Page 1

Operating guide to Amplifier SD1X0

OPERATING GUIDE

AMPLIFIER SD1X0

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 1/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 2

Operating guide to Amplifier SD1X0

Contents

1 General information..................................................................................................................................3

2 Product description..................................................................................................................................3

2.1 General.............................................................................................................................................3

2.2 Field of application............................................................................................................................3

2.3 Conformity ........................................................................................................................................3

2.4 Labelling of the product ....................................................................................................................3

2.5 Type code.........................................................................................................................................4

2.6 Technical data ..................................................................................................................................4

2.7 Block diagram SD1 basic card .........................................................................................................6

2.8 Dimensions.......................................................................................................................................7

3 Safety rules ...............................................................................................................................................7

3.1 Installation / Commissioning / Parameterization ..............................................................................7

4 Construction and Function......................................................................................................................8

4.1 Introduction.......................................................................................................................................8

4.2 Description of the Function...............................................................................................................8

4.3 Analog inputs....................................................................................................................................8

4.4 Digital inputs .....................................................................................................................................9

4.5 Outputs .............................................................................................................................................9

4.6 Mode of operation...........................................................................................................................10

5 Operating and Indicating elements.......................................................................................................11

5.1 Introduction.....................................................................................................................................11

5.2 Top view .........................................................................................................................................11

6 Commissioning.......................................................................................................................................12

6.1 Installation / Connection .................................................................................................................12

6.2 Connection instructions ..................................................................................................................12

6.3 Connection examples .....................................................................................................................15

7 Settings....................................................................................................................................................17

7.1 Introduction.....................................................................................................................................17

7.2 General...........................................................................................................................................17

7.3 Tips for the first commissioning......................................................................................................17

7.4 File - Menu (only PASO - Version) .................................................................................................17

7.5 Fixed preset value - Menu ..............................................................................................................19

7.6 Parameters - Menu.........................................................................................................................20

7.7 Configuration - Menu ......................................................................................................................22

7.8 Analysis - Menu ..............................................................................................................................25

7.9 Help - Menu (only PASO-Version)..................................................................................................26

8 The system does not work ....................................................................................................................27

8.1 Procedure .......................................................................................................................................27

9 Cyclic menu construction......................................................................................................................28

10 PASO Installation and Operation ..........................................................................................................29

10.1 PASO system requirements ...........................................................................................................29

10.2 PASO installation............................................................................................................................29

10.3 PASO connection to the digital card...............................................................................................29

10.4 PASO program description.............................................................................................................30

10.5 Description of Commands..............................................................................................................34

11 Disposal...................................................................................................................................................34

12 Additional information ...........................................................................................................................34

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 2/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 3

Operating guide to Amplifier SD1X0

Operating guide to Amplifier SD1X0

1 General information

This operating guide (OG) makes it possible to use the Wandfluh Amplifier SD1X0 (Amplifier) safely and

according to specification. The OG includes instructions which Wandfluh as the manufacturer, or its resale

organisations (Wandfluh sister companies or distributors), provide to users within their duty to instruct.

For this purpose, the OG mainly includes:

• information about use according to specification, installation and commissioning of the amplifier card

• information about safety in dealing with control.

