Warmhaus LAWA, LAWA PLUS Installation & User Manual

CONVENTIONAL COMBI BOILERS

INSTALLATION & USER MANUAL

LAWA &

LAWA PLUS

Lawa

LawaPlus

Enerwa E24

EnerwaPLUSE24

3

1. DEAR WARMHAUS

CUSTOMER

1.1. GENERAL WARNINGS

1.2. GENERAL WARRANTY CONDITIONS

1.3. GAS LEAKAGES

2. INSTALLATION PERSONNEL

SECTION

2.1. CONTENTS OF PACKING BOX

2.2. COMBI INSTALLATION RULES

2.2.1. General Rules for Installation

Places of Combi Boilers

2.2.2. Places Not Suitable for Installing

Hermetical Combi Boilers

2.2.3. Wall Installation of Combi and

Selecting the Installation Place

2.2.4. Dimensions and Connections

2.2.5. Natural Gas and LPG Connection

(Device Category I2H, II2H3P)

2.2.6. Flammable gas quality

2.2.7. In case of using LPG Tank

2.2.8. In case of using Bottled Gas

2.2.9. Radiator and DHW Use Installations

2.2.10. Exhaust Gas Flue Pipe Set and

Accessories Connection

2.2.11. Peripheral Distances of Flue Output

Connections

2.2.12. Installation with Horizontal Flue Sets

2.2.13. Installation with Vertical Flue Sets

2.2.14. Hermetic Flue Type Use

2.2.15. Installation at Partially Protected

Exteriors

2.2.16. Electrical Connections

2.2.17. Optional Controls: Room Thermostat,

External Weather Temperature Sensor

and Others

2.3. HYDRAULIC INSTALLATION RULES

2.3.1. Radiator (Heating) Water Structure

2.3.2. Filling/Emptying Radiator Installation

2.3.3. Circulation Pump

2.3.4. Controls for Initial Operation of Combi

2.3.5. Boiler Components

3. USER SECTION

3.1. GENERAL WARNINGS FOR USER

3.1.1. Use of Combi

3.1.2. External Weather Temperature Sensor

Use (Optional)

3.2. ON/OFF / STANDBY AND SUMMER

/ WINTER MODES SELECTION

3.2.1. On/Off/Standby Positions

3.2.2. Operation at Winter Position

3.2.3. Operation at Summer Position

3.2.4. Resetting the Combi (Re-Starting)

3.2.5. Shutting off the Combi

3.2.6. Selection of On/Off/Standby and

Summer/Winter Modes

3.2.7. On/Off/Standby Positions

3.2.8. Operation of Winter Position

3.2.9. Operation of Summer Position

3.2.10. Shutting off the Combi

3.2.11. Use with Room Thermostat (Optional)

3.2.12. External Weather Temperature Sensor

Use (Optional)

3.2.13. Customizing Combi Features

3.3. TROUBLESHOOTING

3.3.1. Failure Codes Table

3.4. RECOMMENDATIONS FOR

ECONOMICAL USE OF COMBI

3.5. ISSUES REQUIRED TO BE TAKEN

INTO CONSIDERATION

INDEX

4

We congratulate you for preferring the Warmhaus combi to maintain

your heating and domestic hot water comfort for long years and thank

for your trust. Warmhaus combi, manufactured in accordance with

European Union standards and advanced technology, are also being

imported to many countries. You can benefit from our Authorized

Technical Service network having occupational competency certificate

for all kinds of ordinary maintenance requirements for this product

manufactured with rigorous studies. Our Authorized Services guarantee

protection of your device performance as they always provide original

spare parts service. Carefully read this guide in order to use the combi

in an economic, comfortable and efficient way and keep as a source

of application.

In order to ensure efficient use, we initially recommend you to have

the installation performed by a certified dealer experienced and

competent in installation by the local gas authority.

1.1. GENERAL WARNINGS

Guide Book is an inseparable and integral part of the product and

should be delivered to the new user when the device is transferred.

The aforementioned book should be carefully protected and used

as well as be applicable when required as it contains important

information regarding installation.

Radiator and DHW installations should be engineered and

produced by a competent and certified engineering

company in accordance with measurements defined based

on laws by considering legal regulations in force.

Installation and Maintenance operations should be performed

by the expert personnel having adequate technical

knowledge in installations sector and occupational

competency certificate in accordance with legal regulations in

force. As the result of a false installation, dangers may occur which

the manufacturer company cannot be held responsible for and may

damage people, other live beings (animals, plants) or commodities.

Natural Gas Installation Project; One of the dealers authorized

by a gas company located at your city should be preferred for

performing project and etude studies.

In order to enable use of the combi with LPG tubes or LPG

tanks, conversation of the combi should be performed by our

authorized Warmhaus service. Project design and application

for LPG use should be performed by the company supplying

the tank in accordance with local and legal rules.

1.2. GENERAL WARRANTY CONDITIONS

The Manufacturer company shall not have any

responsibilities within or out of the agreement scope due

to failures arising from failing to follow legal regulations in

force and standards and information given in this guide book (and

information and instructions provided by the manufacturer under

any circumstances) during installation, use or maintenance

operations and device warranty shall also be void.

Only the authorized Warmhaus Service is authorized to make

the electrical connection of Combi and supplying electricity

to the combi.

