WarmFlow Direct DI250UV, Direct DI90UV, Direct DI150UV, Indirect IN120UV, Direct DI300UV User Instructions

...

Cylinder Manual

Direct

DI90UV

DI120UV

DI150UV

DI180UV

DI210UV

DI250UV

DI300UV

Indirect

IN120UV

IN150UV

IN180UV

IN210UV

IN250UV

IN300UV

Eco Direct

ED180UV

ED210UV

ED250UV

ED300UV

Twin Coil

TW180UV

TW210UV

TW250UV

TW300UV

Triple Coil

TR250UV

TR300UV

Incorporating: User Instructions

Installation Instructions

Commissioning Instructions

Maintenance Instructions

Unvented Cylinders

Mains pressure water heaters

EN 12897:2006

Products covered by this manual:

LEAVE THIS MANUAL WITH THE END USER

INSTALLATION, COMMISSIONING & SERVICING

This appliance must be installed as described herein and the installation commissioned by

competent persons as instructed. The Guarantee Registration section of the separate Cylinder

Passport supplied with the product must be completed and the Guarantee Registration only

returned to the manufacturer with proof of purchase (e.g. receipts / invoices).

This appliance must be serviced annually by competent persons, the Service Record section of

the separate Cylinder Passport completed on each occasion and proof of servicing (e.g.

receipts / invoices) retained.

The complete guarantee policy statement is included in Section 9, page 21.

FAILURE TO COMMISSION, REGISTER AND ANNUALLY SERVICE THIS

PRODUCT WILL INVALIDATE ALL GUARANTEES

TECHNICAL, SPARES & GUARANTEE CLAIMS

For technical advice about the installation, commissioning, servicing or use of this appliance,

please contact the Warmflow Customer Care Centre by post, phone, fax or email at the

addresses below. Please also refer to our website.

Should replacement components be required, a list of available spares is provided in Section

8.3, page 19.

In the unlikely event that replacement components might be required within the guarantee

period, please notify the Customer Care Centre in writing, by post, fax or email, stating the

nature of the fault and the part number of the replacement components required.

Warmflow Customer Care Centre

Warmflow Engineering

Lissue Industrial Estate

Moira Road

Lisburn

BT28 2RF

Northern Ireland

Telephone

United Kingdom: 028 9262 1515

Republic of Ireland: 048 9262 1515

Facsimile

United Kingdom: 028 9262 0869

Republic of Ireland: 048 9262 0869

Email

technical@warmflow.co.uk

Website

www.warmflow.co.uk

CONTENTS

1 User Instructions ................................................................................................................. 2

1.1 Cylinder Thermostat ................................................................................................................... 2

1.2 Immersion Thermostat ............................................................................................................... 2

1.3 Discharge ................................................................................................................................ ... 2

2 Installation Requirements ................................................................................................... 3

3 Handling and Storage ......................................................................................................... 4

4 Standard Equipment ........................................................................................................... 4

5 Technical Data ..................................................................................................................... 4

5.1 General ...................................................................................................................................... 4

5.2 Direct Cylinders .......................................................................................................................... 5

5.3 Indirect Cylinders........................................................................................................................ 6

5.4 Eco Direct Cylinders ................................................................................................................... 7

5.5 Twin Coil Cylinders ..................................................................................................................... 8

5.6 Triple Coil Cylinders ................................ ................................................................ ................... 9

6 Installation ......................................................................................................................... 10

6.1 Cylinder Location...................................................................................................................... 10

6.2 Hot & Cold Water Connections ................................................................................................. 10

6.3 Primary, Renewable & Tertiary Circuits .................................................................................... 11

6.4 Tundish .................................................................................................................................... 11

6.5 Expansion Vessel ..................................................................................................................... 11

6.6 Hard water................................................................................................................................ 11

6.7 Pipework Configurations........................................................................................................... 12

6.8 Discharge Pipework ................................................................................................................. 13

6.9 Worked Example ...................................................................................................................... 15

6.10 Electrical Installation ................................................................................................................. 16

7 Commissioning.................................................................................................................. 18

7.1 Draining .................................................................................................................................... 18

8 Maintenance ....................................................................................................................... 19

8.1 Regular Maintenance ............................................................................................................... 19

8.2 Inspection Access .................................................................................................................... 19

8.3 Replacement Parts ................................................................................................................... 19

8.4 Fault Finding ............................................................................................................................ 20

9 Guarantee ........................................................................................................................... 21

10 End-of-Life Information .................................................................................................. 22

10.1 Safety Risks ................................................................ ............................................................. 22

10.2 Disassembly of the Product ...................................................................................................... 22

10.3 Casing and key components .................................................................................................... 23

Page 1 of 23

1 USER INSTRUCTIONS

Control dial

Reset button

Control dial

Reset button

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

The temperature of the hot water can be adjusted, and should ideally be set to 60°C (the

position indicated in the diagram below). A higher setting uses more energy and more fuel.

When a hot tap is turned on there may be a short surge of water – this is quite normal with

unvented systems and does not mean there is a fault. When you first fill a basin the water may

sometimes appear milky. This is due to air bubbles in the water which will clear very quickly.

1.1 Cylinder Thermostat

All cylinders (except Direct models) are fitted with one or more

cylinder thermostats to control the heat input to the cylinder from a

remote heat source, such as a boiler, heat pump or solar thermal

installation. The temperature of each cylinder thermostat is

adjustable between nominally 40°C and 70°C. Turn the control

knob clockwise to increase temperature, and anticlockwise to

decrease.

Each cylinder thermostat has a built-in manually reset safety

thermostat which will ‘lock out’ in the event of the cylinder

overheating and which will need to be reset in order to restore

operation. Remove the lock-out cover and depress the red button

to reset.

1.2 Immersion Thermostat

Isolate ALL electrical supplies to the appliance before removing the immersion cover.

All cylinders are supplied with one or more immersion heaters to

allow the cylinder to be heated electrically. Each immersion

heater has an immersion thermostat, the temperature of which is

adjustable between nominally 10°C and 70°C. Remove the

immersion heater cover and turn the control dial anticlockwise to

increase temperature, and clockwise to decrease.

Each immersion thermostat also has a built-in manually reset

safety thermostat which will ‘lock out’ in the event of the cylinder

overheating and which will need to be reset in order to restore

operation. Remove the immersion heater cover and depress the

red button to reset.

1.3 Discharge

If cold/warm water is discharged from the cylinder via the tundish, call your installer.

The pressure relief valves should be operated regularly to remove lime deposits and to verify

they are not blocked.

If very hot water is discharged, immediately switch off ALL heat sources (which may include

boilers, heat pumps, solar thermal systems and immersion heaters), isolate their electrical

supplies and call your installer.

Page 2 of 23

2 INSTALLATION REQUIREMENTS

Prior to installing this unvented hot water cylinder, please confirm that:

a) The mains water supply is capable of achieving a minimum flow rate of 20 litres per

minute at a minimum dynamic pressure of 1.5 bar at all times. If this performance

cannot be achieved the installation of an unvented cylinder may not be suitable.

b) The maximum mains supply pressure at any time does not exceed 12 bar. If this is the

case an additional ‘special’ pressure reducing valve (not supplied) may be required.

c) The mains water supply is from a public source (i.e. not from a private borehole) and that

the hardness of the water is less than 200 mg/litre. Where hardness in excess of 200

mg/litre is experienced, a suitable and effective hard water treatment must be installed.

d) All circuits supplying heat to the heat exchanger coils of any cylinder (not applicable to

direct cylinders) are fully pumped (gravity circulation is NOT suitable).

e) The pipework supplying the hot water taps is capable of withstanding a maximum

pressure of 7 bar at a temperature of 90°C.

This appliance must be installed vertically (not on its side) in a frost-free indoor location.

