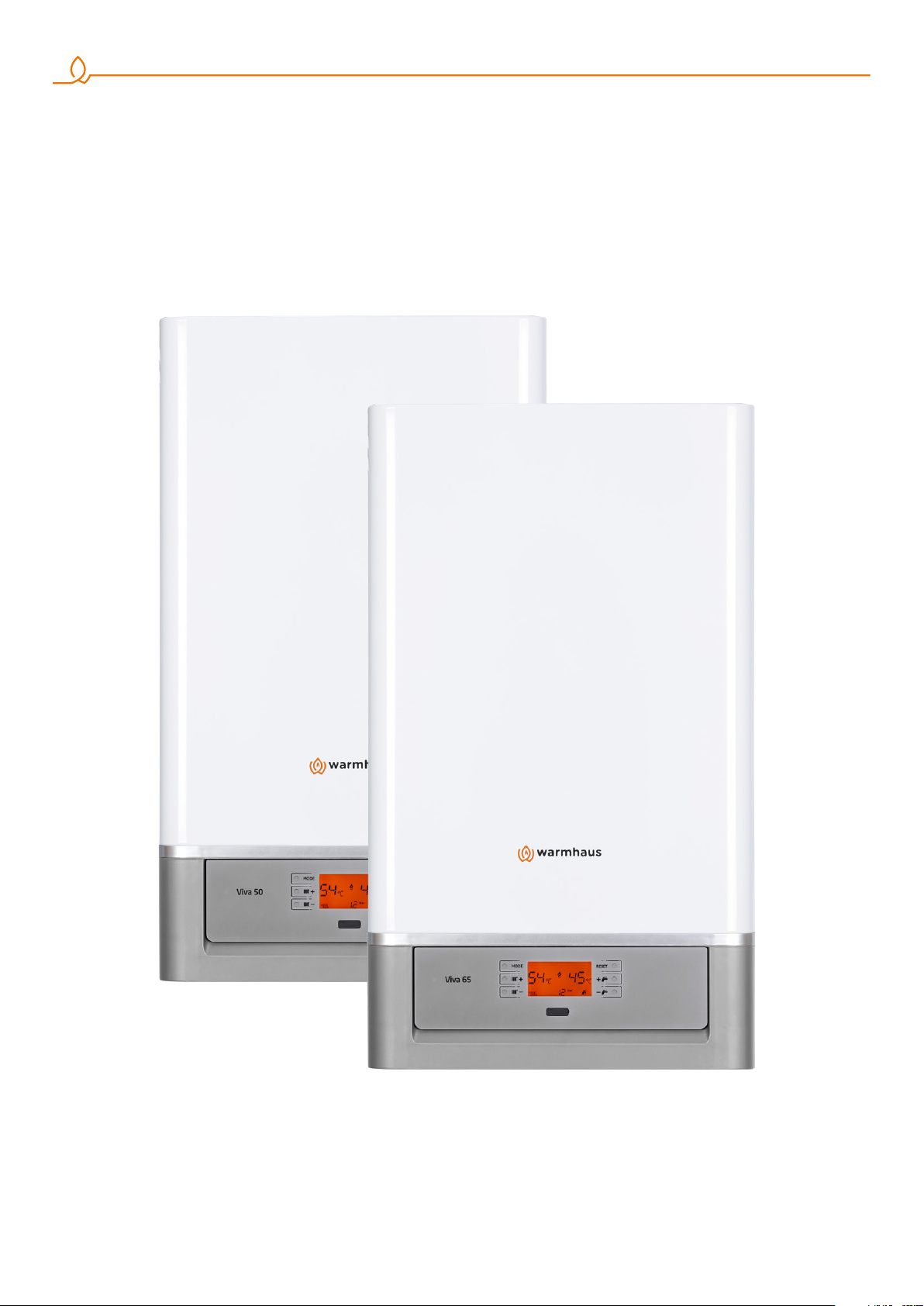

Warmhaus VIWA 50, VIWA 65 Installation & User Manual

VIWA 50

VIWA 65

WALL MOUNTED CONDENSING BOILERS

INSTALLATION & USER MANUAL

Viwa 50

Viwa 65

CONTENTS

1. DEAR WARMHAUS

CUSTOMER

1.1. GENERAL WARNINGS

1.2. TERMS AND CONDITIONS OF

WARRANTY

1.3 GAS LEAKS

1.4 BOILER GAS CATEGORIES &

REGIONS

2. INSTALLATION PERSONNEL

SECTION

2.2. BOILER INSTALLATION RULES

2.2.1. General Rules For Installatıon Place Of

The Boiler

2.2.2. Places Where Hermetic Boilers Cannot

Be Installed

2.2.3. Mounting Of The Boiler To Wall And

Selection Of Installation Place

2.2.4. Dimensions And Connections

2.2.5. Natural Gas And Lpg Connection

(Appliance Category I2h, Ii2h3p)

2.2.6. Flammable Gas Quality

2.2.7. Heating And Domestic Hot Water

Installations

2.2.8. Filling The Flusher For Condensation

Line

2.2.9. Exhaust Gas Flue Pipe Set And

Accessories Connection

2.2.10. Filling The Flusher For Condensation

Line

2.2.11. Exhaust Gas Flue Pipe Set And

Accessories Connection

2.2.12. Peripheral Distances Of The Flue

Outlet Connections

2.2.13. Installation With Vertical Concentric

Flue Sets

2.2.14. Installation With Vertical Concentric

Flue Sets

2.2.15. Use Of Split Flue Type (Hermetic)

2.2.16. Installation At Partially Protected

Outsides

2.2.17. Electrical Connections

2.2.18. Optional Controls: Room Thermostat,

Outside Temperature Sensor And

Others

2.3. HYDRAULIC INSTALLATION RULES

2.3.1. Heating System Water

2.3.2. Filling/Draining The Heating System

2.3.3. Circulation Pump

2.3.4. Checks For Start-Up Of The Boiler

2.3.5. Components Of The Boiler

3. FOR USERS

3.1. GENERAL WARNINGS FOR USERS

3.1.1. Use Of The Boiler

3.2. SELECTION OF ONOFFSTANDBY

AND SUMMER WINTER MODES

3.2.1. On/Off/Stand-By Positions

3.2.2. Operation In Winter Mode

3.2.3. Operation In Summer Mode

3.2.4. Resetting The Boiler (Restart)

3.2.5. Turning Off The Boiler

3.2.6. Selection Of On/Off/Stand-By And

Summer/Winter Modes

3.2.7. On/Off/Stand-By Positions

3.2.8. Operation In Winter Mode

3.2.9. Operation In Summer Mode

3.2.10. Turning Off The Boiler

3.2.11. Use With Room Thermostat (Optional)

3.2.12. Use Of Outside Temperature Sensor

(Optional)

3.2.13. Customization Of Boiler Functions

3.3. TROUBLESHOOTING

3.3.1. Error Codes Table

3.4. RECOMMENDATIONS FOR

ECONOMICAL USE OF THE BOILER

3.5. MATTERS TO PAY ATTENTION FOR

GUARANTEE CONDITIONS

3

1. DEAR WARMHAUS CUSTOMER

We congratulate and thank you for choosing Warmhaus wall mounter

boiler which shall provide you heating and domestic hot water

comfort for years. State-of-art Warmhaus boilers, being manufactured

in compliance with standards of the European Union are also

exported to many countries. You can utilize our Authorized Technical

Service network with professional competence certification for any

ordinary maintenance needs of this product produced meticulously

with hard work. Our authorized services assure sustaining performance

of the device as they shall always provide original spare part services.

Please read this manual thoroughly to use your boiler economically,

comfortably and efficiently, and store to refer when needed.

It is recommended for efficient use to have assembly done by an

authorized dealer approved by the local gas authority and which has

the competence and experience for assembly.

1.1. GENERAL WARNINGS

This manual is an integral part of the product, and must be delivered

to the new user in case of handover of the appliance. The manual

shall be preserved properly and kept in the way to be referred as it

contains significant information about use as well as installation of the

appliance.

