WarmFlow Direct DI250UV, Direct DI90UV, Direct DI150UV, Indirect IN120UV, Direct DI300UV User Instructions

...

Cylinder Manual

Direct

DI90UV

DI120UV

DI150UV

DI180UV

DI210UV

DI250UV

DI300UV

Indirect

IN120UV

IN150UV

IN180UV

IN210UV

IN250UV

IN300UV

Eco Direct

ED180UV

ED210UV

ED250UV

ED300UV

Twin Coil

TW180UV

TW210UV

TW250UV

TW300UV

Triple Coil

TR250UV

TR300UV

Incorporating: User Instructions

Installation Instructions

Commissioning Instructions

Maintenance Instructions

Unvented Cylinders

Mains pressure water heaters

EN 12897:2006

Products covered by this manual:

LEAVE THIS MANUAL WITH THE END USER

INSTALLATION, COMMISSIONING & SERVICING

This appliance must be installed as described herein and the installation commissioned by

competent persons as instructed. The Guarantee Registration section of the separate Cylinder

Passport supplied with the product must be completed and the Guarantee Registration only

returned to the manufacturer with proof of purchase (e.g. receipts / invoices).

This appliance must be serviced annually by competent persons, the Service Record section of

the separate Cylinder Passport completed on each occasion and proof of servicing (e.g.

receipts / invoices) retained.

The complete guarantee policy statement is included in Section 9, page 21.

FAILURE TO COMMISSION, REGISTER AND ANNUALLY SERVICE THIS

PRODUCT WILL INVALIDATE ALL GUARANTEES

TECHNICAL, SPARES & GUARANTEE CLAIMS

For technical advice about the installation, commissioning, servicing or use of this appliance,

please contact the Warmflow Customer Care Centre by post, phone, fax or email at the

addresses below. Please also refer to our website.

Should replacement components be required, a list of available spares is provided in Section

8.3, page 19.

In the unlikely event that replacement components might be required within the guarantee

period, please notify the Customer Care Centre in writing, by post, fax or email, stating the

nature of the fault and the part number of the replacement components required.

Warmflow Customer Care Centre

Warmflow Engineering

Lissue Industrial Estate

Moira Road

Lisburn

BT28 2RF

Northern Ireland

Telephone

United Kingdom: 028 9262 1515

Republic of Ireland: 048 9262 1515

Facsimile

United Kingdom: 028 9262 0869

Republic of Ireland: 048 9262 0869

Email

technical@warmflow.co.uk

Website

www.warmflow.co.uk

CONTENTS

1 User Instructions ................................................................................................................. 2

1.1 Cylinder Thermostat ................................................................................................................... 2

1.2 Immersion Thermostat ............................................................................................................... 2

1.3 Discharge ................................................................................................................................ ... 2

2 Installation Requirements ................................................................................................... 3

3 Handling and Storage ......................................................................................................... 4

4 Standard Equipment ........................................................................................................... 4

5 Technical Data ..................................................................................................................... 4

5.1 General ...................................................................................................................................... 4

5.2 Direct Cylinders .......................................................................................................................... 5

5.3 Indirect Cylinders........................................................................................................................ 6

5.4 Eco Direct Cylinders ................................................................................................................... 7

5.5 Twin Coil Cylinders ..................................................................................................................... 8

5.6 Triple Coil Cylinders ................................ ................................................................ ................... 9

6 Installation ......................................................................................................................... 10

6.1 Cylinder Location...................................................................................................................... 10

6.2 Hot & Cold Water Connections ................................................................................................. 10

6.3 Primary, Renewable & Tertiary Circuits .................................................................................... 11

6.4 Tundish .................................................................................................................................... 11

6.5 Expansion Vessel ..................................................................................................................... 11

6.6 Hard water................................................................................................................................ 11

6.7 Pipework Configurations........................................................................................................... 12

6.8 Discharge Pipework ................................................................................................................. 13

6.9 Worked Example ...................................................................................................................... 15

6.10 Electrical Installation ................................................................................................................. 16

