WarmFlow Solar SHP20, Solar SHP30 System Manual

System Manual

Incorporating: Installation Instructions

Commissioning Instructions

Maintenance Instructions

Guarantee Registration

Solar Thermal Systems

European Solar Keymark Approved

Products covered by this manual:

Solar SHP20 SHP30

Heat pipe vacuum tube collectors and accessories

LEAVE THIS MANUAL WITH THE END USER

Q12-027 rev 02 May ‘10

1

CONTENTS

1 General Information ..................................................................................................... 2

1.1 Warnings ..................................................................................................................... 2

1.2 Information ................................................................................................................... 3

1.3 Product Conformity ...................................................................................................... 3

2 Technical Characteristics ............................................................................................ 4

2.1 Technical Data ............................................................................................................. 4

2.2 Key Components ......................................................................................................... 5

2.3 Circuit Diagrams .......................................................................................................... 7

2.4 Pipework and Expansion Vessel Sizing ....................................................................... 8

2.5 Collector Pressure Drop ............................................................................................... 9

3 Installation ...................................................................................................................10

3.1 General Requirements ................................................................................................10

3.2 Tiled Roof Installation .................................................................................................10

3.2.1 Assemble pitched roof brackets ........................................................................................... 10

3.2.2 Install pitched roof brackets .................................................................................................. 11

3.2.3 Install support frame and manifold ....................................................................................... 12

3.2.4 Connect manifold pipework .................................................................................................. 13

3.3 Slate Roof Installation .................................................................................................14

3.3.1 Install slate roof brackets ...................................................................................................... 14

3.3.2 Install support frame ............................................................................................................. 15

3.3.3 Connect manifold pipework .................................................................................................. 15

3.4 Dual-line Pump Station Installation .............................................................................16

3.4.1 Mount pump station .............................................................................................................. 16

3.4.2 Connect pump station pipework ........................................................................................... 16

3.5 Electrical Installation ...................................................................................................17

3.5.1 Mount controller .................................................................................................................... 17

3.5.2 Connect external wiring centre ............................................................................................. 17

3.5.3 Connect back-up heat source .............................................................................................. 18

4 Commissioning ...........................................................................................................19

4.1 System Filling & Flushing ............................................................................................19

4.1.1 Check expansion vessel pre-charge .................................................................................... 19

4.1.2 Calculate system volume ..................................................................................................... 19

4.1.3 Connect filling station ........................................................................................................... 19

4.1.4 Flush system ........................................................................................................................ 20

4.1.5 Fill system ............................................................................................................................. 20

4.2 Pressure Testing .........................................................................................................21

4.2.1 Pressurise and inspect system ............................................................................................. 21

4.2.2 Set system pressure ............................................................................................................. 21

4.3 Sensor Installation ......................................................................................................21

4.4 Heat Pipe Tube Installation .........................................................................................22

4.4.1 Insert tube into manifold ....................................................................................................... 22

4.5 Circuit Flow Commissioning ........................................................................................23

4.5.1 Set pump speed ................................................................................................................... 23

4.5.2 Set flow adjuster ................................................................................................................... 23

5 Maintenance ................................................................................................................24

5.1 Periodic System Check ...............................................................................................24

5.2 Annual Maintenance ...................................................................................................24

5.2.1 Check installation ................................................................................................................. 24

5.2.2 Check fluid health ................................................................................................................. 24

5.2.3 Check performance .............................................................................................................. 24

5.2.4 Annual service checklist ....................................................................................................... 25

6 Product Guarantee ......................................................................................................26

7 Installation Notes ........................................................................................................27

8 Guarantee Registration ...............................................................................................29

2

1 GENERAL INFORMATION

1.1 Warnings

In order to qualify for the product guarantee the equipment MUST be correctly

commissioned as described herein and the guarantee registration section at the back of

this manual completed and returned.

Failure to commission and register the product may invalidate ALL guarantees.