Heating and Domestic Hot Water installations shall be

projected and implemented a competent and approved

engineering company meeting the criteria prescribed by laws,

by observing the current legislation in force.

Installation and maintenance shall be carried out by the

competent personnel having sufficient knowledge in the

installation industry and professional competence certification

in accordance with the legislation in force and in line with the

directions of the manufacturer. Hazards which may cause injury of

persons, other living beings (animals, plants) and damage to goods

may be caused by wrong installation, for which the manufacturer

cannot be held responsible.

Natural gas installation project; shall be carried out by one

of the dealers authorized by your local gas authority.

1.2. TERMS AND CONDITIONS OF WARRANTY

The manufacturer may not be held responsible for any

faults caused by noncompliance to the legislation and

standards in force and information provided in this manual

(and information and instructions provided by the manufacturer in

any case), within or out of the scope of the contract, and this also

constitute reason for termination of warranty of the appliance.

Only Warmhaus Authorized Service is authorized to carry out

electrical connection of the boiler and to energize the boiler.

In case of any material, design or installation faults occurred within

the warranty period, maintenance and operation shall be carried out

without any charge of labor or spare parts.

(Also see: 3.5 MATTERS TO PAY ATTENTION FOR GUARANTEE

CONDITIONS)

This appliance should only be used for its designed intended

purposes (to be used in closed-circuit heater installation and

production of open circuit domestic hot water production).

. All kinds of other uses are not suitable as well as may create a

potential danger.

Manufacturer shall not be responsible for damages

occurring due to interventions, false installation and initial

starting performed by unauthorized persons and warranty

scope shall be void. As the Combi is an appliance having heating

system, domestic hot water, natural gas/LPG and electrical

connections, do not make and have any interventions made without

the authorized service

This appliance maintenance operations should be performed

by the authorized and competent technical personnel, and

Warmhause Authorized Technical Service Centers constitute

assurance for quality. WARMHAUS is not responsible for damages

arising from repairs, part replacements and maintenance performed by

third persons and companies and combi remains out of the warranty

scope under such conditions.

Attention! Please note & read the warning and informations on the

boiler. Incorrect operation of the boiler can cause significant damage.

For Warmhaus wall-mounted boilers; commissioning, adjustment,

maintenance and cleaning must only be carried out by a specialist OR

approved service by Warmhaus!

When faults occur in the heating system, the plant must be stopped

and damaged parts should only be replaced by an authorized

workshop.

The accessories used must correspond to the technical rules and the

relevant parts must be approved by the manufacturer in connection

with the Warmhaus wall-mounted boiler.

Only APPROVED & ORIGINAL spare parts should be used.

Bolts sealed with paint strictly forbidden to open !

The boiler must not be used by children younger 8 years or

invalid persons without supervision.

These seals provide evidence that the replacement of bolts required

for safe operation. If the seals are damaged, the guarantee of the

device will come to an end!

This appliance has been manufactured to be installed in the

country specified on its technical registration label. Installing

the appliance in any other country than those specified on

the plate may cause damage or injury to persons, animals and goods.

WARMHAUS declares that Viwa 50 & 65 boilers comply with the

essential requirements of the following directives:

- Gas Appliances Regulation (EU) 2016/426

- Boiler Efficiency Directive 92/42/EEC

- Electromagnetic Compatibility Directive 2014/30/UE

- Low Voltage Directive 2014/35/UE

- Ecodesign Directive 2009/125/EC

- Regulation (EU) N. 813/2013 - 811/2013

4

Manufacturer: Warmhaus Isıtma ve Soğutma Sistemleri Tic. A.Ş. Bursa

Teknik resmin orjinal boyutu A3'dür

Organize Sanayi Bölgesi Park Cad. No:10 16140 Nilüfer-Bursa / Turkey

WARMHAUS

50 kW

65 kW

1015 18

1015 18

WARMHAUS A.Ş. reserves the right to make all kinds of technical and commercial modifications without notice, and disclaims any liabilities arising

out of printing and spelling mistakes.

IMPORTANT INFORMATION

It is a statutory requirement that all gas appliances are installed by competent persons, in accordance with the gas safety (installation and use)

regulations (current edition). The manufacturer's instructions must not be taken as overriding any statutory requirements, and failure to comply

with these regulations may lead to prosecution. No modifications to the appliance should be made unless they are fully approved by the

manufacturer. Gas leaks: do not operate any electrical switch, or use a naked flame. Turn off the gas supply and ventilate the area by opening

doors and windows contact the gas emergency service

1.3. GAS LEAKS

187 NATURAL GAS EMERGENCY LINE

HOW TO ACT IN CASE OF DETECTING NATURAL GAS ODOR

Do not use

lighter- matches

Do not turn on, off

or unplug the lamps

or other electrical

appliances.

Ventilate the

environment by

opening doors and

windows.

Close valves of

appliances operating with natural gas

and your gas meter

Do not use/let

anyone use the

doorbell.

IN EMERGENCY CASES

NATURAL GAS

EMERGENCY

FIRE

DEPARTMENT

Do not use phones

in case of a natural

gas leakage. It may

create sparks.

YÜZEY İŞLEMİ

YÜZEY KALİTESİ

A

Boyalı

1. Dereceden görünür yüzey

Kaplamalı

B

2. Dereceden görünür yüzey

Kaplamasız

C

3. Dereceden görünür yüzey

Immediately evacu-

ate the place with

Lawa

Lawa Plus

150.11.606.000001

1000

592 mm

80 mm

(OPTIONAL)

65 mm

ga s o d or.

Priwa / Priwa Plus

Enerwa / Enerwa Plus

Ø110 mm

Ø110 mm

422 mm

725 mm

GAS

G1/2"G1/2"

G3/4" G3/4"G3/4"

65 mm 64 mm

73 mm

75 mm

471

114 mm

94 mm

G. EKER0122.02.2018

REVZ. YAPAN

REV.NO

TARİH

G. EKER

Çizen /Drawn

E. BİNER

Kontrol /Approved

İ. TAŞDEMİR

Onay /Drawn aut.

22.11.2017

Tarih / Date

Aksi belirtilmeyen genel tolerans için ISO 2768-M geçerlidir.

>

>

±0,1 mm

6 30 mm

0,5 3 mm

>

±0,125 mm

3 6 mm

>

30 120 mm

Bu teknik resmin tüm hakları Warhaus'a aittir. Firmanın yazılı izini ve bilgisi olmaksızın üçüncü şahıslarla paylaşılması ve ürettirilmesi yasaktır.

All rights reserved. This drawing is Warmhaus' intellectual property. It's forbidden to reproduce or forward it to any third part without written authorization .

Call the Natural Gas

Emergency Line from

your neighbor or ano-

ther suitable place.

Yoğuşmalı modellerde baca yükselikiği değiştiği için ilave delik yeri eklendi.

AÇIKLAMA

İmza

Isıtma ve Soğutma Sistemleri Sanayi Ticaret A.Ş.

Bursa Organize Sanayi Bölgesi Park Cadde No: 10

(www.warmhaus.com.tr)

Nilüfer / BURSA - TURKEY

Montaj Şablonu

Parça Adı :

471x1000mm Kağıt

Malzeme :

CP00205

Resim No:

>

±0,5mm

120 400 mm

±0,2 mm

>

400 1000 mm

±0,3 mm

150.11.606.000001

Logo Kodu:

±0,8mm

AMBULANCE POLICE

Do not intervene the

installation Wait for

Gas Authorities Team

to arrive.

Never close culverts

ensuring discharge of

the gas from the en-

vironment in case of a

natural gas leakage.

INFORMATION: You can visit web sites of

local gas authorities and NATURAL GAS

EMERGENCY sections.

Advice: Please take note local emergency

phone numbers.

