WarmFlow 50/70 Installation & Servicing Manual

INSTALLATION & SERVICING MANUAL FOR

50/70

WALL MOUNTED BOILER

(INTERNAL)

&

50/70

WALL MOUNTED BOILER

(EXTERNAL)

LEAVE THESE INSTRUCTIONS WITH THE END USER

NATIONAL

ACCREDITATION

OF CERTIFICATION

BODIES

BSI

R

E

G

I

S

T

E

R

E

D

F

I

R

M

CERT. No. FM 29884

BS 5750 PART 2

ISO 9002

Page 2

Commissioning

This appliance must be commissioned. Failure to commission the boiler will

invalidate the warranty. After commissioning ensure that the attached

guarantee registration card is completed and returned.

Servicing

To ensure continued reliable operation and fuel economy it is recommended

that the boiler is serviced annually by a Warmflow or an OFTEC registered

technician.

NI Customers Only

Warmflow Engineering Service division (NI) provides an excellent back-up

service, operating a team of OFTEC trained engineers who can meet all the

servicing, commissioning and breakdown requirements for your appliance.

Telephone: 0870 240 6532

Fax: 028 9262 2827

Email: service@warmflow.co.uk

Web: www.warmflowboilers.co.uk

For Parts, Service Technical & Warranty Contact

Great Britain & N Ireland, Tel: 0870 240 6532

Republic of Ireland, Tel: +44 28 9262 1515

ISSUE 2

AUG ’05

This manual is accurate at the date of printing (E&OE) but will be superseded and should be disregarded

if specifications and/or appearances are changed in the interests of continued product improvement.

Code 2614

Lisburn

Lissue Industrial Estate, Moira Road,

Lisburn, Co Antrim, N Ireland, BT28 2RF

Tel: (028) 9262 1515

Fax: (028) 9262 0869

Email: sales@warmflow.co.uk

technical@warmflow.co.uk

service@warmflow.co.uk

Manchester

144 Bradford Road,

Manchester, M40 7AS

Tel: (0161) 205 4202

Fax: (0161) 205 4818

Email: sales@warmflowgb.co.uk

technical@warmflowgb.co.uk

service@warmflowgb.co.uk

Page 3

Contents Page

1.0 User Instructions

1.1 Thermostat Control ......................................................................................................................................... 2

1.2 Mains Indicator ............................................................................................................................................... 2

1.3 Lock Out ......................................................................................................................................................... 2

1.4 Servicing ......................................................................................................................................................... 2

1.5 User Instructions – Wall Mounted (Internal) .................................................................................................... 3

1.6 User Instructions – Wall Mounted (External) ................................................................................................... 4

1.7.1 Components – Wall Mounted Boiler (Internal) ................................................................................................ 5

1.7.2 Components – Wall Mounted Boiler (External) ............................................................................................... 6

2.0 Introduction

2.1 General Requirements .................................................................................................................................... 7

3.0 Dimensions

3.1 50/70 Wall Mounted Boiler (Internal) ............................................................................................................... 8

3.2 50/70 Wall Mounted Boiler (External) ............................................................................................................. 8

3.3 Easy Fit Low Level Conventional Flue (LLF-R) ............................................................................................... 9

4.0 Installation Requirements

4.1.1 Service Access for WM Boiler (Internal) ......................................................................................................... 9

4.1.2 Servicing ......................................................................................................................................................... 9

4.1.3 Heating System ............................................................................................................................................... 9

4.2 Sealed Systems ............................................................................................................................................ 10

4.2.1 Air Vents ........................................................................................................................................................ 10

4.2.2 Drain Cock .................................................................................................................................................... 10

4.2.3 Expansion Vessels ........................................................................................................................................ 10

4.2.4 System Filling ................................................................................................................................................ 10

4.2.5 Pressure Relief Valve ..................................................................................................................................... 10

4.2.6 Low Pressure Switch .................................................................................................................................... 10

5.0 Boiler Installation

5.1 Heat Exchanger Installation .......................................................................................................................... 11

5.2 Internal Boiler Casing Installation ................................................................................................................. 12

5.3 External Boiler Casing Installation ................................................................................................................ 13

5.4 Baffles ........................................................................................................................................................... 14

6.0 Electricity Supply

6.1 RDB Burner Control Box ............................................................................................................................... 14

6.2.1 Control Panel Wiring (Wall Mounted Boilers – Internal) ................................................................................ 15

6.2.2 Control Panel Wiring (Wall Mounted Boilers – External) ............................................................................... 16

7.0 Technical Data ............................................................................................................................................................. 17

