WarmFlow 50/70, 70/90, 90/120, 120/150, 150/200 Installation & Servicing

50/70 – 70/90 – 90/120 – 120/150 – 150/200

BLUEBIRD BOILERHOUSE MODELS,

GOLDBIRD KITCHEN MODELS

& WHITEBIRD UTILITY ROOM MODELS

50/90

FRONT SERVICING BOILERS

GOLDBIRD KITCHEN MODEL

WHITEBIRD UTILITY ROOM MODEL

200/250

BLUEBIRD BOILERHOUSE MODEL

50/70 – 70/90

WHITEBIRD UTILITY ROOM SYSTEM BOILER

50/70 – 70/90 – 90/120 – 120/150 – 150/200

KABIN PAK EXTERNAL BOILERHOUSE MODULES

50/90

SLIMLINE KABIN PAK

EXTERNAL BOILERHOUSE MODULE

50/70 – 70/90

KABIN PAK BACK OUTLET

EXTERNAL BOILERHOUSE MODULES

300 – 400 – 500

CONVENTIONAL FLUED

INDUSTRIAL BLUEBIRD BOILERHOUSE MODELS

LEAVE THESE INSTRUCTIONS WITH THE END USER

INSTALLATION & SERVICING

MANUAL FOR

ISSUE 6.2

JAN ’04

COMMISSIONING

*THIS APPLIANCE MUST

BE COMMISSIONED

*Failure to commission the boiler will invalidate the warranty.

After commissioning ensure that the pre-paid

warranty registration card is completed

and returned.

SERVICING

To ensure continued reliable operation and fuel

economy it is recommended that the boiler is

serviced annually by an OFTEC registered

technician.

NI CUSTOMERS ONLY

Warmflow Engineering Service division (NI)

provides an excellent back-up service, operating

a team of OFTEC trained engineers who can

meet all the servicing, commissioning and

breakdown requirements for your appliance.

Telephone

0870 240 6532

Fax: 028 9262 2827

E-mail: service@warmflow .co.uk

Contents Page

1.0 User Instructions ............................................................................................................................................................ 2

1.1 Goldbird Models ................................................................................................................................................. 2

1.2 Bluebird, Kabin Pak and Whitebird Models ........................................................................................................ 2

1.3 Servicing ............................................................................................................................................................ 2

1.4 Components 50/70, 70/90, 90/120, 120/150, 150/200, 200/250 ........................................................................ 2

1.5 System Boiler ..................................................................................................................................................... 3

1.6 Components 50/90 Front Servicing Boiler

1.7 Components 300, 400 & 500 Industrial Boilers .................................................................................................. 4

1.8 Baffles ................................................................................................................................................................ 5

2.0 Introduction..................................................................................................................................................................... 6

2.1 General Requirements ....................................................................................................................................... 6

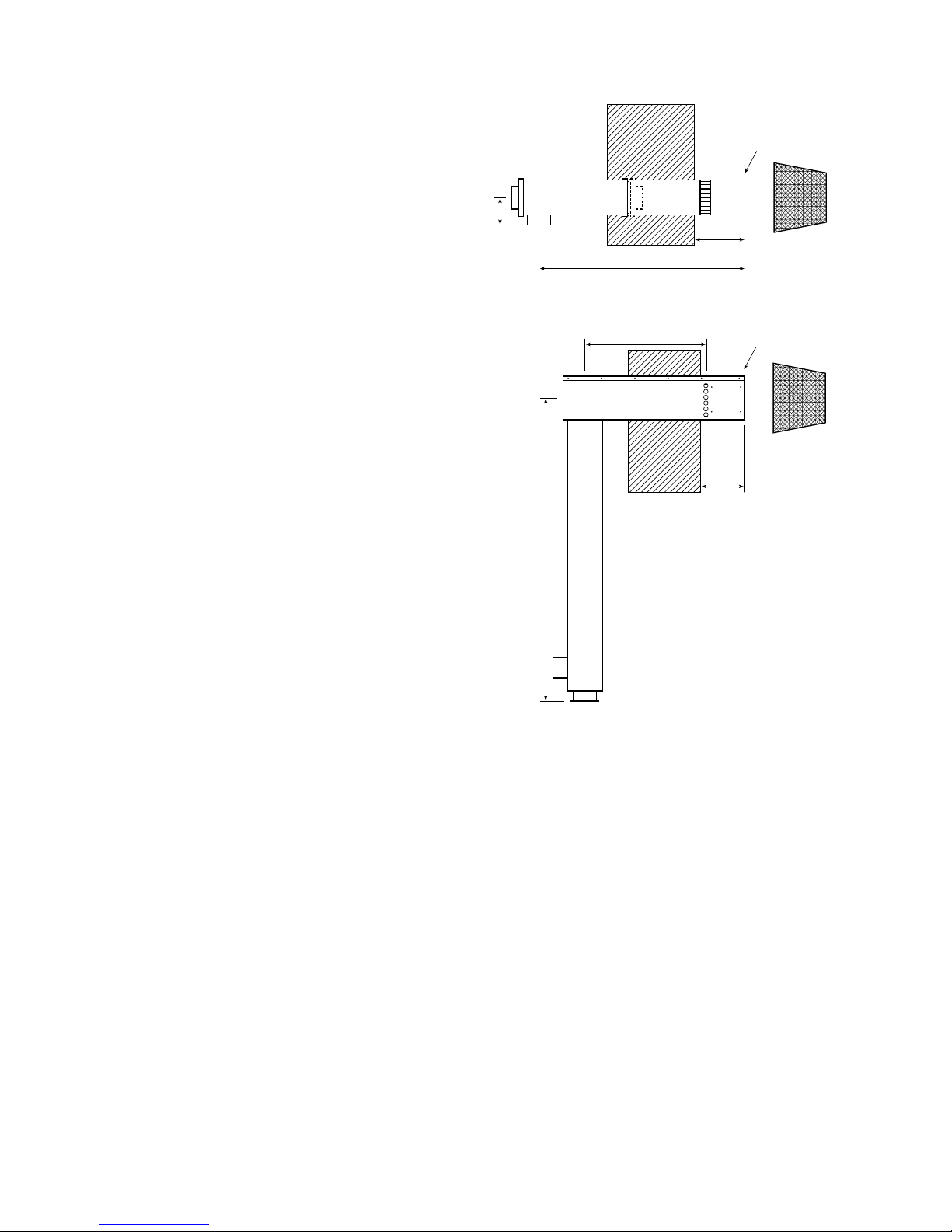

3.0 Dimensions ..................................................................................................................................................................... 7

3.1 Goldbird & Whitebird Models ............................................................................................................................. 7

3.2 Bluebird Models ................................................................................................................................................. 7

3.3 Industrial Bluebird Models .................................................................................................................................. 8

3.4 Kabin Pak ........................................................................................................................................................... 8

3.5 Kabin Pak Back Outlet ....................................................................................................................................... 9

3.6 Slimline Kabin Pak ............................................................................................................................................. 9

3.7 Flue Options ..................................................................................................................................................... 10

4.0 Installation..................................................................................................................................................................... 12

4.1 Service Access ................................................................................................................................................. 12

4.2 Hearth .............................................................................................................................................................. 12

4.3 Heating System ................................................................................................................................................ 12

4.4 Sealed System ................................................................................................................................................. 12

4.5 Air Vents........................................................................................................................................................... 13

4.6 Drain Cock ....................................................................................................................................................... 13

4.7 Expansion Vessels ........................................................................................................................................... 13

4.8 System Filling ................................................................................................................................................... 13

4.9 System Pressure .............................................................................................................................................. 13

5.0 Electricity Supply ......................................................................................................................................................... 14

5.1 Dual Thermostat............................................................................................................................................... 14

5.2 RDB Control Box .............................................................................................................................................. 14

5.3 Control Panel Wiring (Goldbirds) ..................................................................................................................... 15