This equipment must only be installed and commissioned by professionally qualified

personnel in accordance with current laws and standards and in line with the manufacturer’s

instructions. It is recommended that the system is installed by a competent installer such as

those registered under the Microgeneration Certification Scheme (MCS) in the United

Kingdom or with Sustainable Energy Ireland (SEI) in the Republic of Ireland.

The installation must comply with the requirements of:

- the Building Regulations

- current IEE Wiring Regulations or ETCI rules for electrical installations

Where no specific instructions are given, reference should be made to the relevant European

Standards.

This equipment must be used solely for the purpose for which it was designed and

manufactured – indirect heating of stored water (e.g. domestic hot water production).

Any other use is deemed improper and as such dangerous. The manufacturer accepts no

liability for damage or injury to persons or animals caused as a result of errors in the

installation and/or use of the equipment, or through non-compliance with current local and

national standards and/or the manufacturer’s instructions.

This equipment is only suitable for use in a sealed solar thermal system filled with the system

fluid supplied or specifically recommended by the manufacturer. The means of heating

domestic hot water (DHW), a swimming pool or other medium must be via a suitable heat

exchanger, for example the coil of a DHW storage cylinder.

This instruction manual forms an integral and essential part of the equipment and must be

kept in a safe place, available for future reference. This manual, along with the

commissioning and service records and proof of purchase, must be left with the end user.

It is essential that the heat pipe tubes are protected from overheating prior to installation.

NEVER leave uninstalled heat pipe tubes exposed to the sun.

Only unpack and install the heat pipe tubes after the rest of the system had been flushed,

filled and pressure tested and the system is ready to be brought into operation i.e. the DHW

storage cylinder is in use or the swimming pool has been filled.

If for any long periods there will be no heat load on the system (e.g. property unoccupied or

swimming pool emptied) the solar collector must either be covered or the heat pipe tubes

removed. If installing the collector onto a new-build property, DO NOT install the tubes until

the property is, or is about to become, occupied.

Due to the high temperatures that may be generated by a solar installation it is

recommended that a mixing valve be fitted to the hot water outlet from a domestic hot water

storage cylinder in order to limit the domestic hot water temperature. A setting of 60ºC is

recommended.

3

1.2 Information

Suitable personal protective equipment (e.g. hand and eye protection) must be used when

handling glass tubes. Avoid scratching or knocking the tubes and take care to protect the

teat at the base of the tube.

After removing the packaging, check that the equipment has not been damaged. In case of

doubt, do not attempt to install the equipment. Contact the supplier immediately to report the

damage. Packaging materials must not be left within reach of children as these items may

constitute a hazard and should be disposed of responsibly.

In case of a fault and/or malfunction in the equipment, shut the system down and isolate the

electrical supply. Contact your installer for advice.

In order to maintain the efficient and safe operation of this equipment it must be serviced

annually by professionally trained personnel in line with the manufacturer’s instructions.

The equipment can be regarded as electrically safe when connected to an effective earthing

system installed in accordance with the requirements of current regulations. This

fundamental safety requirement must be checked and verified. In case of doubt, have the

electrical installation checked by a qualified electrician. The manufacturer accepts no liability

of damage or injury caused as a result of inadequate or ineffective earthing.

1.3 Product Conformity

The manufacturer declares that this equipment is manufactured to a high specification and in

compliance with the relevant standards. All Warmflow solar products are CE certified and

possess technical characteristics that comply with the following directives and standards:

- Low Voltage Directive 73/23 CEE

- Electromagnetic Compatibility Directive 89/336 CEE

- BS EN 12975 - Thermal solar systems and components – Solar collectors

Warmflow accepts no liability for the consequences of non-observance of the

instructions herein or where actions not specifically described are undertaken.