8.0 Air Supply

8.1 Open Flue Boilers ......................................................................................................................................... 18

8.2 Balanced Flue/Room Sealed Boilers ............................................................................................................ 18

9.0 Flues

9.1 Conventional Flues ....................................................................................................................................... 19

9.2 Low Level Conventional Flue Positions ........................................................................................................ 19

9.3 Low Level Conventional Flue Installation ...................................................................................................... 21

9.4 Installation of Air Intake Duct ........................................................................................................................ 22

9.5 Wall Mounted Boiler (External) Flue Adaptor Installation .............................................................................. 23

9.5.1 Option A ........................................................................................................................................................ 23

9.5.2 Option B ........................................................................................................................................................ 23

10.0 Oil Supply

10.1 One Pipe System .......................................................................................................................................... 24

10.2 Two Pipe System .......................................................................................................................................... 25

10.3 De-aerator System ........................................................................................................................................ 25

10.4 One Pipe Lift System .................................................................................................................................... 26

11.0 RDB Burner

11.1 Components ................................................................................................................................................. 27

11.2 Oil Pump ....................................................................................................................................................... 27

11.3 Air Damper Adjustment ................................................................................................................................. 28

11.4 Electrode Setting .......................................................................................................................................... 28

11.5 Start-Up Cycle .............................................................................................................................................. 28

12.0 Servicing & Commissioning

12.1 Commissioning ............................................................................................................................................. 29

12.2 Servicing ....................................................................................................................................................... 29

12.2.1 General Requirements .................................................................................................................................. 29

12.2.2 External Wall Mounted Boilers ...................................................................................................................... 29

13.0 Fault Finding ................................................................................................................................................................ 30

14.0 Spares

14.1 Burner Spares ............................................................................................................................................... 31

14.2 Short Parts List (Boiler) ................................................................................................................................. 32

Page 4

1.0

User Instructions

All our domestic appliances have been independently tested and accredited as exceeding

the minimum SEDBUK efficiency levels required for its type, in compliance with the

Building Regulations Approved Document L1 2001 for England and Wales and the

Building Standards (Scotland) Regulations 2001 Part J.

