Warmhaus VIWA 90, VIWA 115, VIWA 125, VIWA 150 Installation And User Manual

VIWA 90

VIWA 115

VIWA 125

VIWA 150

WALL MOUNTED CONDENSING BOILERS

INSTALLATION AND USER MANUAL

Viwa 90

Viwa 115

Viwa 125

Viwa 150

CONDITIONS

1. DEAR WARMHAUS

CUSTOMER

1.1. GENERAL WARNING

1.2. GENERAL WARRANTY CONDITIONS

1.3. GAS LEAKS

2. INSTALLATION PERSONNEL

SECTION

2.1. SAFE HANDLING

2.2. CONTENTS OF PACKAGE

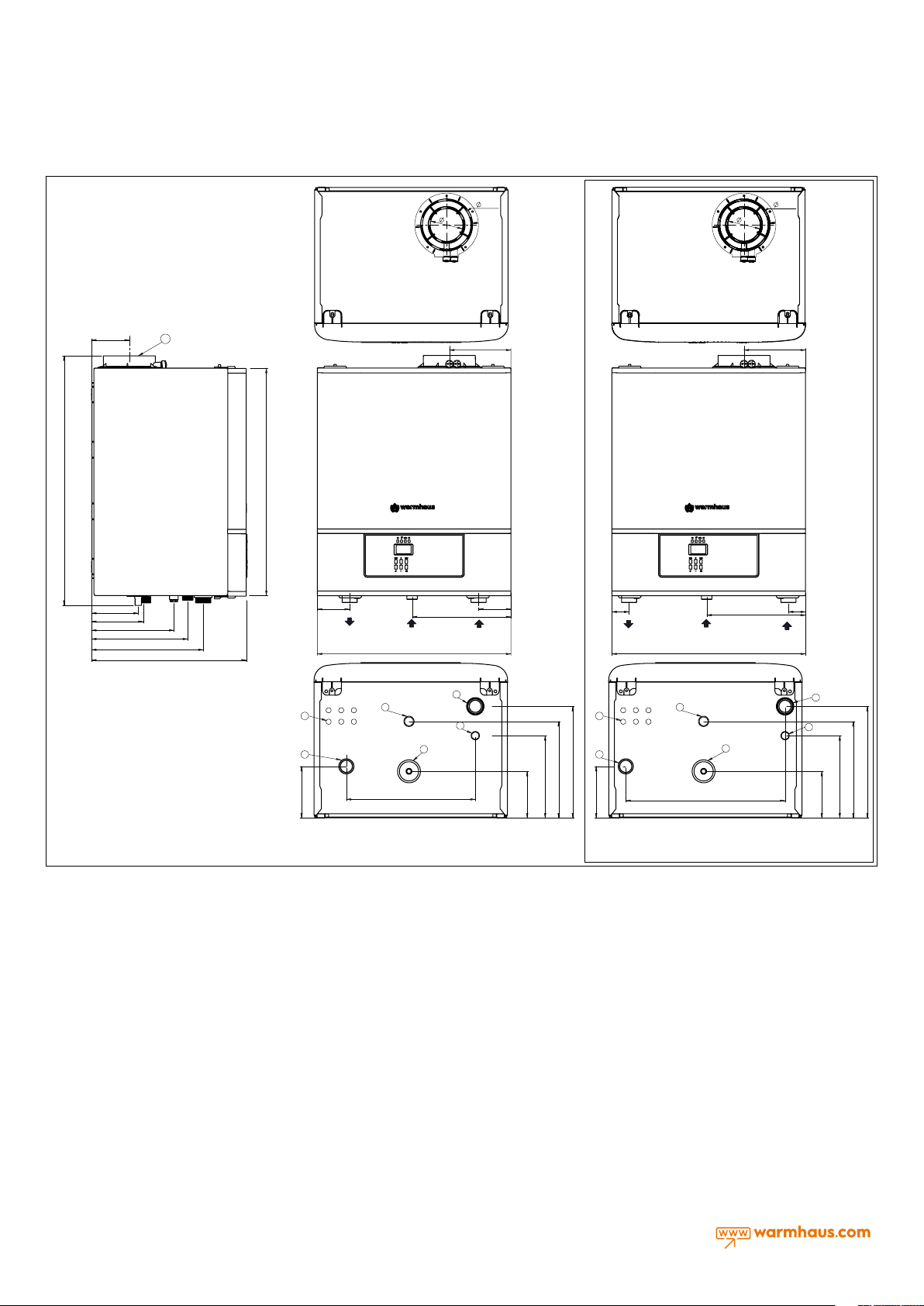

2.2.1. Sizes and Connections

2.3. MOUNTING RULES FOR BOILER

2.3.1. General Rules for Places for Mounting

The Boiler

2.3.2. Places Where Hermetic Boilers Cannot

Be Mounted

2.3.3. Wall Mounting of Boiler and Selection

of Mounting Location

2.3.4. Quick Reference Guide for Air Supply,

Ventilation and Chimney Terminal

Positioning; BS 6644: 2011, IGE / UP /

10 (ed4) 2014 & BS 5440-1: 2008, BS

5440-2: 2009

2.4. NATURAL GAS CONNECTION

DEVICE CATEGORY I

2.4.1. Flammable Gas Quality

2.5. HEATER AND HOT DOMESTIC WATER

INSTALLATIONS

2.6. FILLING THE SIPHON FOR

CONDENSATION LINE

2.7. CONNECTION OF WASTE

GAS CHIMNEY PIPE SET AND

ACCESSORIES

2.7.1. Environmental Distances of Chimney

Outlet Connections

2.7.2. Connection of (Ø100/150 mm)

Horizontal Concentric Chimney Set

and Mounting Horizontal Concentric

Chimney Set to The Boiler

2.7.3. Mounting with Vertical Concentric

Chimney Sets

2.7.4. Mounting with Concentric Chimney

Sets in The Attic

2H

2.8. MOUNTING TO PARTIALLY

PROTECTED OUTER SPACES

2.9. ELECTRIC CONNECTIONS

2.10. OPTIONAL CONTROLS ROOM

THERMOSTAT, EXTERIOR

TEMPERATURE SENSOR AND OTHER

2.11. MOUNTING RULES FOR HYDRAULIC

INSTALLATION

2.11.1. Structure of Heating Water

2.11.2. Filling / Emptying Heating System

2.11.3. Discharge of Condensing Water

2.11.4. Circulation Pump (Optional)

2.11.5. Controls For The First Operation of

The Boiler

2.12. REQUIRED INSTALLATION ELEMENTS

FOR BOILER AND HEATING SYSTEM

OPERATION

2.12.1. Parts of Boiler

3. FOR USERS

3.1. GENERAL WARNING FOR USER

3.1.1. Use of Boiler

3.2. SELECTION OF SWITCHING ON

OFF STANDBY AND SUMMER

WINTER MODES

3.2.1. Positions of Switching On / Off /

Summer and Winter

3.2.2. Resetting the Boiler (Re-operate)

3.2.3. Operating in Winter Position

3.2.4. Operating in Summer Position (if a

boiler is connected)

3.2.5. Use with Room Thermostat (Optional)

3.2.6. Use of Exterior Temperature Sensor

(Optional)

3.2.7. Customization of Boiler Features

3.3. RESTORING FAULTS AND FAILURES

3.3.1. Failure Codes Table

3.4. SUGGESTIONS FOR USING BOILER

ECONOMICALLY

3.5. POINTS TO CONSIDER BY USERS

FOR WARRANTY CONDITIONS

3

1. DEAR WARMHAUS CUSTOMER

We congratulate and thank you for choosing Warmhaus wall mounter

boiler which shall provide you heating and domestic hot water

comfort for years. State-of-art Warmhaus boilers, being manufactured

in compliance with standards of the European Union are also

exported to many countries. You can utilize our Authorized Technical

Service network with professional competence certification for any

ordinary maintenance needs of this product produced meticulously

with hard work. Our authorized services assure sustaining performance

of the device as they shall always provide original spare part services.

Please read this manual thoroughly to use your boiler economically,

comfortably and efficiently, and store to refer when needed.

It is recommended for efficient use to have assembly done by an

authorized dealer approved by the local gas authority and which has

the competence and experience for assembly.

1.1. GENERAL WARNINGS

This manual is an integral part of the product, and must be delivered

to the new user in case of handover of the appliance. The manual

shall be preserved properly and kept in the way to be referred as it

contains significant information about use as well as installation of the

appliance.

