Warbird Messerschmitt Bf 109F-2 Assembly Manual

Copyright 2005 Thomas A. Jacoby and WarbirdKits.com 1

Assembly Manual for

Messerschmitt Bf 109F

Messerschmitt Bf 109FMesserschmitt Bf 109F

Messerschmitt Bf 109F----2222

Version 1.2 – 29 January 2005

Designed by Terry Majewski

Assembly Manual for Messerschmitt Bf 109F-2

Copyright 2005 Thomas A. Jacoby and WarbirdKits.com 2

Materials

Kit Contents

This kit includes the following items:

Laser-cut balsa, 12 sheets

Laser-cut plywood, 1 sheet

Laser-cut elevator horn, 1 each

1/16” x 4” x 15” Balsa, 4 sheets

6” x 6” Clear plastic canopy material, 1 sheet

1/8” x 1” Dowel, 1 each

1/4” x 12” Balsa triangle, 2 each

3/8” x 6” Balsa triangle, 1 each

1/16” x 12” Music wire, 1 each

3/32” x 9” Aluminum tubing, 1 each

Construction manual, 1 each

Decals, 1 sheet

Builder-Provided Materials

You will need to provide the following materials to complete

this kit:

1-3/4” Du-Bro spinner

Aileron linkage (suggest Du-Bro Cat No 189 Aileron

Horn Wire Ball Links)

Elevator pushrod and quick-link

Hinges (ailerons, elevators)

Covering and paint

2 ounce Fiberglass cloth (wing reinforcement)

0.56 ounce Fiberglass cloth (spinner reinforcement)

Pair of super-magnets or bolt and nut (hatch hold-

down)

Motor, propeller and battery

Radio gear: receiver, elevator servo, aileron servo

Power

The prototype was powered by a Mega 16/15/5 brushless

motor, an 8 cell 1100 mAh NiMh battery, and an APC 7x5e

prop.

If built light (17 to 18 ounces) a Speed 400 motor should

provide sufficient power.

Updates and Free Downloads

Please visit our Web site www.warbirdkits.com for product

updates and free downloads!

Assembly Manual for Messerschmitt Bf 109F-2

Copyright 2005 Thomas A. Jacoby and WarbirdKits.com 3

Construction

Wing

The wing is a fully-sheeted spar-less design that achieves

strength without unnecessary weight. The wing is designed

to be permanently attached to the model’s fuselage for

structural integrity.

The wing consists of two panels: port and starboard. Each

panel has a top skin and a bottom skin.