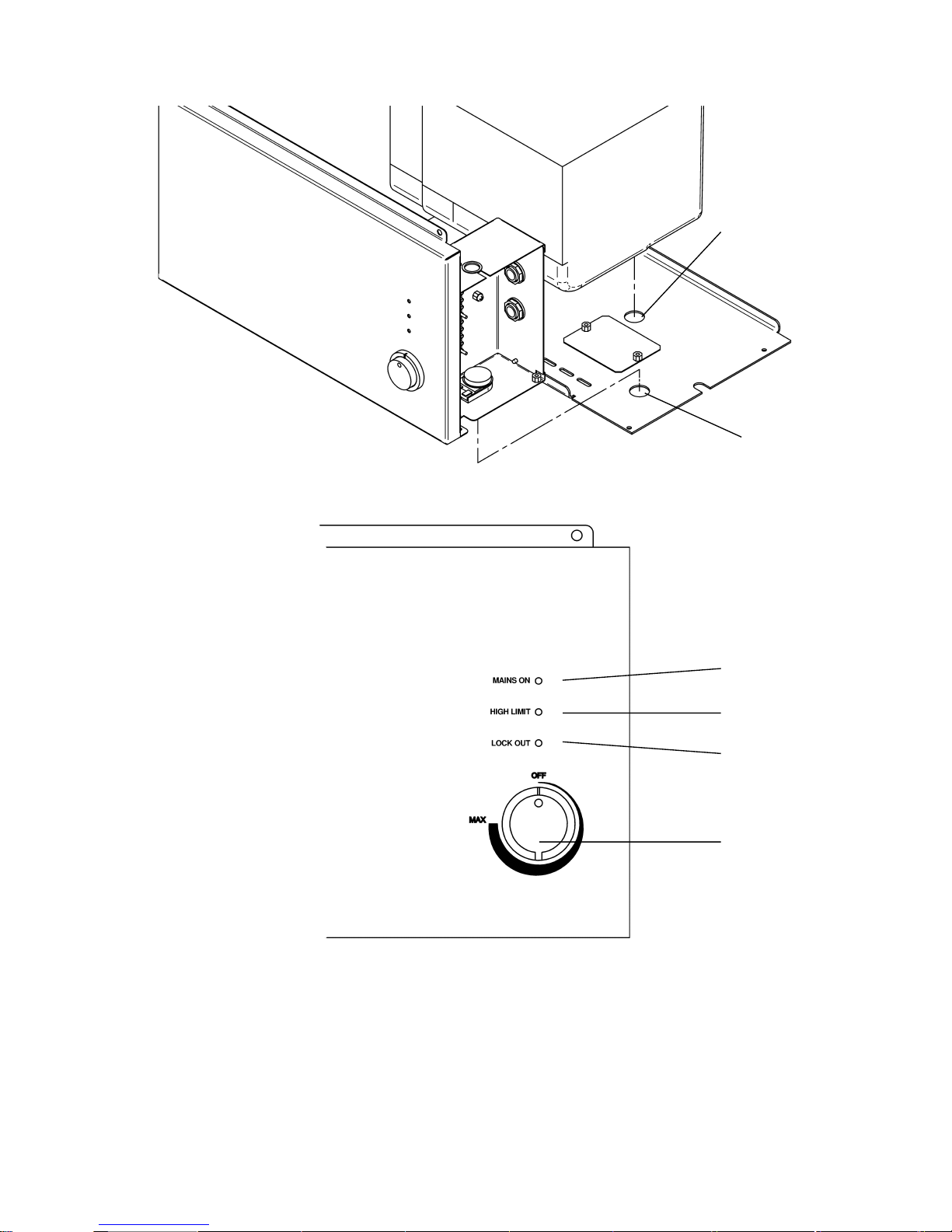

1.1 Thermostat Control

The recommended minimum thermostat is 65°C. Below this ‘cold water corrosion’ is

likely to occur which can reduce the life of the heat exchanger and is not covered by

the boiler warranty. The boiler thermostat is adjustable from 54°C to 84°C.

1.2 Mains Indicator

The green mains lamp will be lit when there is power to the control and limit thermostats.

The yellow high limit reset lamp will be lit when the boiler has overheated and tripped

the high limit thermostat, which then needs to be manually reset. If the high limit

thermostat continues to trip, contact Warmflow or your service engineer/technician.

The manual reset thermostat has a cut out point of 110°C.

1.3 Lock Out

The red lock out lamp will be lit when the burner has failed to fire and can be reset

by pressing the illuminated red reset button on the burner control box.

