WarmFlow Utility Pumped UP70HE, Utility U90HE, Utility Pumped UP90HE, Utility Pumped UP120HE, Utility Pumped UP150HE User Manual

...

Boiler Manual

Incorporating: Guarantee Registration

User Instructions

Installation Instructions

Service Instructions

Service Record

High Efficiency

Condensing Boilers

For use with kerosene only

Models covered by this manual:

U-Series

Utility U70HE U90HE U120HE U150HE

Utility Pumped UP70HE UP90HE UP120HE UP150HE

Utility System US70HE US90HE US120HE

Utility Combi UC70HE UC90HE

K-Series

Kabin Pak K70HE K90HE K120HE K150HE

Kabin Pak Pumped KP70HE KP90HE KP120HE KP150HE

Kabin Pak System KS70HE KS90HE KS120HE

Kabin Pak Combi KC70HE KC90HE

Leave this manuaL with the end user

This manual is accurate at the date of printing (E&OE) but will be superseded and should be disregarded

if specifications and/or appearances are changed in the interests of continued product improvement.

Code 3307

ISSUE 3

AUG 08

LisBurn

Lissue Industrial Estate, Moira Road,

Lisburn, Co Antrim, N Ireland, BT28 2RF

Tel: (028) 9262 1515

Fax: (028) 9262 0869

Email: sales@warmflow.co.uk

technical@warmflow.co.uk

service@warmflow.co.uk

manChester

144 Bradford Road,

Manchester, M40 7AS

Tel: (0161) 205 4202

Fax: (0161) 205 4818

Email: sales@warmflowgb.co.uk

technical@warmflowgb.co.uk

service@warmflowgb.co.uk

Commissioning

This appliance must be commissioned. Failure to commission the boiler

will invalidate the warranty. After commissioning ensure that the attached

guarantee registration card is completed and returned. Alternatively,

you can register your guarantee online at www.warmflow.co.uk

Servicing

To ensure continued reliable operation and fuel economy

it is recommended that the boiler is serviced annually by

a Warmflow or an OFTEC registered technician.

NI Customers Only

Warmflow Engineering Service division (NI) provides an excellent back-up

service, operating a team of OFTEC trained engineers who can meet all the

servicing, commissioning and breakdown requirements for your appliance.

Telephone: 0870 240 6532

Fax: 028 9262 2827

Email: service@warmflow.co.uk

Web: www.warmflow.co.uk

For Parts, Service Technical & Warranty Contact

Great Britain & N Ireland, Tel: 0870 240 6532

Republic of Ireland, Tel: 048 9262 1515

Page 1

Contents Page

User Instructions .....................................................................................................................................................................2

Condensing Boiler Installation Requirements ......................................................................................................................4

Condensing Combi Boiler Pre-Installation Requirements...................................................................................................5

1.0 General Information

1.1 Introduction .....................................................................................................................................................

6

1.2 General Requirements .....................................................................................................................................

6

1.3 Combi General Requirements ..........................................................................................................................

7

1.4 Baffle Positioning .............................................................................................................................................

8

1.5 Components ...................................................................................................................................................

9

2.0 Technical Details

2.1 Combi Sequence of Operation Flow Chart ....................................................................................................18

2.2 Dimensions ...................................................................................................................................................19

2.3 Flue Options, Components & Dimensions

......................................................................................................24

2.4 Condensate Disposal ....................................................................................................................................

27

2.5 Technical Data ...............................................................................................................................................

28

3.0 Electricity Supply & Wiring Details

3.1 Dual-Safe Thermostat (Non-Combi Boilers) ...................................................................................................36

3.2 RDB Burner Control Box ...............................................................................................................................

36

3.3 Combi Wiring Details .....................................................................................................................................

37

3.4 Installation of a Combi Optional Programmer (PC1) .......................................................................................

40

3.5 Remote Timers for Combis ............................................................................................................................41

3.6 Optional Programmer (PU1) for Non-Combi Models ......................................................................................

42

4.0 Oil Supply

4.1 One Pipe Gravity System ...............................................................................................................................46

4.2 Two Pipe System ...........................................................................................................................................

47

4.3 De-aerator System ........................................................................................................................................

47

4.4 One Pipe Lift System .....................................................................................................................................

48

5.0 Flues

5.1 Installation of Balanced Flues

.........................................................................................................................49

5.2 Conventional Flues ........................................................................................................................................51

5.3 Low Level Balanced Flue Terminal Positions ..................................................................................................51

6.0 Air Supply for Combustion & Ventilation

6.1 Open Flue Boilers ..........................................................................................................................................

53

6.2 Balanced Flue Boilers – Boilers in a Compartment .........................................................................................

53

7.0 Installation Requirements

7.1 General Requirements ...................................................................................................................................54

7.2 Sealed Systems ............................................................................................................................................

55

7.3 Combi Domestic Hot Water ...........................................................................................................................

56

8.0 Burners

8.1 RDB Burner ...................................................................................................................................................

57

8.2 Oil Pump .......................................................................................................................................................

57

8.3 Electrode Setting ...........................................................................................................................................

58

8.4 Burner Start-Up Cycle ...................................................................................................................................

58

8.5 Air Damper Adjustment .................................................................................................................................

58

9.0 Commissioning & Servicing

9.1 Commissioning..............................................................................................................................................59

9.2 Servicing .......................................................................................................................................................

59

10.0 Burner Fault Finding

10.1 Riello RDB .....................................................................................................................................................60

11.0 Combi Fault Finding

11.1 Central Heating .............................................................................................................................................61

11.2 Domestic Hot Water ......................................................................................................................................

62

12.0 Optional Boiler Mounted Digital Timer

12.1 Operating Instructions ...................................................................................................................................63

13.0 Spares

13.1 RDB 2.2 Spares ............................................................................................................................................

67

13.2 RDB 3.2 Spares ............................................................................................................................................

68

13.3 Pipe Spares ...................................................................................................................................................

69

13.4 Short Parts List – Boiler .................................................................................................................................71

14.0 Your Guarantee, Terms & Conditions .....................................................................................................................72

Commissioning/Service Record .............................................................................................................................73

Page 2

USER INSTRUCTIONS

Dual Thermostat

The radiator temperature is regulated via the

boiler control thermostat. The thermostat is user

adjustable from 55°C at its minimum setting (dial

‘0’) to 85°C at its maximum setting (dial ‘5’). In

order to provide an additional level of safety there

is a high limit thermostat which has a cut off point

of 110°C; this is factory set and is not adjustable.

If thermostat trips it needs to be reset manually.

High Limit Thermostat Reset

If the high level thermostat trip has operated,

remove the reset cover by using a coin or

screwdriver (turning anti clockwise) and press the

small red button now exposed. Do not press the

reset button while the boiler is still hot as this will

cause damage to the thermostat.

Burner Lockout

When the pressure jet oil fired burner stops after

failing to fire the red reset button will be illuminated.

This indicates that there is a fault or there is no

fuel getting to the burner. The house holder should

only reset the burner twice in succession. If the

burner continues to lockout contact Warmflow or

your service engineer.

System Pressure – System & Combi Boilers

When the boiler is connected to a sealed system

the system pressure should be periodically

checked. The minimum pressure, as indicated by

the black needle, is 0.5 bar when the boiler is cold

and 2.5 bar when the boiler is at normal operating

temperature. If the pressure is outside this range

contact Warmflow or your installer.

Burner Lock Out Reset

System Pressure

USER INSTRUCTIONS

Dual Thermostat

The radiator temperature is regulated via the

boiler control thermostat. The thermostat is user

adjustable from 55°C at its minimum setting (dial

‘0’) to 85°C at its maximum setting (dial ‘5’). In

order to provide an additional level of safety there

is a high limit thermostat which has a cut off point

of 110°C; this is factory set and is not adjustable.

If thermostat trips it needs to be reset manually.

High Limit Thermostat Reset

If the high level thermostat trip has operated,

remove the reset cover by using a coin or

screwdriver (turning anti clockwise) and press the

small red button now exposed. Do not press the

reset button while the boiler is still hot as this will

cause damage to the thermostat.

Control Thermostat

High

Limit

Reset

Reset

Notes

Control Thermostat

High

Limit

Reset

Notes

Page 3

Filling Loop

If the system pressure falls below the minimum

(eg, removal of radiator for decorating purposes)

then the system should be topped up using the

filling loop valve. After the system has been topped

up the pressure gauge should read 1 bar when

the system is cold. The valve must be fully closed

and the filling loop flexible removed from the valve,

expect a small water loss from the pipe.

Combi Control Panel

The heating control thermostat is user adjustable

from 55°C to 85°C. In order to provide an

additional level of safety there is a high limit

thermostat which has a cut off point of 110°C;

this is factory set and is not adjustable. The high

limit thermostat is located under the control

panel to the left hand side, press button to reset.

As standard the panel is fitted with two on/off

selector switches to control hot water and central

heating. These switches can be replaced by the optional two channel digital

programmer, instructions for use are provided in the main boiler handbook.

This boiler must be serviced annually. Contact Warmflow for further

details.

In the event of a breakdown please contact your commissioning engineer

who should then contact our service department whilst at your home, to

report the fault.

High Limit

Reset Button

Underneath

Filling

Loop

Valve

Flexible

Filling

Loop

Hose

Control Thermostat Knob

Page 4

CONDENSING BOILER INSTALLATION

REQUIREMENTS

The Warmflow condensing boiler can be fitted to most installations using

standard practices and techniques.

There are however a number of considerations that must be taken into

account.

1. All existing systems must be properly flushed to remove any sediment/

sludge in order to prevent any blockage or reduction in efficiency of the

boiler.

2. The system must be fully pumped.

3. The primary difference between an ordinary boiler and a condensing

boiler is the condensate drain. The drain can be plumbed from the

condensate trap in any ordinary plastic pipe, eg, plastic overflow pipe,

directly into the household drain or soak away.

Any blockage in the drain could lead to an alteration in the combustion

settings because of partially blocked flueways.

Where the boiler is fitted into a basement a condensate pump may be

required.

4. As an indicator of the increased efficiency of a condensing boiler there

may be a visible plume of ‘steam’ from the flue. Care needs to be

exercised when positioning the appliance and selecting the type of flue

to ensure that the plume does not cause a nuisance to the householder

or to surrounding properties.

As the water temperature in the system rises the pluming effect will

diminish. Even where pluming is not visible the boiler is still operating

more efficiently than a standard boiler.

Page 5

BEFORE FITTING A COMBI BOILER

THE INSTALLER MUST CHECK:

1. What the maximum hot water demand placed on the boiler is likely

to be. Not every installation is suitable for a Combi boiler. Systems

requiring very high hot water flow rates may be better suited with an

unvented cylinder.

2. That the mains are capable of supplying up to 24 litre/min with a

minimum dynamic pressure of 1.8 bar at the boiler. This is to ensure that

the boiler can achieve its maximum output. To protect the appliance

and to prevent excessive flow rates, a pressure reducing valve must be

fitted to limit the maximum supply pressure to 3 bar.

3. Where the mains water pressure is supplied via a borehole pump and

accumulator the pressure variation must not affect the thermostatic

mixer valve. Contact Warmflow for further details.

4. The hardness of the mains water supply. Systems with hard water must

be fitted with a suitable chemical scale preventer (eg Fernox Quantomat

or Combimate).

5. That the flow from any one hot water outlet does not exceed the

maximum recommended. This applies particularly to baths which are

usually fitted with larger taps and larger bore supply pipes. It may be

necessary to restrict the flow to these taps by reducing the bore of the

supply pipework (eg 15mm) or by fitting a restrictor into the pipework.

6. That any outlet when opened does not starve all the other outlets of hot

water. If more than one outlet is open at the same time then the total

flow from all the outlets should not exceed the maximum flow rate of

the boiler.

7. That any showers being supplied with hot water by the boiler are

compatible with this type of appliance.

It should be noted that the boiler has been factory fitted with an

18 litre/min flow restrictor.

The manufacturer’s guarantees are void if the appliance is not installed

and commissioned in accordance with the recommendations made

herein.

Page 6

1.0 General Information

1.1 Introduction

Note: All our domestic appliances have been independently tested and

accredited as exceeding the minimum SEDBUK efficiency levels required for

their type, in compliance with the Building Regulations Approved Document

L1A, L1B for England and Wales, the Building Standards (Scotland)

Regulations Section 6, Part F Northern Ireland and Part L Republic of

Ireland.

Warmflow oil fired condensing boilers are designed to burn Class C2 (28 sec

redwood) kerosene only and to be used on a fully pumped system, and are suitable

for connection to sealed heating systems.

As standard the Combi and System boilers are fitted with a system expansion

vessel, circulating pumps, filling loop, pressure gauge and safety valve. An optional

7-day electronic programmer kit is also available for all Utility boiler models.

The Combi can provide at mains pressure domestic hot water without the need for

a storage cylinder.

The manufacturer’s guarantees are void if the appliance is not installed and

commissioned in accordance with the recommendations made herein.

1.2 General Requirements

The installation of the boiler must be in accordance with the following regulations.

BS5410 : PART 1 Code of practice for oil firing.

BS5449 : PART 1 Forced circulation hot water systems.

BS7593 : Treatment of water in domestic hot water central heating systems.

Current Building Regulations: Part J England and Wales

Section 3 Scotland

Part L Northern Ireland

Part J Republic of Ireland

Current IEE Regulations

BS7074 : PART 1 Application Selection & Installation of Expansion Vessels

The heating system should be installed by a competent installer in accordance with

the recommendations laid down by HVCA, OFTEC and sound engineering practice.

In order to comply with building regulations OFTEC forms CD10 for

installations and CD11 for commissioning should be left with the customer.

Alternatively the installation can be inspected and approved by a building

control officer. CD10 and CD11 forms are available from OFTEC on

Tel: 0845 658 5080, Fax: 0845 658 5181.

Page 7

1.3 Combi General Requirements

The boiler will have a DHW priority when both domestic hot water (DHW) and central

heating (CH) are selected. So if the flow switch is closed or the heat store has not

been satisfied the entire output of the boiler is directed to DHW before the boiler will

switch over to CH. When fully cold it can take up to 20 minutes for the heat store of

a 90,000 Btu/h combi to be satisfied, and slightly longer for a 70,000 Btu/h combi.

After a draw-off of 120L at 24L/min, with an average temperature rise of 32ºC,

the thermal store of a 90,000 Btu/h combi has a recovery time of approximately

7 minutes. A 70,000 Btu/h combi will take slightly longer to recover.

Note: If HW has not been selected no hot water can be produced even if the heat

store is up to temperature.

1.3.1 Pump Overrun

Where there is a build up of excess heat in the boiler primary heat exchanger

and the central heating has not been selected then the pump overrun thermostat

will operate. The excess heat will then be pumped into the heat store. Once the

temperature has fallen in the boiler and the pump overrun stat is satisfied, then the

hot water pump will stop.

