Wanner Engineering P100 Installation & Service Manual

W0032A

T M

P100 Metering Pump

Installation & Service

P100-991-2400B

1204 Chestnut Avenue, Minneapolis, MN 55403

TEL: (612) 332- 56 81 FA X : (612) 332-6937

TOLL-FREE FAX [US only]: (800) 332-6812

www.hydra-cell.com/metering

email: sales@wannereng.com

Metallic Pump shown

P100 Contents

W0032A

Page

Specifications ..........................................................................2

Dimensions .............................................................................3

Installation ...............................................................................4

Maintenance ............................................................................6

Fluid End

Service .................................................................................7

Parts List ...............................................................................9

Hydraulic End Parts List .......................................................11

Reducer Parts List ................................................................12

Troubleshooting.....................................................................13

Replacement Parts Kits ........................................................14

Warranty ................................................................................15

P100 Specifications

Steady State Accuracy ±1%

Linearity ±3%

Repeatability ±3%

Maximum Pressure

Metallic Head: 1500 psi (104 bar)

Non-Metallic Head: Polypropylene: 250 psi (17 bar)

Kynar: 350 psi (24 bar)

Maximum Inlet Pressure 250 psi (17 bar)

Maximum Temperature

Metallic Head: 250°F (121°C) – consult factory for

temperatures above 160°F (71°C)

Non-Metallic Head: 140°F (60°C)

Gallons Per Hour (GPH) Maximum Flow at Designated Pressure†

Inlet Port 1/2 inch NPT or BSPT

Discharge Port 3/8 inch NPT or BSPT

Shaft Rotation Bidirectional

Oil Capacity† 1/8 US quart (0.12 liters)

Weight

Metallic Head: 18.5 lbs (8.4 kg)

Non-Metallic Head: 16.4 lbs (7.4 kg)