5.4 R40 Control Box ............................................................................................................................................... 16

5.5 Installation of Optional Programmer................................................................................................................. 16

5.6 System Wiring Diagrams (Goldbirds) ............................................................................................................... 17

6.0 Technical Data............................................................................................................................................................... 19

6.1 Goldbird, Whitebird & Bluebird ......................................................................................................................... 19

6.2 Industrial Bluebirds........................................................................................................................................... 21

7.0 Air Supply...................................................................................................................................................................... 22

7.1 Open Flue Boilers ............................................................................................................................................ 22

7.2 Balanced Flue Boilers ...................................................................................................................................... 22

8.0 Flues ......................................................................................................................................................................... 23

8.1 Conventional Flues .......................................................................................................................................... 23

8.2 Low Level Flues ............................................................................................................................................... 23

8.3 Installation of Flues .......................................................................................................................................... 25

9.0 Installation of Boilers ................................................................................................................................................... 27

9.1 120/150 & 150/200 White Casings................................................................................................................... 27

9.2 Industrial Bluebird Casings .............................................................................................................................. 27

9.3 Industrial Firebrick ............................................................................................................................................ 27

9.4 Kabin Pak Installations ..................................................................................................................................... 29

9.5 Standard Kabin Paks ....................................................................................................................................... 30

9.6 Kabin Pak Vertical Flue Adaptor....................................................................................................................... 30

9.7 Slimline Kabin Pak ........................................................................................................................................... 31

9.8 Slimline Kabin Pak Vertical Flue Adaptor ......................................................................................................... 31

10.0 Oil Supply ...................................................................................................................................................................... 32

10.1 One Pipe System ............................................................................................................................................. 32

10.2 Two Pipe System ............................................................................................................................................. 33

10.3 Deaerator System ............................................................................................................................................ 33

10.4 One Pipe Lift .................................................................................................................................................... 34

11.0 Burners ......................................................................................................................................................................... 35

11.1 RDB Burner ...................................................................................................................................................... 35

11.2 G10 Burner....................................................................................................................................................... 35

11.3 G20S Burner .................................................................................................................................................... 36

11.4 Oil Supply ......................................................................................................................................................... 36

11.5 Air Damper Adjustment .................................................................................................................................... 37

11.6 Electrode Setting .............................................................................................................................................. 37

11.7 Burner Start-up Cycle....................................................................................................................................... 37

12.0 Servicing & Commissioning ........................................................................................................................................ 38

12.1 Commissioning................................................................................................................................................. 38

12.2 Servicing .......................................................................................................................................................... 38

13.0 User Instructions – Horstmann 626 Internal Programmer........................................................................................ 39

14.0 Fault Finding ................................................................................................................................................................. 44

15.0 Spares ......................................................................................................................................................................... 45

15.1 RDB Burners 1 & 2........................................................................................................................................... 45

15.2 RDB 3 & 4 Burners........................................................................................................................................... 46

15.3 R40 G10 Burner ............................................................................................................................................... 47

15.4 R40 G20S Burner............................................................................................................................................. 48

15.5 Boiler Parts List ................................................................................................................................................ 49

Page 1

1.0 User Instructions

1.1 Goldbird Models

Thermostat Control

The recommended minimum thermostat setting is 65°C. Below this ‘cold water corrosion’

is likely to occur which can reduce the life of the heat exchanger and is not covered by

the boiler warranty. The boiler thermostat is adjustable from 52°C to 88°C.

Mains Indicator

The green mains lamp will be lit when there is power to the control box.

H/L Reset

The yellow H/L reset lamp will be lit when the boiler has overheated and tripped the

high limit thermostat, which then needs to be manually reset. If the high limit thermostat

continues to trip, contact Warmflow or your service engineer/technician. The manual

reset thermostat has a cut out point of 110°C.

Lock-Out

The red lock out lamp will be lit when the burner has failed to fire and can be reset by

pressing the illuminated red reset button on the burner control box.

1.2 Bluebird, Kabin Pak and Whitebird Models

The recommended minimum thermostat setting is 65°C (thermostat setting 1). If the

high limit thermostat operates it may be reset by removing the reset cover and pressing

the reset button. If the burner goes to lockout it can be reset by pressing the illuminated

red reset button on the burner control box. Combustible material must not be placed

on top of the boilerhouse models or on top of the burner cover as the temperature of

certain exposed components can occasionally reach 70°C. The boiler thermostat is

adjustable from 60°C to 90°C and the manual reset limit thermostat has a set point of

110°C.

1.3 Servicing

It is recommended that the boiler is serviced annually by an OFTEC registered engineer.

WARNING: No adjustments to externally situated boilers should be made where wet

weather conditions prevail. In such conditions there may be a risk of ingress of water

into the appliance, which could lead to component failure or electrocution.

