Page 1

Operating instructions to Enhanced Controller module SD6

OPERATING INSTRUCTIONS

ENHANCED CONTROLLER MODULE

SD6

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 1

Edition 12 14

SD636bae.pdf

Page 2

Operating instructions to Enhanced Controller module SD6

Contents

1 General information

2 Product description 3

................................................................................................................................................................................. 32.1 General

................................................................................................................................................................................. 32.2 Field of application

................................................................................................................................................................................. 32.3 Conformity

................................................................................................................................................................................. 32.4 Labelling of the product

................................................................................................................................................................................. 42.5 Type code

................................................................................................................................................................................. 52.6 Technical Data

................................................................................................................................................................................. 82.7 Block diagram

3 Safety rules 9

................................................................................................................................................................................. 93.1 Installation / Commissioning / Parameterisation

4 Construction and Function 10

................................................................................................................................................................................. 104.1 Introduction

................................................................................................................................................................................. 104.2 Description of the Function

................................................................................................................................................................................. 104.3 Characteristic optimisation

................................................................................................................................................................................. 114.4 SD6 State machine

................................................................................................................................................................................. 124.5 Operating mode

................................................................................................................................................................................. 124.6 Analogue inputs

................................................................................................................................................................................. 134.7 Cablebreak detection

................................................................................................................................................................................. 134.8 Digital inputs

................................................................................................................................................................................. 144.9 Input for digital sensor

................................................................................................................................................................................. 154.10 Outputs

................................................................................................................................................................................. 154.11 Controller Modes

................................................................................................................................................................................. 214.12 Mode of operation

5 Operating and Indicating elements

................................................................................................................................................................................. 235.1 General

................................................................................................................................................................................. 235.2 Screw terminator view

................................................................................................................................................................................. 245.3 Control elements

6 Commissioning

................................................................................................................................................................................. 266.1 Connection instructions

................................................................................................................................................................................. 286.2 Connection examples

7 Settings 29

................................................................................................................................................................................. 297.1 Introduction

................................................................................................................................................................................. 297.2 Tips for the first commissioning

................................................................................................................................................................................. 307.3 Start up help

................................................................................................................................................................................. 327.4 Default settings

................................................................................................................................................................................. 347.5 File-Menu

................................................................................................................................................................................. 377.6 Profile-Menu

................................................................................................................................................................................. 437.7 Parameters-Menu

................................................................................................................................................................................. 527.8 Configuration-Menu

................................................................................................................................................................................. 717.9 Commands-Menu

................................................................................................................................................................................. 737.10 Fieldbus-Menu

................................................................................................................................................................................. 737.11 Setup mode

................................................................................................................................................................................. 747.12 Analysis-Menu

................................................................................................................................................................................. 797.13 Help-Menu

8 System does not work 80

................................................................................................................................................................................. 808.1 Procedure

9 PASO DSV/SD6 Installation and Operation 81

................................................................................................................................................................................. 819.1 System presupposition

................................................................................................................................................................................. 819.2 Installation

................................................................................................................................................................................. 819.3 Connection to the Wandfluh card

................................................................................................................................................................................. 829.4 Mode "Off Line" and "On Line"

................................................................................................................................................................................. 829.5 Communication start up

................................................................................................................................................................................. 839.6 Communication interruption

................................................................................................................................................................................. 849.7 Program description

................................................................................................................................................................................. 869.8 Starting of PASO DSV/SD6

................................................................................................................................................................................. 879.9 Store parameter

................................................................................................................................................................................. 879.10 Limiting value error

................................................................................................................................................................................. 889.11 Description of Commands

10 Disposal 89

11 Additional information

23

26

89

3

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 2

Edition 12 14

SD636bae.pdf

Page 3

Operating instructions to Enhanced Controller module SD6

· Part number

· Serial number

· Software version

· Firmware version

· Card type

· Hardware configuration

1 General information

This operating instructions makes it possible to use the SD6-Electronics safely and according to specification.

The operating instructions includes instructions which Wandfluh as the manufacturer, or its resale organisations

(Wandfluh sister companies or distributors), provide to users within their duty to instruct.

For this purpose, the operating instructions mainly includes:

· information about use according to specification, installation and commissioning of the SD6-Electronics

· information about safety in dealing with control.

2 Product description

2.1 General

The SD6-Electronics is integrated in a case for top-hat rail fastening. The connections are provided by terminal

screw blocks.

2.2 Field of application

The field of application of the SD6-Electronics is situated in the industrial field.

2.3 Conformity

The SD6-Electronics have been developed and tested in accordance with the latest technical standards. Applied

in particular was the EU Guideline 2004/108/EG (EMC Guideline).

2.4 Labelling of the product

With the PC parameterisation software PASO DSV/SD6, the following information can be directly read-off the

SD6-Electronics (=electronic type code):

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 3

Edition 12 14

SD636bae.pdf

Page 4

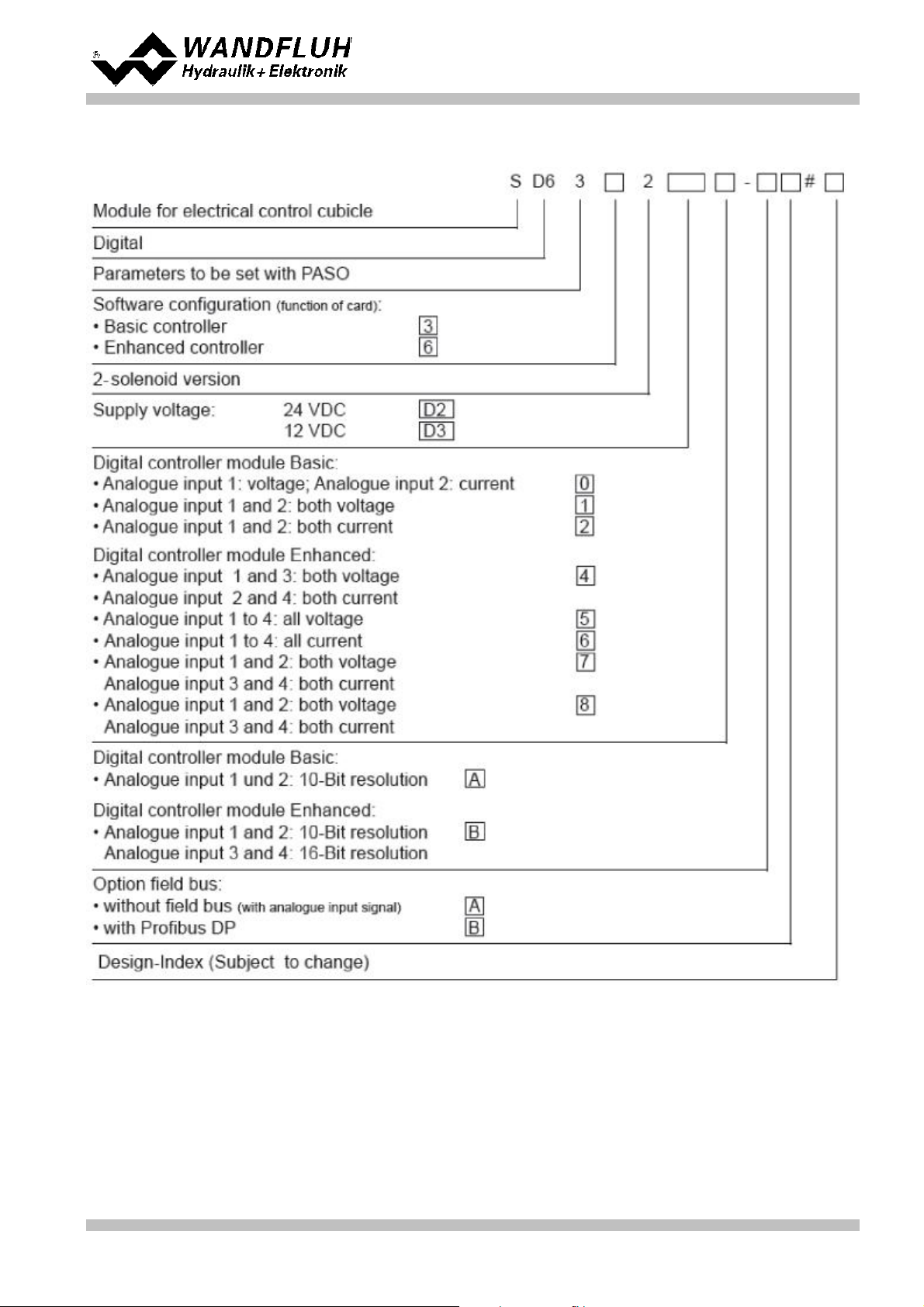

2.5 Type code

Operating instructions to Enhanced Controller module SD6

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 4

Edition 12 14

SD636bae.pdf

Page 5

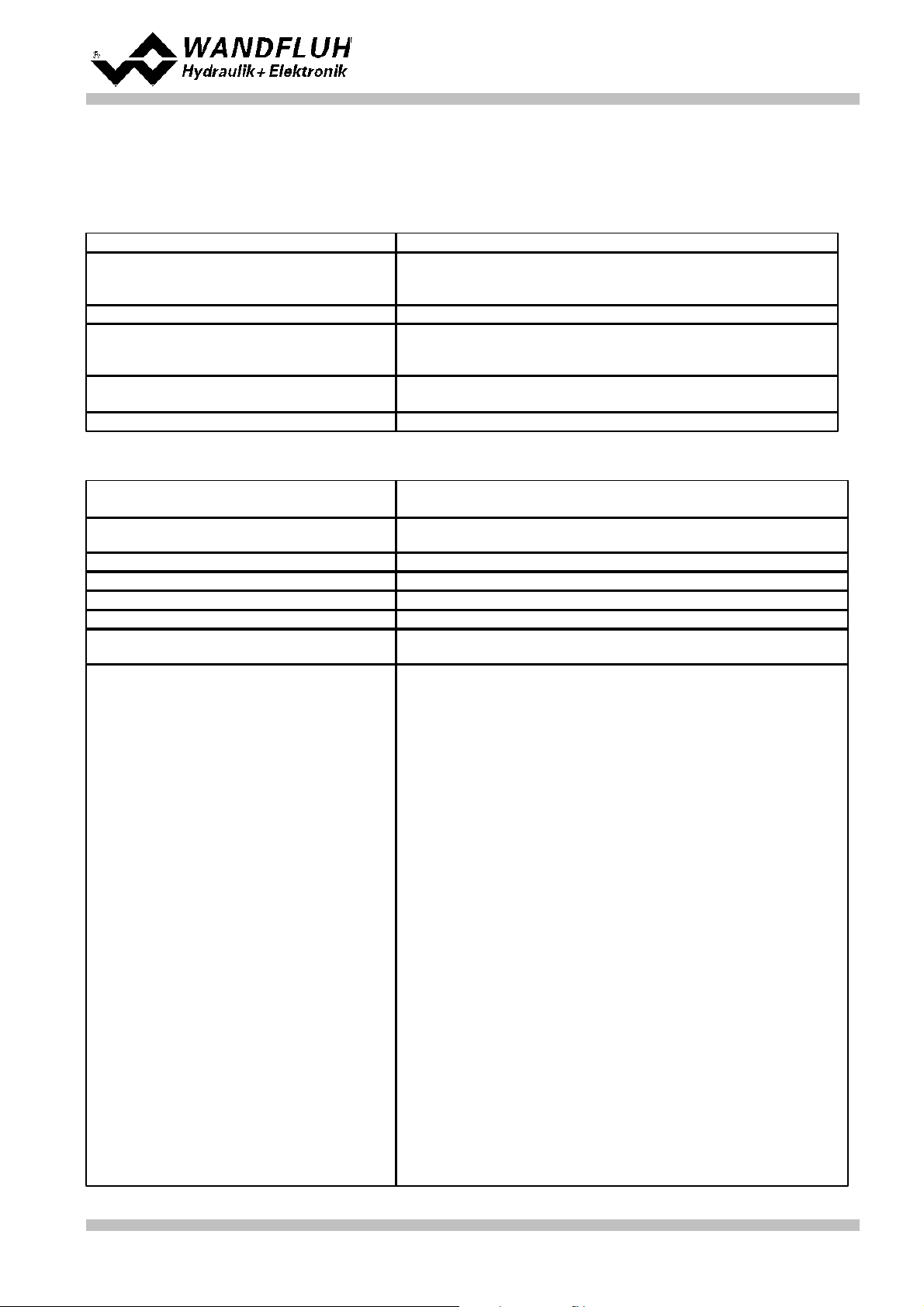

2.6 Technical Data

Design

Integrated in electronic case for top-hat rail clamping

Dimension

Amplifier and Basic Controller: 105 x 114 x 22.5mm

Enhanced Controller: 105 x 114 x 45mm

Amplifier and Controller with Profibus: 105 x 114 x 45mm

Mounting

For top-hat rail clamping

Weight

Amplifier and Basic Controller: 130g

Enhanced Controller: 220g

Amplifier and Controller with Profibus: 240g

Connection

Terminal screw blocks, max dimension 2.5mm

2

1 USB interface (connector type B)

Protection class

IP30 acc. to EN 60 529

Supply voltage

(depending on the type)

24 VDC

or 12 VDC

Voltage range

Supply voltage 24 VDC: 21 ... 30 VDC

Supply voltage 12 VDC: 10.5 ... 15 VDC

Ripple on supply voltage

< ±5 %

Fuse

Customer must integrate a slow fuse into his electrical system

Temperature drift

< 1% with DT = 40°C

No load current

40 ... 50 mA

Max. solenoid current

24VDC version 1.8 A

12VDC version 2.3 A

Analogue inputs

2 differential inputs 10-Bit (analogue input 1 + 2)

2 differential inputs 16-Bit (analogue input 3 + 4)

All inputs are not galvanically separated

SD6362DX4-BX

Analogue input 1:

Analogue input 2:

Analogue input 3:

Analogue input 4:

0...±10VDC

0...20mA, 4...20mA

0...±10VDC

0...20mA, 4...20mA

SD6362DX5-BX

Analogue input 1:

Analogue input 2:

Analogue input 3:

Analogue input 4:

0...±10VDC

0...±10VDC **

0...±10VDC

0...±10VDC

SD6362DX6-BX

Analogue input 1:

Analogue input 2:

Analogue input 3:

Analogue input 4:

0...20mA, 4...20mA

0...20mA, 4...20mA

0...20mA, 4...20mA

0...20mA, 4...20mA

SD6362DX8-BX

Analogue input 1:

Analogue input 2:

Analogue input 3:

Analogue input 4:

0...±10VDC

0...±10VDC

0...20mA, 4...20mA

0...20mA, 4...20mA

SD6362DX8-BX

Analogue input 1:

Analogue input 2:

Analogue input 3:

Analogue input 4:

0...20mA, 4...20mA

0...20mA, 4...20mA

0...±10VDC

0...±10VDC

**) 0...10VDC on SD6 with Profibus

2.6.1 General specifications

2.6.2 Electrical specifications

Operating instructions to Enhanced Controller module SD6

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 5

Edition 12 14

SD636bae.pdf

Page 6

Operating instructions to Enhanced Controller module SD6

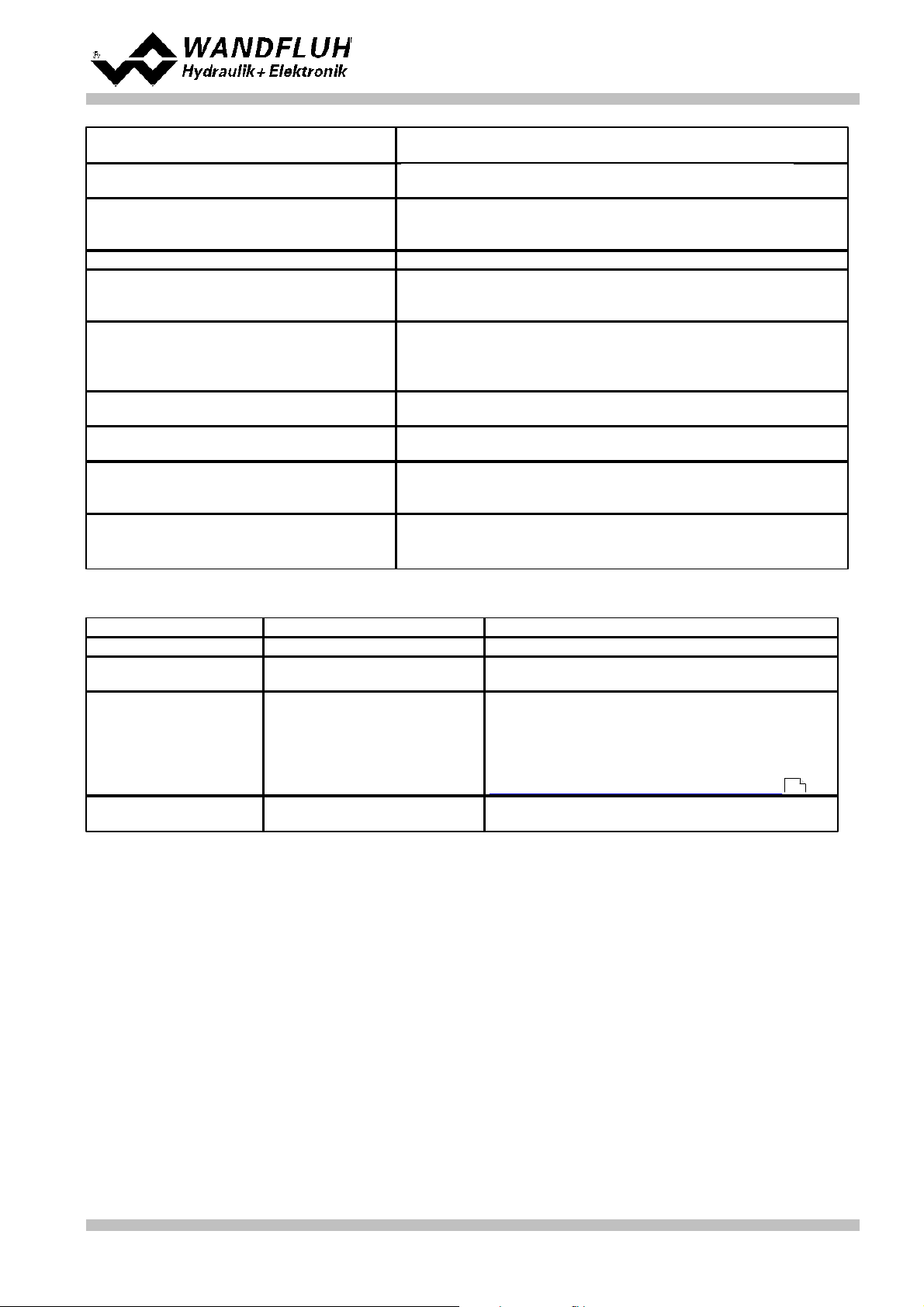

Input resistance

Voltage input against ground > 18 kOhm

Burden for current input = 250 Ohm

Input for digital sensors

9-pin D-SUB connector with RS-422 interface for SSI and

Start/Stop sensors

Digital inputs

8 inputs active-high

Switching threshold high 6 - 30VDC

Switching threshold low 0 - 1VDC

Serial interface

1 USB interface (Connector Type B)

Stabilised output voltage

Supply voltage 24 VDC: + 10 VDC

Supply voltage 12 VDC: + 8 VDC

max. load 30 mA

Solenoid current

Minimum current Imin adjustable 0 ... 950 mA

Maximum current Imax adjustable

- Supply voltage 24 VDC: Imin ... max. 1.8 A

- Supply voltage 12 VDC: Imin ... max. 2.3 A

Dither

Frequency adjustable 20 ... 250 Hz

Level adjustable 0 ... 200 mA

Analogue output

Output voltage range

max. load

+/– 10 VDC

+/– 3 mA

Digital outputs

4 outputs Lowside Switch.

Umax 40 VDC

Imax -0.7 A

EMC

Immunity

Emission

EN 61000-6-2

EN 61000-6-4

Storage

packing:

The module must be stored in the original packing

Temperature range:

-25 ... +85° C

Resistance to alkali and acid:

The module must be protected against alkalis and

acids

In operation

Temperature range

-20 ... +70° C

The total solenoid current of simultaneously

powered solenoids depends on the ambient

temperature.

Further information can be found in chapter

Solenoid outputs and ambient temperature .

Resistance to alkali and acid:

The module must be protected against alkalis and

acids

2.6.3 Environment

7

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 6

Edition 12 14

SD636bae.pdf

Page 7

Operating instructions to Enhanced Controller module SD6

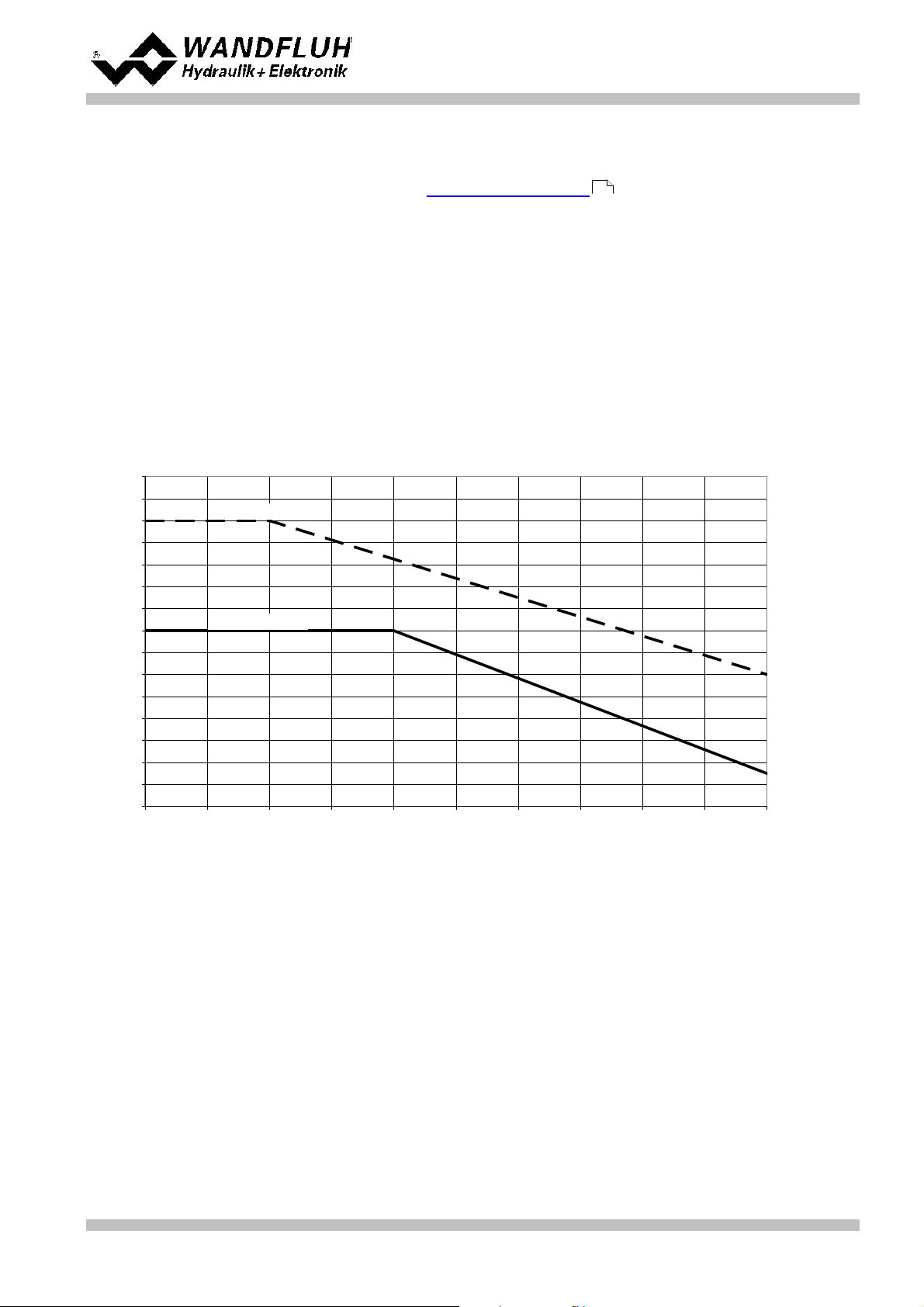

SD6: Derating of Total Solenoid Current when both Solenoid Outputs activated simultaneously

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

4000

4200

4400

4600

4800

5000

20 25 30 35 40 45 50 55 60 65 70

Ambient Temperature [°C]

Total Solenoid Current [mA]

Derating for 12V SD6

Derating for 24V SD6

2.6.4 Solenoid Outputs and Ambient Temperature

If only one solenoid output is powered at a time, then there are no restrictions and the single solenoid current

may reach the maximum current according to the Electrical Specifications over the whole temperature range.

5

But the total solenoid current of simultaneously powered solenoids depends on the ambient temperature.

Exceeding this current limit will trip the overcurrent protection circuit, the SD6 falls into the failure state and

blocks all function.

Solenoids can be powered simultaneously, i.e.on the amplifier in operating mode 4, or with inverted solenoid

outputs.

If solenoids are powered with more voltage than their nominal voltage and are so over-energized, then at fast

switching-on, the overcurrent protection may trip and the SD6 may fall into failure state and block all function.

The following graphics shows the maximum allowed total solenoid current over ambient temperature when both

solenoids are powered at the same time.

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 7

Edition 12 14

SD636bae.pdf

Page 8

LED red

LED yellow

DC

DC

X1-5

X1-6

X1-7

Supply voltage

Stailized

output voltage

+

0 VDC

LED

green

X1-9

X1-10

-

+

Analogue input 1

X1-11

X1-12

-

+

Analogue input 2

X1-1

Digital input 1

X1-2

Digital input 2

Digital ground

Solenoid A

U

I

X1-15

X1-16

Solenoid B

U

I

X1-13

X1-14

Digital output 1

X1-3

Digital output 2

X1-4

Microcontroller

FEPROM

RAM

EEPROM

PWM

A/D

PWM

A/D

+

-

+

-

A

D

Digital output 3

Digital output 4

-

Analogue input 3

-

+

Analogue input 4

+

-

+

-

A

D

10-Bit

16-Bit

Stailized

output voltage

Ref

SPI

Digital input 3

Digital input 4

Digital input 5

Digital input 6

Digital input 7

Digital input 8

SPI

D

A

12-Bit

Analogue output

X2-1

X2-2

X2-4

USBX2-3

+

-

Ref

Output +24VDC

Output +5VDC

Clock output +

Clock output Data input +

Data input -

Sensor-ground

Analogue ground

X1-8

Analog ground

X1-17

X1-18

X1-19

X1-20

X1-21

X1-22

X1-29

X1-31

X1-25

X1-26

X1-27

X1-28

+

X1-32

X1-30

X1-23

X1-24

X3-2

X3-1

X3-6

X3-5

X3-8

X3-9

X3-7

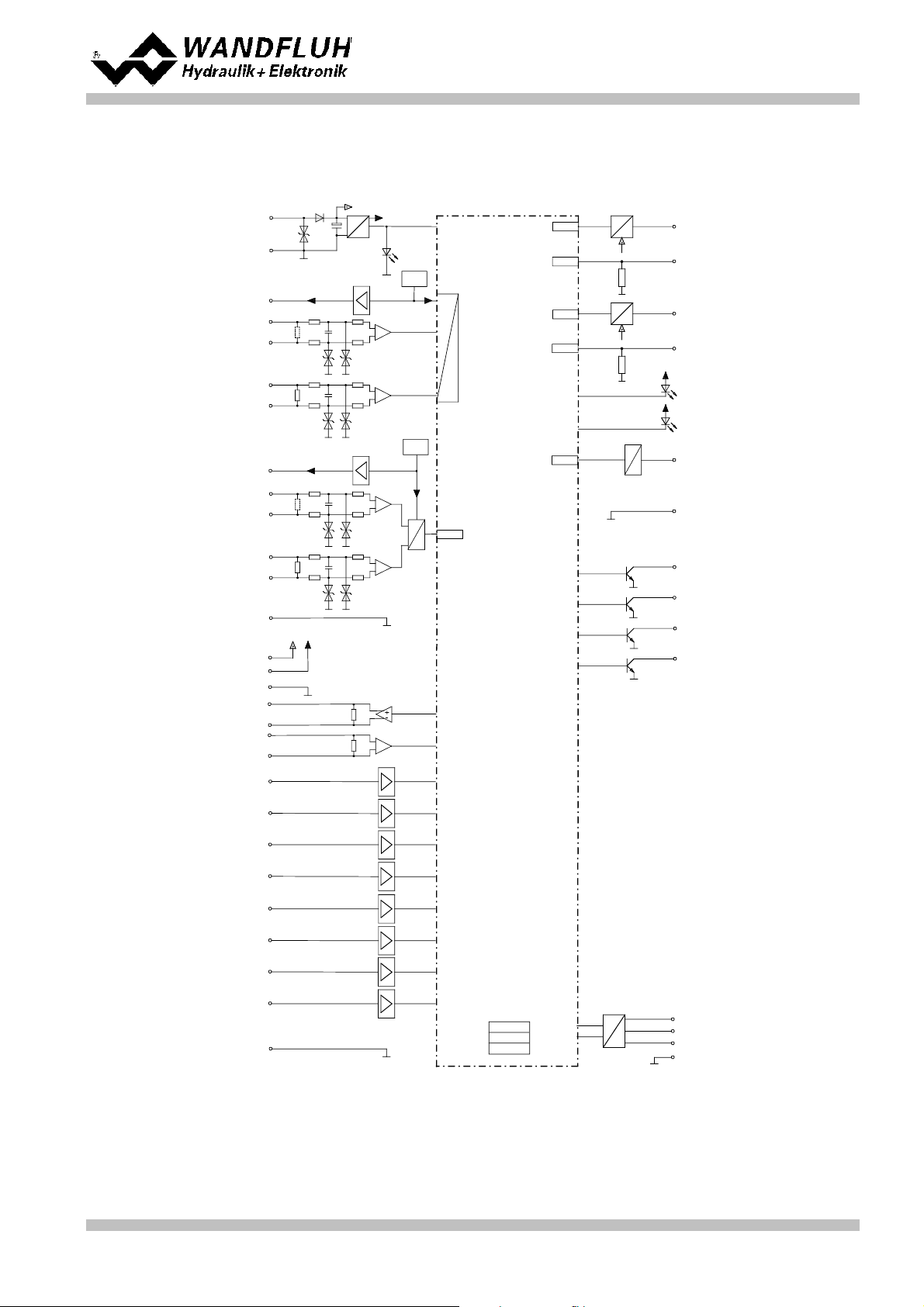

2.7 Block diagram

Driving through the analogue interface

Operating instructions to Enhanced Controller module SD6

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 8

Edition 12 14

SD636bae.pdf

Page 9

Operating instructions to Enhanced Controller module SD6

3 Safety rules

3.1 Installation / Commissioning / Parameterisation

· These operating instructions have to be carefully studied beforehand and the instructions are to be complied

with.