The maintenance and repairs as the result of failure of the product

within the warranty period due to material, production and installation

errors shall be performed as free of charge without claiming any

workmanship costs and spare part payments.

This device should only be used for its designed intended

purposes (to be used in closed-circuit heater

installation and production of open circuit domestic hot

water production). All kinds of other uses are not suitable as well as

may create a potential danger.

Manufacturer shall not be responsible for damages occurring due

to interventions, false installation and initial starting performed by

unauthorized persons and warranty scope shall be void. As the Combi

is a device having heating system, domestic hot water, natural gas/LPG

and electrical connections, do not make and have any interventions

made without the authorized service.

Device maintenance operations should be performed by the

authorized and expert technical personnel, and

It is strictly forbidden to try to detect the gas leakage with

the help of flame.

This device has been manufactured to be installed in the

country given on the technical registry label. Performing the

installation in countries other than the country written on the

table may damage individuals, animals and commodities.

Connections sealed with bolt paint must not be opened

or changed by a person who is absolutely expert and not

approved service. These seals prove that the bolts required

for perfect and safe operation have not been changed. If the seals are

damaged, the guarantee of the device will come to an end!

Combis bear CE mark in accordance with below given directives:

- Gas Directive 2009/142/EEC

- Efficiency Directive 92/42/EEC

- Electromagnetic compatibility

- Directive 2014130/EU

Please visit the below given web site of Warmhaus for acquiring more

detailed information regarding legal regulations on installation of gas

fired heating devices: www.warmhaus.com

Manufacturer: ÇELİKPAN Isıtma ve Soğutma Sistemleri Tic. A.Ş. Bursa

Organize Sanayi Bölgesi Park Cad. No:10 16140 Nilüfer-Bursa / Türkiye

WARMHAUS

Warmhaus Authorized Technical Service Centres maintain an assurance

regarding quality and professionalism on that issue. ÇELİKPAN is not

responsible for damages arising from repairs, part replacements and

maintenances performed by third persons and companies and combi

remains out of the warranty scope under such conditions.

ÇELİKPAN A.Ş. reserves the right to make all kinds of technical and

commercial amendments without giving information and rejects all

responsibilities depending on misspelling.

1. DEAR WARMHAUS CUSTOMER

1015 16

5

HOW TO MOVE WHEN NATURAL GAS ODOUR IS DETECTED...