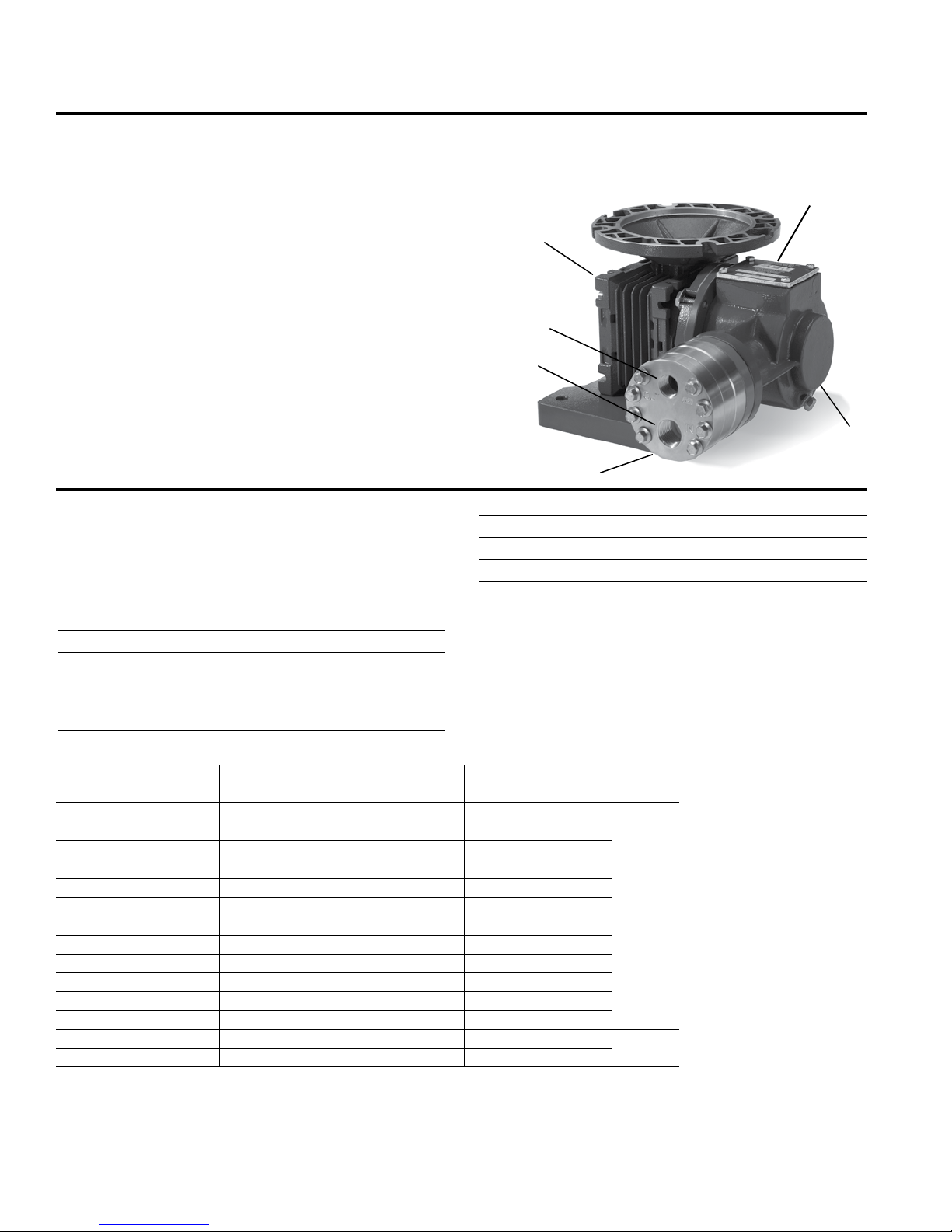

Component Identification

Oil Cover/ID Plate

Reducer

Outlet

Inlet

Pump Assembly

Fluid End

Pump Assembly

Hydraulic End

GPH All Pumps GPH Metallic Pump Heads Only

100 PSI (*) 250 PSI (*) 500 PSI (*) 1000 PSI (*) 1500 PSI (*)

0.66 (¼) 0.57 (¼) 0.51 (¼) 0.32 (¼) ‡ 18 100:1

0.82 (¼)

1.10 (¼) 1.01 (¼) 0.93 (¼) 0.73 (¼) ‡ 30 60:1

1.32 (¼) 1.22 (¼)

1.65 (¼) 1.55 (¼) 1.46 (¼) 1.25 (¼) 0.35 (¼) 45 40:1

2.20 (¼) 2.10 (¼) 2.00 (¼)

2.64 (¼) 2.53 (¼) 2.42 (¼) 2.17 (¼) 1.26 (¼) 72 25:1

3.31 (¼) 3.18 (¼) 3.06 (¼) 2.79 (¼) 1.86 (¼) 90 20:1

4.41 (¼) 4.27 (¼) 4.13 (¼) 3.82 (¼) 2.87 (¼) 120 15:1

6.62 (¼)

8.83 (¼) 8.63 (¼) 8.39 (¼) 7.93 (¼) 6.89 (¼) 240 7.5:1

13.20 (¼) 12.98 (¼) 12.64 (¼) 12.04 (¼) 10.92 (½)

17.66 (¼) 17.33 (¼) 16.90 (¼) 16.16 (½) 14.94 (½) 480 7.5:1

26.50 (¼) 26.04 (¼) 25.42 (¼) 24.38 (½) 22.99 (¾) 720

*Required Motor HP

0.73 (¼) 0.67 (¼) 0.48 (¼) ‡ 22.5 80:1

1.14 (¼) 0.94 (¼) ‡ 36 50:1

1.76 (¼) 0.85 (¼) 60 30:1

6.45 (¼) 6.26 (¼) 5.87 (¼) 4.88 (¼) 180 10:1

† Capacity data shown is for pumps with elastomeric diaphragms. Consult factory for performance

characteristics of pumps with PTFE diaphragms.

‡ Consult factory for performance specifications.