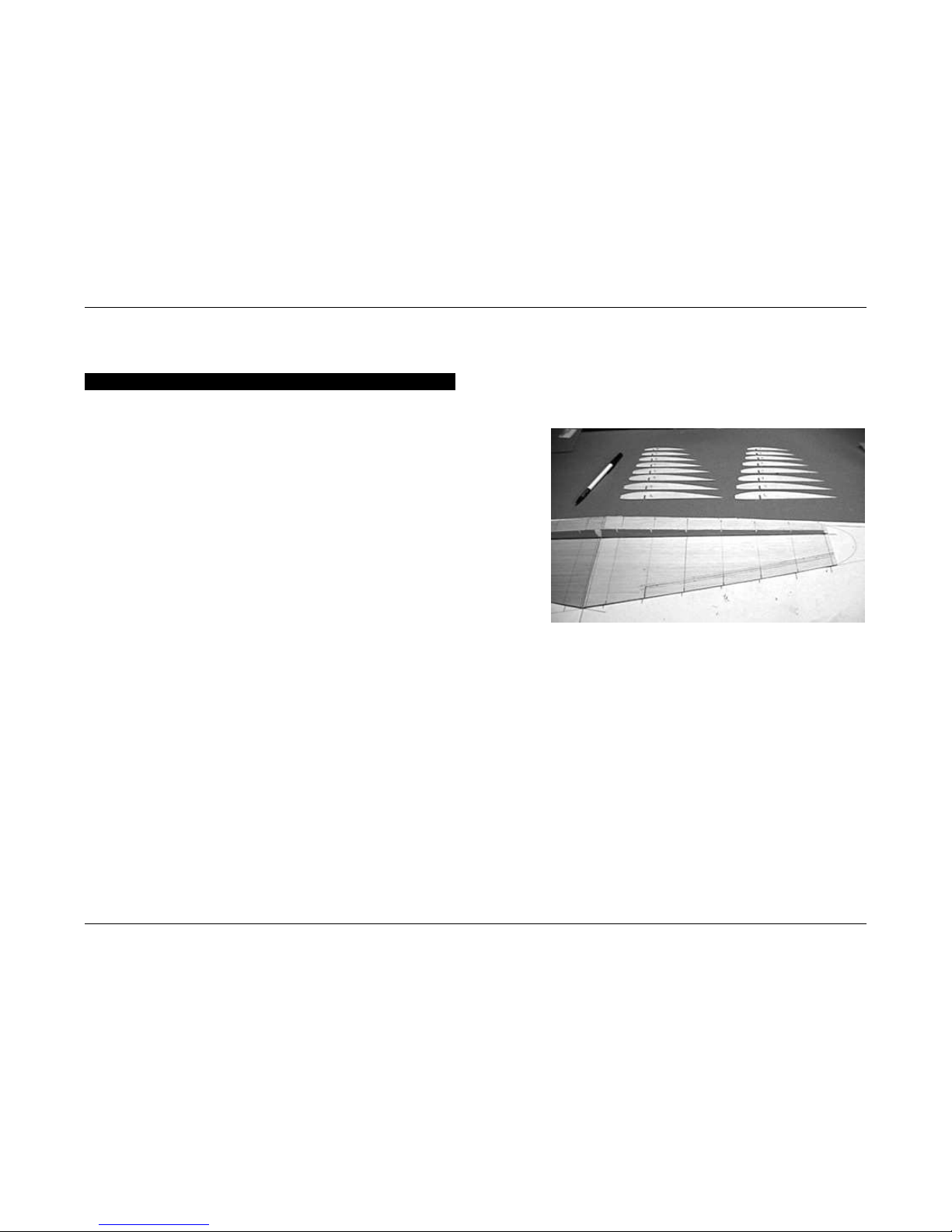

Wing Skins

Each lower wing skin consists of two laser-cut and

etched pieces: forward and aft. Gently clean up the

mating edges of the skin pieces with 220 grit paper

on a sanding block.

Lay the two pieces of a wing skin on a flat board or

table, with the outer surface up. Run a length of

masking tape along the join line. Turn the assembled

skin over, bend the joint open, and run a bead of

wood glue down the joint.

Lay the assembled skin back down on the flat board

– masking tape side down. Run a damp paper towel

over the joint to remove excess glue. Place a sheet

of wax paper over the assembled skin. Then weight

it down with another board, books or what have you.

Keep the weight on the skin until it is completely dry.

While waiting for the bottom skins to dry, prepare

the top skin material as follows. For each top skin,

join two sheets of 1/16” x 4” balsa using the tape

and glue method above.

When the bottom skins are dry, remove the masking

tape from the joints.

Trace the outlines of the bottom skins onto the top

skin material. Then cut out the top skins leaving

about 1/8” extra material at the trailing edges.

Sand each skin as follows. Lay a skin on a flat board

with the outer surface up, and sand it smooth with

120 grit paper on a long sanding block. Be sure to

keep your sanding motion at a 45-degree angle to

the joints and wood grain. Clean the skin with a tack

rag.

Note – it should not be necessary to sand the inner

surfaces of the wing skins. Just be sure to remove

any excess glue.