Page 8

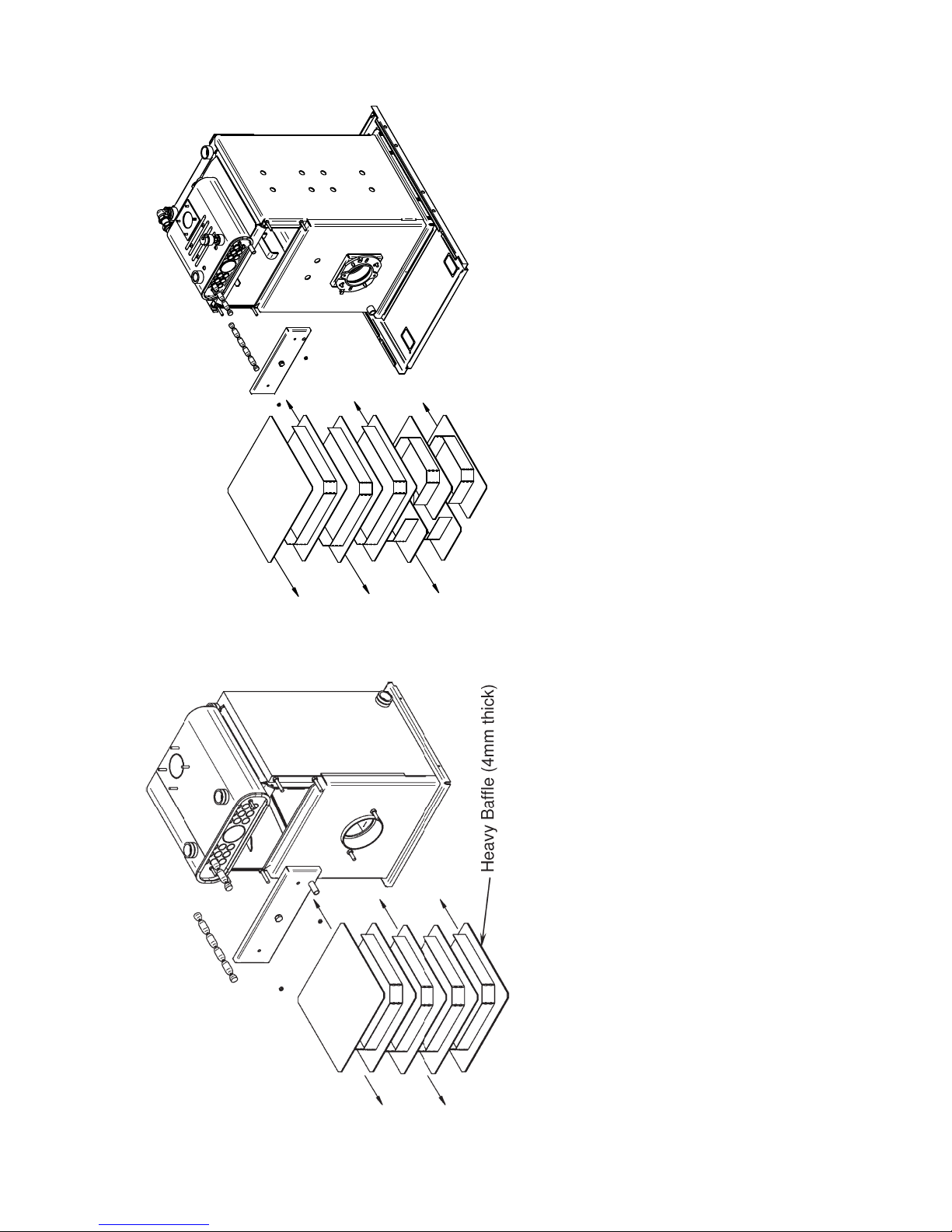

1.4 Baffle Positioning

The primary heat exchanger baffles consist of one

heavy baffle stack (4mm thick) at the bottom, 3

lighter baffle stacks (3mm thick) in the middle and 1

baffle plate (3mm thick) at the top. Upon installation

or after servicing, ensure the baffles are in the correct

order and correctly stacked. To achieve maximum

efficiency push the primary heat exchanger baffles in

the direction of the arrows as shown. The secondary

heat exchanger spring baffles must be fully inserted

into the heat exchanger tubes (narrow end first).

The primary heat exchanger baffles consist of two

half-width baffle stacks at the bottom, 3 full-width

baffle stacks in the middle and 1 baffle plate at the

top. Upon installation or after servicing, ensure the

baffles are in the correct order and correctly stacked.

To achieve maximum efficiency, push the primary

heat exchanger baffles in the direction of the arrows

as shown. The secondary heat exchanger spring

baffles must be fully inserted into the heat exchanger

tubes (narrow end first).