1.3. GAS LEAKAGES

2. INSTALLATION PERSONNEL SECTION

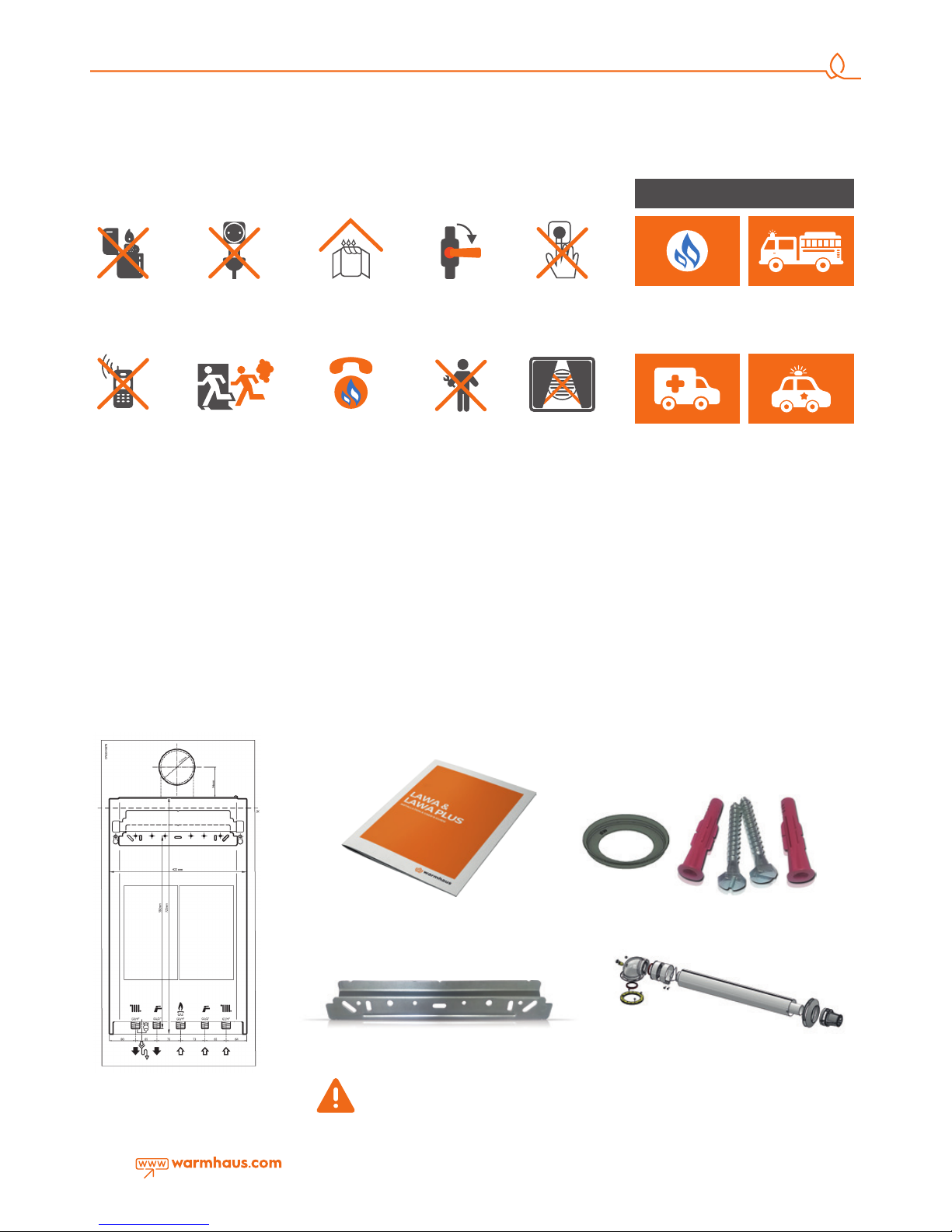

2.1. CONTENTS OF PACKING BOX

Warmhaus is sold as two boxes containing combi

and flue set. Combi box contains below listed

materials and smaller box contains exhaust

gas flue pipes.

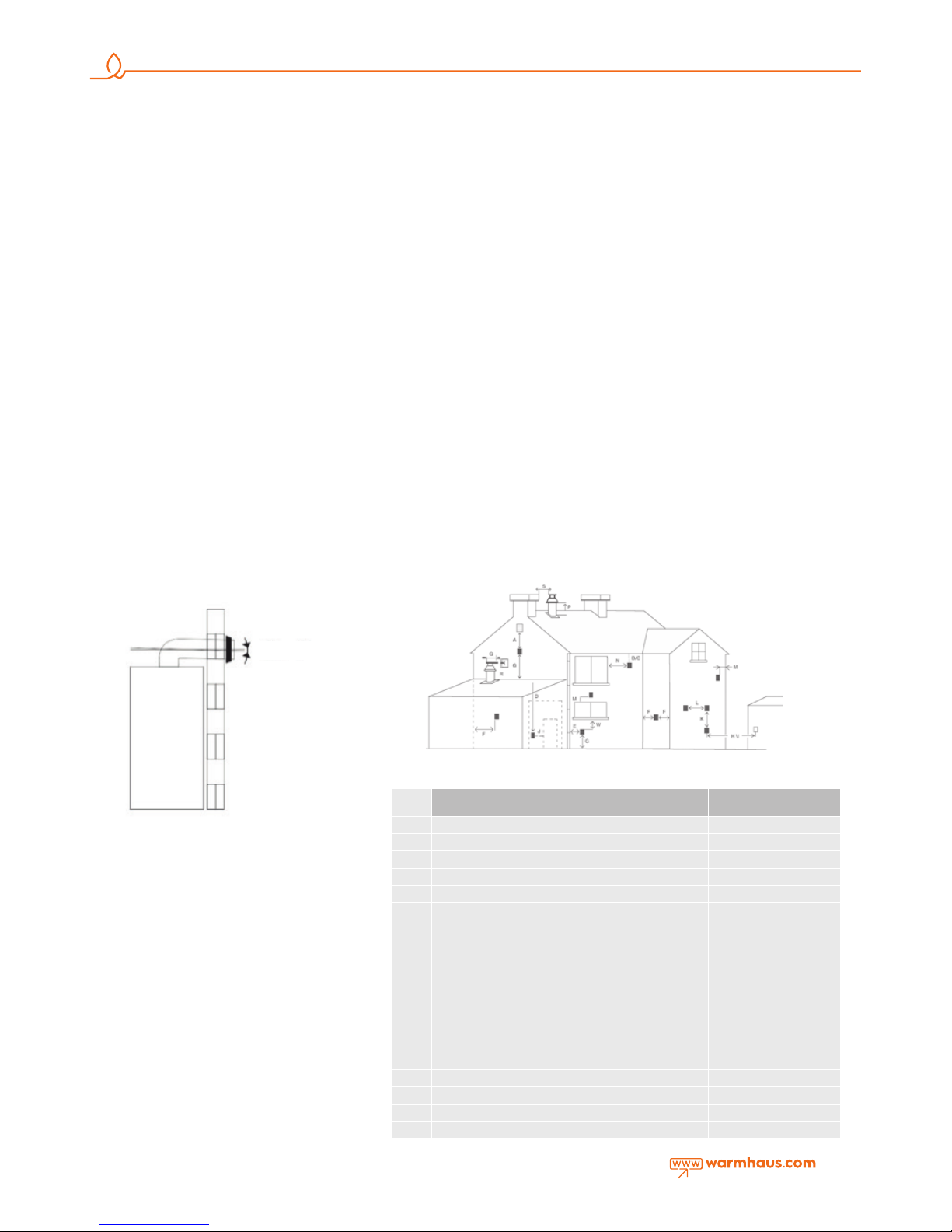

I. Installation Scheme (Figure 1)

II. User Guide (Figure 2)

III. Connection Accessories (Figure 3)

a. 1 Throttle screw (installed at flue output).

b. 2 Hanger screws

c. 2 Dowels

IV. Hanger Plate (Figure 4)

V. Exhaust Gas Flue Set (Figure 5)

Figure 1 Installation scheme

Figure 4 Hanger plate

Figure 3 Connection accessories

Do not leave packing materials (plastic,

nylon, bags, etc.)within a child’s reach

– be safe.