The installation of this appliance is subject to the Building Regulations:

England & Wales Building Regulation G3

Scotland Technical Standard P3

Northern Ireland Building Regulations P5

Republic of Ireland Technical Guidance Document Part L

The appliance and installation must be commissioned as described herein and the Guarantee

Registration section of the separate Cylinder Passport completed and returned to the

manufacturer.

FAILURE TO COMMISSION, REGISTER AND ANNUALLY SERVICE THIS

PRODUCT WILL INVALIDATE ALL GUARANTEES

Under no circumstances must the factory fitted temperature & pressure relief valve be

removed. Removal of the valve would create an extremely dangerous situation and

would invalidate all guarantees.

Page 3 of 23

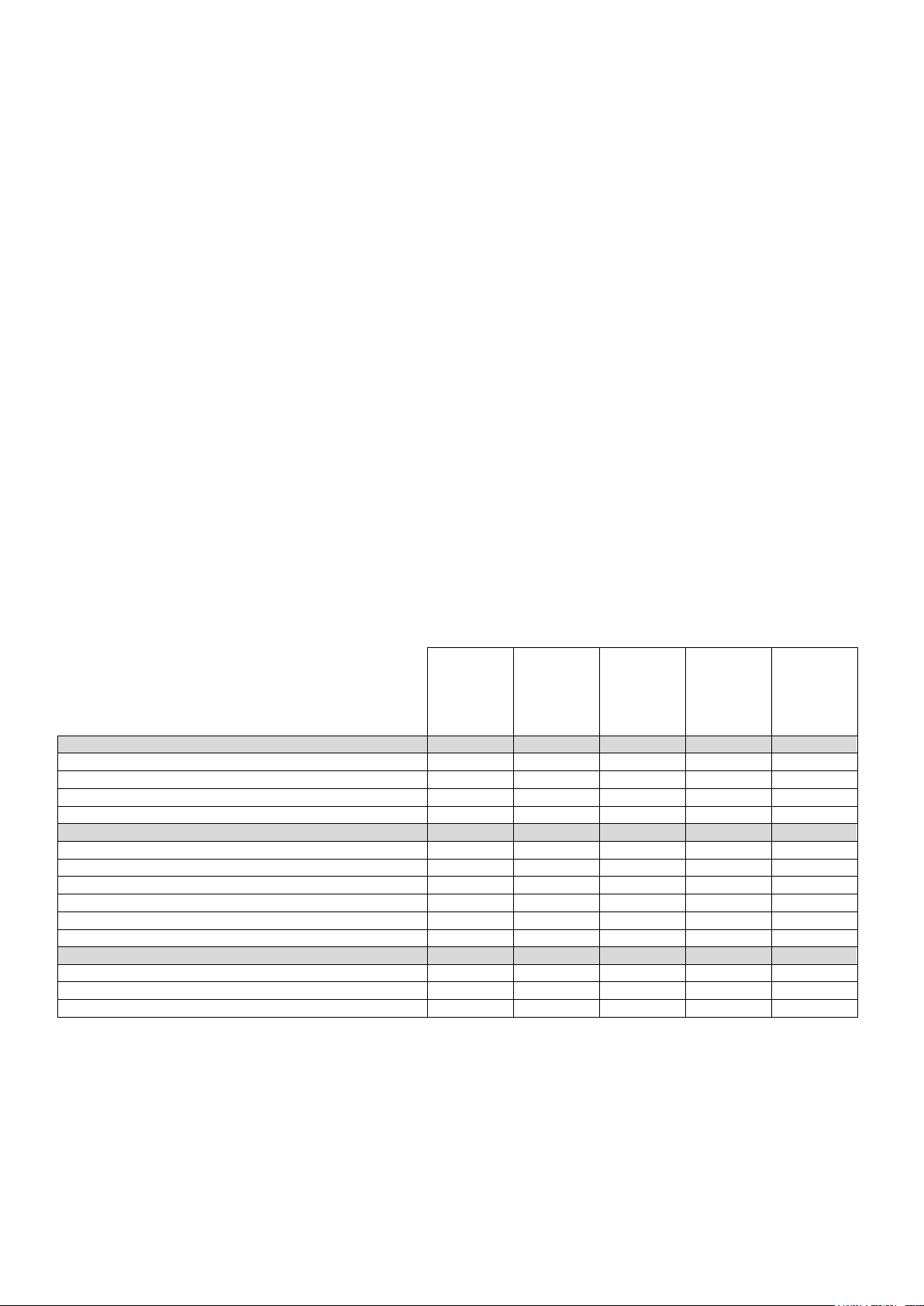

3 HANDLING AND STORAGE

Direct

Indirect

Eco Direct

Twin Coil

Triple Coil

OPERATING DATA

Operating pressure (bar)

3.0

3.0

3.0

3.0

3.0

Maximum design pressure (bar)

6.0

6.0

6.0

6.0

6.0

Maximum supply pressure to inlet group (bar)

12.0

12.0

12.0

12.0

12.0

Expansion vessel bladder pre-charge pressure (bar)

3.0

3.0

3.0

3.0

3.0

SAFETY DEVICE SETTINGS

Pressure reducing valve (bar)

3.0

3.0

3.0

3.0

3.0

Expansion valve (bar)

6.0

6.0

6.0

6.0

6.0

Cylinder thermostat limit temperature (°C)

n/a

80

80

80

80

Immersion thermostat limit temperature (°C)

80

80

80

80

80

Temperature & pressure relief (T&P) valve (°C / bar)

90/7.0

90/7.0

90/7.0

90/7.0

90/7.0

T&P valve temperature probe length (mm)

102

102

102

102

102

HEAT TRANSFER COILS

Maximum circuit temperature (renewable coil) (°C)

n/a

n/a

120

120

120

Maximum circuit temperature (other coils) (°C)

n/a

85

n/a

85

85

Maximum circuit pressure (all coils) (bar)

n/a

6.0

6.0

6.0

6.0

Prior to installation this product should be handled with care and stored upright in a dry location

and in its original packaging.

4 STANDARD EQUIPMENT

Before commencing installation check that all the listed components have been supplied:

1. Temperature & pressure relief valve (factory-fitted)

2. Control thermostats (factory-fitted) (not applicable to Direct models)

3. Unvented kit including:

a. Inlet group

b. Expansion vessel

c. Tundish

4. Immersion heater(s) (packaged inside the unvented kit)

One 2-port motorised zone valve is supplied with Indirect, Twin Coil and Triple Coil models only,

for use on the primary circuit.

Note: This stainless steel cylinder requires no corrosion protection device e.g. anode.

5 TECHNICAL DATA

5.1 General

Table 1: General data (Indirect & Twin Coil models)