· Prior to the installation, all power supply voltages and any other energy sources have to be disconnected.

· The installation/assembly must only be carried out by specialist personnel with electrical knowledge.

· Take into account precautionary measures concerning components on the module, which are subject to

damage as a result of electrostatic discharge.

· Wrong manipulations by the personnel cannot be prevented by the SD6-Electronics.

· Before the switching on of the supply voltage, the fuse protection, the correct wiring and the conformity of the

power supply voltage with the permissible supply voltage range have to be verified.

· The SD6-Electronics monitors the working conditions within the electronics and

within the installation. Uncontrolled movements or force changes caused by

unforeseen errors of the SD6-Electronics cannot be prevented in any case.

· Danger for persons has to be avoided by installing an emergency stop device which

cuts off the power to the system.

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 9

Edition 12 14

SD636bae.pdf

Page 10

4 Construction and Function

Operating instructions to Enhanced Controller module SD6

Refer to section "Block diagram" .

8

4.1 Introduction

· All inputs and outputs have to be contacted through the terminal screw block

· At the device front panel, there is a USB interface, through which the parameterisation and the diagnostics

can be made by using the PC-Parameterisation software PASO DSV/SD6

· In the factory, the SD6-Electronics are adjusted with the default values. The adjustment to the valves being

used, has to performed by the user.

4.2 Description of the Function

With the SD6-Electronics, it is possible to build different closed circuit controls. Apart from controls for pressure,

volume flow or position, also pQ- and alternating controls can be implemented. They can optionally be adjusted

in the form of a controller mode. In addition, an amplifier part is integrated, with which the connected valve resp.

its solenoid is directly driven.

The command value is conducted to the controller as an electric signal, a sensor records the feedback value,

this signal is also conducted to the controller. In correspondence with the control difference (command value feedback value), a control signal (solenoid current) is output to the valve.

By means of the scaling of the command value and feedback value, all further inputs can be made in the

required, resp., selectable physical unit (e.g., bar or mm, etc.). When the command value has been reached,

then the SD6 is capable of outputting a digital signal (optionally an „Error“- or „Target window reached “ - signal).

The SD6 - controller has a command value generator, with which the up - and down ramp of the internal

command value can be predefined. The controller is designed as a PID - controller. The control characteristics

as a result of this can be equalised and adapted to the control circuit. Furthermore, it is also possible to

switch-off the control system completely for testing - and adjusting purposes. The SD6 in this case operates in

correspondence with normal amplifier electronics.

Furthermore the controller module “SD6” comprises digital inputs for the enabling, for controlling the manual

operation and for the profile generator as well as digital outputs, which output the conditions „Error“ or „Target

window reached “.

Changed parameters can be saved in a non-volatile memory, so that following a renewed switching-on of the

control system they are still available once again.

The SD6 - electronics in addition have a signal recording function. By means of PASO, this makes possible a

recording of different system signals, such as, e.g., command value / feedback value, control difference,

solenoid currents, etc., which are able to be graphically displayed on a common time axis.

The manual operating mode makes available commands such as Forwards, Backwards, Rapid Speed and

Creep Speed. With this it is possible to put the connected hydraulics into operation without a super-ordinate

control system.

4.3 Characteristic optimisation

The SD6 electronics are provided with a possibility to optimise the characteristic “Preset value input – solenoid

current output”. The user is able to create a characteristic (e.g. a linearised characteristic) which matches his

own application. The characteristic optimisation can be turned on or off (refer to “Parameters_Valves” on page

21). This setting is available only with a SD6-electronics with software version higher than 1.1.1.6 and PASO with

software version higher than 1.5.0.9!

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 10

Edition 12 14

SD636bae.pdf

Page 11

Operating instructions to Enhanced Controller module SD6

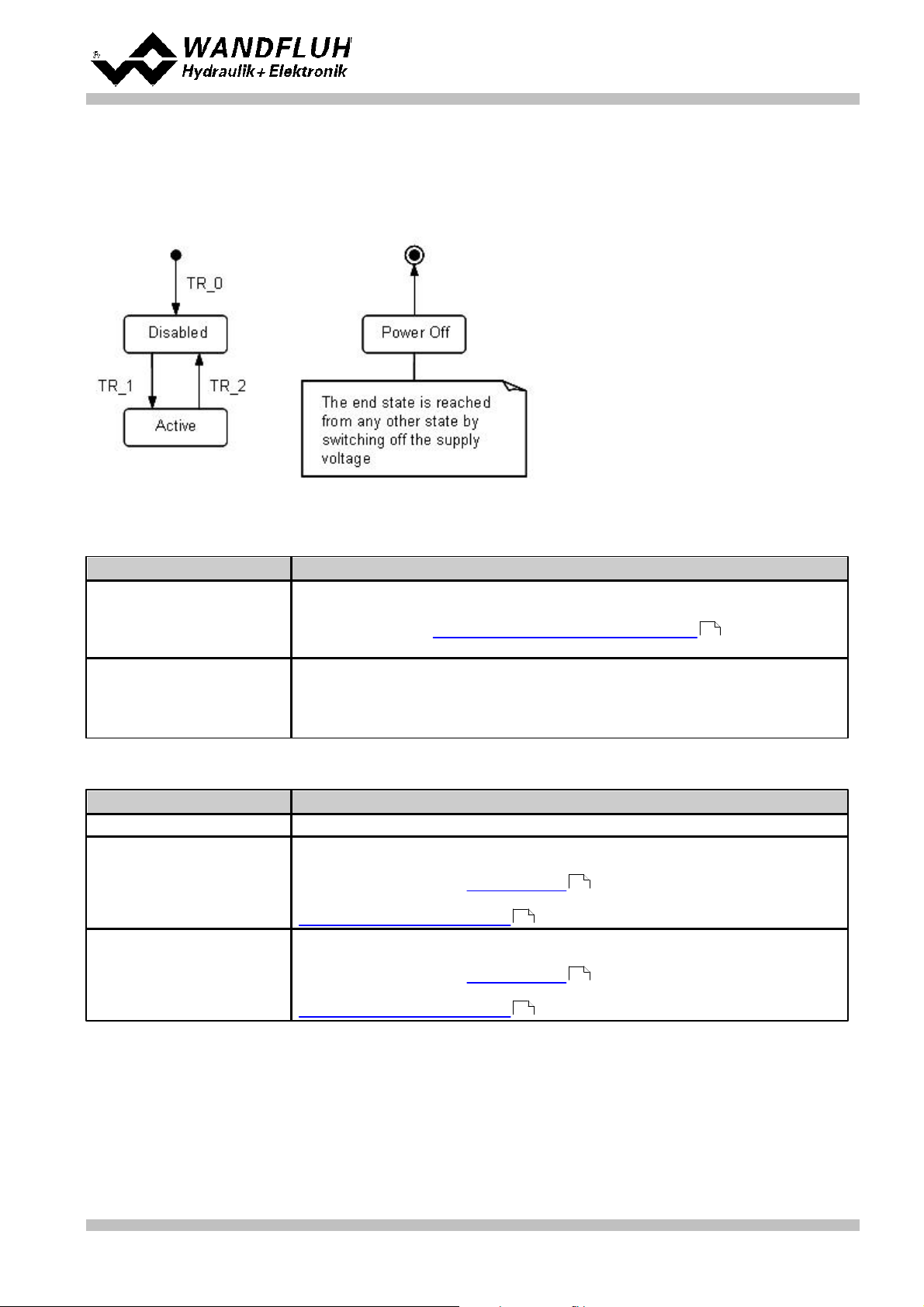

Status

Description

Disabled

· The SD6-Electronics are disabled, no solenoid current will be active

· In this state, with the command "Local operation" resp. "PASO operation"

(refer to section "Commands_Local Operating / PASO" ) the operating

mode can be set.

Active

· The SD6-Electronics are enabled

· The SD6-Electronics can be operated according to the selected operating

mode

· Changing the operating mode is not possible

Transition

Description

TR_0

Switching-on the supply voltage

TR_1

Enable

This is made in the operating mode "Local" through the digital input "Enable

control" (refer to section "Digital inputs" ) and in the operating mode

"Remote PASO" through the command "Enable" (refer to section

"Commands_Disable / Enable" ).

TR_2

Disable

This is made in the operating mode "Local" through the digital input "Enable

control" (refer to section "Digital inputs" ) and in the operating mode

"Remote PASO" through the command "Enable" (refer to section

"Commands_Disable / Enable" ).

4.4 SD6 State machine

In the following, with the help of a status diagram it is described, how the start-up of the SD6-Electronics takes

place and which statuses are reached when and how.

The following table describes the possible statuses and what is done in these statuses:

The following table describes the transitions from one status to the next one:

13

72

13

72

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

72

Page 11

Edition 12 14

SD636bae.pdf

Page 12

Operating instructions to Enhanced Controller module SD6

Operating mode

Activating with

Description

Local

Menu point "Commands_Local Operating"

Operating via analogue and digital inputs

on the SD6-Electronics

Remote PASO

Menu point "Commands_PASO Operating

Operating direct with the PASO

SD6-Type

Analogue input 1

(10-bit resolution)

Analogue input 2

(10-bit resolution)

Analogue input 3

(16-bit resolution)

Analogue input 4

(16-bit resolution)

SD6362DX4-BX

0...10VDC

0...±10VDC

(only with 2-sol

control modes)

0...20mA, 4...20mA

0...10VDC

0...±10VDC

(only with 2-sol

control modes)

0...20mA, 4...20mA

SD6362DX5-BX

0...10VDC

0...±10VDC

(only with 2-sol

control modes)

0...10VDC

0...±10VDC **

(only with 2-sol

control modes)

0...10VDC

0...±10VDC

(only with 2-sol

control modes)

0...10VDC

0...±10VDC

(only with 2-sol

control modes)

SD6362DX6-BX

0...20mA, 4...20mA

0...20mA, 4...20mA

0...20mA, 4...20mA

0...20mA, 4...20mA

SD6362DX7-BX

0...10VDC

0...±10VDC

(only with 2-sol

control modes)

0...10VDC

0...±10VDC **

(only with 2-sol

control modes)

0...20mA, 4...20mA

0...20mA, 4...20mA

SD6362DX8-BX

0...20mA, 4...20mA

0...20mA, 4...20mA

0...10VDC

0...±10VDC

(only with 2-sol

control modes)

0...10VDC

0...±10VDC

(only with 2-sol

control modes)

4.5 Operating mode

The SD6-Electronics have 2 operating modes. The following table describes, what can be done in the different

operating modes and how they can be activated:

The current operating mode is displayed in the status line (refer to section "Starting of PASO DSV/SD6" ).

86

For more information about the operating mode "Local" and "Remote", please refer to section

"Commands_Local Operating / PASO" .

72

4.6 Analogue inputs

· The applied analogue signal is digitised in the 10Bit A/D converter at analogue inputs 1 and 2 resp. in the 16Bit

A/D converter at analogue inputs 3 or 4.

Attention: By the input range 4 ... 20mA, the resolution is < 10Bit resp. < 16Bit!

· Differential inputs

All analogue inputs are differential inputs. Differential inputs are used if the ground potential of the external

command value generator does not agree with the ground on the SD6-Electronics.

If the differential input is intended to use like an analogue input against ground, the - (minus) connection of the

differential input must be connected to the ground of the SD6-Electronics. In this case please attend that the

solenoid current can cause a voltage drop between the SD6-Electronics and the power supply. It is

recommended to connect the - (minus) connection as near as possible to the power supply.

**) 0...+10VDC on SD6 with Profibus

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 12

Edition 12 14

SD636bae.pdf

Page 13

Operating instructions to Enhanced Controller module SD6

4.7 Cablebreak detection

The analogue inputs with input signal range of 4...20mA can be detected for a cablebreak. If a cablebreak is

present (input signal less than 3mA), the corresponding solenoid outputs will be blocked and the output "Error"

will be active. The following conditions had to be performed:

· The input signal must be a current value 4 ... 20mA

· The parameter "Cablebreak" must be on "On"

Attention: Until a cablebreak will be detected, a time delay of about 100ms will pass. During this time, the

cylinder can make unintentional movements or unintentional force changes.

4.8 Digital inputs

· Digital input 1 " Enable control"

The digital input is active-high (refer to section "Electrical specifications" ).

If this input is set, the SD6-Electronics are enabled. Without this enable, no solenoid current will be output.

This digital input can be set also through the parameterisation software PASO DSV/SD6 (refer to section

"Configuration_Digital I/O" ).

65

· Digital input 2 "Automatic / Manual operation"

At manual operation (digital input low) the command value is being generated by digital inputs 3...5. For this

two velocities are available in both directions.

At automatic operation (digital input high) the command value is being generated by the profile generator or

read from an analog input, depending on the state of the digital inputs 3...8.

To switch between manual and automatic operation, the SD6 has to be disabled by deactivating digital input

1.

· Digital input 3 "Manual forward" or "Profile / Sequence"

Manual operation: When the digital input is activated the command value will be incremented. The velocity

depends on digital input 5 "Rapid speed / Creep speed".

Automatic operation: Choice between running through a complete profile (digital input high) or an individual

sequence (digital input low).

· Digital input 4 "Manual reverse" or "Start"

Manual operation: When the digital input is activated the command value will be decremented. The velocity

depends on digital input 5 "Rapid speed / Creep speed".

Automatic operation: Depending on digital input 3 "Profile / Sequence" the running through of the complete

profile or of the next sequence only is started.