Models up to 120 HE 150 HE Models

Page 9

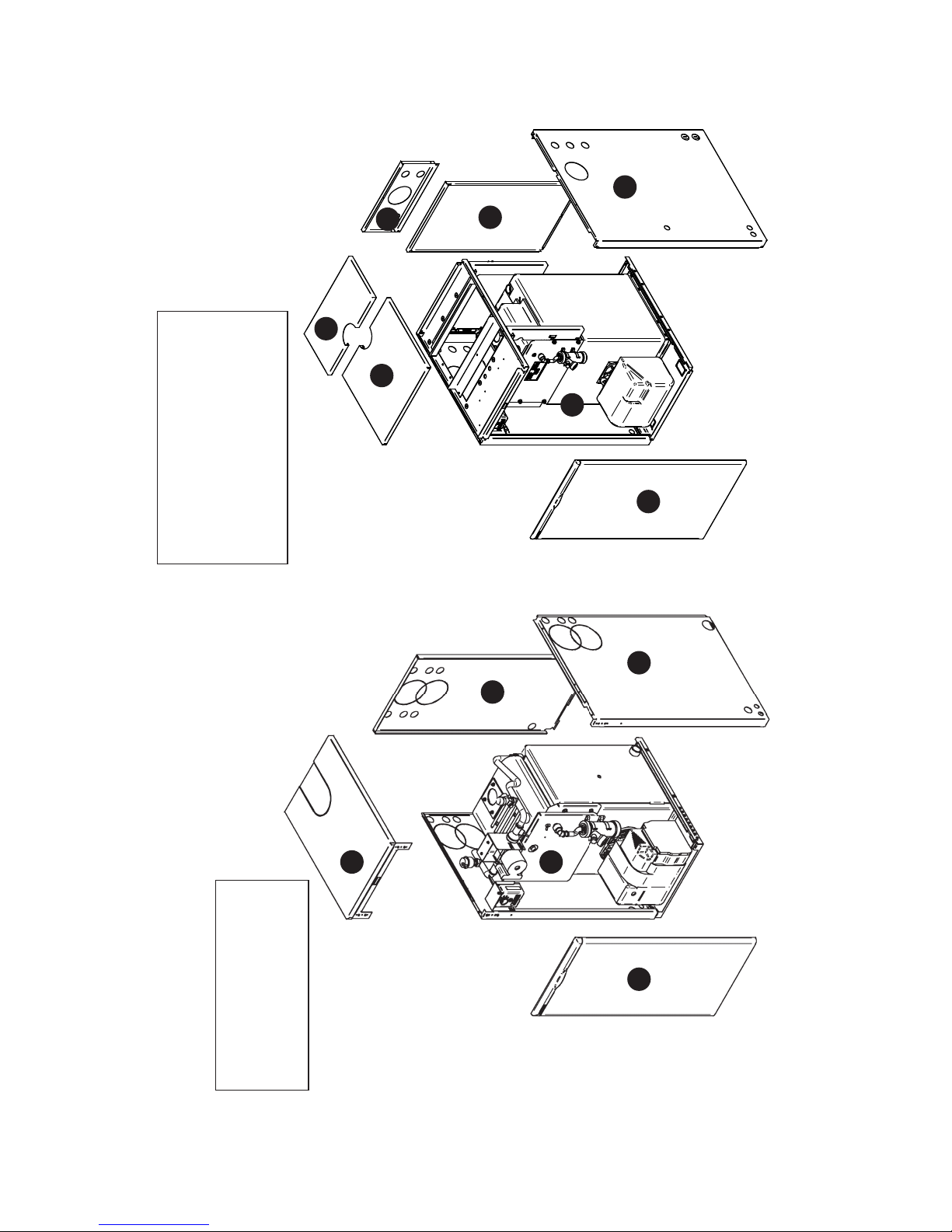

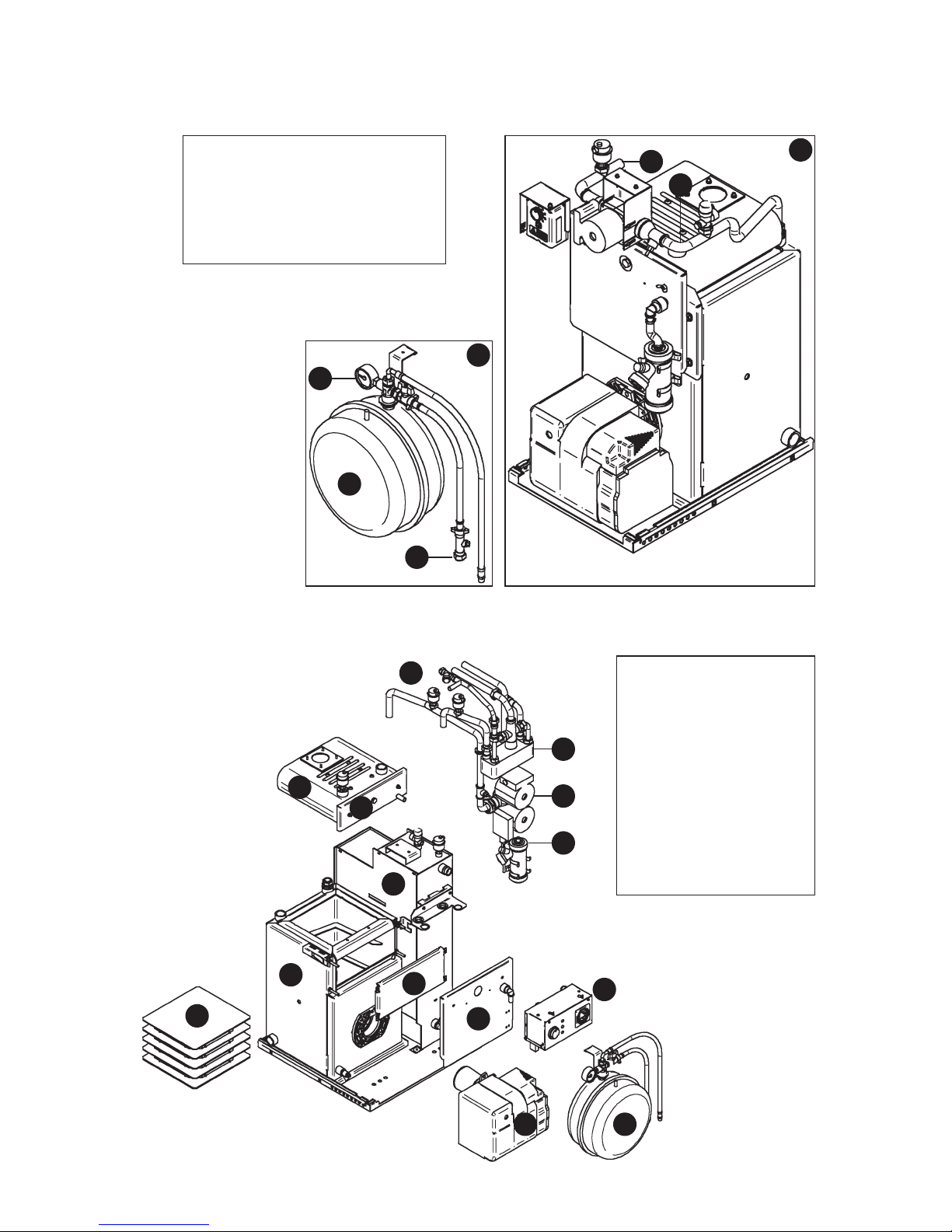

1.5 Components

1.5.1 U-Series Utility – Casing Components

1. Boiler Assembly

2. Top Casing (removable)

3. Rear Casing

4. Side Casing

5. Front Casing (removable)

1

2

3

45

Models up to 120 HE 150 HE Models

1. Boiler Assembly

2. Top Front Casing (removable)

3. Top Rear Casing (removable)

4. Rear Flue Casing

5. Rear Casing (removable)

6. Side Casing

7. Front Casing (removable)

1

2

3

5

7

4

6

Page 10

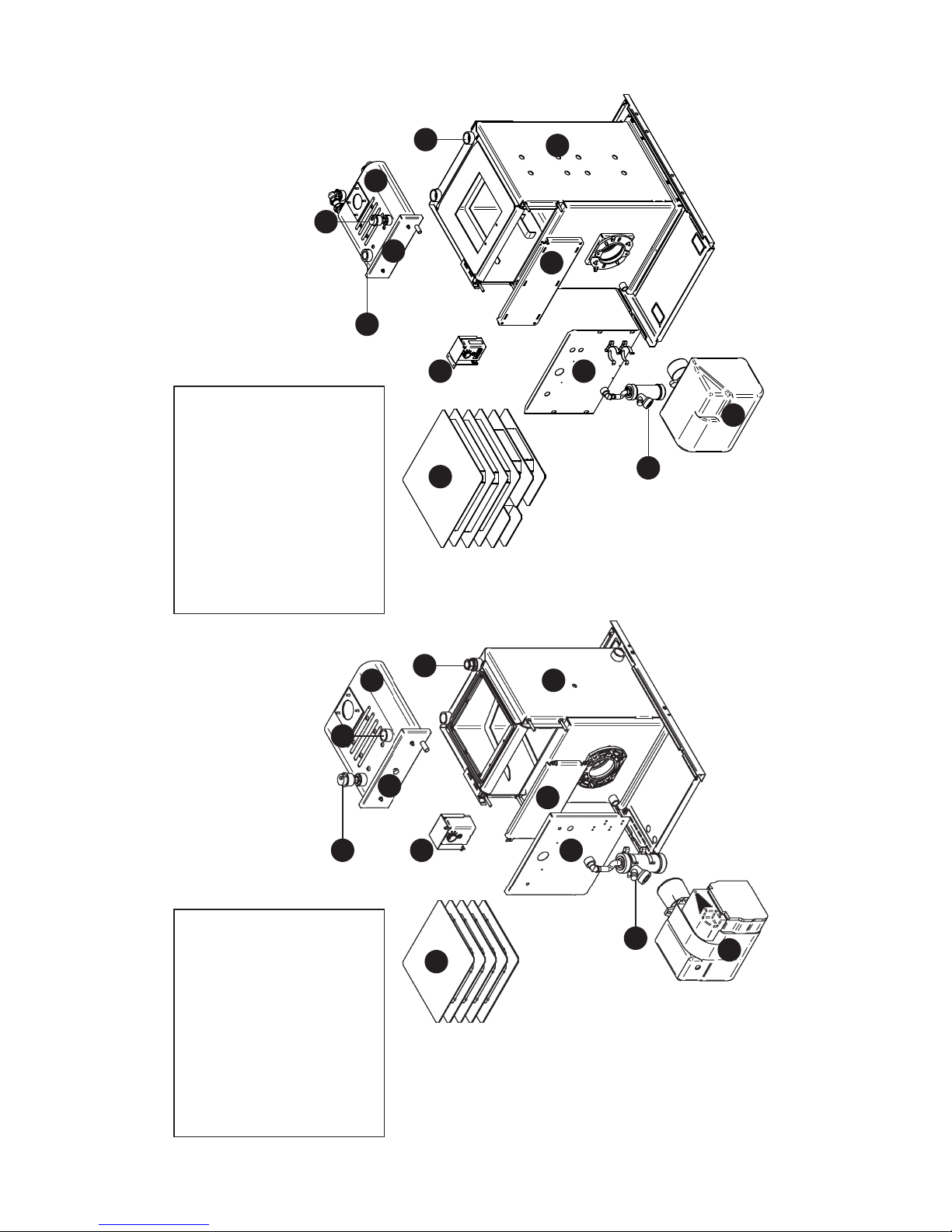

1.5.2 U-Series Utility – Pre-Wired (UHE) – Key Components

1. Heat Exchanger

2. Condensing Unit

3. Auto Air Vent

4. Service Door

5. ‘Dual-Safe’ Thermostat

6. Heat Exchanger Baffles

7. Service Door

8. Service Door Cover

9. Condensate Trap

10. Riello RDB 2.2 Burner

11. Heating Flow Connection

12. Heating Return Connection

1

2

12

4

5

6

7

8

9

11

3

10

Models up to 120 HE 150 HE Models

1

2

3

4

56

7

8

9

11

12

10

1. Heat Exchanger

2. Condensing Unit

3. Auto Air Vent

4. Service Door

5. ‘Dual-Safe’ Thermostat

6. Heat Exchanger Baffles

7. Service Door

8. Service Door Cover

9. Condensate Trap

10. Riello RDB 3.2 Burner

11. Heating Flow Connection

12. Heating Return Connection

Page 11

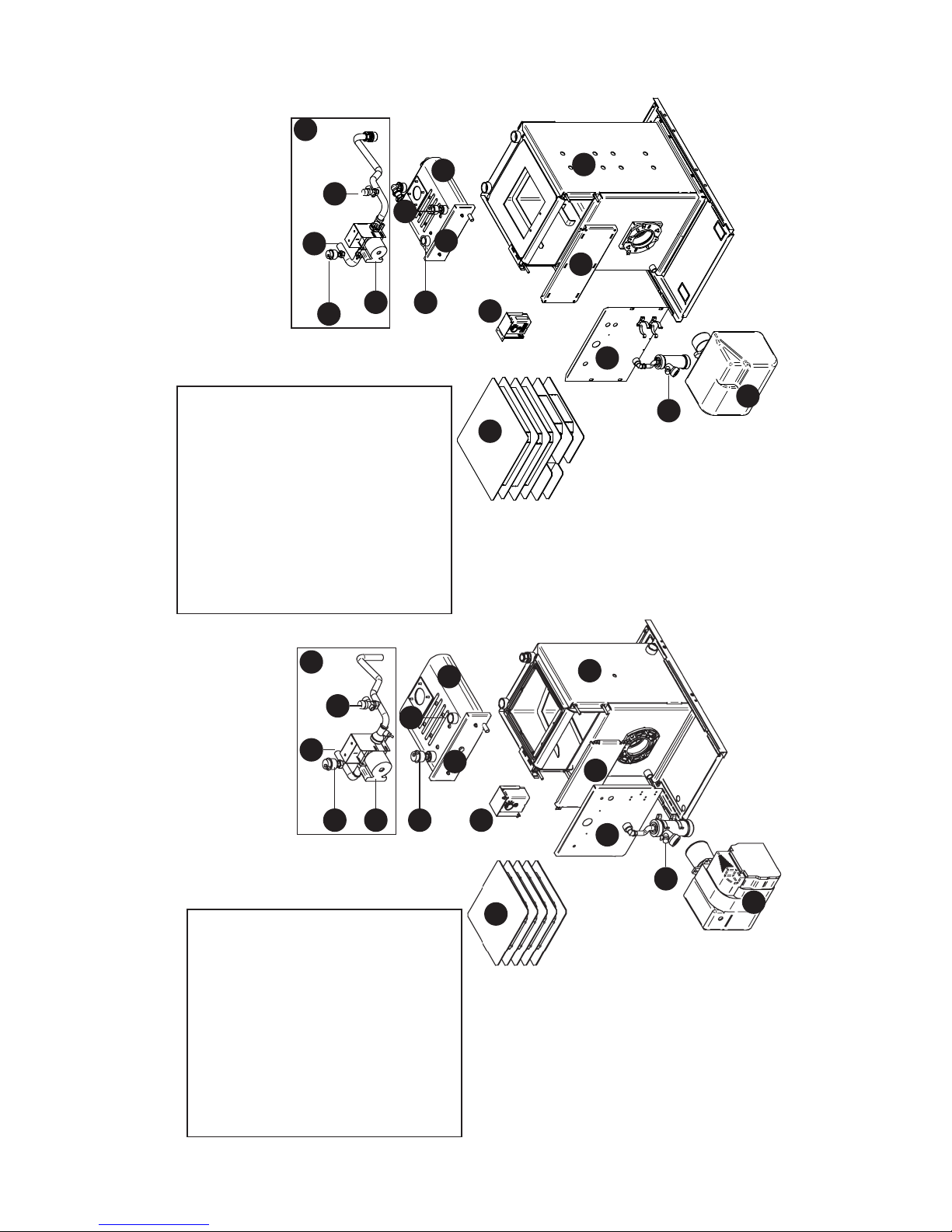

1.5.3 U-Series Utility – Pumped (UPHE) – Key Components

1. Heat Exchanger

2. Condensing Unit

3. Pipework Assembly

4. Pressure Relief Valve

5. Auto Air Vent

6. Circulating Pump

7. Auto Air Vent

8. Service Door

9. ‘Dual-Safe’ Thermostat

10. Heat Exchanger Baffles

11. Service Door

12. Service Door Cover

13. Condensate Trap

14. Riello RDB 2.2 Burner

15. Heating Flow Connection

16. Heating Return Connection

1

11

12

10

2

8

9

16

4

6

5

15

13

14

7

3

Models up to 120 HE 150 HE Models

1

11

12

10

2

8

9

7

4

6

5

15

13

14

16

3

1. Heat Exchanger

2. Condensing Unit

3. Pipework Assembly

4. Pressure Relief Valve

5. Auto Air Vent

6. Circulating Pump