2 Product description

2.1 General

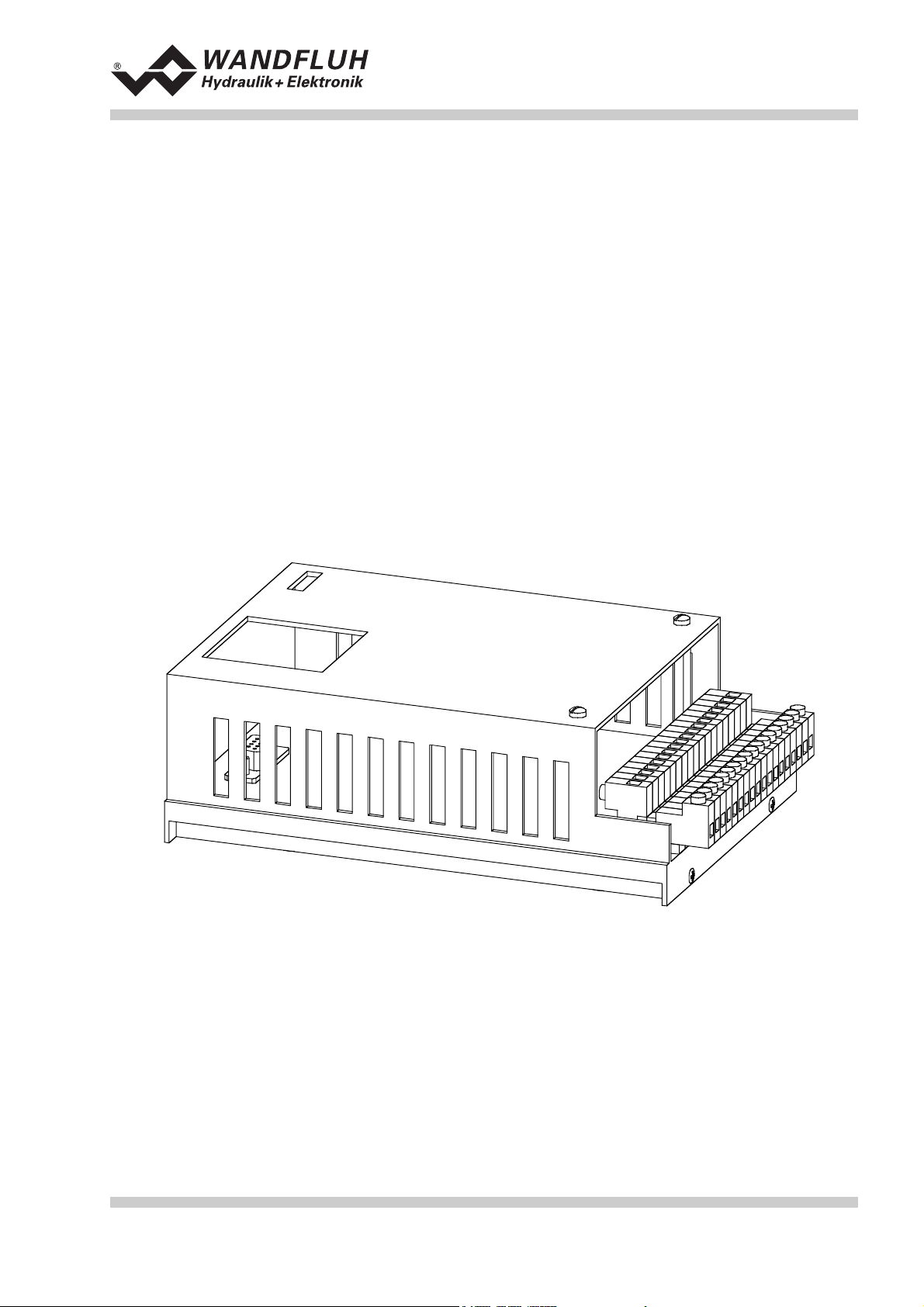

The Amplifier is built in the Eurocard format, put in a housing for mounting on dome-rails, with a screwon/plug-in connector strip.

2.2 Field of application

As an Eurocard, put in a housing for mounting on dome-rails, the field of application of the Amplifier is

situated above all in the industrial field.

2.3 Conformity

The Amplifier has been developed and tested in accordance with the latest technical standards. Applied in

particular was the EU Guideline 89/336/EEC (EMC Guideline).

2.4 Labelling of the product

The housing of the Amplifier is provided with the following adhesive labels:

• with an adhesive type label

• with an adhesive serial number label (with the initials of the tester)

With the PC-Parameterizationsoftware PASO, the following information can be directly read-off the Amplifier:

• Card type

• Software version

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 3/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 4

2.5 Type code

Operating guide to Amplifier SD1X0

Snap.On module

Digital

Parameters to be set with:

Multi-function term. MTG02/TESO

PC-Software

Amplifier basic card

2-solenoid version

24VDC supply voltage

Preset value input selection

Hardware configuration

10-Bit resolution

Hardware configuration

without Bus

wiht profibus DP

with CAN-bus

Design-Index (Subject to change)