· Digital input 5 "Rapid speed / Creep speed" or "Stop"

Manual operation: Changeover between rapid speed (digital input high) and creep speed (digital input low).

Automatic operation: As long as the digital input is high the axis can move. As soon as the digital input

becomes low the movement is stopped (set-point value = feedback value).

· Digital input 6...8 "Profile selection"

These digital inputs only take effect in automatic operation. Profiles can only be used in closed loop control

modes (an exception is the pQ-control mode, where no profiles can be used). How to select the profiles is

shown in the table below. If profile 0 is selected the command value will be read from one of the analogue

input. A detailed description of the profiles is located in the section "Profile-Menu"

5

37

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 13

Edition 12 14

SD636bae.pdf

Page 14

Operating instructions to Enhanced Controller module SD6

Digital input 6

Digital input 7

Digital input 8

Profile

000

* 0 (analogue command value)

100101021103001410150116111

7

* with control mode "Alternating control (2-sol)" the analogue command value will not read if profile selection

is 0. In this case, the command value will be set to the actual value (= axis remains controlled at the actual

position). Should be used an analogue command value, the corresponding signal type must be selected

(refer to section "Configuration_Signal Scaling ").

53

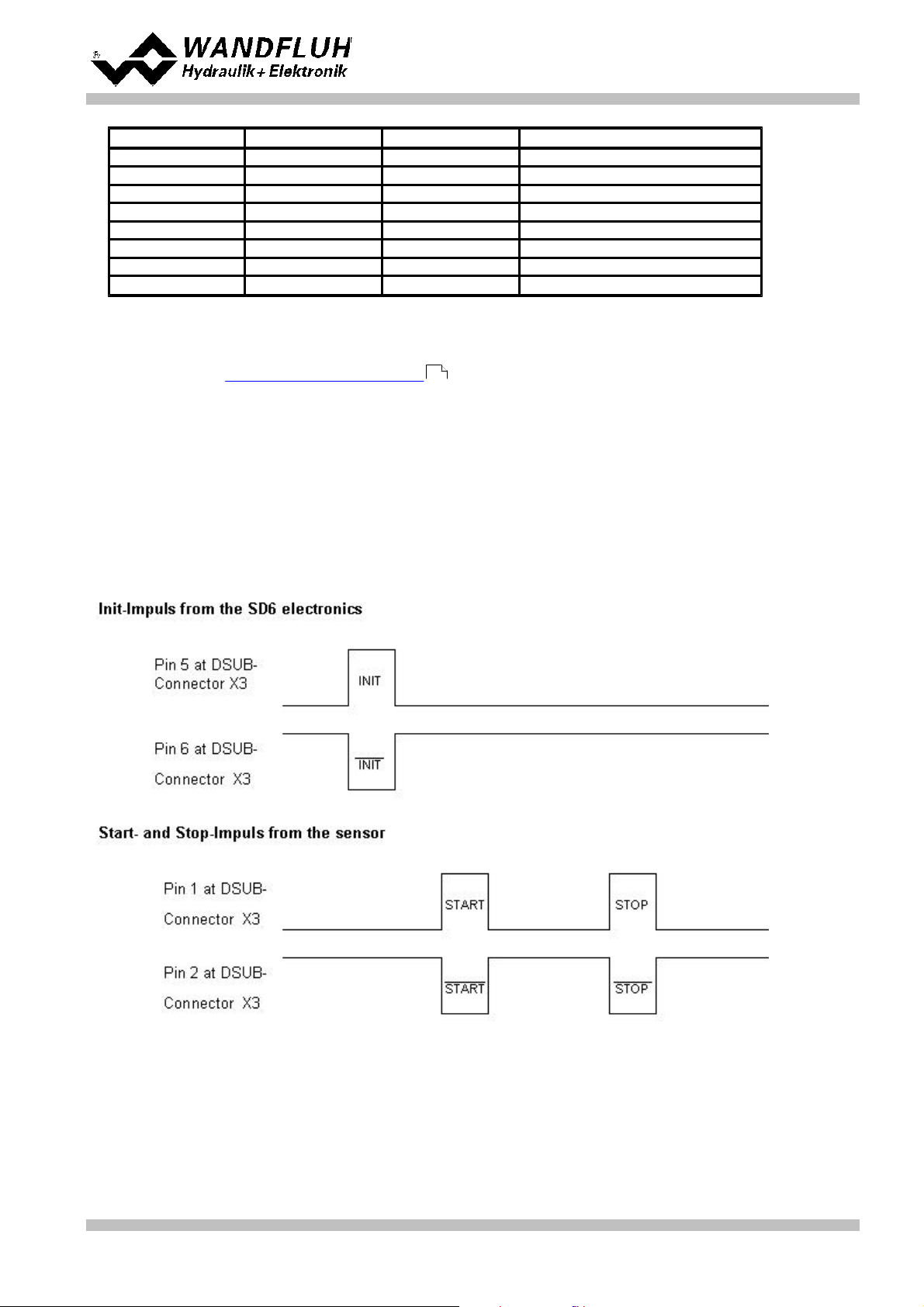

4.9 Input for digital sensor

This input makes it possible to connect digital sensors with SSI- or Start/Stop-Interface.

SSI-Interface

SSI-Interface according RS-422 standard with a baudrate of 300kHz.

Start/Stop-Interface

This Interface supports sensors with a Start/Stop-Interface as they are available e.g. from Balluff or MTS.

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 14

Edition 12 14

SD636bae.pdf

Page 15

4.10 Outputs

· Proportional solenoid outputs A and B

The max. 2 solenoid outputs have a current output with 1000 Hz Pulse-Width-Modulation with superimposed

dither.

· Analog output

The analog output can be assigned to the following signals via the PASO DSV/SD6 (depending on the control

mode, different signals are available):

- command value for the solenoid driver

- scaled command value

- scaled feedback value (only with closed loop control modes)

- scaled control deviation (only with closed loop control modes)

The signal at the analog output can be used for driving a valve with integrated electronics which has a voltage

interface. The output level can be adjusted (refer to section "Configuration_Analog output" ).

· Digital outputs

The following digital outputs are available:

- Digital outut 1 "Error"

- Digital outut 2 "Solenoid B active", "Inside target window / End of Seq"

- Digital outut 3 "Trailing error"

- Digital outut 4 "Profile End reached"

The digital output can be configured by the PASO DSV/SD6 Software (refer to section "Configuration_Digital

I/O" ).

Operating instructions to Enhanced Controller module SD6

65

65

4.11 Controller Modes

The SD6-Electronics provide the following controller modes:

· Controller mode 3 "Pressure/flow valve open loop"

Control of a pressure relief-, pressure reducing- or flow control valve in open loop (without feedback signal).

The number of solenoids, which are activated, depends on the selected mode of operation (refer to section

"Mode of operation" ).

This mode of operation corresponds to the "Device Control Mode = 3" of the fieldbus device profile Fluid

Power Technology.

52

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 15

Edition 12 14

SD636bae.pdf

Page 16

Operating instructions to Enhanced Controller module SD6

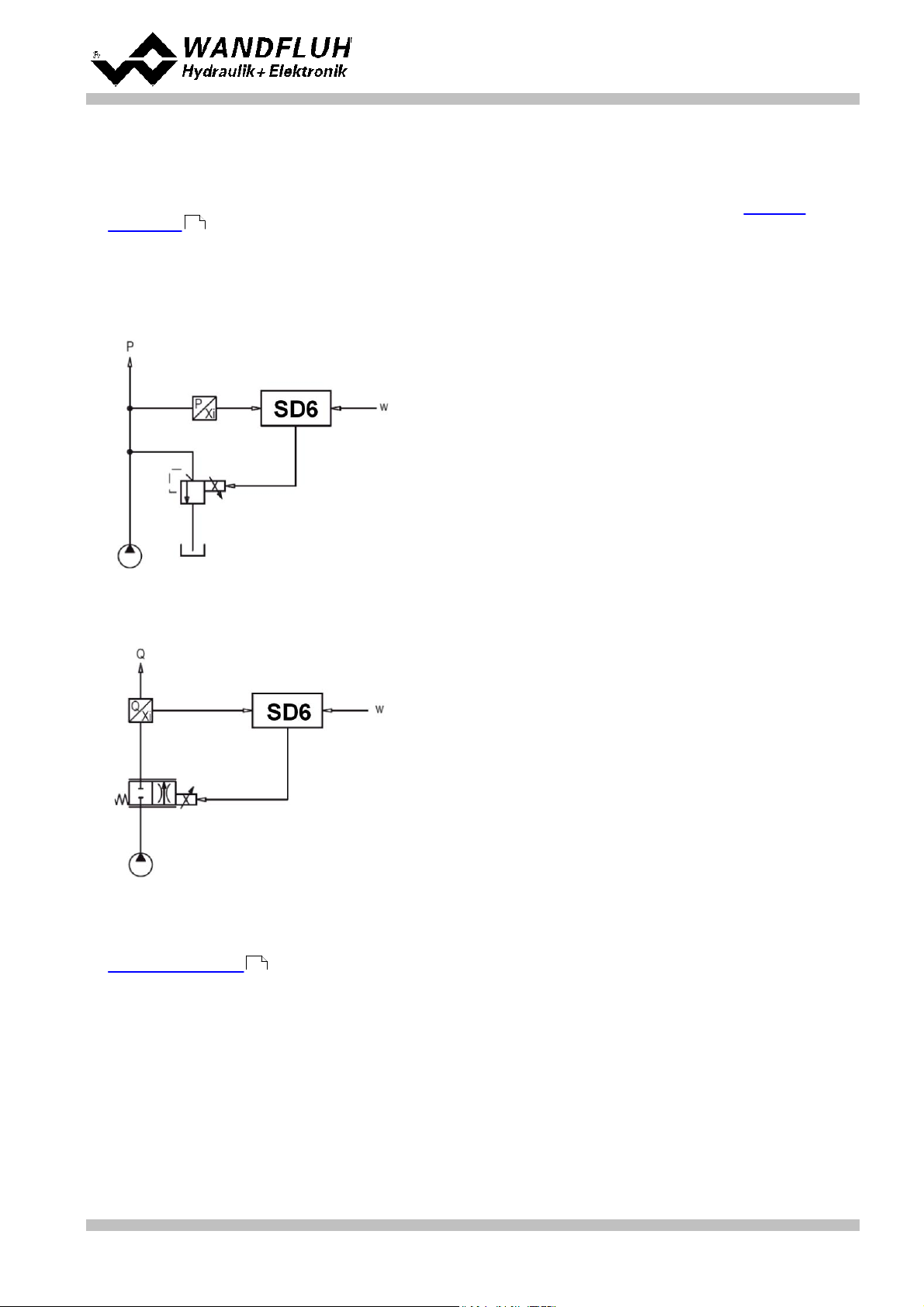

· Controller mode 4 "Pressure/flow valve closed loop (1-sol)"

Control of a 1-solenoid pressure relief-, pressure reducing- or flow control valve in closed loop (with feedback

signal). It can only be activated one solenoid (correspond to solenoid driver 1).

In this controller mode, the parameter "Mode of operation" has no meaning (refer to section "Mode of

Operation" ).

52

This mode of operation corresponds to the "Device Control Mode = 4" of the fieldbus device profile Fluid

Power Technology.

Example Application:

Pressure Control: with one proportional pressure relief valve, the pressure p is held constant to the command

pressure value w.

Example Application: Flow Control: with one proportional throttle valve, the flow Q is held constant to the flow

command value w.

· Controller mode 6 "Position open loop"

Control of a spool valve in open loop (without feedback signal).

The number of solenoids, which are activated, depends on the selected mode of operation (refer to section

"Mode of operation" ).

52

This mode of operation corresponds to the "Device Control Mode = 6" of the fieldbus device profile Fluid

Power Technology.

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 16

Edition 12 14

SD636bae.pdf

Page 17

Operating instructions to Enhanced Controller module SD6

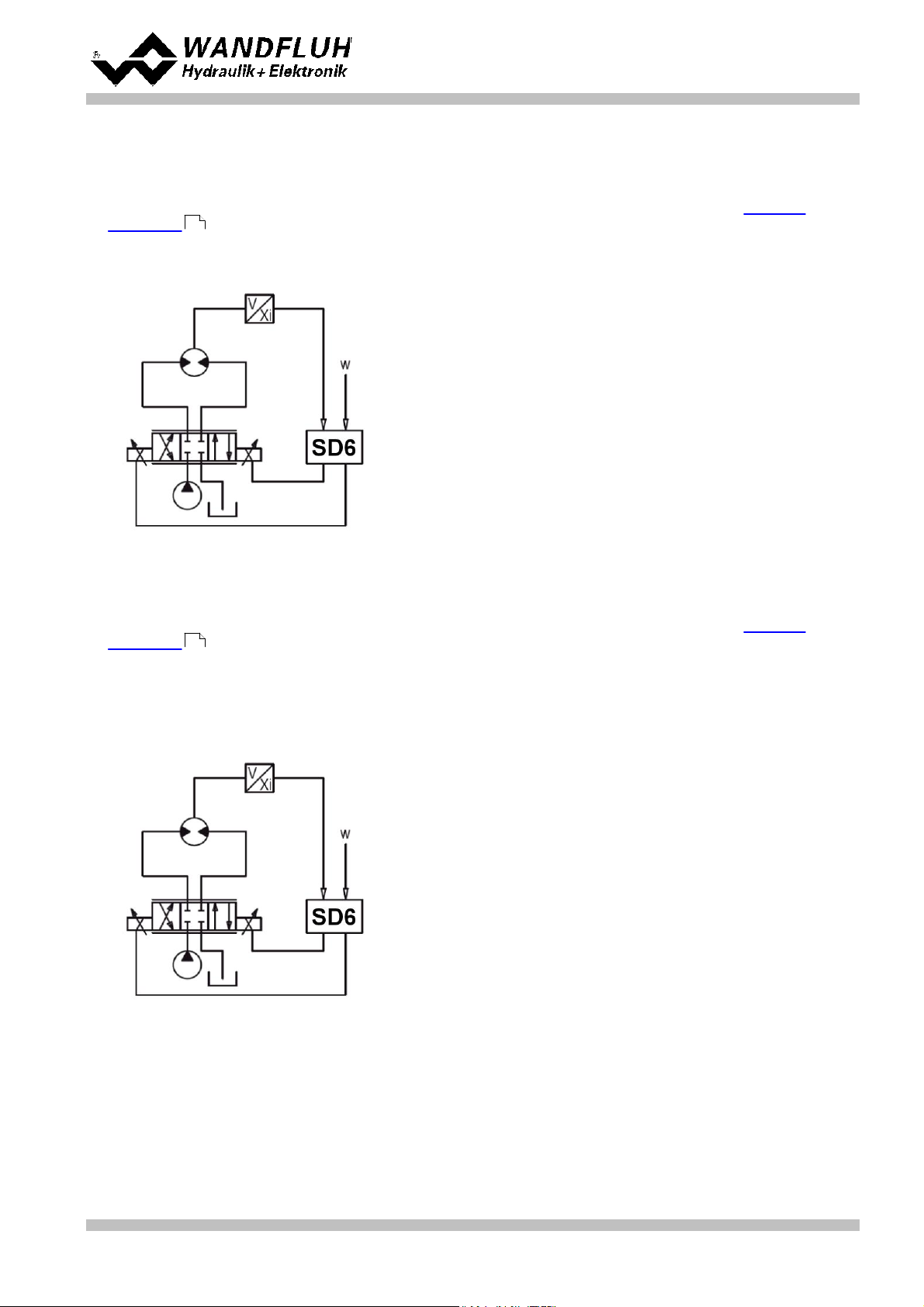

· Controller mode 7 "Speed control closed loop (2-sol)"

Control of a 2-solenoid pressure relief-, pressure reducing- or flow control valve in closed loop (with feedback

signal). It can be activated two solenoids.