Assembly Manual for Messerschmitt Bf 109F-2

Copyright 2005 Thomas A. Jacoby and WarbirdKits.com - 4 -

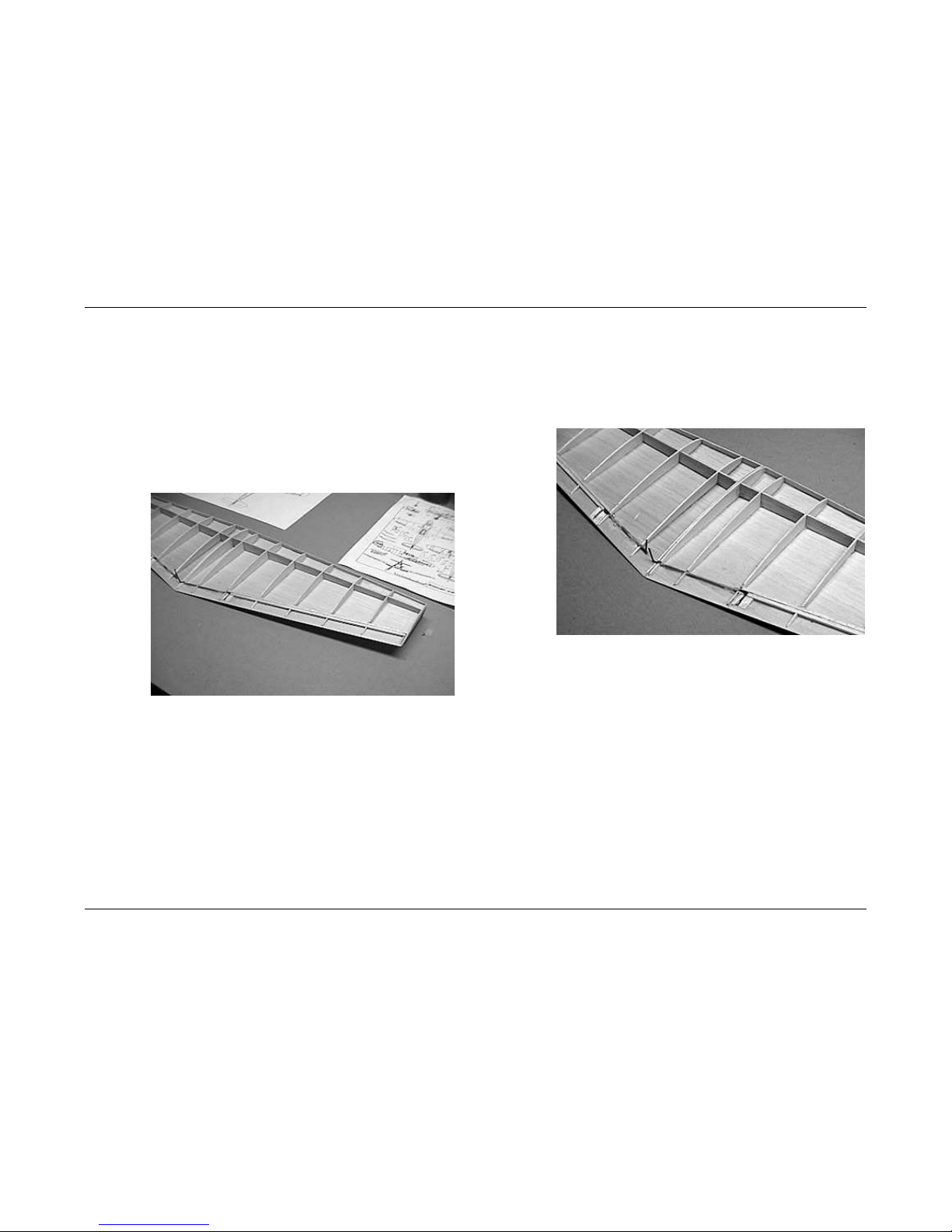

Wing Panels

Pin a lower wing skin to your building board. (The

lower skins are the ones with the rib and aileron

hinge strip positions etched into them.)

NOTE: Ignore the wing main spar in the construction

photos.

Use the laser-cut dihedral gauge to set the root rib in

position. When satisfied with the fit, glue it to the

bottom skin.

Glue the rest of ribs to the bottom skin. Glue the

aileron hinge strips to the ribs and bottom skin, one

on either side of the laser-cut separation line. DON’T

glue the aileron hinge strips together.

NOTE: Use scrap 3/32” material to pack the leading

edge of the bottom skin up so that it is in contact

with the full length of each rib.

Fabricate aileron torque rods from 3/32" aluminum

tubing and 1/16" music wire.

Glue torque rod tubing to the bottom skin BUT NOT

to the aileron. Glue blocks on either side of the

aileron crank. Do not cut the aileron out at this time.

Assembly Manual for Messerschmitt Bf 109F-2

Copyright 2005 Thomas A. Jacoby and WarbirdKits.com - 5 -

Glue the 1/16” sub-leading edge to the front of the

ribs.

Sand the wing panel structure so that the aileron

hinge strips and crank blocks match the wing rib

contour. Sand the top of the trailing edge so that it

tapers to about 1/32” width. This provides a gluing

surface at the trailing edge for the top skin.

Pin a wing panel to the building board, using the

laser-cut washout jigs to establish 1/8” wingtip

washout.

Glue the 1/16" top skin to the wing panel structure.

Let the glue cure thoroughly before unpinning the

wing panel from the building board.

NOTE – The laser-cut 1/8” leading edge strip is not

wide enough to cover the entire leading edge. To

remedy this, simply cut a 1/8” inch wide strip from

the excess 1/8” sheet and edge-glue it to the lasercut leading edge.

Glue the 1/8” laser-cut leading edge to the wing

panel.

