WarmFlow COMBI 70, COMBI 90, KABIN PACK COMBI 90 Installation & Servicing Instructions Manual

INSTALLATION & SERVICING

MANUAL FOR

70/90

COMBI BOILER

&

70/90

KABIN PAK COMBI

LEAVE THESE INSTRUCTIONS WITH THE END USER

NATIONAL

ACCREDITATION

OF CERTIFICATION

BODIES

BSI

R

E

G

I

S

T

E

R

E

D

F

I

R

M

CERT. No. FM 29884

BS 5750 PART 2

ISO 9002

ISSUE 4

MAR ’03

SERVICING

To ensure continued reliable operation and

fuel economy it is recommended that the

boiler is serviced annually.

Warmflow Engineering Service division

provides an excellent back-up service,

operating a team of Oftec trained engineers

who can meet all the servicing,

commissioning and breakdown

requirements for your appliance.

Simply telephone

TEL: (028) 9262 0852

FAX: (028) 9262 0869

E-MAIL: service@warmflow.co.uk

COMMISSIONING

*THIS APPLIANCE MUST

BE COMMISSIONED

*Failure to commission this appliance may invalidate warranty

After commissioning ensure that the pre-paid warranty

registration card is filled in and returned.

BEFORE FITTING THIS BOILER THE

INSTALLER MUST CHECK:

1. What the maximum hot water demand is likely to be placed on

the boiler. Not every installation is suitable for a Combi boiler.

Systems requiring very high hot water flow rates may be better

suited with an unvented cylinder.

2. That the mains are capable of supplying up to 24 litre/min with a

minimum dynamic pressure of 1.8 bar at the boiler. This is to

ensure that the boiler can achieve its maximum output.

3. The hardness of the mains water supply. Systems with hard water

must be fitted with a suitable chemical scale preventer (eg Fernox

Quantomat or Combimate alternatively contact Warmflow for

further details).

4. That the flow from any one hot water outlet does not exceed the

maximum recommended. This applies particularly to baths which

are usually fitted with larger taps and larger bore supply pipes. It

may be necessary to restrict the flow to these taps by reducing

the bore of the supply pipework or by fitting a restrictor into the

pipework.

5. That any outlet when opened does not starve all the other outlets

of hot water. If more than one outlet is open at the same time

then the total flow from all the outlets should not exceed the

maximum flow rate of the boiler.

6. That any showers being supplied hot water by the boiler are

compatible with this type of appliance.

It should be noted that the boiler has been factory fitted with

an 18 litre/min flow restrictor.

The manufacturers guarantees are void if the appliance is

not installed and commissioned in accordance with the

recommendations made herein.

Page 1

Contents Page

1.0 User Instructions ................................................................................................................. 3

1.1 Introduction .................................................................................................................4

1.2 General Requirements ................................................................................................ 4

1.3 Components................................................................................................................ 5

2.0 Technical Details.................................................................................................................. 7

2.1 Sequence of Operation Flow Chart............................................................................. 7

2.2 Baffles ......................................................................................................................... 8

2.3 General Requirements ................................................................................................ 8

2.4 Dimensions ................................................................................................................. 9

2.5 Combi Flue Options .................................................................................................. 10

2.6 Technical Data .......................................................................................................... 13

3.0 Electricity Supply............................................................................................................... 14

3.1 RDB Burner Control Box ........................................................................................... 14

3.2 Fitting a Room Thermostat ....................................................................................... 14

3.3 Combi Wiring Details ................................................................................................ 15

3.4 Kabin Pak Combi Wiring Details ............................................................................... 17

3.5 Frost Thermostats ..................................................................................................... 19

3.6 Timers for Standard Combi ....................................................................................... 20

3.7 Timers for Kabin Pak Combis ................................................................................... 22

4.0 Oil Supply ...........................................................................................................................23

4.1 One Pipe System ...................................................................................................... 23

4.2 Two Pipe System ...................................................................................................... 24

4.3 De-aerator System .................................................................................................... 24

4.4 One Pipe Lift ............................................................................................................. 25

5.0 Flues .................................................................................................................................. 26

5.1 Conventional Flues ................................................................................................... 26

5.2 Low Level Discharge/Low Level Balanced Flues Terminal Position ......................... 26

6.0 Air Supply for Combustion and Ventilation.....................................................................28

6.1 Open Flue Boilers ..................................................................................................... 28

6.2 Balanced Flue Boilers ............................................................................................... 28

6.3 Installation of Flues ................................................................................................... 29

7.0 Thermostat Control Knob Peg Setting............................................................................. 31

8.0 Installation .......................................................................................................................... 32

8.1 Hearth .......................................................................................................................32

8.2 Service Access.......................................................................................................... 32

8.3 Heating System......................................................................................................... 32

8.4 Domestic Hot Water .................................................................................................. 34

8.5 Removal of Flow Restrictor ....................................................................................... 34

8.6 Fitting a Vertical Flue Adaptor ................................................................................... 35

8.7 Installation of Air Intake Duct .................................................................................... 35

9.0 Burners ...............................................................................................................................36

9.1 RDB Burner............................................................................................................... 36

9.2 Oil Supply.................................................................................................................. 36

9.3 Electrical Connections .............................................................................................. 37

9.4 Electrode Setting....................................................................................................... 37

9.5 Burner Start-up Cycle ............................................................................................... 37

10.0 Commissioning and Servicing ......................................................................................... 38

10.1 Commissioning ......................................................................................................... 38

10.2 Servicing ...................................................................................................................38

11.0 Horstmann 626 Electronic Programmer ..........................................................................39

12.0 Fault Finding ...................................................................................................................... 44

12.1 Central Heating ......................................................................................................... 44

12.2 Domestic Hot Water .................................................................................................. 45

12.3 Burner ....................................................................................................................... 46

13.0 Spares ................................................................................................................................. 47

13.1 Riello RDB Burner..................................................................................................... 47

13.2 Pipe Spares .............................................................................................................. 48

13.3 Short Parts List ......................................................................................................... 49

Page 2

1.0 User Instructions

1.0.1 Boiler Control Thermostat

The boiler control thermostat is located on the front of the boiler facia panel and may

be adjusted from 52°C to 85°C. The recommended minimum thermostat setting is

65°C. Below this ‘cold water corrosion’ is likely to occur thus reducing the life of the

heat exchanger and is not covered by the manufacturer’s warranty. When using hot

water only it is recommended that the boiler control thermostat is switched to the off

position.

1.0.2 Mains Indicator

The green mains light will be lit when there is power to the control panel.

1.0.3 H/L Reset

The yellow H/L reset lamp will be lit when the high limit thermostat has tripped at its set

temperature of 110°C. This cuts off power to the burner and may indicate that there is

a fault in the heating system. The high limit thermostat has a manual reset button

located underneath the control panel in line with the control thermostat. Once the

temperature has fallen and the reset button has been pressed the boiler should restart.

If the high limit thermostat continues to trip contact your service engineer/technician.

1.0.4 Lock Out

The red lock out lamp will be lit when the burner has failed and can be reset by pressing

the illuminated red reset button on the burner control box. If there is power and the

thermostat is calling for heat and the burner has been reset it will go through its start

up cycle. If the burner again fails to fire this would indicate a burner fault or oil supply

problem (oil supply problems are not covered by manufacturers warranty).

1.0.5 Tank Control Thermostat

Located on the right hand side of the control panel the tank control thermostat controls

the temperature in the thermal store. The temperature is adjustable up to a maximum

of 80°C. A peg has been fitted to the rear of the knob to prevent the temperature being

set too high. To change the setting see page 31.

1.0.6 Tank Limit Thermostat

Located inside the control panel the tank limit thermostat is a thermal resetting device

controlling the on/off operation of the burner in hot water mode.

1.0.7 Hot Water and Central Heating On/Off Switch

Both hot water and central heating operations can be controlled via these switches.

However it should be noted that when both switches are in the ‘on’ position hot water

will have priority. In addition whenever a timer or programmer is connected to the

boiler one or more of these switches may be bypassed.

1.0.8 Pressure Gauge

The pressure gauge fitted to the front of the control panel measures system pressure.

The pressure should be set at 1 bar when the boiler is cold. As the boiler heats up, the

pressure will rise but should not exceed 3 bar.

1.0.9 Servicing

It is recommended that the boiler is serviced annually by an OFTEC registered engineer.

Page 3

1.1 Introduction

Note: All our domestic appliances have been independently tested and accredited

as exceeding the minimum SEDBUK efficiency levels required for its type, in

compliance with the Building Regulations Approved Document L1 2001 for

England and Wales and the Building Standards (Scotland) Regulations 2001

Part J.

The Warmflow oil fired ‘Combi’ boiler and Kabin Pak Combi are suitable for sealed

central heating systems and can provide at mains pressure domestic hot water without

the use of a cylinder.

The Warmflow oil fired combis are designed to burn Class C2 (28 sec redwood) kerosine

or Class D (35 sec redwood) gas oil. However to comply with building regulations only

kerosine may be burned when using the low level balanced flue or low level conventional

flue.

As standard the appliance is fitted with a system expansion vessel, circulating pumps,

filling loop, pressure gauge and safety valve. An optional 7-day electronic programmer

is also available.

The pressure jet oil burner is covered by the manufacturer’s parts and labour warranty

valid for one year (from the boiler date stamp). The boiler and heat store are covered

by a manufacturer’s warranty of 5 years (from the boiler date stamp) but does not

include burner, labour, handling or shipping. Details of any extended warranties are

contained within the installation pack.

Optional extended guarantees, for the appliance covering parts and labour of up to 5

years initially are also available (although not applicable to the Republic of Ireland).

The manufacturer’s guarantees are void if the appliance is not installed and

commissioned in accordance with the recommendations made herein.

1.2 General Requirements

The installation of the boiler must be in accordance with the following regulations.

BS5410 : PART 1 : 1997 Code of practice for oil firing.

BS5449 : PART 1 : 1997 Forced circulation hot water systems.

BS7593 : 1992 Treatment of water in domestic hot water central heating systems.

Current Building Regulations: Part J England and Wales

Part F Scotland

Part L Northern Ireland

Current IEE Regulations:

BS7074 : PART 1 : Application Selection & Installation of Expansion Vessels

The heating system should be installed by a competent installer in accordance with

the recommendations laid down by HVCA, OFTEC and a sound engineering practice.

In order to comply with GB building regulations OFTEC forms CD10 for

installations and CD11 for commissioning should be left with the customer.

