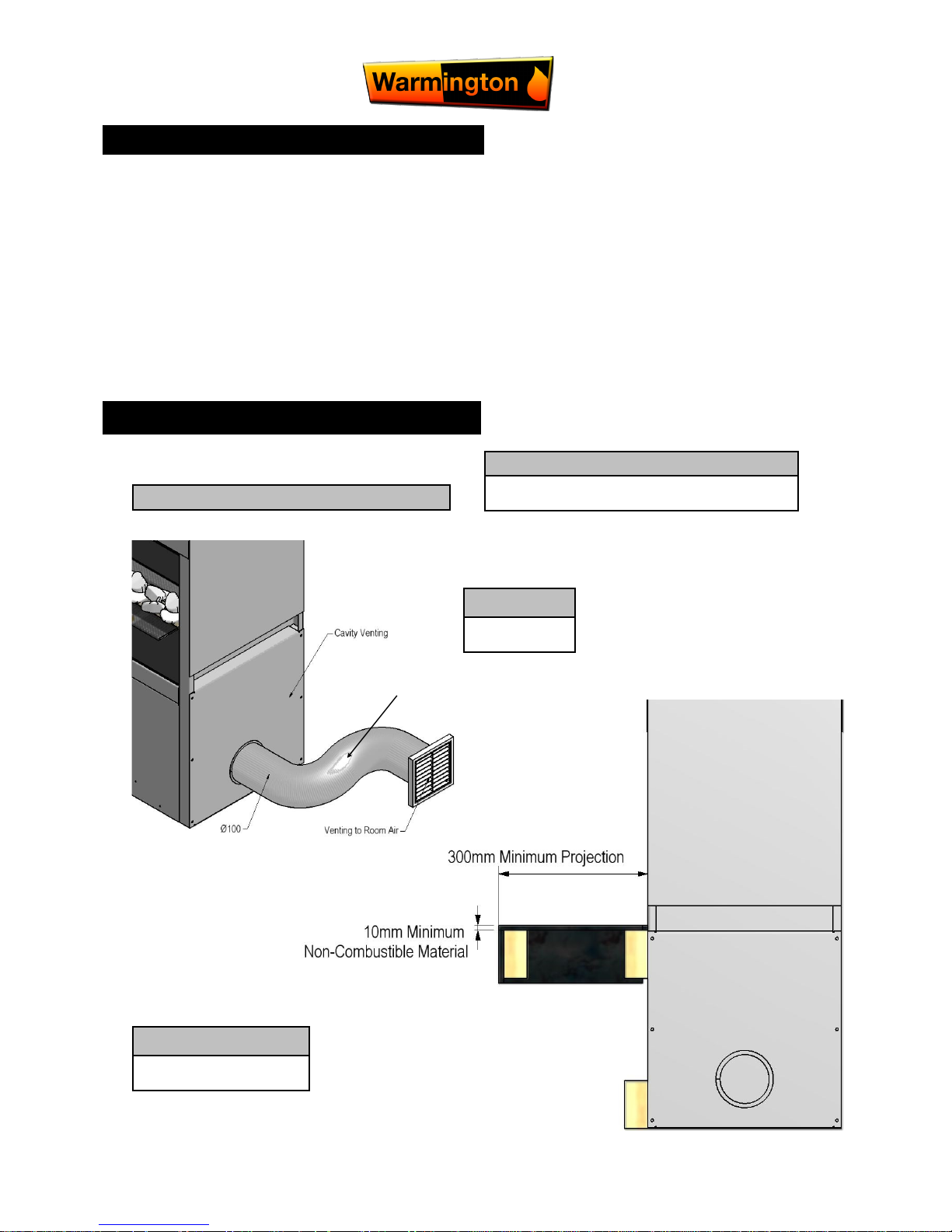

FIREBOX INSTALLATION

This is a general installation guide only – Contact a “NZHHA Installer” or Gas Fitter for Installation Advice.

1. All the dimensions are minimums

2. Fit the Plinth into position in the Cavity. If onto a wooden floor ensure that an insulating plinth is fitted as per

the specifications. Ensure that the plinth is elevated to allow for finishing on the hearth. (See Hearth and

plinth details)

3. Fit the firebox into the Cavity. Bolt the fire box to the plinth or through to the floor with the bolting point provided on the Left and Right hand sides of the fire box (seismic restraints).