Figure 2 Installation Notes

Figure 5 Exhaust gas flue set

Do not use lighter

- matches.

Close valves of

devices operating

with natural gas and

your gas meter.

Immediately

evacuate the place

with gas odour.

Natural Gas

Emergency Line from

your neighbour or

another suitable place.

Do not make any

intervention on

installation.

Never close culverts

ensuring discharge

of the gas from the

environment in case of

a natural gas leakage.

Do not use the

door bell.

Do not use phones

in case of a natural

gas leakage. It may

create sparks.

Do not light on and

off lamps and other

electrical devices or pull

off the plug.

Ventilate the

environment by

opening doors and

windows.

AMBULANCE POLICE

DURING EMERGENCIES

NATURAL GAS

EMERGENCY

FIRE

DEPARTMENT

INFORMATION: You can visit web sites of

local gas authorities and NATURAL GAS

EMERGENCY sections.

Advice: Please take note local emergency

phone numbers.

6

2.2. COMBI INSTALLATION RULES

2.2.1. General Rules for Installation Places of Combi Boilers

No restriction is available for places where Hermetic (C typ) combi

is installed (devices may be installed regardless of the room volume

and ventilation type). Also, they may be installed in partially protected

areas such as balconies, terraces provided that precautions are taken to

ensure boiler is frost proof. Combi should be soundly installed against

a building wall. A flexible connection piece should be used between

the combi and gas line. Flex lengths to be used in A, B and C type

devices should not exceed dimensions allowed by local gas authorities.

Flue outputs of hermetic combis must be connected to ventilated

places with air circulation. Installation (positions of pipe output opening

based on various forms, vertical, horizontal minimum distances, cross

section areas of channels if given to channels, etc.) must be carried out

according to regulation standards, current legislation and in compliance

with local technical regulations and the required technical procedures.

2.2.2. Places Not Suitable for Installing Hermetical Combi Boilers

• Stairways of Buildings,

• Corridors available for general use, ventilation ways and shafts, lofts,

attics, emergency exit doors, cellars, hall and similar communal use

areas,

• Yards between buildings,

• Narrow cornices

• Over flue walls,

• Enclosed balconies,

• Open balconies (except being located in a cabinet approved by the

device company),

• Below protruding structure parts preventing exhaust gas output,

• Places directly subjected to wind resistance,

• It is forbidden to install Hermetic combi (C type) in openings

providing clean air to other units.

2.2.3. Wall Installation of Combi and Selecting the Installation

Place

• Wall installation for the combi boiler should be well secured.

• The hanger plate given as standard with the combi should be

installed according to the technique to a full or semi-full brick wall

according to installation scheme and with connection screws and not

to be used for other purposes.

• If different materials are used for installation, the combi shall be

rendered out of the warranty scope.

• If the wall of installation is not a brick wall, additional support will be

required..

• Combi should be installed on a wall resistant to fire.

• 1,8 - 2,2 m height is recommended for installation of the combi

hanger plate.

• For places with limited installation space, combi should be installed

at minimum of 30 cm height from ground and by leaving at

least 5 cm distance from both sides in order to allow easy access for

the service technician.

• Combi installation must not performed in environments containing

explosive, flammable substances and acid fumes.

• Installation cannot be made near or ovens, radiators or heater

devices.

• Hermetic combis can be installed in cabinets but at least 5 cm

should be left at both sides.

• If installing in a fitted kitchen at least 30 cm distance should be left

under the combi.and 5 cm each side for access.

• Do not put electronic devices, corrosive tools, components furniture

or equipment below the combi against as there may be a risk of

water leakage from the combi safety valve during installation.