4

2 TECHNICAL CHARACTERISTICS

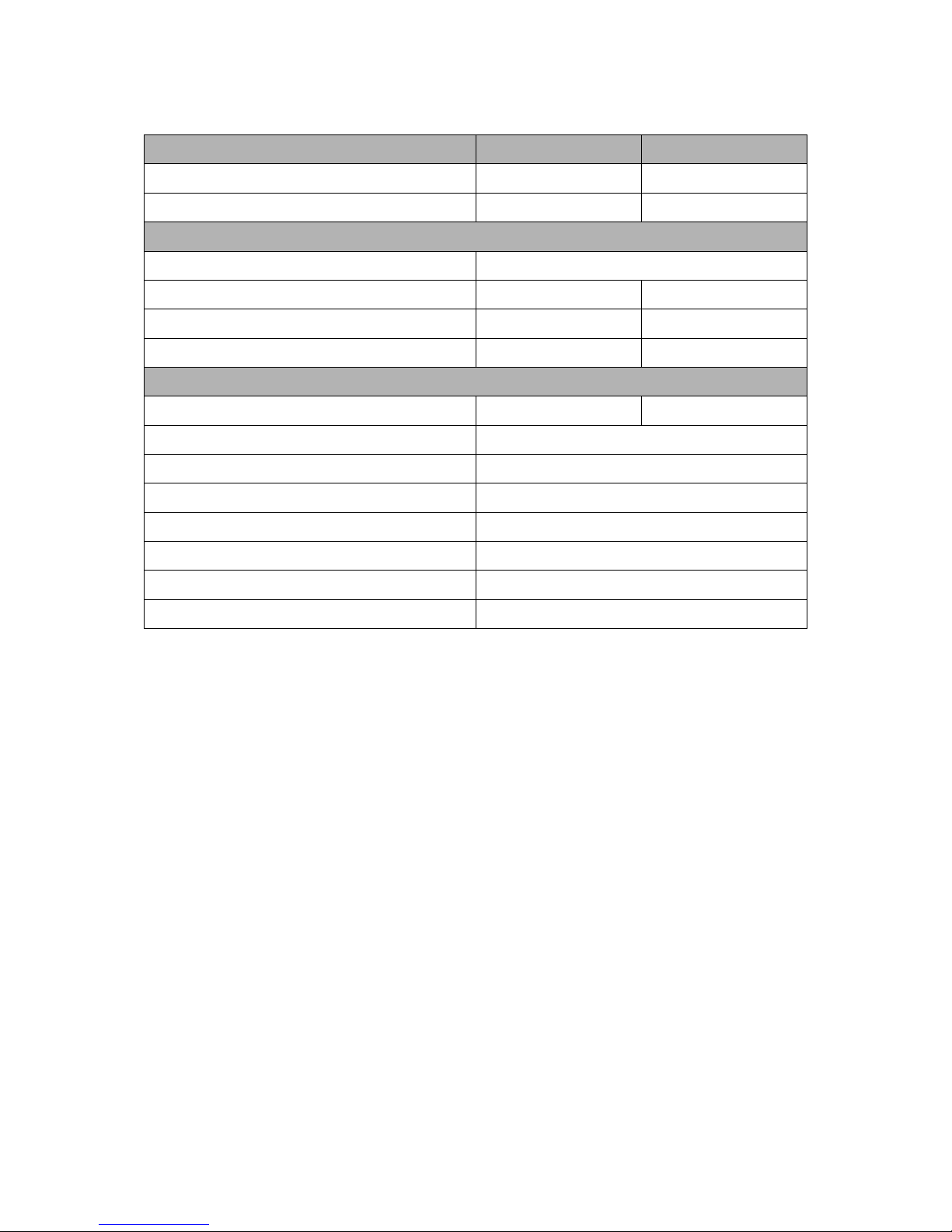

2.1 Technical Data

Model

Solar SHP20

Solar

SHP30

Absorber area (m2) (approx) 1.622 2.432

Aperture area (m2) (approx) 1.891 2.834

Fixed Parameter

Hydraulic connections G ¾” male

Gross size L x W x H (mm) 2050 x 1400 x 154 2050 x 2100 x 154

Weight empty (kg) 66.5 95.0

Fluid volume (litres) 1.2 1.7

Operating data

Rated flow rate per collector (litres/min) 2.0 3.0

Max. flow rate per collector (litres/min) 20

Max. operating pressure (bar) 6.0

Test pressure (bar) 9.0

Heat transfer fluid Warmflow Solar Fluid (water-glycol mix)