Page 4 of 23

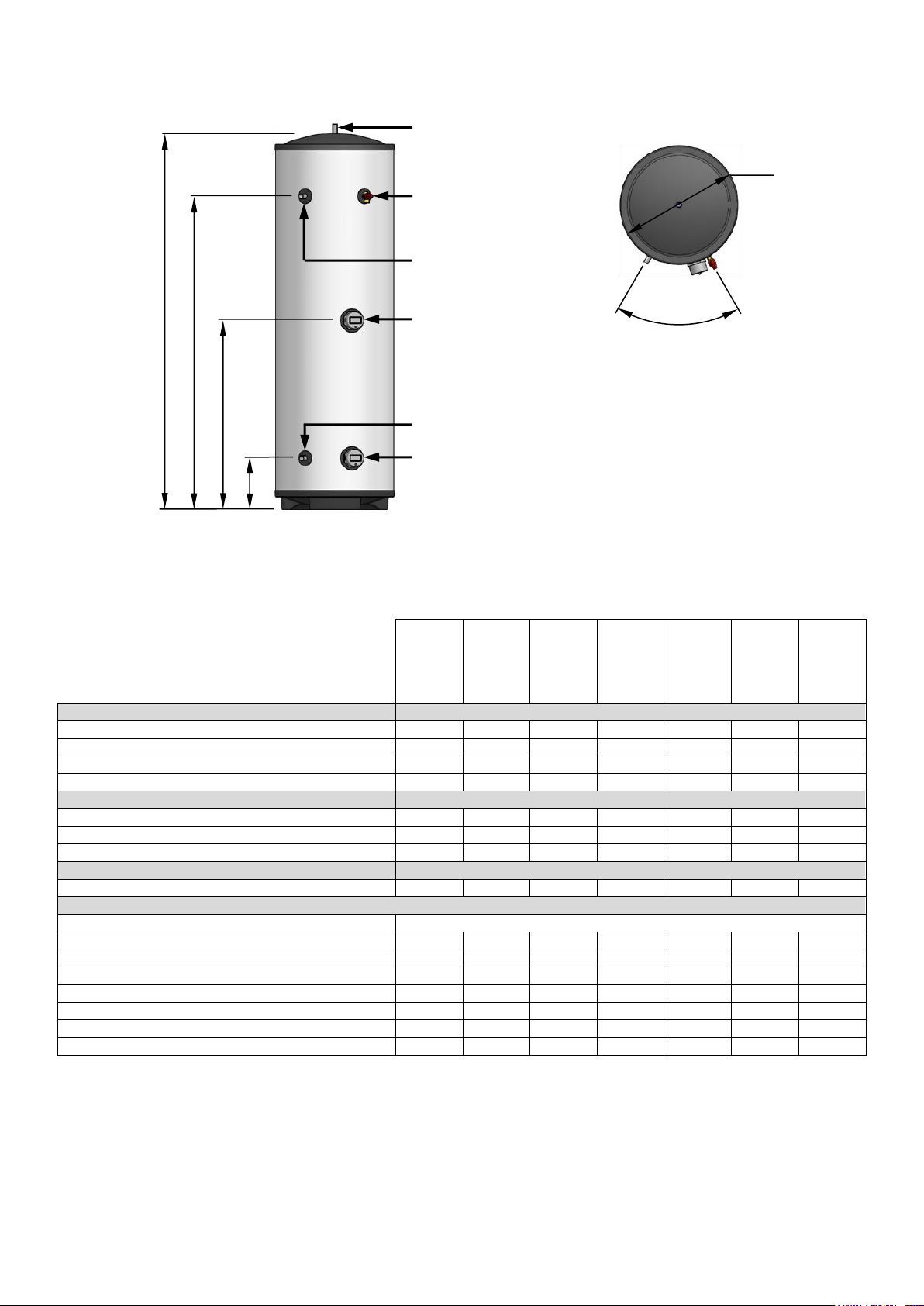

5.2 Direct Cylinders

DI90UV

DI120UV

DI150UV

DI180UV

DI210UV

DI250UV

DI300UV

DIMENSIONS

(A) Height (mm)

767

952

1142

1327

1517

1767

2077

(B) Secondary return connection / T&P (mm)

n/a

n/a

n/a

n/a

1223

1473

1783

(C) Upper immersion (mm)

n/a

482

577

670

765

890

1045

(D) Cold inlet connection / Lower immersion (mm)

243

243

243

243

243

243

243

OPERATING DATA

Cold water capacity (litres)

90

120

150

180

210

250

300

Weight when full (kg)

110

140

180

210

240

290

350

Standing heat loss (kWh/24h)

0.92

1.15

1.31

1.40

1.66

1.92

2.07

PERFORMANCE

Heat up time by lower immersion only (mins)

89

121

154

198

237

287

345

FICHE DATA

Supplier Name

Warmfllow

Supplier Model Identifier

DI90

DI120

DI150

DI180

DI210

DI250

DI300

Declared Load Profile

M M M L L

XL

XL

Energy Efficiency Class

D E D C D C C

Water Heating Energy Efficiency, ηwh (%)

34

30

36

38

37

39

39

Annual Electrical Consumption, AEC (kWh)

1541

1742

1452

2745

2799

4369

4351

Thermostat Setting (°C)

60

60

60

60

60

60

60

Sound Power Level (dB)

15

15

15

15

15

15

15

60°

Ø550

D

C

B

A

Hot Outlet (22mm)

Cold Inlet (22mm)

Temperature & Pressure

Relief Valve (15mm)

Upper Immersion Heater

Secondary Return (22mm)

Lower Immersion Heater

Figure 1: Direct cylinders components & dimensions

Table 2: Direct cylinder data

Page 5 of 23

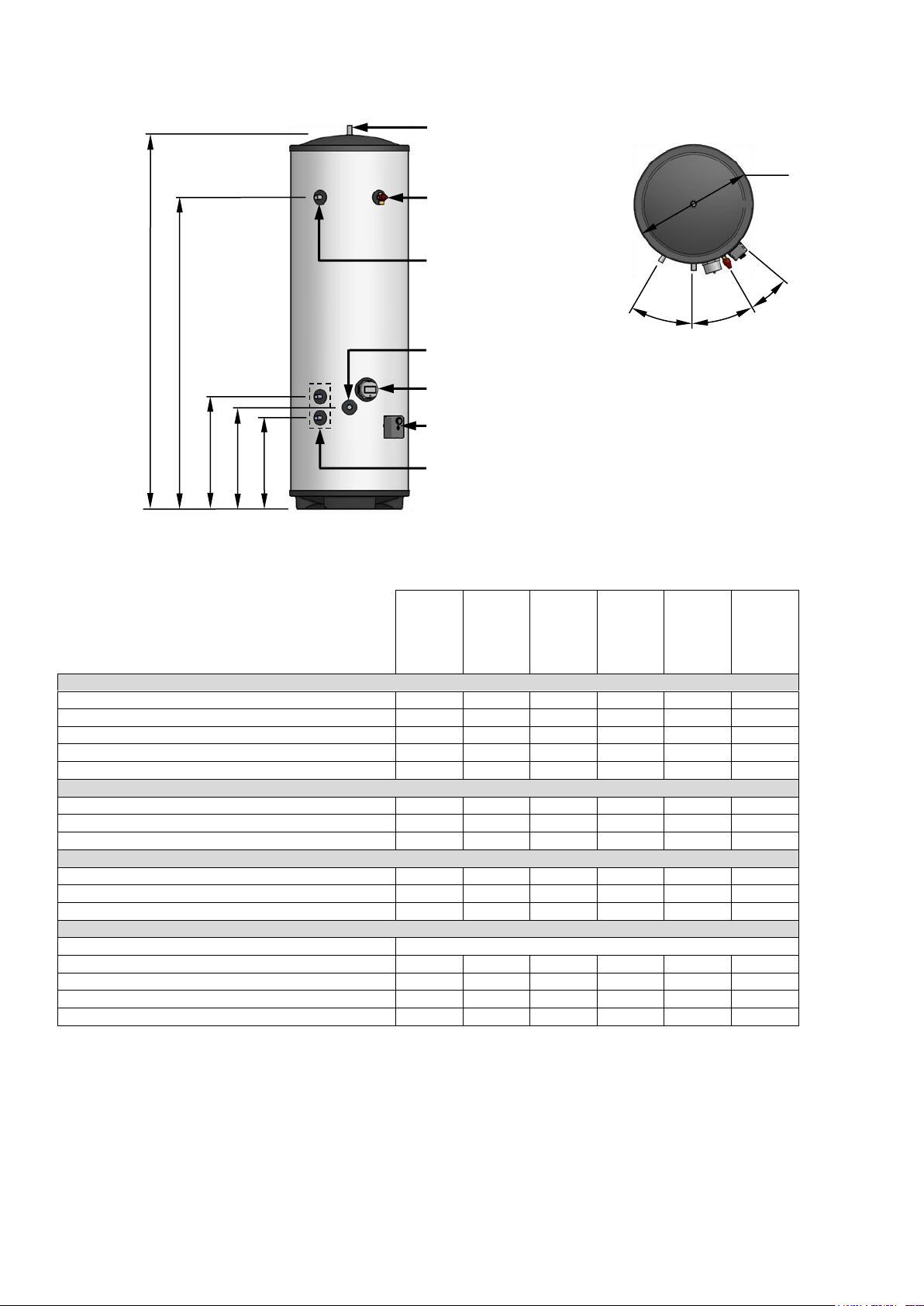

5.3 Indirect Cylinders

IN120UV

IN150UV

IN180UV

IN210UV

IN250UV

IN300UV

DIMENSIONS

(A) Height (mm)