Page 4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

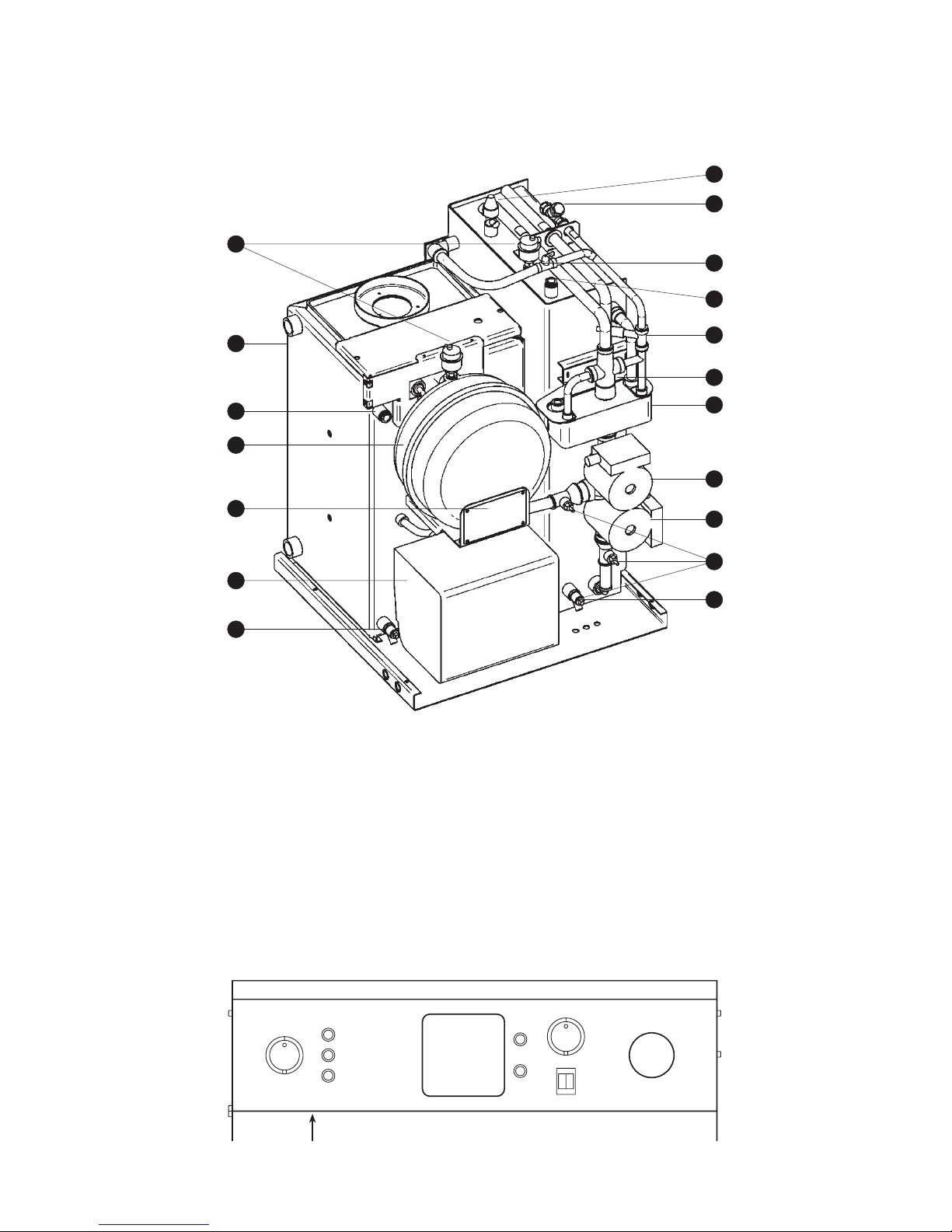

1.3 Components

1.3.1 Combi Assembly

1. Automatic Air Vents

2. Boiler Heat Exchanger

3. Boiler Control and Limit Stat

4. 12 Litre Esxpansion vessel

5. Boiler Data Plate

6. RDB Burner

7. Boiler Drain Valve

8. Pressure Relief Valve

9. Strainer

10. Filling Loop

11.Tank Control and Limit Stat

12. Flow Switch

13. Mixer Valve

14. Plate Heat Exchanger

15. CH Pump Head

16. DHW Pump Head

17. Pump Gate Valves (x3)

18. Tank Drain Valve

1.3.2 Combi Control Panel

BLANKING

PLATE

CH ON/OFF

SWITCH

TANK CONTROL

THERMOSTAT

MAINS ON

LAMP (GREEN)

HIGH LIMIT TRIPPED

LAMP (YELLOW)

BURNER LOCKOUT

LAMP (RED)

SYSTEM

PRESSURE

GAUGE

DHW

PUMP

BOILER

CONTROL

THERMOSTAT

CH

PUMP

HIGH LIMIT THERMOSTAT

RESET (UNDERNEATH)

Page 5

1

2

3

4

5

6

7

8

9

10

11 12 13 16 17 18

20

19

22

21

24

23

14 15

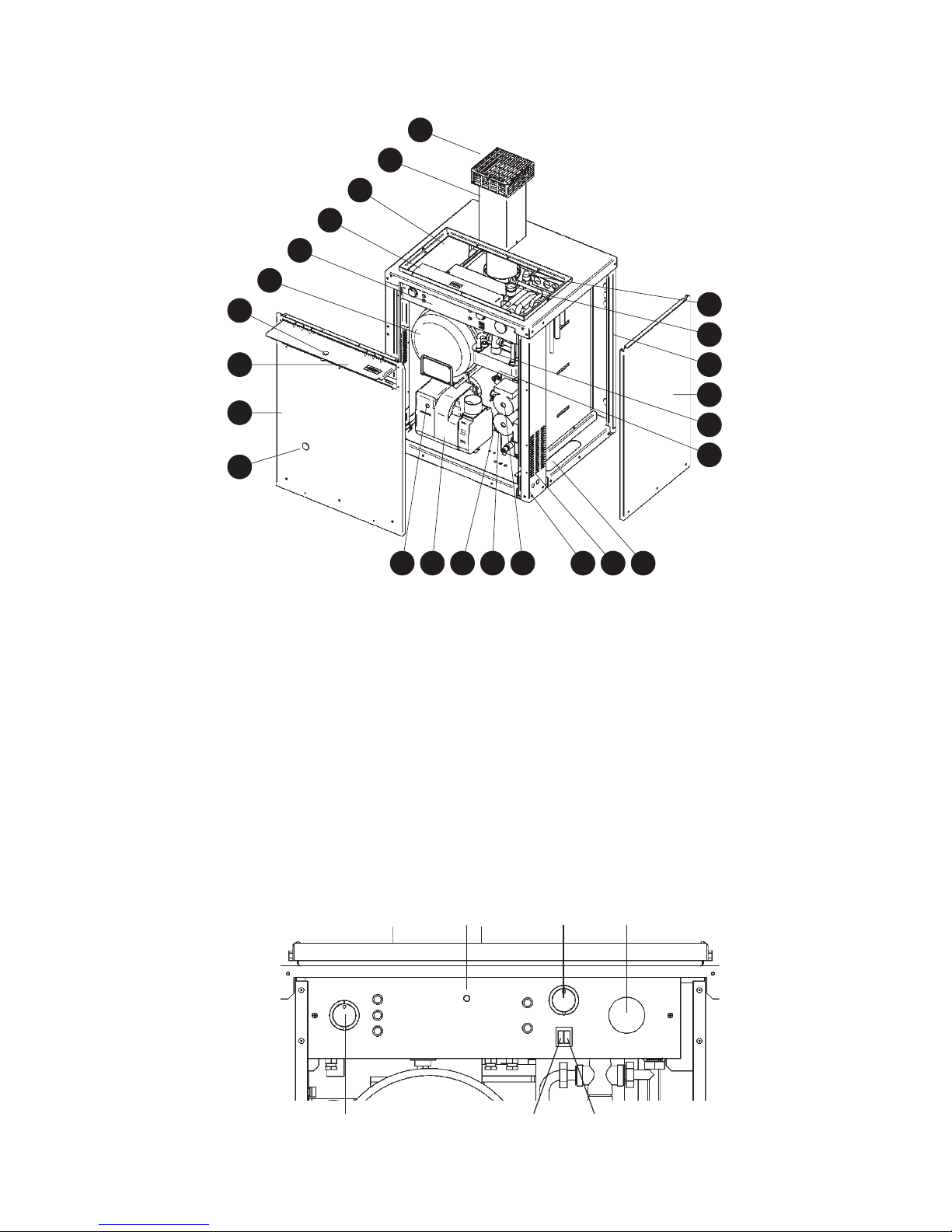

1.3.3 Kabin Combi Assembly

1. Flue Terminal Guard

2. Low Level Flue

3. Service Access Hatch

4. Control Panel Cover

5. Controls

6. Pressure Vessel

7. Control Panel Flap Lock

8. Control Panel Flap

9. Door Panel

10. Burner Reset

11. Burner Reset Button

12. Burner

13. Return Connection

14. DHW Pump

15. CH Pump

16. Cable on Oil Line Grommets

Note: To convert the Kabin Pak for use with a conventional flue use the Kabin Pak adaptor

(KPA).

1.3.4 Kabin Pak Combi Control Panel

17. Air Intake Grill

18. Pipe Access Hole

19. Plate Heat Exchanger

20. Mixing Valve

21. Side Panel

22. Pipe Entry Grommets

23. Auto Air Vent

24. Pressure Relief Valve

Mains On (Green)

High Limit (Yellow)

Burner Lockout (Red)

CH Pump

DHW Pump

Boiler Control

Thermostat

DHW ON/OFF

Switch

CH ON/OFF

Switch

High Limit

Thermostat Reset

Tank Control

Thermostat

System

Pressure Gauge

Page 6

2.0 Technical Details

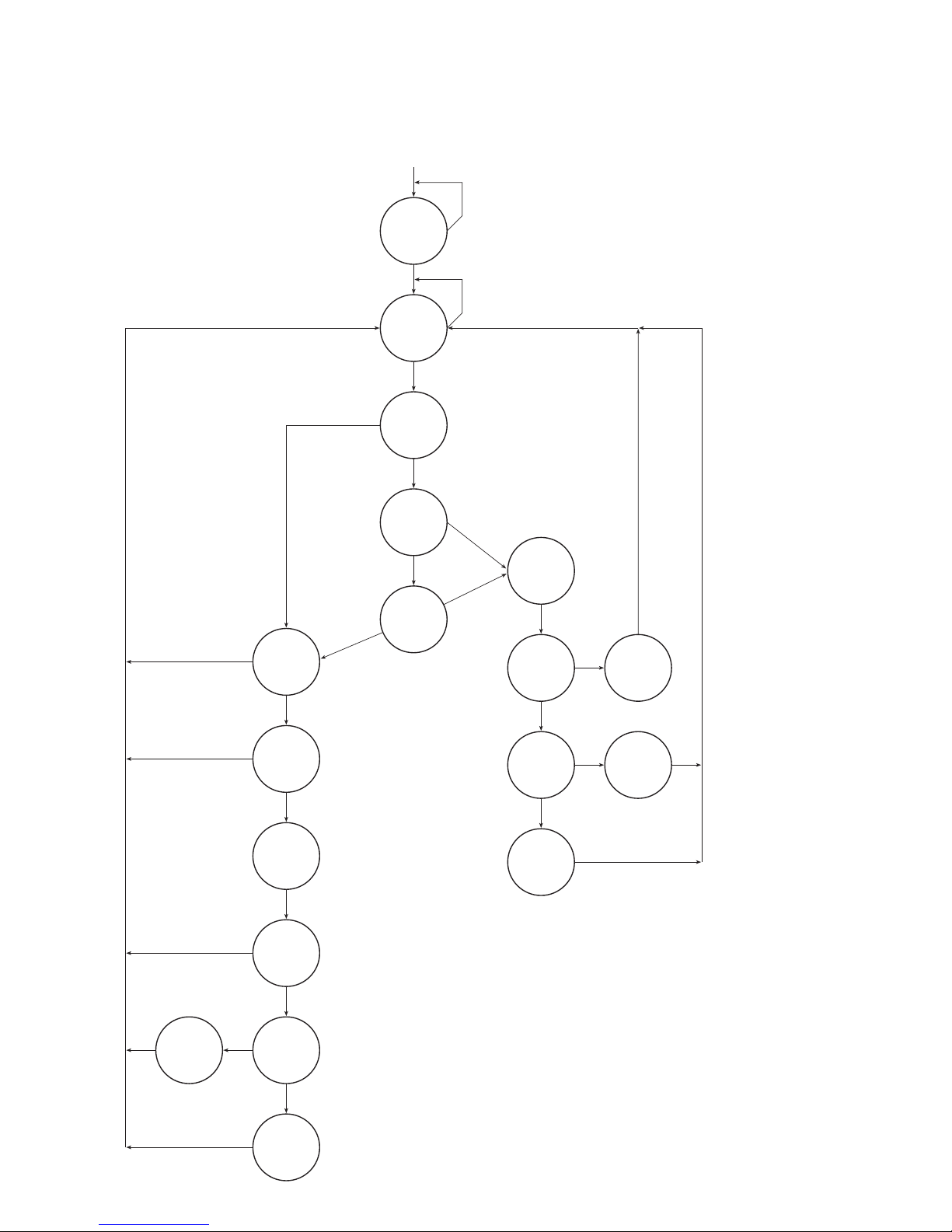

2.1 Sequence of Operation Flow Chart

YES

NO

YES

DHW

Tank Stat

Satisfied

Flow

Switch

Closed

Timer

Calling For

Heat

Power

On

DHW

Pump Only

Runs

HW

Limit Stat

Tr ipped

Burner

Fires

Burner

Stops

CH

Selected

Burner

Fires

CH Pump

Only Runs

Boiler

Stat

Satisfied

Boiler

Limit Stat

Tr ipped

YES

NO

YES

YES

NO

NO

YES

NO

YES

NO

NO

NO

YES

YES

HW

Selected

YES

NO

Room

Stat

Satisfied

NO

YES

Press

Reset

Button

YES

NO

Boiler

Limit Stat

Tr ipped

Press

Reset

Button

The boiler will have a DHW priority when both domestic hot

water (DHW) and central heating (CH) are selected. So if

the flow switch is closed or the heat store has not been

satisfied the entire output of the boiler is directed to DHW

before the boiler will switch over to CH. When fully cold it

can take up to 20 minutes for the heat store to be satisfied.

