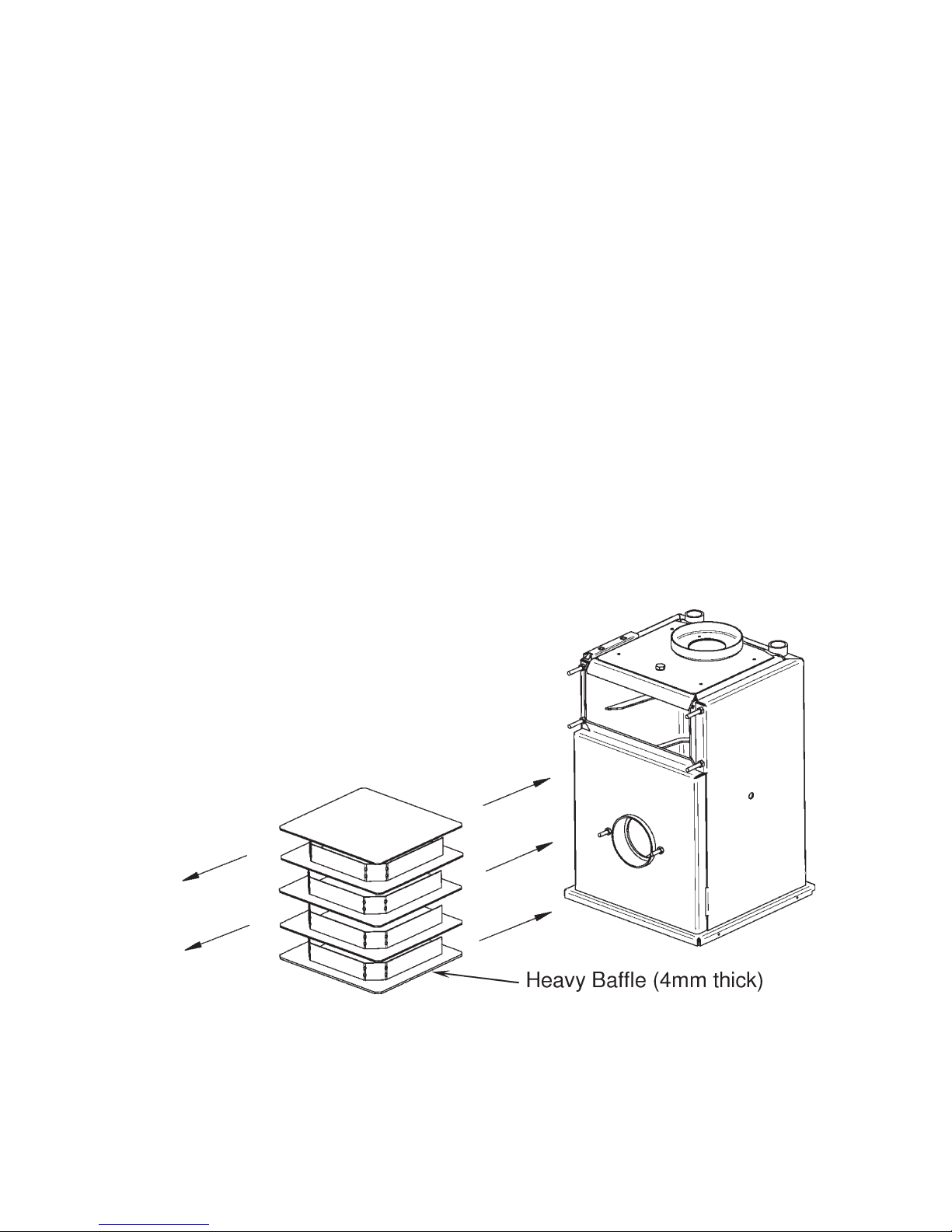

WarmFlow U120, U-Series UP 70, UP90, UP120, US70 Owner's Manual

...

Page 1

Contents Page

User Instructions .....................................................................................................................................................................

2

Combi Boiler Pre-Installation Requirements ........................................................................................................................

4

1.0 General Information

1.1 Introduction .....................................................................................................................................................

5

1.2 General Requirements .....................................................................................................................................

5

1.3 Combi General Requirements ..........................................................................................................................

6

1.4 Baffle Positioning .............................................................................................................................................

6

1.5 Components ...................................................................................................................................................

7

2.0 Technical Details

2.1 Combi Sequence of Operation Flow Chart ....................................................................................................17

2.2 Dimensions ...................................................................................................................................................18

2.3 Flue Options & Dimensions ............................................................................................................................

23

2.4 Technical Data ...............................................................................................................................................

24

3.0 Electricity Supply & Wiring Details

3.1 Dual-Safe Thermostat (Non-Combi Models) ..................................................................................................

33

3.2 RDB Burner Control Box ...............................................................................................................................

33

3.3 Combi Wiring Details .....................................................................................................................................

34

3.4 Installation of a Warmflow Combi Optional Programmer (PC1) .......................................................................

37

3.5 Remote Timers for Combis ............................................................................................................................

38

3.6 Optional Programmer (PU1) for Non-Combi Models ......................................................................................

39

4.0 Oil Supply

4.1 One Pipe Gravity System ...............................................................................................................................

43

4.2 Two Pipe System ...........................................................................................................................................

44

4.3 De-aerator System ........................................................................................................................................

44

4.4 One Pipe Lift System .....................................................................................................................................

45

5.0 Flues

5.1 Installation of Balanced Flues

.........................................................................................................................46

5.2 Conventional Flues ........................................................................................................................................

48

5.3 Low Level Balanced Flue Terminal Positions ..................................................................................................

48

6.0 Air Supply for Combustion & Ventilation

6.1 Open Flue Boilers ..........................................................................................................................................

50

6.2 Balanced Flue Boilers – Boilers in a Compartment .........................................................................................

50

7.0 Installation Requirements

7.1 General Requirements ...................................................................................................................................51

7.2 Sealed Systems ............................................................................................................................................

52

7.3 Combi Domestic Hot Water ...........................................................................................................................

53

8.0 Burners

8.1 RDB Burner ...................................................................................................................................................

54

8.2 Oil Pump .......................................................................................................................................................

54

8.3 Electrode Setting ...........................................................................................................................................

55

8.4 Burner Start-Up Cycle ...................................................................................................................................

55

8.5 Air Damper Adjustment .................................................................................................................................

55

9.0 Commissioning & Servicing

9.1 Commissioning

..............................................................................................................................................56

9.2 Servicing .......................................................................................................................................................

56

10.0 Burner Fault Finding

10.1 Riello RDB .....................................................................................................................................................

57

11.0 Combi Fault Finding

11.1 Central Heating .............................................................................................................................................

58

11.2 Domestic Hot Water ......................................................................................................................................

59

12.0 Optional Boiler Mounted Digital Timer

12.1 Operating Instructions ...................................................................................................................................

60

13.0 Spares

13.1 RDB 2.2 Spares ............................................................................................................................................

64

13.2 Pipe Spares ...................................................................................................................................................

65

13.3 Short Parts List – Boiler .................................................................................................................................

67

14.0 Your Guarantee, Terms & Conditions .....................................................................................................................

68

Commissioning/Service Record .............................................................................................................................69

Page 2

USER INSTRUCTIONS

Dual Thermostat

The radiator temperature is regulated via the

boiler control thermostat. The thermostat is user

adjustable from 55°C at its minimum setting (dial

‘0’) to 85°C at its maximum setting (dial ‘5’). In

order to provide an additional level of safety there

is a high limit thermostat which has a cut off point

of 110°C; this is factory set and is not adjustable.

If thermostat trips it needs to be reset manually.

High Limit Thermostat Reset

If the high level thermostat trip has operated,

remove the reset cover by using a coin or

screwdriver (turning anti clockwise) and press the

small red button now exposed. Do not press the

reset button while the boiler is still hot as this will

cause damage to the thermostat.

Burner Lockout

When the pressure jet oil fired burner stops after

failing to fire the red reset button will be illuminated.

This indicates that there is a fault or there is no

fuel getting to the burner. The house holder should

only reset the burner twice in succession. If the

burner continues to lockout contact Warmflow or

your service engineer.

System Pressure – System & Combi Boilers

When the boiler is connected to a sealed system

the system pressure should be periodically

checked. The minimum pressure, as indicated by

the black needle, is 0.5 bar when the boiler is cold

and 2.5 bar when the boiler is at normal operating

temperature. If the pressure is outside this range

contact Warmflow or your installer.

Control Thermostat

High

Limit

Reset

Notes

USER INSTRUCTIONS

Dual Thermostat

The radiator temperature is regulated via the

boiler control thermostat. The thermostat is user

adjustable from 55°C at its minimum setting (dial

‘0’) to 85°C at its maximum setting (dial ‘5’). In

order to provide an additional level of safety there

is a high limit thermostat which has a cut off point

of 110°C; this is factory set and is not adjustable.

If thermostat trips it needs to be reset manually.

High Limit Thermostat Reset

If the high level thermostat trip has operated,

remove the reset cover by using a coin or

screwdriver (turning anti clockwise) and press the

small red button now exposed. Do not press the

reset button while the boiler is still hot as this will

cause damage to the thermostat.

Control Thermostat

High

Limit

Reset

Reset

Notes

Burner Lock Out Reset

System Pressure

Page 3

Filling Loop

If the system pressure falls below the minimum

(eg, removal of radiator for decorating purposes)

then the system should be topped up using the

filling loop valve. After the system has been topped

up the pressure gauge should read 1 bar when

the system is cold. The valve must be fully closed

and the filling loop flexible removed from the valve,

expect a small water loss from the pipe.

Combi Control Panel

The heating control thermostat is user adjustable

from 55°C to 85°C. In order to provide an

additional level of safety there is a high limit

thermostat which has a cut off point of 110°C;

this is factory set and is not adjustable. The high

limit thermostat is located under the control

panel to the left hand side, press button to reset.

As standard the panel is fitted with two on/off

selector switches to control hot water and central

heating. These switches can be replaced by the optional two channel digital

programmer, instructions for use are provided in the main boiler handbook.

This boiler must be serviced annually. Contact Warmflow for further

details.

In the event of a breakdown please contact your commissioning engineer

who should then contact our service department whilst at your home, to

report the fault.