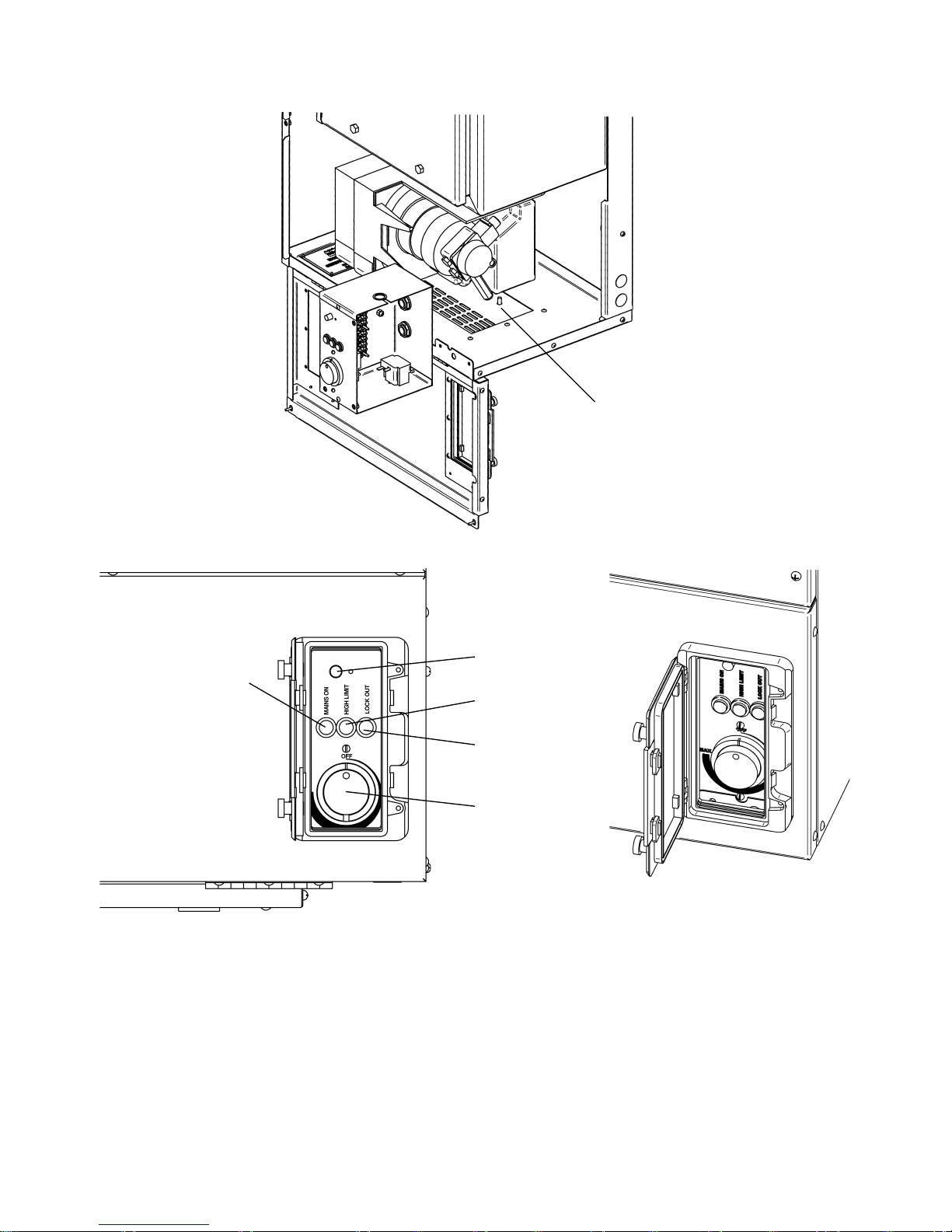

Note: On the external wall mounted boiler the thermostat control indication lamps and high

limit reset button are located behind the lockable plastic cover.

1.4 Servicing

It is recommended that the boiler is serviced annually by an OFTEC registered engineer.

Page 5

1.5 User Instructions – Wall Mounted (Internal)

BURNER

LOCK-OUT

RESET

LIMIT STAT RESET

GREEN

AMBER

RED

CONTROL

THERMOSTAT

(54°C – 84°C)

BURNER

LOCK-OUT

RESET (FROM

UNDERNEATH)

HIGH LIMIT

STAT RESET

(FROM

UNDERNEATH)

➔

➔

Page 6

1.6 User Instructions – Wall Mounted (External)

HIGH LIMIT RESET

AMBER

RED

CONTROL

THERMOSTAT

(54°C – 84°C)

GREEN

BURNER LOCKOUT RESET

(FROM UNDERNEATH)

BURNER

LOCKOUT RESET

(FROM UNDERNEATH)