4. Install the flue system.

HEARTH & PLINTH CONSTRUCTION DETAILS

Note: Hearth and Plinth Construction.

Plinth to be off set above hearth by the hearth finishing’s

( e.g. tiles / granite / plaster / etc )

IMPORTANT NOTE :

Cut to Length

Aluminum Foil Duct

NOT SUPPLIED

Note:

Vent & Duct

NOT SUPPLIED

Vent NOT SUPPLIED

Note:

Hearth to be Constructed as

Per Specification

12 September 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm………….Copyright ©

7

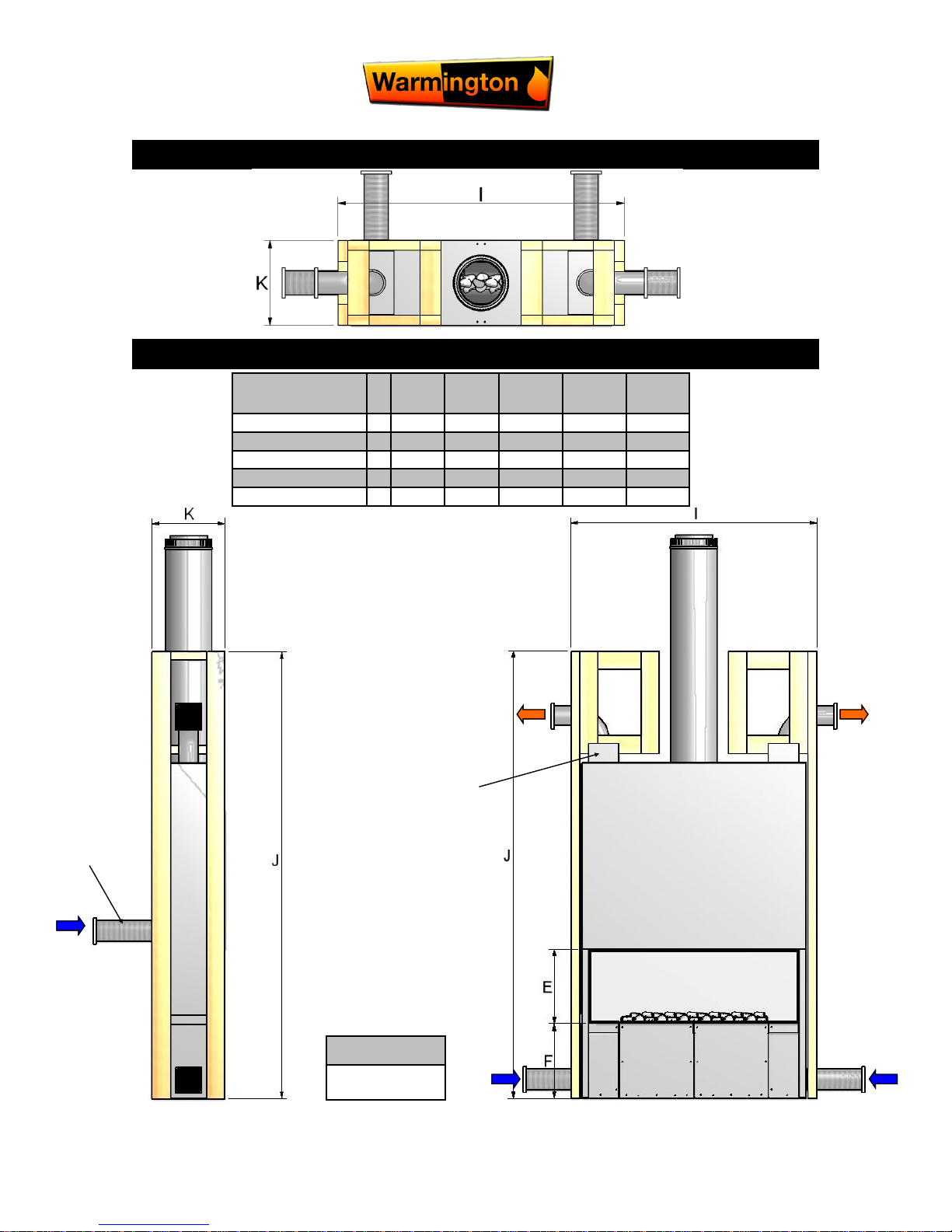

PLAN

FRONT ELEVATION & CROSS SECTION

Firebox is to be Bolted

to Supporting Framing

or Block Work

Vent & Duct

NOT SUPPLIED

Warm Air &

Cavity Venting

Note:

Hearth Details Not

Shown see Page 5

Description 1200 1600 2000 2400 2800

Window Height E 400 400 400 400 400

Base Height F 400 400 400 400 400

Outside Framing I 1317 1717 2117 2517 2917

Framing Height J 2400 2400 2400 2400 2400

Framing Depth K 390 390 390 390 390

12 September 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior no tification.

All Dimension are in mm………….Copyright ©

8

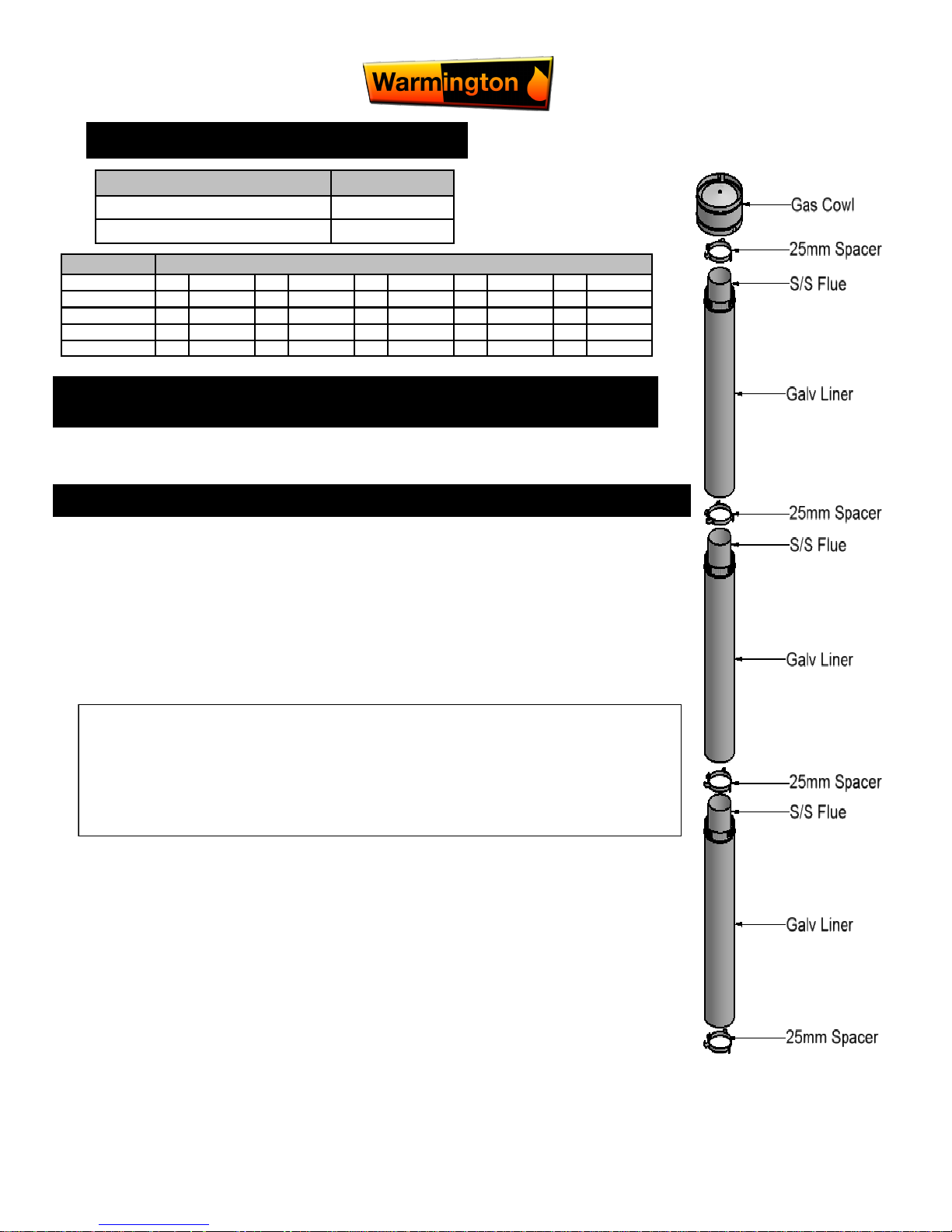

FLUE DETAILS DIMENSIONS Double Flue System

Minimum Flue Height

Flue Height 3600

Measured From Top of Adaptor 3600

NOTE: Ensure that a Standard Tested Warmington Flue system is used on Warmington fires.