Heating and Domestic Hot Water installations shall be

projected and implemented a competent and approved

engineering company meeting the criteria prescribed by laws,

by observing the current legislation in force.

Installation and maintenance shall be carried out by the

competent personnel having sufficient knowledge in the

installation industry and professional competence certification

in accordance with the legislation in force and in line with the

directions of the manufacturer. Hazards which may cause injury of

persons, other living beings (animals, plants) and damage to goods

may be caused by wrong installation, for which the manufacturer

cannot be held responsible.

Natural gas installation project; shall be carried out by one

of the dealers authorized by your local gas authority.

The manufacturer may not be held responsible for any

faults caused by noncompliance to the legislation and

standards in force and information provided in this manual

(and information and instructions provided by the manufacturer in

any case), within or out of the scope of the contract, and this also

constitute reason for termination of warranty of the appliance.

Only Warmhaus Authorized Service is authorized to carry out

electrical connection of the boiler and to energize the boiler.

In case of any material, design or installation faults occurred within

the warranty period, maintenance and operation shall be carried out

without any charge of labor or spare parts.

(Also see: 3.5 MATTERS TO PAY ATTENTION FOR GUARANTEE

CONDITIONS)

This appliance should only be used for its designed intended

purposes (to be used in closed-circuit heater installation and

production of open circuit domestic hot water production).

. All kinds of other uses are not suitable as well as may create a

potential danger.

Manufacturer shall not be responsible for damages

occurring due to interventions, false installation and initial

starting performed by unauthorized persons and warranty

scope shall be void. As the Combi is an appliance having heating

system, domestic hot water, natural gas/LPG and electrical

connections, do not make and have any interventions made without

the authorized service

appliance maintenance operations should be performed by

the authorized and competent technical personnel, and

Warmhause Authorized Technical Service Centers constitute

assurance for quality. WARMHAUS is not responsible for damages

arising from repairs, part replacements and maintenance performed by

third persons and companies and combi remains out of the warranty

scope under such conditions.

Attention! Please note & read the warning and informations on the

boiler. Incorrect operation of the boiler can cause significant damage.

For Warmhaus wall-mounted boilers; commissioning, adjustment,

maintenance and cleaning must only be carried out by a specialist OR

approved service by Warmhaus!

When faults occur in the heating system, the plant must be stopped

and damaged parts should only be replaced by an authorized

workshop.

The accessories used must correspond to the technical rules and the

relevant parts must be approved by the manufacturer in connection

with the Warmhaus wall-mounted boiler.

Only APPROVED & ORIGINAL spare parts should be used.

Bolts sealed with paint strictly forbidden to open!

The boiler must not be used by children younger 8 years or

invalid persons without supervision.

These seals provide evidence that the replacement of bolts required

for safe operation. If the seals are damaged, the guarantee of the

device will come to an end!

1.2. TERMS AND CONDITIONS OF WARRANTY

This appliance has been manufactured to be installed in the

country specified on its technical registration label. Installing

the appliance in any other country than those specified on

the plate may cause damage or injury to persons, animals and goods.

WARMHAUS declares that Viwa 90, Viwa 115, Viwa 125 & Viwa 150

boilers comply with the essential requirements of the following

directives:

- Gas Appliances Regulation (EU) 2016/426

- Boiler Efficiency Directive 92/42/EEC

- Electromagnetic Compatibility Directive 2014/30/UE

- Low Voltage Directive 2014/35/UE

- Ecodesign Directive 2009/125/EC

- Regulation (EU) N. 813/2013 - 811/2013

Manufacturer: Warmhaus Isıtma ve Soğutma Sistemleri Tic. A.Ş. Bursa

Organize Sanayi Bölgesi Park Cad. No:10 16140 Nilüfer-Bursa / Turkey

WARMHAUS A.Ş. reserves the right to make all kinds of technical and

commercial modifications without notice, and disclaims any liabilities

arising out of printing and spelling mistakes.

4

WARMHAUS

WARMHAUS

90 kW

1015 18

115 kW

1015 18

125 kW

1015 18

150 kW

1015 18

IMPORTANT INFORMATION

It is a statutory requirement that all gas appliances are installed by competent persons, in accordance with the gas safety (installation and use)

regulations (current edition). The manufacturer's instructions must not be taken as overriding any statutory requirements, and failure to comply

with these regulations may lead to prosecution. No modifications to the appliance should be made unless they are fully approved by the

manufacturer. Gas leaks: do not operate any electrical switch, or use a naked flame. Turn off the gas supply and ventilate the area by opening

doors and windows contact the gas emergency service

1.3. GAS LEAKS

NATURAL GAS EMERGENCY LINE

HOW TO ACT IN CASE OF DETECTING NATURAL GAS ODOR

IN EMERGENCY CASES

Do not use

lighter- matches

Do not turn on, off

or unplug the lamps

or other electrical

appliances.

Ventilate the

environment by

opening doors and

windows.

Close valves of

appliances operating with natural gas

and your gas meter

Do not use/let

anyone use the

doorbell.

NATURAL GAS

EMERGENCY

FIRE

DEPARTMENT

Do not use phones

in case of a natural

gas leakage. It may

create sparks.

Immediately evacu-

ate the place with

ga s od or.

Call the Natural Gas

Emergency Line from

your neighbor or ano-

ther suitable place.

Do not intervene the

installation Wait for

Gas Authorities Team

to arrive.

Never close culverts

ensuring discharge of

the gas from the en-

vironment in case of a

natural gas leakage.

AMBULANCE POLICE

INFORMATION: You can visit web sites of

local gas authorities and NATURAL GAS

EMERGENCY sections.

Advice: Please take note local emergency

phone numbers.