Page 7

1.7 Components

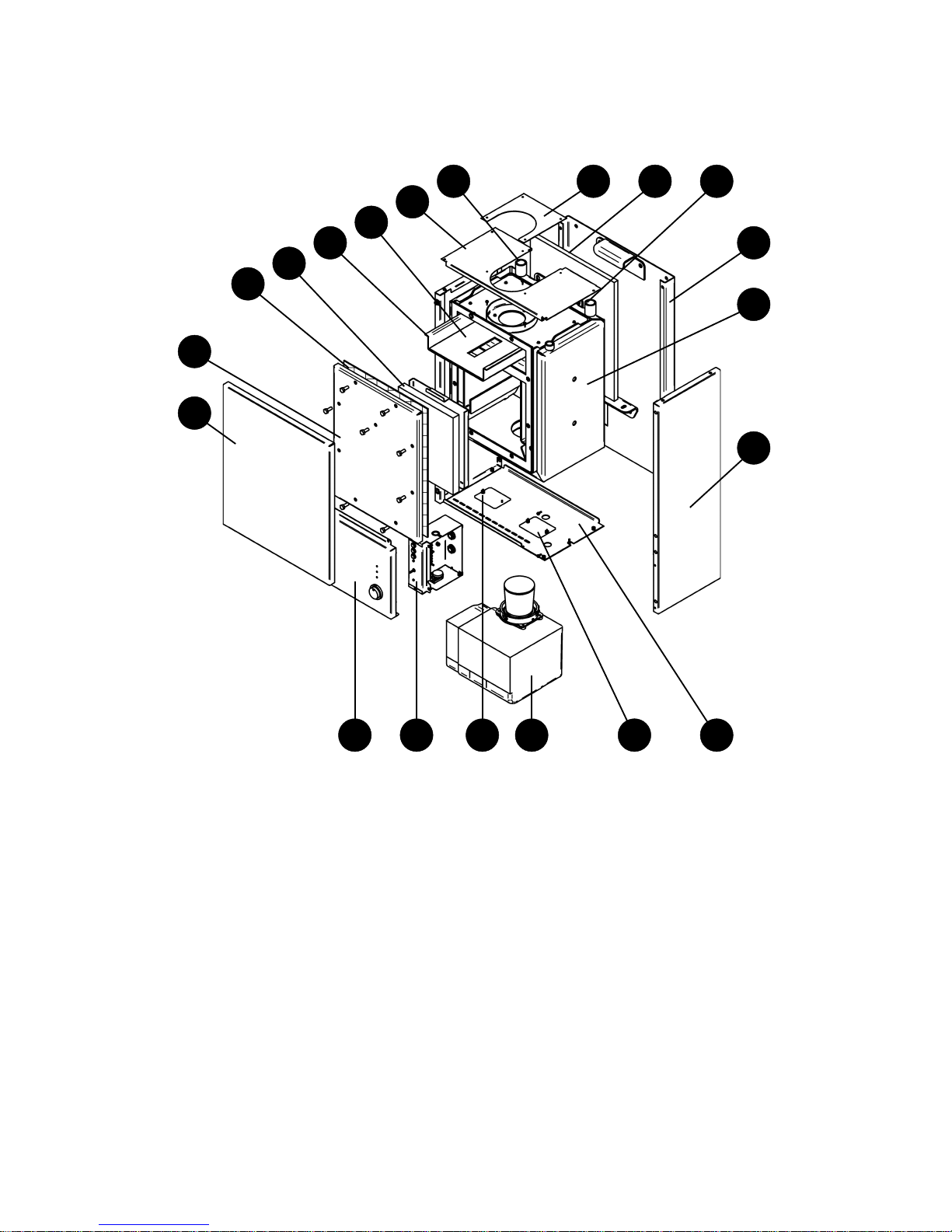

1.7.1 Components – Wall Mounted Boiler (Internal)

1. Front Casing

2. Combustion Chamber Door

3. Door Gasket

4. Door Insulation

5. Top Baffle Support

6. Top Baffle

7. Top Casing & Insulation

8.

3

/4” BSP Flow Connection

9. Flue Closing Plate

10. Mounting Plate Insulation

1

2

3

4

5

6

7

8 9 10 11

12

13

14

1516171920 18

11.