2.6 Technical data

2.6.1 General specifications

Execution

Dimensions

Installations

Weight

Connections

Ambient temperature

snap-on module housing made of alu

with housing

print plate

with snap-on socket for 35mm dome-rail to DIN 46277

with housing 450g

screw-on/plug-in connector

strip

1

3

A

(on request)

B

(on request)

C

S D1 0 2 D2 0- #

172.0 x 111.0 x 60.5 mm

160.0 x 100.0 mm

CAMDEN rising clamp, plug-in,

max. cable size 4mm²

-20 ... +60° C

A

2.6.2 Electrical specifications

Supply voltage

Voltage range

Ripple on supply voltage

Fuse

Temperature drift

No load power

Analog inputs

Input resistance

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 4/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Customer must integrate a slow fuse into his electrical system

(A-value = no load power plus max solenoid current)

< 1% with ∆T = 40°C

1 differential input 10-Bit 0 ... 10 VDC

1 differential input 10-Bit 0/4 ... 20 mA

1 input 10-Bit 0 ... +/- 10 VDC

1 input 10-Bit 0/4 ... 20 mA

Voltage input against ground > 100kOhm

Voltage differential input > 27kOhm

Burden for current input = 250Ohm

24 VDC

21 ... 30 VDC

+/-10 %

1.2 W

Page 5

Operating guide to Amplifier SD1X0

Digital inputs

Serial interface

Stabilized output voltage

Solenoid outputs

Solenoid current

Dither

Digital outputs

Free pins

Status indication by LED

LED green

LED yellow

LED red

EMC

Immunity

Emission

2 inputs acitve-low

6 input acitve-high

Switching threshold high 12 - 34VDC

Switching threshold low 0 - 4VDC

1 interface D-SUB 9-pin socket (female) on the front plate

according to RS232 C standard

1 output + 15 VDC, max. Load 100 mA

1 output + 10 VDC, max. Load 10 mA

The solenoid outputs are short circuit proof and protected

against negative voltage peaks by a suppression diode.

Minimum current Imin adjustable 0 ... 950 mA

Default setting 150 mA

Maximum current Imax adjustable Imin ... 1800 mA

Default setting 700 mA

Frequency adjustable 20 ... 250 Hz

Default setting 100 Hz

Level adjustable 0 ... 200 mA

Default setting 100 mA

2 outputs optically coupled.

Open collector connected to Digital ground

Umax 50 VDC

Imax 15 mA

4 pins AUX1 - AUX4 reserved for customer specific

adaptations on the plug-in modules area

Supply voltage

Function

Error

EN 50082-2

EN 55022 Class B

2.6.3 Environment

Storage

In operation

packing: The card must be stored in the original packing

Temperature range: -25 ... +85° C

Resistance to alkali and acid: The card must be protected against alkalis and

acids

Temperature range -20 ... +60° C

Resistance to alkali and acid: The card must be protected against alkalis and

acids

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 5/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 6