High Limit

Reset Button

Underneath

Filling

Loop

Valve

Flexible

Filling

Loop

Hose

Control Thermostat Knob

Page 4

BEFORE FITTING A COMBI BOILER

THE INSTALLER MUST CHECK:

1. What the maximum hot water demand placed on the boiler is likely

to be. Not every installation is suitable for a Combi boiler. Systems

requiring very high hot water flow rates may be better suited with an

unvented cylinder.

2. That the mains are capable of supplying up to 24 litre/min with a

minimum dynamic pressure of 1.8 bar at the boiler. This is to ensure that

the boiler can achieve its maximum output. To protect the appliance

and to prevent excessive flow rates, a pressure reducing valve must be

fitted to limit the maximum supply pressure to 3 bar.

3. Where the mains water pressure is supplied via a borehole pump and

accumulator the pressure variation must not affect the thermostatic

mixer valve. Contact Warmflow for further details.

4. The hardness of the mains water supply. Systems with hard water must

be fitted with a suitable chemical scale preventer (eg Fernox Quantomat

or Combimate).

5. That the flow from any one hot water outlet does not exceed the

maximum recommended. This applies particularly to baths which are

usually fitted with larger taps and larger bore supply pipes. It may be

necessary to restrict the flow to these taps by reducing the bore of the

supply pipework (eg 15mm) or by fitting a restrictor into the pipework.

6. That any outlet when opened does not starve all the other outlets of hot

water. If more than one outlet is open at the same time then the total

flow from all the outlets should not exceed the maximum flow rate of

the boiler.

7. That any showers being supplied with hot water by the boiler are

compatible with this type of appliance.

It should be noted that the boiler has been factory fitted with an

18 litre/min flow restrictor.

The manufacturer’s guarantees are void if the appliance is not installed

and commissioned in accordance with the recommendations made

herein.

Page 5

1.0 General Information

1.1 Introduction

Note: All our domestic appliances have been independently tested and

accredited as exceeding the minimum SEDBUK efficiency levels required for

their type, in compliance with the Building Regulations Approved Document

L1A, L1B for England and Wales, the Building Standards (Scotland)

Regulations Section 6, Part F Northern Ireland and Part L Republic of

Ireland.

Warmflow standard efficiency boilers are designed for use only on fully pumped

(sealed or open-vented) heating systems and to burn Class C2 kerosene and

Class D gas oil. Note that with class D gas oil the flue MUST exhaust at more than

2m above the surrounding ground level. The low-level flue supplied as standard with

all Kabin Pak models is NOT suitable for Class D gas oil. Alternative options are

available – please contact Warmflow.

As standard the Combi and System boilers are fitted with a system expansion

vessel, circulating pumps, filling loop, pressure gauge and safety valve. An optional

7-day electronic programmer kit is also available for all Utility boiler models.

The Combi can provide at mains pressure domestic hot water without the need for

a storage cylinder.

The manufacturer’s guarantees are void if the appliance is not installed and

commissioned in accordance with the recommendations made herein.

1.2 General Requirements

The installation of the boiler must be in accordance with the following regulations.

BS5410 : PART 1 Code of practice for oil firing.

BS5449 : PART 1 Forced circulation hot water systems.

BS7593 : Treatment of water in domestic hot water central heating systems.

Current Building Regulations Part J England and Wales

Section 3 Scotland

Part L Northern Ireland

Part J Republic of Ireland

Current IEE Regulations

BS7074 : PART 1 Application Selection & Installation of Expansion Vessels

The heating system should be installed by a competent installer in accordance with

the recommendations laid down by HVCA, OFTEC and sound engineering practice.

In order to comply with the building regulations OFTEC forms CD10 for

installations and CD11 for commissioning should be left with the customer.

Alternatively the installation can be inspected and approved by a building

control officer. CD10 and CD11 forms are available from OFTEC on

Tel: 0845 658 5080, Fax: 0845 658 5181.

Page 6

1.3 Combi General Requirements

The boiler will have a DHW priority when both domestic hot water (DHW) and central

heating (CH) are selected. So if the flow switch is closed or the heat store has not

been satisfied the entire output of the boiler is directed to DHW before the boiler will

switch over to CH. When fully cold it can take up to 20 minutes for the heat store of

a 90,000 Btu/h Combi to be satisfied, and slightly longer for a 70,000 Btu/h Combi.

After a draw-off of 120L at 24L/min, with an average temperature rise of 32°C, the

thermal store of a 90,000 Btu/h Combi has a recovery time of approximately 7 mins.

A 70,000 Btu/h Combi will take slightly longer to recover.

Note: If HW has not been selected no hot water can be produced even if the heat

store is up to temperature.

1.3.1 Pump Overrun

Where there is a build up of excess heat in the boiler heat exchanger and the central

heating has not been selected then the pump overrun thermostat will operate. The

excess heat will then be pumped into the heat store. Once the temperature has

fallen in the boiler and the pump overrun stat is satisfied or the central heating pump

starts to operate, then the hot water pump will stop.

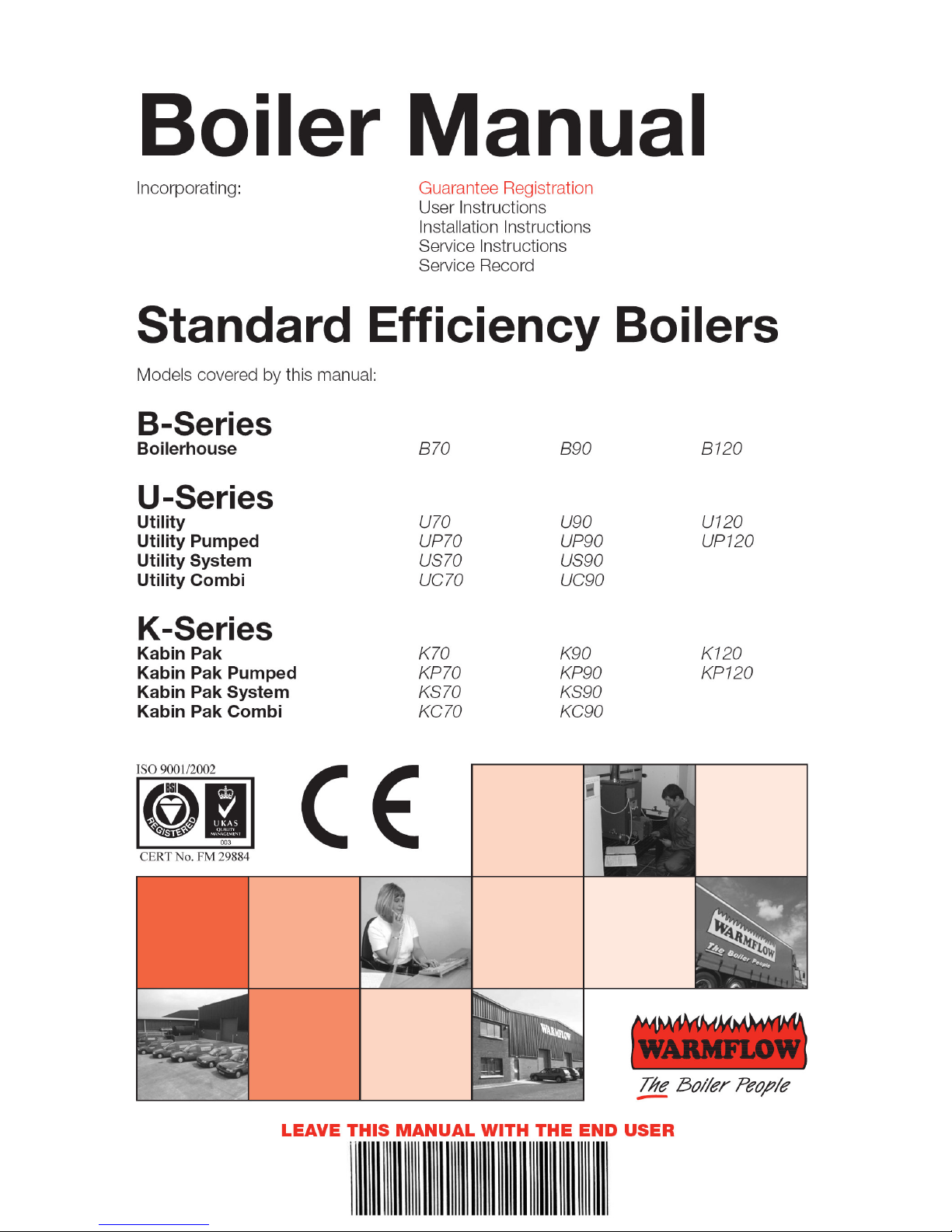

1.4 Baffle Positioning

The heat exchanger baffles consist of one heavy baffle stack (4mm thick) at the

bottom, 3 lighter baffle stacks (3mm thick) in the middle and 1 baffle plate (3mm

thick) at the top. Upon installation or after servicing, ensure the baffles are in the

correct order and correctly stacked.