5

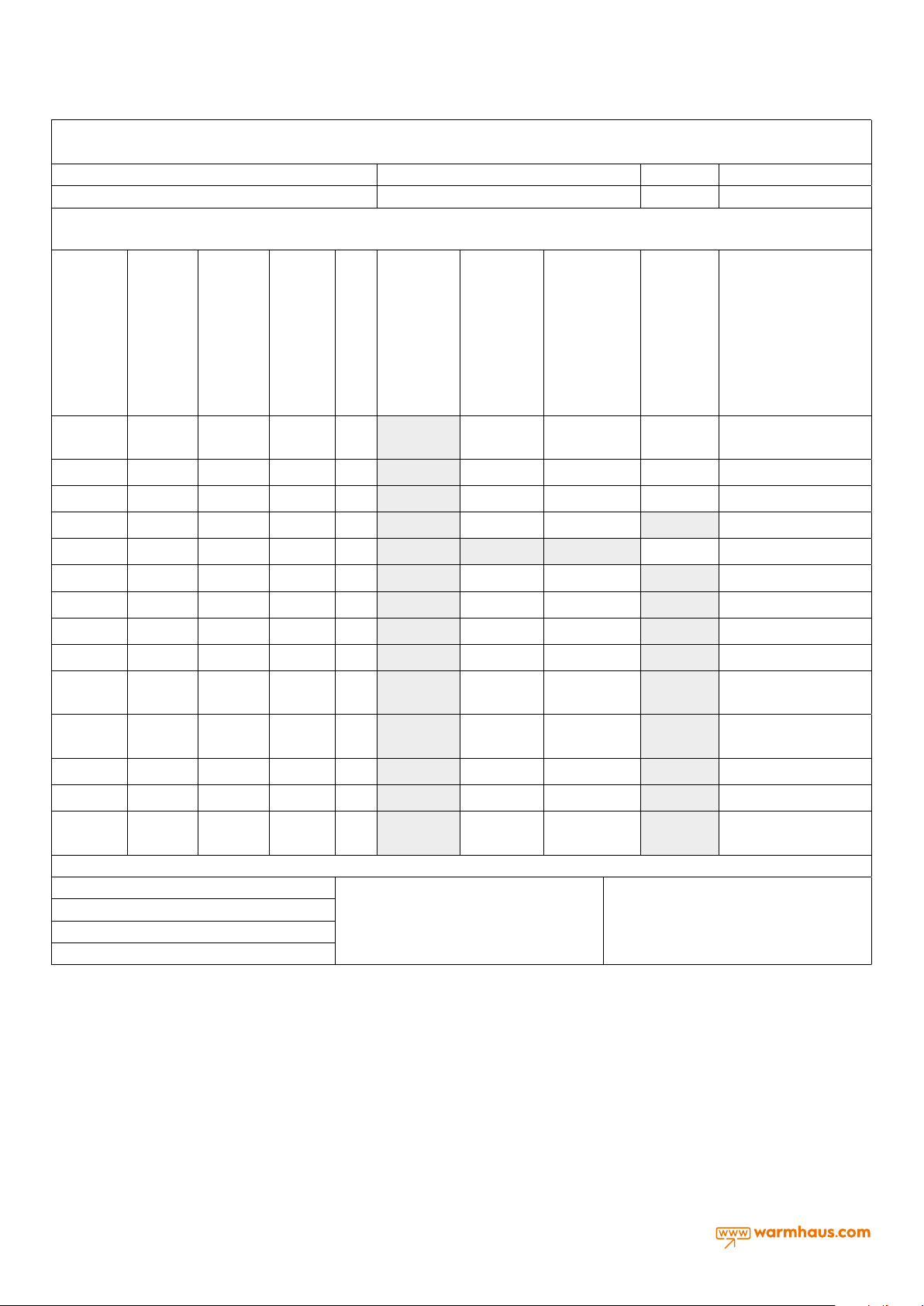

1.4 BOILER GAS CATEGORIES & REGIONS

Designation: Used gas types & Countries

Manufacturer Type Model / Technical Data Conformity Markings

Boiler Gas Categories & Regions Wall mounted type Warmhaus combis and boilers granted

Gas categories for Warmhaus boilers are implemented on the CE certificate given below by SZU Test / BRNO;- appliance categories according to direct destinations are determined in

accordance with EN 15502-1. According to-EN ISO 3166-1 destination countries;- millibar gas supply pressures, can be used for several gas groups if it is under normal pressure. They are

specified with numerical values and "mbar" unit.

Enerwa 24

Enerwa 2530

Document for

conformity

approved by

SZU test

YES I 2H Natural Gas 20 mbar G20 Not Approved Approved Approved Approved

YES I 2H Natural Gas 25 mbar G20 Not Approved Approved Approved Approved HU

YES I 2E Natural Gas 20 mbar G20 Not Approved Approved Approved Approved DE, LU, PL, RO

YES I 2E+ Natural Gas 20 mbar G20 Not Approved Approved Approved Not Approved BE, FR

YES I 2E(S) Natural Gas 20 mbar G20 Not Approved Not Approved Not Approved Approved BE

YES I 2E+ Natural Gas 25 mbar G25 Not Approved Approved Approved Not Approved BE, FR

Appliance

Categories

Gas Type

Gas Inlet

Supply

Pressures

Used

Gas

Lawa 24

Lawa Plus 24

Lawa 28

Lawa Plus 28

Priwa 24

Priwa Plus 24

Priwa 28

Priwa Plus 28

Priwa 33

Priwa Plus 33

Enerwa Plus 24

Enerwa Plus 2530

Enerwa 28

Enerwa 3035

Enerwa Plus 28

Enerwa Plus 3035

Enerwa 33

Enerwa 3540

Enerwa Plus 33

Enerwa Plus 3540

Viwa 50

Viwa 65

Viwa 90

Viwa 115

Viwa 125

Viwa 150

Countries of

Destination **

AT, BG, CH, CZ, DK, EE, ES, FI,

GB, GR, IE, IT, LT, LV, NO, PT, RO,

SE, SI, SK

YES I 2L Natural Gas 25 mbar G25 Not Approved Approved Approved Not Approved NL

YES I 2ELL Natural Gas 20 mbar G20 Not Approved Approved Approved Not Approved DE

YES I 2ELL Natural Gas 20 mbar G25 Not Approved Approved Approved Not Approved DE

YES II 2H3P Natural Gas 20 mbar G20 Not Approved Approved Approved Not Approved

YES II 2H3P Propane LPG 37 mbar G31 Not Approved Approved Approved Not Approved

YES II 2L3P Natural Gas 25 mbar G25 Not Approved Approved Approved Not Approved NL

YES II 2L3P Propane LPG 37 mbar G31 Not Approved Approved Approved Not Approved NL

YES I 3P Propane LPG 37 mbar G31 Not Approved Approved Approved Not Approved

EN ISO 3166-1: 2006, Codes for the representation of names of countries and their subdivisions - Part 1: Country codes (ISO 3166-1: 2006)

Prepared by: İsmail B.Taşdemir / R&D Mng.

Date of Publication: 18/4/2017

Rev. No: 2

Drw. No: WH.17.107

Table 1.1

Approval; revision was made with E-30-00300-18 GAR

certificate and CE-1015CT0615 product number. And

correction 02 Viwa 50 and 150 kW addition equivalent.

This document and the information contained herein

belong to Warmhaus Isıtma ve Soğutma Sistemleri San.

Tic. A.Ş. It shall not be transferred to any person not

authorized by Warmhaus Isıtma ve Soğutma Sistemleri

San. Tic. A.Ş. or copied or used howsoever by any third

persons without prior written approval.

CH, CZ, ES, FR, GB, GR, IE, RO,

CH, CZ, ES, FR, GB, GR, HR, IE,

BE, CH, CZ, ES, FR, GB, GR,

HR, IE, IT, LT, NL, PL, PT, RO,

SI, SK

IT, LT, PT, RO, SI, SK

SI, SK, TR

Table 1.2

6

GAS

G1"

G1 1/2"

G1 1/2"

2. INSTALLATION PERSONNEL

SECTION

2.1. SAFE HANDLING

This boiler may require 2 or more operatives to move it into its

installation site, remove it from its packaging and during movement into

its installation location. Manoeuvring the boiler may include the use of

a sack truck and involve lifting pushing and pulling.

Caution should be exercised during these operations. Operatives

should be knowledgeable in handling techniques when performing

these tasks and the following precautions should be considered:

– Grip the boiler at the base

– Be physically capable

– Use personal protective equipment as appropriate e.g. gloves, safety

footwear.

During all manoeuvres and handling actions, every attempt should be

made to ensure the following unless unavoidable and/or the weight is

light.

– Keep back straight

– Avoid twisting at the waist

– Always grip with the palm of the hand

– Keep load as close to the body as possible

– Always use assistance

WARNING

Caution should be exercised when performing any work on this

appliance.

– Protective gloves and safety glasses are recommended.

– Avoid direct contact with sharp edges.

– Avoid contact with any hot surfaces

NOTICE

Please be aware that due to the wet testing of the appliance, there

may some residual water in the hydraulic circuit.

– Protect any surfaces, carpets or floorings.

– Use a suitable container to catch any water that escape when

removing the protective caps from the connections.

INSTALLATION

The boiler must be installed in a fixed location, by qualified

engineers in compliance with all instructions contained in

this manual. Furthermore, the installation must be in accordance with

current standards and regulations.