After a draw-off of 120L at 24L/min, with an average

temperature rise of 32°C, the thermal store has a recovery

time of approximately 7 mins.

Note: If HW has not been selected no hot water can be

produced even if the heat store is up to temperature.

Page 7

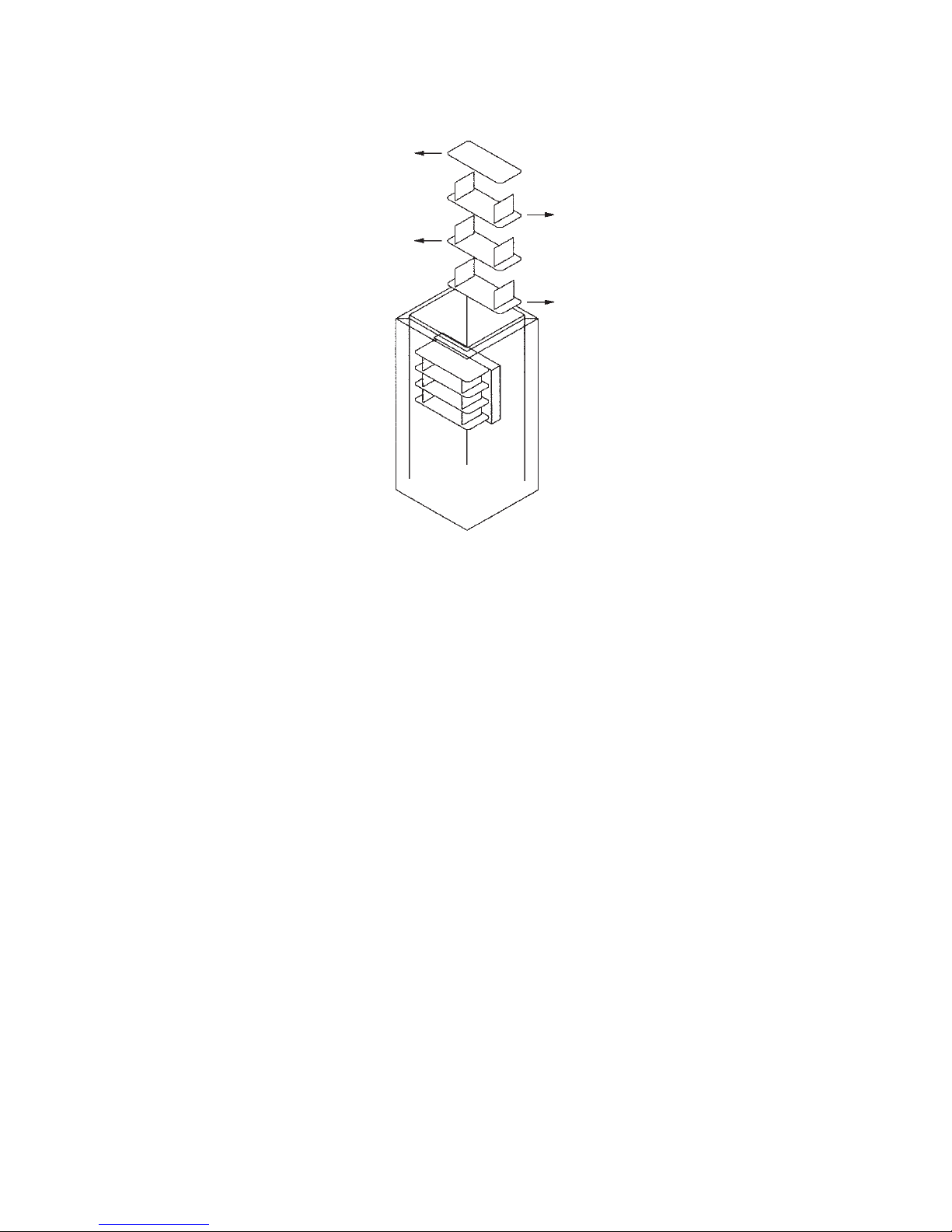

2.2 Baffles

FRONT

Before firing make sure the baffles have not been dislodged in transit and are correctly

positioned. To achieve maximum efficiency push the baffles in the direction of the

arrows as shown.

2.3 General Requirements

1. The Warmflow Combi is supplied with all the necessary components for a sealed heating

system. However, on some larger systems with a total water content greater than

approx 150L, an expansion vessel, in addition to the integral 12L vessel supplied, may

be required.

2. The pressure relief discharge shall be positioned away from any electrical components.

No other valves should be positioned between the relief valve and the discharge, and

the discharge pipe should not be used for any other purposes. The discharge pipe

must be plumbed to an external drain in a position where the discharge can been seen

but cannot cause any injury or damage.

3. Where there is a catastrophic loss of water from the system the boiler thermostats

may fail to operate which would result in serious damage to the appliance. To prevent

this it is recommended that a low pressure cut out switch set at 0.2 bar is fitted to the

system and wired in series with the boiler limit thermostat.

4. The boiler should be stored in a dry environment. No heavy objects should be placed

on top of the boiler. Where possible the boiler should be moved on its pallet or trucked

from its rear. Manhandling the boiler by its casings will result in damage and must be

avoided.

Page 8

1

8045

8000

8130

1620

1310

460

820

REAR VIEW

2 3 4

5

6

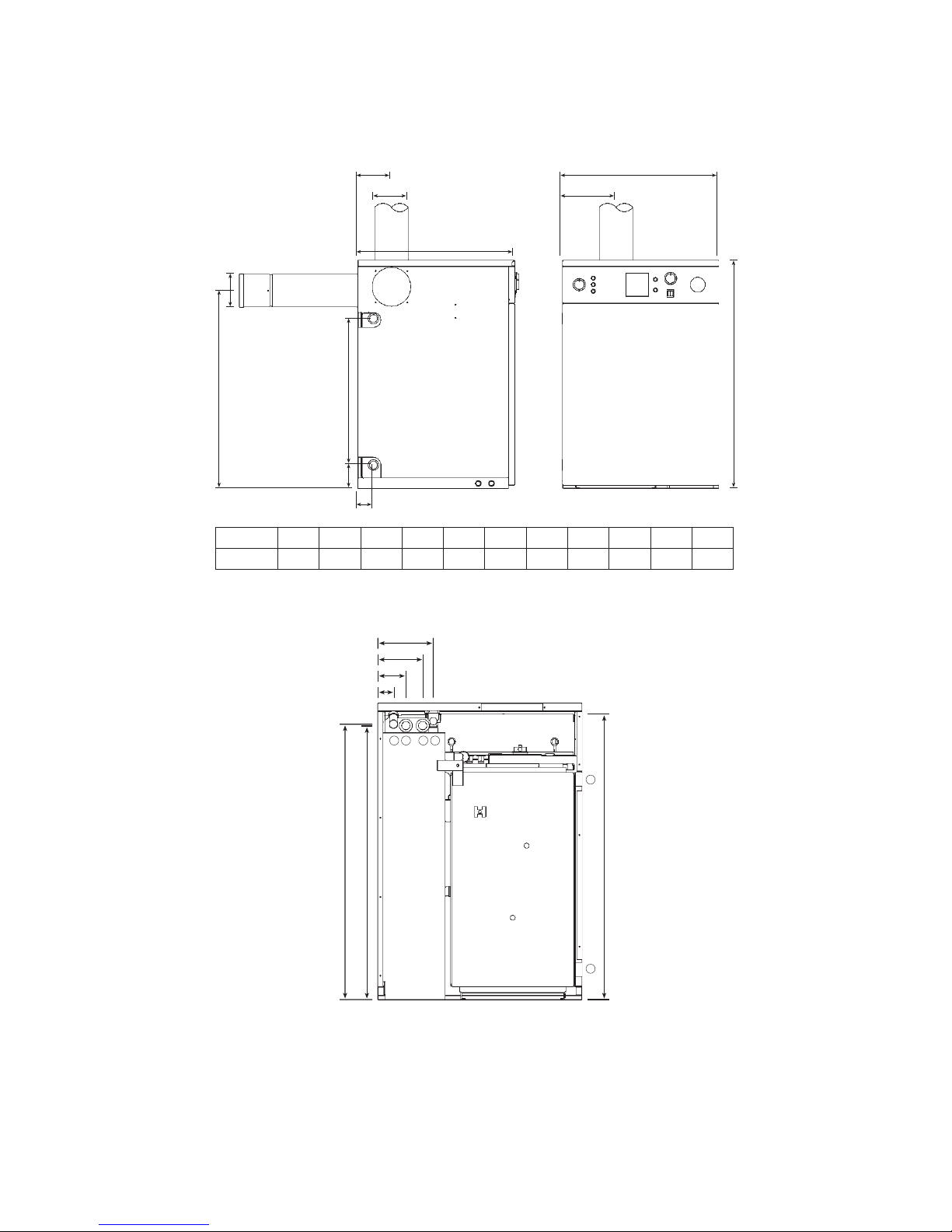

2.4 Dimensions

2.4.1 Combi Dimensions

2.4.2 Combi Boiler Connections

All dimensions are given in mm.

1. Cold Mains (15mm)

2. Heating Flow (22mm)

3. Domestic Hot Water (22mm)

4. Pressure Relief Discharge (15mm)

5. Spare Connection (1” BSP)

6. Central Heating Return (1” BSP)

MODEL

70/90

J

127

A

865B595C595D90E59F554G750H125

K

127L203

J

H

K

C

E

G F

D

B

L

A

Page 9

2.4.3 Kabin Pak Combi Dimensions

MODEL

70/90

J

371

A

892B732C636D373E188F191G376H172

102

712 MAX

225 MAX

175 MIN

490 MIN

Ø125

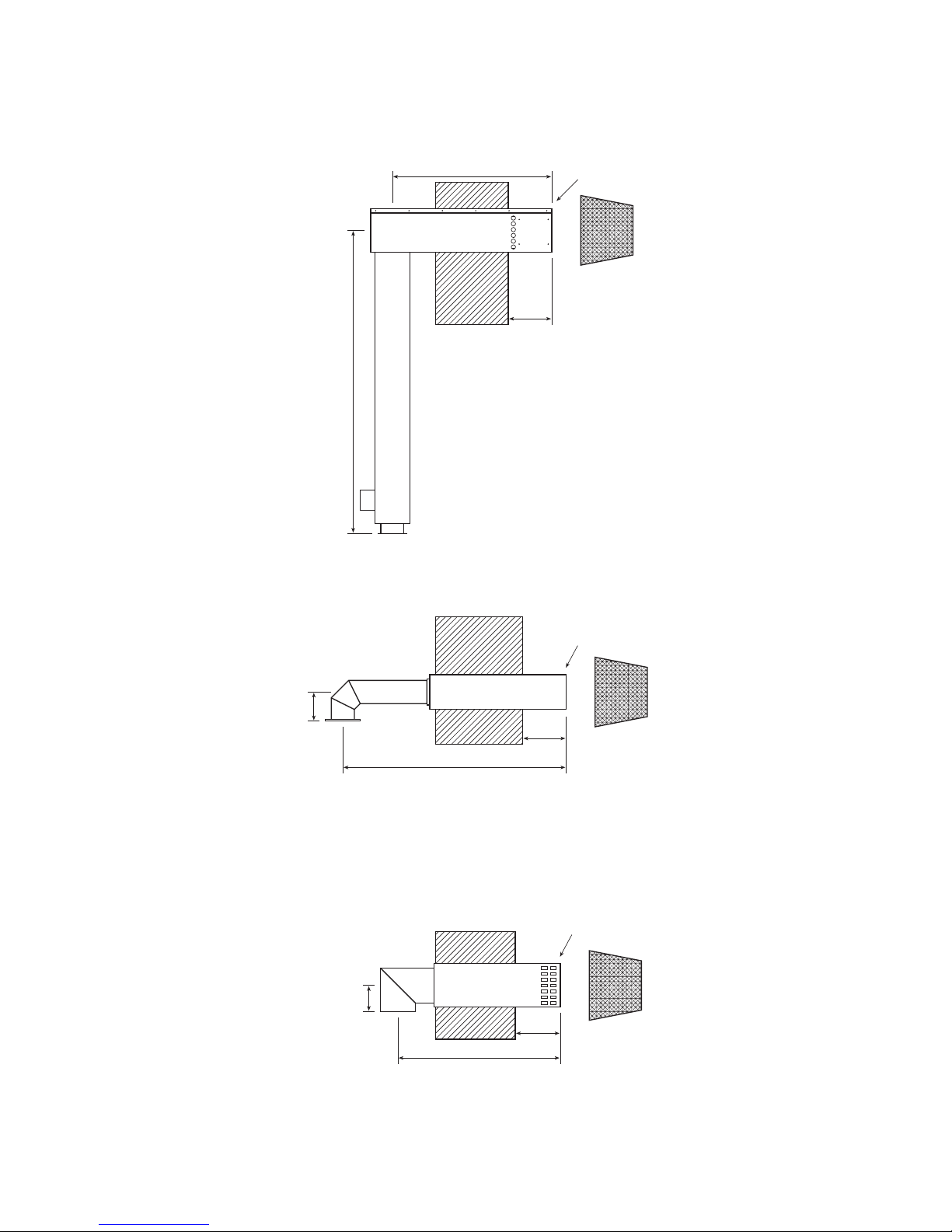

2.5 Combi Flue Options (not applicable to the Kabin Pak Combi)

Note: Low level flue options are rear or left hand outlet only.