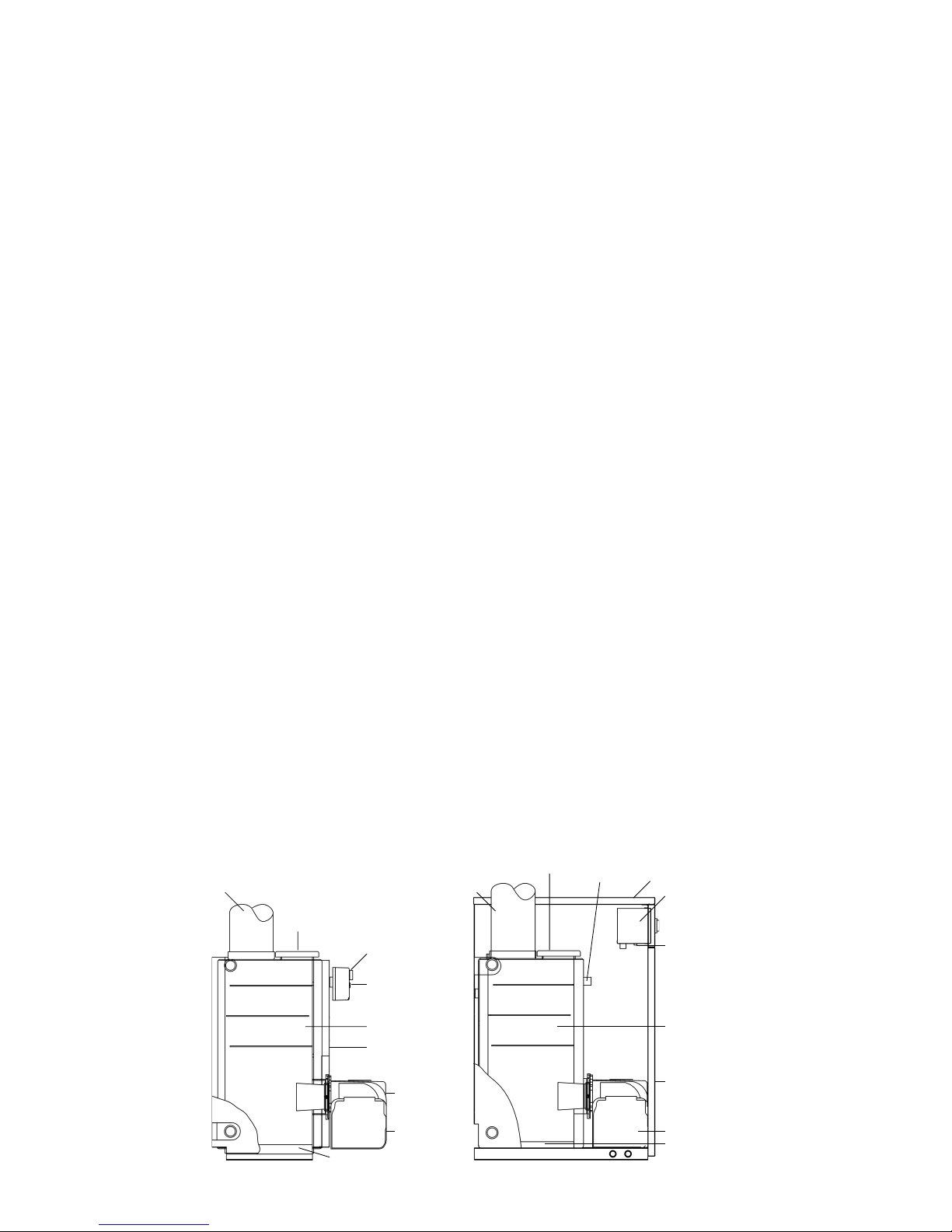

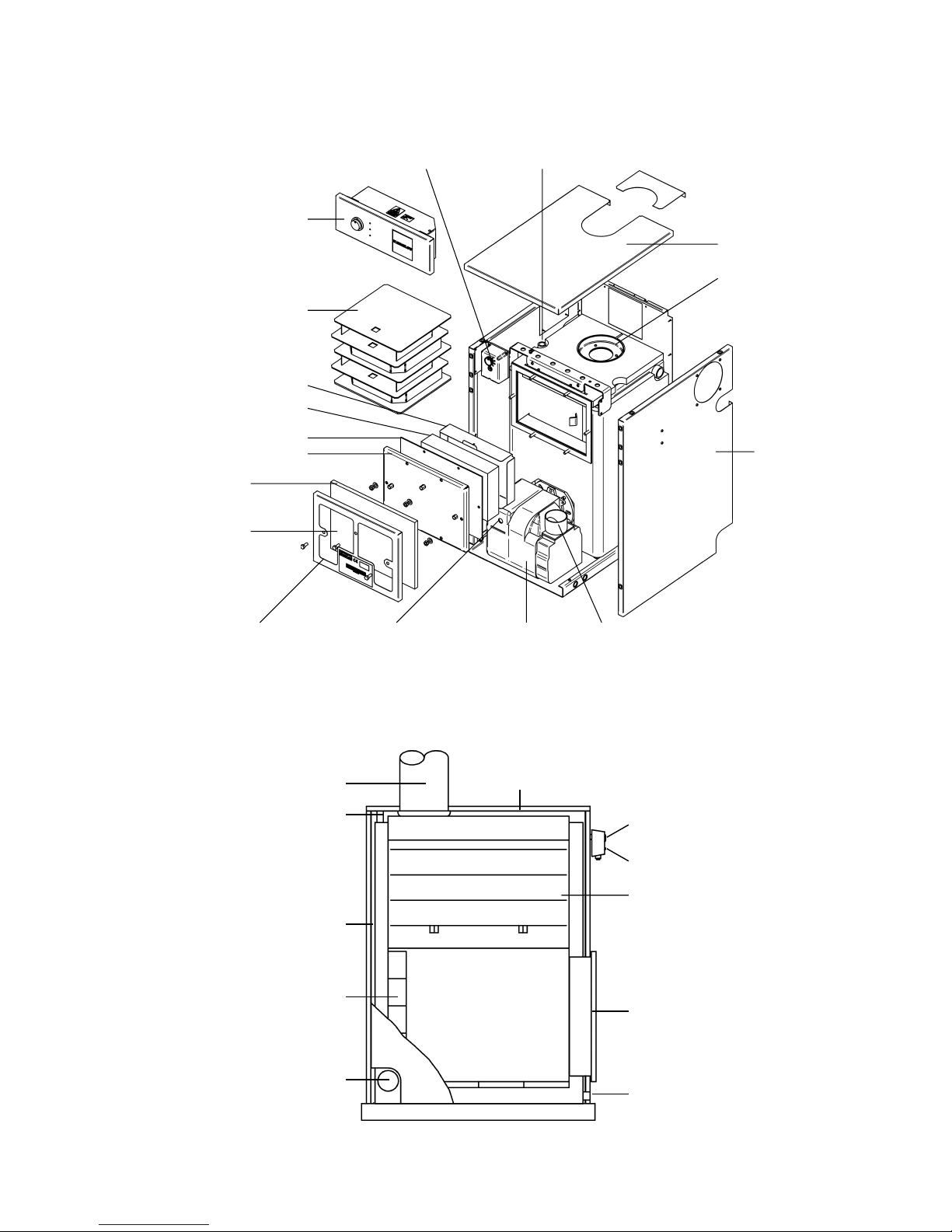

1.4 Components – 50/70, 70/90, 90/120, 120/150, 150/200, 200/250

LIMIT THERMOSTAT

RESET BUTTON COVER

BOILER

THERMOSTAT

CONTROL

TOP LID

FLUE

BURNER

LOCKOUT LAMP

& RESET BUTTON

BAFFLES

BOILER CASING

BURNER COVER

BASE INSULATION

TOP LID

FLUE

BURNER

LOCKOUT LAMP

& RESET BUTTON

BURNER COVER

BASE INSULATION

BAFFLES

LIMIT THERMOSTAT

MANUAL RESET

BUTTON COVER

BOILER

THERMOSTAT

CONTROL

THERMOSTAT

POCKET

BOILER

CASING

Bluebird Goldbird/Whitebird

Page 2

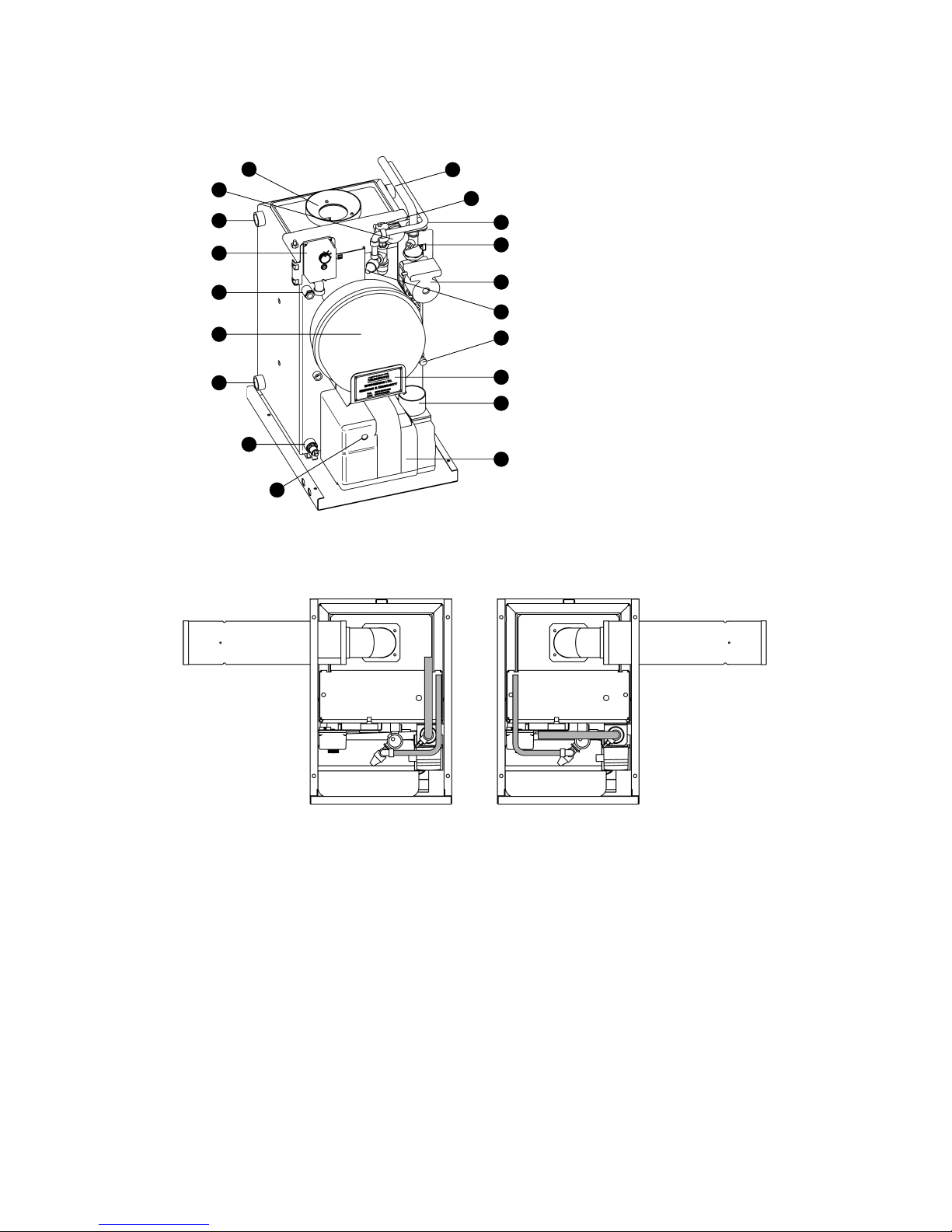

1 Flue

2 System Pressure Gauge

3 Spare BSP Connection (x2)

4 Boiler Limit Thermostat

5 Thermostat Pocket

6 12L Expansion Vessel

7 Heating Return (x2) 1” BSP

8 Drain Cock

9 Heating Flow

10 Automatic Air Vent

11 Pressure Relief Discharge

12 Isolation Gate Valve (x2)

13 Grundfoss Pump

14 Pressure Relief Valve

15 Filling Loop Connection

16 Data label

17 Optional Air Intake Spigot

18 RDB Burner

19 Burner Reset Button/Lock Out Lamp

1.5.2 Pipe Layout

1.5.3 Mains Water Supply

The mains water connection for the filling loop has been left free for the installer to fit

a 15mm copper pipe. The pipe can be routed over the top of the boiler, down one of

the side channels or through the cable entry grommets towards the front of the base

tray.

Note: Also our domestic appliances have been independently tested and accredited

as exceeding the minimum SEDBUK efficiency levels required for its type, in

compliance with the Building Regulations Approved Document L1 2001 for

England and Wales and the Building Standards (Scotland) Regulations 2001

Part J.

1.5 System Boiler