Page 7

1.5 Components

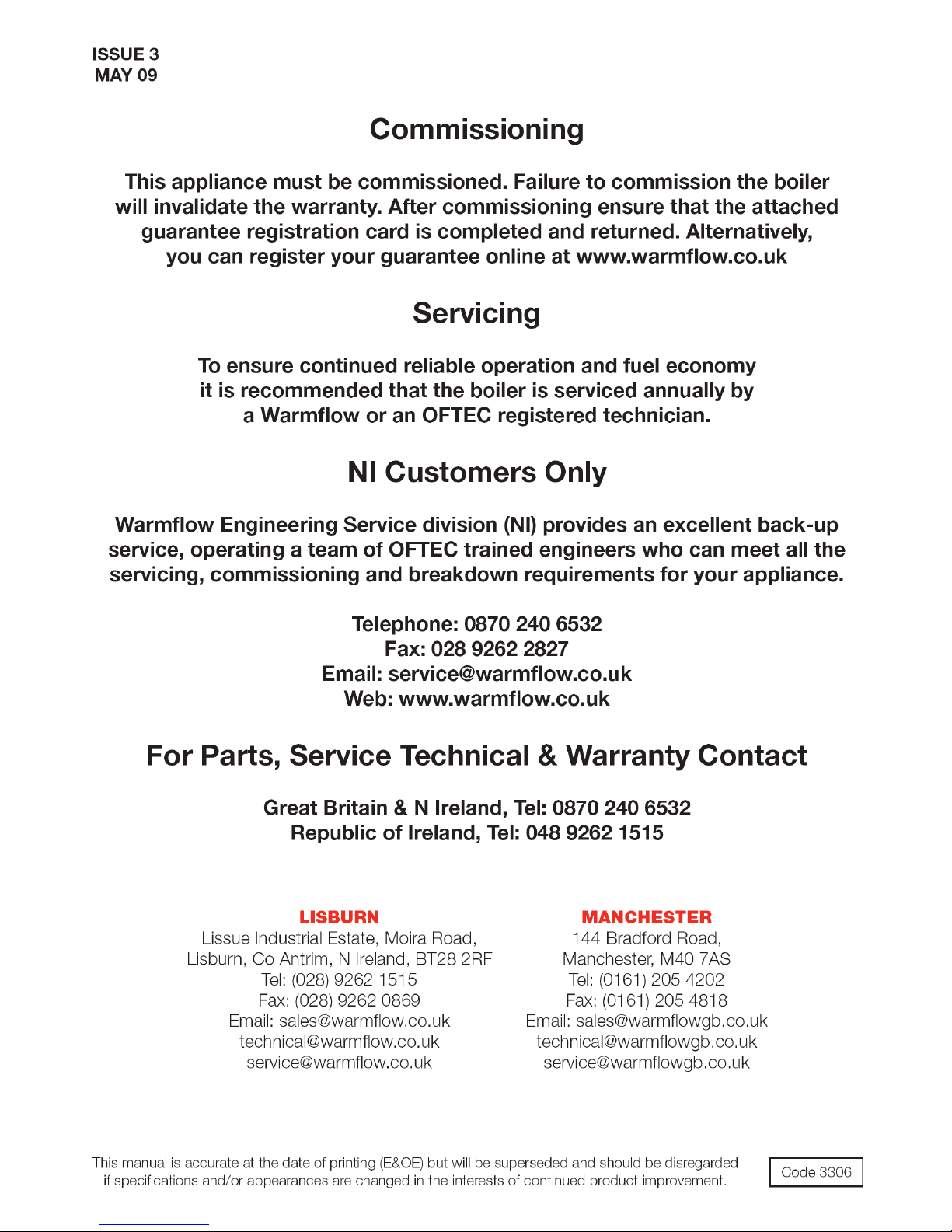

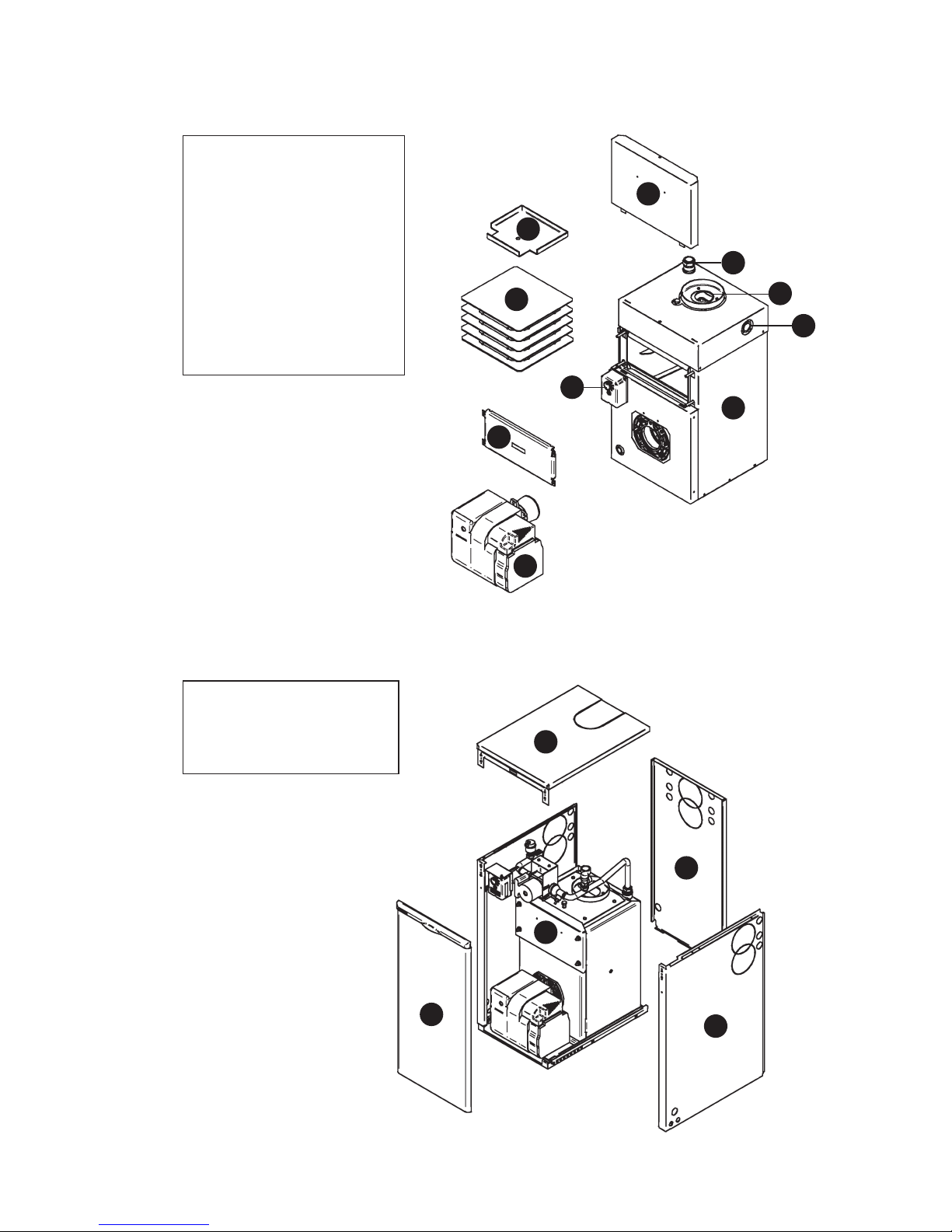

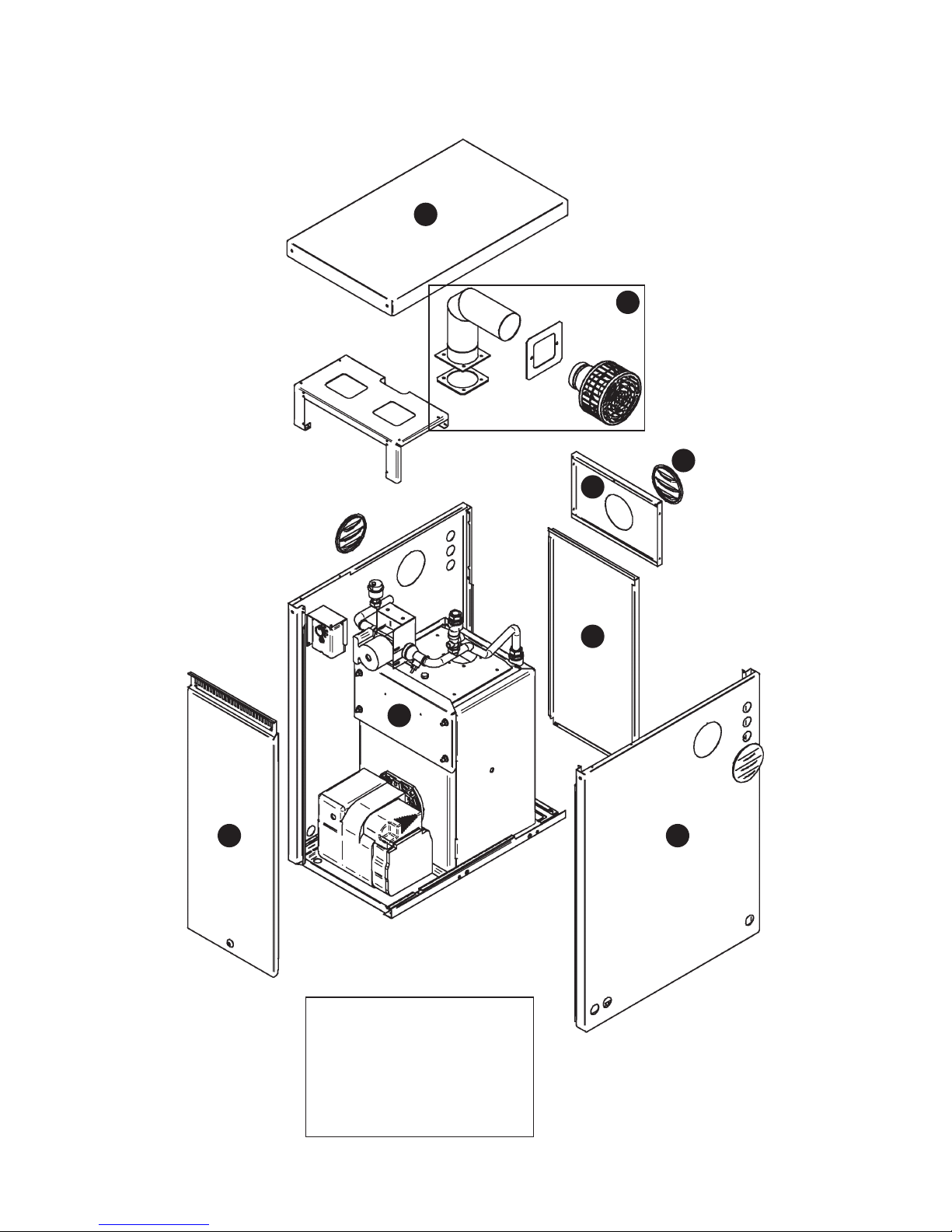

1.5.1 B-Series Boilerhouse – Casing Components

1. Boiler Assembly

with Casing

2. Service Door

Cover (removable)