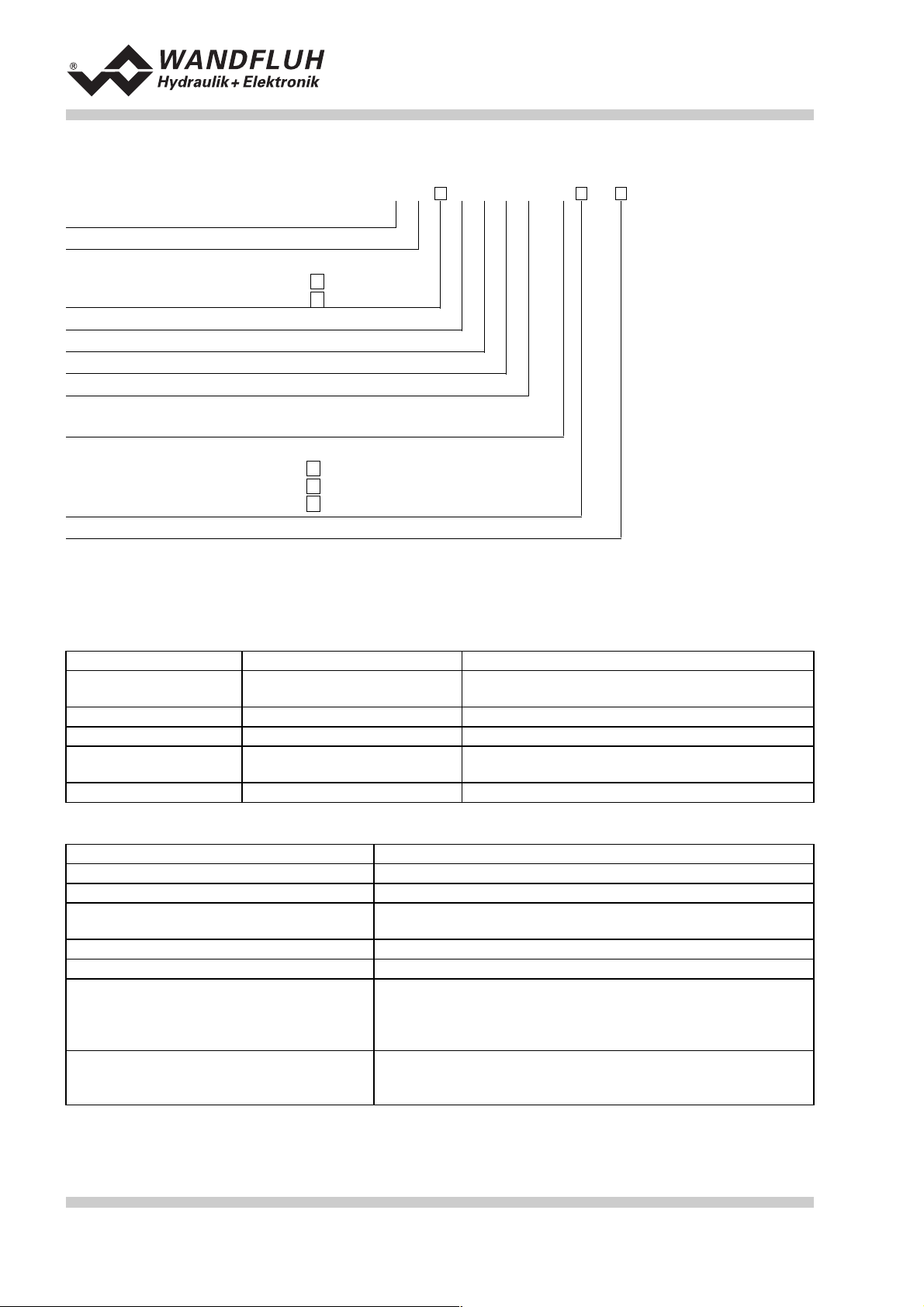

2.7 Block diagram SD1 basic card

Operating guide to Amplifier SD1X0

Earth

Supply voltage 24VDC

Internale GND

Stabilizied output

voltage +10VDC

Analog ue input 1

Voltage signal

Analog ue input 2

Curren t signal

Analog ue input 3

Voltage signal

Analog ue input 4

Curren t signal

Analog ue ground

Analog ue ground wi th

cablebr eak dete ction

Digital input 1

Disable solenoid A

Digital input 2

Disable solenoid B

Digital input 3

Enable control

1

Stabilizied output

5

3

15

19

27

25

31

29

33

35

23

21

2

4

6

+

A/D

-

A/D

A/D

A/D

A/D

controller

PWM

PWM

Micro-

+

-

+

-

+

-

LED g reen

U

I

I-mess

U

I

I-mess

Provision for

plug-in modules

17

9

7

13

11

36

34

32

24

26

28

30

voltage +15VDC

Solenoid A

Solenoid B

AUX5

AUX6/RS23C

AUX7/RS23C

AUX 1

AUX 2

AUX 3

AUX 4

Digital input 4

Solenoid B active

Digital input 5

Ramp Off

Digital input 6

Fixed preset value 1

Digital input 7

Fixed preset value 2

Digital input 8

Fixed preset value 4

Digita l ground

RS 232C

J2-9

J2-2

J2-3

J2-5

8

10

12

14

16

18

+5VDC

EPROM

RAM

EEPROM

20

22

Solenoid B active

18

Solenoid B active

Digi tal ou tput 1

Error

Digi tal ou tput 2

Digital ground

LED red

Error

LED yellow

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 6/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 7