2.5.1 ‘Easy Fit’ Telescopic Low Level Balanced Flue (BF-R)

The horizontal dimension can be increased up to an additional 1200mm using a

combination of long extension pieces (E600 = 600mm) and short extension pieces

(E300 = 300mm).

E

B C

FGJH

D

A

Page 10

2.5.2 ‘Easy Fit’ High Level Balanced Flue (HLBF)

The HLBF is available in 4 fixed horizontal lengths which are:

Option 1 – 455mm

Option 2 – 655mm

Option 3 – 585mm

Option 4 – 785mm

2.5.4 Standard Low Level Conventional Flue (LLF)

The factory supplied elbow may be extended up to 1m horizontally and 1.5m vertically

by welding on additional pipe or by using vitreous enamelled flue pipe.

2.5.3 ‘Easy Fit’ Telescopic Low Level Conventional Flue (LLF-R)

102

792 MAX

155 MIN

540 MIN

Ø125

225 MAX

575

155 MIN

102

155x155

225 MAX

225 MAX

175 MIN

1128

SEE OPTIONS

160x160

Page 11

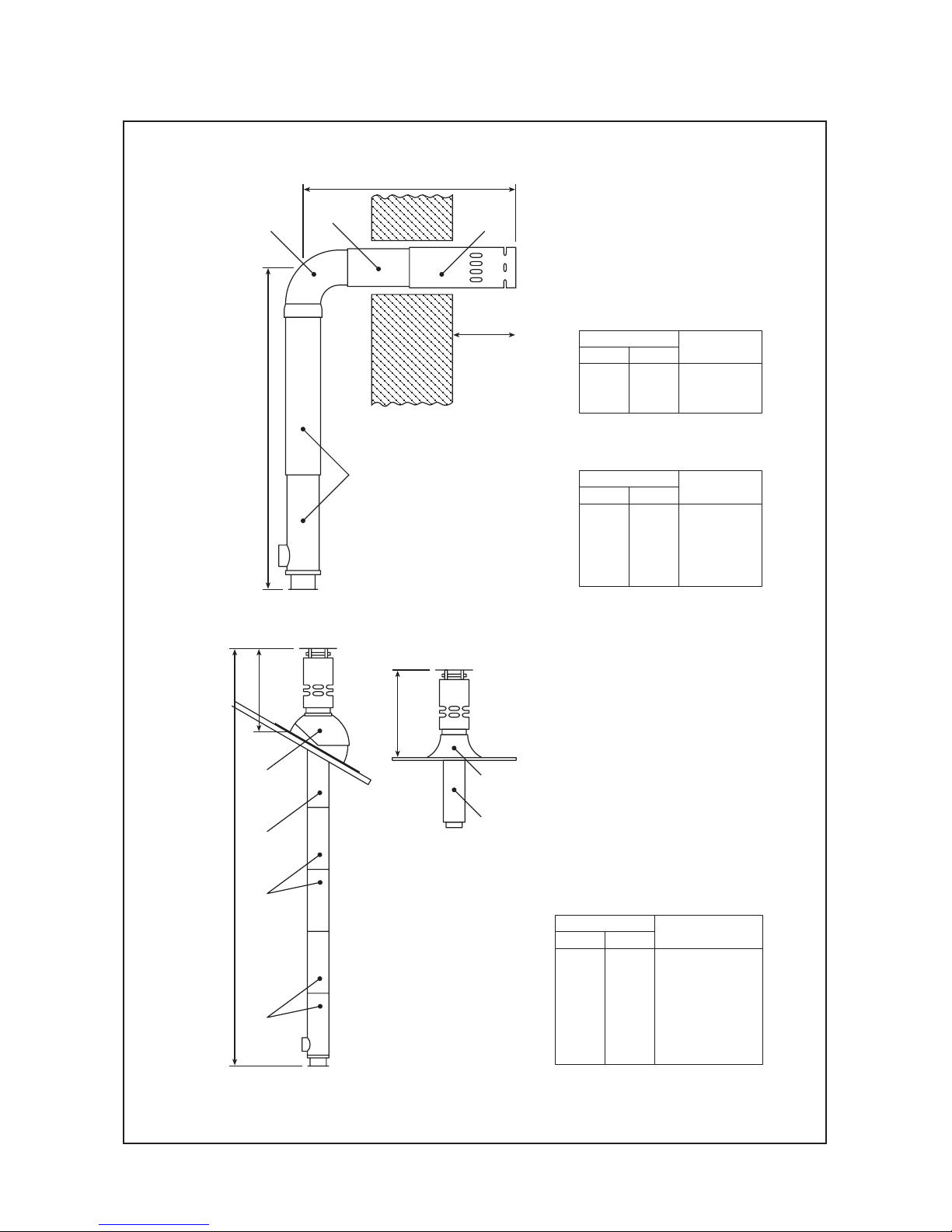

2.5.5 Easy Fit Telescopic High Level Balanced Flue (HLBF-R)

2.5.6 Easy Fit Vertical Balanced Flue (VBF)

EXTENSION KITS

AS REQUIRED

(PACKS C OR D)

PACK E OR F PACK E OR F

A

175 MIN

225 MAX

1570 MIN

2070 MAX

PACK A

PACK H

PITCHED ROOF

FLASHING

(22" – 45"

ADJUSTABLE)

PACK B

VBF TERMINAL

SECTION

EXTENSION KITS

(PACK C OR D) AS

REQUIRED

MAX 2 NO PACK D

PACK A

675mm

MIN

675mm

MIN

PACK G

FLAT ROOF

FLASHING

PACK B

VBF TERMINAL

SECTION

MIN

435

560

735

MAX

610

860

910

A + E

A + F

A + C + E

FLUE PACKS

DIM A

ALL MODELS

MIN

860

1035

1160

1385

1510

MAX

1160

1210

1510

1560

1860

A + C + F

A + C + C + E

A + C + C + F

A + D + E

A + D + F

FLUE PACKS

DIM A

50/70, 70/90 & 90/120 MODELS ONLY

MIN

1340

1640

1940

2290

2590

2890

3240

MAX

1840

2140

2440

2740

3040

3340

3740

A + B

A + B + C

A + B + C + C

A + B + D

A + B + D + C

A + B + D + C + C

A + B + D + D

FLUE PACKS

FLUE HEIGHT

ALL MODELS

Note: When using a VBF or HLBF-R on a 120/150 or 150/200 model ensure that the

boiler is fitted with a RDB3 burner.

AVAILABLE FROM SPRING 2003

Page 12

2.6 Technical Data

Model

Nominal heat KW

Input Btu/hr

Nominal heat KW

Output Btu/hr

Efficiency at max output (net) %

Burner

Head

Flue mm

Size in

Max CO

2

%

Smoke

FGT at max output °C

Water resistance at 20°C ∆T mbar

Approx fuel l/h

Flow rate gals/h

Nozzle make

(kerosine) size

Pump bar

Pressure psi

Nozzle make

(gas oil) size

Pump bar

Pressure psi

Dry weight kg

Primary water content L

Min inlet dynamic pressure bar

for max hot water flow psi

Max DHW flow rate achievable

(refer to page 1)

Factory set DHW flow rate

Min DHW flow rate

DHW temp rise °C

Pressure Relief

Heating flow

Heating return

DHW outlet

Cold water mains inlet (refer to page 1)

Ingress Protection

70/90 Combi

29.3

100,000

26.4

90,000

90

RDB 1

LD3

100 or 127

4 or 5

11.5-12.0

0-1

235

12.0

3.15

0.69

DANFOSS 60°S

0.75

8

116

DANFOSS 60°S

0.6

12

175

155

70

1.8

26

Unrestricted

24 l/min (5.3 gals/min) recommended

18 l/min (4.0 gals/min)

2.5 l/min (0.55 gals/min)

32°C @ 24 L/min for 120L draw off

3 bar (43.5 psi)

22 mm

1” BSP

22 mm

Unrestricted 15 mm bore (minimum)

IPX0

70/90 Kabin Pak Combi

29.3

100,000

26.4

90,000

90

RDB 1

LD3

Integral

Low Level

11.5-12.0

0-1

235

12.0

3.15

0.69

DANFOSS 60°S

0.75

8

116

DANFOSS 60°S

0.6

12

175

155

70

1.8

26

Unrestricted

24 l/min (5.3 gals/min) recommended

18 l/min (4.0 gals/min)

2.5 l/min (0.55 gals/min)

32°C @ 24 L/min for 120L draw off

3 bar (43.5 psi)

22 mm

22 mm Comp.

22 mm

Unrestricted 15 mm bore (minimum)

IP45

Page 13

3.0 Electricity Supply

220 - 240V. 1PH, 50 Hz

The boiler/burner and other external electrical equipment should be wired via a fused

double pole isolating switch which should be fitted with a 5 amp fuse.

In order to ensure the safety of the Kabin Pak Combi Warmflow recommends that

power to the appliance is supplied through a suitable CE approved RCD trip switch.

The appliance must be effectively earthed and all external wiring should comply with

current IEE Regulations. It is the responsibility of the installer to ensure that the appliance

has been properly earthed.