1.5.2 B-Series Boilerhouse (B70, B90 & B1) – Key Components

1. Heat Exchanger

with Casing

2. Service Door Cover

3. Heat Exchanger Baffles

4. ‘Dual-Safe’ Thermostat

5. Service Door

6. Riello RDB 2.2 Burner

7. Flue Ring

8. Heating Flow

Connection

9. Heating Return

Connection

1

2

1

2

3

4

5

6

7

9

8

Page 8

1.5.3 B-Series Boilerhouse (B120) – Key Components

8

1. Heat Exchanger

Assembly with Casing

2. Service Door Cover

3. Secondary Exchanger

Inspection Lid

4. Primary Exchanger Baffles

5. ‘Dual-Safe’ Thermostat

6. Service Door

7. Riello RDB 2.2 Burner

8. Flue Opening

9. Heating Flow

Connection x 2

10. Heating Return

Connection

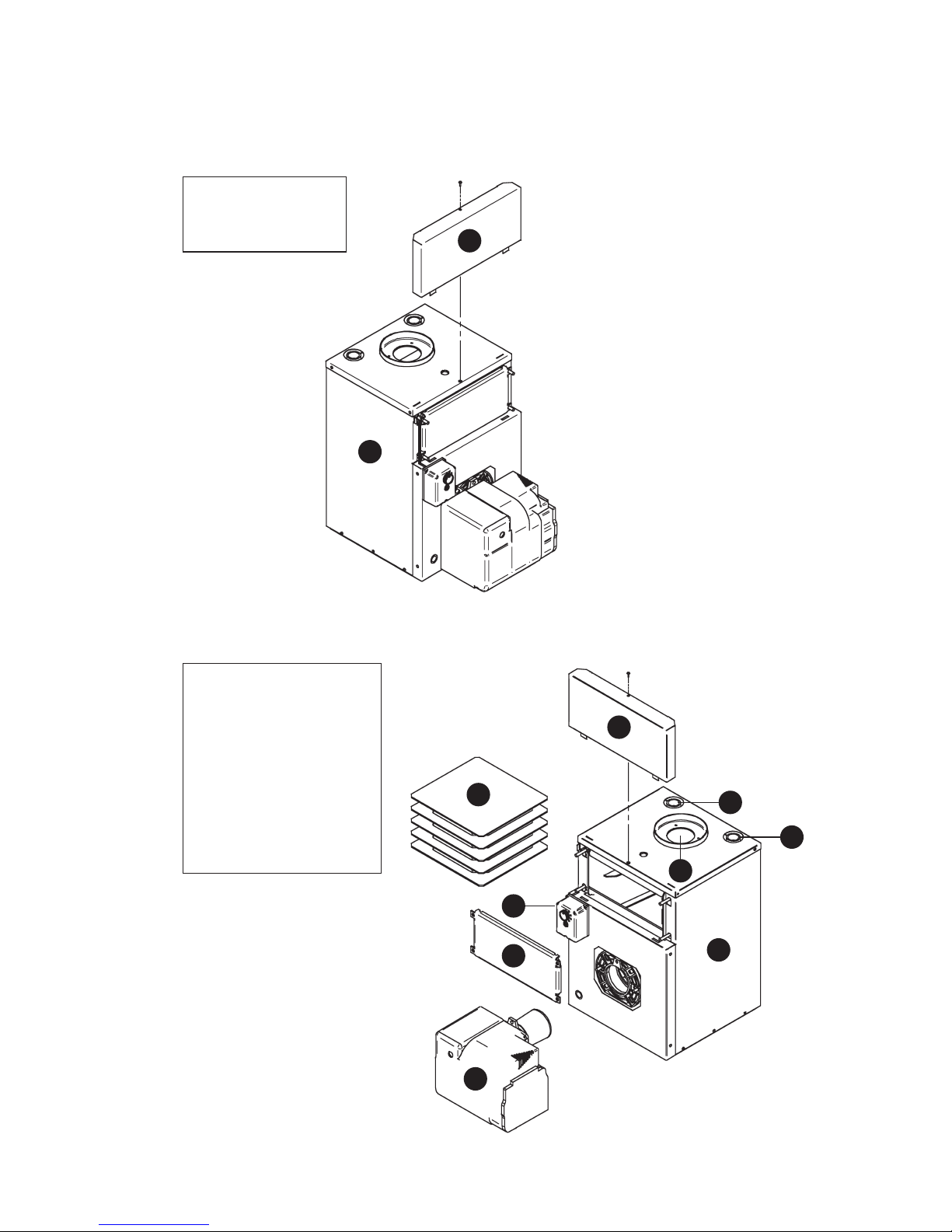

1.5.4 U-Series Utility – Casing Components

1. Boiler Assembly

2. Top Casing (removable)

3. Rear Casing

4. Side Casing

5. Front Casing (removable)

1

2

3

4

5

6

7

9

10

1

2

3

4

5

Page 9

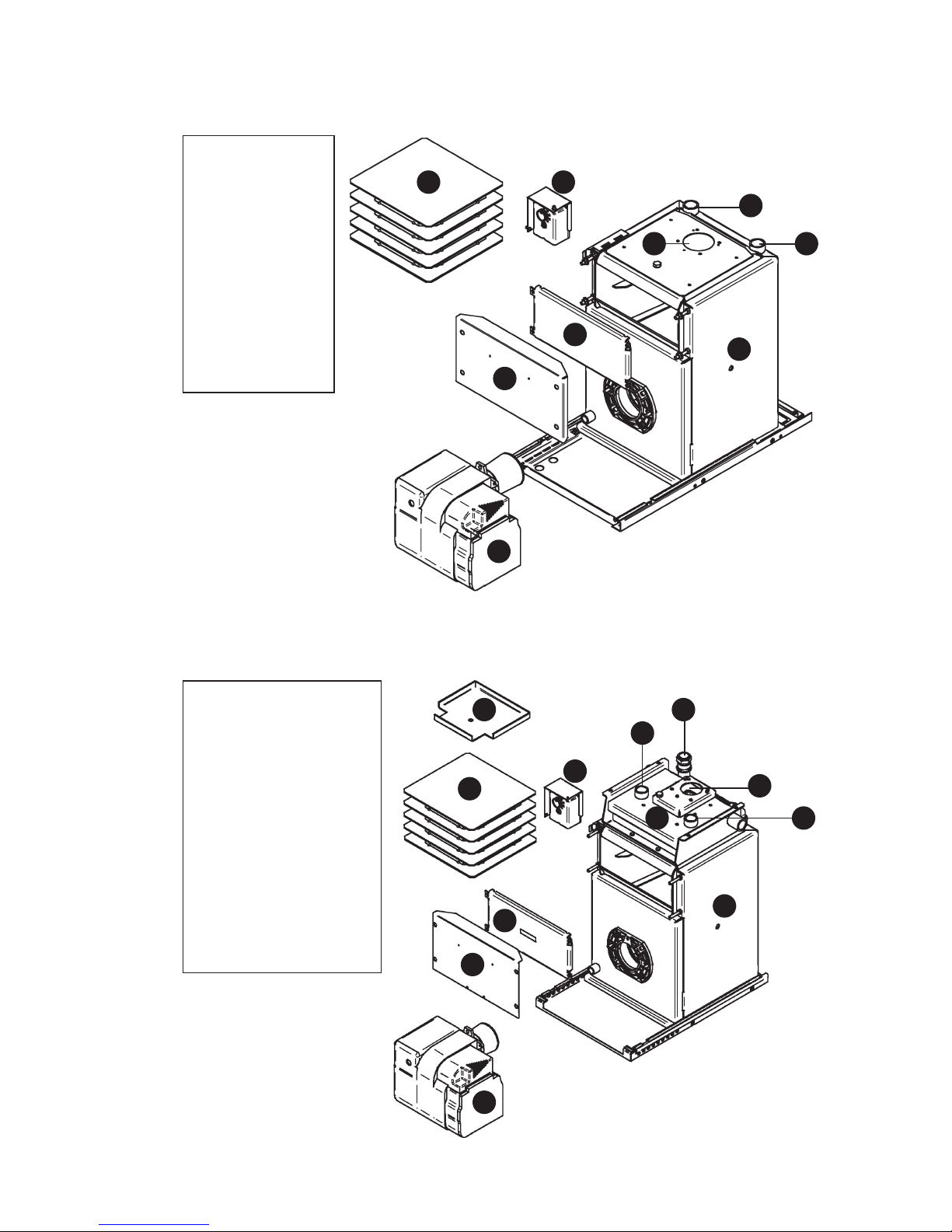

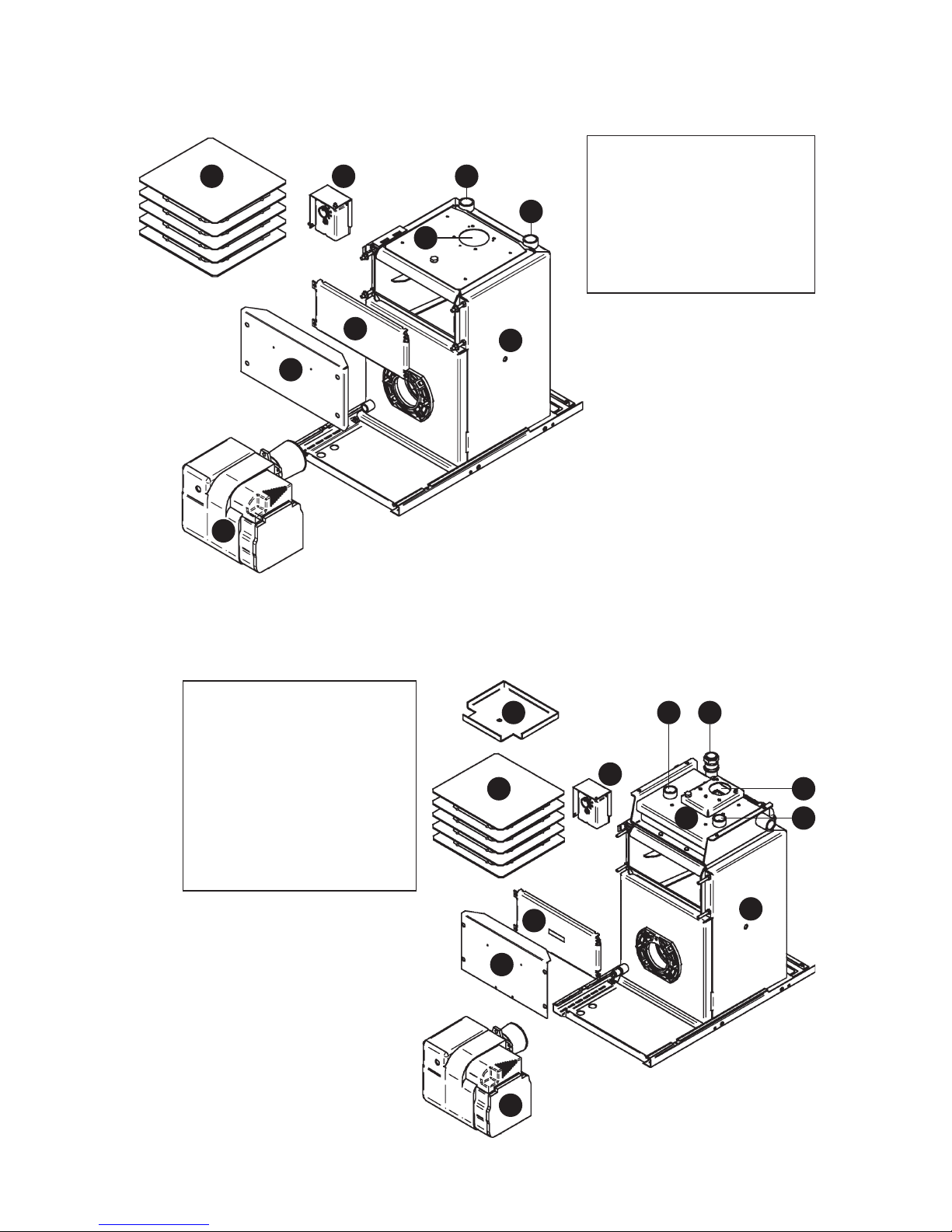

1.5.5 U-Series Utility – Pre-Wired (U70 & U90) – Key Components

1. Heat Exchanger

2. ‘Dual-Safe’