7 Commissioning.................................................................................................................. 18

7.1 Draining .................................................................................................................................... 18

8 Maintenance ....................................................................................................................... 19

8.1 Regular Maintenance ............................................................................................................... 19

8.2 Inspection Access .................................................................................................................... 19

8.3 Replacement Parts ................................................................................................................... 19

8.4 Fault Finding ............................................................................................................................ 20

9 Guarantee ........................................................................................................................... 21

10 End-of-Life Information .................................................................................................. 22

10.1 Safety Risks ................................................................ ............................................................. 22

10.2 Disassembly of the Product ...................................................................................................... 22

10.3 Casing and key components .................................................................................................... 23

Page 1 of 23

1 USER INSTRUCTIONS

Control dial

Reset button

Control dial

Reset button

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

The temperature of the hot water can be adjusted, and should ideally be set to 60°C (the

position indicated in the diagram below). A higher setting uses more energy and more fuel.

When a hot tap is turned on there may be a short surge of water – this is quite normal with

unvented systems and does not mean there is a fault. When you first fill a basin the water may

sometimes appear milky. This is due to air bubbles in the water which will clear very quickly.

1.1 Cylinder Thermostat

All cylinders (except Direct models) are fitted with one or more

cylinder thermostats to control the heat input to the cylinder from a

remote heat source, such as a boiler, heat pump or solar thermal

installation. The temperature of each cylinder thermostat is

adjustable between nominally 40°C and 70°C. Turn the control

knob clockwise to increase temperature, and anticlockwise to

decrease.

Each cylinder thermostat has a built-in manually reset safety

thermostat which will ‘lock out’ in the event of the cylinder

overheating and which will need to be reset in order to restore

operation. Remove the lock-out cover and depress the red button

to reset.

1.2 Immersion Thermostat

Isolate ALL electrical supplies to the appliance before removing the immersion cover.

All cylinders are supplied with one or more immersion heaters to

allow the cylinder to be heated electrically. Each immersion

heater has an immersion thermostat, the temperature of which is

adjustable between nominally 10°C and 70°C. Remove the

immersion heater cover and turn the control dial anticlockwise to

increase temperature, and clockwise to decrease.

Each immersion thermostat also has a built-in manually reset

safety thermostat which will ‘lock out’ in the event of the cylinder

overheating and which will need to be reset in order to restore

operation. Remove the immersion heater cover and depress the

red button to reset.

1.3 Discharge

If cold/warm water is discharged from the cylinder via the tundish, call your installer.

The pressure relief valves should be operated regularly to remove lime deposits and to verify

they are not blocked.

If very hot water is discharged, immediately switch off ALL heat sources (which may include

boilers, heat pumps, solar thermal systems and immersion heaters), isolate their electrical

supplies and call your installer.

Page 2 of 23

2 INSTALLATION REQUIREMENTS

Prior to installing this unvented hot water cylinder, please confirm that:

a) The mains water supply is capable of achieving a minimum flow rate of 20 litres per

minute at a minimum dynamic pressure of 1.5 bar at all times. If this performance

cannot be achieved the installation of an unvented cylinder may not be suitable.

b) The maximum mains supply pressure at any time does not exceed 12 bar. If this is the

case an additional ‘special’ pressure reducing valve (not supplied) may be required.

c) The mains water supply is from a public source (i.e. not from a private borehole) and that

the hardness of the water is less than 200 mg/litre. Where hardness in excess of 200

mg/litre is experienced, a suitable and effective hard water treatment must be installed.

d) All circuits supplying heat to the heat exchanger coils of any cylinder (not applicable to

direct cylinders) are fully pumped (gravity circulation is NOT suitable).

e) The pipework supplying the hot water taps is capable of withstanding a maximum

pressure of 7 bar at a temperature of 90°C.

This appliance must be installed vertically (not on its side) in a frost-free indoor location.