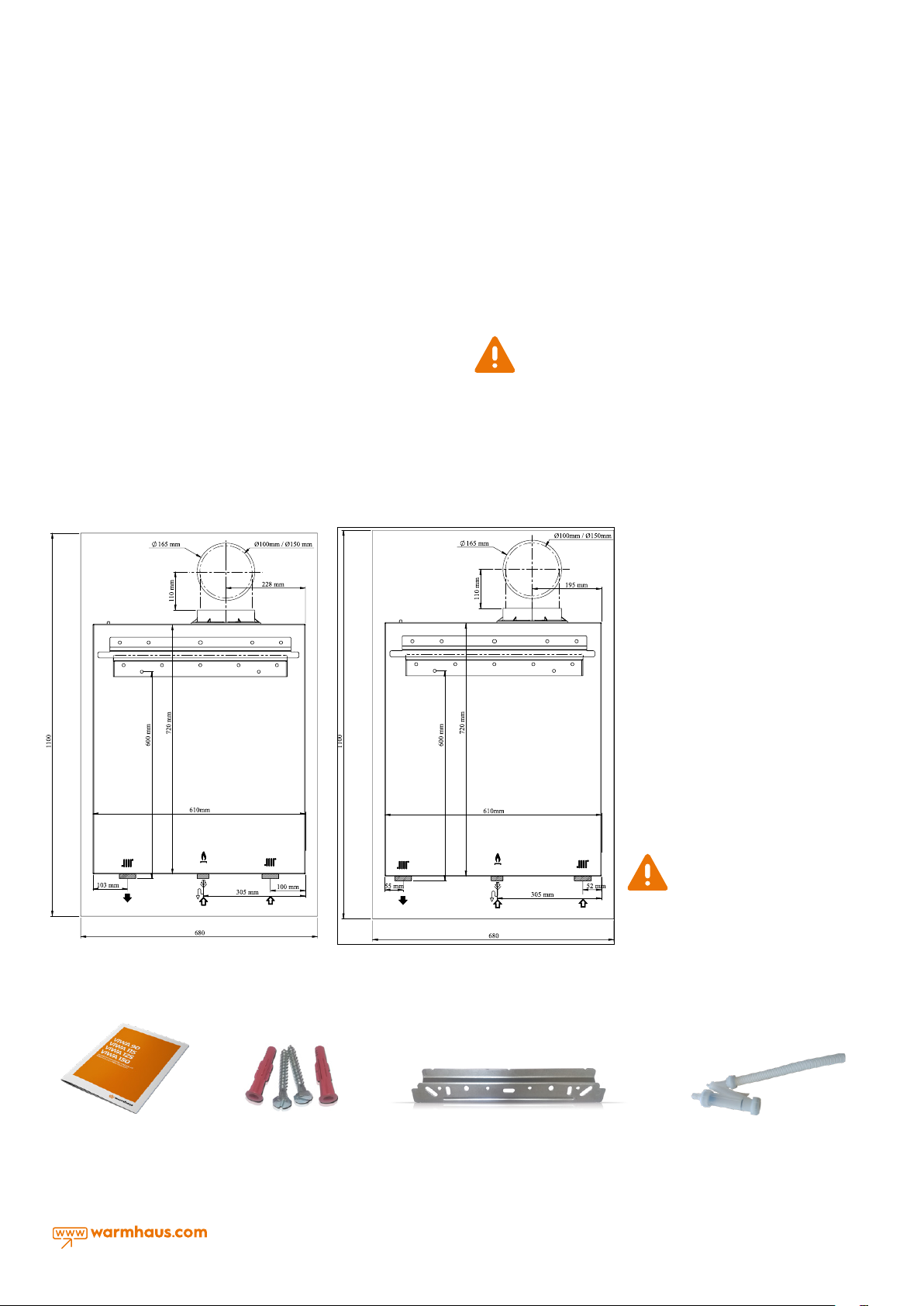

2.2. CONTENTS OF PACKAGE

There are the following materials in the boiler box. In the Viwa 90-150

boiler group, waste gas chimney sets are not supplied with the boiler

and must be ordered separately.

GAS

G1 1/2"

Figure 2.2 Mounting Template of Viwa 90 & Viwa 115

(Back view)

Figure 2.3 User manual

G1"

G1 1/2"

Accessories

Figure 2.1 Mounting Template of Viwa 125 & Viwa 150

(Back view)

Figure 2.5 Rod-fastening plateFigure 2.4 Connection

I. Mounting Template (Figure 2.1 and 2.2)

II. User Manual (Figure 2.3)

III. Connection Accessories (Figure 2.4)

a. 1 Throttle Screw (mounted on the

chimney outlet.)

b. 2 Hanger Screws

c. 2 Dowels

IV. Rod-fastening plate (Figure 2.5)

V. Condensing Siphon (Figure 2.6)

Do not leave the packaging material (plastic bag, nylon, etc.) in a

place where children can reach it,

in order not to create a health hazard.

Figure 2.6 Siphon part for discharging

condensing water

7

2.2.1. Sizes and Connections

790

120

148

164

261

305

330

498

153,4

103,4

18

720

102

CH Flow

G1 1/2"

Gas İnlet

G 1"

615

322

195

CH Return

G1 1/2"

102

54

CH Flow

G1 1/2"

Gas İnlet

G 1"

615

103,4

322

153,4

195

CH Return

G1 1/2"

54

Warmhaus Vwa 125 / Vwa 150

1) Heater Return Line

2) Sediment-Air Separator Discharge Line

6

3) Condensing Water Discharge Line

4) Gas Inlet Line

5) Heater Stream Line

5

6) Cable Outlets

7) Waste Gas Outlet Connection (Ø100mm)

8) Fresh Air Inlet Connection (Ø150 mm)

164

9) Fresh Air Measurement Point

10) Waste Gas Measurement Point

Figure 2.7 Boiler sizes and connections Viwa 90 / Viwa 115 Viwa 125 / Viwa 150

2.3. MOUNTING RULES FOR BOILER

2.3.1. General Rules for Places for Mounting The Boiler

There is no ventilation limitation for places where the hermetic (C

type) boiler is mounted (the devices can be mounted regardless of

the volume and ventilation form of the room). In addition, it can be

mounted in partially protected areas such as balconies and terraces

provided that it is in the protective cabin and necessary precautions

are taken against freezing in the installation water. However, the

installation requirements of the local gas company in the area to be

mounted must also be taken into consideration, so be careful about

the mounting locations for over a certain capacity!

The boiler should be mounted firmly on the building wall. A flexible

connection element must be used between the boiler and the gas

line. Flexure lengths to be used on A, B and C type devices shall not

exceed the permissible limits from local gas companies. The chimney

outlets of the hermetic boilers must be connected directly to the

outdoor with open air circulation. The gas outlet conditions of waste

gas installation of these devices should be in accordance with the

rules set out in TS 12514 standard (positions of the pipe outlets in

relation to various forms, vertical, horizontal minimum distances, crosssectional areas of the ducts if connected to ducts).

3

CONDANSATE

DRAIN

1

305

6

5

330

164

2

261

148

4

3

CONDANSATE

DRAIN

507

4

411

1

2

330

305

261

148

2.3.2. Places Where Hermetic Boiler Cannot Be Mounted

• To the stairwells of buildings

• To the common spaces of the buildings which are open to general

use, air wells and day spaces, to the attic, to the under the roof, to

emergency exit doors, and similar places such cellar, hall etc.

• To the yards between buildings

• To narrow eaves gaps

• On chimney walls,

• To closed balconies,

• To open balconies except for being in a cabin and permitted by

device company and local gas company),

• Underneath the protruding parts of the structure which prevent the

outler of waste gas,

• To places where can be exposed to direct wind pressure

• It is forbidden to mount hermetic boilers (type C) in openings that

provide fresh air to other units!

2.3.3. Wall Mounting of Boiler and Selection of Mounting Location

• It must be checked and guaranteed wall-mounting of boiler is sound

and safe.

8

Figure 2.8 Environmental locations of flue

Chimney Position

A

Under a window 300 mm.

B

Under water groove 75 mm. 75 mm.

C

Under fringes 20 mm. 200 mm.

W

Under balcony 200 mm.

E

To vertical water discharge pipes 150 mm.

F

To inside or outside corners 300 mm.

G

To ground, roof or balcony level 300 mm.

H (*)

To another wall corresponding to the wall 600 mm.

S

To another chimney 1200 mm.

J

From the garage wall to another door 1200 mm.

R

From same wall to another chimney (vertically) 1500 mm.

Q

From same wall to another chimney (horizontally) 300 mm.

M

On another window / culvert 300 mm.

N

Horizontally another window / culvert 300 mm.

P

To the roof level 300 mm.

F

To a neighbouring wall 300 mm.

I (*)

On the window on the neighbouring wall 1000 mm.

L

To another chimney 600 mm.

(*) Not recommended for C5 ve C6 !

• The hanger plate supplied as standard with the boiler shall be

mounted on a full or half-full brick wall in accordance with the

connection screws and mounting template in compliance with its

technique and shall not be used for any other purpose.

• If different materials are used for mounting, the boiler will be out of

warranty.

• If the wall to be mounted on is not a brick wall, the durableness of

the support system must first be checked.

• The boiler must be mounted on a fire-resistant wall.

Minimum

Distance

• It is recommended to mount the boiler between 1.8 - 2.2 m length

of hanger plate from the ground.

• In places where mounting area is limited, the boiler must be

mounted minimum 30 cm above the ground, with a space of

minimum 5 cm from the sides and 90cm from the front for easy

intervention of service technician.

• The boiler is not mounted in places with explosive, flammable

material and acid vapor.

• It is not mounted on sides of above cookers, ovens or heating

devices.

• Hermetic boilers can be mounted inside the furniture as well, but at

least 5 cm spacing should be left on their sides.