Thermostat

3. Heat Exchanger

Baffles

4. Service Door

5. Service Door

Cover

6. Riello RDB

2.2 Burner

7. Flue Opening

8. Heating Flow

Connection

9. Heating Return

Connection

1

4

6

7

3 2

9

5

1.5.6 U-Series Utility – Pre-Wired (U120) – Key Components

1. Primary Heat

Exchanger

2. Secondary Heat

Exchanger

3. ‘Dual-Safe’ Thermostat

4. Secondary Exchanger

Inspection Lid

5. Primary Exchanger

Baffles

6. Service Door

7. Service Door Cover

8. Riello RDB 2.2 Burner

9. Flue Opening

10. Heating Flow

Connection x 2

11. Heating Return

Connection

1

2

3

4

8

10

9

5

6

7

10

11

8

Page 10

1

8

10

6

7

4 2

11

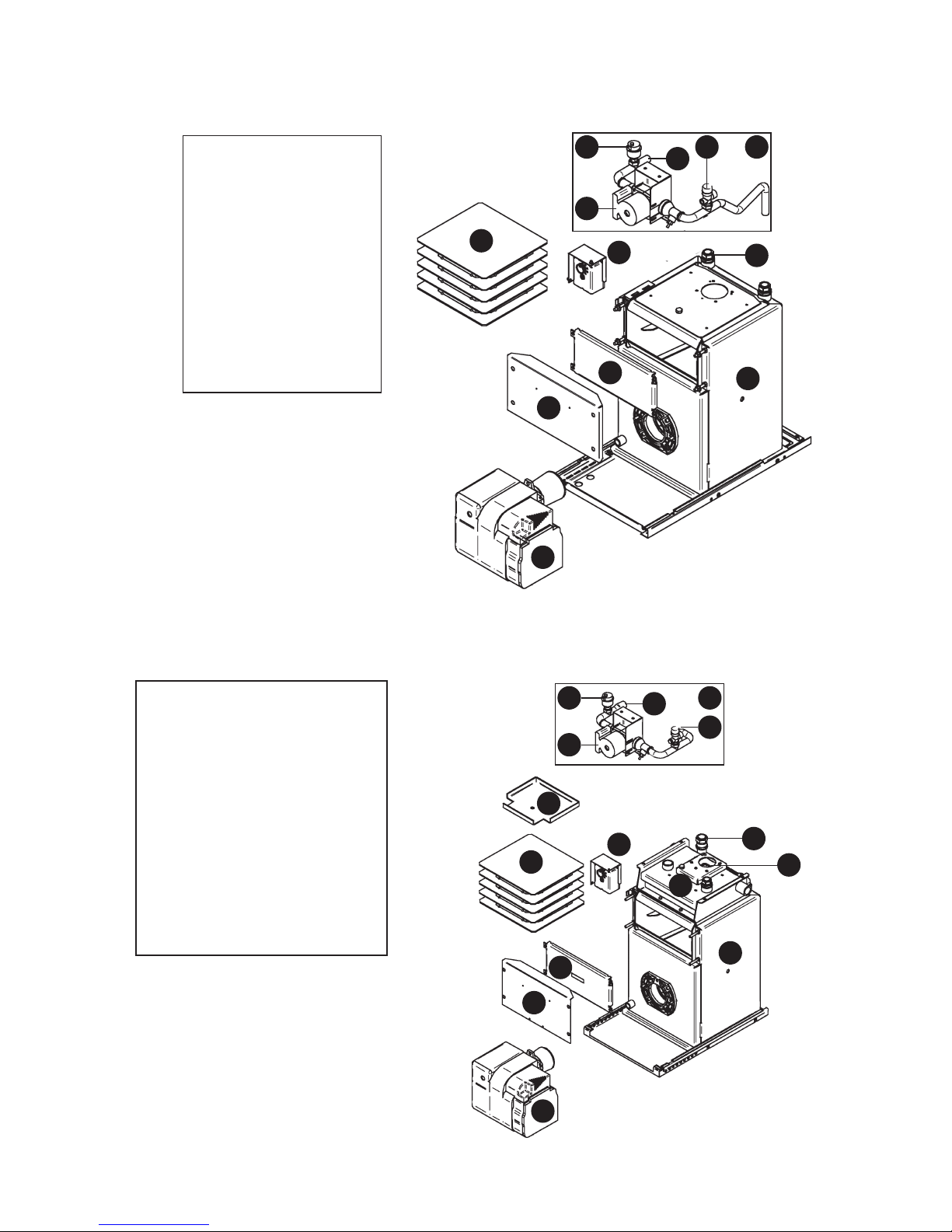

1.5.7 U-Series Utility – Pumped (UP70 & UP90) – Key Components

1. Heat Exchanger

2. Pipework Assembly

3. Pressure Relief Valve

4. Auto Air Vent

5. Circulating Pump

6. ‘Dual-Safe’ Thermostat

7. Heat Exchanger Baffles

8. Service Door

9. Service Door Cover

10. Riello RDB 2.2 Burner

11. Heating Flow

Connection

12. Heating Return

Connection

5

3

9

1. Primary Heat Exchanger

2. Secondary Heat Exchanger

3. Pipework Assembly

4. Pressure Relief Valve

5. Circulating Pump

6. Auto Air Vent

7. ‘Dual-Safe’ Thermostat

8. Secondary Exchanger

Inspection Lid

9. Primary Exchanger Baffles

10. Service Door

11. Service Door Cover

12. Riello RDB 2.2 Burner

13. Flue Opening

14. Heating Flow Connection

15. Heating Return Connection

1

8

7

5

2

6 3

15

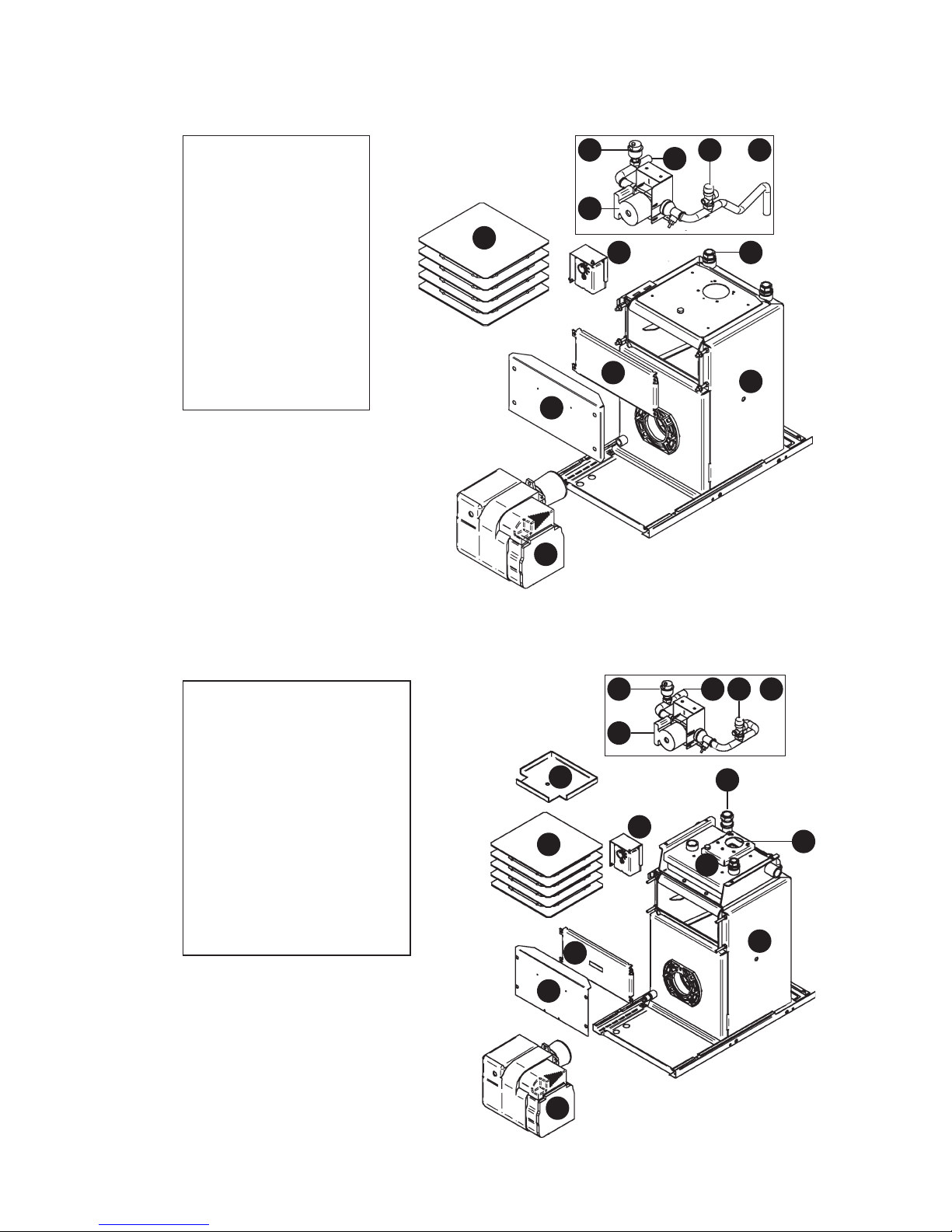

1.5.8 U-Series Utility – Pumped (UP120) – Key Components

14

4

9

10

11

12

12

13

Page 11

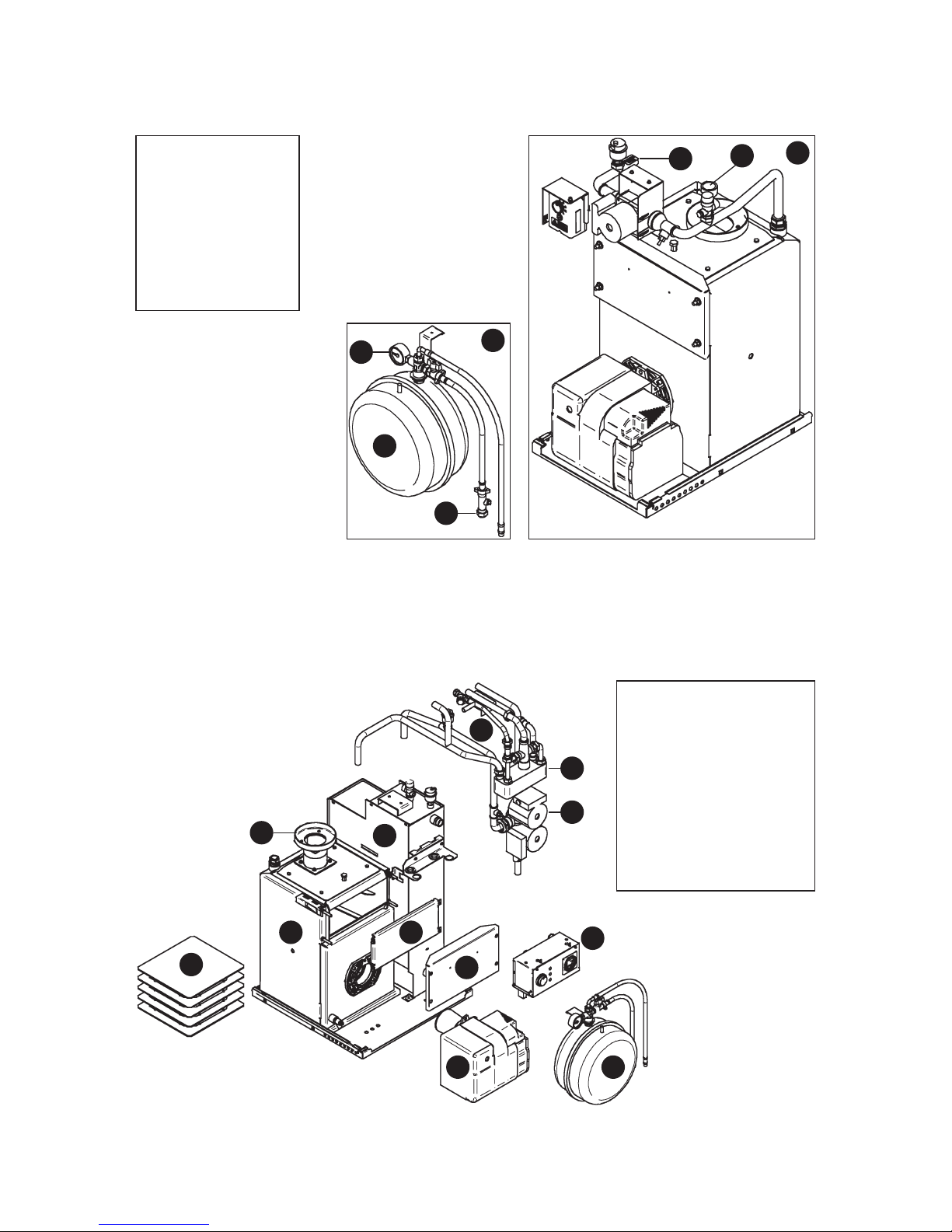

1.5.9 U-Series Utility – System (US70 & US90) – Key Components

1. Pumped (UP)

Boiler Assembly

2. System Kit (SK1)