The installation of this appliance is subject to the Building Regulations:

England & Wales Building Regulation G3

Scotland Technical Standard P3

Northern Ireland Building Regulations P5

Republic of Ireland Technical Guidance Document Part L

The appliance and installation must be commissioned as described herein and the Guarantee

Registration section of the separate Cylinder Passport completed and returned to the

manufacturer.

FAILURE TO COMMISSION, REGISTER AND ANNUALLY SERVICE THIS

PRODUCT WILL INVALIDATE ALL GUARANTEES

Under no circumstances must the factory fitted temperature & pressure relief valve be

removed. Removal of the valve would create an extremely dangerous situation and

would invalidate all guarantees.

Page 3 of 23

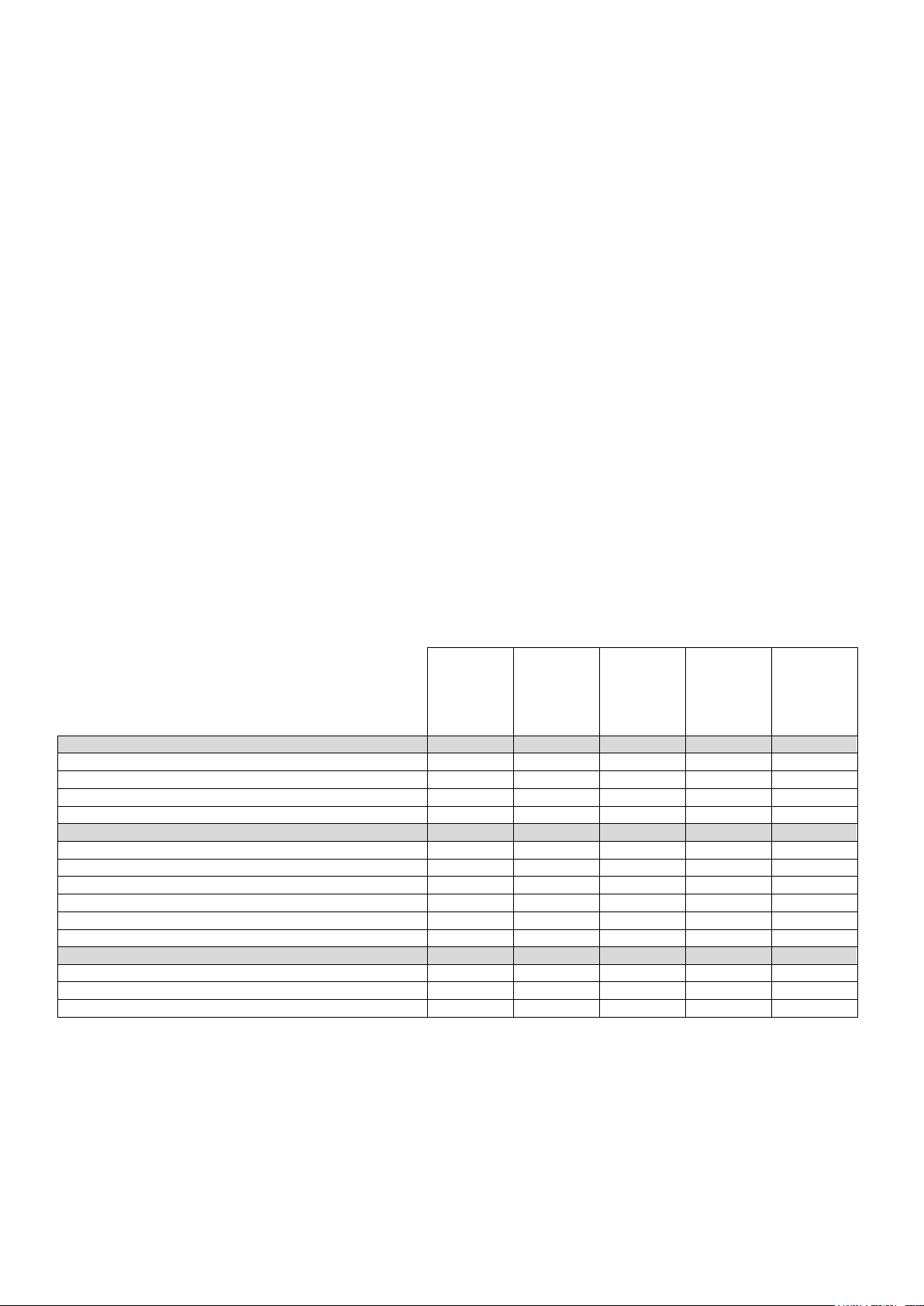

3 HANDLING AND STORAGE

Direct

Indirect

Eco Direct

Twin Coil

Triple Coil

OPERATING DATA

Operating pressure (bar)

3.0

3.0

3.0

3.0

3.0

Maximum design pressure (bar)

6.0

6.0

6.0

6.0

6.0

Maximum supply pressure to inlet group (bar)

12.0

12.0

12.0

12.0

12.0

Expansion vessel bladder pre-charge pressure (bar)

3.0

3.0

3.0

3.0

3.0

SAFETY DEVICE SETTINGS

Pressure reducing valve (bar)

3.0

3.0

3.0

3.0

3.0

Expansion valve (bar)

6.0

6.0

6.0

6.0

6.0

Cylinder thermostat limit temperature (°C)