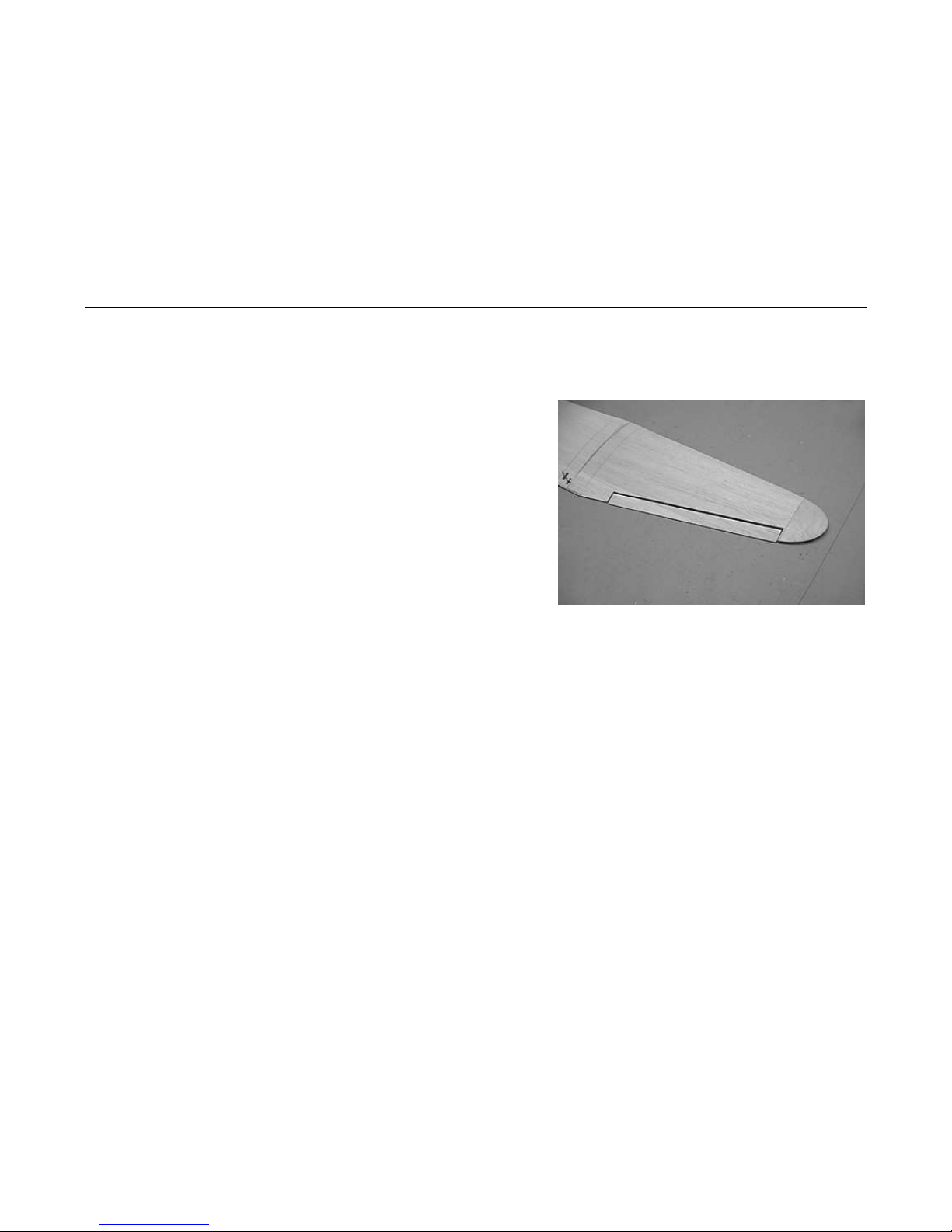

Glue the laser-cut wingtip to the tip rib. NOTE –

laminate a scrap of 1/16” sheet to the top of the

wingtip block.

Shape the leading edge and wingtip of each wing

panel to the shapes shown on the plans.

Prepare to join the wing panels by pinning one wing

panel, with its washout jigs, to your building board.

Jig the other wing panel so that its center rib

matches the center rib on the pinned-down panel,

and raise its wingtip 2” above the building board.

Assembly Manual for Messerschmitt Bf 109F-2

Copyright 2005 Thomas A. Jacoby and WarbirdKits.com - 6 -

Glue the panels together. We suggest 15-minute

epoxy for this joint.

Wrap the center section of the assembled wing with

a strip of 2.6oz fiberglass cloth. Soak the cloth with

thin CA glue.

Cut the ailerons free from the completed wing.

Bevel the aileron leading edges slightly to allow for

3/16” movement both up and down.

Hinge the ailerons to the wing.

Loading...

Loading...