3. Pressure Gauge

4. Expansion Vessel

5. Filling Loop

6. Heating Flow

Connection

7. Heating Return

Connection

4

3

5

2

1

6

7

1.5.10 U-Series Utility – Combi (UC70 & UC90) – Key Components

1. Heat Exchanger

2. Heat Store

3. Pipework Assembly

4. Plate Heat Exchanger

5. Twin Head Pump

6. Service Door

7. Service Door Cover

8. Control Panel

9. Expansion Vessel

10. Riello RDB 2.2 Burner

11. Heat Exchanger Baffles

12. Flue Ring

1

2

3

4

5

8

9

6

7

10

11

12

Page 12

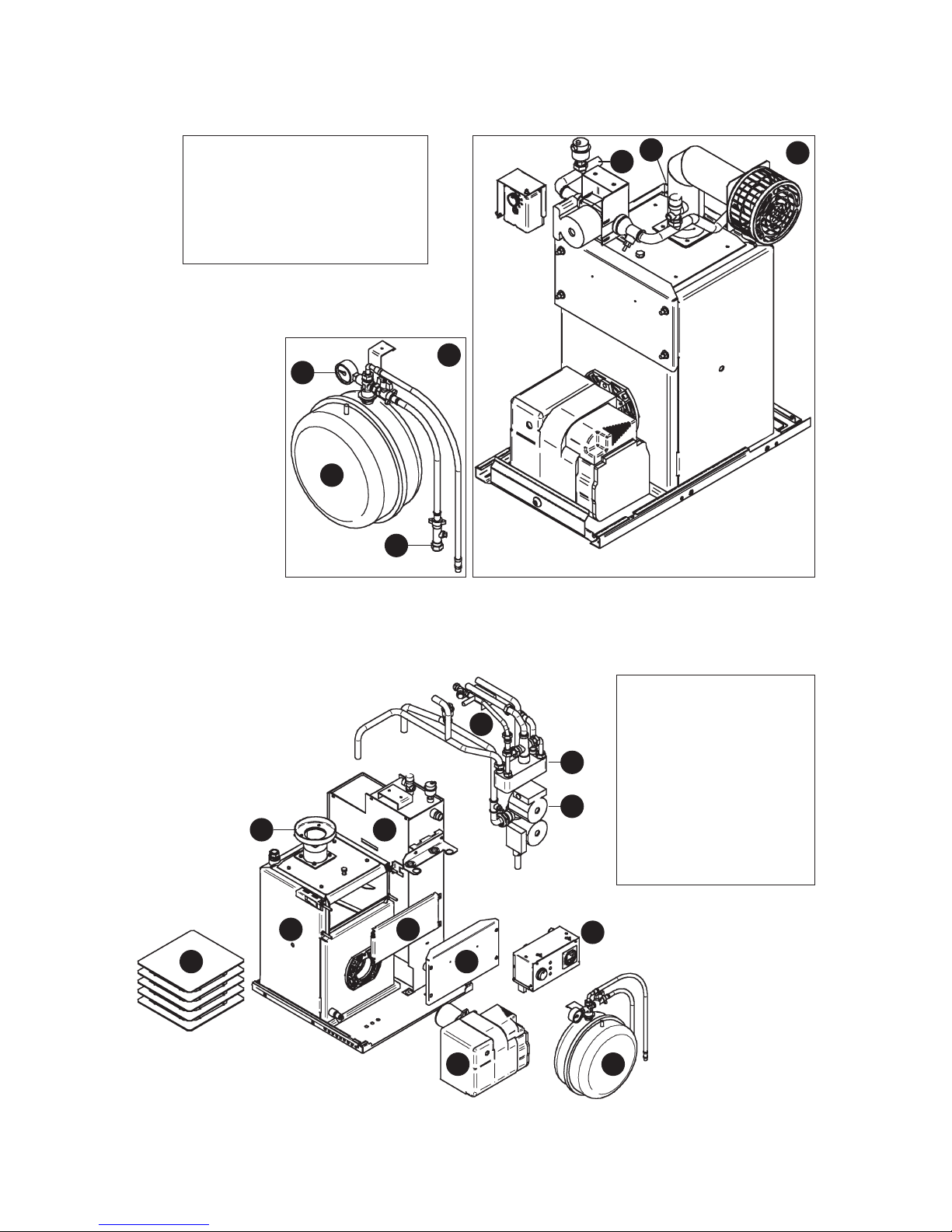

1.5.11 K-Series Kabin Pak – Casing Components

1. Boiler Assembly

2. Top Casing (removable)

3. Flue Assembly (removable)

4. Rear Flue Casing

5. Blanking Plug (removable)

6. Rear Casing (removable)

7. Side Casing

8. Front Casing (removable)

1

2

3

4

5

6

78

Page 13

1.5.12 K-Series Kabin Pak – Pre-Wired (K70 & K90) – Key Components

1. Heat Exchanger

2. ‘Dual-Safe’ Thermostat

3. Heat Exchanger Baffles

4. Service Door

5. Service Door Cover

6. Riello RDB 2.2 Burner

7. Flue Opening

8. Heating Flow Connection

9. Heating Return Connection

1

23

5

4

6

7

8

9

1.5.13 K-Series Kabin Pak – Pre-wired (K120) – Key Components

1. Primary Heat Exchanger

2. Secondary Heat Exchanger

3. ‘Dual-Safe’ Thermostat

4. Secondary Exchanger

Inspection Lid

5. Primary Exchanger Baffles

6. Service Door

7. Service Door Cover

8. Riello RDB 2.2 Burner

9. Flue Opening

10. Heating Flow Connection x 2

11. Heating Return Connection

1

2

3

4

5

6

7

8

1110

10

9

Page 14

1.5.14 K-Series Kabin Pak – Pumped (KP70 & KP90) – Key Components

1

8

11

5

6

7

9

10

12

3 2

1. Heat Exchanger

2. Pipework Assembly

3. Pressure Relief Valve

4. Auto Air Vent

5. Circulating Pump

6. ‘Dual-Safe’