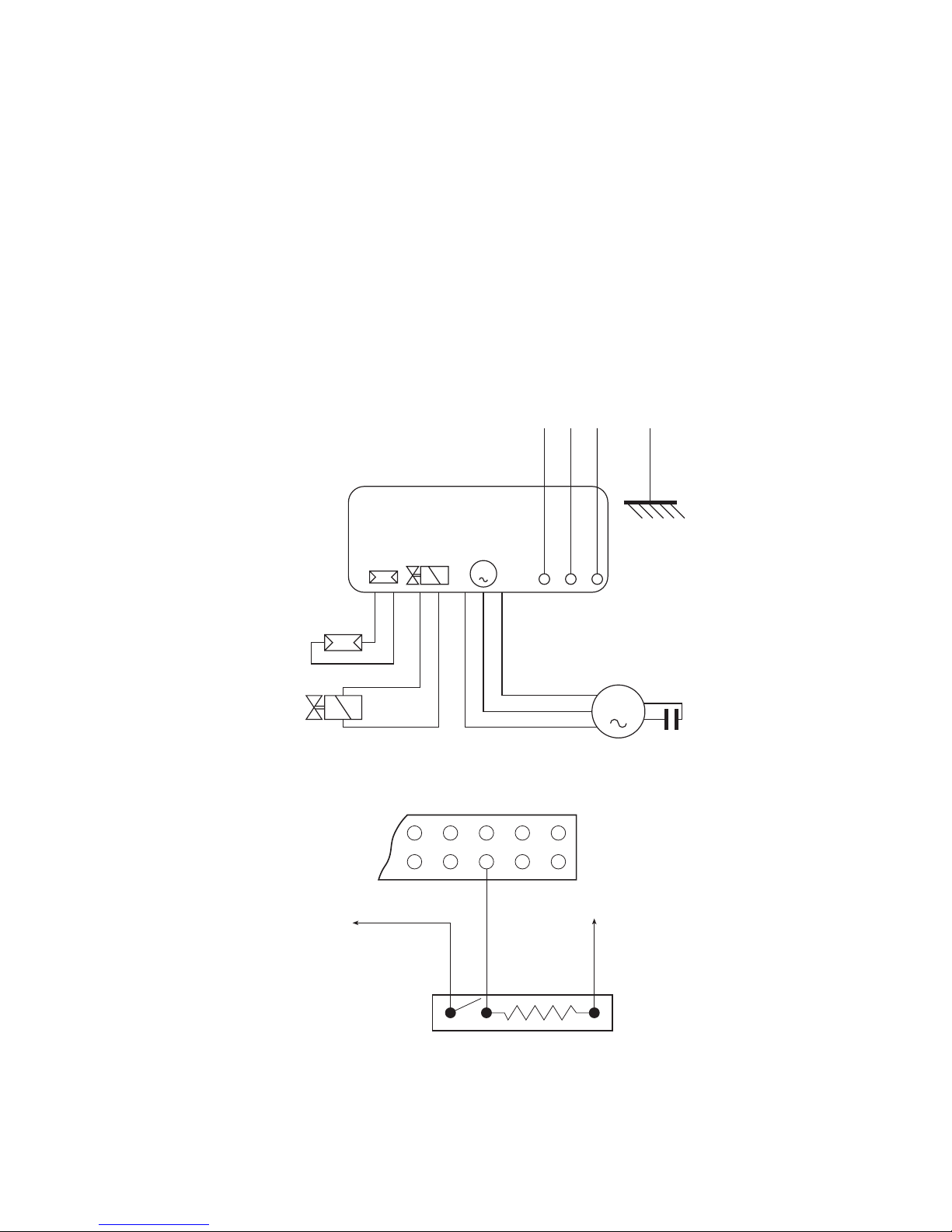

3.1 RDB Burner Control Box

CONTROL BOX

535SE/LD

M

M

Oil Valve

Photoresistance

Black

White

Blue

Motor

Capacitor

Lock Out

Live

Neutral

Earth

Fan

Housing

3.2 Fitting a Room Thermostat

Remove the purple wire from no 5 and no 28 on the PCB and wire the thermostat as

shown. The room thermostat should be located where it is not subjected to extraneous

heat gains, direct sunlight or draughts.

ROOM THERMOSTAT

282726

PCB

N

5

29 30

Page 14

3.3 Combi Wiring Details

3.3.1 Wiring Diagram

P– Purple

O– Orange

Y– Yellow

R– Red

W– White

BR – Brown

BL – Blue

B– Black

G/Y – Green/Yellow

Page 15

3.3.2 Combi Wiring Schematic

BREAK INTO THE WHITE

WIRE BETWEEN NO 16 ON

THE PCB AND THE LIMIT

STAT AND CONNECT IN THE

PRESSURE SWITCH WITH A

WIRING BLOCK AS SHOWN

Page 16

3.4 Kabin Pak Combi Wiring Details

3.4.1 Kabin Pak Combi Wiring Diagram

P– Purple

O– Orange

Y– Yellow

R– Red

W– White

BR – Brown

BL – Blue

B– Black

G/Y – Green/Yellow

GY – Grey

Page 17

3.4.2 Kabin Pak Combi Wiring Schematic

BREAK INTO THE WHITE

WIRE BETWEEN NO 16 ON

THE PCB AND THE LIMIT

STAT AND CONNECT IN THE

PRESSURE SWITCH WITH A

WIRING BLOCK AS SHOWN

Page 18

3.5 Frost Thermostats

3.5.1 Combi Boilers

The switched live from the frost thermostat (the frost thermostat must be supplied by a

permanent live) should be connected to number 5 on the boiler terminal block. In order

to protect the fabric of the building as well as the boiler and pipework, the thermostat

should be located in the coldest part of the house but where it can respond to any

temperature rise.

3.5.2 Kabin Pak Combi Boilers

As the boiler is supplied with a factory fitted frost thermostat all that is required is for a

permanent live to be supplied to the control panel.

FROST THERMOSTAT

PERMANENT

LIVE

543 6

Page 19

3.6 Timers for Standard Combi

Note: Single channel timers or programmers are not recommended.

3.6.1 Installation of a remote two channel programmer (option 1)

Remove the purple wire connecting 5

and 28 and the white wire connecting 3

and 19.

Connect the programmer as shown via

a fused isolator.

This bypasses the central heating and

hot water on/off switch.

If the connection to terminal 12 is not

made the mains on lamp is also

bypassed.

A separate live supply to the boiler is

not required. However a neutral and

earth must be supplied to the boiler.

3.6.2 Installation of a remote two channel programmer (option 2)

Remove the purple, white and brown wires

connecting the central heating and hot water

on/off switches to the 6 pin male plug.

Connect the programmer as shown.

The mains is supplied via a fused isolator

to the boiler 3 pin mains plug.

OFFOFFENL

COM

ON

22 21 20 19

PCB CONTROLLER

ON

COM

CH HW

26 25 24 2328 27

12

11

EARTH

POST

OFFOFFENL

COM

ON ON

COM

CH HW

1

2

3

4

5

6

EARTH

POST

Page 20

3.6.3 Installation of W armflow Optional Programmer (not applicable to the Kabin Pak

Combi)

1. Disconnect the electrical supply.

2. Remove top casing (4 studs) and control box cover (1 screw).

3. Remove 2 screws securing blanking plate/programmer bracket. Remove bracket and

blanking plate from the control panel.

4. Disconnect the blanking plate from bracket (2 screws).

5. Feed programmer harness through the hole in the bracket. The programmer is secured

to the bracket with 2 screws.

6. Disconnect the 6 pin plug from the CH and HW on/off plugs.

7. Connect the programmer 6 pin plug into the socket.

8. Locate the programmer into the hole in the facia and secure the bracket to the control

panel (2 screws).

9. Set the time switch on the rear of the programmer to ‘G’ or ‘P’ (see programmer

instructions).

10. Replace the control panel cover and reconnect electrical supply.

11. Operational instructions are included in this handbook. (Section 11, Page 27)

CONTROL PANEL

BLANKING PLATE

OPITIONAL

PROGRAMMER

BLANKING PLATE/

PROGRAMMER

BRACKET

Page 21

3.7 Timers for Kabin Pak Combis

Note: Single channel timers or programmers are not recommended.

3.7.1 Installation of a Remote Two Channel Programmer

ONOFF

COM

ENL

CH

ONOFF

COM

HW

5

3

RCD

LNE

BOILER MAINS PLUG

ISOLATOR TO BE

FITTED WITHIN

BOILER CASING

THE HW AND CH SELECTOR

SWITCHES ON THE BOILER

CONTROL PANEL SHOULD BE

LEFT IN THE OFF POSITION

BUT CAN BE USED AS

SERVICING SWITCHES TO

TURN THE BOILER ON EVEN

WHEN THE CLOCK IS OFF

Page 22

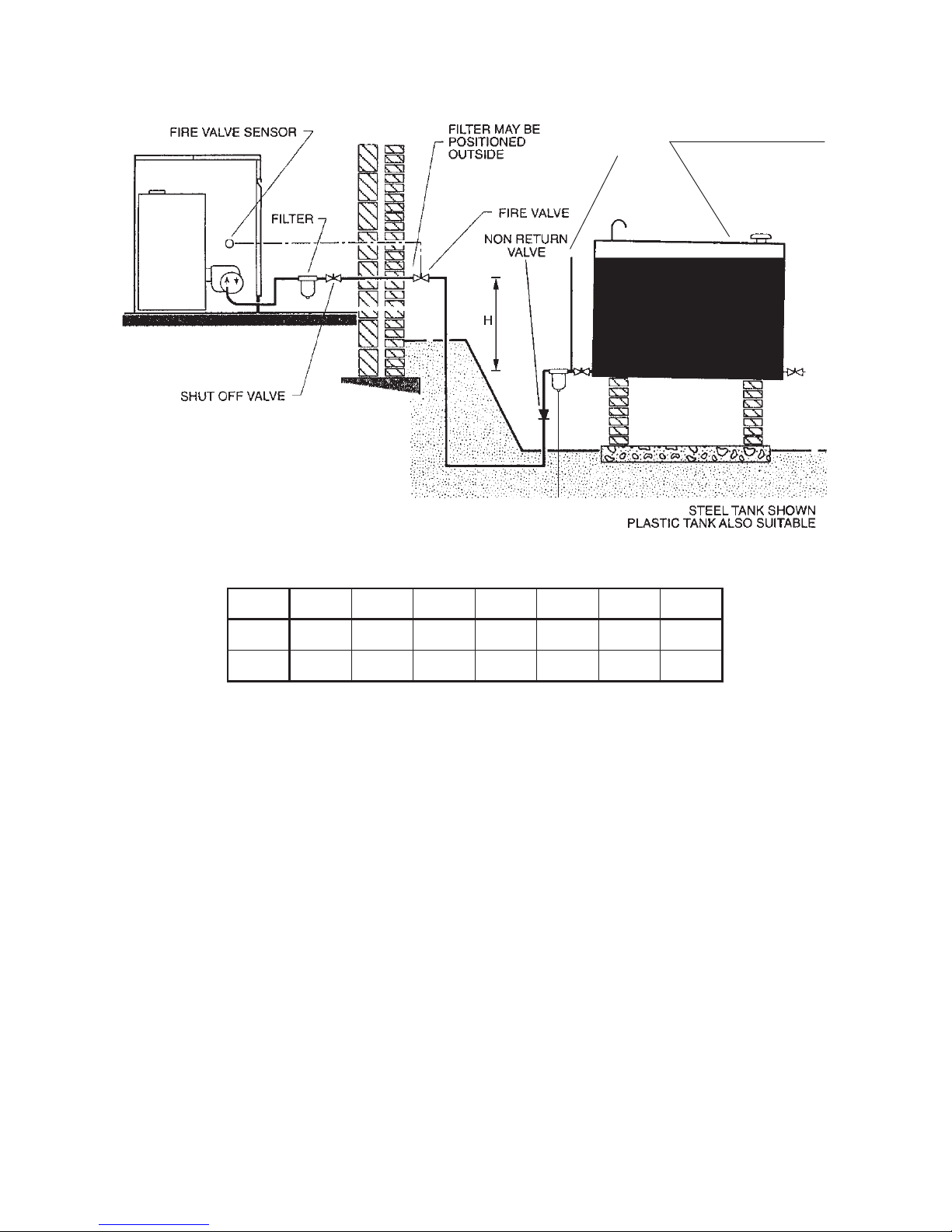

4.0 Oil Supply

1. Oil Tank

Steel tanks constructed to BS 799 Part 5 1987 should be painted on the outside only

and mounted on piers to prevent corrosion. Plastic oil tanks are also available and can

be suitable for installation at ground level. However, oil should never be stored in

translucent plastic containers.

The tank outlet should be at a height to provide sufficient clearance to allow for proper

maintenance of any isolation valve oil filter or water separator fitted.

2. The pipe from the oil tank to the burner should be run in copper, steel or aluminium

pipework. Galvanised pipe and fittings should not be used. The pipework should

terminate close to the boiler and be fitted with an isolating valve and filter. It is also

recommended that a remote sensing fire valve should be fitted to the oil line preferably

before the oil line enters the building (BS5410 : PART 1). Where a fire valve is fitted to

a Kabin Pak Combi the valve body must be situated at least one metre away from this

appliance.

Depending on the position of the tank a two pipe system may be required. One and

two pipe oil systems are shown below. As an alternative to a two pipe system a Tigerloop

or other approved de-aerator. may be used.

4.1 One Pipe System

0.5

10

20

1

20

40

1.5

40

80

2

60

100

I.D.

8 mm

I.D.

10 mm

Head H

(m)

Total Maximum Pipe Length (m)

Note: Plastic oil level gauges may shrink when

exposed to kerosene thus allowing the ingress of

water. Pump failures due to water contamination

are not covered under the warranty.

WATER

SEPARATOR

20mm PER METRE SLOPE

Page 23

0.5

35

100

0.5

30

100

1

25

100

1.5

20

90

I.D.

8 mm

I.D.

10 mm

Lift H

(m)

Total Maximum Pipe Length (m)

2

15

70

3

8

30

3.5

6

20

4.2 Two Pipe System

4.3 De-aerator System

For maximum pipe length and lift contact de-aerator manufacturer.