7. Auto Air Vent

8. Service Door

9. ‘Dual-Safe’ Thermostat

10. Heat Exchanger Baffles

11. Service Door

12. Service Door Cover

13. Condensate Trap

14. Riello RDB 3.2 Burner

15. Heating Flow Connection

16. Heating Return Connection

Page 12

1.5.4 U-Series Utility – System (USHE) – Key Components

1. Pumped (UPHE) Boiler Assembly

2. System Kit (SK1)

3. Pressure Gauge

4. Expansion Vessel

5. Filling Loop

6. Heating Flow Connection

7. Heating Return Connection

1

6

7

3

4

2

5

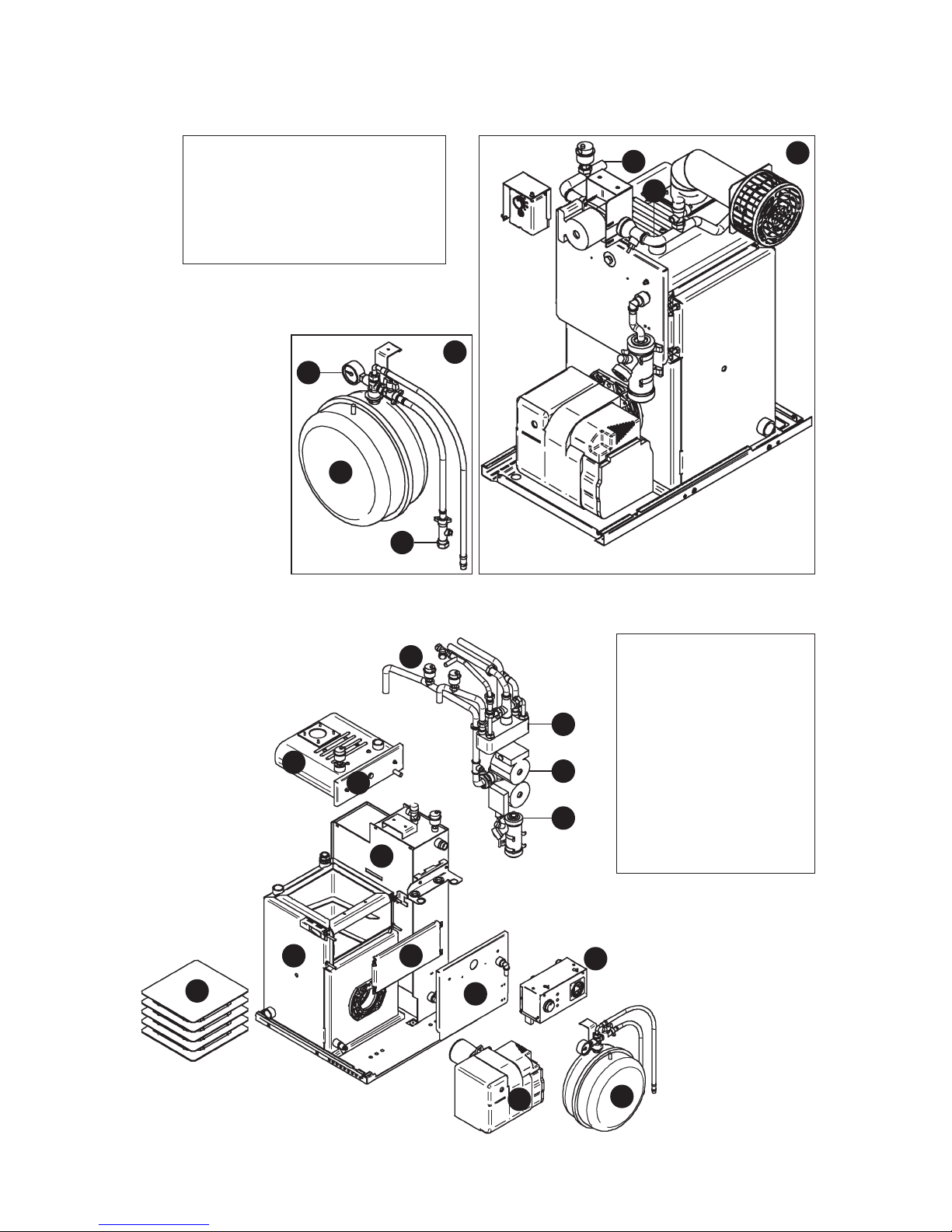

1.5.5 U-Series Utility – Combi (UCHE) – Key Components

1. Heat Exchanger

2. Heat Store

3. Condensing Unit

4. Service Door

5. Pipework Assembly

6. Plate Heat Exchanger

7. Twin Head Pump

8. Condensate Trap

9. Service Door

10. Service Door Cover

11. Control Panel

12. Expansion Vessel

13. Riello RDB 2.2 Burner

14. Heat Exchanger Baffles

1

2

3

4

5

6

7

8

9

10

11

1213

14

Page 13

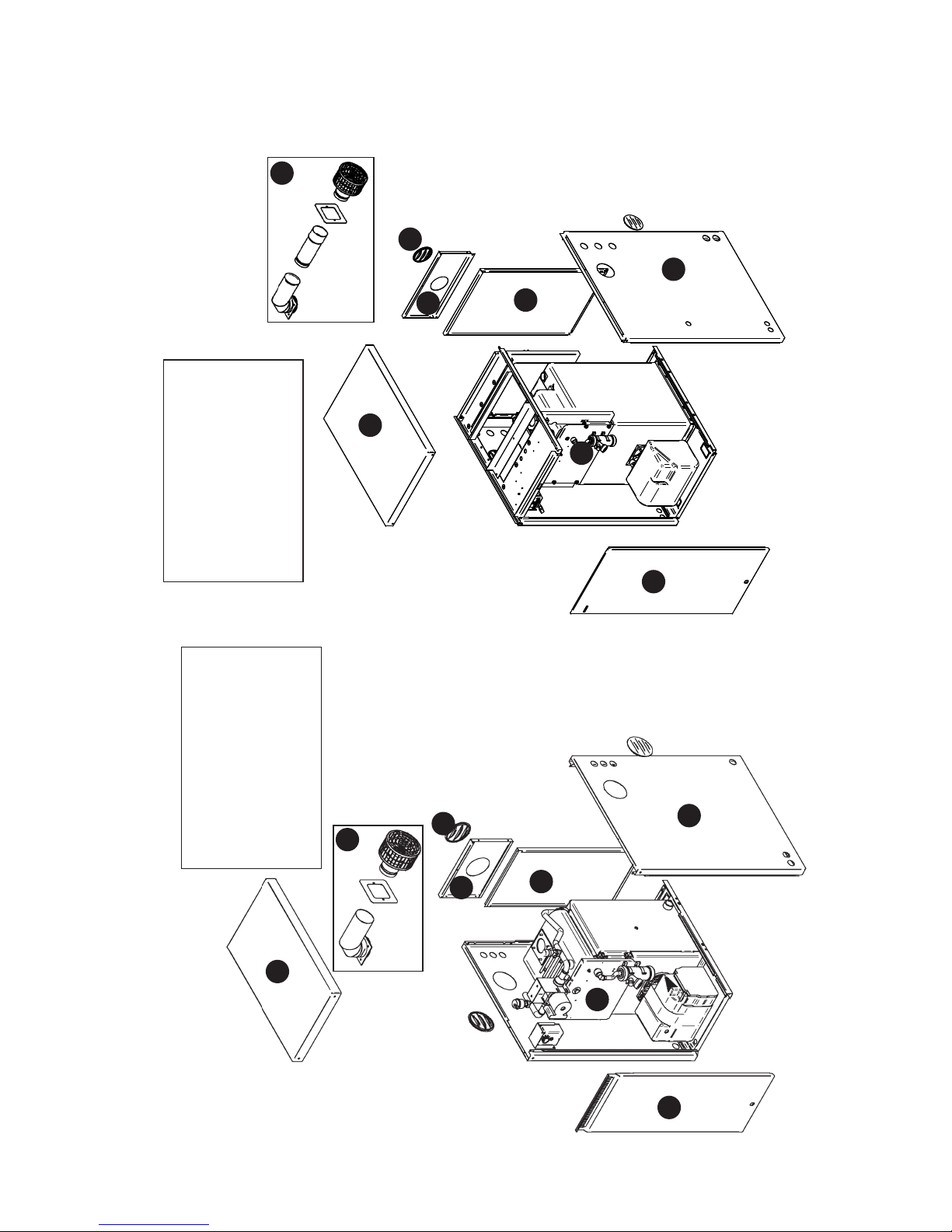

1.5.6 K-Series Kabin Pak – Casing Components

1. Boiler Assembly

2. Top Casing (removable)

3. Flue Assembly (removable)

4. Rear Flue Casing

5. Blanking Plug (removable)

6. Rear Casing (removable)

7. Side Casing

8. Front Casing (removable)

1

2

3

4

5

6

7

8

Models up to 120 HE 150 HE Models

1

2

3

4

5

6

7

8

1. Boiler Assembly

2. Top Casing (removable)

3. Flue Assembly (removable)

4. Rear Flue Casing

5. Blanking Plug (removable)

6. Rear Casing (removable)

7. Side Casing

8. Front Casing (removable)

Page 14

1.5.7 K-Series Kabin Pak – Pre-Wired (KHE) – Key Components

1. Heat Exchanger

2. Condensing Unit

3. Auto Air Vent

4. Service Door

5. ‘Dual-Safe’ Thermostat

6. Heat Exchanger Baffles

7. Service Door

8. Service Door Cover

9. Condensate Trap

10. Riello RDB 2.2 Burner

11. Heating Flow Connection

12. Heating Return Connection

1

2

3

5

4

6

7

8

9

10

11

12

Models up to 120 HE 150 HE Models

1

2

3

4

56

7

8

9

11

12

10

1. Heat Exchanger

2. Condensing Unit

3. Auto Air Vent

4. Service Door

5. ‘Dual-Safe’ Thermostat