In this controller mode, the parameter "Mode of operation" has no meaning (refer to section "Mode of

Operation" ).

52

This mode of operation corresponds to the "Device Control Mode = 7" of the fieldbus device profile Fluid

Power Technology.

· Controller mode 9 "Position closed loop"

Control of a 2-solenoid spool valve in closed loop (with feedback signal). It can be activated two solenoids.

In this controller mode, the parameter "Mode of operation" has no meaning (refer to section "Mode of

Operation" ).

52

This mode of operation corresponds to the "Device Control Mode = 9" of the fieldbus device profile Fluid

Power Technology.

Example application: with a 4/3-proportional-spool valve, the axis position is held constant to the command

position value w..

· Controller mode –5 "Pressure control closed loop (2-sol)"

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 17

Edition 12 14

SD636bae.pdf

Page 18

Operating instructions to Enhanced Controller module SD6

Control of two 1-solenoid throttle valves in closed loop (with feedback signal) as a pressure reducing system.

One throttel valve is the loading valve, the other throttel valve is the unloading valve. The loading valve

corresponds to solenoid driver 1, the unloading valve to the solenoid driver 2.

In this controller mode, the parameter "Mode of operation" has no meaning (refer to section "Mode of

Operation" ).

52

This controller mode is a WANDFLUH specific controller mode and does not correspond to the fieldbus

device profile Fluid Power Technology.

This setting is available only with a SD6-electronics with software version > 1.1.1.6 and PASO with software

version > 1.5.0.9!

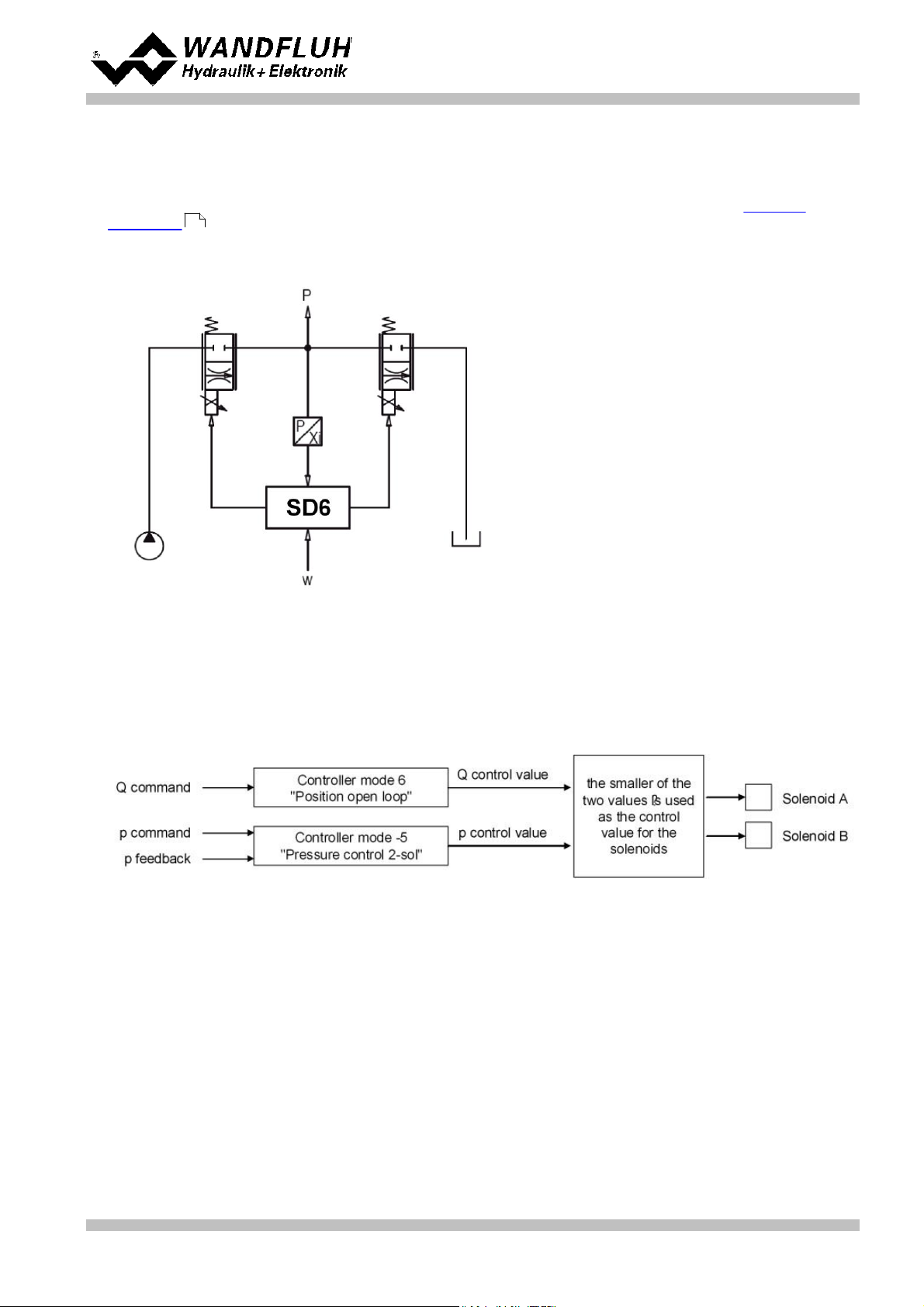

· Controller mode –9 "pQ control (2-sol)"

Driving of a direction control valve in open loop control circuit (without feedback signal) with monitoring of a

predefined pressure (with feedback signal).

There is a Q and a p command value. With the Q command value, the cylinder can move in open loop in both

directions. The p command value defines the maximum allowed pressure. If this pressure is exceeded, the

controller reduces the output signal to the valve. In this case the preset pressure is not exceeded. A rear

dodge (cylinder moves backward) is possible. The p feedback value can be either an absolute signal (V or

mA) from a pressure or force sensor or can be built as a differential signal from two pressure or force sensors

(V or mA).

With this controller mode, the choice of the proportional valve has a high influence on the system behavior.

More details about it are available from factory.

Example application: with a 4/3-proportional-spool valve, the axis will move in open loop (without feedback

signal). Simultaneously the pressure is monitored (measured with the pressure sensor).

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 18

Edition 12 14

SD636bae.pdf

Page 19

Operating instructions to Enhanced Controller module SD6

This setting is available only with a SD6-electronics with software version higher than 1.1.3.0 and PASO with

software version higher than 1.5.1.2!

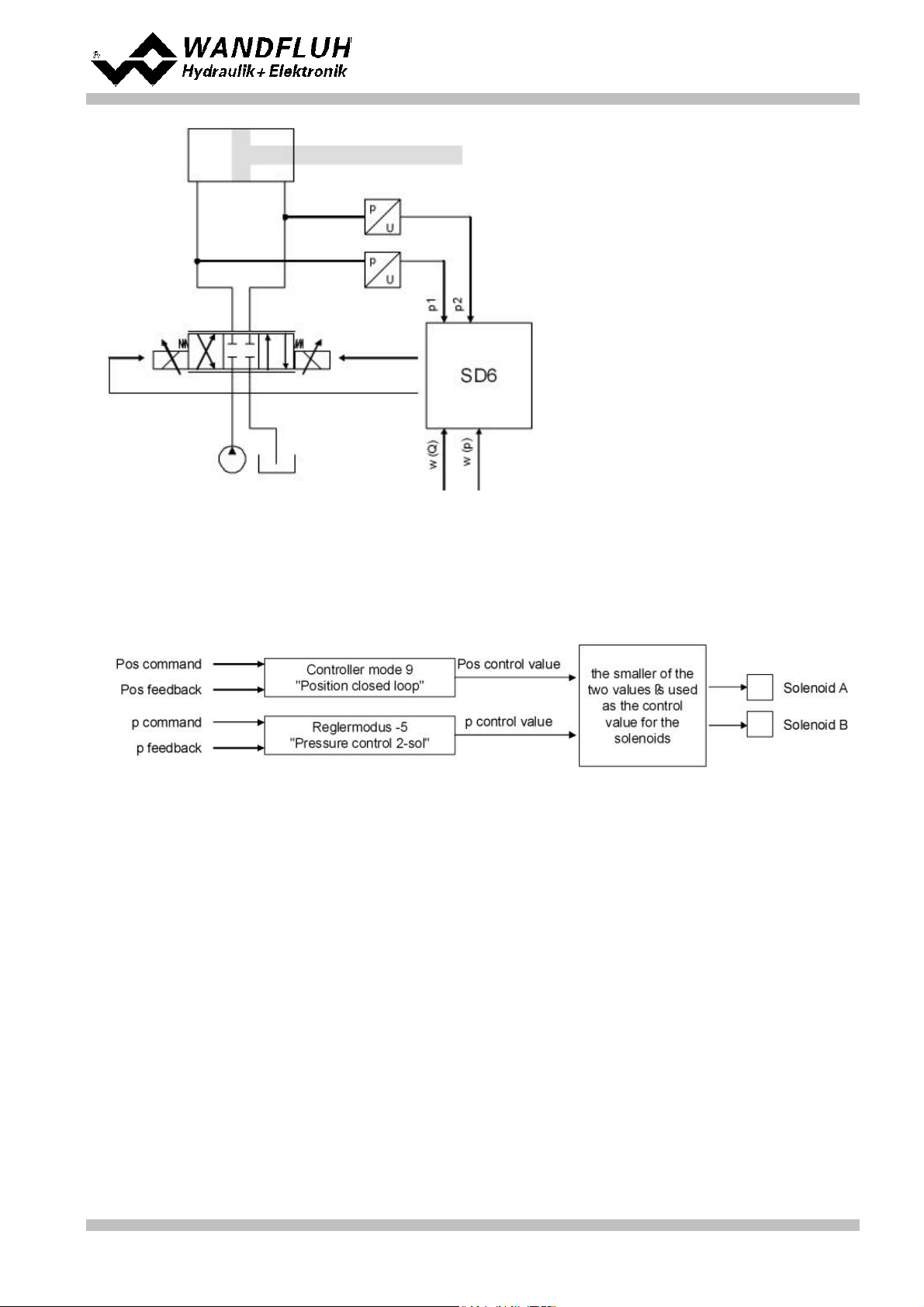

· Controller mode –10 "Alternating control (2-sol)"

Driving of a direction control valve in closed loop control circuit (with feedback value return) with monitoring of

a predefined pressure (with feedback value return).

There is a pos and a p command value. With the pos command value, the cylinder can move in closed loop

in both directions. The p command value defines the maximum allowed pressure. If this pressure is

exceeded, the position controller is swichted off and the controller reduces the output signal to the valve. In

this case the preset pressure is not exceeded. If the actual pressure is smaller than the p command value,

the position controller is switched on. A rear dodge (cylinder moves backward) is possible. The p feedback

value can be either an absolute signal (V or mA) from a pressure or force sensor or can be built as a

differential signal from two pressure or force sensors (V or mA).

With this controller mode, the choice of the proportional valve has a high influence on the system behavior.

More details about it are available from factory.

Example application: with a 4/3-proportional-spool valve, the axis position is held constant to the command

position value w. Simultaneously the pressure is monitored (measured with the pressure sensor).

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 19

Edition 12 14

SD636bae.pdf

Page 20

Operating instructions to Enhanced Controller module SD6

This setting is available only with a SD6-electronics with software version higher than 1.1.3.0 and PASO with

software version higher than 1.5.1.2!

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 20

Edition 12 14

SD636bae.pdf

Page 21

Operating instructions to Enhanced Controller module SD6

0%

...

100% command value

= Imin ... Imax solenoid A

0%

...

50% command value

= Imax ... Imin solenoid B

50%

...

100% command

value

= Imin ... Imax solenoid A

-100%

...

0% command value

= Imax ... Imin solenoid B

0%

...

100% command

value

= Imin ... Imax solenoid A

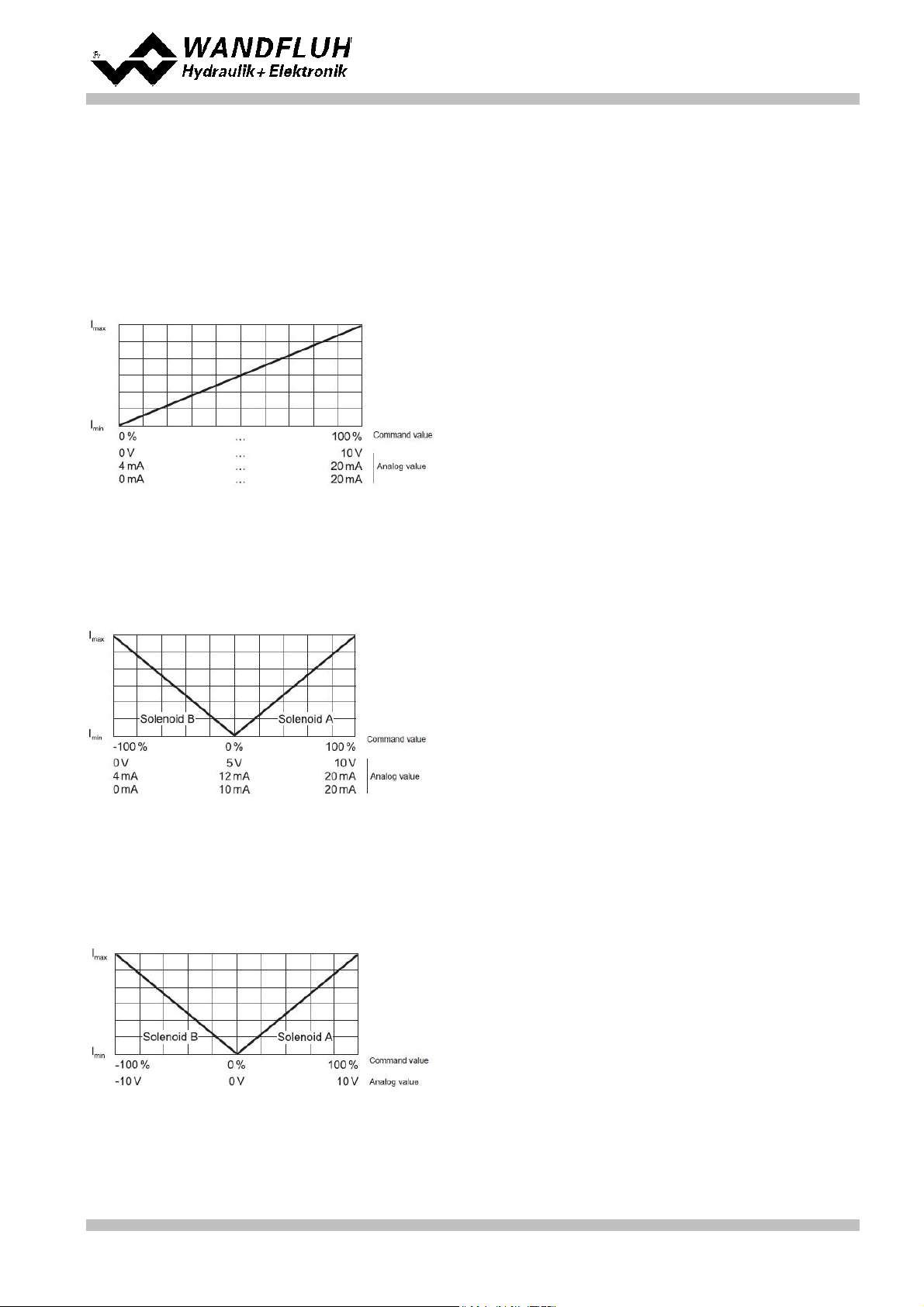

4.12 Mode of operation

The mode of operation is only of significance in controller mode "Pressure/flow valve open loop", "Position open

loop" and "pQ control (2-sol)". In all other controller modes the mode of operation is not taken into consideration.