• It is advisable to connect the outlet of the boiler to the outlet line

by means of a transparent hose to prevent the possibility of water

coming from safety valve of boiler after mounting. If this is not

possible; do not put electronic devices, tools, parts and equipment

that can breakdown, rust, etc. under the boiler.

• Due to the above reasons, it is not recommended to put any

furniture under the boiler.

2.3.4. Air Supply, Ventilation and Flue Terminal Positioning Quick

Reference Guide for; BS 6644:2011, IGE/UP/10 (ed4) 2014 & BS

5440-1:2008, BS 5440-2:2009, BS6644:2011 Specification for the

Installation of gas-fired hot water boilers of rated inputs between

70 kW (net) and 1.8 MW (net) (2nd and 3rd family gases) & IGE/

UP/10 2014 Edition 4 Installation of Gas Appliances in Industrial

and Commercial Premises

For BS 6644 and IGE UP 10 Installations the ventilation openings might

need to be increased if the following air temperatures are exceeded.

(@15°C Ambient)

High-Level (100mm Below Ceiling Level) 40°C

Mid-level (1500mm Flow Floor Level) 32°C

Low-Level (100mm Above Floor Level) 25°C

As a guide, reduction of air temperature may be achieved by increasing

the inlet and outlet air supply by 0.15 m3/h or 0.2 cm2/kW of net heat

input per 0C of temperature reduction required.

9

Room Sealed Appliances Installed within an Enclosure (Natural ventilation requirements direct to Outside Air)

Grille Location

System Type

600m from any obstruction

High Level (Free Area/kW) 5 cm

Low Level (Free Area/kW) 5 cm

Heating &/or HWS

Operation < 50% during summer months

2

2

Heating &/or HWS

Operation > 50% < 75% during summer

months

2

6 cm

2

6 cm

Heating &/or HWS

Operation > 75% during summer months

2

7 cm

2

7 cm

Room Sealed Appliances Installed within an Enclosure (Natural ventilation requirements Via an internal Space)

Grille Location

600m from any obstruction

High Level (Free Area/kW) 10 cm

Low Level (Free Area/kW) 10 cm

System Type

Operation < 50% during summer months

Heating &/or HWS

2

2

Operation > 50% < 75% during summer

Heating &/or HWS

months

2

11 cm

2

11 cm

Operation > 75% during summer months

Heating &/or HWS

2

12 cm

2

12 cm

Room Sealed Appliances Installed within a Boiler Room / Heated Space (Natural ventilation requirements direct to Outside Air.)

Grille Location

600m from any obstruction

High Level (Free Area/kW) 2 cm

Low Level (Free Area/kW) 2 cm

System Type

Operation < 50% during summer months

Heating &/or HWS

2

2

Operation > 50% < 75% during summer

Heating &/or HWS

months

2

3 cm

2

3 cm

Operation > 75% during summer months

Heating &/or HWS

2

4 cm

2

4 cm

Max Operating Pressure < 100mbar, Room Air Change Rate >0.5/hour = No Additional Ventilation. If the air change rate is less than 0.5/hour them

the following must be applied.

Appliances without draught diverters with or without draught stabilisers

Grille Location

600m from any obstruction

High Level (Free Area/kW) 1.35 +/- 0.18 (m

Low Level (Free Area/kW) 2.6 (m

System Type

Operation < 50% during summer months

Heating &/or HWS

3

/h/kW) 1.35 +/- 0.18 (m3/h/kW) 1.35 +/- 0.18 (m3/h/kW)

3

/h/kW) 3.32 (m3/h/kW) 4.04 (m3/h/kW)

Operation > 50% < 75% during summer

Heating &/or HWS

Operation > 75% during summer months

months

Heating &/or HWS

VENTILATION

“Viwa 90 - 150” boilers an be installed in boiler rooms whose size and

requirements meet current regulations. The following is provide for your

guidance only, and assumes the ventilation air is taken directly from

outside. The sizes of the vents may need to be increased inrespect

of other appliances installed in the same area, and seasonal use. Take

care that the position of low level vents would not subject to adverse

weather conditions, ie flooding.

Ventilation requirements for Viwa 90 -150 boilers and cascade systems.

BS6644 has a requirement that the temperatures in a room or

compartment do not exceed certain levels:

- +25 °C at floor level (0-100 mm)

- +32 °C at mid level (1.5 m above the floor level)

- +40 °C at ceiling level (0-100mm from ceiling)

When installed as a class B appliance (open flued, not roomed sealed).

Installed in a room High level (within 15% of the room height from

ceiling) - 2 cm²/kW of net heat input Low level (low as possible within

1 metre from floor natural gas ) – 4 cm²/kW of net heat input A single

Viwa 125 (116 kW net input) boiler would require 232 cm² at high level

and 464 cm² at low level. Installed in a compartment or enclosure

High level (within 15% of the room height from ceiling) - 5 cm²/kW of

net heat input Low level (low as possible within 1 metre from floor

natural gas) –10 cm²/kW of net heat input. A single Viwa 125 (116 kW net

input) boiler would require 580 cm² at high level and 1160 cm² at low

level. When installed as a class C appliance (room sealed). Installed in

a room High level (within 15% of the room height from ceiling) - 2 cm²/

kW of net heat input Low level (low as possible within 1 metre from

floor natural gas) – 2 cm²/kW of net heat input A single Viwa 125 (116

kW net input) boiler would require 232 cm² at high level and 232 cm²

at low level.

2.4. NATURAL GAS CONNECTION DEVICE

CATEGORY I2H

Our boilers were manufactured to run with methane gas (G20).

Gas supply pipes must be equal to or greater than 3/4 "G boiler

connections. Before connecting the gas, a careful internal cleaning of

the pipe laying of the entire fuel supply installation must be carried

out, since possible waste will damage the best performance and

efficiency of the boiler. It must be checked that the gas distributed

from the main line is in the type stipulated for the boiler (see the label

on the boiler).

In addition, the network dynamic pressure (methane) to be used

in feeding the boiler and in case of it is inadequate, that may

affect the power of the boiler and cause difficulties for the user.

Make sure the gas valve connection is made correctly. The

flammable gas supply pipe must be designed and dimensioned

according to the current MMO and local gas company

specifications and instructions in order to ensure that the boiler is

capable of delivering sufficient gas to the burner while the boiler

is operating at maximum power and the device is efficient. The

connection system must comply with legal regulations.

2.4.1. Flammable Gas Quality

The boiler is designed to be used with pure fuel which does not

contain foreign substance in; for this reason it is absolutely necessary

to add the necessary filter systems in the gas supply line (in order to

ensure that the fuel is purified).