3

/4” BSP Return Connection

12. Mounting Plate

13. Heat Exchanger

14. Side Casing

15. Bottom Casing

16. Oil Pump Access Plate

17. Burner

18. Air Damper Access Plate

19. Control Panel

20. Control Panel Casing

Page 8

1

2

3

4 5 6 7 8

9

10 11

12

13

14

15

16

17

18

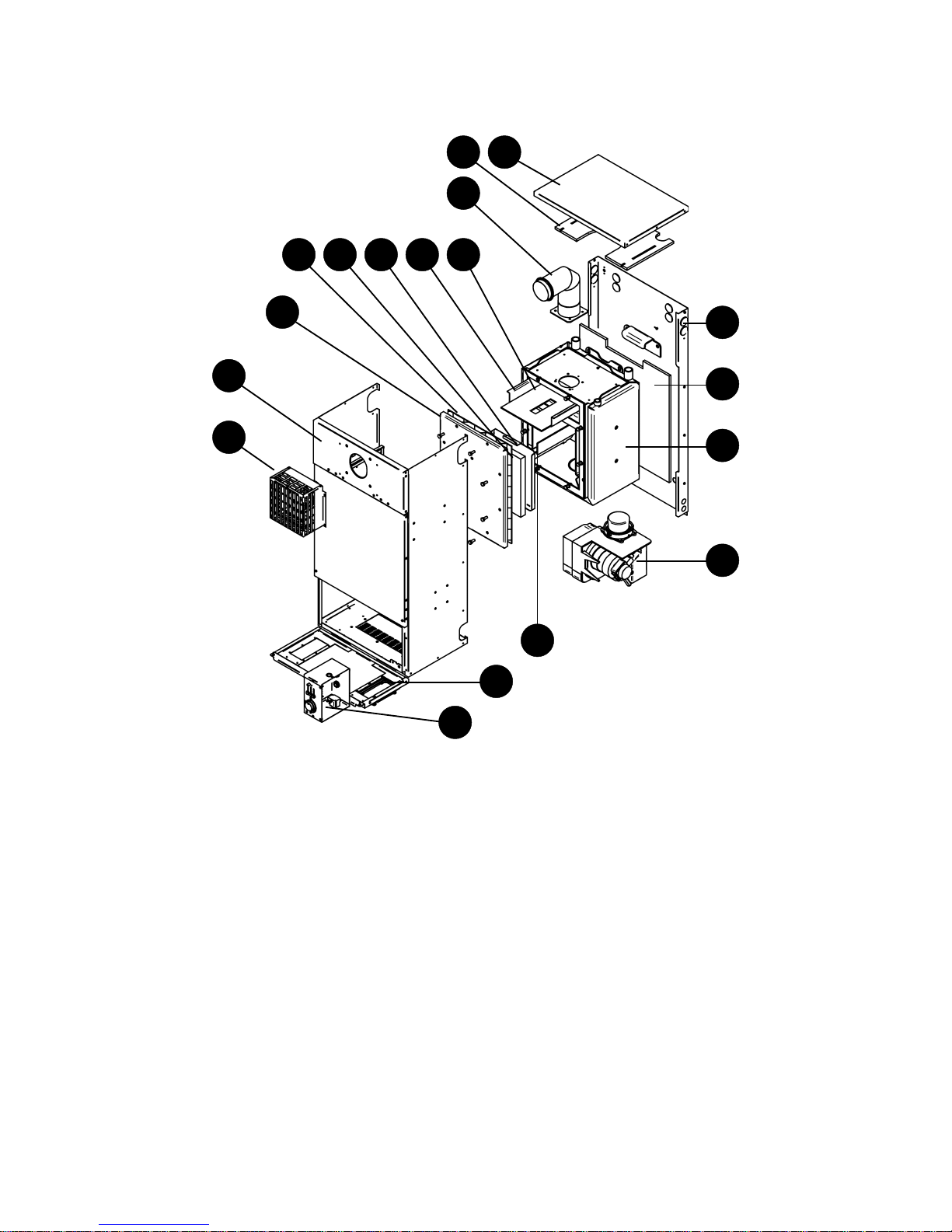

1.7.2 Components – Wall Mounted Boiler (External)

1. Flue Terminal Guard

2. Main Casing Assembly

3. Combustion Chamber Door

4. Door Gasket

5. Door Insulation

6. Insulation Heat Shield

7. Top Baffle Support

8. Top Baffle

9. Flue Elbow

10. Top Insulation

11. Top Casing

12. Mounting Plate

13. Mounting Plate Insulation

14. Heat Exchanger

15. Burner

16. Bottom Baffles

17. Controls Inspection Flap

18. Control Panel

Page 9

2.0 Introduction

The boilers are fired by a pressure jet oil burner which is covered by the manufacturer’s

parts and labour warranty valid for one year (from boiler date stamp). Optional

extended guarantees covering parts and labour are also available (although not

applicable to the Republic of Ireland).

The Warmflow wall mounted oil fired boilers are designed to burn 28 second redwood

No 1 (Kerosene Class C2) fuel.

The boiler shells are fabricated from the best quality mild steel plate electrically

welded and pressure tested to 4.5 bar (65 PSIG) making them suitable for either open

or pressurised systems (max working pressure 1.5 bar). They incorporate one flow

and return connection on the top of the boiler for combined connection to the

central heating and domestic hot water systems. Each shell is covered by the

manufacturer’s warranty of 5 years (effective from date stamped on warranty label)

but does not include burner, labour, handling or shipping.

The manufacturers guarantees are void if the appliance is not installed and commissioned

and serviced in accordance with the recommendations made herein.

2.1 General Requirements

The installation of the boiler must be in accordance with the following regulations.

BS5410 : PART 1 : 1997 Code of Practice for oil firing.

BS5410 : PART 2 : 1997

BS5449 : PART 1 : 1977 Forced Circulation Hot Water Systems.

BS7593 : 1992 Treatment of water in domestic hot water central heating systems.

Current Building Regulations: Part J England and Wales

Part F Section III Scotland

Part L Northern Ireland

Current IEE Wiring Regulations:

The heating system should be installed by a competent installer in accordance with

the recommendations laid down by HVCA and a sound engineering practice.

In order to comply with GB building regulations OFTEC Form CD10 for installations

and CD11 for commissioning should be left with the customer.