Thermostat

7. Heat Exchanger

Baffles

8. Service Door

9. Service Door Cover

10. Riello RDB 2.2 Burner

11. Heating Flow

Connection

12. Heating Return

Connection

1.5.15 K-Series Kabin Pak – Pumped (KP120) – Key Components

1. Primary Heat Exchanger

2. Secondary Heat Exchanger

3. Pipework Assembly

4. Pressure Relief Valve

5. Circulating Pump

6. Auto Air Vent

7. ‘Dual-Safe’ Thermostat

8. Secondary Exchanger

Inspection Lid

9. Primary Exchanger Baffles

10. Service Door

11. Service Door Cover

12. Riello RDB 2.2 Burner

13. Flue Opening

14. Heating Flow Connection

15. Heating Return Connection

4

1

2

7

8

9

10

11

12

6

5

14 4 3

15

13

Page 15

1.5.16 K-Series Kabin Pak – System (KS70 & KS90) – Key Components

1. Pumped (KP) Boiler Assembly

2. System Kit (SK1)

3. Pressure Gauge

4. Expansion Vessel

5. Filling Loop

6. Heating Flow Connection

7. Heating Return Connection

1.5.17 K-Series Kabin Pak – Combi (KC70 & KC90) – Key Components

1. Heat Exchanger

2. Heat Store

3. Pipework Assembly

4. Plate Heat Exchanger

5. Twin Head Pump

6. Service Door

7. Service Door Cover

8. Control Panel

9. Expansion Vessel

10. Riello RDB 2.2 Burner

11. Heat Exchanger Baffles

12. Flue Ring

3

5

4

2

1

6

7

1

2

3

4

5

6

7

8

910

11

12

Page 16

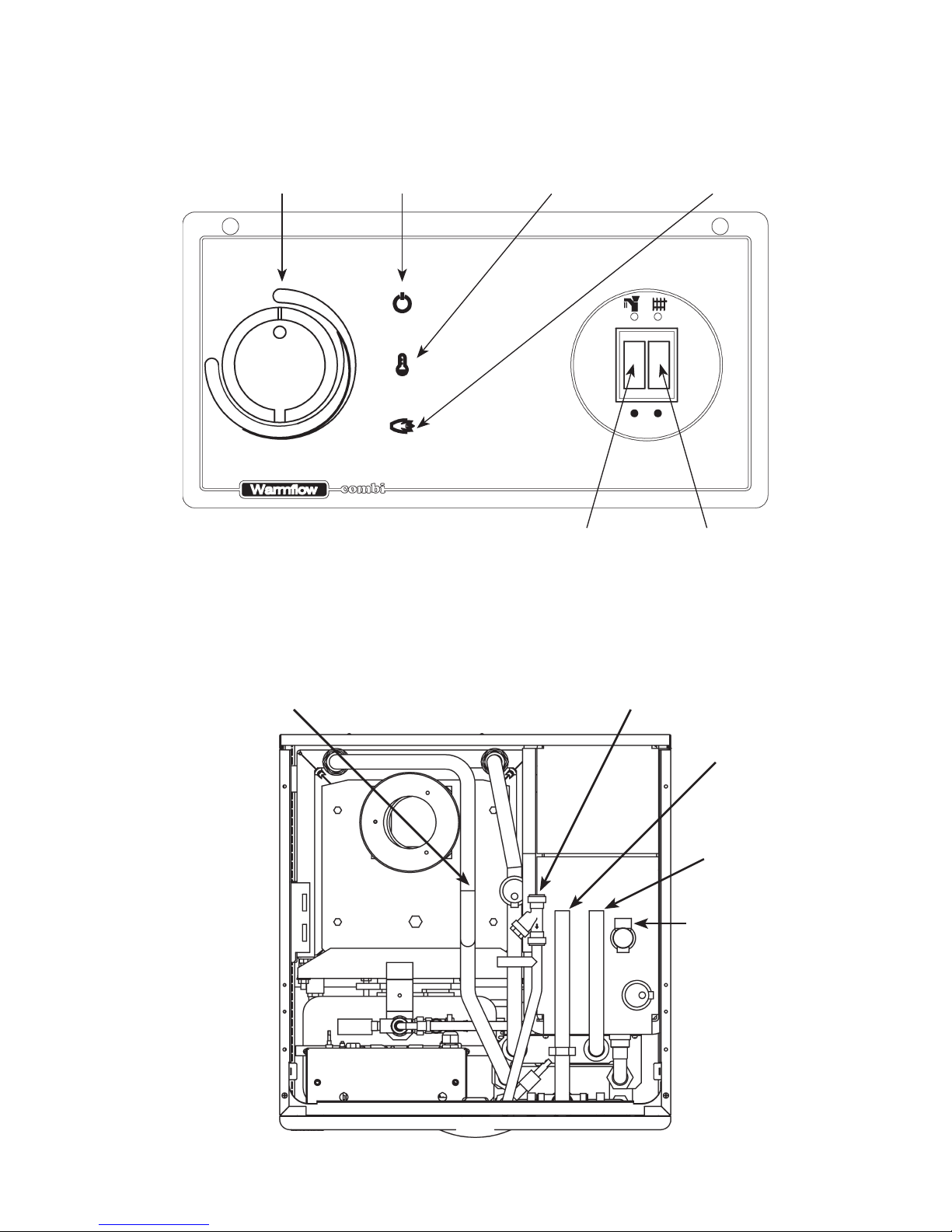

1.5.18 Combi Control Panel Layout

Control

Thermostat

Mains On

Lamp (Green)

High Limit Tripped

Lamp (Yellow)

Burner Lockout

Lamp (Red)

HW On/Off

Switch

CH On/Off

Switch

High Limit Thermostat Reset

(Underneath)

1.5.19 Combi Pipe Layout (UC & KC Models)

Central Heating

Return (22mm Copper)

Cold Water

Mains (15mm)

Domestic Hot

Water (22mm)

Central Heating

Flow (22mm)

Pressure Relief

Discharge (15mm)