10

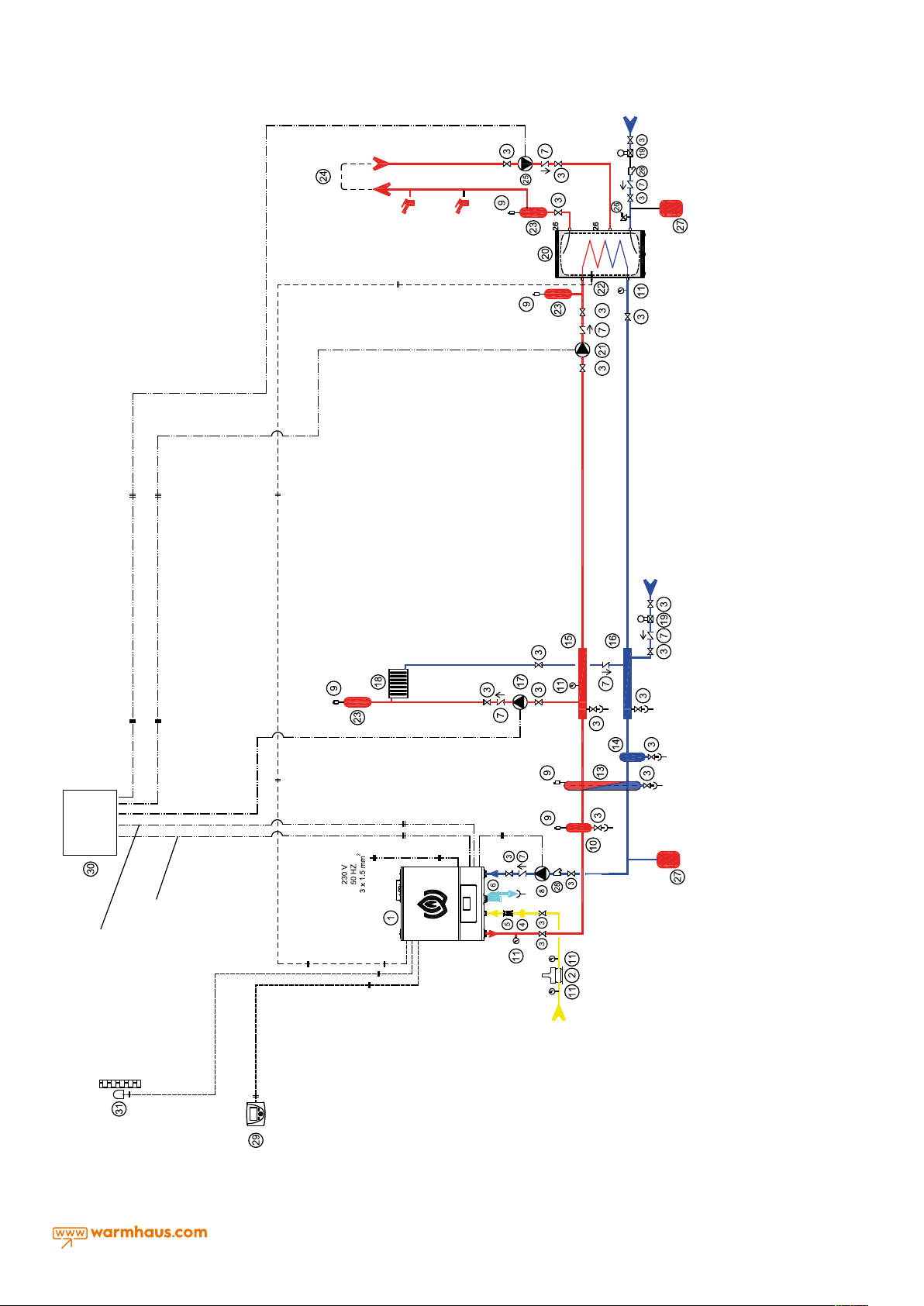

Resirculation pump

Outside Air Sensor

2 x 1.0 mm

Stroge Tank Pump

Stroge Tank

2

Sensor

2 x 1.0 mm

COLD

WATER

RESIRCULATION CIRCUIT

24. Hot Water Tank Recirculation Line

25. Recirculation Pump

26. Safety Valve

27. Expansion Tank

28. Filter

29. Timer/Room Thermostat

30. Boiler Electrical Panel

31. Outside Air Sensor

COLD

WATER

Collector

16. Heating System Return Water

17. Heating System Pump

18. Heating System

19. Pressure Reducer

20. Hot Water Tank

21. Hot Water Tank Pump

22. Hot Water Tank Sensor

23. Air Separator

Boiler

Electrical

Panel

2

Boiler panel and

Electrical Panel connection

for System Pump

3 x 1.0 mm

2

Boiler panel and

Electrical Panel relay connection

for System Pump

3 x 1.0 mm

Timer/Room

2

Thermostat

2 x 1.0 mm

2

System Pump

3 x 1.0 mm

2

Collector

8. Boiler (Return) Pump

9. Automatic Air Purge Valve

10. Sediment-Dirt-Air Separator

11. Manometer

12. Hydraulic Separator Sensor

13. Hydraulic Separator

14. Sediment-Dirt Separator

Pump

cable

3 x 1.0 mm

FLUE

15. Heating System Steam Water

Figure 2.9 A Radiator Circuit Viwa and A Hot Water Supply connection diagram with Viwa 90 / Viwa 150 boiler

Line

INSTALLATION EQUIPMENT

1. Boiler

2. Gas Safety Solenoid Valve

3. Ball Valve

4. Gas Filter

5. Vibration İsolator

6. Condensate Siphon and Drainage

7. Check Valve

GAS LINE

2

11

2.5. HEATER AND HOT DOMESTIC WATER

INSTALLATIONS

Radiator and floor heating installations should be performed according

to TSE and MMO technical specifications according to heat loss

calculation. The type and quantity of the radiator and the quantity of

piping of the heating installation must also be appropriate for the

calculation of heat loss.

• The heating installation must be installed at a pressure enduring at

least 6 bar.

• If the city pressure is higher than 6.5 bar, the pressure reducer must

be assembled.

• It is recommended that the heating installation be performed as

double or mobile line (at least) and avoiding the elbows and joints

as many as possible.

• A strainer filter must be definitely installed in return line of heater and

if a hot water tank will be used, in inlet line of domestic water (city).

• An additional expansion tank of at least 50 litres should be used

depending on the volume of the heating water and the working

temperature of the heating circuit (closed circuit).

• If room thermostat and thermostatic radiator valve will be used

together; the thermostatic valve should not be installed in radiators

in places where the room thermostatic available!

• Radiators longer than 1.5 m must be cross-connected for efficient

operation.

• Sheaths should be used in the passages of the heating and hot

water from the walls and they should be fixed with wall clamps so

as not to incline in the expansion due to heating.

• For Hot Domestic Water supply, an external hot water tank must be

connected to the boiler. In case of use with a hot water tank, the

three-way valve and hot water tank sensor in the product accessory

group must be used.

• The heater must be washed and cleaned of dirt before filling!

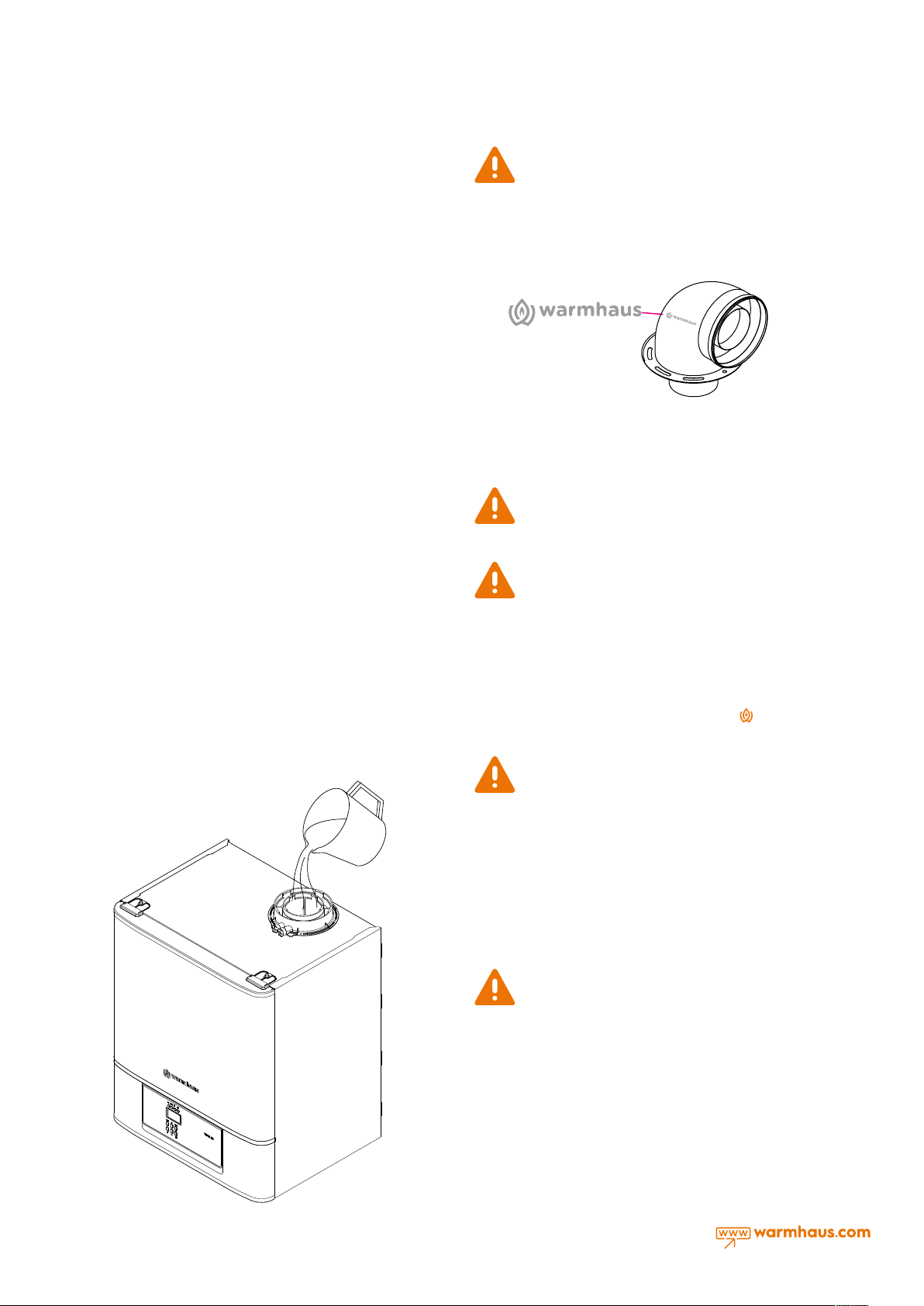

2.6. FILLING THE SIPHON FOR CONDENSATION LINE

The condensation siphon must be filled with water after completing

wall-hanging of the condensation boiler, electrical connections, heating

lines, hot domestic water connections and condensate drainage line

(Figure 10).