Max. working temperature (0C) 250

Permissible wind load (m/s) 25

Permissible snow load (mm) 500

Table 1: Technical data for Warmflow Solar heat pipe collectors

5

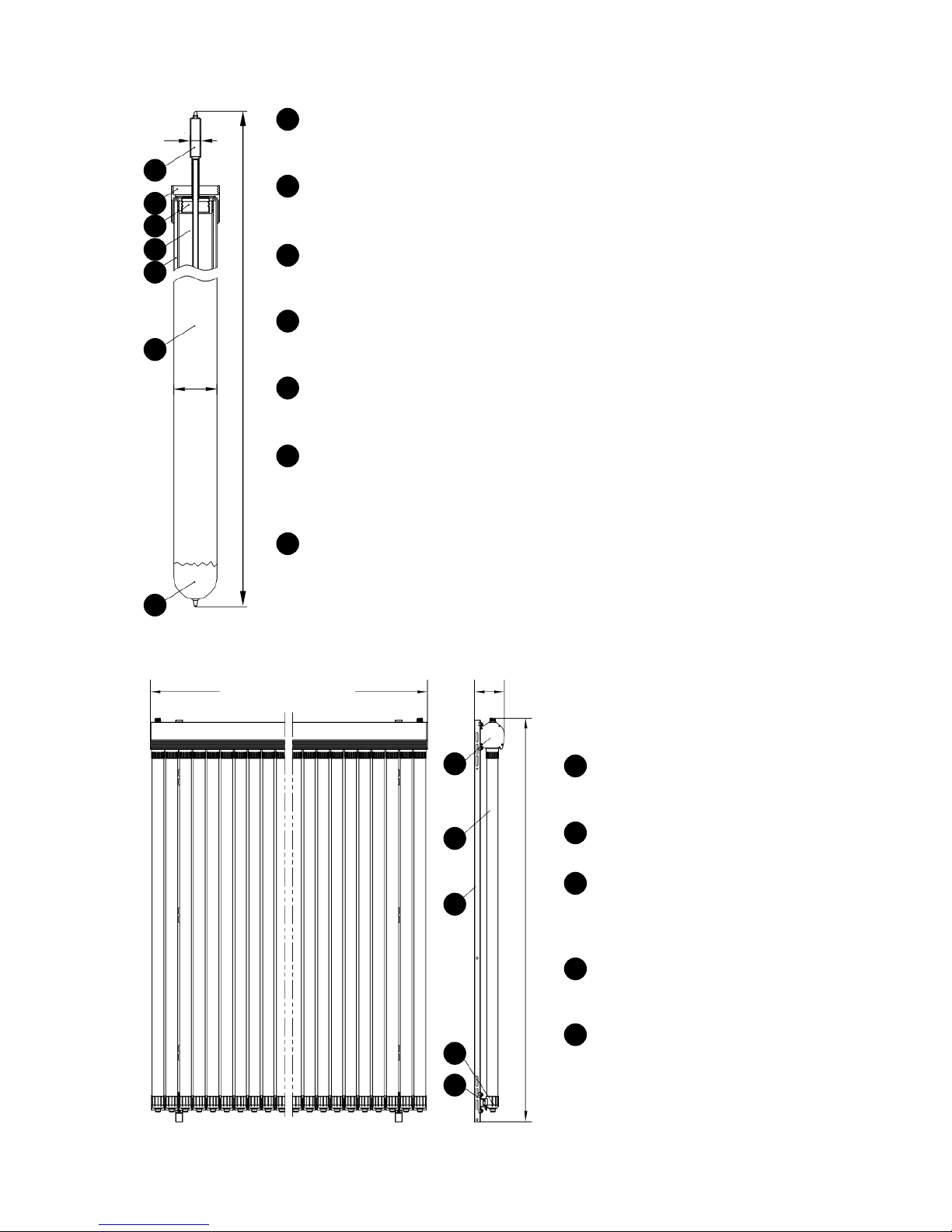

2.2 Key Components

Figure 1: Warmflow Solar heat pipe tubes

Figure 2: Warmflow Solar heat pipe collectors

Heat Pipe

Rapidly and efficiently transfers the sun’s energy from within the vacuum tube

into the manifold where it is transferred into the system fluid.