The following 4 modes of operation are possible:

· Mode of operation 1 "Command value unipolar (1-solenoid)"

This mode of operation is only selectable with the 1-solenoid version.

With an analogue input (voltage or current) with a 1-solenoid valve the solenoid A is driven.

· Mode of operation 2 "Command value unipolar (2-solenoid)"

This mode of operation is only selectable with the 2-solenoid version.

With an analogue input (voltage or current) with a directional control valve, solenoid A and solenoid B are

driven.

· Mode of operation 3 "Command value bipolar (2-solenoid)"

This mode of operation is only selectable with the 2-solenoid version.

With an analogue input (voltage) of 0 ... ±10V with a directional control valve, solenoid A (positive voltage)

and solenoid B (negative voltage) are driven.

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 21

Edition 12 14

SD636bae.pdf

Page 22

Operating instructions to Enhanced Controller module SD6

0%

...

100% command

value,

= Imin ... Imax solenoid A

Digital input 2 "high":

0%

...

100% command

value,

= Imin ... Imax solenoid B

· Mode of operation 5 "Command value unipolar (2-solenoid)"

This mode of operation is only selectable with the 2-solenoid version.

With an analogue input (voltage or current) with a directional control valve, depending on the digital input 2,

solenoid A or solenoid B is driven.

Digital input 2 "low":

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 22

Edition 12 14

SD636bae.pdf

Page 23

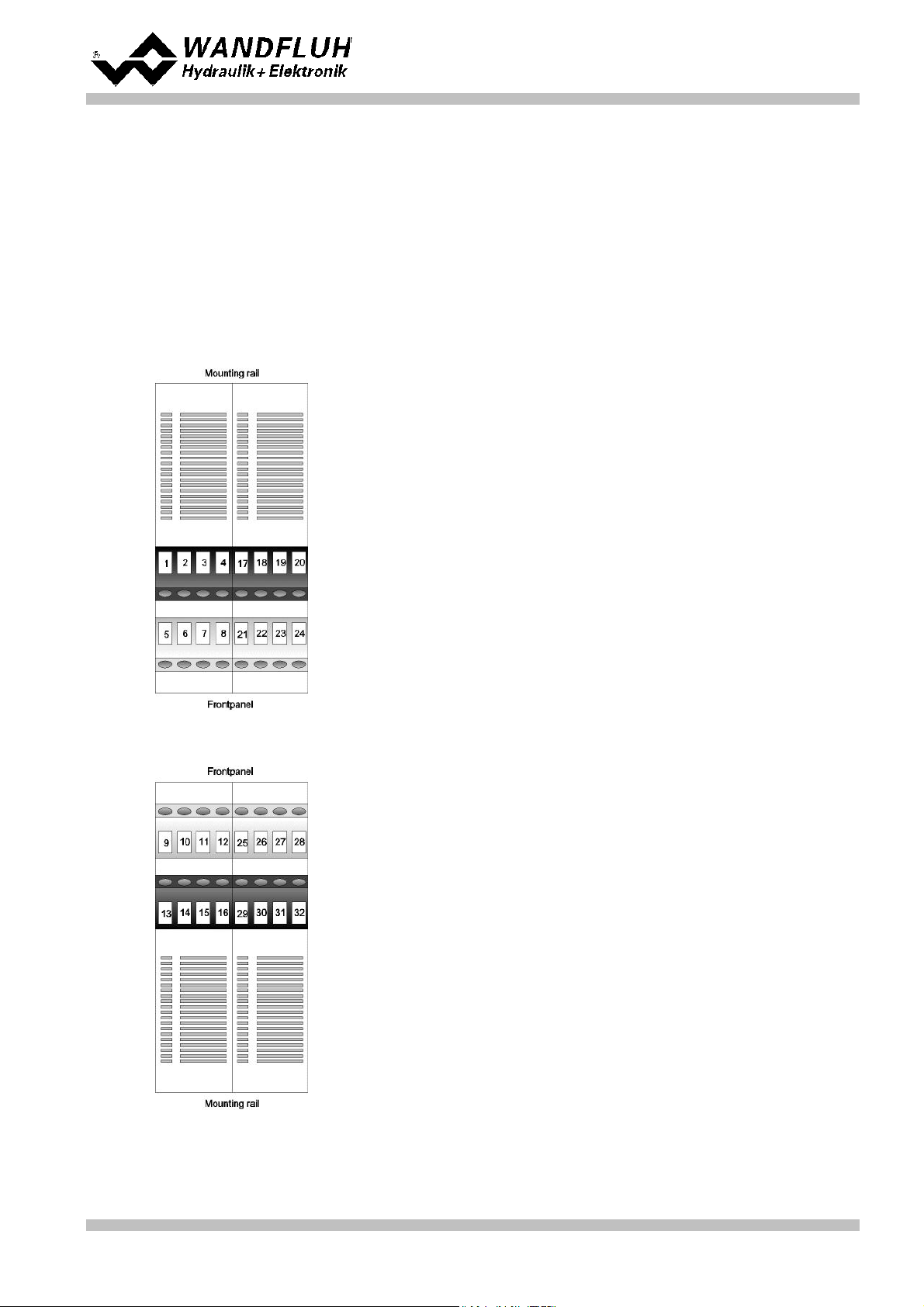

Operating instructions to Enhanced Controller module SD6

Top view of box

X1-1 = Digital input1

X1-2 = Digital input 2

X1-3 = Digital output 1

X1-4 = Digital output 2

X1-5 = Supply voltage +

X1-6 = Supply voltage 0 VDC

X1-7 = Stabilised output voltage

X1-8 = Analogue ground

X1-17 = Digital input 3

X1-18 = Digital input 4

X1-19 = Digital input 5

X1-20 = Digital input 6

X1-21 = Digital input 7

X1-22 = Digital input 8

X1-23 = Digital output 3

X1-24 = Digital output 4

Bottom view of box

X1-9 = Analogue input 1 +

X1-10 = Analogue input 1 X1-11 = Analogue input 2 +

X1-12 = Analogue input 2 X1-13 = Output Solenoid B +

X1-14 = Output Solenoid B X1-15 = Output Solenoid A +

X1-16 = Output Solenoid A X1-25 = Analogue input 3 +

X1-26 = Analogue input 3 X1-27 = Analogue input 4 +

X1-28 = Analogue input 4 X1-29 = Digital ground

X1-30 = Analogue ground

X1-31 = Stabilized output voltage

X1-32 = Analogue output

5 Operating and Indicating elements

5.1 General

All inputs and outputs have to be contacted through the terminal screw blocks. On the front panel of the

electronic housing, there is a USB interface, through which the parameterisation and the diagnostics can be

made by using the PC-Parameterisation software PASO DSV/SD6.

5.2 Screw terminator view

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 23

Edition 12 14

SD636bae.pdf

Page 24

Operating instructions to Enhanced Controller module SD6

5.3 Control elements

5.3.1 General

The front panel of the SD6-Electronics contains the connector to the USB-Interface. Additionally the front panel

is provided with three LED's, which inform the user about the device functioning.

5.3.2 ERROR-LED (red)

The ERROR-LED displays, when an error is detected (refer to section "The system does not work" ).

80

5.3.3 FUNCTION-LED (yellow)

In the controller modes "Pressure/flow valve open loop" and "Position open loop" the FUNCTION-LED is lighting

as soon as a solenoid current is forced (solenoid A and/or solenoid B).

In the controller modes "Pressure/flow valve closed loop", "Speed control closed loop", "Position closed loop"

and "Pressure control closed loop" the FUNCTION-LED is lighting when the target window is reached.

In the controller modes "pQ-control" and "Alternating control" the FUNCTION-LED is lighting depending on the

state of the digital output 2 (refer to section "Configuration_Digital I/O" )

65

5.3.4 SUPPLY-LED (green)

The SUPPLY-LED is lighting, when the SD6-electronics are supplied.

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 24

Edition 12 14

SD636bae.pdf

Page 25

Operating instructions to Enhanced Controller module SD6

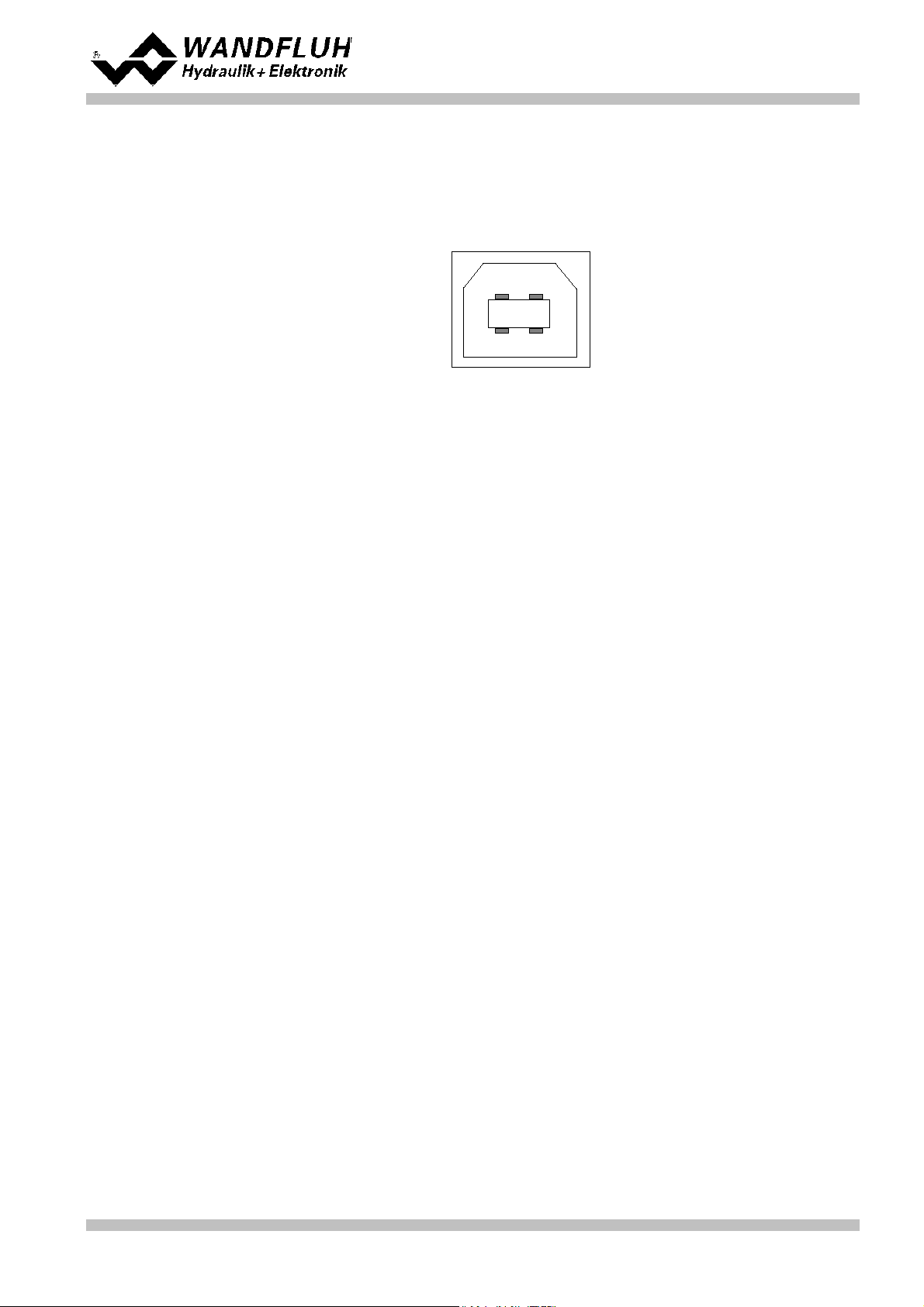

View of the USB-interface:

1

2

3 4

X2-1 = VBUS

X2-2 = DX2-3 = D+

X2-4 = GND

5.3.5 USB-interface

The USB-interface allows the parameterisation and the analysis of the SD6-electronics by PASO software. The

connection to the PC is realised by standard USB-cables (USB Type A connector PC-side, USB Type B

connector SD6-side).

Connector USB Type B

Hint: The USB-cable is not included.