Page 17

2.0 Technical Details

2.1 Combi Sequence of Operation Flow Chart

Power

On

Timer Calling

For Heat

HW

Selected

Flow Switch

Closed

DHW Tank

Stat Satisfied

CH

Selected

CH Pump

Only Runs

Room Stat

Satisfied

Boiler Stat

Satisfied

Boiler Limit

Stat Tripped

Burner

Fires

DHW Pump

Only Runs

HW Limit

Stat Satisfied

Boiler Limit

Stat Tripped

Burner

Fires

Burner

Stops

Press

Reset Button

Press

Reset Button

Pump Overrun

Stat Satisfied

DHW Pump

Only Runs

YES

YES

YES

NO

YES

NO

YES

YES

YES

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES NO

NO

NO

Page 18

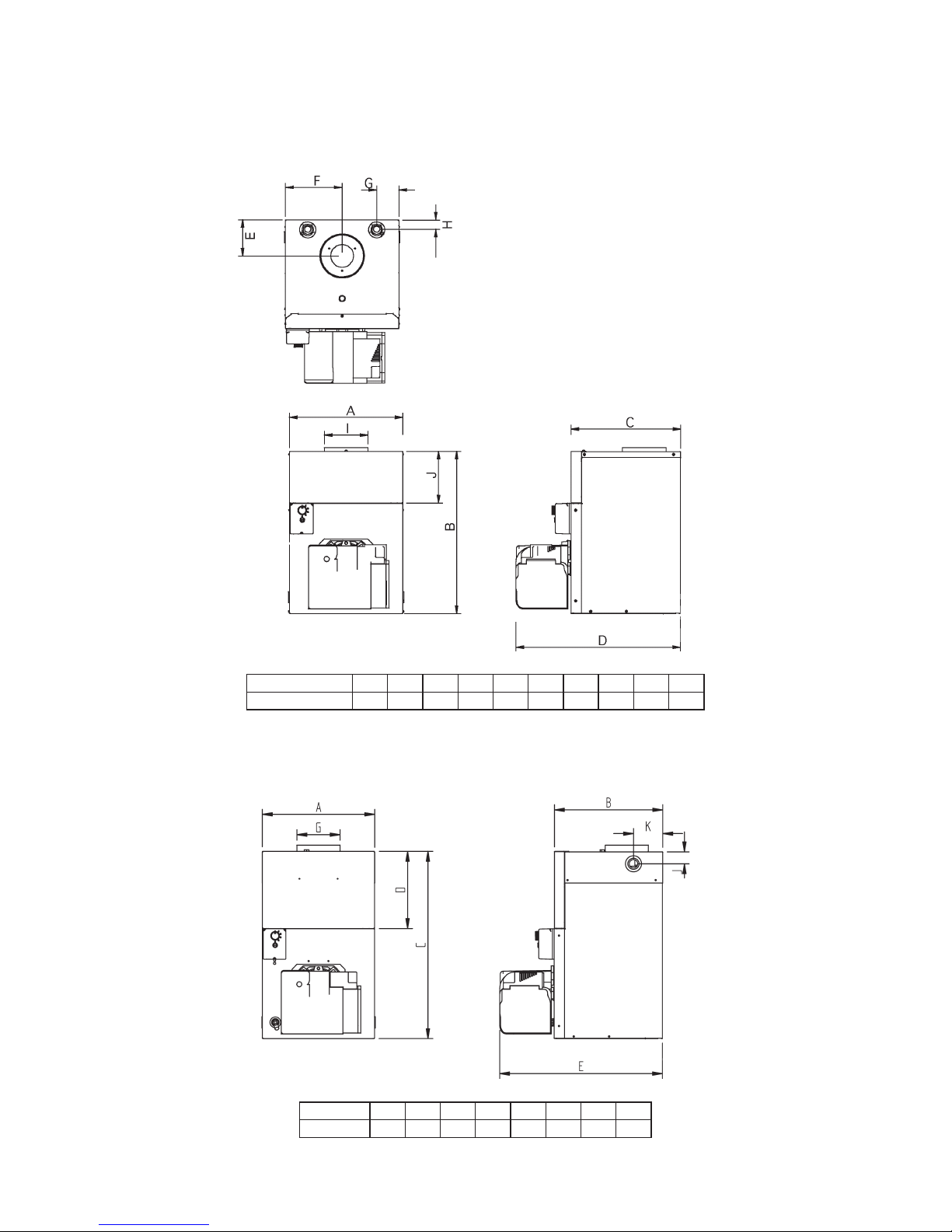

2.2 Dimensions

2.2.1 B-Series Boilerhouse (70 & 90 Output Models)

JHGFEDCBAMODEL

B70 / B90 / B1 396 573 383 574 127 198 78 32 183

I

152

2.2.2 B-Series Boilerhouse (120 Output Model)

KJGEDCBAMODEL

B120 397 383 662 273 575 152 42 103

Page 19

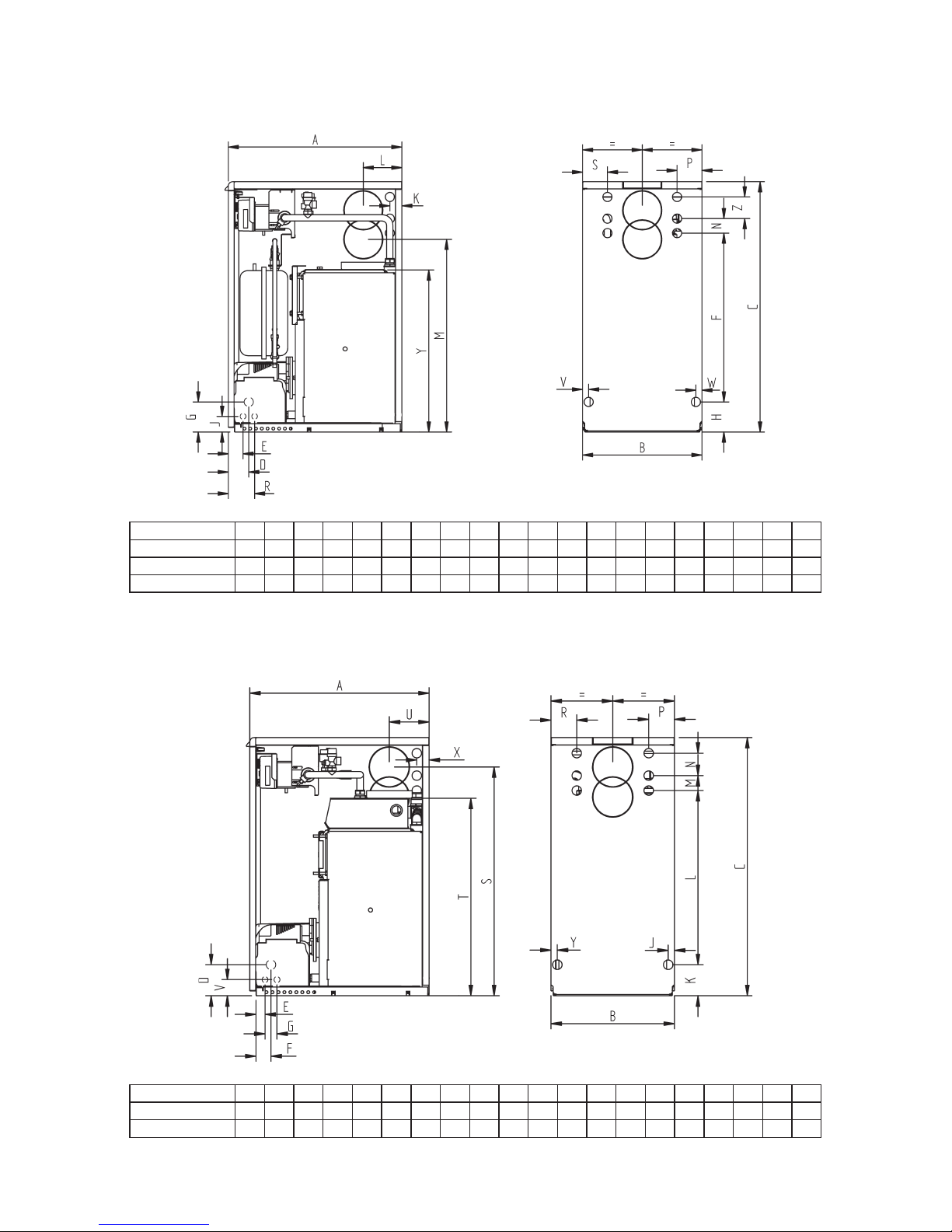

2.2.3 U-Series Utility (70 & 90 Output Non-Combi Models)

RPNMLKJHGFEDCBAMODEL

U70 & U90 600 413 865 71 51 583 104 104 54 42 134 666 50 86 91

UP70 & UP90

US70 & US90

S86V21W21Y

560Z75

600 413 865 71 51 583 104 104 54 42 134 666 50 86 91 86 21 21 560 75

600 413 865 71 51 583 104 104 54 42 134 666 50 86 91 86 21 21 560 75

2.2.4 U-Series Utility (120 Output Models)

RPNMLKJGFEDCBAMODEL

U120 600 413 865 104 30 50 40 21 104 583 50 75 86 86

UP120

S

766T662V134 54

X Y

42 21

U

600 413 865 104 30 50 40 21 104 583 50 75 86 86 766 662 134 54 42 21

Page 20

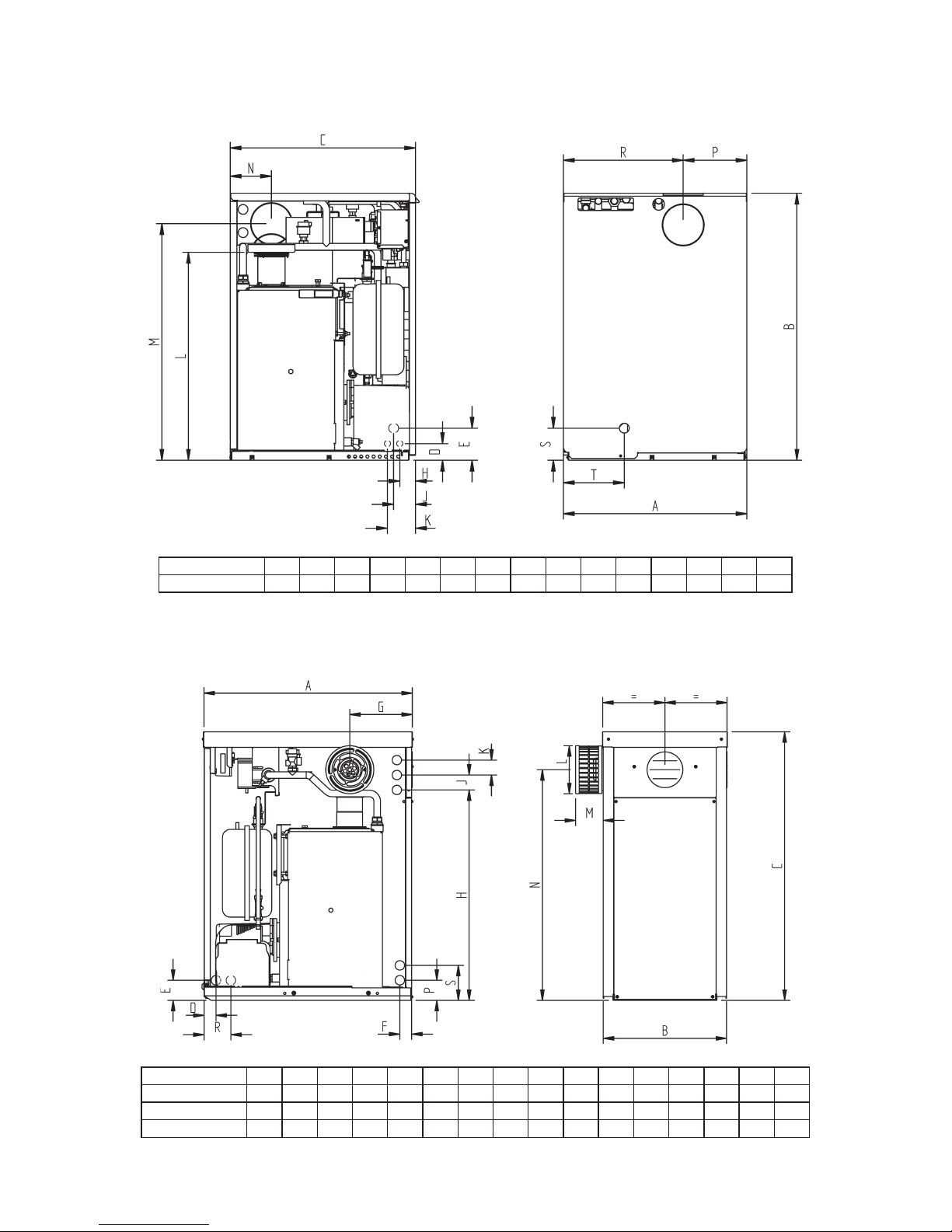

2.2.6 K-Series Kabin Pak (K, KP & KS Models)

2.2.5 U-Series Utility (UC Models)

RPNMLKJHEDCBAMODEL

UC70 & UC90 595

S T

865 600 54 104 51 71 91 674 766 134 207 388 104 197

RPNMLKJHGFEDCBAMODEL

K70 & K90 700

S

KP70 & KP90

KS70 & KS90

413 900 40 67 40 210 705 50 50 160 93 773 67 90 117

700 413 900 40 67 40 210 705 50 50 160 93 773 67 90 117

700 413 900 40 67 40 210 705 50 50 160 93 773 67 90 117

Page 21

2.2.7 K-Series Kabin Pak (120 Output Models)

PONMLKJHGFEDCBAMODEL

K120 700

KP120

I

413 900 40 67 117 705 50 50 67 40 773 160 210 50 90

700 413 900 40 67 117 705 50 50 67 40 773 160 210 50 90

2.2.8 K-Series Kabin Pak Base Tray (K, KP & KS Models)

Loading...

Loading...