Page 10

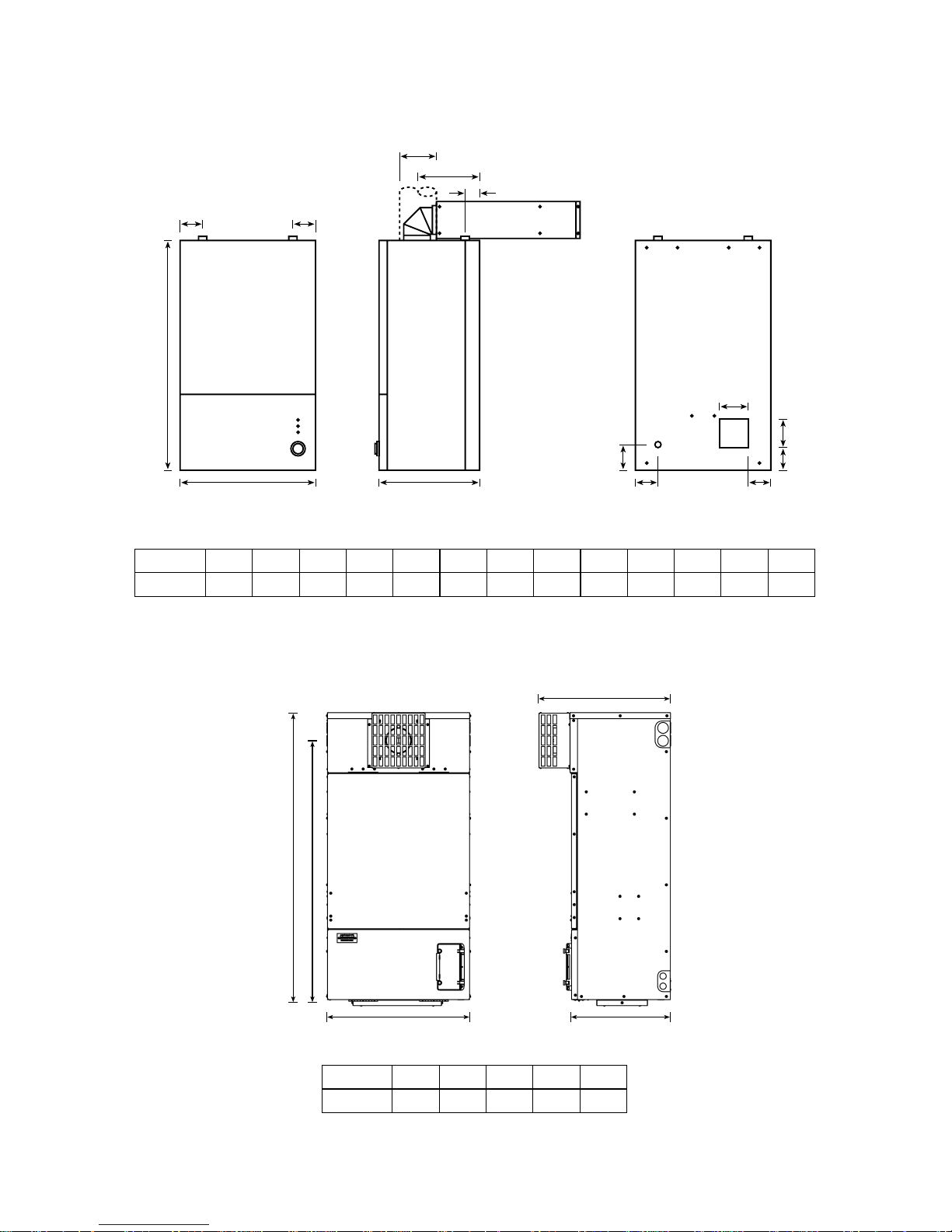

3.0 Dimensions

3.1 50/70 Wall Mounted Boiler (Internal)

F

D D

A B

E

C

H J

M

G

K

L

FRONT VIEW SIDE VIEW REAR VIEW

N

MODEL

50-70 WM

J

77

A

450B330C762D79E100F207G86

H

73

K

77

L

90

M

90

N

22

3.2 50/70 Wall Mounted Boiler (External)