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 25

Edition 12 14

SD636bae.pdf

Page 26

6 Commissioning

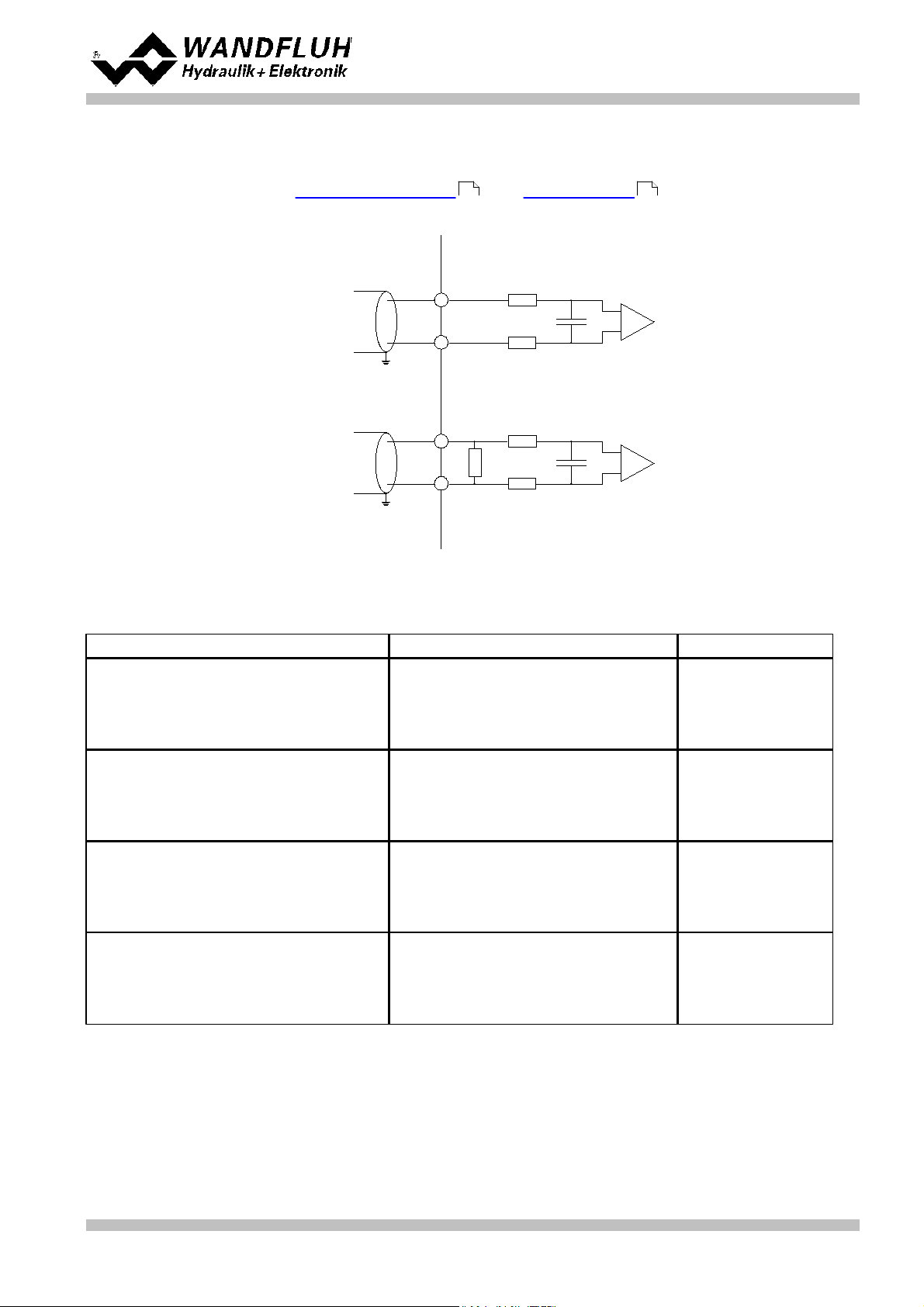

control extern control intern

6 ... 30V

control intern

max 40V / 0.7A

control extern

Operating instructions to Enhanced Controller module SD6

Please refer to section "Safety rules" .

9

6.1 Connection instructions

The contact assignment of the following description refers to section "Operating and Indicating elements" and

to section "Connection examples" .

28

For an installation / connection appropriate for EMC, the following points absolutely have to be observed:

· Cable length longer than 10m requires shielded cables. The shield of the cable must only be connected with

the earthing on the switchboard side using a large surface area and low Ohm connection.

· The top-hat rail has to be connected with the earthing with an as short as possible conductor with a strand

cross section >= 1.5 mm2.

· Solenoid- and signal cables must not be laid parallel to high voltage cables.

6.1.1 Supply voltage

· For the dimensioning of the power supply, the maximum current demand of the solenoids (in case of

directional control valves only the maximum current demand of 1 solenoid) has to be increased by the no load

current from the SD6-Electronics (refer to section "Electrical specifications" ).

5

· The limit values of the supply voltage and its residual ripple indispensably have to be complied with (refer to

section "Electrical specifications" ).

5

· The SD6-Electronics have to be protected with a slow acting fuse

23

6.1.2 Digital inputs and outputs

· The digital inputs are active-high and not galvanically separated

· For activation, they have to be connected to a voltage between 6 ... 30VDC (e.g. power supply)

· The digital outputs are "Lowside Switch" outputs (open collector)

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 26

Edition 12 14

SD636bae.pdf

Page 27

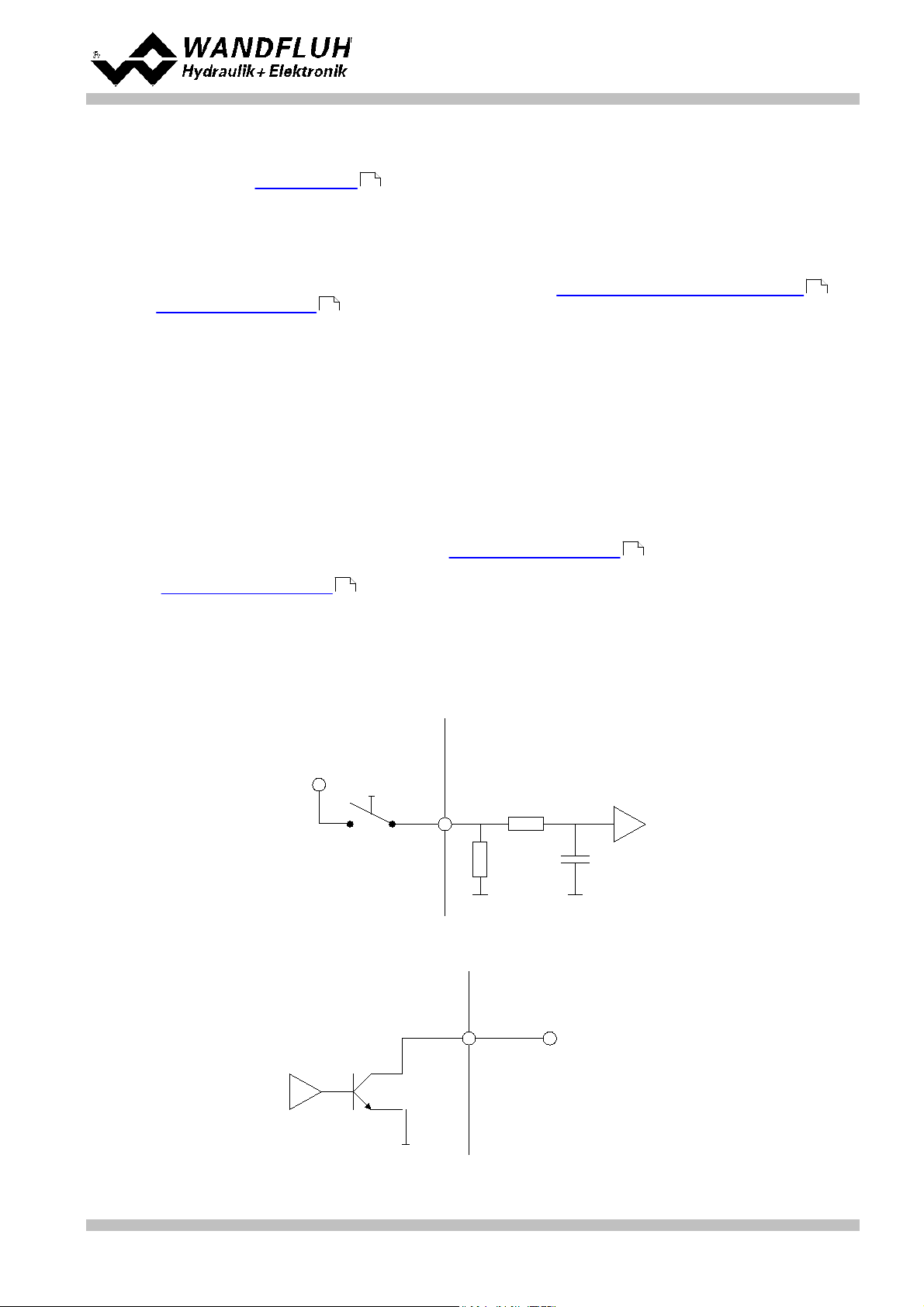

6.1.3 Analogue inputs 10-Bit and 16-Bit

· Depending on the card type current and / or voltage inputs with 10-bit ore possibly with 16-bit resolution are

available (rrefer to section "Electrical specifications " and "Analogue inputs ")

· All inputs are differential inputs.

control extern control intern

+

-

voltage

input

large surface

connection

+

-

current

input

large surface

connection

Input signal

Pin configuration screw terminators

Input range

Voltage against ground

10-Bit (example with AnaInp1):

+ at Pin X1-9 / Pin X1-10 at ground

16-Bit (example with AnaInp3):

+ at Pin X1-25 / Pin X1-26 at ground

0 ... +10V

0 ... ±10V

Differential voltage

10-Bit (example with AnaInp1):

+ at Pin X1-9 / - at Pin X1-10

16-Bit (example with AnaInp3):

+ at Pin X1-25 / - at Pin X1-26

0 ... +10V

0 ... ±10V

Current against ground

10-Bit (example with AnaInp2):

+ at Pin X1-11 / Pin X1-12 at ground

16-Bit (example with AnaInp4):

+ at Pin X1-27 / Pin X1-28 at ground

0 ... 20mA

4 ... 20mA

Differential current

10-Bit (example with AnaInp2):

+ at Pin X1-11 / - at Pin X1-12

16-Bit (example with AnaInp4):

+ at Pin X1-27 / - at Pin X1-28

0 ... 20mA

4 ... 20mA

Operating instructions to Enhanced Controller module SD6

5 12

6.1.4 Configuration of the analogue inputs 10-Bit and 16-Bit

The analogue inputs can be configured as follows:

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 27

Edition 12 14

SD636bae.pdf

Page 28

6.1.5 Digital Sensor

X3-1 = Digital input + / Data +

X3-2 = Digital input – / Data X3-3 = Reserved

X3-4 = Reserved

X3-5 = Clock output + / Clock +

X3-6 = Clock output – / Clock X3-7 = Output +5VDC

X3-8 = Sensor-ground

X3-9 = Output +24VDC

Operating instructions to Enhanced Controller module SD6

This interface for digital sensors works as RS-422 standard (refer to section "Input for digital sensor" )

28

Pin assignment:

6.2 Connection examples

The contact assignment of the following description refers to section "Operating and Indicating elements" .

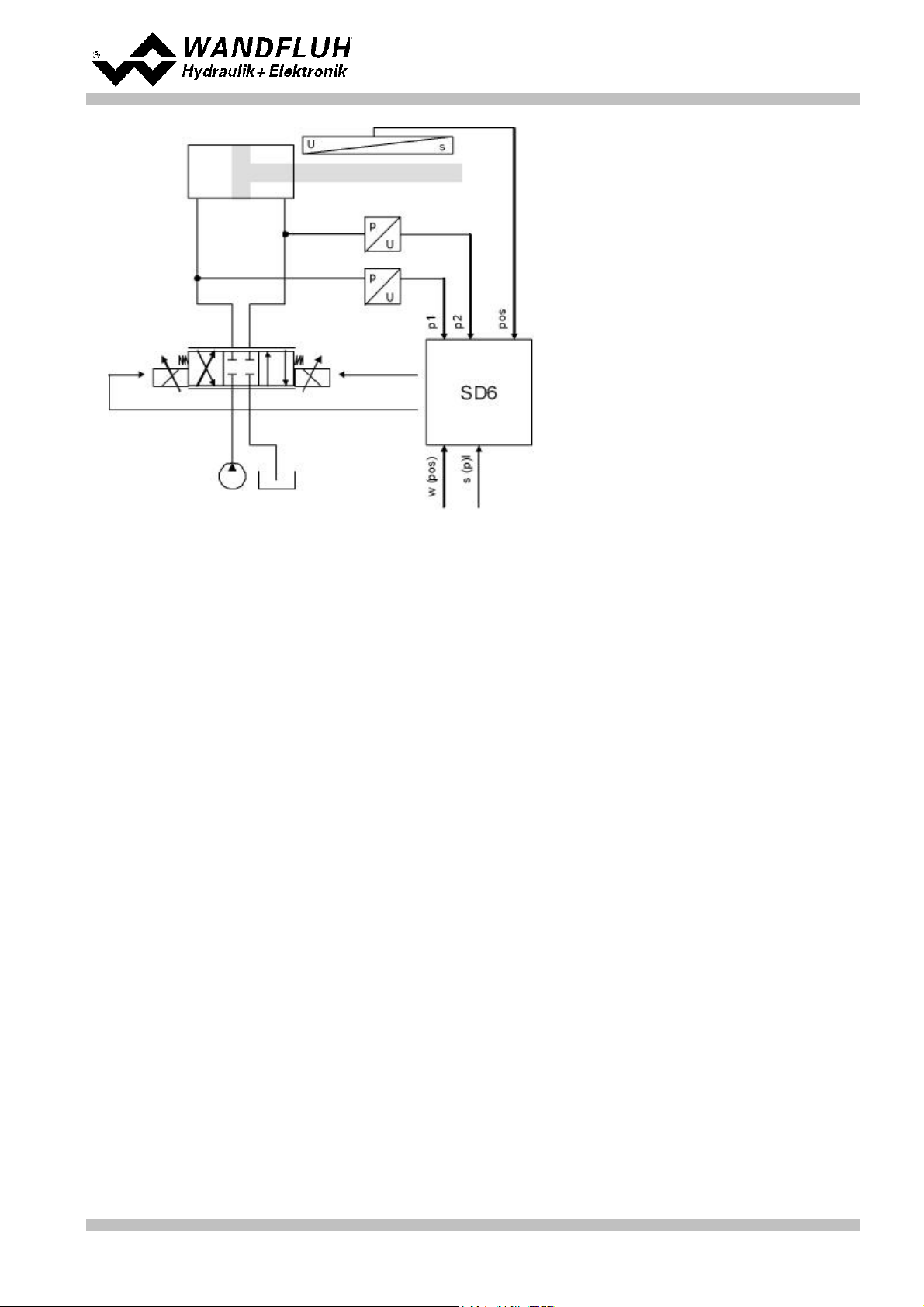

6.2.1 Position Control

23

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 28

Edition 12 14

SD636bae.pdf

Page 29

7 Settings

Operating instructions to Enhanced Controller module SD6

Please refer to section "Safety Rules" .

9

7.1 Introduction

· The system- and parameter settings can be made via the RS232 interface with the PC-Parameterisation

software PASO DSV/SD6.

· For information about the operation via the PC-Parameterisation software PASO DSV/SD6 please refer to

section "PASO DSV/SD6 Installation and Operation".