Tube Securing Nut

Locates and secures the vacuum tube into the manifold ensuring a positive

engagement.

Tube Seal

Seals the inner chamber of the vacuum tube to minimise convection losses

and protect the heat pipe and transfer fin from corrosion.

Transfer Fin

Conducts the sun’s energy from the vacuum tube’s absorber surface into the

heat pipe.

Vacuum Chamber

Insulates the heat pipe and transfer fin to minimise thermal losses, similar to a

vacuum flask.

Vacuum Tube

High efficiency twin-wall glass tube with 3600 advanced Al-N/Al coated

absorber surface applied by Magnetron Sutter CVD for maximum absorption of

the sun’s rays from any angle.

Getter

Intelligent boron coating that maintains the vacuum within the vacuum

chamber by chemically absorbing any air. The getter has a mirror-like

appearance when new and becomes white when spent, indicating that the

vacuum tube needs to be replaced.

1

2

3

4

5

6

7

14

58

1945

1

2

3

4

5

6

7

1

1400 (Solar SHP20)

2100 (Solar SHP30)

154

2050

2

3

4

5

Manifold

Transfers heat from the heat

pipes to the system fluid.

Vacuum tube

See previous figure.

Support Frame

Is secured to the roof and

provides support for the

manifold and bottom rail.

Tube End Supports

Support the bottom of the

vacuum tubes.

Bottom Rail

Fixes the tube end supports.