1.5.1 Components

18

17

16

15

14

13

12

11

10

9

8

7

6

4

3

2

1

19

5

Page 3

1.6 Components 50/90 Front Servicing Boiler

INSULATION

RETAINER

BOILER TEST POINT

EXTERNAL DOOR

INSULATION

BURNER RESET BUTTON/

LOCK OUT LAMP

RDB

BURNER

OPTIONAL AIR

INTAKE SPIGOT

SIDE

CASING

FLUE RING

TOP CASING

THERMOSTAT

POCKET

WHITEBIRD

THERMOSTAT

GOLDBIRD

CONTROL PANEL

BAFFLES

INSULATION SHIELD

DOOR INSULATION

DOOR GASKET

SERVICE DOOR

BOILER CONTROL

THERMOSTAT

LIMIT THERMOST AT

RESET BUTTON COVER

SERVICING DOOR

1" BSP DRAIN VALVE

CONNECTION

BAFFLES

4 No 3" BSP CONNECTIONS

FIREBRICK REAR

AND BOTTOM

BOILER CASING

2 No 1/2" BSP CONNECTIONS

FLUE TOP LID

1.7 Components – 300, 400 and 500 BB Industrial Boilers (x 1000 Btu/hr)

Page 4

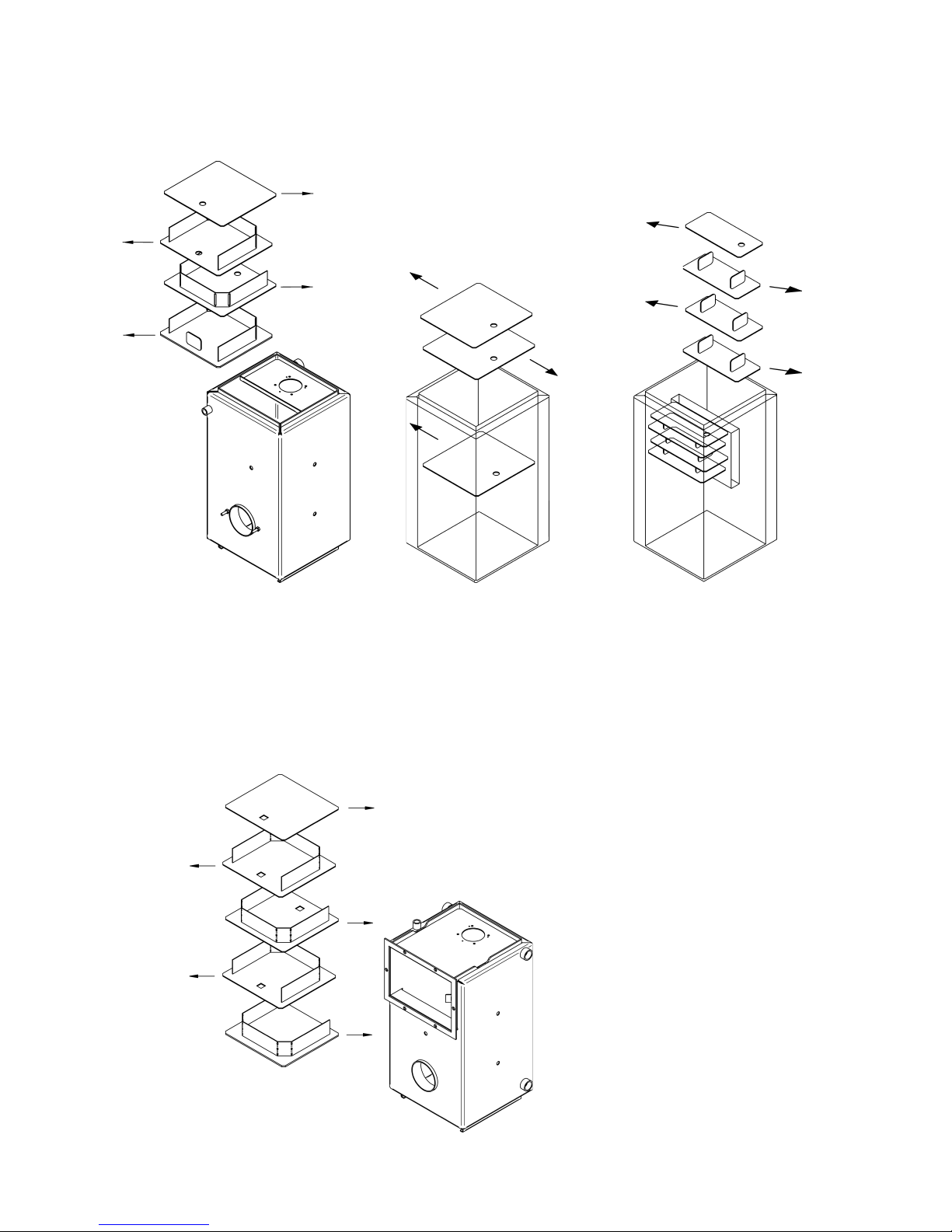

1.8 Baffles

1.8.1 Top Servicing Boilers

50/70

(3 in number)

70/90 & 120/150 (8 in number)

90/120, 150/200, 300, 400 & 500

have a similar arrangement

(12, 12, 12, 16 and 16

baffles respectively)

FRONT FRONT

50/90

(4 in number)

heavy baffle to the bottom

Note: Before firing make sure

the baffles have not been

dislodged in transit and are

correctly positioned. T o achieve

maximum efficiency push the

baffles in the direction of the

arrows as shown.

1.8.2 Components 50/90 Front Servicing Boiler

50/90

(5 in number)

heavy baffle to the bottom

Page 5

2.0 Introduction

The boilers are fired by a pressure jet oil burner which is covered by the manufacturer’s

parts and labour warranty valid for one year (from boiler date stamp). Optional extended

guarantees covering parts and labour are also available (although not applicable to

the Republic of Ireland).