1.4. CONTENTS OF THE PACKING BOX

Warmhaus is delivered in two boxes as Boiler and Flue Set Box. The Boiler box

contains the materials listed below and the small box contains

I. Installation Scheme (Figure 1)

II. Operation Manual (Figure 2)

III. Connection Accessories (Figure 3)

a. 1 throttle screw (installed at flue outlet.)

b. 2 hanger screws

c. 2 Dowels

IV. Hanger Plate (Figure 4)

İmza

1:5

Ölçek

Rev.No

0.0

V. Exhaust Gas Flue Set (optional) (Figure 5)

A3

Ölçü birimi: MM

Figure 2 Operation Manual Figure 5 Exhaust gas flue set

Figure 1 Installation scheme

Figure 3 Connection Accessories

Figure 4 Hanger Plate

Keep packaging materials (plastic, bag, nylon, etc.) away from

children in order to avoid risks to health.

5

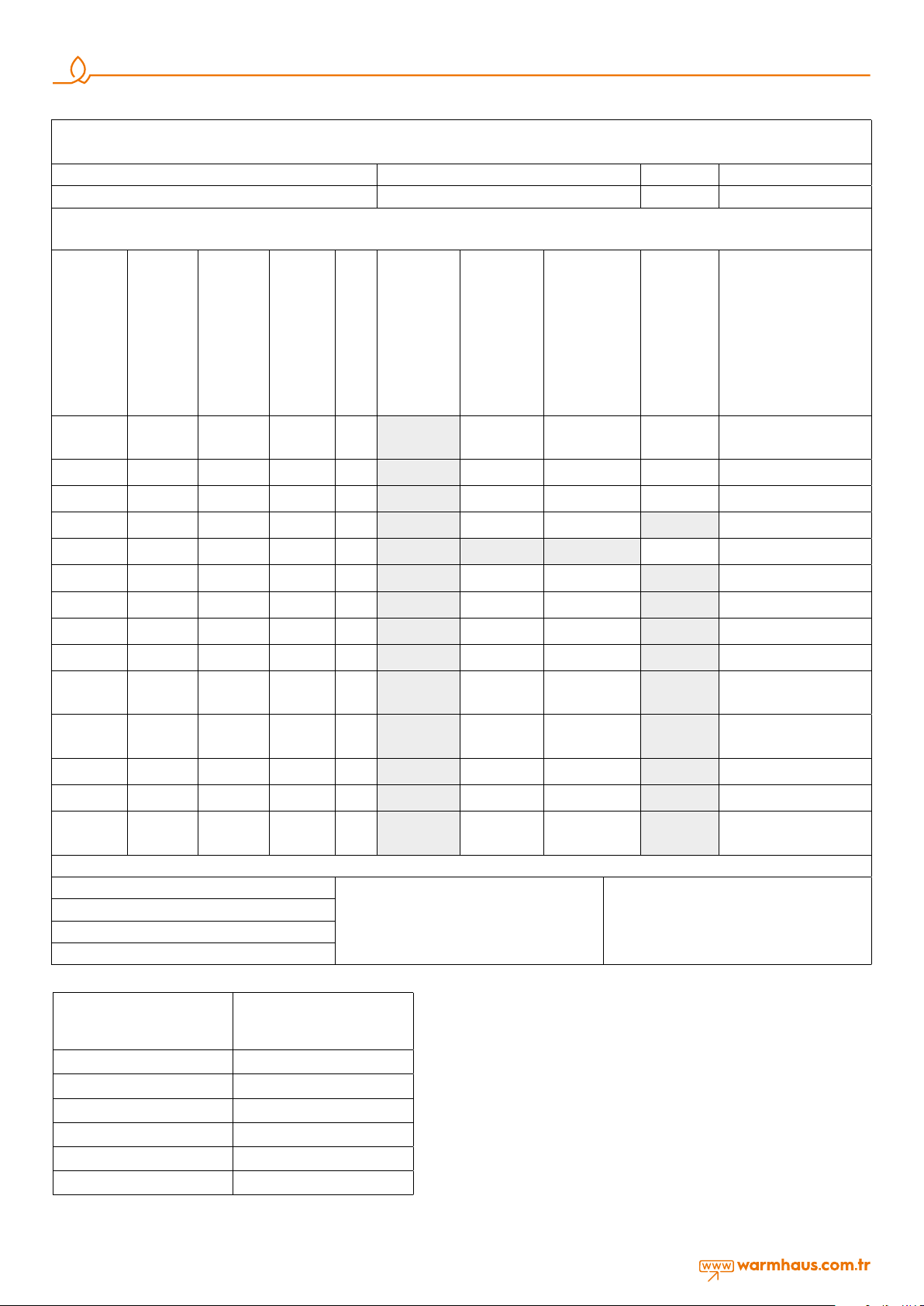

1.4 BOILER GAS CATEGORIES & REGIONS

Designation: Used gas types & Countries

Manufacturer Type Model / Technical Data Conformity Markings

Boiler Gas Categories & Regions Wall mounted type Warmhaus combis and boilers granted

Gas categories for Warmhaus boilers are implemented on the CE certificate given below by SZU Test / BRNO;- appliance categories according to direct destinations are determined in

accordance with EN 15502-1. According to-EN ISO 3166-1 destination countries;- millibar gas supply pressures, can be used for several gas groups if it is under normal pressure. They are

specified with numerical values and "mbar" unit.

Enerwa 24

Enerwa 2530

Document for

conformity

approved by

SZU test

YES I 2H Natural Gas 20 mbar G20 Not Approved Approved Approved Approved

YES I 2H Natural Gas 25 mbar G20 Not Approved Approved Approved Approved HU

YES I 2E Natural Gas 20 mbar G20 Not Approved Approved Approved Approved DE, LU, PL, RO

YES I 2E+ Natural Gas 20 mbar G20 Not Approved Approved Approved Not Approved BE, FR

YES I 2E(S) Natural Gas 20 mbar G20 Not Approved Not Approved Not Approved Approved BE

YES I 2E+ Natural Gas 25 mbar G25 Not Approved Approved Approved Not Approved BE, FR

Appliance

Categories

Gas Type

Gas Inlet

Supply

Pressures

Used

Gas

Lawa 24

Lawa Plus 24

Lawa 28

Lawa Plus 28

Priwa 24

Priwa Plus 24

Priwa 28

Priwa Plus 28

Priwa 33

Priwa Plus 33

Enerwa Plus 24

Enerwa Plus 2530

Enerwa 28

Enerwa 3035

Enerwa Plus 28

Enerwa Plus 3035

Enerwa 33

Enerwa 3540

Enerwa Plus 33

Enerwa Plus 3540

Viwa 50

Viwa 65

Viwa 90

Viwa 115

Viwa 125

Viwa 150

Countries of

Destination **

AT, BG, CH, CZ, DK, EE, ES, FI,

GB, GR, IE, IT, LT, LV, NO, PT, RO,

SE, SI, SK

YES I 2L Natural Gas 25 mbar G25 Not Approved Approved Approved Not Approved NL

YES I 2ELL Natural Gas 20 mbar G20 Not Approved Approved Approved Not Approved DE

YES I 2ELL Natural Gas 20 mbar G25 Not Approved Approved Approved Not Approved DE

YES II 2H3P Natural Gas 20 mbar G20 Not Approved Approved Approved Not Approved

YES II 2H3P Propane LPG 37 mbar G31 Not Approved Approved Approved Not Approved

YES II 2L3P Natural Gas 25 mbar G25 Not Approved Approved Approved Not Approved NL

YES II 2L3P Propane LPG 37 mbar G31 Not Approved Approved Approved Not Approved NL

YES I 3P Propane LPG 37 mbar G31 Not Approved Approved Approved Not Approved

EN ISO 3166-1: 2006, Codes for the representation of names of countries and their subdivisions - Part 1: Country codes (ISO 3166-1: 2006)

Prepared by: İsmail B.Taşdemir / R&D Mng.

Date of Publication: 18/4/2017

Rev. No: 2

Drw. No: WH.17.107

Table 1.1

Product Name (as on product

data badge & installation

instructions)

Approval; revision was made with E-30-00300-18 GAR

certificate and CE-1015CT0615 product number. And

correction 02 Viwa 50 and 150 kW addition equivalent.

G.C. No Allocated by

British Gas**

This document and the information contained herein

belong to Warmhaus Isıtma ve Soğutma Sistemleri San.

