Warco DG 20 Operator's Manual

OPERATOR'S MANUAL

Warren Machine Tools Ltd

Warco House, Fisher Lane, Chiddingfold, Surrey GU8 4TD

Tel: 01428 682929 Fax: 01428 685870

e-mail: warco@warco.co.uk

web: www.warco.co.uk

Drill Grinding Machine

DG 20

Possible dangers caused by the drill bit grinder

The drill bit grinder is state of the art.

Nevertheless, there is a residual risk as the drill bit grinder operates with

high revolutions,

rotating parts,

an abrasive wheel (flying sparks)

electrical voltage and currents.

We have used construction resources and safety techniques to minimize the health risk to persons resulting from these hazards.

If the drill bit grinder is used and maintained by personnel who are poorly qualified, then there

may be a risk resulting from incorrect operation and unsuitable maintenance.

INFORMATION

All persons involved in the assembly, commissioning, operation and maintenance must

be duly qualified,

strictly follow this operating manual.

Due to improper use

there is a risk for personnel,

the drill bit grinder and further property might be endangered,

the function of the drill bit grinder could be affected.

Always disconnect the drill bit grinder when cleaning or maintenance work is being carried out.

WARNING!

The drill bit grinder may only be used with the safety devices activated.

Disconnect the drill bit grinder immediately whenever you detect a failure in the safety

device or when they are not mounted!

All additional installations carried out by the operator must incorporate the safety

devices prescribed.

This is your responsibility being the operator!

WARNING!

The separating protective equipment which is made available and delivered together with

the machine is designed to reduce the risk of workpieces or fractions of them which

being expelled, but not to remove them completely.

Safety check

Check the drill bit grinder at least once per shift. Inform the person responsible immediately of

any defect or change in the operation function.

Check all safety devices

at the beginning of each shift (with the machine stopped),

once a week (with the machine in operation),

after every maintenance and repair work.

Check that the prohibition, warning and information labels as well as the markings on the drill bit

grinder

are legible (clean them, if necessary),

are complete.

Assembly

Delivery volume

When the machine is delivered, please check immediately that it has not been damaged during

transport and that all components are included. Take all parts off and compare them to the following list.

• drill bit grinder

• 1 x water basin

• 1 x cup wheel (mounted)

• operation manual

The use of other cup wheels or abrasive wheels is only possible when the maximum admissible

speed for the application "grinding of twist drills, sintered carbide drills" coincides with the maximum speed of the drill bit grinder. It is further necessary that the maximum grinding speed does

not exceed 16 m/s or that the outer diameter of the cup wheel / abrasive wheel does not exceed

42mm.

• injuries to eyes by flying sparks,

• injuries to hands,

• fatal electrocution.

The drill bit grinder includes the following safety devices:

an ON/OFF switch with EMERGENCY-STOP function

a safety protection of the cup wheel.

WARNING!

The separating protective equipment which is made available and delivered together with

the machine is designed to reduce the risk of workpieces or fractions of them which

being expelled, but not to remove them completely.

Safety check

Check the drill bit grinder at least once per shift. Inform the person responsible immediately of

any defect or change in the operation function.

Check all safety devices

at the beginning of each shift (with the machine stopped),

once a week (with the machine in operation),

after every maintenance and repair work.

Check that the prohibition, warning and information labels as well as the markings on the drill bit

grinder

are legible (clean them, if necessary),

are complete.

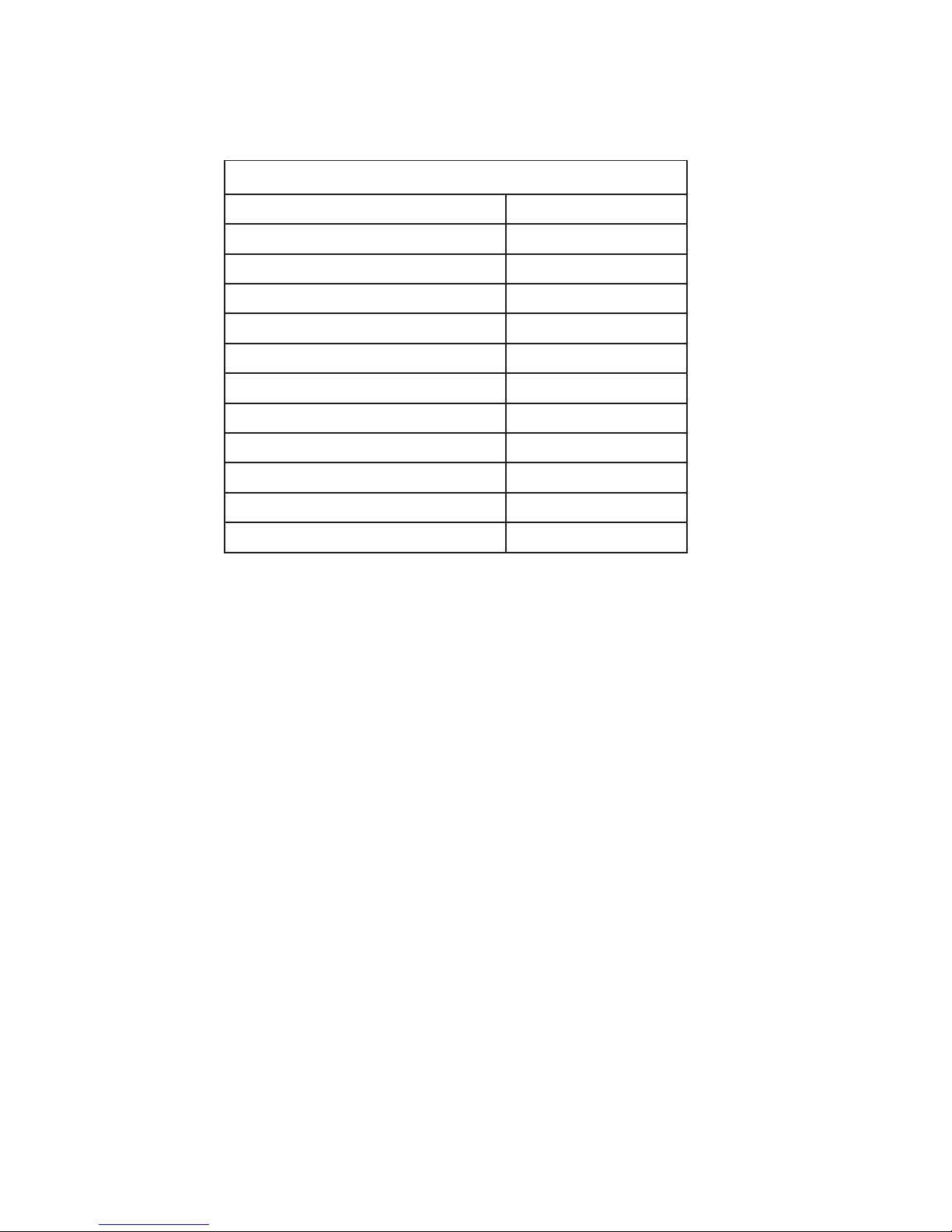

Specifications

drill diameter 3-20mm

center point 8

0°-160°

speed 5

00-7600rpm

grin

ding speed 16m/s

cup wh

eel outside 40mm

cup wh

eel inside 26mm

cup wh

eel thread M10

depth of the cup wh

eel 22mm

work lamp power 5W

motor power (brushless motor) 5

00W/240V/50HZ

weig

ht 26kg

Loading...

Loading...