Pump

RPM

360 5:1

2

Gear

Ratio

5:1

Motor

RPM

1800

3600

P100-991-2400B

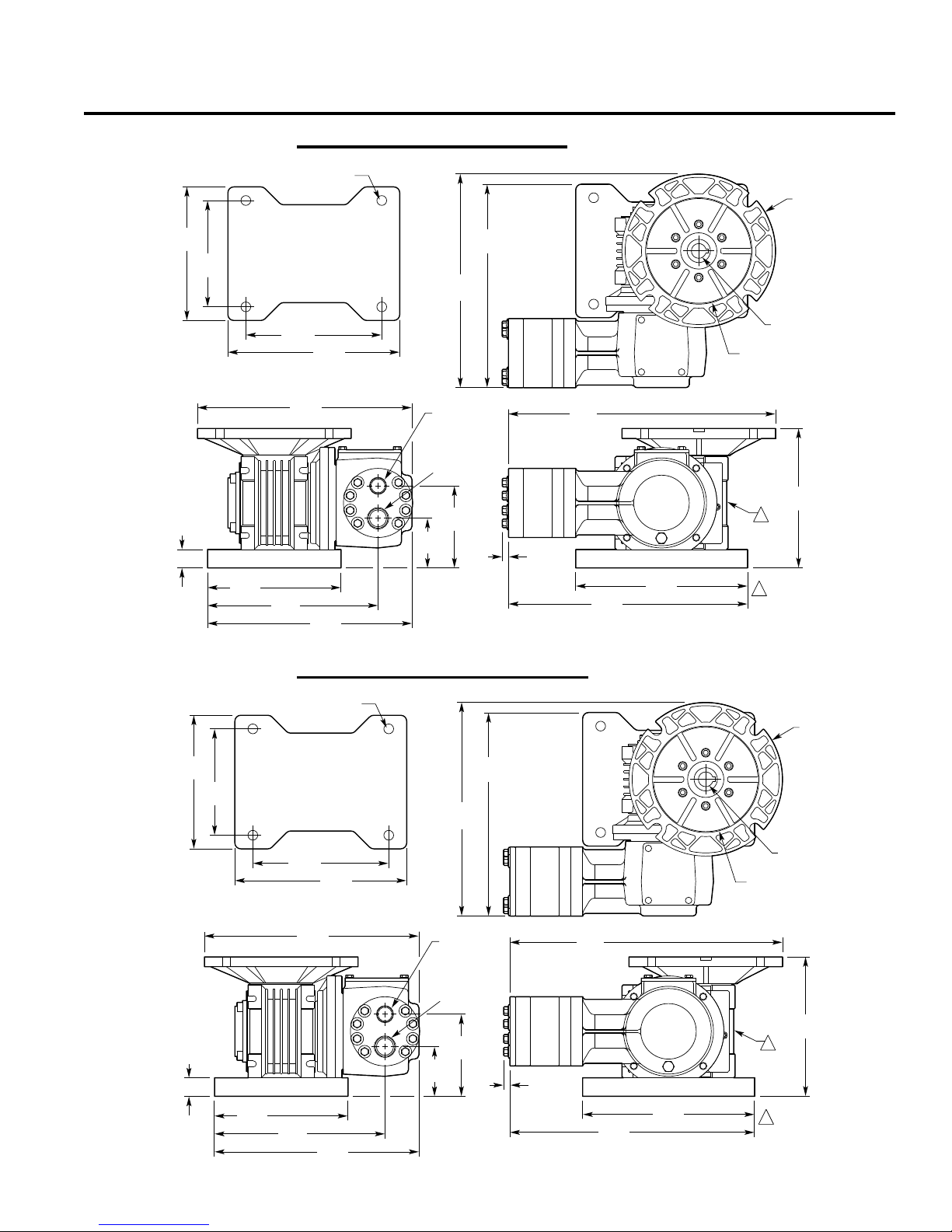

1/2" NPT or

1/2" BSPT

3/8" NPT or

3/8" BSPT

OUT

IN

5.75

(146.1)

7.27

(184.7)

8.61

(218.7)

9.03

(229.4)

Ø0.41

(10.4)

(4X)

5.65

(143.5)

4.50

(114.3)

0.78

(19.8)

5.90

(149.9)

Ø6.50

(165.1)

NEMA 56C

Ø0.625

(15.88)

Square Key

0.187

(4.75)

NEMA 56C Flange

Pilot

Ø4.500

(114.3)

Bolt Circle

Ø5.875

(149.2)

10.36

(263.1)

0.27

(6.9)

7.27

(184.7)

11.55

(293.4)

9.07

(230.4)

5.65

(143.5)

7.21

(183.1)

8.65

(219.7)

2.10

(53.3)

3.47

(88.1)

1

1

Note:

Worm Gear Reducer available

in the following ratios: 5:1, 7.5:1,

10:1, 15:1, 20:1, 25:1, 30:1, 40:1,

50:1, 60:1, 80:1, 100:1.