Tic. A.Ş. It shall not be transferred to any person not

authorized by Warmhaus Isıtma ve Soğutma Sistemleri

San. Tic. A.Ş. or copied or used howsoever by any third

persons without prior written approval.

CH, CZ, ES, FR, GB, GR, IE, RO,

CH, CZ, ES, FR, GB, GR, HR, IE,

BE, CH, CZ, ES, FR, GB, GR,

HR, IE, IT, LT, NL, PL, PT, RO,

Enerwa 2530 47-786-01

Enerwa Plus 2530 47-786-02

Enerwa 3035 47-786-03

Enerwa Plus 3035 47-786-04

Enerwa 3540 47-786-05

Enerwa Plus 3540 47-786-06

Table 1.2

SI, SK

IT, LT, PT, RO, SI, SK

SI, SK, TR

6

2. INSTALLATION PERSONNEL SECTION

70

04

158

765

207

124

127

207

127

725

30

385

420

40

100

121,5 105,5 90

88,5

136

MODE

RESET

+

-

-

+

1

2

3

4

5

6

7

9

10

11

12

13

1415

16

17

18

Kalorifer Gidiş

G1 1/4

Kalorifer Dönüş

G1 1/4

GAZ

G 3/4

1

2

9

8

7

6

5

4

3

10

11

12

13

14

15

16

17

230V AC MAIN SUPLLY

MANOMETER

PRESSURE RELIEF VALVE OUTLET

GAS INLET

CENTRAL HEATING FLOW (CH)

CENTRAL HEATING RETURN (CH)

CONDANSATE DRAIN

CH/DHW MODE PUSH BUTTON

DIRT COLLECCTOR DRAIN

CH TEMPERATURE - ADJ. BUTTON

LCD DISPLAY

SERVICE ACCESS POINT

RESET BUTTON

DHW TEMPERATURE + ADJ. BUTTON

DHW TEMPERATURE - ADJ. BUTTON

FLUE OUTLET

MOUNTING BRACKET

18

CH TEMPERATURE + ADJ. BUTTON

8

İmza

E. BİNER

İ. TAŞDEMİR

Aksi belirtilmeyen genel tolerans için ISO 2768-M geçerlidir.

Onay /Drawn aut.

Kontrol /Approved

Çizen /Drawn

Tarih / Date

0.0

Rev.No

Ölçek

10.01.2018

YÜZEY KALİTESİ

Kaplamasız

Kaplamalı

Boyalı

YÜZEY İŞLEMİ

G. EKER

Isıtma ve Soğutma Sistemleri Sanayi Ticaret A.Ş.

Nilüfer / BURSA - TURKEY

(www.warmhaus.com.tr)

Bursa Organize Sanayi Bölgesi Park Cadde No: 10

WARMHAUS BOILER (CH ONLY)

Viwa 50/Viwa 65

2.1. BOILER INSTALLATION RULES

2.1.1. General Rules for Installatıon Place of the Boiler

There are not any ventilation limitations for areas where hermetic

(C type) boiler is to be installed (it can be installed independent of

the volume and ventilation of the room). It can also be installed in

protected areas like balcony and terrace provided that it is placed in a

protective closure and that precautions against freezing of the system

water are taken. The boiler shall be securely mounted to the building

wall. A flexible joint shall be used between the boiler and gas line.

Lengths of the flex ducts to be used in Type A, B and C appliances

shall not exceed the values permitted by the local gas authority. Flue

outlets of hermetic boilers must be connected to the areas which

are directly open to outside area, and have sufficient air circulation.

Conditions of exhaust gas system gas outlets of these appliances

(position of the pipe outlets in various forms, vertical, horizontal

minimum distances, cross-sectional areas of ducts if used, etc.) shall be

in compliance with TS 12514 standard.

2.1.2. Places where hermetic boilers cannot be installed

• Stairwells of buildings,

• common aisles, ventilation ducts, garret, attics, emergency exit doors,

storage rooms and other similar common areas,

• Yards between buildings,

• Narrow gaps between eaves

• On the chimney walls,

• Closed balconies,

• Open balconies (except placed in an enclosure and permitted by

the manufacturer),

• Under the extending structures hindering outlet of exhaust gas,

• Places exposed to direct wind force,

• Openings supplying fresh air to other units (C type) It is forbidden to

install hermetic boilers at places specified above!

• It is necessary to leave a spesific

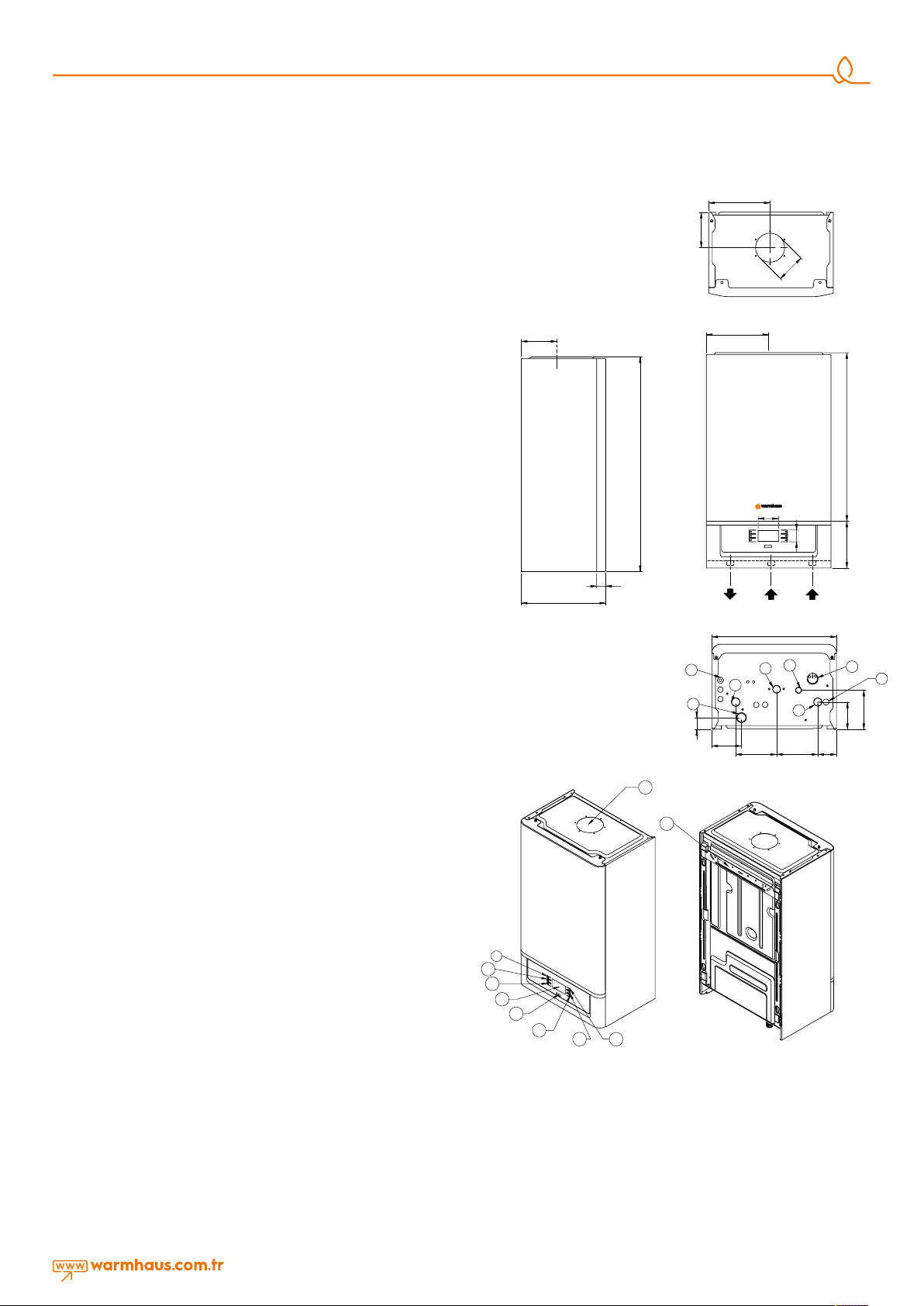

2.1.4. Dimensions and

Connections

distance 1.0 mt between the

heating device and the building

material containing combustible

material even the maximum

allowable temperature value of 85

° C in the rated heat capacity of

the appliance is not exceeded.