952

1142

1327

1517

1767

2077

(B) Secondary return connection (mm)

n/a

n/a

n/a

1223

1473

1783

(C) Primary coil upper connection (mm)

462

462

532

532

532

532

(D) Cold inlet connection (mm)

412

412

482

482

482

482

(E) Primary coil lower connection (mm)

362

362

432

432

432

432

OPERATING DATA

Cold water capacity (litres)

120

150

180

210

250

300

Weight when full (kg)

140

180

210

250

290

350

Standing heat loss (kWh/24h)

1.15

1.31

1.40

1.66

1.92

2.07

COIL PERFORMANCE (EN12897)

Primary coil rating @ 15L/min (kW)

17.5

17.2

21.3

19.9

22.2

20.4

Primary coil pressure drop @ 15L/min (mbar)

54

54

67

67

67

67

Heat up time by primary coil (mins)

19.1

24.9

24.7

31.4

33.6

41.4

FICHE DATA

Supplier Name

Warmflow

Supplier Model Identifier

IN120

IN150

IN180

IN210

IN250

IN300

Energy Efficiency Class

A B B B C

C

Standing Loss (W)

36

55

58

60

84

86

Storage Volume (litres)

115

146

175

205

245

290

Ø550

E

C

B

Hot Outlet (22mm)

Cold Inlet (22mm)

Temperature & Pressure

Relief Valve (15mm)

Secondary Return (22mm)

Primary Coil Connections (22mm)

Primary Coil Thermostat

Immersion Heater

D

A

30°

30°

20°

Figure 2: Indirect cylinders components & dimensions

Table 3: Indirect cylinder data

Page 6 of 23

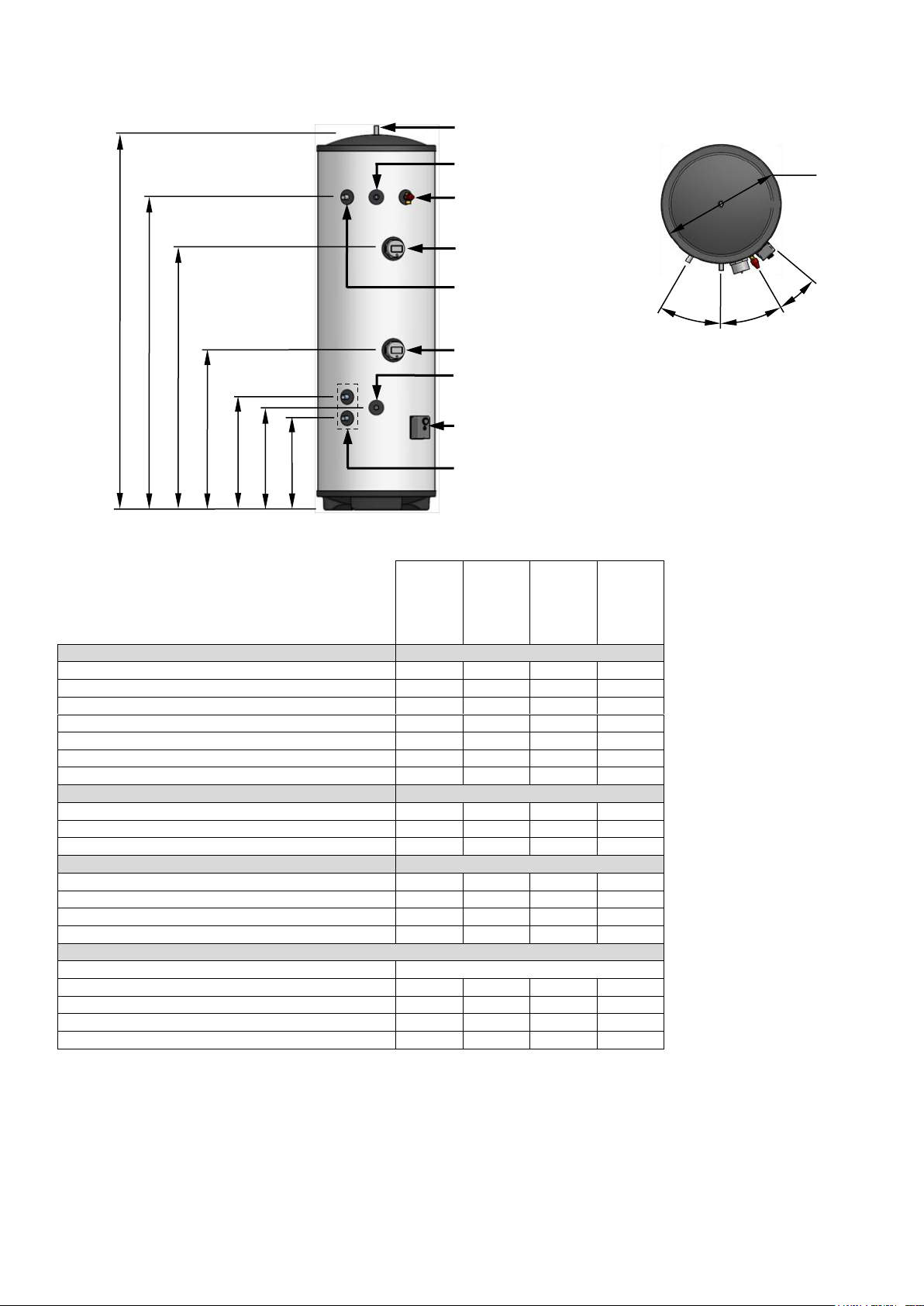

5.4 Eco Direct Cylinders

ED180UV

ED210UV

ED250UV

ED300UV

DIMENSIONS

(A) Height (mm)

1327

1517

1767

2077

(B) Secondary return connection (mm)

n/a

1223

1473

1783

(C) Upper immersion (mm)

891

1078

1230

1540

(D) Lower immersion (mm)

596

752

752

1062

(E) Renewable coil upper connection (mm)

532

532

532

532

(F) Cold inlet connection (mm)

482

482

482

482

(G) Renewable coil lower connection (mm)

432

432

432

432

OPERATING DATA

Cold water capacity (litres)

180

210

250

300

Weight when full (kg)

210

250

290

350

Standing heat loss (kWh/24h)

1.40

1.66

1.92

2.07

PERFORMANCE

Renewable coil rating @ 15L/min (kW)

21.4

20.2

21.8

19.3

Renewable coil pressure drop @ 15L/min (mbar)

67

67

67

67

Heat up time by lower immersion only (mins)

127

138

184

188

Dedicated renewable volume (litres)

65

90

110

145

FICHE DATA

Supplier Name

Warmflow

Supplier Model Identifier

ED180

ED210

ED250

ED300

Energy Efficiency Class

B

B C C

Standing Loss (W)

58

60

84

86

Storage Volume (litres)

175

205

245

290

30°

Ø550

G

E

D

Hot Outlet (22mm)

Cold Inlet (22mm)