Condensation line outlet connection must be sealed.

However, against the risk of waste gas leak in the first

chimney-mounting of siphon in the boiler. Thus, the water in the siphon

will prevent the leakage of waste gas.

The tilt of the condensation water hose and line must always be

downward.

Figure 2.11 There is a Warmhaus log in the chimney elbow.

operation, pout about 1 litre of water into the chimney before

2.7. CONNECTION OF WASTE GAS CHIMNEY PIPE

SET AND ACCESSORIES

Chimney accessory of hermetic boilers sets to be used in

the waste gas installation should be original Warmhaus

sizes and restrictions given in the mounting instructions.

Authorized Service and therefore cannot be guaranteed!

The boiler should only be mounted with plastic material and the

original Warmhaus air intake and waste degazing device.

Plastic ducts cannot be installed outdoors, at intervals over 40 cm,

without proper protection against UV and weather conditions. Each

pipe is identified by a promoting and distinctive

the notes.

chimney sets and they should be used taking into account

If different waste gas pipes and/or accessories are used

other than original Warmhaus waste gas chimney pipes

and accessories, the boiler will not be started by the

Warmhaus sign in

12

Figure 2.10 Filling the condensation flusher

If more than one Viwa 90-150 boilers are connected in

parallel to the same hydraulic installation and operated as

cascade, it is necessary to use the product code for each

boiler is: Ø100 / 100 Waste Gas Chimney Block with 153.11.660.600040

product code or (Ø100-Ø100) Chimney Block products with

153.11.660.600068 product code must be used for each boiler. In the

same installation, the blocks should not be used together and the

same block product should be used for each boiler.

If the Viwa 90, Viwa 115, Viwa 125 and Viwa 150 boilers are used as

cascade systems and our blocking products are not used in each

boiler, boilers will not be started by our authorized service!

IMPORTANT

The following must be checked during staring the boiler:

- Make sure that there is no liquid or combustible materials

near the boiler.

- Ensure that the electrical connections are made correctly

and that the ground wire is connected to a good grounding system.

- Open the gas valve and check the durability of connections including

the burner, burner exchangers and heat exchangers.

- Ensure that the boiler is adjusted for operating for the supplied gas

type.

- Check that the chimney pipe in outlet of combustion products is not

blocked and is properly mounted.

- Make sure that any (safety) shut-off valve is open.

- Ensure that the system is filled with water and thoroughly ventilated.

- Check that the circulation pump is not jammed.

- Discharge the air that may be in the gas line, discharge the air in the

gas pipe by operating the pressure discharge valve at the gas pipe

inlet.

Ar

Waste Gas

C

53

13

C

Discharge with Concentric

Flue Connection

Cauton: In use of C13 type chimney, a 90°

cantilever gas directing set must be installed on

Figure 2.12 Hermetic (concentric) and

Chimney (Split-Flue type)

the cage end.

C83

Discharge to Building Chimney

with Split-Flue Connection

and Fresh Air Intake

For C8 type sealed boilers with combustion

a) overheating combustion products temp.:

b) CO2 content; 9.00% (tolerance +0.5%/-0.5%)

c) Chimney characteristics to which the boiler

can be connected depend on Figure 2.15.

d) Condensation water isn’t allowed to flow

Figure 2.15 Hermetic vertical Split-Flue

connection.

chamber;

<105 °C

into device.

C

53

Exhaust Gas Discharge and

Fresh Air Intake with Concentric

Flue Sets and Split Flue Sets

Cauton: Terminals should not be mounted against

building walls for supply of combustion air of C5

type sealed boilers with combustion chambers and

discharge of combustion products.

Figure 2.13 Hermetic concentric and vertical

Split-Flue connection.

C

Exhaust Gas Discharge from Building

Chimney with Split-Flue Kits and

Fresh Air Intake From The Outside

For C6 type sealed boilers with combustion chamber

a) for chimney, overheating combustion products temp.: <105 °C

content in nominal operating conditions; 9.00% (tolerance

b) CO

2

+ 0.5% / -0.5%)

c) dierence of the maximum permissible draught and the

maximum permissible pressure between combustion air inlet and

chimney gas outlet (including wind pressures): 120 Pa.

d) characteristics and applications of the duct system to which the

boiler can be connected;

1) Condensation water isn’t allowed to flow into device.

2) maximum permissible temperature of the combustion air; 40°C

3) maximum permissible recirculation rate in wind conditions is 10%.

Caution: Terminals should not be mounted against building walls for

supply of combustion air and discharge of combustion products.

Figure 2.16 Connection of hermetic split-flue

and building chimney

C33C33

Exhaust Gas Discharge Fresh Air

Intake with Split Flue Sets

Cauton: In case of using C33 type Split-Flue Set (for

horizontal and vertical types), the distance

between the exhaust gas outlet and the clean air

intake should be minimum 50cm, maximum 100cm.

Figure 2.14 Vertical Type Hermetic

Use with Split-Flue Set

B

23

Exhaust Gas Discharge from Building

Chimney with Split-Flue Sets and

Fresh Air Intake From The Inside

Figure 2.17 Chimney use with split-flue

set

2.7.1. Environmental Distances of Chimney Outlet Connections

See Figure 16 for positioning the outlet pipe of chimney set. The

chimney must be mounted in accordance with national and local

regulations.

Any part of the outlet pipe should not be blocked and should not

interfere with other connections. If the outlet pipe is passing 1000 mm

near a plastic or painted conduit or 500 mm near the painted eaves, an

aluminium guard of at least 1000 mm in length should be placed under

the conduit or eaves. The outlet pipe should be at least 2 m above the

surface that people can reach. In some weather conditions, the outlet

pipe may emit water vapor; so it should not be mounted in places

where this vapor may cause irritation.

It should be ensured that combustion products (waste gas) do not

enter the roof ventilation openings. The boiler chimney system can be

installed inside the room without the need to intervene on the outside

wall. To do this, especially in thick walls, a bed must be used in the wall

for lining the inner surface of the duct, through which the outlet pipe

passes through the wall.

13

Figure 2.18 Ø 80/125 mm Concentric Chimney Set

1. 90° elbow

2. Sealing gasket

3. Sealing gasket

4. Centring wire

5. Exterior chimney pipe

6. Inner wall blind flange

7. Outer wall blind flange

8. Interior chimney pipe

9. 60 Sealing gasket

10. Protection cage

11. Flange gasket

12. Flange connecting screws

13. Control measurement stopper

14. Fresh air control cover

• Concentric extension pipes and plug-in type

seal for elbows. To connect the possible

extension connections of the waste gas

chimneys to other elements of chimneys:

connect the male (straight) side of concentric

pipe or concentric elbow to the female

side (sealed side) of the previous part, in this

case make sure you have fitted the required

washer, so the connection will be tight and

integrity of parts of the set will be ensured.

Please note that in the case where

shortening of the discharge chimney

and/or extension is required, the

inner chimney must always be 5 mm ahead of

the outer pipe.

For safety reasons, the absorption/

discharge chimney of the boiler

should not be blocked, even if for

short-time or temporarily.

During installation of the horizontal

pipes, the pipe tilt must be kept

upwardly a minimum of 3%, dowelled

in every 3m and a retaining clamp must be

used.