2.1.3. Mounting of the Boiler to Wall and Selection of Installation

Place

• Mounting of the boiler to wall must be checked and ensured to be

stable and safe.

• The hanger plate and connection screws supplied with the boiler

shall be mounted on a filled or semi-filled brick wall in accordance

with the installation scheme, and shall not be used for other

purposes.

• In case any different materials are used for mounting, the warranty

of the boiler shall be terminated.

• If the wall to which the boiler is to be mounter is not brick, strength

of the support system shall be checked.

• The boiler shall be mounted on a fire resistant wall.

• The boiler should be mounted so as the height of the hanger plate

to be between 1,8-2,2 mm from the ground.

• The boiler shall be mounted with gaps as minimum 30 cm above

the ground, minimum 5 cm from both sides and minimum 90 cm

from the front side where the installation area is limited, for allowing

easy intervention of the service technician.

• The boiler shall not be installed in areas which contain or may

contain explosives, flammables and acid vapors.

• It shall not be installed next to or above ovens, cookers, radiators or

heaters.

• Hermetic boilers can also be installed in cabinets, provided that

minimum 5 cm from each side is left.

• If the boiler is to be mounted over the kitchen countertop or

kitchen set, there shall be a minimum 50 cm distance under the

boiler.

• Due to possibility of water draining from the Safety Valve of the

boiler after mounting, the outlet shall be connected to the drainage

line. If this is not possible; do not place electronic appliances, and

tools, parts and materials which may breakdown, be deformed or

form rust.

• Any furniture should not be placed under the boiler due to the

reasons specified above.

• Make sure that there are no liquids or inflammable materials in the

immediate vicinity of the boiler.

9

10

11

12

13

16

Figure 6 Viwa 50 / Viwa 65 boiler dimensions and connections

Warmhaus Viwa 50 / 65

1) 230 V AC Main Power Supply

2) Manometer

3) Safety Valve Drainage Line

4) Gas Inlet Line

5) Heating Supply Line

6) Heating Return Line

7) Condensate Drainage Line

8) Sediment-Air Separator Discharge

9) Heating/Domestic Hot Water MODE

Button

10) Heating Temperature Increasing

Setting Button,

17

18

1415

11) Heating Temperature Reducing

Setting Button

12) LCD Display

13) Service Port

14) RESET Button

15) Domestic Hot Water Temperature

Increasing Setting Button

16) Domestic Hot Water Temperature

Reducing Setting Button

17) Exhaust gas/Flue outlet

18) Hanger plate

7

2.1.5. Natural Gas Connection (Appliance Category I2H)

The boilers are designed to run on methane (G20) gas. Gas supply

pipes shall be equal to or larger than 3/4"G boiler fittings. Prior to

making the gas connection, a thorough internal cleaning shall be

carried out to all fuel supply installation pipe furnishings as possible

wastes may distort smooth operation and reliability of the boiler.

Ensure that the gas supplied by the mains line is of the type prescribed

for the boiler (refer to the label on the boiler).

Also, in case of reduced pressure, the network dynamic pressure

(methane or LPG) used for supplying the combi should be carefully

controlled and will impact the boiler strength. Ensure that gas valve

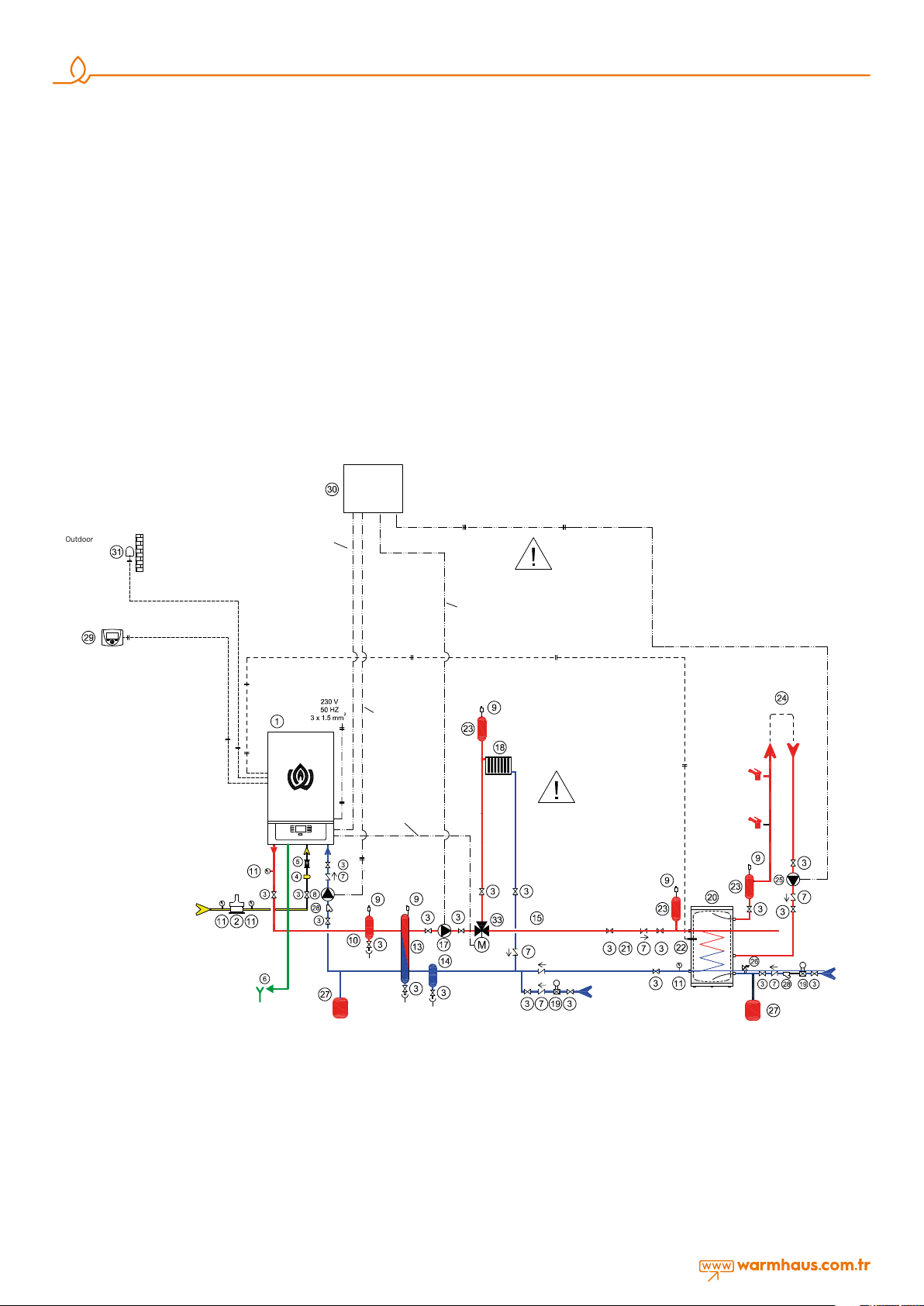

SAMPLE INSTALLATION SCHEME

Sngle Boler Scheme

Main

Electric

Panel

Boiler Pump

Outdoor Sensor

2

2 x 1.0 mm

Panel - Relay

Connection

3 x 1.0 mm

2

connection is correct. Flammable gas supply pipe should be able to

supply correct adequate gas amount to the boiler when the boiler is

at full power and be projected and sized according to force and local

gas company specification and instructions in order to guarantee the

appliance efficiency. Connection system shall comply with the legislation

in force.

2.1.6. Flammable Gas Quality

The boiler is designed to be used with pure fuel not containing any

foreign substances; therefore, required filter systems must be available in

the gas supply line (for ensuring purification of the fuel).