Temperature & Pressure

Relief Valve (15mm)

Secondary Return (22mm)

Renewable Coil Connections (22mm)

Renewable Coil Thermostat

Lower Immersion Heater

F

30°

20°

Upper Immersion Heater

Sensor Pocket (1/2”)

C

B

A

Figure 3: Eco Direct cylinders components & dimensions

Table 4: Eco Direct cylinder data

Page 7 of 23

5.5 Twin Coil Cylinders

TW180UV

TW210UV

TW250UV

TW300UV

DIMENSIONS

(A) Height (mm)

1327

1517

1767

2077

(B) Secondary return connection (mm)

n/a

1223

1473

1783

(C) Primary coil upper connection (mm)

973

1078

1078

1388

(D) Primary coil lower connection (mm)

873

978

978

1288

(F) Renewable coil upper connection (mm)

532

532

532

532

(F) Cold inlet connection (mm)

482

482

482

482

(G) Renewable coil lower connection (mm)

432

432

432

432

OPERATING DATA

Cold water capacity (litres)

180

210

250

300

Weight when full (kg)

210

250

290

350

Standing heat loss (kWh/24h)

1.40

1.66

1.92

2.07

COIL PERFORMANCE (EN12897)

Primary coil rating @ 15L/min (kW)

20.7

21.3

20.2

21.0

Primary coil pressure drop @ 15L/min (mbar)

54

54

54

54

Heat up time by primary coil @ 15L/min (mins)

15.7

16.3

22.6

21.9

Renewable coil rating @ 15L/min (kW)

20.7

22.3

22.0

20.7

Renewable coil pressure drop @ 15L/min (mbar)

67

67

67

67

Dedicated renewable volume (litres)

70

105

105

155

FICHE DATA

Supplier Name

Warmflow

Supplier Model Identifier

TW180

TW210

TW250

TW300

Energy Efficiency Class

B

B C C

Standing Loss (W)

58

60

84

86

Storage Volume (litres)

175

205

245

290

30°

Ø550

G

E

D

Hot Outlet (22mm)

Cold Inlet (22mm)

Temperature & Pressure

Relief Valve (15mm)

Secondary Return (22mm)

Renewable Coil Connections (22mm)

Renewable Coil Thermostat

Immersion Heater

F

30°

20°

C

B

A

Primary Coil Connections (22mm)

Primary Coil Thermostat

Figure 4: Twin Coil cylinders components & dimensions

Table 5: Twin Coil cylinder data

Page 8 of 23

5.6 Triple Coil Cylinders

TR250UV

TR300UV

DIMENSIONS

(A) Height (mm)

1767

2077

(B) Secondary return connection (mm)

1473

1783

(C) Tertiary coil ‘A’ upper connection (mm)

1403

1683

(D) Primary coil ‘B’ upper connection (mm)

1363

1643

(E) Tertiary coil ‘A’ lower connection (mm)

564

844

(F) Primary coil ‘B’ lower connection (mm)

524

804

(G) Renewable coil upper connection (mm)

462

532

(H) Cold inlet connection (mm)

412

482

(J) Renewable coil lower connection (mm)

362

432

OPERATING DATA

Cold water capacity (litres)

248

298

Weight when full (kg)

290

350

Standing heat loss (kWh/24h)

1.92

2.07

COIL PERFORMANCE (EN12897)

Tertiary coil ‘A’ rating @ 15L/min (kW)

18.9

20.1

Tertiary coil ‘A’ pressure drop @ 15L/min (mbar)

16

16

Heat up time by Tertiary coil ‘A’ @ 15L/min (mins)

25.7

24.6

Primary coil ‘B’ rating @ 15L/min (kW)

18.2

19.2

Primary coil ‘B’ pressure drop @ 15L/min (mbar)

16

16

Heat up time by Primary coil ‘B’ @ 15L/min (mins)

27.9

26.9

Renewable coil rating @ 15L/min (kW)

20.0

20.9

Renewable coil pressure drop @ 15L/min (mbar)

54

67

Dedicated renewable volume (litres)

70

115

FICHE DATA

Supplier Name

Warmflow

Supplier Model Identifier

TR250

TR300

Energy Efficiency Class

C

C

Standing Loss (W)

84

86

Storage Volume (litres)

245

290

30°

Ø550

J

G

F

Hot Outlet (22mm)

Cold Inlet (22mm)

Temperature & Pressure

Relief Valve (15mm)

Secondary Return (22mm)

Renewable Coil Connections (22mm)

Renewable Coil Thermostat

Immersion Heater

H

30°

20°

E

D

Primary Coil ‘B’ Connections

(28mm)

Primary Coil Thermostat

Tertiary Coil ‘A’

Connections

(28mm)

Tertiary Coil Thermostat

C

B

A

Figure 5: Triple Coil cylinders components & dimensions

Table 6: Triple Coil cylinder data

Page 9 of 23

6 INSTALLATION

6.1 Cylinder Location

The unit can be located in any convenient, frost-free, indoor location. As it is connected directly

to the mains water supply it is equally efficient on any floor – ground, first, second, etc. The unit

can be fitted into a conventional airing cupboard and does not require any additional insulation

or ventilation.

When selecting a location, consideration should be given to the routing of the discharge pipe

and to the relative location of the heat sources (solar panels, heat pumps or boilers) as well as

to the main outlets – pipe runs should be kept as short as possible for maximum economy,

especially hot water discharge pipes running down from the unit.

Ensure the cylinder is positioned such that future servicing and part replacement is possible.

The routing of pipework must not prevent thermostats, immersion heaters, temperature &

pressure relief valve, inlet group or expansion vessel from being removed for maintenance.

6.2 Hot & Cold Water Connections

The factory-fitted temperature and pressure relief valve must NOT be removed from the

cylinder or tampered with in any way. The valve is pre-calibrated to operate at 7 bar or

90°C and any attempt to adjust or remove it will invalidate the guarantee and could

adversely affect the safety of the appliance.

All connections to the cylinder must be made using compression fittings. Mains supply

pipework must be a minimum of 22mm diameter to provide adequate flow rate.

6.2.1 Inlet group

The inlet group (supplied) must be fitted on the cold water mains prior to the unit. When

connecting the inlet group, ensure the arrow on the body is pointing in the direction of flow

(towards the cylinder).

The maximum supply pressure to the inlet group is 12 bar. If the mains supply pressure is likely

to exceed 12 bar at any time, an additional suitable pressure reducing valve (not supplied) will

be required.

A balanced cold connection is provided on the inlet group, from which the cold water supply to

the rest of the property can be connected to provide balanced supply pressure throughout. If

this facility is not required, the connection should be capped / stop-ended.

6.2.2 Stop cock & drain

Install a full bore stop cock or ball valve (not supplied) before the inlet group assembly on the

incoming mains water supply so the unit can be isolated when required. A full bore drain cock

(not supplied) must be fitted to the supply pipework, between the cylinder and the inlet group, at

as low a level as possible, to facilitate draining (see Figure 6).

6.2.3 Distribution pipework

Pipework supplying the hot water taps must be capable of withstanding a maximum pressure of

7 bar at a temperature of 90°C and should be run in 22mm throughout the property. Only short

lengths (max 1 metre) of 15mm should be used to connect baths, showers and basin taps. If

using a secondary / pumped return circuit, all pipework must be well insulated. The circulator

(bronze pump) should be time and/or temperature controlled to reduce energy consumption.

6.2.4 Taps & fittings

All taps and fittings incorporated into the unvented system should have a rated operating

pressure of 7 bar or above.

Page 10 of 23

6.3 Primary, Renewable & Tertiary Circuits

The working pressure and temperature for all heat exchanger coils is given in Table 1. All

connection to the cylinder must be made using compression fittings.