DE-AERATOR MAY BE ABOVE OR

BELOW BURNER AND MUST BE

POSITIONED OUTSIDE

NON-

RETURN

VALV E

FILTER MAY BE

POSITIONED OUTSIDE

DE-AERATOR

Must be upright

FIRE VALVE SENSOR

FIRE VALVE

FILTER

SHUT OFF VALVE

‘T’ & TAP FOR DRAIN

PLASTIC TANK SHOWN

STEEL TANK ALSO SUITABLE

20mm PER

METRE SLOPE

WATER

SEPARATOR

APPROVED

SITE GAUGE

APPROVED

SITE GAUGE

Page 24

4.4 One Pipe Lift

20mm PER METRE SLOPEAPPROVED

SITE GAUGE

WATER

SEPARATOR

Note: The pump vacuum should

not exceed a maximum of 0.4 bar.

Above this gas is released from the

oil thus leading to burner lock out.

Total Maximum Pipe Length (m)

0.5

35

100

0.5

30

100

1

25

100

1.5

20

90

2

15

70

3

8

30

3.5

6

20

Lift H

(m)

ID 8mm

ID 10mm

Page 25

5.0 Flues

5.1 Conventional Flues

The flue should be designed in

accordance with the local bye-laws

and the Clean Air Act. Draught

stabilisers are not recommended

for oil fired boilers. Sharp bends or

horizontal runs should be avoided

and the flue should terminate 2 feet

(600 mm) above the ridge of the

dwelling. Terminals which restrict

the discharge or allow ingress of

water should be avoided.

It is recommenced that when

connecting to an existing masonry

chimney a flexible stainless steel

liner of the correct diameter should

be used. The annular space must

be sealed top and bottom and filled

with insulation.

5.2 Low Level Convert/Low Level Balanced Flues T erminal Positions and Kabin Pak

Flues

Attention should be given to the position of the flue discharge; we recommend the

following guidelines be adopted.

1. The flue should not discharge beneath opening windows or within 2 metres of other

accesses to the building.

2. The flue should not discharge near internal/external corners of the building where

turbulent wind conditions could occur.

3. A terminal guard should be fitted at all times.

4. The terminal should not discharge over property boundaries.

5. Discharge into narrow passageways should be avoided.

6. The actual siting of the flue should be determined by the installer after consultation

with the householder.

7. In positioning this flue the wind direction should be considered.

Installation in exposed positions is not recommended.

Page 26

Terminal Position Min Distance

A Below gutters, soil pipes or drain pipes 1000

B From a door, window or air vent 600

C Above ground, flat roof or balcony level 600

D Below eaves or balconies 1000

E From an internal or external corner 600

F From a terminal facing the terminal 600

G From a surface facing the terminal 600

HVertically from a terminal on the same wall 1500

I Horizontally from the terminal on the same wall 600

J Directly below an opening, air brick, window, etc. 600

K From a vertical drain pipe or soil pipe 1000

These are minimum dimensions and are only quoted as a guideline but they will

satisfy the requirements of all UK Building regulations.

Where the flue terminal is within 1 metre of any plastic material, such material

should be shielded from the effects of the combustion products of the flue.

Page 27

6.0 Air Supply for Combustion and Ventilation

(see BS 5410)

6.1 Open Flue Boilers

When the boiler is sited in a cellar where the only access for combustion and ventilation

air is at high level then the combustion air should be ducted to low level.

Combustion Air Supply

Boiler in Room

Boiler in Compartment

6.2 Balanced Flue Boilers in a Compartment

Air Supply for Ventilation

No Combustion Air Inlet required to Room

Page 28

6.3 Installation of Flues

OPTIONAL

EXTENSION PIECES

Easy Fit Vertical

Balanced

Flue (VBF)

Easy Fit High

Level Balanced

Flue (HLBF)

Standard Low

Level Conventional

Flue (LLF)

Easy Fit Low Level

Conventional Flue

(LLF-R)

Easy Fit

Balanced Flue

(BF-R)

Easy Fit High

Level Balanced

Flue (HLBF-R)

RIELLO RDB

BURNER

AIR INTAKE

COVER

AIR INTAKE

ADAPTER

SPIGOT &

GASKET

BOILER LID

CONVENTIONAL

FLUE RING

HORIZONTAL

FLUE ADAPTOR

FLUE TERMINAL

TOP PANEL

TEST HOLE

PLUG

FLUE

GASKET

OPTIONAL FLUE

DRESSING RING

TOP PANEL

BLANKING PLATE

Page 29

6.3.1 Installation of a Balanced Flue (BF-R, HLBF-R & VBF)

1. Make a suitable sized hole in the wall or ceiling for the flue kit. Add the dimensions

given on pages 6 (Dimension G) and 8 (Flue Vertical Dimension). The cavities around

the opening must be sealed and protected by a non-combustable sleeve.

2. Remove the top panel (kitchen and utility models) and the combustion chamber lid.

3. Remove the flue ring from the top of the boiler (3 screws) ensuring that any remaining

silicone sealant has been cleaned away.

4. Carefully fit the inner and out seals to the flue adaptor.

Note: After fitting the seals to the flue smear them with soap or any suitable lubricant

which does not react with the silicone rubber.

5. Place the gasket correctly on the boiler and locate the flue adaptor over this, fixing it in

position using the nuts and bolts provided. For BF-R side outlet options on white case

boilers it will be necessary to manoeuvre the adaptor through the side panel before

fixing it to the boiler after the blanking plate has been removed. Push boiler into position

against the wall.

6. If fitting extension pieces ensure the seals are correctly fitted and lubricated before

pushing through the wall and attaching to the flue adaptor.

Note: Any combination of short (300mm) and long (600mm) extension pieces for the

BF-R can be used up to a maximum additional length of 1200mm.

7. Slide the flue terminal into position with a twisting movement ensuring that it protrudes

through the wall by a minimum of 175mm and a maximum of 225mm or through the

roof by a minimum of 665mm.

8. Seal the gap between the flue and the wall both inside and out after which the protective

basket must be fitted to the wall over the flue terminal.

9. After removing the air inlet cover fit the air intake adaptor spigot and gasket to the

burner. Connect one end of the air duct to the flue and the other end to the air intake

spigot on the burner. Both ends should be securely fastened with the jubilee clips.

10. The boiler is now ready to be connected to the plumbing, oil supply and mains electricity.

11. The baseplate of the Goldbird and Whitebird has been designed to allow the oil pipe

and electric cable to pass unnoticed inside the unit from the rear of the installation.

Alternatively the grommeted holes either side, towards the front of the baseplate, can

be used.

12. A test hole for commissioning purposes has been provided on the boiler lid.

Page 30

6.3.2 Installation of Telescopic Low Level Conventional Flue

Installation instructions as per the balanced flue except there is only an inner seal, the

burner does not require modification and there is no flexible hose to be fitted. In addition

the low level flue should only protrude through the wall by a minimum of 155mm and a

maximum of 225mm.

6.3.3 Installation of Standard Low Level Flue (LLF)

After cutting a hole in the wall place the flue in the hole. The flue must be a minimum of

155mm through the wall. Fit the steel elbow into the pressed ring on the boiler and the

end of the flue kit. The elbow should then be sealed into both rings using high

temperature silicone sealant or fire cement which may also be used in conjunction

with glass fibre rope.

6.3.4 Installation of High Level Balanced Flue (HLBF)

Installation instructions as per the balanced flue except there are no seals involved as

the flue is not telescopic. There are no extension pieces available for these units.

Note: When filling a HLBF to a Combi a new top panel with a larger cut out for the flue

is required.

7.0 Thermostat Control Knob Peg Setting

Tank

DECREASE

TEMPERATURE

SETTING

INCREASE

TEMPERATURE

SETTING

REAR VIEW

Page 31

8.0 Installation

The boiler installation must be in compliance with BS 5410 Part 1 1997 and the Building

Regulations.

8.1 Hearth

The boiler hearth temperature is between 50

O

C and 85OC and should be stood on a

rigid, non-porous, non-combustible base, which is not softened by warmth to comply

with the Building Regulations.

8.2 Service Access

8.2.1 Combi

24" (600 mm) Clearance should be provided above and in front of the boiler to allow

for routine servicing. If placed under a worktop ensure that the worktop is easily removed.

8.2.2 Kabin Pak Combi

The Kabin Pak Combi has been designed to allow fitting into a corner. However a

minimum clearance of 600mm should be provided to the front and right hand side of

the Kabin Pak to allow access for servicing.

8.3 Heating System

The heating system should be installed to HVCA current codes of practice.

Before installing the boiler the new or existing system should be thoroughly flushed to

clear all sludge or other foreign matter such as solder, steel wool and copper fillings.

We recommend that the system is cleaned out in accordance with BS 5449 and BS

7593:1992 using a suitable non-corrosive commission cleanser.

It is further recommended that a suitable corrosion inhibitor is added to the heating

system, which will not damage the synthetic rubber membrane of the expansion vessel.

8.3.1 Air Vents

An automatic air vent complete with is own check valve is fitted to the top of the heat

store and boiler heat exchanger. However it is recommended that another air vent is

fitted at the highest point in the system.

8.3.2 Drain Cock

Drain cock(s) should be fitted to the lowest points in the system to enable the system

to be fully drained. A drain cock has also been fitted to the heat store and boiler heat

exchanger.

Page 32

8.3.4 Boiler Connections

All connections to the appliance should be made with compression fittings.

8.3.5 Additional Requirements for a Kabin Pak Combi

1. Although the Kabin Pak is manufactured from galvanised sheet it is recommended

that after a period of weathering (approx 4-8 weeks) that the Kabin Pak is painted with

a suitable primer and finish coat to prevent corrosion.

2. When using the Kabin Pak with the integral low level flue only 28 second redwood

number 1 (kerosine) may be used in order to comply with building regulations. Suitable

flue terminal positions are shown on page 27.

3. The boiler must be provided with a suitable well drained hard standing area to prevent

the formation of pools of water in order to eliminate any risk to the service engineer or

end user.

4. The boiler must not be serviced or the panels removed where there is a risk of the

ingress off water.

5. Although the Kabin Pak has been weatherproofed to IP45 it should not be subjected to

a jet of water from a hose or power washer.

8.3.6 Expansion Vessel

A 12 litre expansion vessel charged to 0.5 bar is supplied with the boiler. This can

accommodate a maximum system volume of approximately 150 litres. If this volume

is exceeded an additional vessel will be required. Refer to BS 7074: Part 1 or BS

5449 for details of sizing. The values given in the table are for total system values

which includes the primary water capacity. See page 4.

8.3.7 System Filling

As standard, a filling point complete with a filling loop has been included within the

appliance. The temporary hose must be disconnected after filling. A system pressure

when cold of 1 bar is recommended.

Water loss from the system as indicated by a reduction in pressure on the pressure

gauge may be made up through the filling loop.

After filling, vent all air from the system. Ensure the caps on the automatic air vents are

loose and bleed both circulating pumps.

VESSEL VOLUMES

0.5 2.1 4.2 6.3 8.3 10.5 12.5 14.6 16.7 18.7 20.8 22.9 25.0

1.0 2.7 5.4 8.2 10.9 13.6 16.3 19.1 21.8 24.5 27.2 30.0 32.7

1.5 3.9 7.8 11.7 15.6 19.5 23.4 27.3 31.2 35.1 39.0 42.9 46.8

25 50 75 100 125 150 175 200 225 250 275 300

INITIAL CHARGE

TOTAL

SYSTEM

VOLUME

Page 33

8.4 Domestic Hot Water

The mains water supply pressure must be less than 5 bar. If this pressure is exceeded

a pressure reducing valve must be fitted. The final 600 mm of the mains supply pipe to

the appliance must be in copper. The flow rate of water from individual taps is dependant

on the number of outlets being operated together, as well as the length and size of

pipework in the system and the mains supply pressure flow regulators.

Whenever a pressure reducing valve or any other device containing a non-return valve

is fitted to the mains water supply pipe entering the boiler, it is recommended that a

mini expansion vessel, suitable for use on potable water, is fitted between the device

and the closed tap.

Although many of the DHW components are designed to resist lime scale formation, in

areas of hard water it may still be necessary to fit an inline chemical water softener.

For further information contact Warmflow and your local water company.

To ensure economic use, the pipe runs between the boiler and the taps should be as

short as possible and insulated to reduce heat loss. For boilers that have to be sited

remotely from the main point of use, there is likely to be very long pipe runs which can

lead to excessive water usage and poor fuel efficiency. It is recommended that a pumped

hot water return is used in order to improve HW reaction times. Contact Warmflow for

details.