Figure 2.20 Combi concentric chimney wall outlet for hermetic use.Figure 2.19 Installation of chimney set parts

All horizontally fitted ducts (air/flue)

should be fitted at a slight 2° or 3°

upwards incline to allow

condensate water drain to the boiler.

• The parts of standard horizontal flue

kit are available in "Concentric (Optional)

Chimney Accessories (Ø100/150 mm) for

VIWA 90, 115, 125 and 150".

The horizontal flue connections should

be assembled as to have an upwards

inclination of 2° or 3° as to allow the return

of condensate to the device.

o

3

Figure 2.21 Condensed boiler chimney tilt

Ø100/150 mm

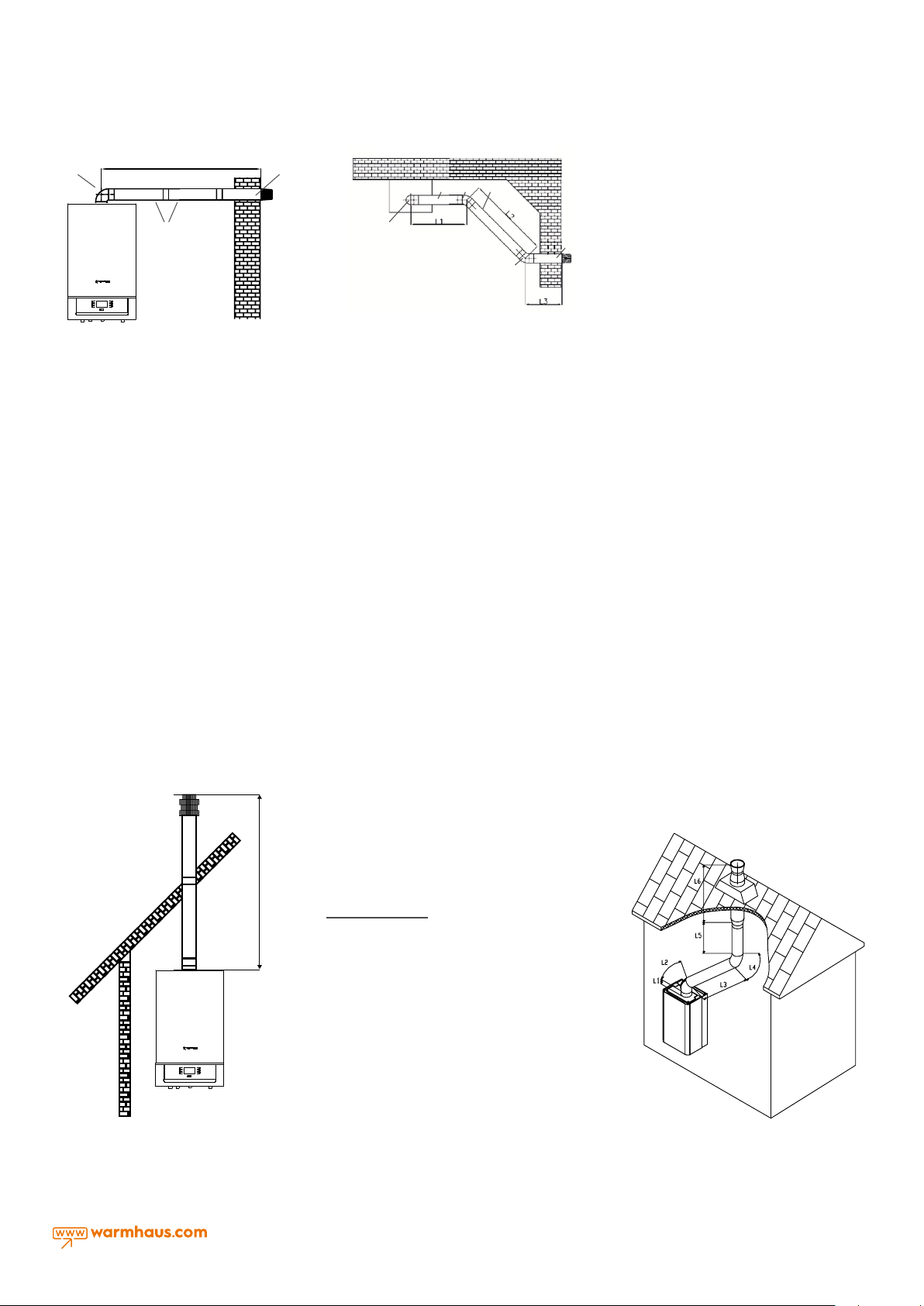

a + b + c + d < 19 m = (Viwa 90)

19 m = (Viwa 115)

18 m = (Viwa 125)

10 m = (Viwa 150)

d

b

a

Figure 2.22 II. Two 90° cantilever sample chimney ins-

tallation

c

a- Horizontal Chimney Set Elbow (90°)

b-Chimney Extension Pipe

c- Additional 90 ° Elbow

d-Horizontal Chimney Set Pipe

The total length of the

concentric chimney set must

not exceed 10m horizontally

with a single elbow. In additions, this

total length is reduced by 1 m for each

90° elbow use and 0.5m for each 45°

elbow use. Up to 3 90° elbow can be

used.

14

Ø100/150 mm

Lmax= 18 m (Viwa 90)

Lmax= 17 m (Viwa 115)

Lmax= 17 m (Viwa 125)

a d

Lmax= 10 m (Viwa 150)

b

Ø100/150 mm

a + b + c + d + e + f < 19 m = (Viwa 90)

19 m = (Viwa 115)

18 m = (Viwa 125)

10 m = (Viwa 150)

b c

d

a

e

a- Horizontal Chimney Set Elbow (90°)

b- Chimney Extension Pipe

c- Additional 45° Elbow

d- Standard Chimney Set Pipe

e- Additional 45° Elbow

f

f- Horizontal Chimney Set Pipe

Figure 2.23 Single 90° angled sample

chimney installation

Figure 2.24 III. Single 90° and two 45° angled

sample chimney installation

Connection of (Ø100 / 150 mm) Horizontal Concentric Chimney

Set and Mounting Horizontal Concentric Chimney Set to The

Boiler

Since your boiler is hermetic model, if it is used with concentric

chimney sets, it takes the air that it uses from the outside and emits

waste gases due to combustion to the outside from the same chimney

group. The use and installation of the chimney is very important

to avoid emission of waste gases which are extremely harmful, so

cautions should be taken into account when connecting chimney.

• Select the chimney necessary for the chimney connection from the

mounted place of your boiler and outside. If the horizontal/vertical

chimney set is insufficient, select the most appropriate elements from

our list of connection accessories, taking into account the warnings

mentioned in our operating manual.

• Fix the flange under Elbow part (1) in Figure 17 on holes on the boiler

by using the Flange Seal (10) and screwing with the flange connection

screws (11).

• Two sealing gaskets (2) from the concentric chimney set are placed in

the inner pipe slots at both ends of the 90° elbow.

• To group the chimney outlet terminal, intertwine the outer wall

(EPDM) gasket with chimney terminal as seen in Figure 17. After

intertwining the chimney outlet terminal from the outer side of wall and

previouslyopened holes insert the Internal Wall Connection Gasket (7)

in chimney terminal. Insert the other end of EPDM connection gasket

you have already inserted in 90° chimney elbow, into the chimney

outlet terminal Be careful that gaskets are placed properly.

2.7.2. Mounting with Vertical Concentric Chimney Sets

The boiler also has the possibility to connect vertically to the flat

and sloped roof by means of the accessories it has according to the

situation of the environment you will mount on. In straight connections,

(Ø100 / 150 mm) vertical chimney set should not exceed 11m.

Figure 2.25 Vertical chimney set mounting

Lmax= 11 m (Viwa 150)

Lmax= 19 m (Viwa 125)

In practice

Ø100/150 mm

Lmax= 20 m (Viwa 90)

Lmax= 20 m (Viwa 115)

L1 =0.3 m.

L2 =0.5 m. (45° elbow equivalent length)

L3 =4.5 m.

L4 =0.5 m. (45° elbow equivalent length)

L5 =4.7 m.

L6 =1.0 m.

L Total =11.5 m.

Correct in practice for Viwa 90,

Viwa 115, Viwa 125 but not suitable

in practice for Viwa 150.

Figure 2.26 Vertical chimney set

mounting practice

15

Loading...

Loading...