Recirculation Pump

The recirculation pump

will not be managed

by Boiler. It will be

managed by the main

electric panel.

System Pump Boiler Panel

Relay Connection

1. Zone + Storage Tank

Timer / Room Thermostad

Timer / Room Thermostad

2 x 1.0 mm

GAS

PIPELINE

2

FLUE

Boiler Pump

3 x 1.0 mm

3-Way Motorized

Valve Line

3 x 1.0 mm

Pump Cable

2

3 x 1.0 mm

Boiler Sensor

2

2 x 1.0 mm

2

In this electric scheme,

the boiler pump and

the system pump will be

managed via main electric

2

panel contactor.

RECIRCULATION CIRCUIT

COLD WATER

COLD WATER

INSTALLATION EQUIPMENT

1. Boler

2. Gas Safety Solenod Valve

3. Ball Valve

4. Gas Flter

5. Vbraton Isolator

6. Condensate Water Sphon

and Dranage Lne

Figure 7 Viwa 50-65 Single Boiler with 1 High Temperature Zone + Hot Water Storage Tank System Scheme Example.

8

7. Check-Valve

8. Boler (Return) Pump

9. Automatc Ar Vent

1O. Sedment-Drt-Ar Separator

11. Manometer

13. Hydraulc Separator

14. Sedment-Drt-Separator

17. Heatng System Pump

18. Heatng System

19. Pressure Reducer

20. Hot Water Storage Tank

22. Hot Water Storage Tank Sensor

23. Ar Separator

24. Hot Water Storage Tank

Recrculaton Crcut

25. Recrculaton Pump

26. Safety valve

27. Vessel Tank

28. Flter

29. Tmer / Room Thermostat

30. Man Electrc Panel

31. Outsde Sensor

2.1.7. Heating and Domestic Hot Water Installations

Radiator and ground heating installation shall be configured in

accordance with technical specifications of the TSE (Turkish Standards

Institution) and MMO (Chamber of Mechanical Engineers), and

according to the heat loss calculation. Radiator type and amount and

ground heating installation pipe amount shall comply with the heat loss

calculation.

• The design pressure strength of the heating installation shall be

minimum 6 bar.

• If the mains pressure is more than 6.5 bar, a pressure reducer must

be fitted.

• It is recommended to construct the radiator installation as double

line and without using bends and joints as much as possible.

• Strainer filter shall be installed in heating return and tap water (city

network) intake line if a boiler is to be used.

• An additional expansion tank with 50 liters capacity shall be used

depending upon the volumetric capacity of the heating water of the

heating circuit (closed circuit) and working temperature.

• If room thermostat and thermostatic radiator valve are to be used

together; thermostatic valve shall not be installed in radiators in the

place where room thermostat is present.

• Cross connection must be made for efficient functioning in radiators

longer than 1,5 m.

• Covers shall be used for radiator and domestic hot water wall

passages and fixed with wall clamps to prevent expansions due to

heating.

• An external boiler shall be fitted to the boiler for supply of domestic

hot water. In case of using domestic water boiler, the three-way

valve and boiler sensor within the product accessories.

• The heating installation must be washed and cleared off dirt before

filling!

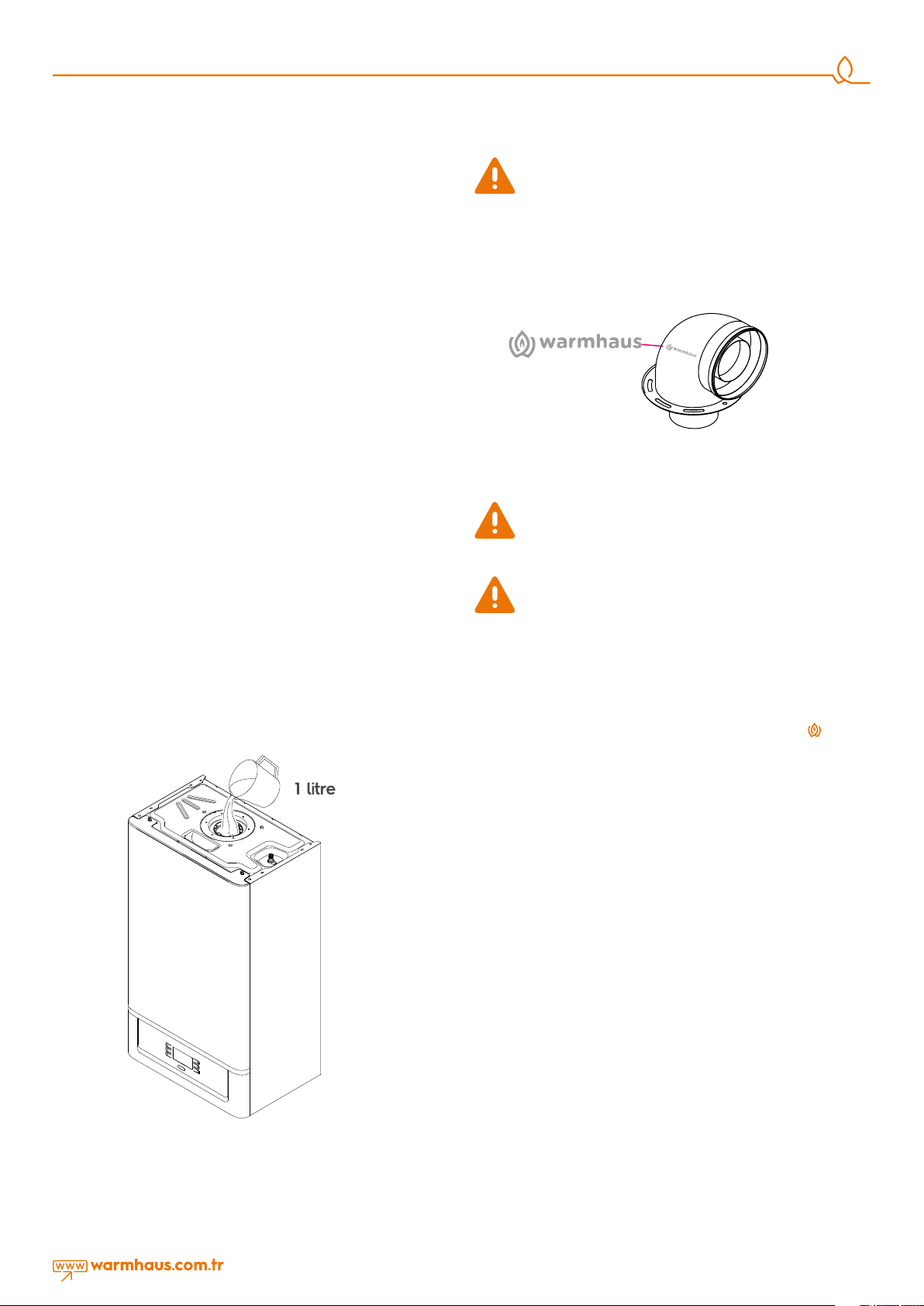

Leak-tightness of the drainage connection of the condensation

line shall be ensured. However, pour approximately 1-liter

water into the internal flue prior to fitting the flue bend of the

flusher in the boiler against the gas leak risk during start-up. Thus,

exhaust gas leakage will be prevented thanks to the water in the

flusher.

Slope of the condensate water hose and line shall always be

downwards

Figure 9 There is a Warmhaus logo on the flue bend.

2.1.9. Exhaust Gas Flue Pipe Set and Accessories Connection

Flue accessory sets to be used in exhaust gas installation of

hermetic boilers shall be original Warmhaus flue sets and they

shall be used by observing measurements and restrictions

given in installation instructions.

In case of using exhaust gas pipe and/or accessories other

than Warmhaus original exhaust gas flue pipes and

accessories, boiler shall not be commissioned by the

Authorized Service and thus, no warranty is provided!

2.1.8. Filling the flusher for Condensation Line

After the wall mounting operation of condensing boiler, electrical

connections, radiator lines, hot tap water connections and

condensation water drainage line are completed, condensation flusher

shall be filled with water (Figure 8).