· Depending on the connected SD6-Electronics, certain settings may be blocked.

7.2 Tips for the first commissioning

· Connect the power supply, leave the SD6-Electronics still switched-off.

· Switch-off the hydraulic drive (hydraulics switched-off).

· Carefully check the connections.

· Switch-on the power supply.

· Establish communication with PASO (connect PC and axis controller with a standard USB cable and start

PASO).

· Configure the SD6-Electronics specific to the installation. In doing so, the following sequence should be

observed:

1. Make the corresponding settings in the menu "Configuration_Controller mode "

2. Select the corresponding mode of operation In the menu "Configuration_Mode of operation " (only witht

open loop controller modes)

3. make the corresponding settings in the menu "Configuration_Signal scaling "

· Switch-on the hydraulics.

· For the card to be enabled, the digital input "Enable Control" has to be set (refer to section "Digital Input

").

· Corresponding to the set-point value command, the axis should now run up to the required position.

If the axis only runs up to the mechanical stop in one direction, then the system control sense is probably

wrong (change it in the menu point "Configuration_Controller mode ").

52

· The command value direction (e.g., potentiometer left/right) should correspond to the axis direction. If not,

either change the set-point value direction or the feedback value direction (change in the menu point "

Configuration_Signal scaling "). If the feedback value direction is reversed, then simultaneously the

53

connection of the solenoids 1 and 2 have to be switched.

· Set the drive currents of the valves in the menu "Parameter_Valves ".

· Set the control parameters in the menu "Parameter_Controller ".

· Make the settings in the menu "Parameter_Window ”.

50

43

48

52

52

53

65

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 29

Edition 12 14

SD636bae.pdf

Page 30

Operating instructions to Enhanced Controller module SD6

· The parameter 'Imin A' resp. 'Imin B' should be set in the way that the axis just slightly move

· The parameter 'Imax A' resp. 'Imax B' should be set in the way that the max. desired speed is reached at the

axis

· Adjust the desired value for the target window (control deviation < target window threshold = target

window reached)

· Adjust the desired value for the trailing error window (control deviation > trailing error window threshold =

trailing error)

· Adjust the desired value for the solenoid-off window (control deviation < solenoid off window threshold =

solenoids are switched off)

Please note therfore the following:

· The solenoid off function is only active, if the parameter 'Solenoid In position' in the menu 'Configuration -

Control mode' is set to 'off'. If it sets to 'on', the solenoid are never switched off

· If the value for the parameter 'Solenoid off threshold' is higher than the value for the parameter 'Target

window threshold', then the target window will never be reached (the solenoids are switched off before the

target position is reached)

· Using the parameters of the PID controller , the control behavior can be adjusted

· Because a position control is a dynamic control system, it can be waived to the I-term in many cases

· First, the P-term should be set

· Therefore increase gradually the parameter 'P-Ampl' until the desired response time is reached, without the

system oscillates

· If necessary, the running in the final position can be changed with the I-term

· With the parameter 'Velocity feed forward', the riding of the cylinder can be accelerated. The change of the

command value (the increase speed of the command value) is multiplied with this factor and added to the

correcting variable of the controller. If this factor is 0, no command value addition is added to the correcting

variable

· The parameter 'Command feed forward' should be set to 0 in this control mode

· Set all controller parameters (P-Ampl, I-Window, I-Time, D-Ampl and D-Time, at a time positive and

negative) to 0

· Set parameter 'Command feed forward' to 1.0

· Change the preset value from min to max. The actual value should follow with a difference

· Change the value from the parameter 'Command feed forward' in the case that the difference between preset

and actual value is as small as possible. The difference is not the same over the whole range. Select the

smalles difference in the range, where the system will work mostly

· Increase the value from the parameter 'P-Ampl'. As long as the system does not start to swing, this

parameter can be increased

· Find out the highest control deviation (with the Menu 'Analysis - Signal recording' )

· The highest control deviation plus 10 bar will be the value for the parameter 'I-Window outside'

· Set parameter 'I-Window Inside' to 1 bar

· Set parameter 'I-Time' to 1 s. If the system is not fast enough, decrease the value from 'I-time'

7.3 Start up help

The following description is intended as a guide for the setting of a control system. It is important that the default

order is maintained. The value of each parameter is always system dependent. Larger deviations in the setting

can occur quiteof different systems.

Start up Position controller

50

50

50

52

Start up Pressure controller

48

48

76

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 30

Edition 12 14

SD636bae.pdf

Page 31

Operating instructions to Enhanced Controller module SD6

· First, set the parameter for the position controller analog to the start up position controller (set Setup mode

to 'Position')

· Afterwards, set the parameter for the pressure controller analog to the start up pressure controller (set Setup

mode to 'Pressure')

· Please note therfore the following:

· The Dithersignal must be active resp. set high enough (lower frequency / higher level)

Therefore the adjusted values for Imin A resp. Imin B are also corrrect for the pressure controller

· The smaller of the two control values is active. A "stronger" controller loses out to a "weaker" controller.

With a corresponding adjustment it is possible to prioritized the position or pressure controller (e.g.

performs a fast integral to a higher control value and loses against the 'weak regulator')

· Set parameter "I-term, if control deviation > I-Window outside" to "leave value"

· Set parameter "I-term, if controller is not active" to "leave value"

· Set parameter 'Command feed forward' to 0

· The feedback pressure signal should be read as a differential pressure with two sensors (there can be a

problem with starting the movement with one sensor)

· With a double acting cylinder, the pressure feedback value should read in as a differential pressure with two

pressure sensor

· With a single acting cylinder, the pressure feedback value can read in also with only one pressure sensor.

This should be installed on the working side (active side).

· Instead of a pressure sensor also a force sensor can be used

· A 4/3-way spool valve with central position A-B-T connected (valve type ...-ADB-...) is not suitable

Start up pQ-controller and Alternating controller

73

73

43

48

48

48

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 31

Edition 12 14

SD636bae.pdf

Page 32

Operating instructions to Enhanced Controller module SD6

Parameter

Werkseinstellung

Reglermodus

Achsposition gesteuert

Ausgang Magnet A

Strom nicht invertiert

Ausgang Magnet B

Strom nicht invertiert

Imin immer aktiv

nein

Systemregelsinn

nicht invertiert

Magnet 'In Position'

ein

Betriebsart

Sollwert unipolar (2-Mag)

Signaltyp Sollwert

0...10V

Benutzter Eingang Sollwert

Analogeingang 1

Invertierung Sollwert

nein

Kabelbruch-Überwachung Sollwert

nein

Skalierung Sollwert

20.000 %/V

Offset Sollwert

0.00 V

Min. Interface Sollwert

0.000 V

Max. Interface Sollwert

10.000 V

Min. Reference Sollwert

0.0 mm

Max. Reference Sollwert

100.0 mm

Signaltyp Istwert

0...10 V

Benutzter Eingang Istwert

Analogeingang 3

Kabelbruch-Überwachung Istwert

nein

Min. Interface Istwert

0.000 V

Max. Interface Istwert

10.000 V

Min. Reference Istwert

0.0 mm

Max. Reference Istwert

100.0 mm

Offset Istwert

0.00 mm

Auflösung Istwert

0.005 mm/Inc

Max. Reference digitales Messsystem

100.00 mm

Bit Anzahl SSI

24

v-Ausbreitung Istwert

2850880 mm/s

Anzeige Einheit

mm

Totband

0.0 %

IminA

150 mA

ImaxA

700 mA

IminB

150 mA

ImaxB

700 mA

Min. Interface Analogausgang

-10.00V

Max. Interface Analogausgang

10.00V

Rampe A auf

0.00 s

Rampe A ab

0.00 s

Rampe B auf

0.00 s

Rampe B ab

0.00 s

Geschwindigkeit +

1000 mm/s

7.4 Default settings

In the factory, the SD6-Electronics will be set to the following default values:

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 32

Edition 12 14

SD636bae.pdf

Page 33

Operating instructions to Enhanced Controller module SD6

Parameter

Werkseinstellung

Geschwindigkeit -

1000 mm/s

Eilgang

500 mm/s

Schleichgang

100 mm/s

Ditherfrequenz

100 Hz

Ditherpegel

100 mA

Sollwertaufschaltung

0.00

Geschwindigkeitsaufschaltung

0.000

Regeldifferenz, wenn I-Anteil > I-Fenster Aussen

auf 0 setzen

P-Vestärkung positiv

5.0

I-Zeit positiv

0.100

I-Fenster Aussen positiv

5.00

I-Fenster Innen positiv

0.00

D-Zeit positiv

0.000

D-Verstärkung positiv

0.0

P-Vestärkung negativ

5.0

I-Zeit negativ

0.100

I-Fenster Aussen negativ

5.00

I-Fenster Innen negativ

0.00

D-Zeit negativ

0.000

D-Vestärkung negativ

0.0

Ziel Fenster Schwelle

10.00 mm

Ziel Fenster Verzögerungszeit

50 ms

Schleppfehler Fenster

10.00 mm

Schleppfehler Verzögerungszeit

50 ms

Magnet-Aus Fenster Schwelle

10.00 mm

Magnet-Aus Fenster Verzögerungszeit

50 ms

In the sections "Parameters - Menu" and "Configurations - Menu" you will find detailed descriptions of

43 52

each of these parameters.

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 33

Edition 12 14

SD636bae.pdf

Page 34

Operating instructions to Enhanced Controller module SD6

Function

· Amplifier

· Amplifier with manual operation

· Amplifier with fixed command values

· Basic Controller

· Enhanced Controller

Analogoutputs

· Input 1 voltage or current

· Input 2 voltage or current

· Input 2 current

only if Function = Enhanced Controller

· Input 3 voltage or current

· Input 4 voltage or current

Number of solenoids

· 1-Solenoid

· 2-Solenoid

Mode of operation

· without mode of operation 'Solenoid single' (only if Function = Amplifier)

· with mode of operation 'Solenoid single' (only if Function = Amplifier)

Fieldbus

· without Fieldbus

· with Profibus DP (only if Funciton = Amplfier, Basic Controller or Enhanced Controller)

7.5 File-Menu

Contained in the File menu are the menu points, which concern the file handling and the printing of the

parameters. In the "On Line"-mode, some of these menu points are blocked.

7.5.1 File_New

This menu point is active only in the "Off Line"-mode.

With this command, a new file can be opened. Near it, all parameters are set to default values. A question will be

displayed, if the current configuration will be retain or not.

If "Yes" will be selected, the current configuration will not be changed.

If "No" will be selected, a selection window will be displayed. In this window, the following configuration can be

selected.

The modified configuration only affects the "Off Line"-mode. By switching to "On Line"-mode the

configuration of the connected SD6-electronics will be read in.

7.5.2 File_Open

This menu point is only active in the "Off Line"-mode.

With this command, an existing file from a storage medium is opened. First the file selection window appears. In

this window the required file can now be selected and opened with ”OK”. If the configuration of the selected file

does not correspond to the current configuration of the PASO DSV/SD6, a message will be displayed and the

current configuration from the PASO DSV/SD6 will change automatically over to the new configuration of the

selected file. The read parameter values will be checked in the case of a limiting value excess. If one or more

parameter values are outside the tolerance, a message will be displayed and the parameter value will be set to

the default value (refer to section "Limiting value error" ). The parameter values can now be edited and

87

changed as required under the corresponding menu points.

7.5.3 File_Save

With this command, the parameters are saved on a data storage medium. All parameter values of all input

windows are saved under the current file name. If no file name has been defined yet, then first the file selection

window appears (refer to section "File_Save as..." ).

Wandfluh AG

Postfach

CH-3714 Frutigen

Tel: +41 33 672 72 72

Fax: +41 33 672 72 12

35

Email: sales@wandfluh.com

Internet: www.wandfluh.com

Page 34

Edition 12 14

SD636bae.pdf

Page 35

Operating instructions to Enhanced Controller module SD6

Date, time

Date, time of saving.

File name:

The file name, under which the file has been saved.

Valve type:

The valve type of the connected SD6-Electronics at the moment of saving. If no SD6-Electronics

are connected, then this indication remains empty. In case of saving during ”On Line Operation”,

this indication is updated.

Operator:

The name of the originating person.

Remarks:

Possibility to enter remarks concerning the file.

7.5.4 File_Save as

With this command, the parameters are saved on a data storage medium. All parameter values of all input

windows are saved under the file name entered.

First the file selection window appears. In this window the desired file name can now be entered. If the file name

is entered without an extension, then the extension ”.par” is automatically assigned to it. After actuating the key

”Save”, the file information window appears (refer to section "File-Info" ). In this window the required entries

35

can now be made. With the key ”Save”, the file is then finally saved under the selected file name. With the key

”Cancel”, one changes back to the file window.

7.5.5 File_Print

With this command, the current parameters are printed in ASCII text format. The File_Print window is opened. In

this window one can now select, whether the printing process is to be to a printer or to a file.

If the output is to be to a printer, then the Windows printer selection window is opened.. In this window, please

do not select ”Print to File”. If you do, a new program start might possibly be required and you could lose any

data not yet saved.

If the output is to be to a file, then the file selection window appears. In this window the desired file name can

now be entered. If the file name is entered without an extension, then automatically the extension ”.txt” is

assigned to it.

7.5.6 File_Info

With this command, the file information of an existing file is displayed. The file information consists of the

following parts:

When the File_Info window appears during the execution of the command ”File_Save”, then the corresponding

entries can be made in the various fields (with the exception of ”Date”, ”Time”, ”File name” and ”Card type”,

which cannot be edited). When the File_Info window appears during the execution of the command

”File_File-Info”, then the various fields cannot be edited.

7.5.7 File_Activate Off Line / Activate On Line

Off Line

With this command, the connection with the SD6-Electronics is interrupted. All menu points, which call for a

communication with the SD6-Electronics, are blocked. The PASO DSV/SD6 software now runs in the ”Off Line

mode”. The loading, saving and the editing of parameter files is possible in this mode.

On Line

With this command, the connection with the SD6-Electronics is established. The communication with the

SD6-Electronics is briefly tested. If the connection works, then the user has the option of taking over the

parameters from the SD6-Electronics or of transfering the parameters to the SD6-Electronics. During the

transfer of the parameters, the user has the possibility of aborting the operation.

Before parameters are transferred to the SD6-Electronics, a verification is carried out as to whether the

configuration of the SD6-Electronics supports the parameter values. The configuration corresponds here to the

number of the solenoids. If the configuration of the connected SD6-Electronics do not match with the current

configuration of the PASO DSV/SD6, a message will be displayed and the current configuration from the PASO

DSV/SD6 will change automatically over to the new configuration.

If the parameters have been taken over by the SD6-Electronics, then they will be checked in the case of a

limiting value excess. If one or more parameter values are outside the tolerance, a message will be displayed

and the parameter value will be set to the default value (refer to section "Limiting value error" ). The PASO

Wandfluh AG

Postfach

CH-3714 Frutigen