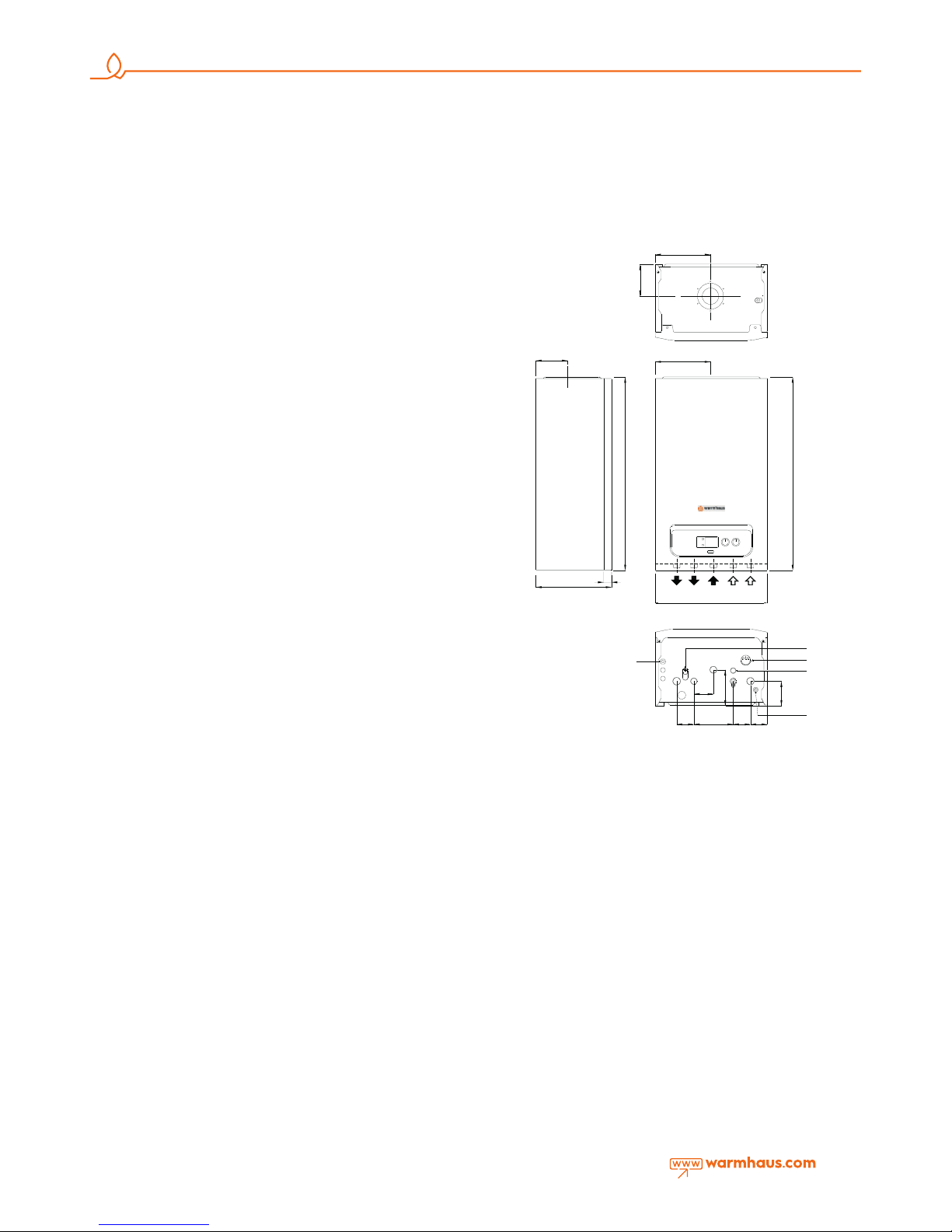

2.2.4. Dimensions and Connections

Figure 6 Lawa Combi dimensions connections

288

30

118

725

725

208

208

118

94

136

74

65 148

65

65

J

G

F

H

I

420

A B

C

D E

A CENTRAL HEATING FLOW

B DOMESTIC HOT WATER OUTLET

C GAS INLET

D DOMESTIC HOT WATER INLET

E CENTRAL HEATING RETURN

F FILLING VALVE

G MANOMETER

H PRESSURE RELIEF VALVE OUTLET

I DRAIN POINT

J 230V 50HZ AC

WARMHAUS LAWA

Warmhaus Lawa

A: Central heating flow

B: Domestic hot water outlet

C: Gas inlet

D: Domestic hot water inlet

E: Central heating return

F: Filling valve

G: Manometer

H: Pressure relief valve outlet

I: Drain point

J: 230V 50HZ AC

7

2.2.5. Natural Gas and LPG Connection

(Device Category I2H, II2H3P)

Our combi devices are manufactured to be operated with methane

gas (G20) and L.P.G. Gas supply pipes should be equal to or higher

than 3/4"G combi connections. Prior to making the gas connection, a

thorough internal cleaning should be made to all fuel supply installation

pipe furnishings as possible wastes may distort smooth operation and

reliability of the combi. Only a mains gas supply can be used with the

combi (see the label located on the combi device). In case of any

conversions to the supply, changes should only be made to the combi

by an authorised professional. Also, in case of reduced pressure, the

network dynamic pressure (methane or LPG) used for supplying the

combi should be carefully controlled and will impact the boilercombi

strength. Ensure that gas valve connection is correct. Flammable gas

supply pipe should be able to supply correct adequate gas amount to

the boiler when the combi is at full power and be projected and sized

according to force and local gas company specification and instructions

in order to guarantee the device efficiency. Connection system should

comply with gas company legal regulations.

2.2.6. Flammable Gas Quality

The combi is designed to be used with pure fuel not containing any

foreign substances; therefore, required filter systems must be available in

the gas supply line (for ensuring purification of the fuel).

2.2.7. In Case of Using LPG Tank

LPG use is recommended for heat requirements over 24 kW. New LPG

stock tanks may contain settled gas residues (nitrogen) however, that

fouls the mixture assigned to that device and may cause abnormal

operations.

- Various alloy layers may be formed during transit of LPG gas in

tanks depending on mixture compositions. That causes a change in

heating power of mixture assigned to the device and may compromise

efficiency of the device.