GENERAL FLUE SYSTEM INSTALLATION GUIDE ONLY ( MAY VARY ON SITE INSTALL )

ANY OPENING OR CAVITY MUST BE MORE THAN 1 METER AWAY FROM WHERE

EXHAUST GASES ARE PRESENT.

Flue details No: 1200 1600 2000 2400 2800 No: No: No: No:

Cowl 1 200 275 200 250 250 1 2 2 2

Spacer 3 200 275 200 250 250 3 6 6 6

Flue Diameter 3 200 275 200 250 250 3 6 6 6

Liner Diameter 3 250 325 250 300 300 3 6 6 6

Bottom Spacer 1 200/250 275/325 200/250 250/300 250/300 1 2 2 2

This is a general installation guide only – Contact a “NZHHA Installer” for Installation Advice.

1. Install the first length of flue pipe with the crimped end down, inside the Adaptor collar, ensure that the

flue pipe is sealed into the collar with exhaust sealant. Rivet the flue in 3 places around the Adaptor

collar. Place a bottom spacer around the flue pipe approximately 150mm above the adaptor collar.

Secure in position by tightening the screw and nut.

2. Install the second length of flue pipe with the crimped end down and fit by riveting in at least 3 places

around the flue pipe joint. Ensure that the flue is sealed into position with sealant.

3. Install the first section of flue pipe liner with the Crimped end up, over the flue pipe and over the spacer

that is fixed to the flue pipe. This spacer will keep the liner concentric about the flue pipe.

4. Position flue spacer at the flue pipe joint for every length of “Flue pipe” and “Liner”.

Repeat the Steps from 1 – 4 to the installed required height of the flue system. The flue system is to

comply with the current standards.

IF FLASHING CONE NEEDED

1. NOTE: The last lengt h o f flue pipe n eeds to extend p ast th e liner s o that w hen the “ top spid er”

and the “Flashing cone” are fitted, that the “flashing cone” and the “flue pipe” are flush, or that the “flue

pipe” is 5mm lower that the “Flashing cone”.

2. Fit the “Top Spider” into position, ensure that the legs of the spider are fitted inside the liner and that the

spider is positioned hard down onto the liner and tighten with the screw and nut.

3. Place the “Flashing cone” over the “flue pipe” and press hard down onto the “Top Spider”. (Note that the

“Flue pipe” and the “Flashing Cone” are either flush or the “Flue pipe” is 5mm Lower than the “Flashing

cone”.) Ensure that the “Flashing cone” is clear for the venting from the “Liner” and the “flue pipe”.

4. Fit the “Cowl” to the top of the flue pipe. The “Cowl”, “Flashing cone”, and the “Flue pipe” can be secured

to each other with the uses of a stainless steel self tapping screw. This will allow the “Cowl” to be removed for cleaning.

5. Flue system may require Bird Proofing due to the installation and locations, discuss this with your installer for the best advice.

6. If the Flue system is installed into a “Chimney Chase”, allow for air vent as close to the top of the chase

as practical, or allow venting through the “Chimney Chase Flashing”. A “Venting Flashing cone” and a

25mm gap around the Liner with a “Venting Flashing Cone-Spider” can be used. Ref : to Figures ……

In this Specification

a “the flue pipe shall extend not less than 4.6m above the top of the floor protector.”

b “ the minimum height of the flue system within 3 m distance from the highest point of the roof shall be 600mm

above that point.”

c “the minimum height of the flue system further than 3 m from the highest point of the roof shall be 1000mm

above the roof penetration.”

d “no part of any building lies in or above a circular area described by a horizontal radius of 3 m about the flue

system exit.”

Loading...

Loading...