1

2

3

4

5

6

Figure 3: Warmflow Solar dual-line pump station

Expansion Vessel

Connection

6 bar Pressure Relief Valve

Flow

from Collector

Return

to Collector

Flow

to Solar Coil

Return

from Solar Coil

Filling Point

Circulating Pump

Flow Adjuster

Flow Indicator

Pressure Gauge

Flow Temperature Gauge

Return Temperature Gauge

Bleed Point

Continuous Air Separator

Multifunction

Ball Valves

7

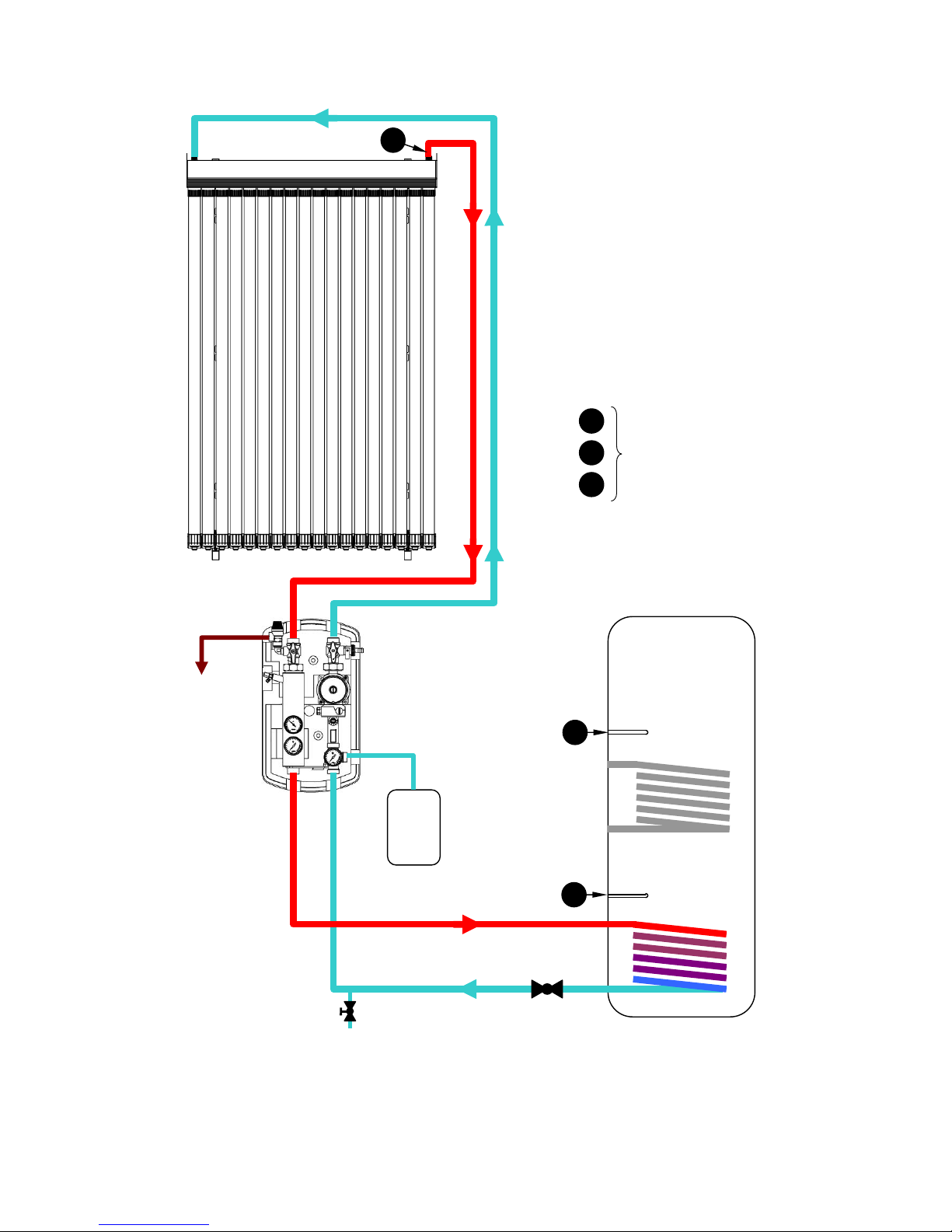

2.3 Circuit Diagrams

Figure 4: Typical domestic circuit diagram

Solar Collector

Dual

-

line

Pump Station

Pressure Relief

Discharge

Solar

Expansion Vessel

Motorised Valve

(if required)

Drain Cock

(at lowest point)

DHW

Storage Cylinder

Solar Coil

Boiler Coil

(if applicable)