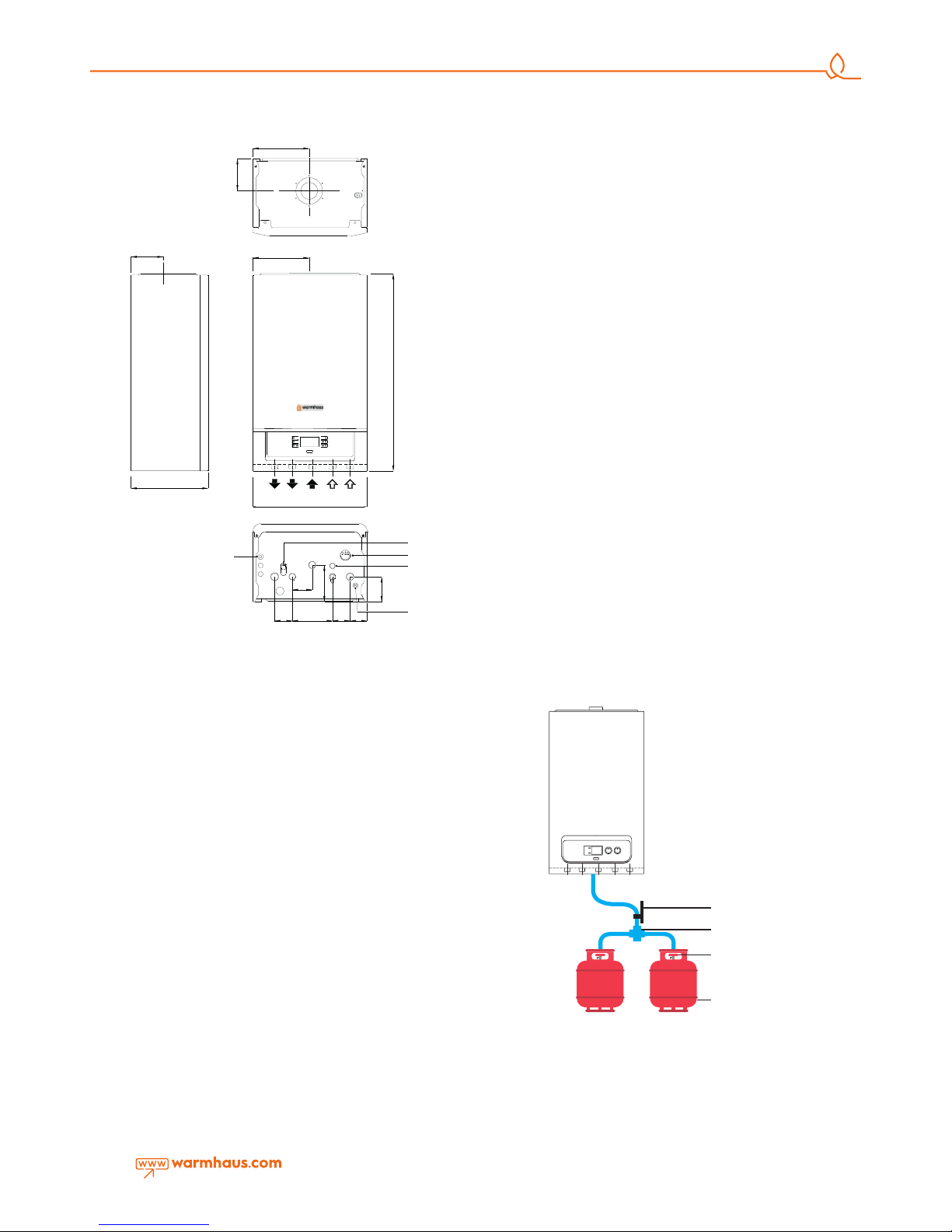

2.2.8. In Case of Using Bottled Gas

• 300 mmSS pressurized hood should be used for LPG.

• 500 mmSS hood should not be used.

• 370 mmSS pressurized hood should be used for Propane.

• Do not place tubes in cold places at risk of snow or.

• Do not place tubes in hot placescontaining ovens or

• Do not make connections with single tubes and use

LPG collector set for double, triple uses.

• The distance between the collector and tube should

be maximum 125 cm.

• Copper pipe installation should not used for distances

longer than 125 cm.

• Hose connection ends should be tightened with clamp

and no other tools should be used.

• Gas installation rules with use of LPG tank and industrial tubes should

comply with local standards and to be performed by expert installation

teams and certified by the company undertaking the construction. In

case of failing to fulfil these conditions, combi will not be covered

under warrantee by Warmhaus Authorized Services.

Figure 7 LawaPlus Combi dimensions and connections

LPG LPG

Ball Valve

COLLECTOR

370 mmSS

2 kg

Hood

12 kg or

24 kg

LPG TUBE

Figure 8 Combi bottled gas connection

Warmhaus LawaPlus

A: Central heating flow

B: Domestic hot water outlet

C: Gas inlet

D: Domestic hot water inlet

E: Central heating return

F: Filling valve

G: Manometer

H: Pressure relief valve outlet

I: Drain point

J: 230V 50HZ AC

420

725

MODE

RESET

+ +

208

208

118

118

288

A B

C

D E

94

136

74

65 148

65

65

G

F

H

I

A CENTRAL HEATING FLOW

B DOMESTIC HO T WATER OUTLET

C GAS IN LET

D DOMESTIC HOT WATER INLET

E C ENTRAL HEATING RETURN

F FILLING VALVE

G MANOMETER

H PRESSUR E RELIEF VALVE OUTLET

I DRAIN POINT

J 230V 50HZ AC

J

WARMHAUS LAWA PLUS

8

2.2.9. Radiator and Domestic Hot Water Installations

Radiator and ground heating installation should be constructed in

accordance with technical specifications and heat loss calculation.