n/a

80

80

80

80

Immersion thermostat limit temperature (°C)

80

80

80

80

80

Temperature & pressure relief (T&P) valve (°C / bar)

90/7.0

90/7.0

90/7.0

90/7.0

90/7.0

T&P valve temperature probe length (mm)

102

102

102

102

102

HEAT TRANSFER COILS

Maximum circuit temperature (renewable coil) (°C)

n/a

n/a

120

120

120

Maximum circuit temperature (other coils) (°C)

n/a

85

n/a

85

85

Maximum circuit pressure (all coils) (bar)

n/a

6.0

6.0

6.0

6.0

Prior to installation this product should be handled with care and stored upright in a dry location

and in its original packaging.

4 STANDARD EQUIPMENT

Before commencing installation check that all the listed components have been supplied:

1. Temperature & pressure relief valve (factory-fitted)

2. Control thermostats (factory-fitted) (not applicable to Direct models)

3. Unvented kit including:

a. Inlet group

b. Expansion vessel

c. Tundish

4. Immersion heater(s) (packaged inside the unvented kit)

One 2-port motorised zone valve is supplied with Indirect, Twin Coil and Triple Coil models only,

for use on the primary circuit.

Note: This stainless steel cylinder requires no corrosion protection device e.g. anode.

5 TECHNICAL DATA

5.1 General

Table 1: General data (Indirect & Twin Coil models)