6.3.1 Safety thermostat

Each heat exchanger coil has an associated combined control & safety thermostat. The system

controls must be wired in such a manner as to cut off the flow of heat to the cylinder in the event

of overheating in order to comply with Building Regulations and to ensure a safe installation.

This is typically achieved using a motorised valve wired in series with the thermostat. Refer to

Section 6.10 for suggested wiring schematics.

6.3.2 Motorised valve

A motorised valve is supplied with all Indirect, Twin Coil & Triple Coil models. This must be

fitted to the pipework supplying the primary coil (usually the coil connected to the boiler) and

wired in series with the combined control & safety thermostat in order to comply with Building

Regulations and to ensure a safe installation. In this manner, if the boiler malfunctions and

produces excess heat, the motorised valve will close preventing the cylinder from overheating.

Refer to Section 6.10 for suggested wiring schematics.

Uncontrolled solid fuel boilers and gravity circulation systems must not be used with an

unvented hot water system. For guidance on connecting a controllable solid fuel appliance

(such as a wood pellet stove or boiler) to an unvented cylinder, reference should be made to the

appliance manufacturer’s instructions and to Building Control.

6.3.3 Solar installations

If connecting a solar thermal installation, for example, to the renewable coil of a Twin Coil, Triple

Coil or Eco Direct model, the controls must be wired in series with the combined control & safety

thermostat. If using a solar pump station with check valves to prevent gravity circulation, a

motorised valve may not be required. Refer to the appliance manufacturer’s instructions and to

Building Control for further guidance. Additional motorised valves (not supplied) may be

required.

6.4 Tundish

The tundish supplied must be fitted so it is visible to the occupier, away from electrical

equipment, and must be connected with copper pipe (not plastic). Guidance on the Building

Regulations requirements for the discharge pipework is provided in Section 6.8.

6.5 Expansion Vessel

An expansion vessel is supplied as part of the unvented kit and must be connected to the

pipework between the inlet group and the cylinder in order to accommodate expansion of the

stored water due to heating. For ease of installation a dedicated expansion vessel port is

provided on the body of the inlet group itself.

Ensure the expansion vessel is mounted with the connection at the bottom and that access is

left available for future servicing and removal.

Where a secondary return circuit is used, increased expansion capacity may be required.

6.6 Hard water

In areas with moderately hard water, choosing a lower control thermostat temperature can result

in less scale being deposited within the cylinder. Where water hardness in excess of

200mg/litre is experienced, a suitable and effective hard water treatment must be installed. A

devise rated for a flow rate of 50 litres per minute is recommended in order to maintain

maximum performance.

Page 11 of 23

6.7 Pipework Configurations

HOT OUTLET

COLD INLET

Balanced Supply to cold taps

Discharge

M

1

2

3

4

5

Primary

Flow / Return

6

7

Mains stopcock (not supplied)

Inlet group

Temperature & pressure relief valve

Tundish

Motorised zone valve

Expansion vessel

Full bore drain cock (not supplied)

1

2

3

4

5

6

7

To drain

via tundish

To cylinder

‘COLD INLET’

From mains

To cold taps

To expansion vessel

Figure 6: Typical pipework configuration

Figure 7: Inlet group connections

stop cock

Page 12 of 23

6.8 Discharge Pipework

The following is an extract from Section G3 of the Building Regulations for England and Wales

and provides the most up-to-date guidance on the requirements for discharge pipework. Refer

also to Figure 8.

Discharge Pipe D1

3.50 Safety devices should discharge either directly or by way of a manifold via a short length

of metal pipe (D1) to a tundish.

3.51 The diameter of discharge pipe (D1) should be not less than the nominal bore of the

safety device.

3.52 Where a manifold is used it should be sized to accept and discharge the total discharge

from the discharge pipes connected to it.

3.53 Where valves other than a temperature and pressure relieve valve from a single

unvented hot water system discharge by way of the same manifold that is used by the safety

devices, the manifold should be factory fitted as part of the hot water storage system unit or

package.

Tundish

3.54 The tundish must be vertical, located in the same space as the unvented hot water

storage system and be fitted as close as possible to, and lower than, the safety device, with no

more than 600mm of pipe between the valve outlet and the tundish (see Figure 8).

Note: To comply with the Water Supply (Water Fittings) Regulations, the tundish should

incorporate a suitable air gap.

3.55 Any discharge should be visible at the tundish. In addition, where discharges from safety

devices may not be apparent, e.g. in dwellings occupied by people with impaired vision or

mobility, consideration should be given to the installation of suitable safety device to warn when

discharge takes place, e.g. electronically operated.

Discharge Pipe D2

3.56 The discharge pipe (D2) from the tundish must:

a. have a vertical section of pipe at least 300mm long below the tundish before any elbows

or bends in the pipework (see Figure 8); and

b. be installed with a continuous fall of at least 1 in 200 thereafter.

3.57 The discharge pipe (D2) should be made of:

a. metal; or

b. other material that has been demonstrated to be capable of safely withstanding

temperatures of the water discharged and is clearly and permanently marked to identify

the product and performance standard (e.g. as specified in the relevant part of BS 72911:2006).

3.58 The discharge pipe (D2) should be at least one pipe size larger than the nominal outlet

size of the safety device unless its total equivalent hydraulic resistance exceeds that of a

straight pipe 9m long, i.e. for discharge pipes between 9m and 18m the equivalent resistance

length should be at least two sizes larger than the nominal outlet size of the safety device, and

so on; bends must be taken into account in calculating the flow resistance. See Figure 8, Table

7 and the worked example.

Page 13 of 23

Note: An alternative approach for sizing discharge pipes would be to follow Annex D, Section

D.2 of BS 6700:2006 + A1:2009.

3.59 Where a single common discharge pipe serves more than one system, it should be at

least one pipe size larger than the largest individual discharge pipe (D2) to be connected.

3.60 The discharge pipe should not be connected to a soil discharge stack unless it can be

demonstrated that the soil discharge stack is capable of safely withstanding temperatures of the

water discharged, in which case, it should:

a. contain a mechanical seal, not incorporating a water trap, which allows water into the

branch pipe without allowing foul air from the drain to be ventilated through the tundish;

b. be a separate branch pipe with no sanitary appliances connected to it;

c. if plastic pipes are used as branch pipes carrying discharge from a safety device, they

should be either polybutalene (PB) or cross-linked polyethylene (PE-X) complying with

national standards such as Class S or BS 7291-2:2006 or Class S of BS 7291-3:2006

respectively; and

d. be continuously marked with a warning that no sanitary appliances be connected to the

pipe.

Notes:

1. Plastic pipes should be joined and assembled with fittings appropriate to the

circumstances in which they are used as set out in BS EN ISO 1043-1:2002.

2. Where pipes cannot be connected to the stack it may be possible to route a dedicated

pipe alongside or in close proximity to the discharge stack.

Termination of Discharge Pipe

3.61 The discharge pipe (D2) from the tundish should terminate in a safe place where there is

no risk to persons in the vicinity of the discharge.

3.62 Examples of acceptable discharge arrangement are:

a. to a trapped gully with the end of the pipe below a fixed grating and above the water seal;

b. downward discharges at low level; i.e. up to 100mm above external surfaces such as car

parks, hard standings, grassed areas, etc. are acceptable providing that a wire cage or

similar guard is positioned to prevent contact, whilst maintaining visibility; and,

c. discharges at high level: e.g. into a metal hopper and metal downpipe with the end of the

discharge pipe clearly visible or onto a roof capable of withstanding the temperature

discharges of water and 3m from any plastic guttering system that would collect such

discharges.

3.63 The discharge would consist of high temperature water and steam. Asphalt, roofing felt

and non-metallic rainwater goods may be damaged by such discharges.

The discharge pipe within the building is to be located within a frost free environment.