The boiler shall only be installed with original Warmhaus air suction and

exhaust gas discharge device made of plastic material.

Plastic channels cannot be installed without suitable protection against

UV and weather conditions to distances over 40 cm and outsides.

Every pipe is defined with an explanatory and discriminative

Warmhaus mark mentioned in remarks.

IMPORTANT

When carrying out commissioning of the boiler, you are highly

recommended to perform the following checks:

- Make sure that there are no liquids or inflammable materials in the

immediate vicinity of the boiler.

- Make sure that the electrical connections have been made correctly

and that the earth wire is connected to a good earthing system.

- Open the gas valve and check the soundness of the connections,

including that of the burner to fan and burner hood to heat

exchanger

- Make sure that the boiler is set for operation for the type of gas

supplied.

- Check that the flue pipe for the outlet of the products of the

combustion is unobstructed and has been properly installed.

- Make sure that any shutoff valves are open.

- Make sure that the system is charged with water and is thoroughly

vented.

- Check that the circulating pump is not jammed.

- Purge the system, bleeding off the air present in the gas pipe by

operating the pressure relief valve on the gas valve inlet.

Figure 8 Filling the condensation flusher

9

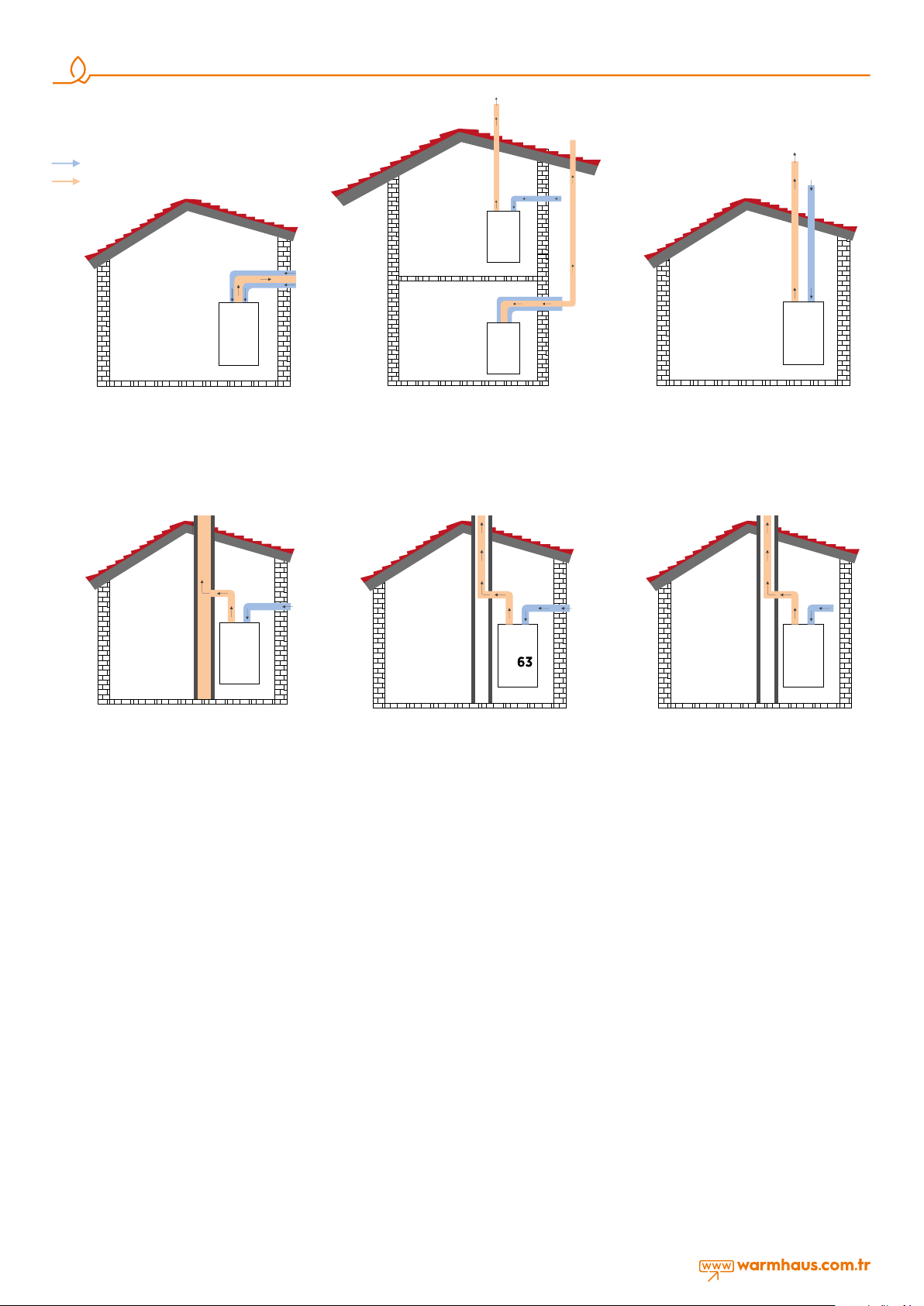

Ar

Exhaust Gas

C

53

C13

Dscharge wth homocentrc flue connecton

Figure 10 Hermetic (Concentric) and Flue

(Split-Flue type

C83

Dscharge to buldng chmney and fresh

ar ntake wth splt flue connecton

For room sealed applances of the type C8 bolers

a) overheat combuston products temperature; < 105 C°

b) CO2-content; 9.00 % ( tolerance +%0,5 / -0,5 % )

c) characterstcs of the chmney to whch the

boler may be connected, accordng to fg 13.

d) condensate flow nto the applance s not allowed.

Figure 13 Hermetic vertical split flue connection.

C

53

Exhaust gas dscharge and fresh ar ntake

wth concentrc flue kt and splt flue kts

For room sealed applances of the type C5 bolers

Attenton: The termnals for the supply of combuston

ar and for the evacuaton of combuston products

shall not be nstalled on opposte walls of the buldng.

Figure 11 Hermetic concentric and vertical split

flue connection.

C

Exhaust gas discharge through the building chimney and fresh

intake from outside with split flue sets

For room sealed appliances of the type C6 boilers

overheat combustion products temperature for flue; < 105 °C

CO

content at nominal operating conditions; 9.00 % (tolerance

2

+%0,5 / -0,5 % ) maximum allowable draught and maximum

allowable pressure dierence between combustion air inlet and

flue gas outlet (including wind pressures); 120 Pa. characteristics

and the applications of the duct system to which the boiler

can be connected; condensate flow into the appliance is not

allowed. Maximum allowable temperature of combustion air;

40 C° maximum allowable recirculation rate of 10 % under wind

conditions.

Attention: The terminals for the supply of combustion air and for

the evacuation of combustion products shall not be installed on

opposite walls of the building.