Page 4 of 23

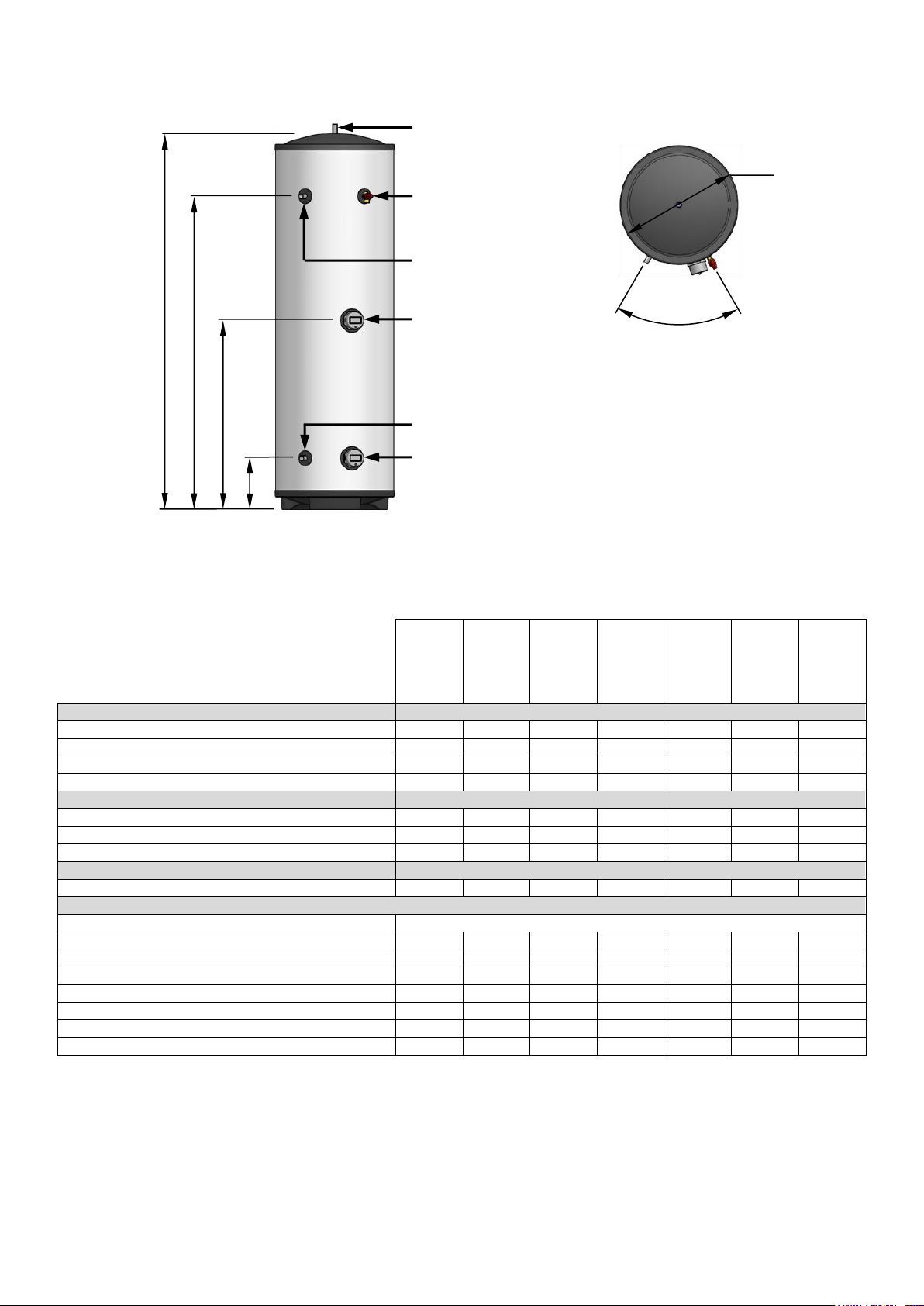

5.2 Direct Cylinders

DI90UV

DI120UV

DI150UV

DI180UV

DI210UV

DI250UV

DI300UV

DIMENSIONS

(A) Height (mm)

767

952

1142

1327

1517

1767

2077

(B) Secondary return connection / T&P (mm)

n/a

n/a

n/a

n/a

1223

1473

1783

(C) Upper immersion (mm)

n/a

482

577

670

765

890

1045

(D) Cold inlet connection / Lower immersion (mm)

243

243

243

243

243

243

243

OPERATING DATA

Cold water capacity (litres)

90

120

150

180

210

250

300

Weight when full (kg)

110

140

180

210

240

290

350

Standing heat loss (kWh/24h)

0.92

1.15

1.31

1.40

1.66

1.92

2.07

PERFORMANCE

Heat up time by lower immersion only (mins)

89

121

154

198

237

287

345

FICHE DATA

Supplier Name

Warmfllow

Supplier Model Identifier

DI90

DI120

DI150

DI180

DI210

DI250

DI300

Declared Load Profile

M M M L L

XL

XL

Energy Efficiency Class

D E D C D C C

Water Heating Energy Efficiency, ηwh (%)

34

30

36

38

37

39

39

Annual Electrical Consumption, AEC (kWh)

1541

1742

1452

2745

2799

4369

4351

Thermostat Setting (°C)