Page 14 of 23

6.9 Worked Example

Valve

outlet size

Minimum size of

discharge pipe D1

Minimum size of

discharge pipe D2

from tundish

Maximum resistance allowed,

expressed as a length of straight

pipe (i.e. no elbows or bends)

Resistance

created by each

elbow or bend

G½”

15mm

22mm

Up to 9m

0.8m

28mm

Up to 18m

1.0m

35mm

Up to 27m

1.4m

The example below is for a G½” temperature relief valve with a discharge pipe (D2) having 4

no. elbows and a length of 7m from the tundish to the point of discharge. The calculation shows

that 22mm pipe would be unacceptable.

UNACCEPTABLE

Discharge pipe (D2) run in 22mm copper:

Length of straight pipe = 7.0m

Resistance created by bends (0.8m x 4) = 3.2m

Total resistance of discharge pipe = 10.2m

Maximum resistance allowed for a 22mm copper

discharge pipe (D2) from a G½” temperature relief

valve is 9.0m, which is less than 10.2m.

Therefore, installation unacceptable:

Discharge pipe (D2) needs to be larger than 22mm.

Note: Data provided for G½” outlet size and copper pipework only. Other outlet sizes and pipe materials should

be calculated using data prepared for the size and type of pipe being used.

ACCEPTABLE

Discharge pipe (D2) run in 28mm copper:

Length of straight pipe = 7.0m

Resistance created by bends (1.0m x 4) = 4.0m

Total resistance of discharge pipe = 11.0m

Maximum resistance allowed for a 28mm copper

discharge pipe (D2) from a G½” temperature relief

valve is 18.0m, which is more than 11.0m.

Therefore, installation acceptable:

Discharge pipe (D2) can be run in 28mm.

Table 7: Sizing of copper discharge pipe (D2) for G½” valve outlet

Figure 8: Typical discharge pipe arrangement

Page 15 of 23

6.10 Electrical Installation

Do not

use

To system controls

B

2

Earth

S-Plan

3

Link wire

(supplied)

Do not

use

To system controls

B

2

Connection to terminal 3

is only required if using a

3-port mid-position valve.

Earth

Y-Plan

To isolating

B

A

Live

Neutral

Earth

Main (lower)

solar sensor location

Twin Coil

Triple Coil

Eco Direct

Additional (upper)

solar sensor location

(if applicable)

6.10.1 Cylinder thermostats

Figure 9: Control thermostat wiring

6.10.2 Immersion heater(s)

(Y-plan system wiring)

switch

Figure 10: Immersion heater wiring

6.10.3 Solar temperature sensors

Solar sensors should be located in the pocket(s) behind the cylinder thermostat(s). Remove the

thermostat cover and base. Pass the sensor through the base then insert downwards into the

pocket as shown in Figure 11. Anchor the cable using the clamp provided. A stand-alone

pocket is provided on Eco Direct models only.

Figure 11: Solar sensor installation

Page 16 of 23

6.10.4 System controls

N

N

N

2

E

E E E

L

L

L

X

Y

1

3

L

G N E 3 2

B

E O N

G

L

E

O

Pump

Boiler

Programmer

Room Thermostat

Heating Zone Valve

Cylinder Thermostat

HW Zone Valve

5 Amp Fused

Spur Isolator

Live (L)

N)

E)

X)

Hot Water On (Y)

L N E

N

N

N

N N N

N

L G N

E

3 2 B

E O N G W

E

O

N

N

N

2

E

E

E

E

L

L

L

X

Y

1

3

Z

Room Thermostat

Programmer

Boiler

Pump

HW Zone Valve

Cylinder Thermostat

Mid-position Valve

5 Amp Fused

Spur Isolator

Live (L)

N)

E)

X)

Y)

Z)

L N E

N

N

N

N

N

N

N

Neutral (

Earth (

Heating On (

Figure 12: S-plan system wiring

Neutral (

Earth (

Heating On (

Hot Water On (

Hot Water Off (

Figure 13: Y-plan system wiring

Page 17 of 23

7 COMMISSIONING

The appliance and installation must be commissioned as described below and the Cylinder

Passport completed and returned to the manufacturer along with proof of purchase.

FAILURE TO COMMISSION, REGISTER AND ANNUALLY SERVICE THIS

PRODUCT WILL INVALIDATE ALL GUARANTEES

Isolate all electrical supplies until otherwise instructed during the commissioning process.

1 Prior to filling the cylinder (or with the mains isolated and a hot tap open), check the

expansion vessel bladder pre-charge – it should be 3.0 bar.

2 Check that all connections are tight and correctly configured.

3 Fill the cylinder and system as follows:

Open the main stopcock and fill the cylinder.

Open successive hot taps.

Leave each tap open for a few minutes in order to flush out air and debris.

Close all taps.

4 Drain the cylinder as described in Section 7.1 below.

5 Refill the cylinder as above, closing each tap when water flows freely.

6 Manually operate (by rotating the knob) both the expansion relief and the temperature

and pressure relief valves for a short period to remove trapped air from behind the

valve seat and to prove the correct function of the discharge arrangement.

7 Check all joints for leaks and rectify as necessary.

8 Check that all immersion and control thermostats are set to the desired temperature.

9 Commission each primary circuit as follows (not applicable to Direct models):

Fill each primary circuit (e.g. boiler, heat pump or solar circuits) following each

heat source manufacturers’ instructions.

Check for leaks in each primary circuit and rectify as necessary.

Commission each heat source in accordance with the manufacturer’s instructions

activating the system controls as required.

10 Activate each heat source to confirm that the system controls function correctly.

11 Check that, while the cylinder is heating up, no water exits from either the expansion

relief or the temperature and pressure relief valves, and that the system controls

deactivate all heat sources when the cylinder is up to temperature.

7.1 Draining

Isolate all electrical supplies before draining the cylinder / secondary (hot water) circuit.

1 Close the main stopcock.

2 Connect hose to the drain cock and route to a suitable discharge.

3 Open the drain cock.

4 Open the hot water tap nearest the cylinder. If water fails to drain, vent the system by

opening the temperature and pressure relief valve.

5 Allow the system to drain fully then close the drain cock when complete.

Page 18 of 23

8 MAINTENANCE

Isolate all electrical supplies before removing any components for inspection or repair, or

before draining the cylinder or heat source circuits.

8.1 Regular Maintenance

This appliance must be serviced annually to ensure continued safe operation and to maintain

the guarantee. Servicing must be undertaken by a competent person i.e. qualified professional.

1 Isolate the mains water supply and open a hot tap. Check the expansion vessel

bladder pre-charge – it should be 3.0 bar.

2 Check the strainer on the inlet group. Clean the strainer if necessary by unscrewing

the pressure reducing valve and withdrawing the strainer.

3 Check and service all hard water treatment devices (if fitted) in accordance with each

device manufacturer’s instructions.

4 Check that all connections are tight and correctly configured.

5 Manually operate (by rotating the knob) both the expansion relief and the temperature

and pressure relief valves to prove the correct function of the discharge arrangement.

6 Check all joints for leaks and rectify as necessary.

7 Check that all immersion and control thermostats are appropriately set.

8 Activate each heat source to confirm that the system controls function correctly.

9 Check that, while the cylinder is heating up, no water exits from either the expansion

relief or the temperature and pressure relief valves, and that the system controls

deactivate all heat sources when the cylinder is up to temperature.

8.2 Inspection Access

Where necessary, the internal components of the cylinder can be inspected by means of the

immersion heater boss (1¾”) using an appropriate inspection tool e.g. boroscope.