W0036

1/2" NPT or

1/2" BSPT

3/8" NPT or

3/8" BSPT

OUT

IN

5.75

(146.1)

7.27

(184.7)

8.61

(218.7)

9.03

(229.4)

Ø0.41

(10.4)

(4X)

5.65

(143.5)

4.50

(114.3)

0.78

(19.8)

5.90

(149.9)

Ø6.50

(165.1)

NEMA 56C

Ø0.625

(15.88)

Square Key

0.187

(4.75)

NEMA 56C Flange

Pilot

Ø4.500

(114.3)

Bolt Circle

Ø5.875

(149.2)

10.11

(256.8)

0.27

(6.9)

7.27

(184.7)

11.30

(287)

9.07

(230.4)

5.65

(143.5)

7.21

(183.1)

8.65

(219.7)

2.10

(53.3)

3.47

(88.1)

1

1

Note:

Worm Gear Reducer available

in the following ratios: 5:1, 7.5:1,

10:1, 15:1, 20:1, 25:1, 30:1, 40:1,

50:1, 60:1, 80:1, 100:1.

W0035

P100 Dimensions

P100 Models with Metallic Pumping Head

316 Stainless Steel

Hastelloy® C

Inches (mm)

P100 Models with Non-Metallic Pump Head

Kynar

Polypropylene

3

P100-991-2400B

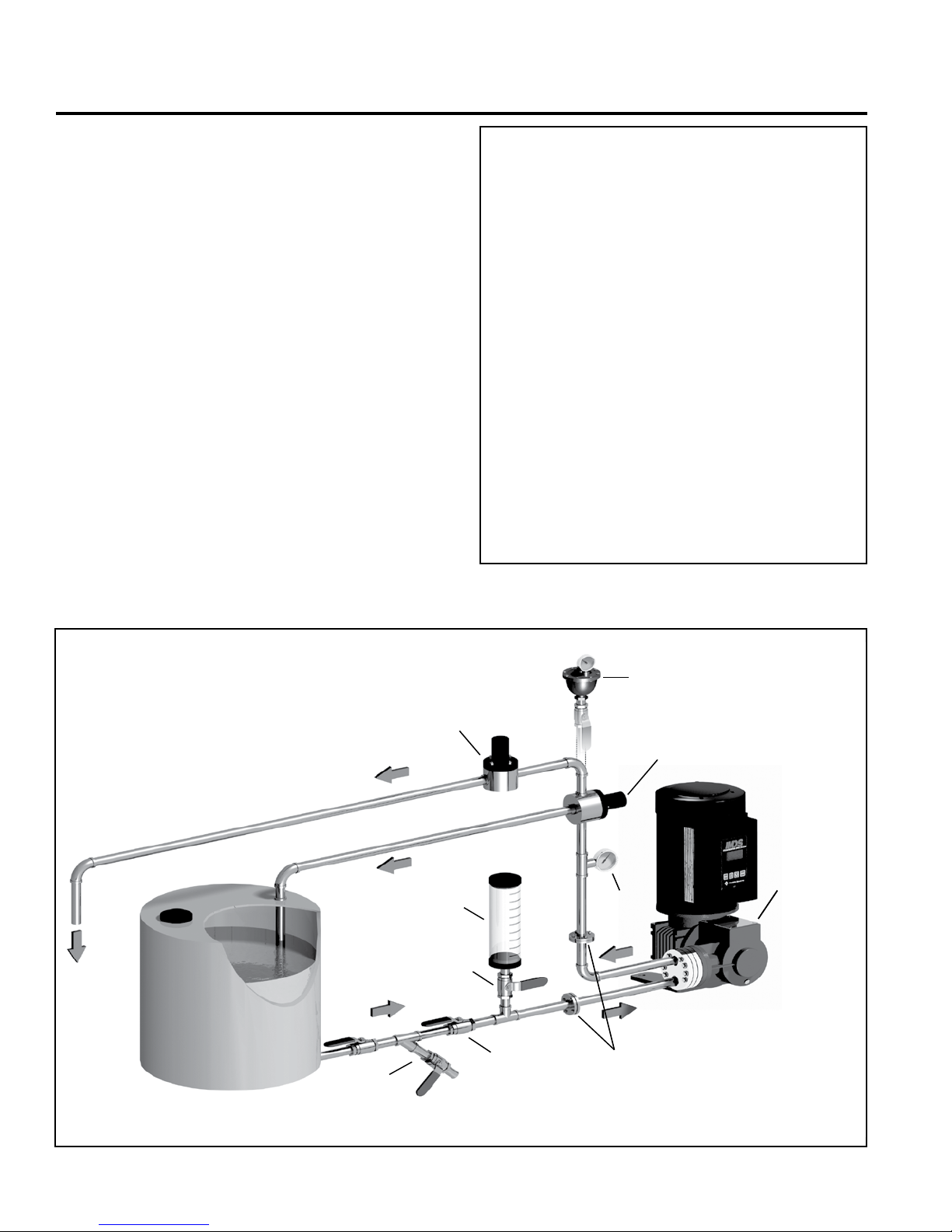

P100 Installation

P100

METERING PUMP

W0323

PULSATION

DAMPENER

(OPTIONAL)

CALIBRATION

CYLINDER

Y-STRAINER

ISOLATING VALVE

BALL VALVE

RELIEF

VALVE

FLANGES & MANIFOLDS

BACK PRESSURE

VALVE

(To process)

PRESSURE

GAUGE

P100

METERING PUMP

Location

NOTE: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

Locate the pump as close to the supply source as possible.