60

60

60

60

60

60

60

Sound Power Level (dB)

15

15

15

15

15

15

15

60°

Ø550

D

C

B

A

Hot Outlet (22mm)

Cold Inlet (22mm)

Temperature & Pressure

Relief Valve (15mm)

Upper Immersion Heater

Secondary Return (22mm)

Lower Immersion Heater

Figure 1: Direct cylinders components & dimensions

Table 2: Direct cylinder data

Page 5 of 23

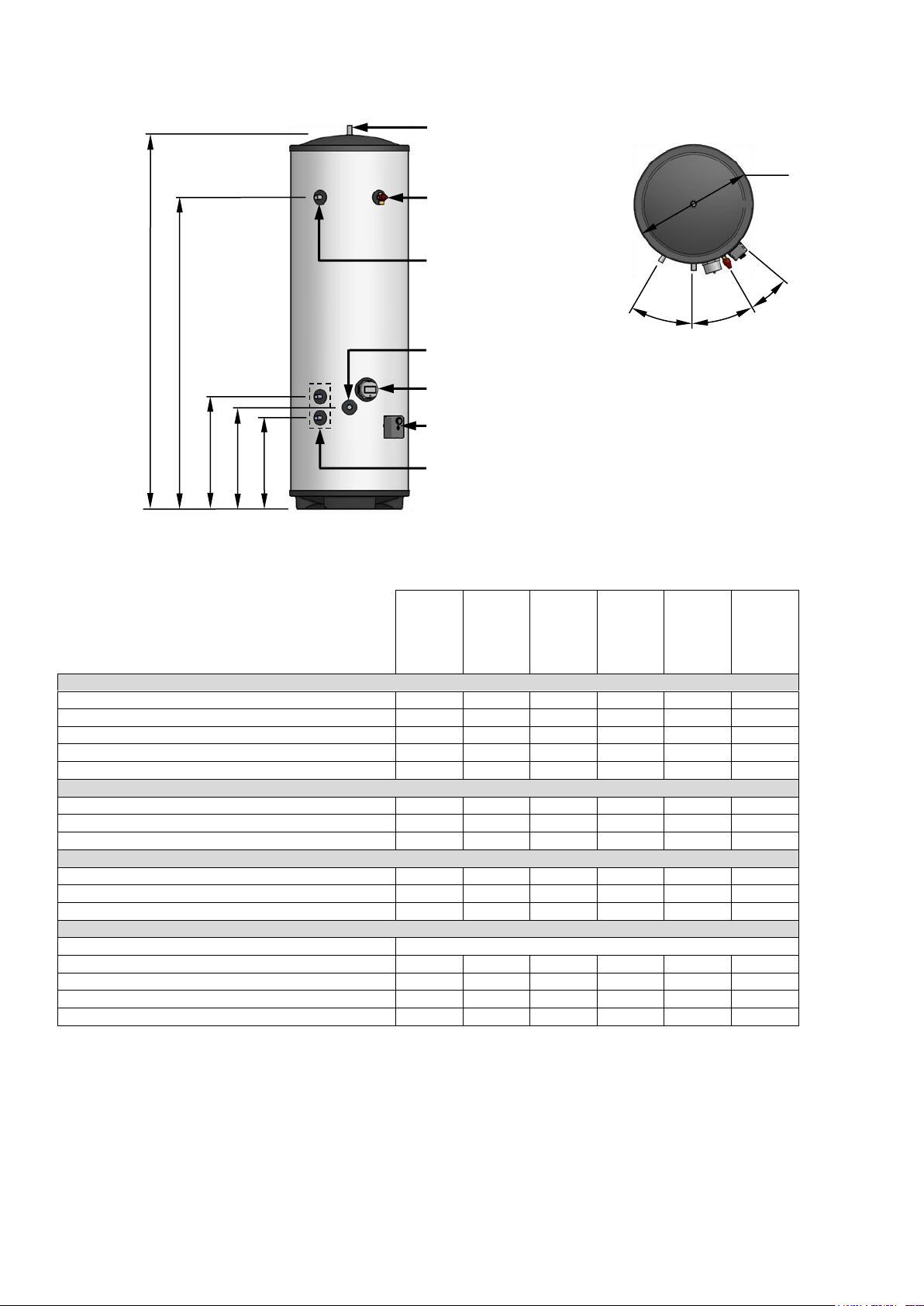

5.3 Indirect Cylinders

IN120UV

IN150UV

IN180UV

IN210UV

IN250UV

IN300UV

DIMENSIONS

(A) Height (mm)