6. Heat Exchanger Baffles

7. Service Door

8. Service Door Cover

9. Condensate Trap

10. Riello RDB 3.2 Burner

11. Heating Flow Connection

12. Heating Return Connection

Page 15

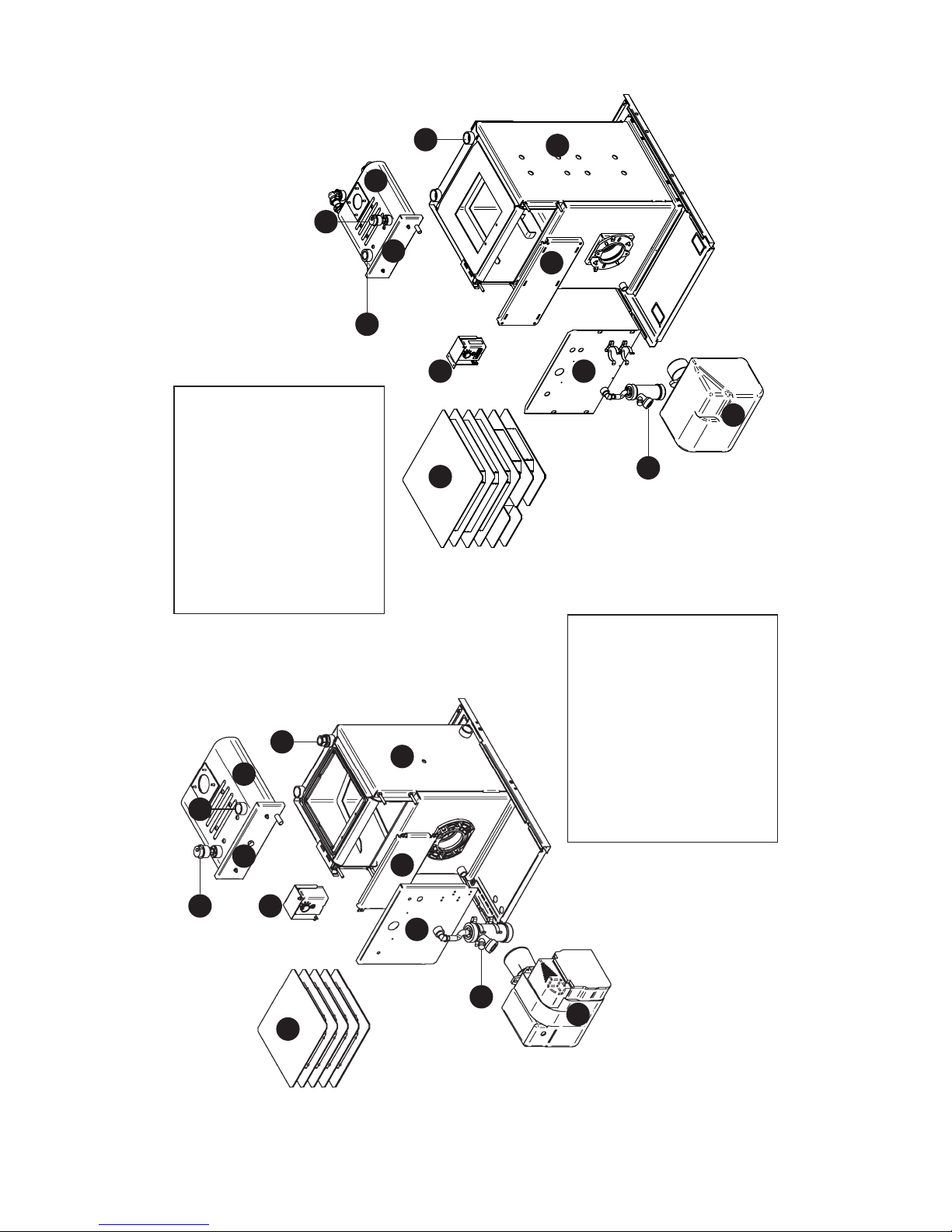

1.5.8 K-Series Kabin Pak – Pumped (KPHE) – Key Components

1. Heat Exchanger

2. Condensing Unit

3. Pipework Assembly

4. Pressure Relief Valve

5. Auto Air Vent

6. Circulating Pump

7. Auto Air Vent

8. Service Door

9. ‘Dual-Safe’ Thermostat

10. Heat Exchanger Baffles

11. Service Door

12. Service Door Cover

13. Condensate Trap

14. Riello RDB 2.2 Burner

15. Heating Flow Connection

16. Heating Return Connection

1

8 2

45

6

7

9

10

11

12

13

14

15

16

3

Models up to 120 HE 150 HE Models

1

11

12

10

2

8

9

7

4

6

5

15

13

14

16

3

1. Heat Exchanger

2. Condensing Unit

3. Pipework Assembly

4. Pressure Relief Valve

5. Auto Air Vent

6. Circulating Pump

7. Auto Air Vent

8. Service Door

9. ‘Dual-Safe’ Thermostat

10. Heat Exchanger Baffles

11. Service Door

12. Service Door Cover

13. Condensate Trap

14. Riello RDB 3.2 Burner

15. Heating Flow Connection

16. Heating Return Connection

Page 16

1.5.9 K-Series Kabin Pak – System (KSHE) – Key Components

1. Pumped (KPHE) Boiler Assembly

2. System Kit (SK1)

3. Pressure Gauge

4. Expansion Vessel

5. Filling Loop

6. Heating Flow Connection

7. Heating Return Connection

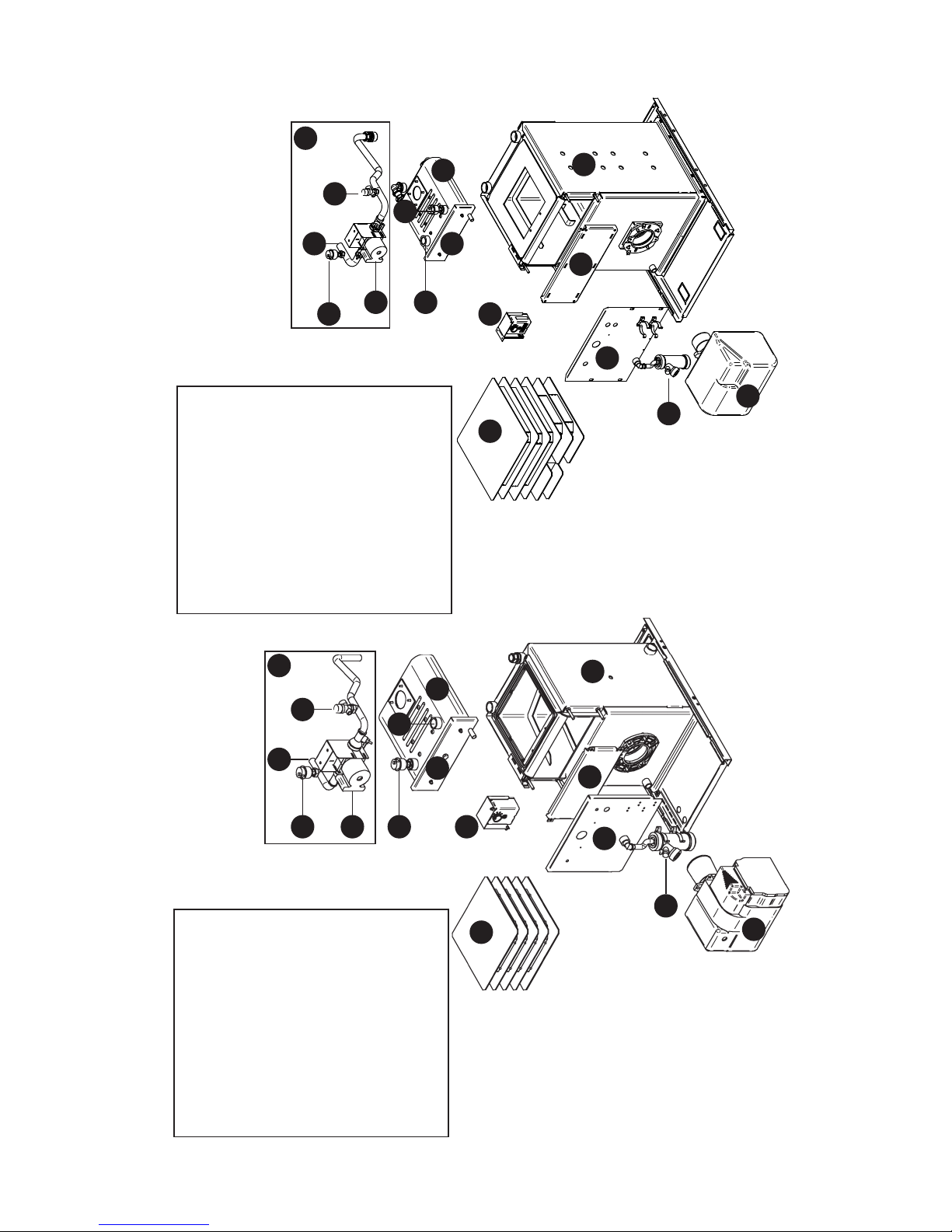

1.5.10 K-Series Kabin Pak – Combi (KCHE) – Key Components

1. Heat Exchanger

2. Heat Store

3. Condensing Unit

4. Service Door

5. Pipework Assembly

6. Plate Heat Exchanger

7. Twin Head Pump

8. Condensate Trap

9. Service Door

10. Service Door Cover

11. Control Panel

12. Expansion Vessel

13. Riello RDB 2.2 Burner

14. Heat Exchanger Baffles

6

7

4

2

3

5

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Page 17

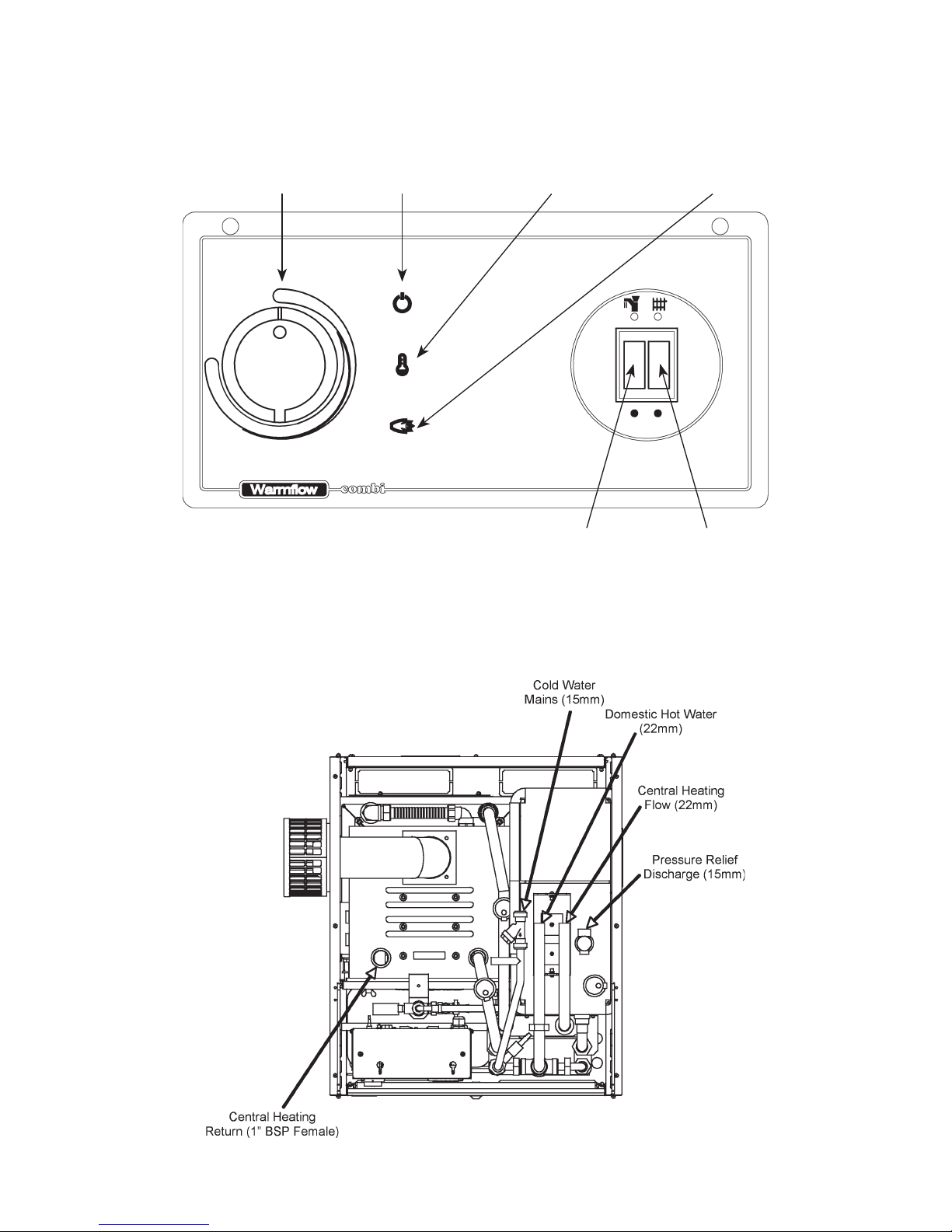

1.5.11 Combi Control Panel Layout

Control

Thermostat

Mains On

Lamp (Green)

High Limit Tripped

Lamp (Yellow)

Burner Lockout

Lamp (Red)