Figure 14 Building chimney connection with hermetic split flue

C33

Exhaust Gas Dscharge Fresh Ar

Intake wth Splt Flue Sets

Figure 12 Vertical Type Hermetic Use with

Split Flue Set

B

23

Exhaust gas dscharge through the

buldng chmney and fresh ntake

from outsde wth splt flue sets

Figure 15 Use with split flue set

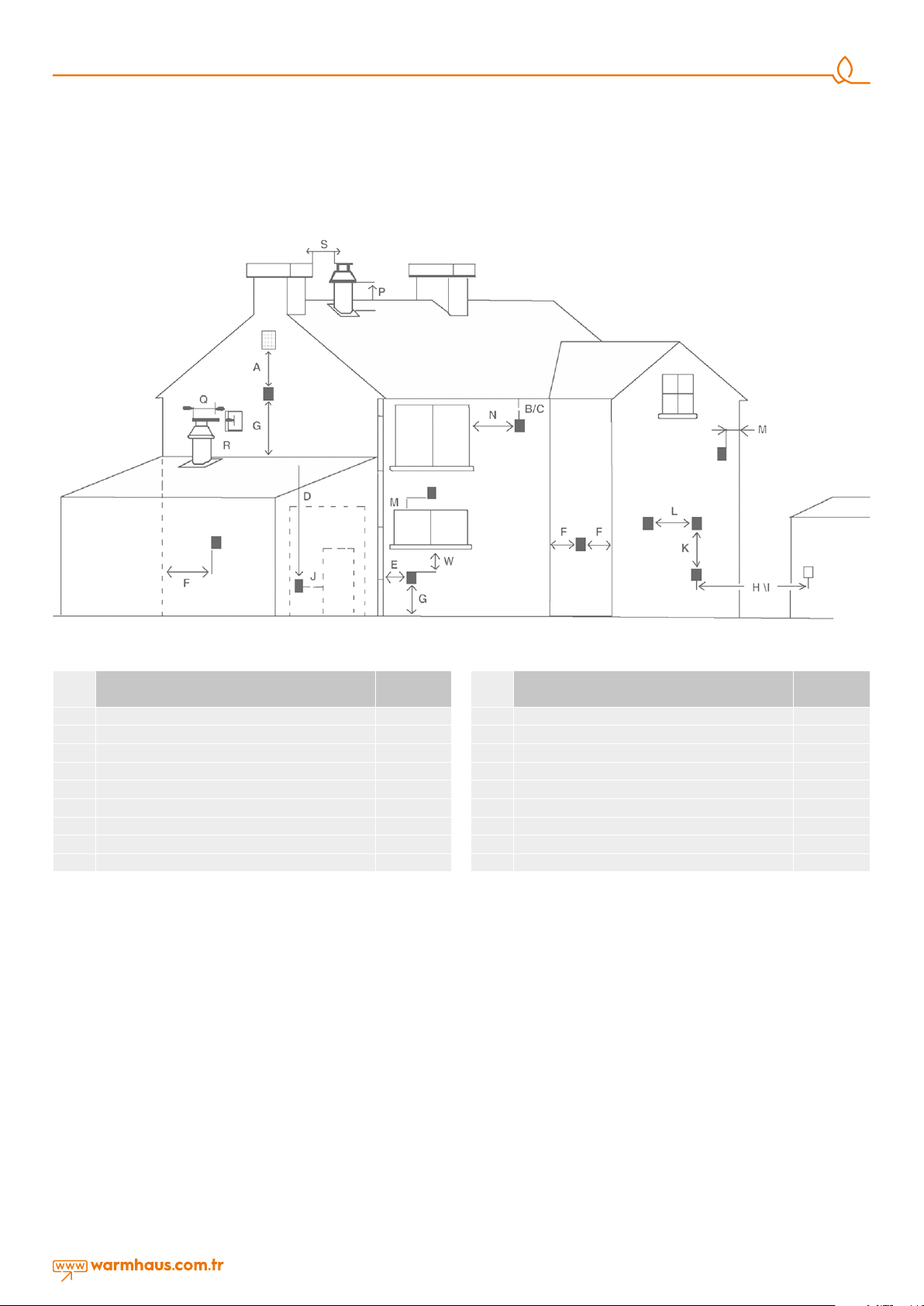

2.1.10. Peripheral Distances of the Flue Outlet Connections

For positioning of the flue set outlet pipe, see Figure 16. The flue shall

be installed in accordance with the national and local regulations.

No part of the outlet pipe or connections shall be blocked. If the

outlet pipe passes1000 mm nearby of a plastic or painted groove or

500 mm of painted fringes, an aluminum shield with at least 1000mm

length shall be placed below the groove or fringe. Outlet pipe shall

be at least 2 m over surfaces within reach by individuals. Under certain

weather conditions, outlet pipe may emit water vapor; installation shall

not be performed at places where this vapor may cause discomfort.

Exhaust gases shall be prevented from entering flue ventilation spaces.

Flue system of combi may be installed from inside the room without

requiring intervention from the external wall. For that reason, an

enclosure shall be installed in the wall for lining the internal surface of

channel wherein the outlet pipe passes through the wall, particularly

for thick walls.

10

2.1.11. Installation with (Ø80/125 mm) horizontal homocentric flue

sets Connection of (Ø80/125 mm) horizontal homocentric flue set

to the boiler

Since your boiler is a hermetic model, it takes the used air from outside and

discharges exhaust gases created as the result of burning through the same

flue group. In order to prevent emission of extremely harmful exhaust gases,

flue usage and installation is very important, therefore warnings should be

taken into consideration when flue connections are being performed.

• Carry out required flue selection for the external flue connection. If

the standard flue set is not adequate, please select most suitable

components from our list of connection accessories considering

warnings given in our user guide.

Select the most suitable components by also considering our

warnings.

• Fix the flange under the Bend piece (1) by using the Flange Bolt (10)

Flange Connection Screws (11) to holes on the boiler.

(10) secure it with Flange Connection Screws (11) onto the holes on

the boiler.

• 2 impermeability bolts within the hermetic flue set (2) are placed

into internal pipe slots at both ends of the 90° Bend.

• Place the exterior wall (EPDM) bolt into the flue terminal as seen in

Figure 11a for grouping the flue outlet terminal.

After placing the flue outlet terminal through exterior of wall and the

previously drilled hole, fix the Interior Wall Connection Bolt (7) into the flue

terminal. Place the other end of EPDM connection bolt installed on 90°

flue bend of your boiler to the flue outlet. Ensure that sealings are placed

properly:

Figure 16 Environmental locations of flue

Flue Location

A

Under a window 300 mm.

B

Under water groove 75 mm.

C

Under fringes 200 mm.

W

Under balcony 200 mm.

E

To vertical water discharge pipes 150 mm.

F

Interior or exterior corners 300 mm.

G

On the ground, roof or balcony level 300 mm.

H(*)

On another wall corresponding to the flue 600 mm.

S

To another flue 1200 mm.

(*) Not recommended for C5 and C6

VENTILATION

“Viwa 50 -65” boilers an be installed in boiler rooms whose size and

requirements meet current regulations. The following is provide for your

guidance only, and assumes the ventilation air is taken directly from

outside.

The sizes of the vents may need to be increased inrespect of other

appliances installed in the same area, and seasonal use. Take care that

the position of low level vents would not subject to adverse weather

conditions, ie flooding. Ventilation requirements for Viwa 50 -65 boilers

and cascade systems. BS6644 has a requirement that the temperatures

in a room or compartment do not exceed certain levels:

- +25°C at floor level (0-100 mm)

- +32°C at mid level (1.5 m above the floor level)

- +40°C at ceiling level (0-100 mm from ceiling)

When installed as a class B appliance (open flued, not roomed sealed).

Installed in a room High level (within 15% of the room height from

ceiling) - 2 cm²/kW of net heat input

Minimum

Distance

Flue Location

J

To a door other than garage wall 1200 mm.

R

To another flue from the same wall (vertical) 1500 mm.

Q

To another flue from the same wall (horizontal) 300 mm.

M

On another window/manhole 300 mm.

N

On another window/manhole horizontally 300 mm.

P

On the roof level 300 mm.

F

To an adjacent wall 300 mm.

I(*)

To the window on adjacent wall 1000 mm.

L

To another flue 600 mm.

Low level (low as possible within 1 meter from floor natural gas ) - 4

cm²/kW of net heat input a single Viwa 50 (46.88 KW net input) boiler

would require 100 cm² at high level and 200 cm² at low level.

Installed in a compartment or enclosure High level (within 15% of the

room height from ceiling) - 5 cm²/kW of net heat input Low level (low

as possible within 1 meter from floor natural gas) - 10cm²/kW of net

heat input.

A single Viwa 50 (46.88 KW net input) boiler would require 250 cm² at

high level and 500 cm² at low level.

When installed as a class C appliance (room sealed). Installed in a

room High level (within 15% of the room height from ceiling) - 2 cm²/

kW of net heat input Low level (low as possible within 1 meter from

floor natural gas) - 2 cm²/kW of net heat input A single Viwa 50 (46.88

kW net input) boiler would require 100 cm² at high level and 100 cm²

at low level.

Minimum

Distance

11

Loading...

Loading...