Warmflow oil fired boilers are designed to burn 28 second redwood No 1 (Kerosene

Class C2) fuel or with some adjustment 35 second redwood No 1 (Gas Oil Class D). In

order to comply with current building regulations only kerosene must be burned when

used with low level flue or low level balanced flue. The 400 and 500 Bluebirds are only

suitable for use with 35 second redwood No 1 (Gas Oil Class D).

The boiler shells are fabricated from the best quality mild steel plate electrically welded

and pressure tested to 4.5 bar (65 PSI) making them suitable for either open or

pressurised systems (max working pressure 1.5 bar). Note that all industrial boilers

are tested to 6 bar (90 PSI). They incorporate two flow and return connections on each

side of the boiler for connection to the central heating and domestic hot water systems.

Each shell is covered by the manufacturer’s warranty of 5 years (effective from date

stamped on warranty label) but does not include burner, labour, handling or shipping.

The manufacturers guarantees are void if the appliance is not installed and

commissioned and serviced in accordance with the recommendations made herein.

2.1 General Requirements

The installation of the boiler must be in accordance with the following regulations.

BS5410 : PART 1 : 1997 Code of Practice for oil firing.

BS5410 : PART 2 : 1977

BS5449 : PART 1 : 1977 Forced Circulation Hot Water Systems.

BS7593 : 1992 Treatment of water in domestic hot water central heating systems.

Current Building Regulations: Part J England and Wales

Part F Section III Scotland

Part L Northern Ireland

Current IEE Wiring Regulations:

The heating system should be installed by a competent installer in accordance with

the recommendations laid down by HVCA and a sound engineering practice.

In order to comply with GB building regulations OFTEC forms CD10 for

installations and CD11 for commissioning should be left with the customer.

Page 6

H

A

B

J

F

D

E

C

= =

G

K

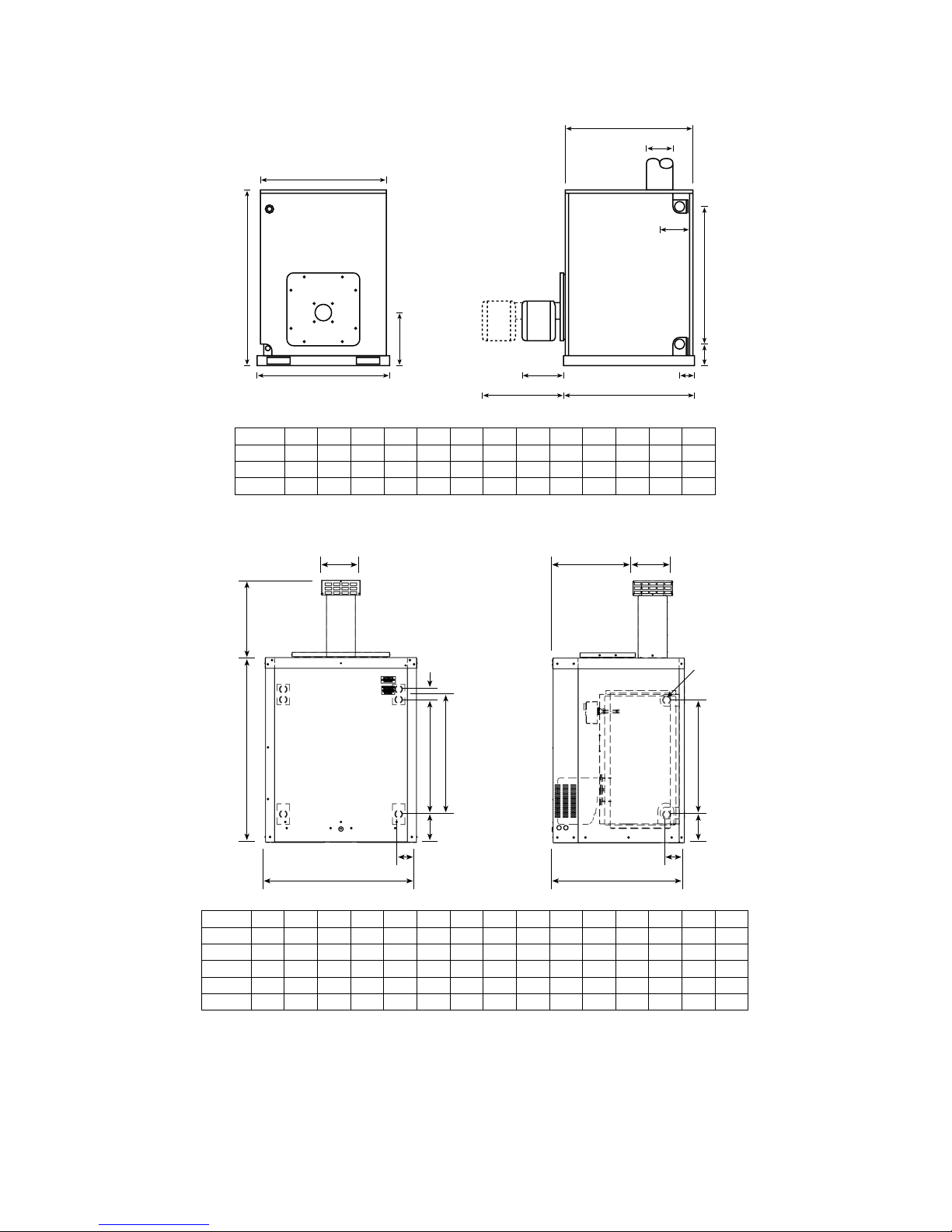

3.0 Dimensions

3.1 Goldbird Kitchen, Whitebird and Whitebird System Utility Room Models (including

front servicing boilers)

J

127

127

127

127

127

OUTPUT (kW)

14.6-20.5

20.5-26.4

26.4-35.2

35.2-44.0

44.0-58.6

A

865

865

865

1168

1168

B

413

413

595

495

495

C

599

599

599

785

785

D

90

90

90

102

102

E

59

59

59

72

72

F

554

554

541

809

809

G

664

664

664

956

956

H

128

128

128

128

128

MODEL

50-70

70-90

90-120

120-150

150-200

K

4x1”

4x1”

4x1

1

/2”

4x1

1

/2”

4x1

1

/2”

3.2 Bluebird Boilerhouse Models

B E

K

= = J

H

C

A

F G

D

L

J

127

127

127

127

127

152

A

688

688

688

965

965

965

B

405

405

585

490

490

490

C

387

387

392

530

530

530

D

88

88

88

102

102

102

E

62

62

67

72

72

72

F

554

554

541

809

809

809

G

662

662

662

956

956

956

H

130

130

138

119

119

139

MODEL

50-70

70-90

90-120

120-150

150-200

200-250

OUTPUT (kW)

14.6-20.5

20.5-26.4

26.4-35.2

35.2-44.0

44.0-58.6

58.6-73.3

K

188

188

188

188

246

246

L

4x1”

4x1”

4x1

1

/2”

4x1

1

/2”

4x1

1

/2”

4x1

1

/2”