HW On/Off

Switch

CH On/Off

Switch

High Limit Thermostat Reset

(Underneath)

1.5.12 Combi Pipe Layout (UCHE & KCHE Models)

Page 18

2.0 Technical Details

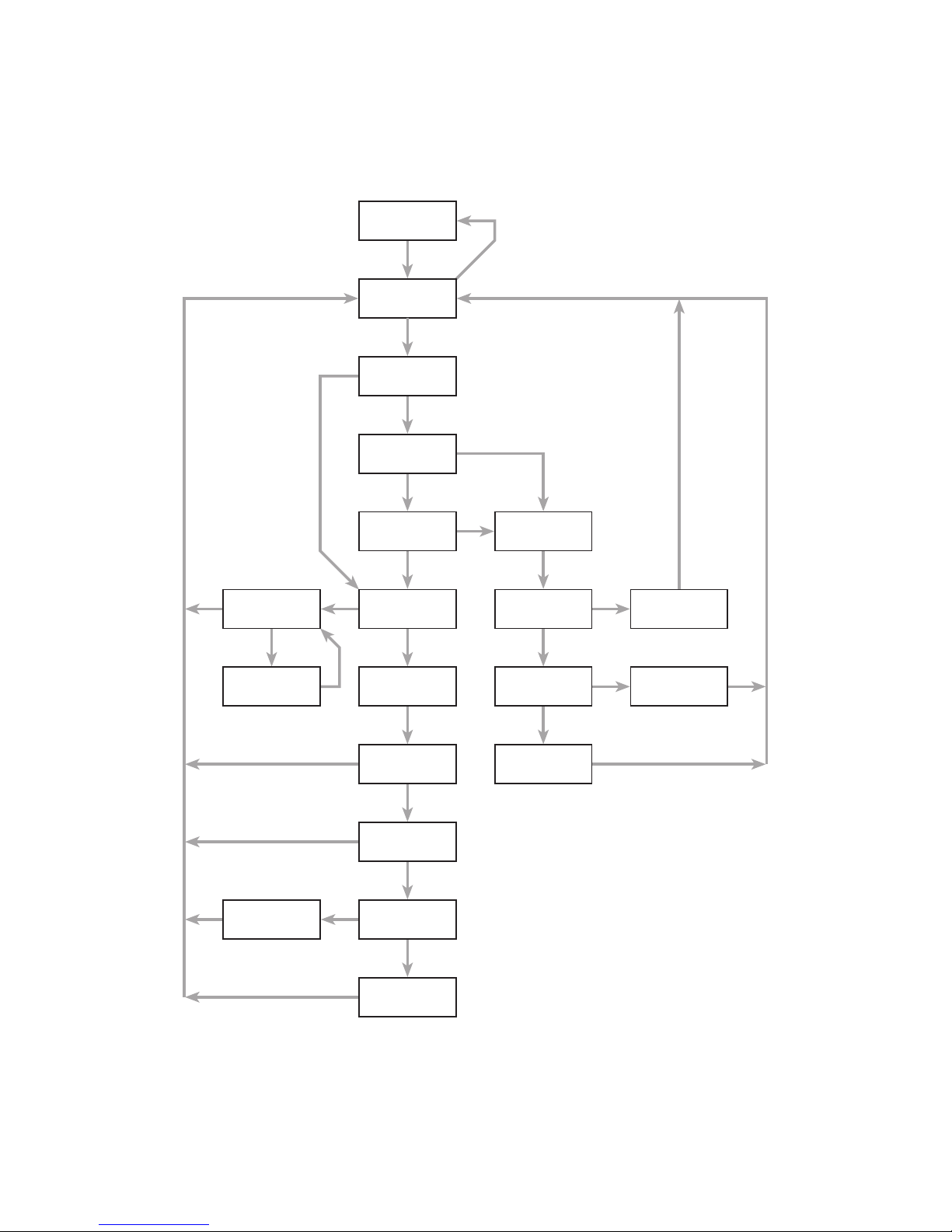

2.1 Combi Sequence of Operation Flow Chart

Power

On

Timer Calling

For Heat

HW

Selected

Flow Switch

Closed

DHW Tank

Stat Satisfied

CH

Selected

CH Pump

Only Runs

Room Stat

Satisfied

Boiler Stat

Satisfied

Boiler Limit

Stat Tripped

Burner

Fires

DHW Pump

Only Runs

HW Limit

Stat Satisfied

Boiler Limit

Stat Tripped

Burner

Fires

Burner

Stops

Press

Reset Button

Press

Reset Button

Pump Overrun

Stat Satisfied

DHW Pump

Only Runs

YES

YES

YES

NO

YES

NO

YES

YES

YES

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES NO

NO

NO

Page 19

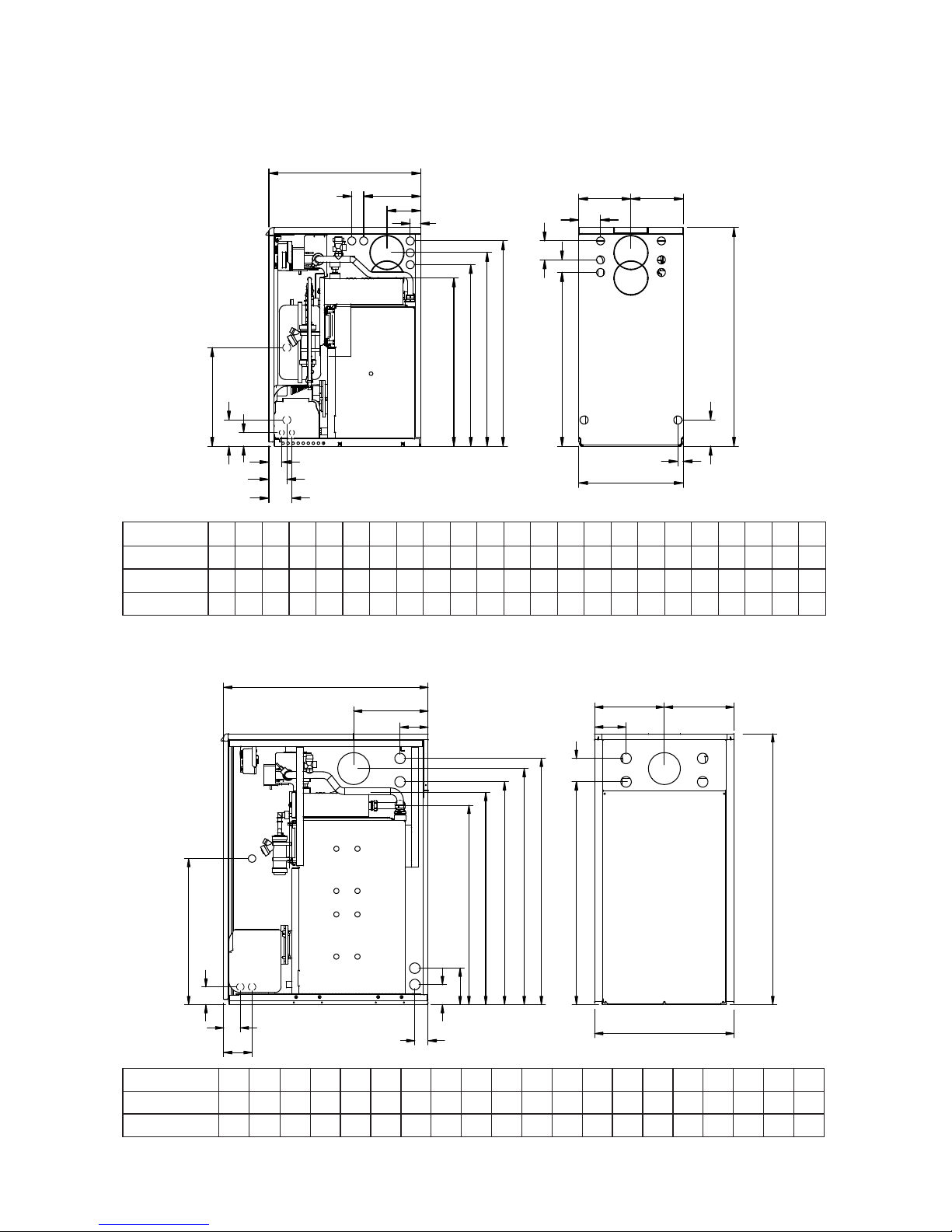

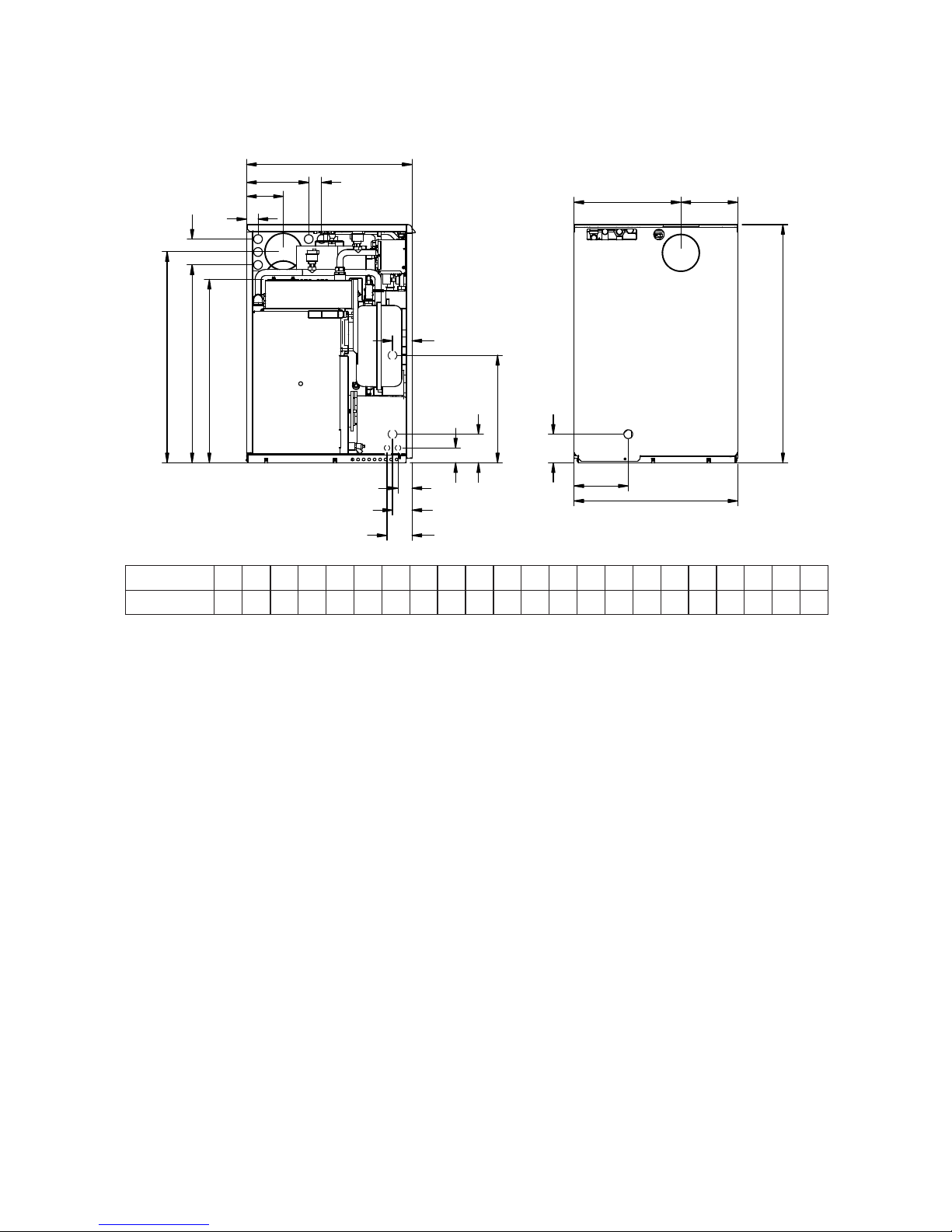

2.2 Dimensions

2.2.1 U-Series Utility (UHE, UPHE & USHE Models up to 120HE)

2.2.2 U-Series Utility (150 HE Models)

MODEL

ABCDEFGHJKLMNPRSTUVWXYZ

U~

600

413

865

766

134

66686755068721104

2264741

390

10454517191

718

812

UP~

600

413

865

766

134

66686755068721104

2264741

390

10454517191

718

812

US~

600

413

865

766

134

66686755068721104

2264741

390

10454517191

718

812

MODEL

ABCDEFGHJKLMNPRSTUV

W

U150HE

872

595

1155

1007

134

9057571

1215785

155

850

950

100

318

120

623

950

1050

UP150HE

872

595

1155

1007

134

9057571

1215785

155

850

950

100

318

120

623

950

1050

Page 20

2.2.3 U-Series Utility (UCHE Models)

MODEL

ABCDEFGHJKLMNPRSTUVWX

Y

UC~

600

595

865

766

134

388

207

666472264294

71891715154

104

39071104

197

Page 21

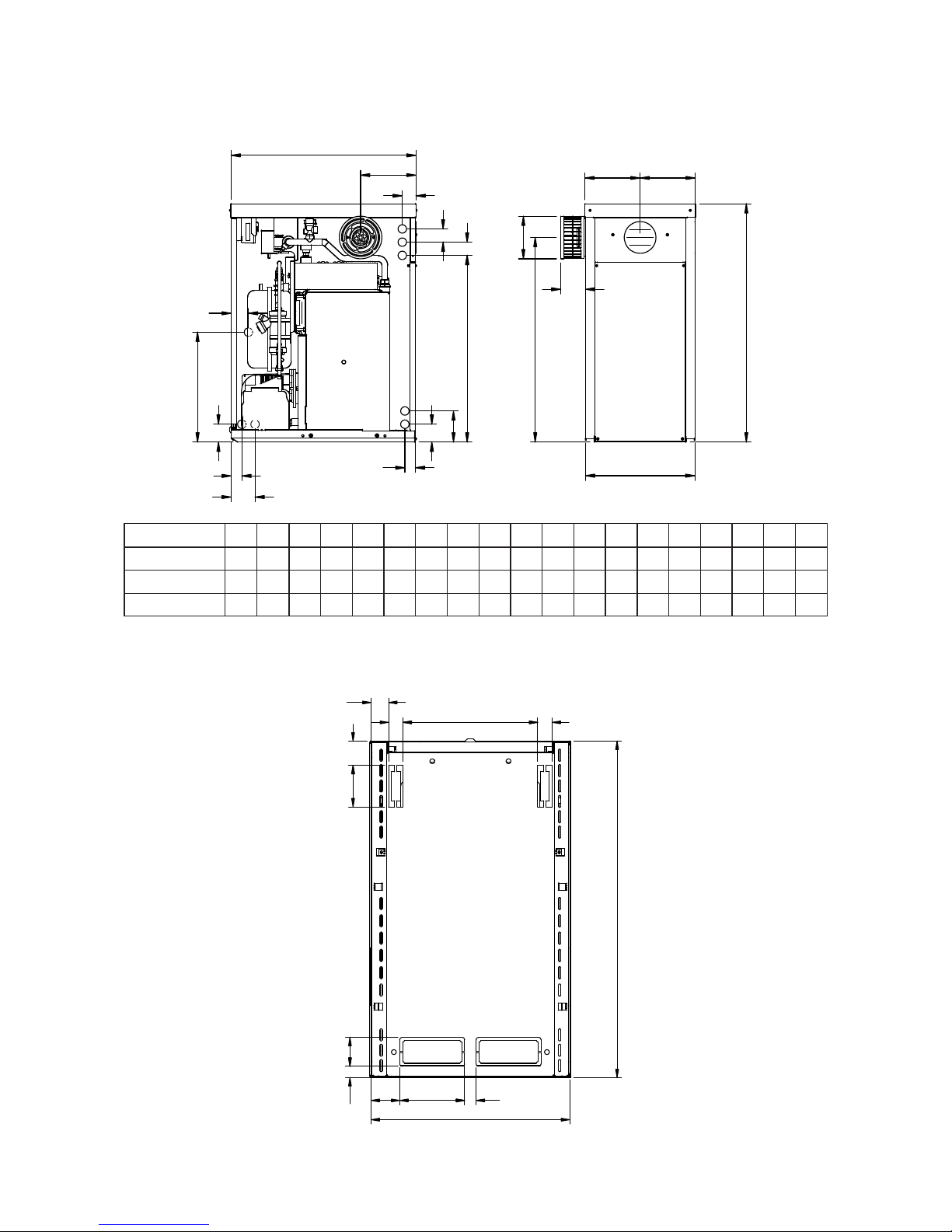

2.2.4 K-Series Kabin Pak (KHE, KPHE & KSHE Models up to 120HE)

2.2.5 K-Series Kabin Pak Base Tray (KHE, KPHE & KSHE Models up to 120HE)

FRONT

MODEL

ABCDEFGHJKLMNPRSTUV

K~

700

413

900406740210

7055050

161937736790

11752415

65

KP~

700

413

900406740210

7055050

161937736790

11752415

65

KS~

700

413

900406740210

7055050

161937736790

11752415

65

Page 22

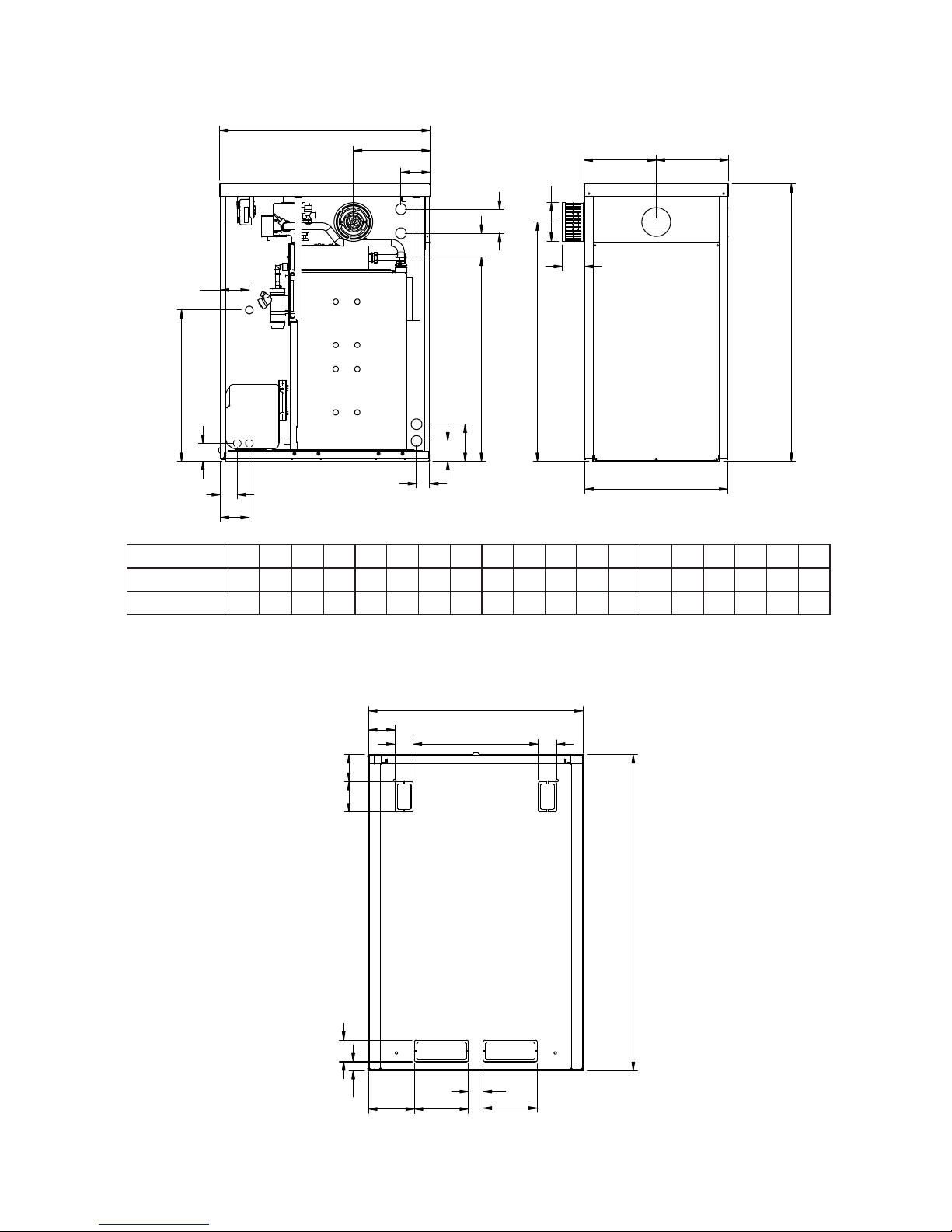

2.2.6 K-Series Kabin Pak (150HE Models)

2.2.7 K-Series Kabin Pak Base Tray (150HE Models)

FRONT

MODEL

ABCDEFGHJKLMNPRSTUV

K150HE

595

997

876

1155931617570

1205585

155

850

100

100

320

122

630

120

KP150HE

595

997

876

1155931617570

1205585

155

850

100

100

320

122

630

120

Page 23

2.2.8 K-Series Kabin Pak (KCHE Models)

2.2.9 K-Series Kabin Pak Base Tray (KCHE Models)

FRONT

MODEL

ABCDEFGHJKLMNPRSTUVWX

KC~

700

600

900

770

210

396

20992161525050705

1176740904067415

65

Page 24

2.3 Flue Options, Components & Dimensions

The use of any flue system other than that supplied or recommended by the

manufacturer will invalidate the warranty.

2.3.1 HE Low Level Balanced Flue Kit (FBF)

Comprising the following four main components.

1. Diverter Assembly

2. Extension

3. Elbow

4. Terminal End

5. Mounting Brackets

1

2

5

2

3

5

5

4

2.3.2 Plume Management Kit

Plume Management Kits are available for

our range of appliances. Please refer to the

Installation Instructions supplied with the kits.

Page 25

2.3.3 Warmflow HE Boiler Flue Components: 80/125 Ø

Note:

1. Flue fitting kit required.

2. If terminal is less than 2 metres above ground level terminal guard must be fitted.

3. Extension pipes and flue adaptor lengths quoted are effective lengths and not the actual length

of the piece.

4. All dimensions in mm unless otherwise stated.

Page 26

2.3.4 Vertical & High Level Terminal Options

Note:

1. All flues can utilise any combination of bends, straights, adaptors and terminals.

2. Ensure flue is arranged such that it falls continuously towards the boiler.

3. The Low Level, High Level and Vertical Balanced Flue Systems can use any combination of

flue extension pieces up to the maximum equivalent length depending upon boiler output as

illustrated in the above table.

BOILER

OUTPUT

(kW)

TOTAL EQUIVALENT FLUE LENGTH (m)

Vertical Balanced Flue High/Low Level Balanced Flue

8.0 5.015

8.0 5.021

8.0 5.026

6.0 3.530

4.0 2.533

4.0 2.544

Page 27

2.4 Condensate Disposal

The Warmflow high efficiency condensing boiler is supplied with a factory fitted, self

sealing condensate trap. The trap has been fitted inside the boiler casing to the right

hand side.

The condensate drainage pipe within the boiler is a flexible plastic hose which can

be trimmed to length. 3/4” or 22mm pipe should be connected to the flexible hose.

The pipe should not be made from steel or copper. The drainage pipe may run

into an internal soil stack or waste pipe, an external gulley, hopper or soakaway as

shown below.

The boiler when fully condensing will produce a maximum of 1.5 litres per hour of

condensate. It is recommended that the drainage pipe should have a minimum fall

of 1:20.