T

3

T

2

T1

T1

T

2

T

3

Solar Sensors

refer to instructions for

Solar System Controller

M

FLOW

RETURN

FLOW

RETURN

8

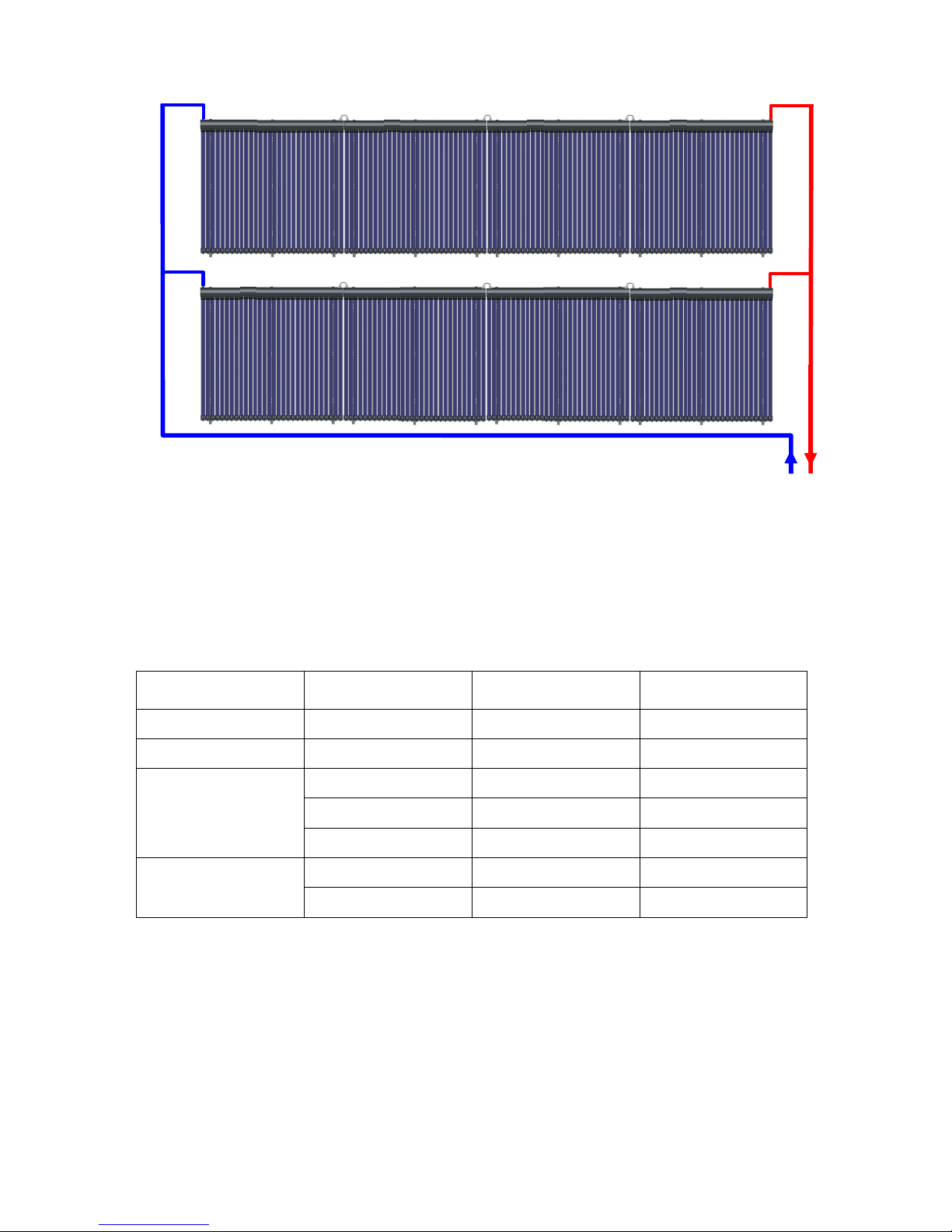

Figure 5: Circuit layout for 20m2 array (240 tubes)

2.4 Pipework and Expansion Vessel Sizing

Table 2 provides general guidance on the sizing of the system pipework and expansion

requirements. The expansion capacity is expressed as the number of Warmflow Solar

SEV18 expansion vessels required, each vessel having a volume of 18 litres.

No. of

vacuum tubes

Total length

of pipework

Minimum

pipe size

Minimum

expansion capacity

20 up to 70m 15mm 1 x SEV18

30 up to 45m 15mm 1 x SEV18

40

up to 30m 15mm 1 x SEV18

up to 40m 22mm 1 x SEV18

up to 75m 22mm 2 x SEV18

50

up to 10m 15mm 1 x SEV18

up to 45m 22mm 2 x SEV18

Table 2: Pipework and expansion vessel sizing

NOTE:

• The total length of pipework is the sum of both the flow and return runs from the cylinder

to the collector and back e.g. if the cylinder and collector were 5 metres apart, the total

length of pipework would be 10 metres (if piped directly).

• It is recommended that the minimum pipe size be used, otherwise expansion capacity

additional to that quoted may be required.

DN

32

DN

32

DN20

DN20

DN20

DN20

4 x SHP30 = 120 tubes

4 x SHP30 = 120 tubes

Note:

It is not recommended that more than

180 tubes be connected in series

Loading...

Loading...