Radiator type and amount and ground heating installation pipe amount

should comply with the heat loss calculation.

• Radiator installation should be designed as resisting to at least 6 bars.

• If the city grid pressure is higher than 6,5 bars, pressure reducer must

be installed.

• It is recommended to construct the radiator installation as double line

and without using bends and joints as much as possible.

• Strainer filter must be installed in radiator return and tap water (city

grid) input line.

• For example; as the radiator cycle's 8 litres expansion (24 kW) tank

can support maximum (80 ⁰C in radiator system) 140 litre and

(55. ⁰C in ground heating system) 170 litre installation water expansion,

additional expansion tank should be used for larger installation volumes.

170 litre installation water expansion, additional expansion tank should be

used for larger installation volumes.

• If the room thermostat and thermostatic radiator valve will be used

together; thermostatic valve should not be installed in radiators in the

place where room thermostat is available.

• Cross connection must be made for efficient functioning in radiators

longer than 1,5 m.

• Covers should be used for radiator and domestic hot water wall

passages and fixed with wall clamps to prevent expansions due to

heating.

• Combi can function under minimum 0,5 bar domestic hot water

pressure and that corresponds to a very low flow rate and therefore,

it shall not possible to adjust the requested domestic hot water

temperature. For this reason, domestic hot water line should be installed

at shortest distance with pipe having at least ½” internal diameter and

by using bends as low as possible. At least 1 bar pressurized grid input

water should be supplied to ensure adequate domestic hot water.

Hydrophore should be used if required.

• Prior to filling the radiator installation, it must be flushed and all wastes

must be cleaned

2.2.10. Exhaust Gas Flue Pipe Set and Accessories Connection

Flue accessory sets to be used in exhaust gas installation of Hermetic

combis should be original Warmhaus flue sets and they should be used

according to installation instructions.

2.2.11. Peripheral Distances of Flue Output Connections

See Figure 10a for placement of flue set output pipe.

Flue should be installed in accordance with national and local directives.

No part of the output pipe or connections should be blocked. If the

output pipe passes 1000 mm nearby of a plastic or painted groove

or 500 mm of painted fringes, an aluminium shield with at least 1000

mm length should be placed below the groove or fringe. Output pipe

should be at least 2 m over surfaces within reach by individuals.

Under certain weather conditions, output pipe may emit water vapour;

installation should not be performed at places where this vapour may

cause discomfort.

Exhaust gases should be prevented from entering flue ventilation

spaces. Flue system of combi may be installed from inside the room

without requiring intervention from the external wall. For that reason, a

housing should be installed in the wall for lining the internal surface of

channel wherein the output pipe passes through the wall, particularly

for thick walls.

Figure 9 Condensing combi flue slope

Figure 10 Flue peripheral positions

Flue Position Minimum Distance

A

30 mm under a window

B

Under water groove 75 mm.

C

Under fringes 20 mm.

W

Under balconies 200 mm.

E

To vertical water discharge pipes 150 mm.

F

interior or exterior corners 300 mm.

G

At ground, roof or balcony level 300 mm.

H

On another wall corresponding to the flue 600 mm.

S

To another flue

To another wall than the garage wall

1200 mm.

J

To another wall than the garage wall 1200 mm.

R

To another flue than the same wall (vertical) 1500 mm.

Q

To another flue than the same wall (vertical) 300 mm.

M

On another window/culvert

On another window /culvert vertically

300 mm.

P

On the roof level 300 mm.

F

To an adjacent wall 300 mm.

I

To the window on adjacent wall 300 mm.

L

To another flue 1000 mm.