MODEL

50-70 WMEA502B349C1023D465E926

BA

D

EC

Page 11

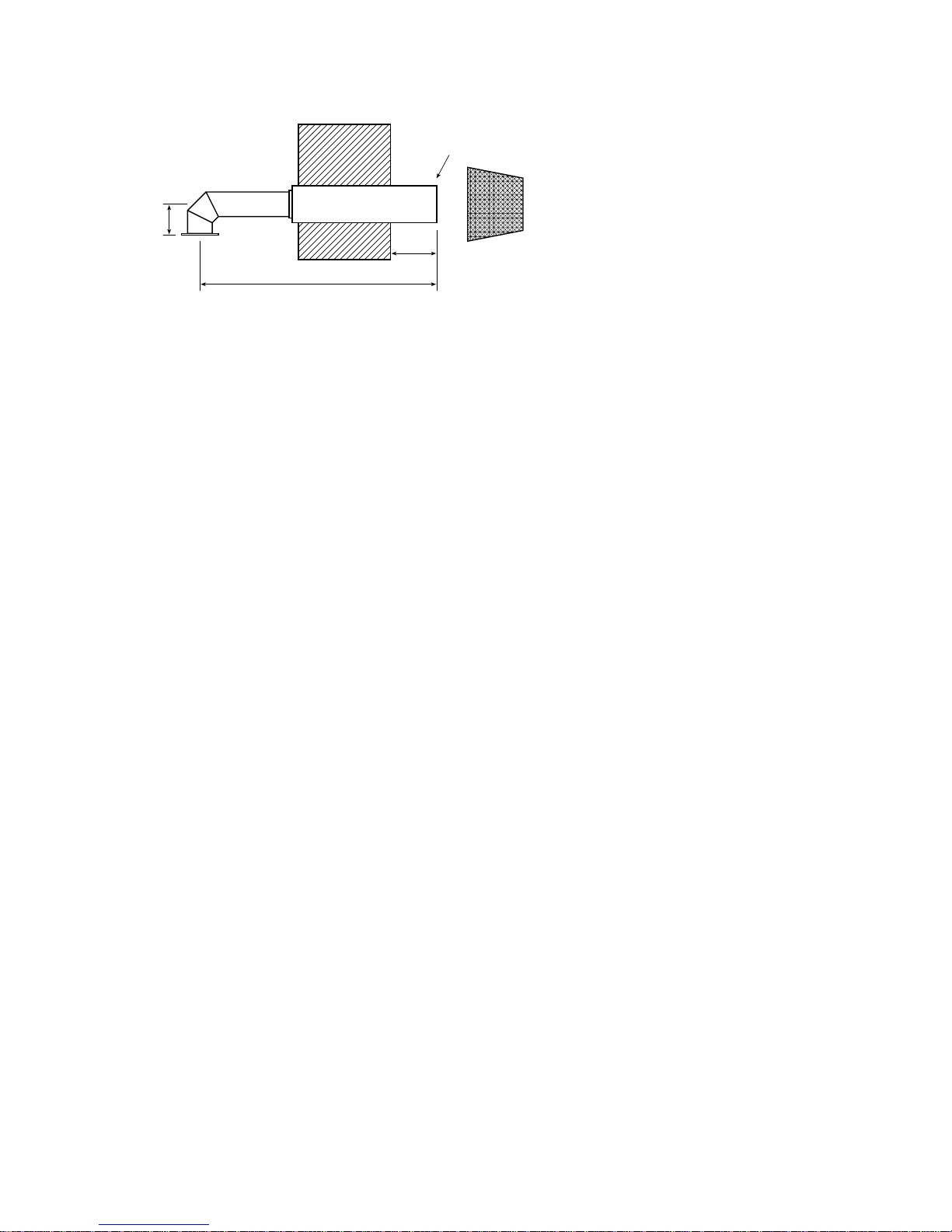

3.3 ‘Easy Fit’ Low Level Conventional Flue (LLF-R)

102

792 MAX

155 MIN

540 MIN

Ø125

225 MAX

4.0 Installation

The boiler installation must be in compliance with BS 5410 and the Building Regulations.

Failure to install and commission in accordance with the instructions contained

within this booklet will invalidate the warranty.

4.1.1 Service Access for WM Boiler (Internal)

600mm clearance should be provided above and in front of the boiler to allow for

routine servicing. If placed under a worktop ensure that the worktop is easily removed.

Additionally the wall mounted boiler requires 200mm beneath the bottom casing and 100

above the top casing as well as 600mm in front to allow clearance for routine servicing.

4.1.2 Servicing WM Boiler (External)

For the external wall mounted boiler there should be a suitable well drained hard

standing area directly in front of the boiler in order to eliminate any risk to the service

engineer or end user from pools of water.

It is recommended that the boiler should not be serviced or the panels removed where

there is a risk of the ingress of water.

Although external wall mounted casing has been weather proofed to IP45 it should not

be subjected to a jet of water from a power washer or hose.

4.1.3 Heating System

The heating system should be installed to HVCA current codes of practice and the

recommendations made in the relevant British Standards.

The use of inappropriate pipe sizes and incorrect plumbing leading to system and boiler

noise is not covered under the boiler warranty.

New and existing systems should be flushed in accordance with BS7593 : 1992

‘Treatment of water in central heating systems’. It is recommended that a non-corrosive

commission cleanser is used when flushing the system.

Note: One 300mm extension piece

may be used to extend the

horizontal length to 1100mm

max and 790mm min.

Loading...

Loading...