Page 28

2.5 Technical Data

2.5.1 U-Series Utility – Pre-Wired (UHE)

U90HEU70HEMODEL

Nominal kW

Heat Output Btu/hr

Nominal kW

Heat Input Btu/hr

Burner

Head

Secondary Air Damper

Flue mm

Diameter in

Flue Gas Temp °C

Smoke Bacarach

14.7

50,000

17.6

60,000

21

71,6502171,650

23.5

80,000

27.1

92,380

15.3

52,150

18.4

62,6002275,0002275,000

24.4

83,1752895,550

RDB 2.2 15-21 RDB 2.2 21-26

T1SH T2SH

B N/A

100 or 125

4 or 5

100 or 125

4 or 5

86 88 90 90 93 95

0 0

Kerosene Settings

Nozzle make

size

Oil Pump bar

Pressure psi

Max CO2 %

Approx Fuel litres/h

Flow Rate gals/h

Flow Connection

Return Connection

Water litres

Content gals

Boiler Weight Dry kg

Boiler Weight Wet

SEDBUK Efficiency %

Factory Settings

Danfoss 60°ES

0.5 0.5 0.6

Danfoss 60°ES

0.6 0.65 0.75

7.0

102

9.0

130

8.0

116

8.0

116

8.0

116

7.0

102

11.5 11.5 11.5 11.5 11.5 11.5

1.65

0.36

1.98

0.44

2.35

0.52

2.35

0.52

2.65

0.58

2.98

0.65

28mm Compression

1” BSP Female

28mm Compression

1” BSP Female

22

4.8

22

4.8

90

112

92.2

90

112

92.8

Highlighted in Bold

U120HE

27.1

92,380

32.7

111,600

28

95,550

29

99,050

34

116,000

RDB 2.2 26-33

T5S

N/A

100 or 125

4 or 5

95 98 110

0

Danfoss 60°ES

0.75 0.85 0.85

7.0

102

8.0

116

10.0

145

11.5 11.5 11.5

2.98

0.65

3.40

0.75

3.81

0.84

28mm Compression

1” BSP Female

22

4.8

90

112

92.4

30

102,400

U150HE

33

112,629

44

150,128

33

112,629

38.5

131,362

46.8

159,681

RDB 3.2 33-44

Adjustable @ setting 5

N/A

100 or 125

4 or 5

75 90 105

0

Danfoss 80°H

0.85 1.00 1.25

10.0

145

9.5

138

9.5

138

11.5 11.5 11.5

3.81

0.84

4.48

0.99

5.25

1.16

1¼” BSP Female

1¼” BSP Female

45

9.9

175

220

91.9

40

136,139

Page 29

2.5.2 U-Series Utility – Pumped (UPHE)

UP90HEUP70HEMODEL

Nominal kW

Heat Output Btu/hr

Nominal kW

Heat Input Btu/hr

Burner

Head

Secondary Air Damper

Flue mm

Diameter in

Flue Gas Temp °C

Smoke Bacarach

14.7

50,000

17.6

60,000

21

71,6502171,650

23.5

80,000

27.1

92,380

15.3

52,150

18.4

62,6002275,0002275,000

24.4

83,1752895,550

RDB 2.2 15-21 RDB 2.2 21-26

T1SH T2SH

B N/A

100 or 125

4 or 5

100 or 125

4 or 5

86 88 90 90 93 95

0 0

Kerosene Settings

Nozzle make

size

Oil Pump bar

Pressure psi

Max CO2 %

Approx Fuel litres/h

Flow Rate gals/h

Flow Connection

Return Connection

Water litres

Content gals

Boiler Weight Dry kg

Boiler Weight Wet kg

SEDBUK Efficiency %

Factory Settings

Danfoss 60°ES

0.5 0.5 0.6

Danfoss 60°ES

0.6 0.65 0.75

7.0

102

9.0

130

8.0

116

8.0

116

8.0

116

7.0

102

11.5 11.5 11.5 11.5 11.5 11.5

1.65

0.36

1.98

0.44

2.35

0.52

2.35

0.52

2.65

0.58

2.98

0.65

22mm Copper

1” BSP Female

22mm Copper

1” BSP Female

22

4.8

22

4.8

95

117

92.2

95

117

92.8

Highlighted in Bold

UP150HE

33

112,629

44

150,128

33

112,629

38.5

131,362

46.8

159,681

RDB 3.2 33-44

Adjustable @ setting 5

N/A

100 or 125

4 or 5

75 90 105

0

Danfoss 80°H

0.85 1.00 1.25

10.0

145

9.5

138

9.5

138

11.5 11.5 11.5

3.81

0.84

4.48

0.99

5.25

1.16

28mm copper

1¼” BSP Female

45

9.9

185

230

91.9

40

136,139

UP120HE

27.1

92,380

30

102,400

32.7

111,600

28

95,550

34

116,000

RDB 2.2 26-33

T5S

N/A

100 or 125

4 or 5

95 98 110

0

29

99,050

Danfoss 60°ES

0.75 0.85 0.85

7.0

102

8.0

116

10.0

145

11.5 11.5 11.5

2.98

0.65

3.40

0.75

3.81

0.84

28mm Compression

1” BSP Female

22

4.8

95

117

92.4

Page 30

2.5.3 U-Series Utility – System (USHE)

US90HEUS70HEMODEL

Nominal kW

Heat Output Btu/hr

Nominal kW

Heat Input Btu/hr

Burner

Head

Secondary Air Damper

Flue mm

Diameter in

Flue Gas Temp °C

Smoke Bacarach

14.7

50,000

17.6

60,000

21

71,6502171,650

23.5

80,000

27.1

92,380

15.3

52,150

18.4

62,6002275,0002275,000

24.4

83,1752895,550

RDB 2.2 15-21 RDB 2.2 21-26

T1SH T2SH

B N/A

100 or 125

4 or 5

100 or 125

4 or 5

86 88 90 90 93 95

0 0

Kerosene Settings

Nozzle make

size

Oil Pump bar

Pressure psi

Max CO2 %

Approx Fuel litres/h

Flow Rate gals/h

Flow Connection

Return Connection

Water litres

Content gals

Boiler Weight Dry kg

Boiler Weight Wet kg

SEDBUK Efficiency %

Factory Settings

Danfoss 60°ES

0.5 0.5 0.6

Danfoss 60°ES

0.6 0.65 0.75

7.0

102

9.0

130

8.0

116

8.0

116

8.0

116

7.0

102

11.5 11.5 11.5 11.5 11.5 11.5

1.65

0.36

1.98

0.44

2.35

0.52

2.35

0.52

2.65

0.58

2.98

0.65

22mm Copper

1” BSP Female

22mm Copper

1” BSP Female

22

4.8

22

4.8

105

127

92.2

105

127

92.8

Highlighted in Bold

US120HE

27.1

92,3802999,050

32.7

111,600

28

95,55030102,400

34

116,000

RDB 2.2 26-33

T5S

N/A

100 or 125

4 or 5

95 98 110

0

Danfoss 60°ES

0.75 0.85 0.85

7.0

102

8.0

116

10.0

145

11.5 11.5 11.5

2.98

0.65

3.40

0.75

3.81

0.84

28mm Compression

1” BSP Female

22

4.8

105

127

92.4

Page 31

2.5.4 U-Series Utility – Combi (UCHE)

UC90HEUC70HEMODEL

Nominal kW

Heat Output Btu/hr

Nominal kW

Heat Input Btu/hr

Burner

Head

Secondary Air Damper

Flue mm

Diameter in

Flue Gas Temp °C

Smoke Bacarach

14.7

50,000

17.6

60,000

21

71,6502171,650

23.5

80,000

27.1

92,380

15.3

52,150

18.4

62,6002275,0002275,000

24.4

83,1752895,550

RDB 2.2 15-21 RDB 2.2 21-26

T1SH T2SH

B N/A

100 or 125

4 or 5

100 or 125

4 or 5

86 88 90 90 93 95

0 0

Kerosene Settings

Nozzle make

size

Oil Pump bar

Pressure psi

Max CO2 %

Approx Fuel litres/h

Flow Rate gals/h

Flow Connection

Return Connection

Water litres

Content gals

Boiler Weight Dry kg

Boiler Weight Wet kg

SEDBUK Efficiency %

Factory Settings

Danfoss 60°ES

0.5 0.5 0.6

Danfoss 60°ES

0.6 0.65 0.75

7.0

102

9.0

130

8.0

116

8.0

116

8.0

116

7.0

102

11.5 11.5 11.5 11.5 11.5 11.5

1.65

0.36

1.98

0.44

2.35

0.52

2.35

0.52

2.65

0.58

2.98

0.65

22mm Copper 22mm Copper

74

16.3

140

214

90.0 90.0

Highlighted in Bold

74

16.3

140

214

Domestic Hot Water (DHW) Production

Minimum Inlet Dynamic Pressure bar

for Maximum DHW Flow Rate psi

Maximum Achievable

DHW Flow Rate

Maximum Recommended litres/m

DHW Flow Rate gals/m

Factory Set litres/m

DHW Flow Rate gals/m

Minimum litres/m

DHW Flow Rate gals/m

DHW Temperature Rise

(at Maximum Output)

Pressure Relief bar

psi

Cold Water Mains Inlet Connection

DHW Outlet Connection

1.8

26

1.8

26

Unrestricted Unrestricted

18

4.0

24

5.3

18

4.0

18

4.0

2.5

0.55

2.5

0.55

32°C @ 18 litres/min

for 120 litre draw-off

32°C @ 24 litres/min

for 120 litre draw-off

3

43.5

3

43.5

Minimum 15mm

Unrestricted

Minimum 15mm

Unrestricted

22mm Copper 22mm Copper

22mm Copper 22mm Copper

Page 32

2.5.5 K-Series Kabin Pak – Pre-Wired (KHE)

K120HEK90HEK70HEMODEL

Nominal kW

Heat Output Btu/hr

Nominal kW

Heat Input Btu/hr

Burner

Head

Secondary Air Damper

Flue mm

Diameter in

Flue Gas Temp °C

Smoke Bacarach

14.7

50,000

17.6

60,000

21

71,6502171,650

23.5

80,000

27.1

92,380

27.1

92,380

30

102,400

32.7

111,600

15.3

52,150

18.4

62,6002275,0002275,000

24.4

83,1752895,5502895,550

34

116,000

RDB 2.2 15-21 RDB 2.2 21-26 RDB 2.2 26-33

T1SH T2SH T5S

B N/A N/A

100 or 125

4 or 5

100 or 125

4 or 5

100 or 125

4 or 5

86 88 90 90 93 95 95 98 110

0 0 0

Kerosene Settings

Nozzle make

size

Oil Pump bar

Pressure psi

Max CO2 %

Approx Fuel litres/h

Flow Rate gals/h

Flow Connection

Return Connection

Water litres

Content gals

Boiler Weight Dry kg

Boiler Weight Wet kg

SEDBUK Efficiency %

Factory Settings

Danfoss 60°ES

0.5 0.5 0.6

Danfoss 60°ES

0.6 0.65 0.75

Danfoss 60°ES

0.75 0.85 0.85

7.0

102

9.0

130

8.0

116

8.0

116

8.0

116

7.0

102

7.0

102

8.0

116

10.0

145

11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5

1.65

0.36

1.98

0.44

2.35

0.52

2.35

0.52

2.65

0.58

2.98

0.65

2.98

0.65

3.40

0.75

3.81

0.84

28mm Compression

1” BSP Female

28mm Compression

1” BSP Female

28mm Compression

1” BSP Female

22

4.8

22

4.8

22

4.8

90

112

92.2

90

112

92.8

90

112

92.4

29

99,050

Highlighted in Bold

K150HE

33

112,629

44

150,128

33

112,629

38.5

131,362

46.8

159,681

RDB 3.2 33-44

Adjustable @ setting 5

N/A

100 or 125

4 or 5

75 90 105

0

Danfoss 80°H

0.85 1.00 1.25

10.0

145

9.5

138

9.5

138

11.5 11.5 11.5

3.81

0.84

4.48

0.99

5.25

1.16

1¼” BSP Female

1¼” BSP Female

45

9.9

175

220

91.9

40

136,139

Page 33

2.5.6 K-Series Kabin Pak – Pumped (KPHE)

KP90HEKP70HEMODEL

Nominal kW

Heat Output Btu/hr

Nominal kW

Heat Input Btu/hr

Burner

Head

Secondary Air Damper

Flue mm

Diameter in

Flue Gas Temp °C

Smoke Bacarach

14.7

50,000

17.6

60,000

21

71,6502171,650

23.5

80,000

27.1

92,380

15.3

52,150

18.4

62,6002275,0002275,000

24.4

83,1752895,550

RDB 2.2 15-21 RDB 2.2 21-26

T1SH T2SH

B N/A

100 or 125

4 or 5

100 or 125

4 or 5

86 88 90 90 93 95

0 0

Kerosene Settings

Nozzle make

size

Oil Pump bar

Pressure psi

Max CO2 %

Approx Fuel litres/h

Flow Rate gals/h

Flow Connection

Return Connection

Water litres

Content gals

Boiler Weight Dry kg

Boiler Weight Wet kg

SEDBUK Efficiency %

Factory Settings

Danfoss 60°ES

0.5 0.5 0.6

Danfoss 60°ES

0.6 0.65 0.75

7.0

102

9.0

130

8.0

116

8.0

116

8.0

116

7.0

102

11.5 11.5 11.5 11.5 11.5 11.5

1.65

0.36

1.98

0.44

2.35

0.52

2.35

0.52

2.65

0.58

2.98

0.65

22mm Copper

1” BSP Female

22mm Copper

1” BSP Female

22

4.8

22

4.8

95

117

92.2

95

117

92.8

Highlighted in Bold

KP120HE

27.1

92,380

30

102,400

32.7

111,600

28

95,550

34

116,000

RDB 2.2 26-33

T5S

N/A

100 or 125

4 or 5

95 98 110

0

29

99,050

Danfoss 60°ES

0.75 0.85 0.85

7.0

102

8.0

116

10.0

145

11.5 11.5 11.5

2.98

0.65

3.40

0.75

3.81

0.84

28mm Compression

1” BSP Female

22

4.8

95

117

92.4

KP150HE

33

112,629

44

150,128

33

112,629

38.5

131,362

46.8

159,681

RDB 3.2 33-44

Adjustable @ setting 5

N/A

100 or 125

4 or 5

75 90 105

0

Danfoss 80°H

0.85 1.00 1.25

10.0

145

9.5

138

9.5

138

11.5 11.5 11.5

3.81

0.84

4.48

0.99

5.25

1.16

28mm Copper

1¼” BSP Female

45

9.9

185

230

91.9

40

136,139

Page 34

2.5.7 K-Series Kabin Pak – System (KSHE)

KS90HEKS70HEMODEL

Nominal kW

Heat Output Btu/hr

Nominal kW

Heat Input Btu/hr

Burner

Head

Secondary Air Damper

Flue mm

Diameter in

Flue Gas Temp °C

Smoke Bacarach

14.7

50,000

17.6

60,000

21

71,6502171,650

23.5

80,000

27.1

92,380

15.3

52,150

18.4

62,6002275,0002275,000

24.4

83,1752895,550

RDB 2.2 15-21 RDB 2.2 21-26

T1SH T2SH

B N/A

100 or 125

4 or 5

100 or 125

4 or 5

86 88 90 90 93 95

0 0

Kerosene Settings

Nozzle make

size

Oil Pump bar

Pressure psi

Max CO2 %

Approx Fuel litres/h

Flow Rate gals/h

Flow Connection

Return Connection

Water litres

Content gals

Boiler Weight Dry kg

Boiler Weight Wet kg

SEDBUK Efficiency %

Factory Settings

Danfoss 60°ES

0.5 0.5 0.6

Danfoss 60°ES

0.6 0.65 0.75

7.0

102

9.0

130

8.0

116

8.0

116

8.0

116

7.0

102

11.5 11.5 11.5 11.5 11.5 11.5

1.65

0.36

1.98

0.44

2.35

0.52

2.35

0.52

2.65

0.58

2.98

0.65

22mm Copper

1” BSP Female

22mm Copper

1” BSP Female

22

4.8

22

4.8

105

127

92.2

105

127

92.8

Highlighted in Bold

KS120HE

27.1

92,380

30

102,400

32.7

111,600

28

95,550

34

116,000

RDB 2.2 26-33

T5S

N/A

100 or 125

4 or 5

95 98 110

0

29

99,050

Danfoss 60°ES

0.75 0.85 0.85

7.0

102

8.0

116

10.0

145

11.5 11.5 11.5

2.98

0.65

3.40

0.75

3.81

0.84

28mm Compression

1” BSP Female

22

4.8

105

127

92.4

Page 35

2.5.8 K-Series Kabin Pak – Combi (KCHE)

KC90HEKC70HEMODEL

Nominal kW

Heat Output Btu/hr

Nominal kW

Heat Input Btu/hr

Burner

Head

Secondary Air Damper

Flue mm

Diameter in

Flue Gas Temp °C

Smoke Bacarach

14.7

50,000

17.6

60,000

21

71,6502171,650

23.5

80,000

27.1

92,380

15.3

52,150

18.4

62,6002275,0002275,000

24.4

83,1752895,550

RDB 2.2 15-21 RDB 2.2 21-26

T1SH T2SH

B N/A

100 or 125

4 or 5

100 or 125

4 or 5

86 88 90 90 93 95

0 0

Kerosene Settings

Nozzle make

size

Oil Pump bar

Pressure psi

Max CO2 %

Approx Fuel litres/h

Flow Rate gals/h

Flow Connection

Return Connection

Water litres

Content gals

Boiler Weight Dry kg

Boiler Weight Wet kg

SEDBUK Efficiency %

Factory Settings

Danfoss 60°ES

0.5 0.5 0.6

Danfoss 60°ES

0.6 0.65 0.75

7.0

102

9.0

130

8.0

116

8.0

116

8.0

116

7.0

102

11.5 11.5 11.5 11.5 11.5 11.5

1.65

0.36

1.98

0.44

2.35

0.52

2.35

0.52

2.65

0.58

2.98

0.65

22mm Copper 22mm Copper

74

16.3

140

214

90.0 90.0

Highlighted in Bold

74

16.3

140

214

Domestic Hot Water (DHW) Production

Minimum Inlet Dynamic Pressure bar

for Maximum DHW Flow Rate psi

Maximum Achievable

DHW Flow Rate

Maximum Recommended litres/m

DHW Flow Rate gals/m

Factory Set litres/m

DHW Flow Rate gals/m

Minimum litres/m

DHW Flow Rate gals/m

DHW Temperature Rise

(at Maximum Output)

Pressure Relief bar

psi

Cold Water Mains Inlet Connection

DHW Outlet Connection

1.8

26

1.8

26

Unrestricted Unrestricted

18

4.0

24

5.3

18

4.0

18

4.0

2.5

0.55

2.5

0.55

32°C @ 18 litres/min

for 120 litre draw-off

32°C @ 24 litres/min

for 120 litre draw-off

3

43.5

3

43.5

Minimum 15mm

Unrestricted

Minimum 15mm

Unrestricted

22mm Copper 22mm Copper

22mm Copper 22mm Copper

Page 36

3.0 Electricity Supply & Wiring Details

220 – 240V. 1PH, 50 Hz

The boiler/burner and other external electrical equipment should be wired with heat

resistant cable via a fused double pole isolating switch which should be fitted with a

5 amp fuse.

The appliance must be effectively earthed and all external wiring should comply with

current IEE Regulations.

3.1 Dual-Safe Thermostat (Non-Combi Boilers)

Warning: Do not fit any other wires or loop wires to this stat as this will bypass the

thermostats.

3.2 RDB Burner Control Box

CONTROL BOX

535SE/LD

M

M

Oil Valve

Photoresistance

Black

White

Blue

Motor

Capacitor

Lock Out

Live

Neutral

Earth

Fan

Housing

To Burner

From Power Supply (Switched Live)

Page 37

3.3 Combi Wiring Details

3.3.1 Wiring Diagram

The 3 pin mains plug must be supplied with a permanent live to allow the pump overrun stat and relay to operate correctly.

Page 38

3.3.2 Wiring Schematic

BURNER

D.H.W. PUMP

C.H. PUMP

TRIPLE POLE RE LAY

N.C.

BOILER STA T

N.O.

N.C.

N.O.

N.O.

N.C.

C

C

C

COIL

7

20 21

2425

22

14

N

N

N

N

N

10

8

1

26

29

N

26

28

30

3 19

23

17

18

16

5

L1

N

E

L1

N

MAINS PLUG

H.W.

C.H.