The air flue terminal

should be fitted at %3

downwards incline to

prevent any water drop

or condensation water

from entering the boiler

Bevel 3⁰

9

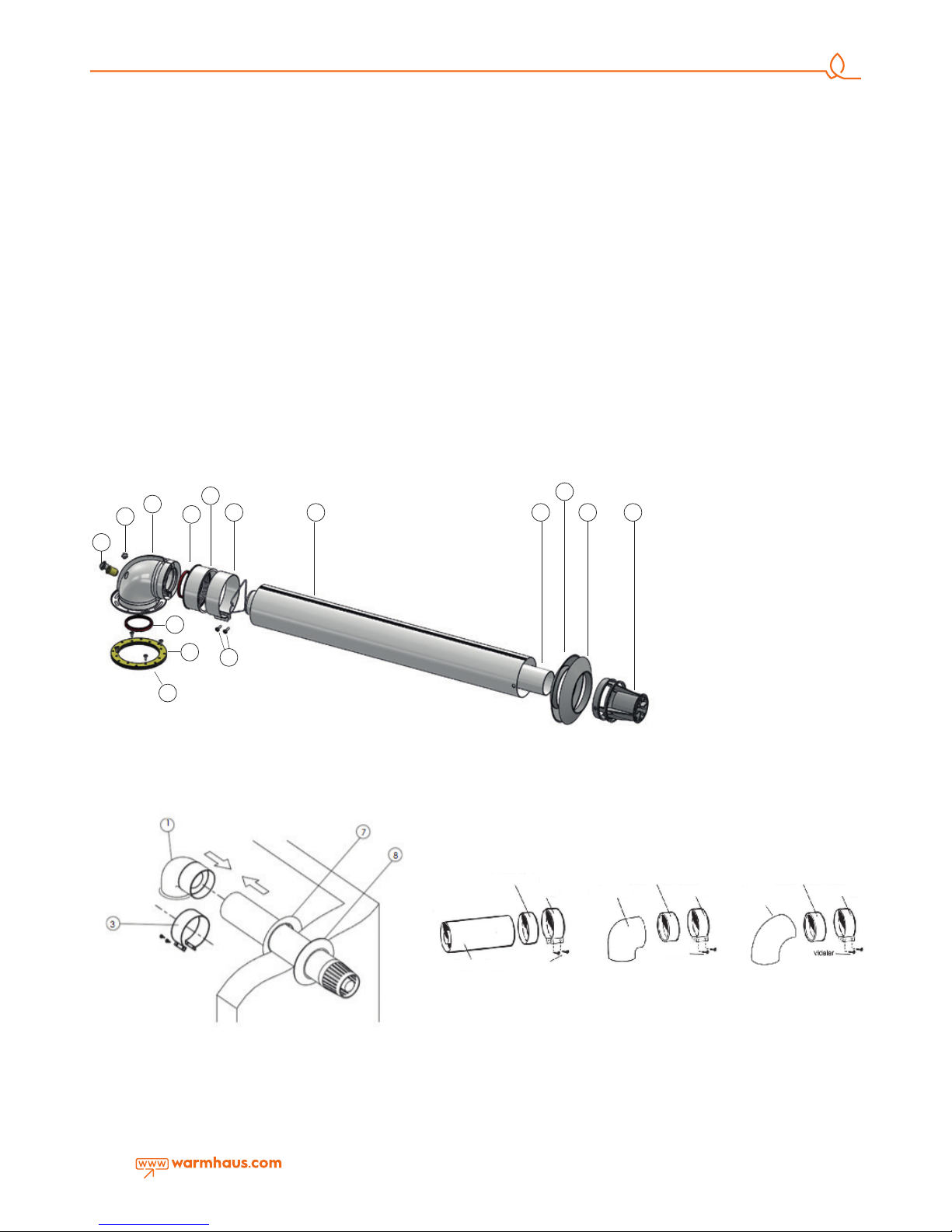

2.2.12. Installation with Horizontal Flue Sets

Connecting Horizontal Hermetic Flue Set to the Combi

Since your combi is a hermetic model, it takes the used air from

outsideand discharges exhaust gases created as the result of burning

through the same flue group. In order to prevent emission

of excessively harmful exhaust gases, flue usage and installation is very

important, therefore warnings should be taken into consideration when

flue connections are being performed.

• Make required flue selection for the external flue connectionIf the

standard flue set is not adequate, please select most suitable elements

from our list of connection accessories considering warnings given in

our user guide.

• Fix the flange under the Bend piece (1) by using the Flange Bolt (10)

via Flange Connection Screws (11) to holes on the combi.

• 2 impermeability bolts within the hermetic flue set (2) are placed into

internal pipe slots at both ends of the 90° Bend.

• Place the EPDM Connection Bolt (8) on the 90° bend contacting with

the restrictive set within the bolt.

• Place the exterior wall (EPDM) bolt into the flue terminal as seen in

Figure 11a for grouping the flue output terminal. After placing the flue

output terminal through exterior of wall and the previously made hole,

fix the Interior Wall Connection Bolt (7) into the flue terminal. Place

other end of EPDM connection bolt installed on 90° flue bend of your

combi to the flue output terminal and the clamp (3) should be insatlled

on the EPDM connection bolt and slightly tighten with screw (Figure 12).

Then fit the 90° bend on flue connection flange and fix with tightening

screws. Finally, after tightening screws placed on EPDM bolt and left

loose, push the interior wall connection bolt on the wall surface and

ensure flue and wall impermeability.

In case the hermetic flue set available in the product package does

not have adequate length, hermetic flue accessories should be ordered

from an authorized Warmhaus dealer according to requirements, nonoriginal hermetic flue accessories should never be used.

- Hermetic flue set accessories for horizontal connection;

a) Extension pipe (1000 mm), EPDM bolt, clamp and clamp screws.

b) 90° bend, EPDM bolt, clamp and clamp screws.

c) 45° bend, EPDM bolt, clamp and clamp screws.

1. 90° bend

2. Sealing gasket

3. EPDM connection bolt

4. Clamp

5. Exterior flue pipe

6. Interior flue pipe

7. Interior wall closing flange

8. Exterior wall closing flange.

9. Protection cage

10. Flange gasket

11. Flange connection screws

12. Clamp screws

13. Fresh air control cap

14. Control measurement cork

Figure 12 Hermetic combi homocentric flue wall output

Figure 13 Installation of flue set pieces

11

10

14

13

1

2

3

4 5 6 8 9

7

2

12

Figure 11 Hermetic combi homocentric flue set.

EPDM Sealing Ring

Metal collar Metal collar

Metal collar

Screw

Screw

90° Elbow

45° Elbow

EPDM Sealing Ring for 90° Elbow EPDM Sealing Ring for 45° Elbow

Concantric Extension

Loading...

Loading...