Install it in a lighted clean space where it will be easy to inspect

and maintain.

Motor and Controller

The P Series pump shaft can rotate in either direction, therefore

direction of motor shaft rotation is not critical.

Accessories

Consult installation drawing below for typical precision metering

fluid system components. Contact Wanner Engineering or the

distributor in your area for more details.

Important Precautions

Ad equat e F luid Supply. To avoid cavitat ion and

premature pump failure, be sure that the pump will have

an adequate fluid supply and that the inlet line will not be

obstructed. See Inlet Piping on page 6.

Positive Displacement. This is a positive-displacement

pump. To avoid severe system damage if the discharge line

ever becomes blocked, install a relief valve downstream

from the pump. See Discharge Piping on page 6.

Safety Guards. Follow all codes and regulations regarding

installation and operation of the pumping system.

Shut-Off Valves. Never install shut-off valves between

the pump and discharge pressure regulator, or in the

regulator bypass line.

Consult the Factory for the following situations:

• Extreme temperature applications (above 160°F or

below 40°F)

• Pressure feeding of pumps

• Viscous or abrasive fluid applications

• Chemical compatibility problems

• Hot ambient temperatures (above 110°F)

4

P100-991-2400B

P100 Installation

Inlet Piping

Provide for permanent or temporary installation of a compound

pressure gauge to monitor the inlet pressure. To maintain

maximum flow, the pump inlet should be under flooded suction

conditions at all times. Do not supply more than one pump

from the same inlet line.

Supply Tank

Use a supply tank that is large enough to provide time for any

trapped air in the fluid to escape. The tank size should be at

least twice the maximum pump flow rate.

Install a separate inlet line from the supply tank to each

pump.

Place a cover over the supply tank, to prevent foreign objects

from falling into it.

Hose Sizing and Routing

To minimize acceleration head and frictional losses, size the

suction line at least one size larger than the pump inlet, and

keep the suction line as short and direct as possible.

Recommendations:

• Keep inlet lines less than 3 ft. (1 m) long

• Use at least 5/8” (16 mm) I.D. inlet hose

• Minimize fittings (elbows, valves, tees, etc.)

Inlet Piping (Pressure Feed)

Provide for permanent or temporary installation of a pressure

gauge to monitor the inlet pressure. Pressure at the pump inlet

should not exceed 250 psi (17.3 bar). For higher pressures

install a pressure reducing valve. Do not supply more than

one pump from the same inlet line.

Note: System back pressure must exceed the pump inlet

pressure by at least 15 psi (1 bar) in order to prevent flow

thru.

Discharge Piping

Hose and Routing

Use the shortest, most-direct route for the discharge line.

Select pipe or hose with a working pressure rating of at least

1.5 times the maximum system pressure. EXAMPLE: Select a

1500 psi (103 bar) W.P. rated hose for a system to be operated

at 1000 psi (69 bar) gauge pressure.

Support the pump and piping independently.

Pressure Regulation

Install a pressure relief valve in the discharge line. Bypass

pressure must not exceed the pressure limit of the pump.

Size the valve so that, when fully open, it will be large enough

to relieve the full capacity of the pump without overpressurizing

the system.

Locate the valve as close to the pump as possible and ahead

of any other valves.

Adjust the pressure relief valve to no more than 10% over the

maximum working pressure of the system. Do not exceed the

manufacturer’s pressure rating for the pump or valve.

Route the bypass line to the supply tank.

CAUTION: Never install shutoff valves in the bypass line or

between the pump and pressure regulator or relief valve.

Provide for permanent or temporary installation of a pressure

gauge to monitor the discharge pressure at the pump.

Minimum Discharge Pressure

To ensure proper capacity control, a minimum discharge

pressure of 50 psi (3.5 bar) is required.

5

P100-991-2400B

Loading...

Loading...