Page 7

B

M

E

L

N Q

P

A

D

C

K

FG

H

J

R

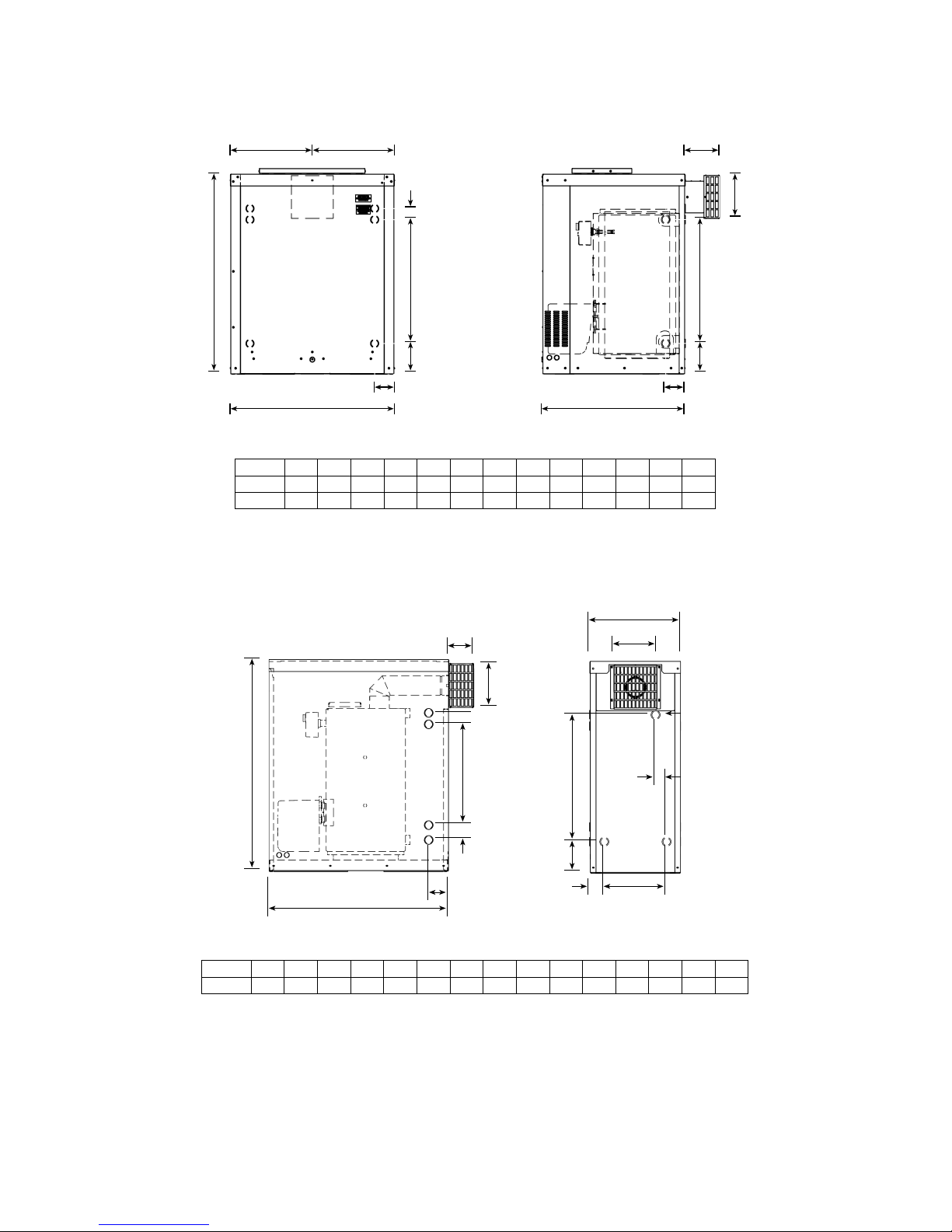

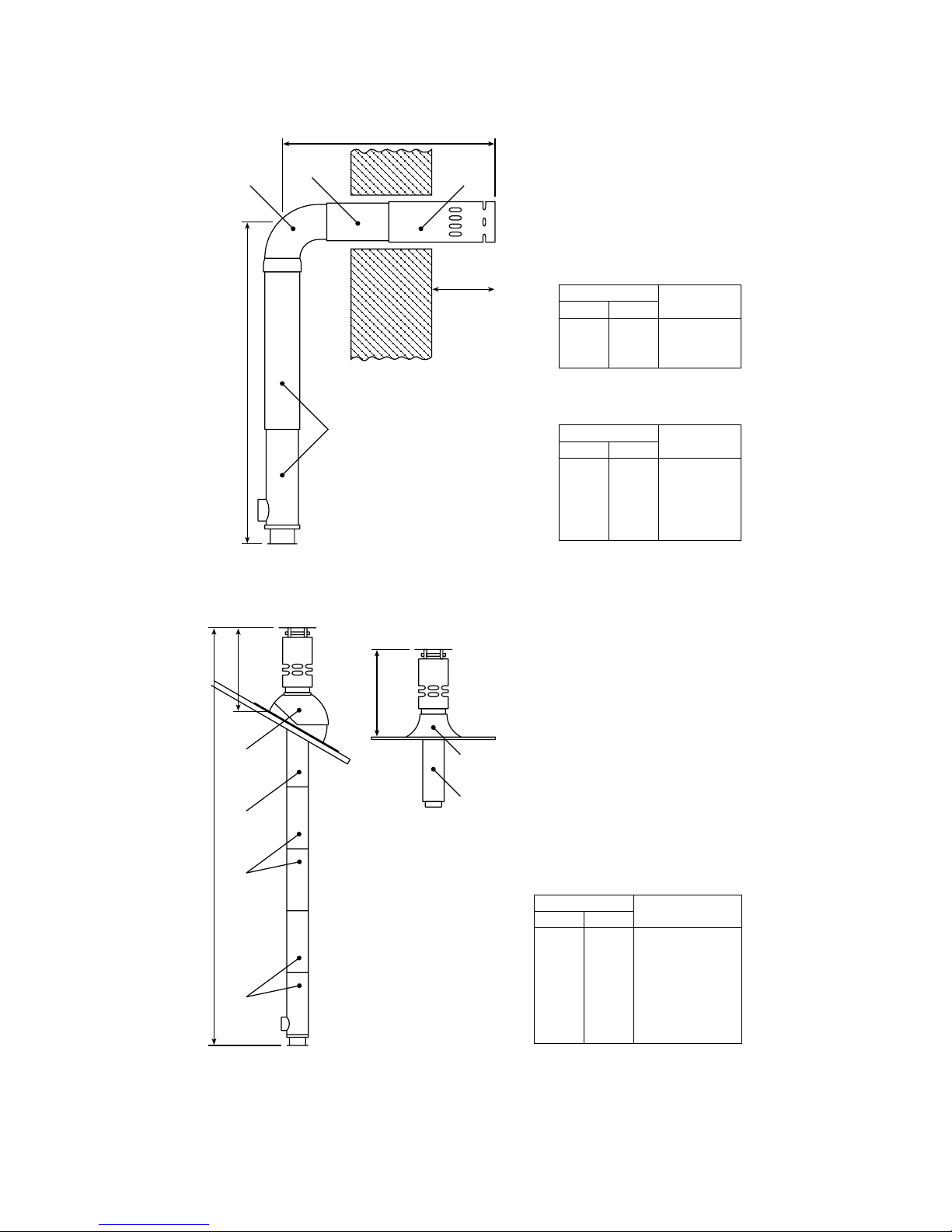

3.3 Industrial Bluebird Models

3.4 Kabin Pak

The Kabin Pak comes factory fitted with a Warmflow Bluebird Boiler and insulated low

level flue kit complete with a terminal guard.

An adaptor is available to allow the low level flue to be extended using standard twin

wall round flue. Only the outer flue and flue end cap need be removed.