Note: An 18L/min flow restrictor has been factory fitted but can be easily removed if

required.

8.5 Removal of Flow Restrictor

FLOW SWITCH

FLOW RESTRICTOR

WASHER

Page 34

8.6 Fitting a Vertical Flue Adaptor

1. Remove the 2 self tappers connecting the flue main body to the Kabin Pak and lift off.

It may be necessary to break the seal between the flue main body and the top of the

flue pipe.

2. Ensure that the gap between the existing flue pipe and the top of the Kabin Pak is

properly sealed with high temperature silicone sealant.

3. Once the flue main body has been removed fit the Kabin Pak adaptor (KPA) into

position and secure with the 2 self tapping screws. A 5” conventional flue can now be

attached.

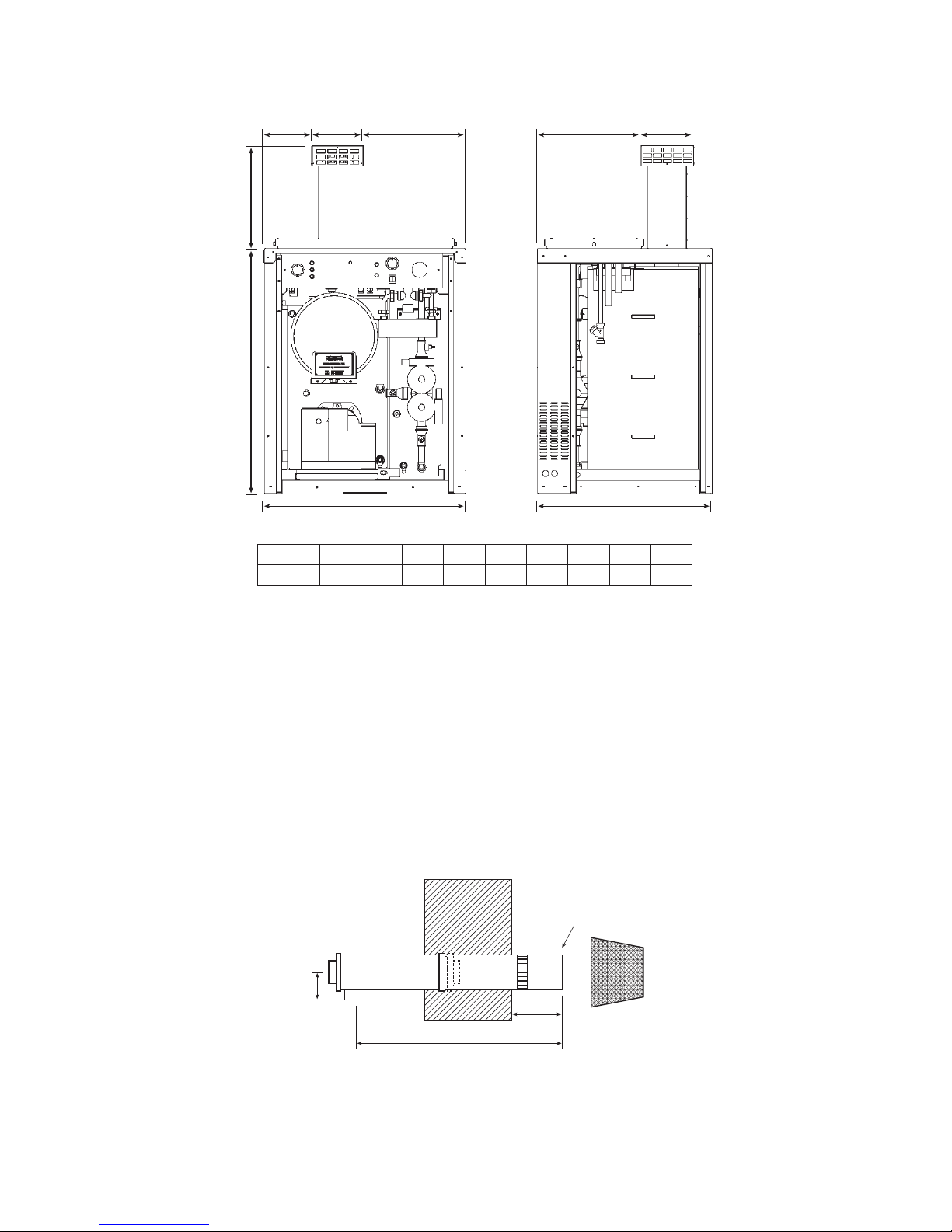

8.7 Installation of Air Intake Duct

1. Cut a 4” hole through the wall, minimum 300mm above the ground.

2. Cut plastic vent tube to suit wall thickness and insert into the hole in the wall.

3. Remove plastic air inlet cover on the burner. Attach the air intake gasket and adapter

to the burner using the screws supplied.

4. Attach one end of the flexible duct to the burner air intake adapter using 1 no 3” jubilee

clip as supplied.

5. Feed the flexible duct through the plastic vent tube to the outside of wall and fix to the

air intake duct using the remaining jubilee clip, cut the flexible duct to a suitable length

ensuring adequate length for rotation of burner during removal.

6. Once the flexible duct is attached to the air intake duct, insert into the vent tube and fix

it to the wall using appropriate fixings. Ensure the perforated side of the air intake duct

is facing downwards.

Air Intake Duct

Jubilee Clip

Flexible Duct

Plastic Vent Pipe

Jubilee Clip

Page 35

9.0 Burners

9.1 RDB Burner

The burner is fitted with the correct nozzle and the pressure set. All that is further

required before commissioning, is to connect the oil and electricity supply.

1. Pump 5. Air damper adjustment screw

2. Control box 6. Air tube connection (supplied with BF kit)

3. Reset button with lock-out lamp 7. Pump pressure adjustment screw

4. Flange with insulating gasket 8. Pressure gauge port

9.2 Oil Supply

The burner is supplied for use with a one pipe system. For use on a two pipe system,

it is necessary to remove the return port plug and fit a small by-pass plug as shown.

1. Suction port

2. To nozzle

3. Pressure gauge port/air bleed

4. Pump pressure adjustment

5. Vacuum port

6. To hydraulic ram

7. Return port

8. By-pass plug

Page 36

Attention

Before assembling or removing the nozzle,

loosen the screw (A) and move the electrodes

away from the nozzle.

9.3 Electrical Connections

The boiler control equipment and the burner are provided ex works, it is only necessary

to connect a 230V 50Hz supply in accordance with the electrical drawings.

9.4 Electrode Setting

9.5 Burner Start-up Cycle

~ 12s

Thermostat

Motor

Ignition transformer

Valve

Flame

Lock-out lamp

~ 12s

Normal Lock-out due to failure to light

~ 5s

Page 37

10.0 Commissioning and Servicing

10.1 Commissioning

Note:IT IS RECOMMENDED THAT AN OFTEC TRAINED AND REGISTERED TECHNICIAN

SHOULD BE USED.

IT IS THE RESPONSIBILITY OF THE INST ALLER TO ENSURE THAT THE BOILER

IS PROPERLY COMMISSIONED. SEE BS 5410. FAILURE TO DO SO MAY

INVALIDATE THE WARRANTY.

Combustion tests must be carried out using a Combustion Analyser. The pump pressure

can be checked by fitting a manifold and a pressure gauge to the oil pump.

Before firing ensure that all the baffles are in place as they may have been displaced

during transit as shown in on page 8. Set the boiler control to 80°C switch on, ensuring

all controls are calling for heat. Typical burner settings and test data are shown in

section 2.2.

Check the smoke reading, CO

2

content and flue gas temperature with the boiler up to

temperature. Testing while the boiler is still relatively cold gives inaccurate results and

leads to incorrect adjustments being made.

Where a balanced flue has been fitted ensure the air duct connecting the flue and

burner has been properly connected before commissioning. On the Kabin Pak Combi

refit the front door panel before doing a flue gas analysis.

To comply with GB building regulations OFTEC form CD11 should be completed

and a copy left with the householder.

10.2 Servicing

10.2.1 General Requirements

It is recommended that the appliance is serviced annually by an OFTEC registered

service technician in accordance with the recommendations laid out in OFTEC’s

technical information book 2 – ‘Pressure Jet Appliances – Commissioning Requirements

for Technicians’.

Additionally when servicing special attention should be paid to the condition of the oil

nozzle, flexible oil line, fuel filter and lid and base insulation all of which will need to be

replaced on a regular basis.

Note: Second year or other extended warranties will be invalidated if the appliance is

not serviced annually.

10.2.2 Kabin Pak Combis

1. The boiler must be provided with a suitable well drained hard standing area to prevent

the formation of pools of water in order to eliminate any risk to the service engineer or

end user.

2. The boiler must not be serviced or the panels removed where there is a risk of the

ingress of water.

Page 38

P

123456LN

HEATING SUPPLYWATER

G

HORSTMANN TIMERS & CONTROLS Ltd:

NEWBRIDGE ROAD, BATH.

626 OEM - WARMFLOW

220-250V 50Hz 5(2)A T.55

11.0 Horstmann 626 Electronic Programmer (not applicable to Kabin Pak Combi)

User Instructions

Note: Ensure selection switch on the rear of the

programmer is at the correct setting ‘G’ for HW

only or HW and CH. ‘P’ for independent HW and

CH.

The programmer is factory set at its mid-position.

The 626 Boiler Mounted Programmer is an

electronic, 7 day central heating and hot water control; extremely reliable and easy to

operate. Properly programmed it will help you save energy and create a comfortable

environment in your home.

The 626 Electronic Programmer has the following features:

•3 ON and 3 OFF periods every 24 hours with a choice of different programmes for

each day of the week.

• Override programme options of AUTO, ALL DAY, 24 HOUR and OFF.

•A choice of HOT WATER and CENTRAL HEATING.

•A central heating ADVANCE button allowing an instant switch from ON to OFF, or from

OFF to ON, without affecting normal settings.

Most of the control buttons on your programmer are dual purpose buttons.

They can be used as SET buttons for inputting time of day, ON/OFF times, etc, or as

SELECT buttons for using the advance facility and choosing override programme

options.

The diagram below can be used to identify the SET buttons, indicators and symbols

referred to in the following sections of these instructions.

1. Set indicator.

2. Set positions.

3. Time-of-Day.

4. Day-of-Week indicator.

5. ON/OFF switch period symbol.

6. SET button.

7. Minus(-) adjust button.

8. Plus(+) adjust button.

9. ENTER button.

10. COPY button.

Page 39

Setting the Time of Day

Press the SET button so that the SET indicator is pointing to

the CLOCK position on the front of the programmer. The DAY

OF THE WEEK indicator will now flash.

Use the PLUS(+) or MINUS(-) buttons to move the DAY OF THE WEEK Indicator to

the current day of the week. Numbers relating to the days of the week are printed

along the top of the programmer display,

i.e. 1 = Monday, 2 = Tuesday, etc.

Press the ENTER button. The TIME OF DAY will now flash.

Now use the (+) or (-) buttons to alter the display to the correct time of day, making

sure that the AM/PM SYMBOL is also correct (see figure 4).

Note: By pressing and releasing the (+) and (-) buttons you advance

or retard the time in 1 minute steps. If you keep the button

depressed the display will fast cycle and the time can be

changed more rapidly.

Press the ENTER button and then use the SET button to return the SET indicator to

the RUN POSITION.

Setting the ‘ON’ and ‘OFF’ Times

Note: The minimum ON/OFF time that can be set is TEN MINUTES.

The programmer already has a factory pre-set programme of ON/OFF times in its

memory. These are based on the most commonly used settings and are as follows.

Monday to Friday:

1st ON: 7.00am 1st OFF: 10.00am

2nd ON: 12.00pm 2nd OFF: 12.00pm

3rd ON: 5.00pm 3rd OFF: 11.00pm

If these settings do not meet your own requirements then they can be easily changed

as follows:

Press the SET button so that the SET indicator is in the position

shown. The display will indicate ‘DAY’ and the DAY OF THE

WEEK indiactor will now flash.

Use the (+) and (-) buttons to move the indicator to the day of

the week you wish to change the times for. Press ENTER.

The display will now show ‘1 ON’ and the first ON time for that

day will flash.