952

1142

1327

1517

1767

2077

(B) Secondary return connection (mm)

n/a

n/a

n/a

1223

1473

1783

(C) Primary coil upper connection (mm)

462

462

532

532

532

532

(D) Cold inlet connection (mm)

412

412

482

482

482

482

(E) Primary coil lower connection (mm)

362

362

432

432

432

432

OPERATING DATA

Cold water capacity (litres)

120

150

180

210

250

300

Weight when full (kg)

140

180

210

250

290

350

Standing heat loss (kWh/24h)

1.15

1.31

1.40

1.66

1.92

2.07

COIL PERFORMANCE (EN12897)

Primary coil rating @ 15L/min (kW)

17.5

17.2

21.3

19.9

22.2

20.4

Primary coil pressure drop @ 15L/min (mbar)

54

54

67

67

67

67

Heat up time by primary coil (mins)

19.1

24.9

24.7

31.4

33.6

41.4

FICHE DATA

Supplier Name

Warmflow

Supplier Model Identifier

IN120

IN150

IN180

IN210

IN250

IN300

Energy Efficiency Class

A B B B C

C

Standing Loss (W)

36

55

58

60

84

86

Storage Volume (litres)

115

146

175

205

245

290

Ø550

E

C

B

Hot Outlet (22mm)

Cold Inlet (22mm)

Temperature & Pressure

Relief Valve (15mm)

Secondary Return (22mm)

Primary Coil Connections (22mm)