D

G

J

A

E

F

N

B

K

L

MH

C

MODEL

50-70

70-90

90-120

120-150

150-200

J

554

554

541

809

809

A

892

892

892

1089

1089

B

732

732

942

902

902

C

636

636

636

836

836

D

373

373

373

373

373

E

188

188

188

188

188

F

191

191

191

191

191

G

390

390

390

602

602

H

137

137

137

151

151

K

84

84

84

96

96

L

86

86

86

86

86

M

137

137

137

191

191

N

554

554

554

—

—

P

50

50

50

—

—

Q

—

—

—

729

729

MODEL

300

400

500

J

412

446

461

A

814

934

1062

B

824

934

1072

C

864

974

1085

D

864

974

1085

E

432

407

464

F

1313

1313

1570

G

263

263

297

H

272

306

321

K

166

166

170

L

1032

1032

1466

M

111

111

102

N

203

203

203

Page 8

P

K

A

F

D

E

G

I

H

B

L

C

J

M

N

Q

J

B

H

C

== D

K

L

M

A

G

F

E x N

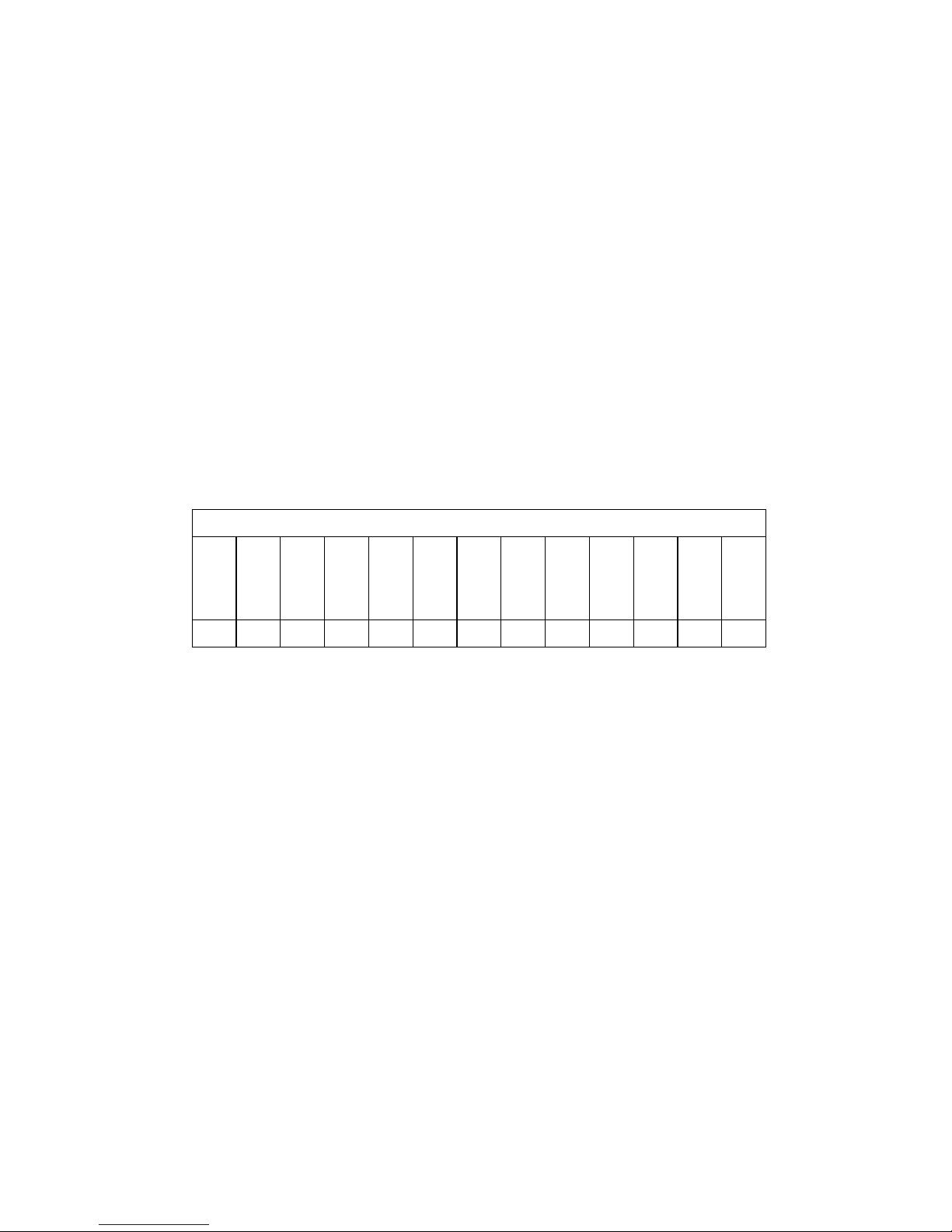

3.5 Kabin Pak Back Outlet

MODEL

50-70

70-90

J

85

85

A

892

892

B

732

732

C

636

636

D

156

156

E

191

191

F

554

554

G

138

138

H

85

85

K

137

137

L

554

554

M

50

50

N

188

188

3.6 Slimline Kabin Pak

When installing a Slimline Kabin Pak against a wall allow 600mm to the front and rear

of the appliance for servicing.

MODEL

50-90

I

190

A

784B925C398D109E86F65G440H50

J

272K61L188M134N554P48

Page 9

3.7 Flue Options

3.7.1 ‘Easy Fit’ Low Level Balanced Flue

The horizontal dimension can be

increased up to an additional

1200mm using a combination of long

extension pieces (600mm) and short

extension pieces (300mm).

102

712 MAX

225 MAX

175 MIN

490 MIN

Ø125

3.7.2 ‘Easy Fit’ High Level Balanced Flue

The HLBF is available in 4 fixed

horizontal lengths which are:

Option 1 – 455mm

Option 2 – 655mm

Option 3 – 585mm

Option 4 – 785mm

225 MAX

175 MIN

1128

SEE OPTIONS

160x160

Page 10

3.7.4 Easy Fit Vertical Balanced Flue (VBF)

EXTENSION KITS

AS REQUIRED

(PACKS C OR D)

PACK E OR F PACK E OR F

A

175 MIN

225 MAX

900 MIN

1400 MAX

PACK A

PACK H

PITCHED ROOF

FLASHING

(22" – 45"

ADJUSTABLE)

PACK B

VBF TERMINAL

SECTION

EXTENSION KITS

(PACK C OR D) AS

REQUIRED

MAX 2 NO PACK D

PACK A

675mm

MIN

675mm

MIN

PACK G

FLAT ROOF

FLASHING

PACK B

VBF TERMINAL

SECTION

MIN

435

560

735

MAX

610

860

910

A + E

A + F

A + C + E

FLUE PACKS

DIM A

ALL MODELS

MIN

860

1035

1160

1385

1510

MAX

1160

1210

1510

1560

1860

A + C + F

A + C + C + E

A + C + C + F

A + D + E

A + D + F

FLUE PACKS

DIM A

50/70, 70/90 & 90/120 MODELS ONLY

MIN

1340

1640

1940

2290

2590

2890

3240

MAX

1840

2140

2440

2740

3040

3340

3740

A + B

A + B + C

A + B + C + C

A + B + D

A + B + D + C

A + B + D + C + C

A + B + D + D

FLUE PACKS

FLUE HEIGHT

ALL MODELS

Note: When using a VBF or HLBF-R on a 120/150 or 150/200 model ensure that the boiler is

fitted with a RDB3 burner.

3.7.3 Easy Fit Telescopic High Level Balanced Flue (HLBF-R)

Page 11

4.0 Installation

The boiler installation must be in compliance with BS 5410 and the Building Regulations.

Failure to install and commission in accordance with the instructions contained

within this booklet will invalidate the warranty.

4.1 Service Access

24” (600mm) clearance should be provided above and in front of the boiler (and the

rear for Slimline Kabin Paks) to allow for routine servicing. When top servicing boilers

are placed under a worktop ensure that the worktop is easily removed.

4.2 Hearth

The boiler hearth temperature is between 50°C and 85°C to comply with the Building

Regulations. The boiler should be stood on a rigid, non-porous, non-combustible base,

which is not softened by warmth. For the heavier industrial boilers it would be advisable

to have a level concrete base raised 50mm above floor level.

4.3 Heating System

The heating system should be installed to HVCA current codes of practice and the

recommendations made in the relevant British Standards.

The use of inappropriate pipe sizes and incorrect plumbing leading to system and

boiler noise is not covered under the boiler warranty.