TANK STAT

FLOW SW ITCH

TANK LIMIT

STAT

9

BOILER LIMIT ST AT

15

2

13

1

6

4

MAINS ON

LAMP

(GRE EN)

H/L RESET

LAMP

(YELLOW )

LOCKOUT

LAMP

(GRE EN)

LAMP

7

16

BOILER LIMIT ST AT

15

H/L RESET

LAMP

(YELLO W)

BREAK INTO T HE WHITE

WIRE BETWEE N NO 16 ON

THE PCB AND THE LIMIT

STAT AND CONNECT IN THE

PRESSURE SWITCH WI TH A

WIRING BLOCK AS SHOW N

LOW PRES SURE

SWIT CH

LOW PRES SURE

SWIT CH

WIRING A L OW PRESSURE SWITCH

12

WIRING

BLOCK

COIL

N

11

PUMP OVER

RUN STAT

PUMP OVER

RUN RELAY

27

WIRING

BLOCK

NC

NO

C

2

4

3

Page 39

3.3.3 Fitting a Room Thermostat to a Combi

In order to provide frost protection for the fabric of the building a frost thermostat

should be fitted in the coldest room in the house. To prevent over heating of the

property a pipe thermostat should be fitted on the return pipe close to the boiler.

The Kabin Pak Combi boiler is factory fitted with a frost thermostat as standard.

3.3.5 Combi Pump Overrun Thermostat

The condensing Combi boilers have been fitted with a pump overrun thermostat.

In order for the thermostat to work effectively the boiler must be supplied with a

permanent live. Failure to do this will result in nuisance trip outs.

Remove the purple wire from no 5 and no 28 on the PCB and wire the thermostat

as shown. The room thermostat should be located where it is not subjected to

extraneous heat gains, direct sunlight or draughts.

3.3.4 Fitting Frost Protection to a Combi

ROOM THERMOSTAT

282726

PCB

N

5

29 30

FROST THERMOSTAT

PERMANENT

LIVE

543 6

PIPE THERMOSTAT

Page 40

3.4 Installation of a Warmflow Combi Optional Programmer (PC1)

1. Disconnect the electrical supply.

2. Drop down control box front (2 screws).

3. Disconnect the 6 pin plug from the CH/HW on/off switched.

4. With a sharp knife cut out the outline of the panel knockout through the facia label

from the front of the panel.

5. With a hacksaw blade or snips remove the knockout piece ensuring that all metal

tags or burrs have been removed from the hole.

6. Feed the programmer and harness through the hole from the front of the panel.

7. Secure in position by attaching the securing bracket to the rear of the programmer.

8. Plug the wiring harness into the 6 way socket.

9. Activate battery back up on the programmer by removing the plastic strip.

10. Close the control panel cover and reconnect the electrical supply.

11. Using the operating instructions located towards to back of this manual or supplied

with the programmer, set the switching times.

Page 41

3.5 Remote Timers for Combis

3.5.1 Installation of a remote two channel programmer (option 1)

Connecting the programmer in this

manner will bypass the CH and HW on/

off switches on the boiler control panel.

A separate connection to the boiler 3 pin

mains plug is NOT required.

Inside the boiler control panel, remove

the purple and white wires connecting

terminals 5 and 3 on the terminal block

with terminals 19 and 28 on the PCB.

Connect the programmer to the

permanent live mains supply via a fused

isolator as shown.

Connect the boiler to the programmer via a 5 core cable as shown ensuring that the

earth is connected to one of the earth post inside the control panel and that the

permanent live is connected to terminal 12 on the PCB. Failure to connect the

permanent live to the boiler in this way will prevent the mains lamp and pump

overrun thermostats from operating. It will also prevent the built-in frost protection of

a Kabin Pak Combi from operating.

3.5.2 Installation of a remote two channel programmer (option 2)

Connecting the programmer in this

manner will bypass the CH and HW on/

off switches on the boiler control panel.

The boiler and programmer will both

be powered from the boiler 3 pin mains

plug.

Inside the boiler control panel, remove

the purple, white and brown wires

connecting the CH and HW switches to

the 6 pin connector of the terminal block.

Connect the programmer to the 6 pin

connector via a 5 core cable as shown

ensuring the earth is connected to one of

the earth posts inside the control panel.

Connect the boiler 3 pin mains plug to a permanent live mains supply via a fused

isolator. Failure to connect a permanent live to the boiler will prevent the programmer,

boiler mains lamp and pump overrun thermostats from operating. It will also prevent

the built-in frost protection of a Kabin Pak Combi from operating.

OFFOFFE N L

COM

ON

22 21 20 19

PCB CONTROLLER

ON

COM

CH HW

26 25 24 2328 27

12

11

EARTH

POST

OFFOFFE N L

COM

ON ON

COM

CH HW

1

2

3

4

5

6

EARTH

POST

Page 42

3.6 Optional Programmer (PU1) for Non-Combi Models

3.6.1 Programmer Control Box Wiring Diagram

3.6.2 General Requirements

1. The optional programmer as supplied will supply power to the pump and burner via

the central heating channel.

2. When connecting to external controls, eg ‘Y’ plan or ‘S’ plan it will be necessary to

remove the loop between 3 and 12 on the programmer terminal block.

3. The programmer is not suitable for gravity hot water systems.

Page 43

3.6.3 Programmer Installation

1. Disconnect electrical supply.

2. Drop down control box front (2 screws).

3. Secure control box to the horizontal casing bracket (2 screws) and right hand side

(1 screw).

4. Connect the thermostat, circulating pump and the mains supply to the leads on the

rear of the control box.

5. Two examples of system wiring are shown in the following sections.

6. If fitting the programmer to a Utility model

without an integral pump, disconnect the

pump plug from terminals 1 and 2 of the programmer terminal block and from the

earth post. Remove the pump plug then wire the external plug into terminals 1 and

2 of the programmer terminal block and the earth post, feeding the wire in through

the pump plug cable clamp.

7. Activate battery backup on programmer by removing the plastic strip.

8. Close the control panel cover (2 screws) and reconnect the electrical supply.

9. Using the operating instructions located towards the back of this manual or supplied

with the programmer, set the switching times.

Page 44

3.6.4 Honeywell ‘Y’ Plan – Independent CH & DHW (Fully Pumped Only)

Note: Before fitting programmer remove loop between 3 and 12 on the terminal block.

Page 45

3.6.5 Honeywell ‘S’ Plan – Independent CH & DHW (Fully Pumped Only)

Note: Before fitting programmer remove loop between 3 and 12 on the terminal block.

Page 46

4.0 Oil Supply

1. Oil Tank

Steel tanks constructed to BS799 : PART 5 should be painted on the outside only

and mounted on piers to prevent corrosion. Plastic oil tanks are also available and

can be suitable for installation at ground level. However, oil should never be stored in

translucent plastic containers.

The tank outlet should be at a height to provide sufficient clearance to allow for

proper maintenance of any isolation valve, oil filter or water separator fitted.

2. The pipe from the oil tank to the burner should be run in copper, steel or aluminium.

Galvanised pipe and fittings should not be used. The pipework should terminate

close to the boiler and be fitted with an isolating valve and filter. A remote sensing

fire valve must be fitted to the oil line preferably before the oil line enters the building

(BS5410 : PART 1).

Depending on the position of the tank a two pipe system may be required. One and

two pipe oil systems are shown below. As an alternative to a two pipe system a

Tigerloop or other approved de-aerator may be used.

4.1 One Pipe Gravity System

Head H(m)

ID 8mm

ID 10mm

0.5 1 1.5 2

10 20 40 60

20 40 80 100

Total Maximum Pipe Length (m)

Note: Plastic oil level gauges may shrink when

exposed to kerosene thus allowing the ingress of

water. Pump failures due to water contamination

are not covered under the warranty.

Page 47

Head H(m)

ID 8mm

ID 10mm

0.5 1 2 3

35 25 15 8

100 100 70 30

0.5

30

100

3.5

6

20

1.5

20

90

Total Maximum Pipe Length (m)

4.2 Two Pipe System

For maximum pipe length and lift contact de-aerator manufacturer.

4.3 De-aerator System

Page 48

Head H(m)

ID 8mm

ID 10mm

0.5 1 2 3

35 25 15 8

100 100 70 30

0.5

30

100

3.5

6

20

1.5

20

90

Total Maximum Pipe Length (m)

4.4 One Pipe Lift System

Note: The pump vacuum should

not exceed a maximum of 0.4 bar.

Above this gas is released from the

oil thus leading to burner lock out.

Page 49

5.0 Flues

5.1 Installation of Flues

Page 50

5.1.1 Installation of a Balanced Flue (FBF)

1. Make a suitable sized hole in the wall or ceiling for the flue. For the dimensions of

the boiler, see the Dimensions Section of this manual. For the dimensions of the flue

system, see the Flue Kits & Dimensions Section of this manual.

Note: The cavities around the opening must be sealed and protected by a non-

combustible sleeve.

2. Remove the top casing panel. If fitting a low level horizontal flue (FBF), remove the

upper casing panel knockout from the appropriate side or rear panel using a pair

of tin snips. Push the boiler into position against the wall then install the flue starter

piece, securing it in position using the nuts provided and ensuring the black rubber

gasket is correctly seated. The white fibre gasket supplied in the Flue Fittings Kit

(FFK) is not required and should NOT be fitted.

3. If installing extension pieces, ensure the seals are correctly fitted and lubricated

before pushing through the wall and into the starter piece.

Note: Refer to the Flue Options, Components and Dimensions Section for details of

the maximum number of extension pieces and total flue lengths allowed.

4. If installing a vertical flue, correctly fit the flashing kit then slide the flue terminal into

position with a twisting movement. Ensure that the terminal protrudes through the

roof by a minimum of 665mm.

If installing a horizontal flue, slide the flue terminal into position with a twisting

movement then seal the gap between the flue and the wall both inside and outside.

Ensure that the terminal protrudes through the wall by a minimum of 175mm and a

maximum of 225mm.

If installing a Plume Management Kit, fit the starter piece and horizontal terminal as

described above then install the Plume Management Kit as instructed in the leaflet

supplied with the kit.”

5. If installing a low-level horizontal flue, fit the terminal guard (basket) over the flue

terminal using the cardboard mounting template supplied with the flue kit to locate

and drill the necessary screw holes in the wall.

6. Remove the air inlet cover from the burner then fit the intake adaptor spigot and

gasket. Connect one end of the air duct / hose to the flue and the other end to the

adaptor spigot and secure.

Page 51

5.2 Conventional Flues

The flue system should be designed in accordance with local

bye-laws and the Building Regulations. Draught stabilisers

are not recommended for oil fired boilers. Sharp bends

or horizontal runs should be avoided and the flue should

terminate 2 feet (600mm) above the ridge of the dwelling.

Terminals which restrict the discharge or allow ingress of

water should be avoided.

When connecting to an existing masonry chimney, a flexible

flue liner suitable for use with oil fired condensing boilers and

of an appropriate diameter must be used. The annular space

must be filled with insulation and sealed top and bottom.

The starter piece should be sealed into the conventional

flue adaptor using a high temperature silicone sealant, fire

cement must not be used.

Only proprietary flue systems designed specifically

for use with oil-fired condensing boilers may be used.

The flue system manufacturer’s installation instruction

must be followed.

For recommended conventional flue systems, contact

Warmflow.

5.3 Low Level Balanced Flue Terminal Positions

Attention should be given to the position of the flue discharge;

we recommend the following guidelines be adopted.

1. The flue should not discharge beneath opening windows or

near other accesses to the building.

2. The flue should not discharge near internal/external corners

of the building where turbulent wind conditions could occur.

3. A terminal guard must be fitted at all times.

4. The terminal should not discharge over property boundaries.

5. Discharge into narrow passageways should be avoided.

6. The location of the terminal and routing of the flue should

be determined by the installer after consultation with the

householder.

7. In positioning the flue the wind direction should be

considered.

Installation in exposed positions is not recommended.

8. Account must be made of the pluming from the flue. If it is

likely to be a nuisance to the householder the use of a vertical

balanced flue or conventional flue should be considered.

Page 52

These are minimum dimensions and are only quoted as a guidelines.

Terminating positions must be at least 1.8 metres from an oil storage tank unless

a wall with at least 30 min fire resistance and extending 300mm higher and

wider than the tank is provided between the tank and the terminating position.

From an internal or external corner or surface or boundary alongside the terminal.F 300

Above ground or balcony level.G 300

From a surface or a boundary facing the terminal.H 600

From a terminal facing the terminal.J 1,200

Vertically from a terminal on the same wall.K 1,500

Horizontally from a terminal on the same wall.L 750

Above the highest point of an intersection with the roof.M 600

From a vertical structure on the side of the terminal.N 750

Above a vertical structure less than 750mm from the side of the terminal.O 600

From a ridge terminal to a vertical structure on the roof.P 1,500

A 600Directly below an opening, air brick, opening window etc.

B 600Horizontally to an opening, air brick, opening window etc.

C 75

Below a gutter or a balcony without protection.D 600

From vertical sanitary pipework.E 300

Below a gutter, eaves or balcony with protection.

MINIMUM DISTANCES TO TERMINALS IN MILLIMETRES AS MEASURED FROM

THE TOP OF THE CHIMNEY OR THE RIM OF A LOW LEVEL DISCHARGE OPENING

Page 53

6.0 Air Supply for Combustion & Ventilation

(see BS5410)

6.1 Open Flue Boilers

When the boiler is sited in a cellar where the only access for combustion and

ventilation air is at high level then the combustion air should be ducted to low level.

Combustion Air Supply

Boiler in Room

Boiler in Compartment

6.2 Balanced Flue Boilers – Boilers in a Compartment

Air Supply for Ventilation

No Combustion Air Inlet required to Room

Page 54

7.0 Installation Requirements

The boiler installation must be in compliance with BS5410 : PART 1 and the Building

Regulations.

7.1 General Requirements

7.1.1 Hearth

The boiler has a hearth temperature of between 50°C and 85°C and should be stood

on a rigid, non-porous, non-combustible base, which is not softened by warmth, to

comply with the Building Regulations.

7.1.2 Service Access

24” (600mm) Clearance should be provided above and in front of the boiler to allow

for routine servicing. Pumped, System and Combi models may require access to

the top.

7.1.3 Heating System

The heating system should be installed to HVCA current codes of practice. Before

installing the boiler the new or existing system must be thoroughly flushed to clear

all sludge or other foreign matter such as solder, steel wool and copper filings. The

system must be cleansed, neutralised and protected from corrosion in accordance

with BS5449 and BS7593 using suitable cleansing agent(s) and inhibitor(s) and

carried out in accordance with the cleanser / inhibitor manufacturers’ instructions.

The system must be dosed to the concentrations specified by the inhibitor

manufacturer (refer to the Technical Data section of this manual for the volume of the

boiler when calculating the total system volume). Failure of components such as, but

not limited to, pumps, auto air vents, pressure relief valves, plate heat exchangers

and non-return valves due to corrosion product in the system will not be covered by

warranty.

7.1.4 Air Vents

The plastic plugs of the auto air vent(s) factory-fitted to the boiler must be loosened

when filling the system in order to bleed the air from the boiler. In addition to any

factory fitted air vents it is recommended that another air vent is fitted at the highest

point in the system. Where the flow pipework drops down from the boiler the installer

must ensure that an automatic air vent is fitted to the top of the pipework to prevent

air being trapped in the boiler.

7.1.5 Drain Cock