Saturday/Sunday:

1st ON: 7.30am 1st OFF: 11.30am

2nd ON: 12.00pm 2nd OFF: 12.00pm

3rd ON: 5.00pm 3rd OFF: 11.00pm

Page 40

Adjust the flashing time as required by using the (+) AND (-)

BUTTONS THEN PRESS ENTER.

The display will now show ‘1 OFF’ and the first programmed

OFF time for the day will flash.

This can be altered in the same way as the ‘1 ON’.

Follow the same procedure for the 2nd and 3rd ON/OFF times

remembering to press ENTER after each change to the

programme. If you do not wish to alter a particular time then

simply press ENTER and the display will move on to the next

ON/OFF time leaving the previous one unchanged.

When the 3rd OFF time has been entered the programmer will display the word COPY

and the DAY OF THE WEEK indicator will flash (see figure 8).

You can now copy the ON/OFF times you have just input for one day onto any other

days that you wish them to apply. This saves you having to separately programme

days with identical switching times.

Use the (+) and (-) buttons to mov the DAY OF THE WEEK indicator to the next day

that you wish the times to apply and press the COPY button, the display will indicate

‘IN’.

Continue in this way until the programme has been copied to all the days that you wish

it to apply to.

When you have finished copying simply press ENTER. The word COPY will be replaced

with ‘DAY’ and the DAY OF THE WEEK indicator will flash.

You can now programme those days that require different times to the ones that you

have just copied by following the same procedure as described at the start of this

section, parts (ii) to (v).

Note:Your programmer allows you to have up to three ON/OFF periods each day. If you do

not want to use all of these, a switch period can be cancelled by programming the ON

operation the same time as the OFF operation, eg, 2nd ON at 12.00pm and 2nd OFF

at 12.00pm.

The next diagram can be used to identify the SELECT buttons and indicators referred

to in the following sections of this leaflet.

Page 41

1. Hot water ON indicator.

2. Central heating ON indicator.

3. Advance button.

4. Hot water programme select button.

5. Central heating programme select button.

6. Programme positions.

7. Central heating programme indicator.

8. Hot water programme.

Programme Selection

The following programmes can be selected for either HOT WATER by itself, CENTRAL

HEATING by itself or HOT WATER and HEATING together.

AUTO

When AUTO is selected the programmer will switch ON and OFF according to the

switching times held in the memory, i.e. up to three ON/OFF periods per day.

ALL DAY

When ALL DAY is selected the programmer will switch the system on at the 1st ON

TIME and OFF at the 3rd OFF TIME.

24 HOUR

When 24 HOUR is selected the system remains on continuously, ignoring all time

settings.

OFF

When OFF is selected the programmer clock continues to operate but the system

remains off.

To select a programme for hot water press the HW

PROGRAMME SELECT button until the HW (HOT WATER)

PROGRAMME indicator is pointing to the required programme,

eg AUTO.

To select a central heating programme follow the same procedure using the CH

PROGRAME SELECT button.

Note: When HOT WATER or HEATING is switched to ON the relevant indicator light will be

illuminated.

Page 42

Using the Advance

The ADVANCE facility allows you to bring forward the next ON

or OFF period without having to alter the programmed ON/

OFF times.

Press the ADVANCE button once and release. The word

ADVANCE will appear in the display.

If the programmer was originally ON it will now switch OFF and stay OFF until the next

programmed ON time.

The opposite will apply if the programmer was originally OFF.

In both cases the unit will then revert to the normal programme times.

If you wish to cancel the advance simply press the ADVANCE button again and the

word ADVANCE will disappear from the display.

Note: The ADVANCE facility has no effect when the CH PROGRAMME indicator is in either

the 24 HOUR or OFF position.

Electronic equipment can, in exceptional

circumstances be affected by electrical interference.

If your programmers’ display or switching

programme becomes frozen or scrambled, or you

wish to revert to the factory pre-set programme you

can RESET your programmer by pressing the

MINUS(-) adjust button and the ENTER/HW

SELECT button together.

After using the RESET procedure you will need to re-programme the day and time of

day plus any changes you wish to make to the factory pre-set programme.

Reserve Battery

Your programmer is fitted with a NON-RECHARGEABLE LONG LIFE battery which

will maintain the programmed ON/OFF settings for a period in excess of two years.

This is more than sufficient to cover all the expected power interruptions during the life

of the unit.

Heating Systems

Information for use with various systems is available on request from Warmflow on

(028) 9262 1515.

Page 43

12.0 Fault Finding

12.1 Central Heating

NO

Switch on power,

set selectors for

CH on and DHW

off.

Set all controls to

call for heat.

Does the burner

fire?

Is lockout lamp on

burner or panel

lit?

Is high limit

thermostat lamp

lit?

Is there continuity

across the boiler

stat connections

17 and 18 on the

PCB?

Is there continuity

across the

connections 28

and 30 on the

PCB?

Check power

from clock or

switch, check

wiring fuses and

mains supply.

Refer to burner

fault finding.

Press reset

button, replace if

necessary.

Check wiring,

replace boiler

thermostat.

Check relay and

PCB, replace.

Do radiators get

hot?

Does boiler cycle

on its thermostat?

Check all valves

are open and

pump is working,

check pressure,

check all air is

vented.

Check boiler

thermostat,

replace if

necessary.

HEATING IS

WORKING

NORMALLY

YES

YES

NO

NO

NO

NO

YES

YES

YES NO

YES

YES

NO

Page 44

12.2 Domestic Hot Water

Switch on power, set

selectors to CH off and

DHW on.

Is DHW pump working?

Is there continuity

across connection 20

and 21 on the PCB?

Check wiring, replace

tank thermostat.

Is there continuity

across 25 and 27?

Check wiring, replace

relay, replace PCB.

Check wiring, replace

pump.

Does burner fire? Do radiators get hot?

Check plumbing,

replace non-return

valve.

Refer to burner fault

finding.

Is lockout lamp on

burner or pump lit?

Does tank get hot?

Vent all air from system

pumps, ensure all

valves are open.

Press reset button,

replace limit thermostat.

Is high limit thermostat

lamp lit.

Does boiler shut down

when tank reaches

temperature?

Replace tank stat,

replace relay.

Check wiring, replace

tank limit stat.

Is there continuinity

across 23 and 22?

With tap closed, switch

the CH switch to on.

Check wiring, replace

relay, replace PCB.

Is there continuinity

across 22 and 16?

Do radiators get hot? Check CH fault finding.

Check power from

clock or switch, check

wiring, check fuses.

Does CH pump stop

when tap is opened?

Check flow switch,

check relay.

Is hot water produced

when tap is opened.

BOILER IS WORKING

NORMALLY

NO NO

NO

YES

NO

NO

NO

YES

YES

YES

NO

NO

NO

NO

YES

YES

NO

YES

YES

YES

YES

YES

Check mixer valve,

check plate heat

exchanger for blockage,

ensure all air is vented

from boiler.

YES

YES

NO

NO

NO

YES

Page 45

Does burner motor start?

YES

NO

START

Switch on electricity supply. Set all boiler

controls and external controls to call for heat.

Burner operating satisfactorily.

Press reset button. Check for pump

seizure. Faulty capacitor or faulty motor.

Check for correct fitting of photocell, or

change photocell. Check there is oil in tank,

all oil pipe valves are open, oil pipe and

pump are purged of air. Check oil pump drive

and oil pump. Check oil pump solenoid

opens. Check wiring to solenoid coil. Check

for kinks in flexible oil pipe. Check nozzle

for blockage. Check fire valve.

Check pump solenoid is operating correctly.

Check correct nozzle is fitted. Check pump

pressure and air shutter setting. Check

correct fuel is used. Check flue for blockage

or inadequate draught.

Is flame stable?

Is flame established?

Is burner lockout lamp lit?

12.3 Burner

YES

NO

NO

YES

YES

NO

YES

NO

Is oil delivered to combustion chamber?

Clean reset or change electrodes, check

ignition transformer and leads, check nozzle

for damage or carbon build up.

Check motor wiring fuse, boiler control and

limit thermostat. Check power supply.

Page 46

13.0 Spares

13.1 Riello RDB Burner

NO CODE 3748757 DESCRIPTION

16 3008654 • Pump

17 3007162 • ‘O’ Ring

18 3008653 • Filter ‘O’ Ring

19 3003602 • Connector

20 3005720 • Flexible

21 3008644 • Tube

22 3008876 • Pressure Gauge

23 3000443 • Joint

24 3008648 • Coil

25 3008650 • Motor

25 3002836 • Motor

26 3008649 • Protection

27 3008652 • Control Box 535 RSE/LD

28 3008877 • Lead Coil

29 3008879 • Cover

30 3008878 • Kit Seal

NO CODE 3748757 DESCRIPTION

1 3005787 • Gasket

2 3006384 • Flange

3 3008769 • Cup-shaped Head

4 3007513 • Electrode Assembly

5 3006552 • Electrode Bracket

6 3008642 • Nozzle Holder

7 3008643 • Collar

8 3008794 • High Voltage Lead

9 3008647 • Air Damper Assembly

10 3008645 • Fan

11 3008646 • PE Cell

12 3007479 • Capacitor 4

µF

12 3002837 • Capacitor 4

1

/2µF

13 3007582 • Needle Valve

14 3008651 • Regulator

15 3000439 • Pump Seal

Note: The 41/2µF capacitor is only suitable for use with the 3002837 motor and the 4µF capacitor is only suitable

for use with the 3008650 motor.

Page 47

13.2 Pipe Spares

CH Pump to Boiler

Flexible Pipe 2056

Plate Heat Exchanger to Boiler

Flexible Pipe 2057

Boiler to Pressure Vessel

Flexible Pipe 2056

Flow Switch to Strainer

Pipe 1999

From CH Pump

Pipe 1996

Plate Heat Exchanger to Boiler

Pipe 1997

Plate Heat Exchanger to Flow Switch

Pipe 1992

Hw Pump to Pipe Support

Pipe 1993

Plate Heat Exchanger to Mixer Valve

Pipe 1994

From Mixer Valve

Pipe 1995

All Combis All Combis All Combis

Std Combis Std Combis

All Combis All Combis All Combis

All Combis Std Combis

Flow Switch to Strainer

Pipe 2490

From Mixer Valve

Pipe 2491

From CH Pump

Pipe 2492

Kabin Pak Combis Kabin Pak Combis Kabin Pak Combis

Page 48

13.3 Short Parts List

Part Description Code

Flow Switch 1476

Tank & Boiler Control Thermostat 2131

Boiler Limit Thermostat 281

Tank Limit Thermostat 2126

Plate Heat Exchanger 599

Twin Head Grundfoss Pump 2130

Grundfoss 15/60 Pump (for replacement head) 602

3 Pole Relay 1827

Auto Air Vent C/W Check Valve 614

Pressure Relief Valve 2132

Filling Loop 2133

Pressure Gauge C/W Capillary 2169

Mixer Valve 1621

Low Pressure Switch 2270

Burner Reset Button Membrane R7627

PCB Controller MK4 2419

Frost Thermostat 2508

Conventional Flue Adaptor KPA

Air Intake Duct AID

12 Litre Pressure Vessel 2128

When ordering replacement casing panels it should be noted that due to the painting process

there may be some variation in colour.

This manual is accurate at the date of printing but will be superseded and should be disregarded if specifications

and/or appearances are changed in the interests of continued product improvement.

Code 991

FOR PARTS, SERVICE &

WARRANTY CONTACT

FOR TECHNICAL ASSIST ANCE

CONTACT WARMFLOW ON

TEL: (028) 9262 1515

E-MAIL: technical@warmflow .co.uk

TEL: (028) 9262 1515

FAX: (028) 9262 2827

N IRELAND

service@warmflow.co.uk

TEL: (DUBLIN) 8416158

REP OF IRELAND

FAX: (DUBLIN) 8416614

TEL: (0161) 205 4202

ENGLAND,

FAX: (0161) 205 4818

SCOTLAND & WALES

Lisburn

Lissue Industrial Estate, Moira Road,

Lisburn, Co Antrim, N Ireland, BT28 2RF

Tel: (028) 9262 1515 Fax: (028) 9262 0869

E-mail: sales@warmflow.co.uk

Manchester

144 Bradford Road,

Manchester, M40 7AS

Tel: (0161) 205 4202

Fax: (0161) 205 4818

E-mail: sales@warmflow.co.uk

Dublin

Balbriggan Industrial Estate,

Dublin

Tel: (01) 841 6158

Fax: (01) 841 6614

Loading...

Loading...