Primary Coil Thermostat

Immersion Heater

D

A

30°

30°

20°

Figure 2: Indirect cylinders components & dimensions

Table 3: Indirect cylinder data

Page 6 of 23

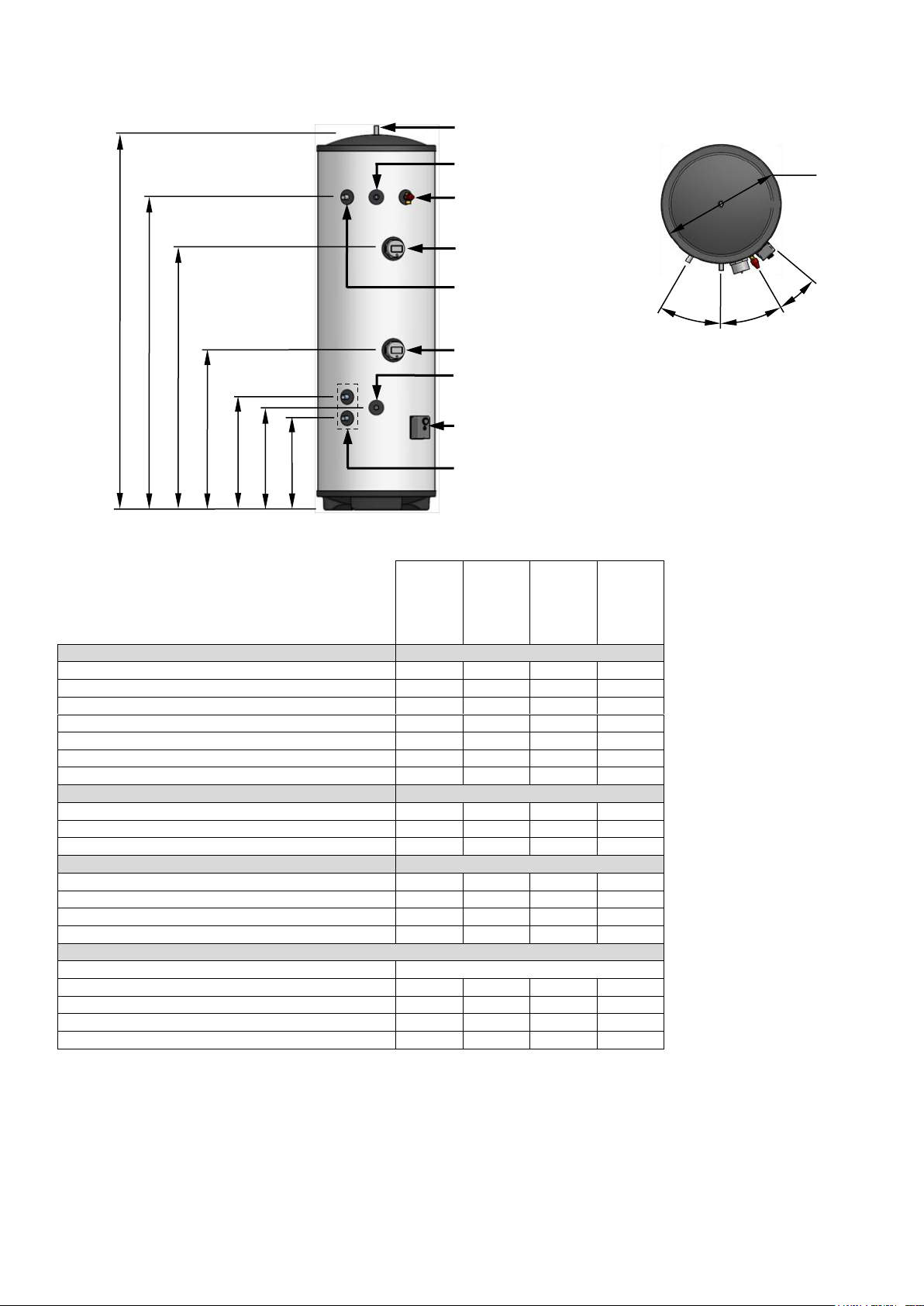

5.4 Eco Direct Cylinders

ED180UV

ED210UV

ED250UV

ED300UV

DIMENSIONS

(A) Height (mm)

1327

1517

1767

2077

(B) Secondary return connection (mm)

n/a

1223

1473

1783

(C) Upper immersion (mm)

891

1078

1230

1540

(D) Lower immersion (mm)

596

752

752

1062

(E) Renewable coil upper connection (mm)

532

532

532

532

(F) Cold inlet connection (mm)

482

482

482

482

(G) Renewable coil lower connection (mm)

432

432

432

432

OPERATING DATA

Cold water capacity (litres)

180

210

250

300

Weight when full (kg)

210

250

290

350

Standing heat loss (kWh/24h)

1.40

1.66

1.92

2.07

PERFORMANCE

Renewable coil rating @ 15L/min (kW)

21.4

20.2

21.8

19.3

Renewable coil pressure drop @ 15L/min (mbar)

67

67

67

67

Heat up time by lower immersion only (mins)

127

138

184

188

Dedicated renewable volume (litres)

65

90

110

145

FICHE DATA

Supplier Name

Warmflow

Supplier Model Identifier

ED180

ED210

ED250

ED300

Energy Efficiency Class

B

B C C

Standing Loss (W)

58

60

84

86

Storage Volume (litres)

175

205

245

290

30°

Ø550

G

E

D

Hot Outlet (22mm)

Cold Inlet (22mm)

Temperature & Pressure

Relief Valve (15mm)

Secondary Return (22mm)

Renewable Coil Connections (22mm)

Renewable Coil Thermostat

Lower Immersion Heater

F

30°

20°

Upper Immersion Heater

Sensor Pocket (1/2”)

C

B

A

Figure 3: Eco Direct cylinders components & dimensions

Table 4: Eco Direct cylinder data

Page 7 of 23

Loading...

Loading...