It is recommended that the flow and return pipes are connected on opposite sides of

the boiler.

It is recommended that new and existing systems are commissioned in accordance

with BS7593 : 1992 ‘Treatment of water in central heating systems’. It is recommended

that a non-corrosive commissioning cleanser is used when flushing the system.

We would also recommend that the system is further treated with a corrosion inhibitor .

These products should be used strictly in accordance with the manufacturers

instructions.

In areas of hard water a suitable water softener would also be recommended.

4.4 Sealed Systems

All Warmflow boilers are suitable for use on a sealed heating system. It is recommended

that a CE approved pressure relief valve (PRV) set at 3 bar is fitted to the system. The

industrial bluebirds can be fitted with a 4 bar PRV. On the system boiler a 3 bar PRV

has been factory fitted.

Page 12

4.5 Air Vents

On the system boiler an automatic air vent complete with its own check valve is fitted

to the top of the boiler heat exchanger. It is recommended that an air vent is fitted at

the highest point in the system. However where the pipework comes off the boiler and

drops down an automatic airvent should be fitted to the top of the boiler.

4.6 Drain Cock

Drain cock(s) should be fitted to the lowest points in the system to enable the system

to be fully drained. On the system boiler a drain cock has been fitted to the system

boiler heat exchanger.

4.7 Expansion Vessels

Refer to BS 7074: part 1 or BS 5449 for details of the pressure vessel sizing. The

values given in the table are for a total system values which includes the primary water

capacity . On the system boiler a 12 litre expansion vessel charged to 0.5 bar is supplied.

This can accommodate a maximum system volume of approximately 150 litres. If this

volume is exceeded an additional vessel will be required.

0.5 2.1 4.2 6.3 8.3 10.5 12.5 14.6 16.7 18.7 20.8 22.9 25.0

1.0 2.7 5.4 8.2 10.9 13.6 16.3 19.1 21.8 24.5 27.2 30.0 32.7

1.5 3.9 7.8 11.7 15.6 19.5 23.4 27.3 31.2 35.1 39.0 42.9 46.8

25 50 75 100 125 150 175 200 225 250 275 300

INITIAL CHARGE

TOTAL

SYSTEM

VOLUME

VESSEL VOLUMES

4.8 System Filling

Water loss from a sealed system, as indicated by a reduction in pressure on the pressure

gauge, may be made up through a filling loop, however the cause of the water loss

should be fully investigated and corrected.

After filling, vent all air from the system. Ensure the caps on the automatic air vents are

loose, bleed the circulating pump and disconnect the temporary filling loop.

As standard, a filling point complete with a filling loop has been included within the

system boiler. A system pressure, when cold, of 1 bar is recommended.

4.9 System Pressure

The pressure relief discharge shall be positioned away from any electrical components.

No other valves should be positioned between the relief valve and the discharge, and

the discharge pipes should not be used for any other purposes. The discharge pipe

must be plumbed to an external drain in a position where the discharge can be seen

but cannot cause any injury or damage.

Where there is a catastrophic loss of water from the system the boiler thermostats

may fail to operate which would result in serious damage to the appliance. To prevent

this it is recommended that a low pressure cut out switch set at 0.2 bar is fitted to the

system and wired in series with the boiler thermostats.

Page 13

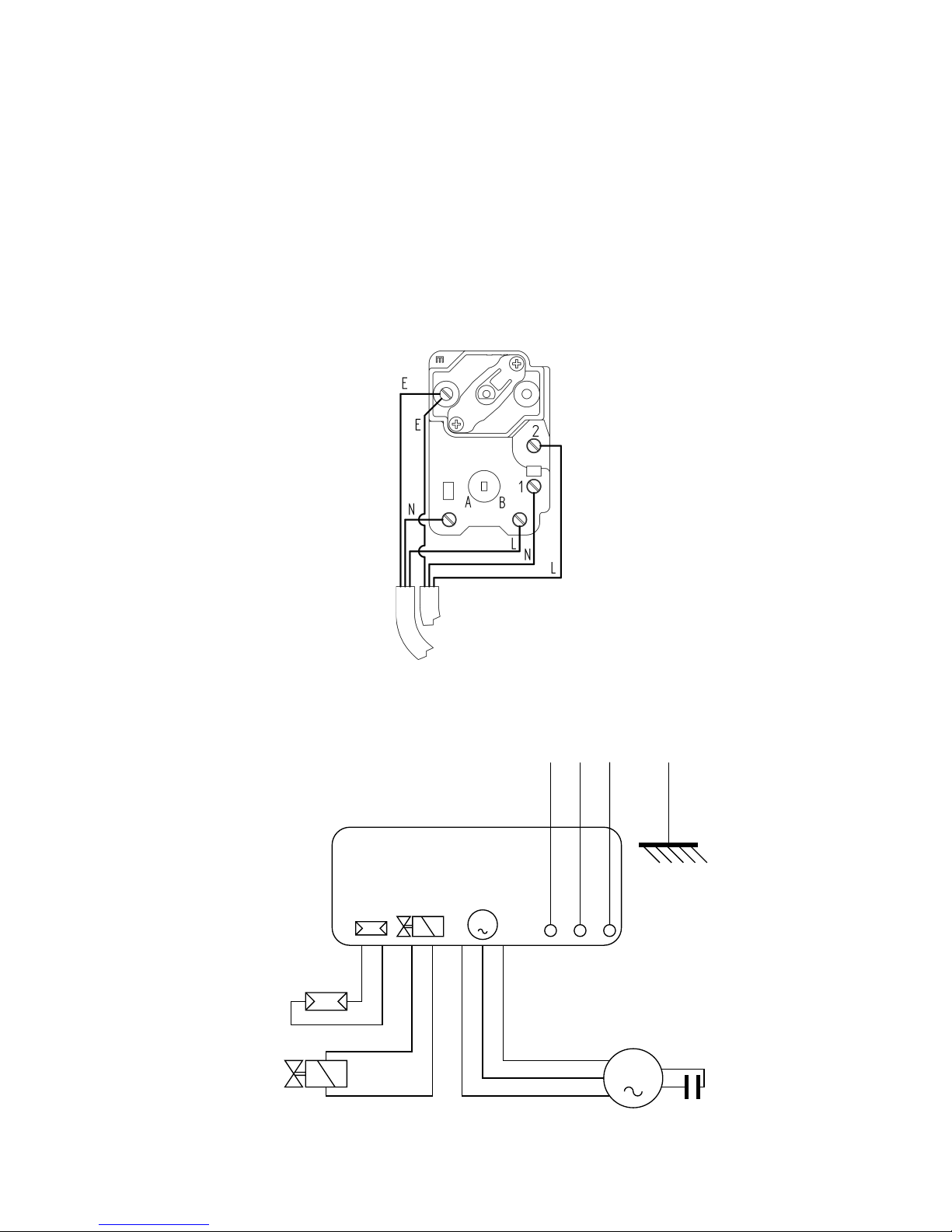

TO BURNER

FROM POWER SUPPLY (SWITCHED LIVE)

5.0 Electricity Supply

220 – 240V. 1PH, 50 Hz

The boiler/burner and other external electrical equipment should be wired with heat

resistant cable via a fused double pole isolating switch which should be fitted with a

5 amp fuse.

The appliance must be effectively earthed and all external wiring should comply with

current IEE Regulations.

5.1 Dual Immersion Thermostat (Bluebird and Whitebird Boilers)

CONTROL BOX

535SE/LD

M

M

Oil Valve

Photoresistance

Black

White

Blue

Motor

Capacitor

Remote

Lock Out

(Goldbirds only)

Live

Neutral

Earth

Fan

Housing

Note: A remote lock out lamp is only factory fitted wired on Goldbird models.

Warning: Do not fit any other wires or loop wires to this stat as this will bypass the

thermostats.

5.2 RDB Burner Control Box

Page 14

Loading...

Loading...