8.3 Replacement Parts

Part description Code

Cylinder thermostat WDS6

Immersion heater c/w stat (1¾”) 3602

Motorised valve (22mm) 3603

T&P valve (½” x 15mm) 3654

Inlet group (22mm) 3890

Expansion vessel (12 litres) 3891

Expansion vessel (19 litres) 3892

Expansion vessel (24 litres) 3893

Tundish (15mm x 22mm) 3670

Page 19 of 23

8.4 Fault Finding

Symptom

Possible cause

Possible remedy

Little / no hot water flow

Mains water supply isolated

Open stopcock.

Strainer blocked

Turn water supply off, remove strainer and clean.

Pressure reducing valve fitted the wrong

way

Refit with arrow pointing in direction of flow

(refer to Figure 7).

Water from hot taps is cold

Boiler programmer or immersion timer

not calling for hot water

Set programmer / timer to call.

Cylinder thermostat high limit tripped or

immersion thermostat high limit tripped

Check and reset (refer to Section 1).

Heat source malfunction

(e.g. boiler / immersion heater / etc)

Check heat source – if faulty, refer to heat source

manufacturer’s instructions.

Motorised valve malfunction

(where fitted, n/a to Direct models)

Manually activate motorised valve.

If cylinder begins to heat, replace valve.

Pump malfunction

(n/a to Direct models)

Check wiring and/or plumbing connections to pump.

Intermittent water

discharge from tundish

Expansion vessel has lost its pre-charge

Turn off water supply, open hot tap, check bladder pre-charge

and recharge to 3 bar.

Inlet group balanced cold / cylinder

connections reversed

Check and reconnect (refer to Figure 7).

Continuous water

discharge from tundish

Pressure reducing valve not working

Check pressure from pressure reducing valve – if greater

than 3 bar, replace cartridge.

Expansion relief valve not seating

correctly

Manually operate the valve to clear any debris from the seat.

Temperature & pressure relief valve not

seating correctly

Manually operate the valve to clear any debris from the seat.

System control / safety feature failure

IMMEDIATELY switch off all power supplies.

Contact your installer.

Page 20 of 23

9 GUARANTEE

Warmflow unvented cylinders are supplied with the following guarantees from the date of purchase:

(a) A 25 year guarantee on the duplex stainless steel cylinder body against defects of material.

(b) A 2 year guarantee on all parts and components as well as any defects that may have occurred from time

to time during the normal manufacturing process of the cylinder as carried out by those exercising all

relevant skill and experience and complying with all relevant legislation, regulations and codes of practice

relating to the manufacturing process.

1. The guarantees provided are from the date of purchase and are conditional upon:

1.1 the unit being installed and commissioned by competent persons in accordance with the

manufacturer’s instructions and relevant legislation, regulations and codes of practice in force at the

time;

1.2 the product being registered with Warmflow within 30 days of installation and the guarantee

registration completed and returned to Warmflow along with evidence of the date of purchase;

1.3 the unit not being modified in any way, or misused or subject to neglect;

1.4 the unit being serviced annually by competent persons in accordance with the manufacturer’s

instructions and all regulations and codes of practice in force at the time;

1.5 each service record being completed and proof of purchase and servicing being retained and made

available to Warmflow in respect of any claim;

1.6 the unit being used solely for the purpose of heating potable water that complies at all times with EU

standards and not fed from a private source.

Failure to comply with any of the conditions outlined in this clause will invalidate the warranty in its entirety.

2. The guarantee is not transferable and excludes:

2.1 labour costs associated with the replacement of the unit or its components;

2.2 any defects that appear after the customer makes any modification or alteration to the unit;

2.3 defects caused by the improper use or storage of the unit and in particular (but without limitation)

Warmflow shall not be liable in the case of defects arising from normal deterioration or improper or

faulty handling or processing of the unit by the customer;

2.4 consequential losses however caused.

3. If within the 2 year guaranteed period, as set out at (b) above, a material defect is discovered in the Unit:

3.1 the customer must send written notification following discovery giving particulars and either at its own

expense and risk shall return the unit to Warmflow within 2 weeks of written notice being provided by

Warmflow; or (at Warmflow’s sole option) shall permit Warmflow to inspect same; and

3.2 if such defect has arisen from faulty materials employed or workmanship carried out by Warmflow and

is existing but not reasonably discoverable upon inspection at the time of receipt then Warmflow shall

supply such part(s) free of charge along with the costs of transporting same to the customer.

3.3 The replacement parts must be fitted in accordance with the terms of the guarantee set out above.

3.4 The replacement parts shall be covered under this guarantee for the remainder of the unexpired term

of two years.

3.5 Invoices for call out and/or repair by any third party or parts supplied by a third party will not be

accepted unless previously authorised by Warmflow in writing.

4 Warmflow’s liability for defective units is limited in all circumstances to delivery of parts for the defective

unit and the customer shall accept same as fulfilment of Warmflow’s obligations.

5 Warmflow disclaims all other warranties whether express, implied or statutory. Your statutory rights are

not affected.

6 This guarantee applies to Warmflow cylinders installed on the UK mainland (excluding Scottish Isles), Isle

of Man, Channel Islands, Northern Ireland and Republic of Ireland only. Provision of in warranty cover

elsewhere is subject to the agreement in writing of Warmflow.

Page 21 of 23

10 END-OF-LIFE INFORMATION

Warmflow Unvented Cylinders must be disposed of according to local regulations by

using a public or private waste collection service.

10.1 Safety Risks

Prior to disassembly, the appliance should be electrically isolated and disconnected.

Any fluids within the appliance must be drained, and disposed of in-line with local

regulations.

Care should be taken when handling the appliance due to weight, use appropriate

PPE and lifting aids.

Polyisocyanurate foam insulation – suitable PPE should be used for respiration

protection, and to avoid skin or eye contact.

10.2 Disassembly of the Product

The main materials of the components are:

Mild Steel

Stainless Steel

Polyisocyanurate Foam

Plastic Components

Electronic Components

These may be recycled – depending on the local recycling facilities available.

The appliance is assembled by using mechanical fasteners and can be

disassembled with standard tools.

The components of a typical appliance are shown below (not all components may be

fitted, depending on appliance specification)

Page 22 of 23

10.3 Casing and key components

Item

Description

Main Materials

Special Notes

1

Casing

Coated Galvanised Steel

2 T&P Relief Valve

Plastic, Brass

Consult Component Manufacturer

3

Foam Insulation

Polyisocyanurate Foam

Wear Appropriate PPE

4

Storage Tank

Stainless Steel

5

Thermostat Housing

Plastic, Copper, Electronic

Components

6

Immersion Heater

Plastic, Brass, Incoloy,

Electronic Components

Consult Component Manufacturer

7

Casing Top

Plastic

8 Heating Coils

Stainless Steel

9 Dip Pipe

Stainless Steel

10

Solar Coil

Stainless Steel

11

Casing Base

Plastic

Others

Expansion Vessel

Steel, Rubber, Brass

Consult Component Manufacturer

1

2

3

4

5

6

9

10

7

8

11

Figure 14: Key Component Diagram

Various other brackets, fasteners and components may be used, with up to 5% of

appliance weight.

Page 23 of 23

BLANK PAGE

BLANK PAGE

WARMFLOW Engineering Company Limited

Lissue Industrial Estate, Moira Road, Lisburn BT28 2RF

Tel: 028 9262 1515 Fax: 028 9262 0869

WARMFLOW Customer Care Centre

UK: 028 9262 1515 ROI: 048 9262 1515

Email: service@warmflow.co.uk

THIS MANUAL IS ACCURATE AT THE DATE OF

PRINTING (E&OE) BUT MAY BE SUPERSEDED

AND SHOULD BE DISREGARDED IF

SPECIFICATIONS AND/OR APPEARANCES ARE

CHANGED IN THE INTERESTS OF CONTINUED

PRODUCT IMPROVEMENT.

3683 rev 04 March 2016

Loading...

Loading...