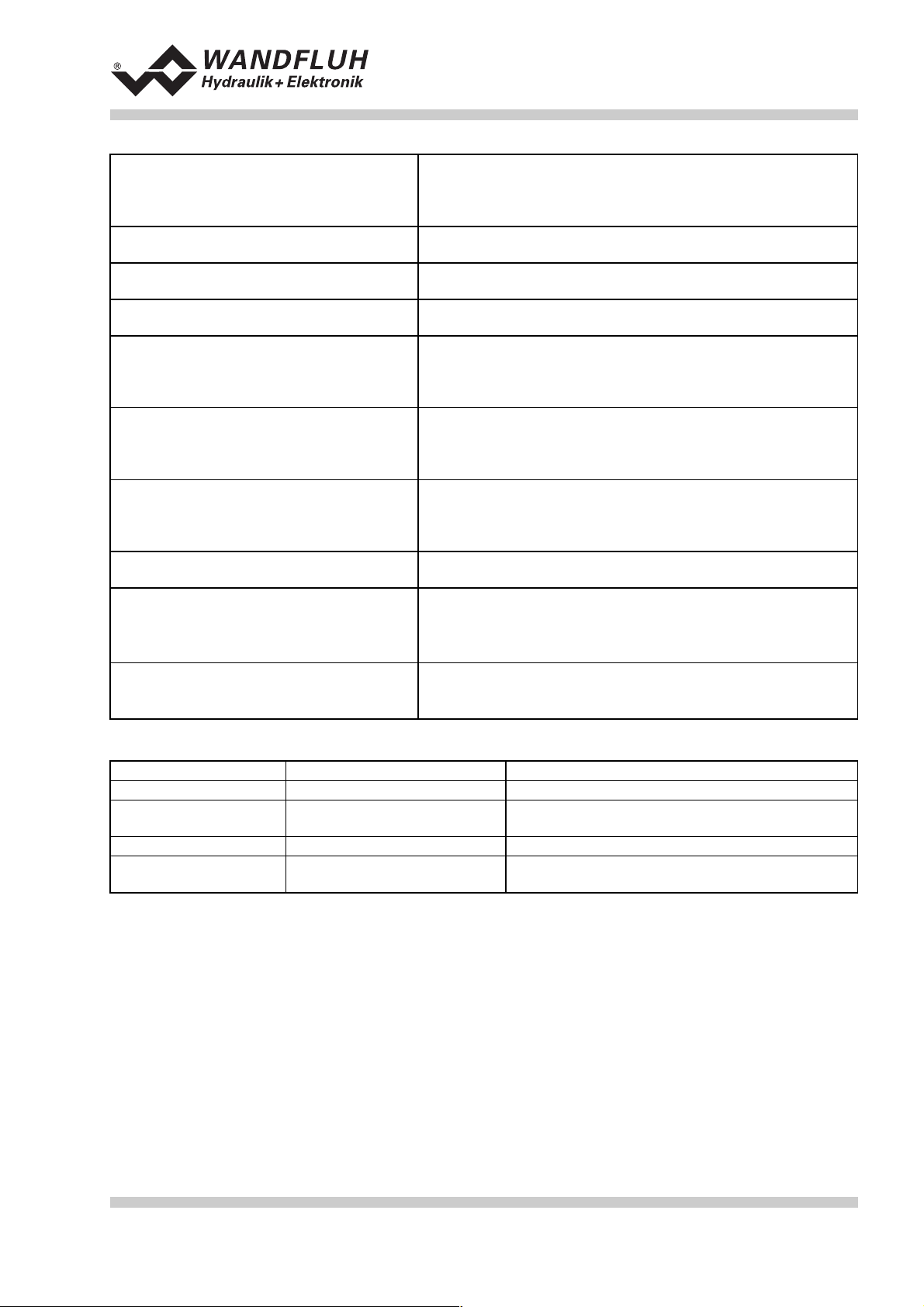

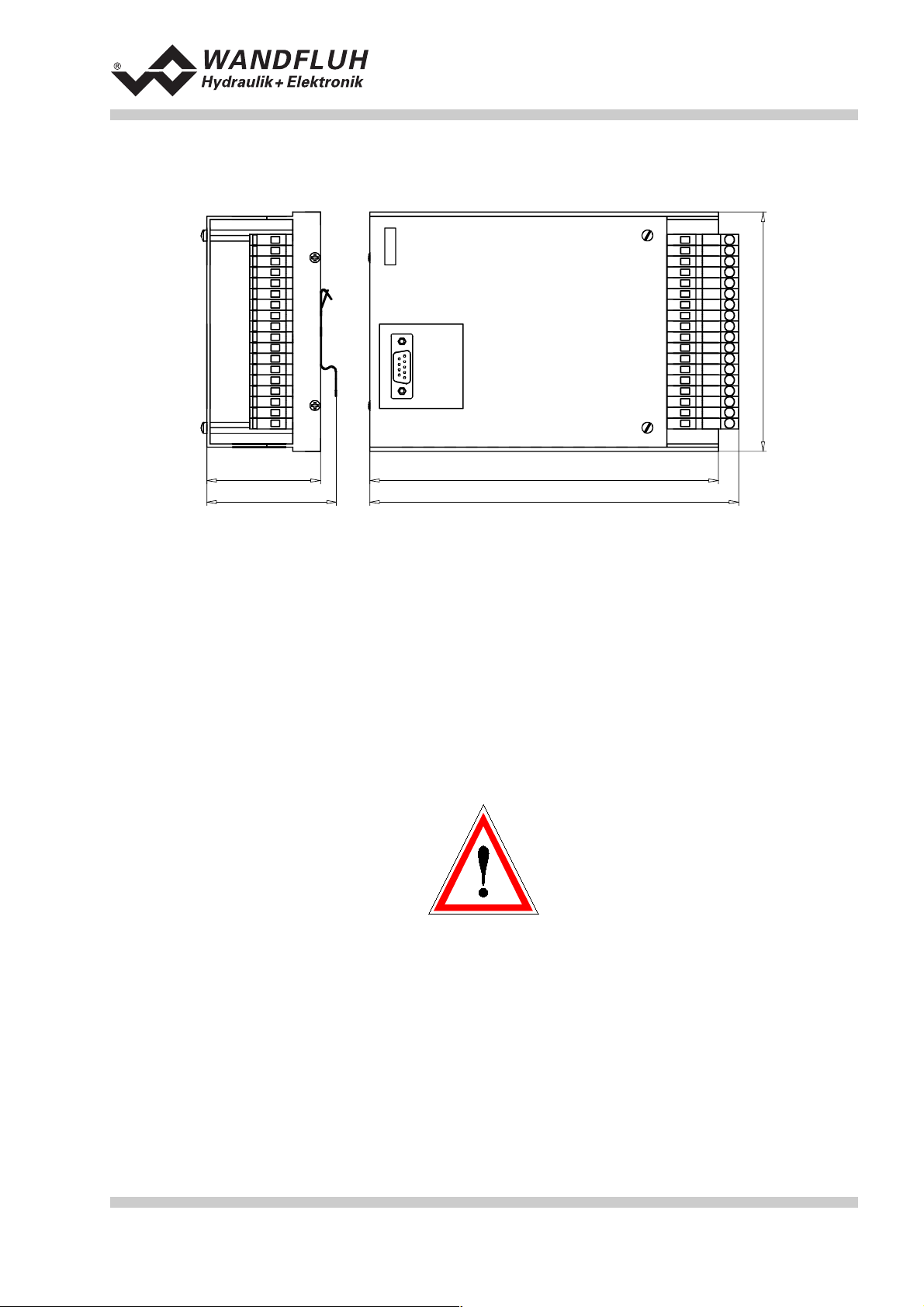

2.8 Dimensions

Operating guide to Amplifier SD1X0

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

111

53

60,5

162,5

172

3 Safety rules

3.1 Installation / Commissioning / Parameterization

• These operating instructions has to be carefully studied beforehand and the instructions are to be

complied with.

• Prior to the installation, all power supply voltages and any other energy sources have to be disconnected.

• During unpacking and when installing it, the card must only be gripped on the housing. Any contact with

soldering points, components and contact pins of the card should be avoided.

• W rong manipulations by the personal cannot be prevented by the card.

• Before the switching on of the supply voltage, the fuse protection, the correct wiring and the conformity of

the power supply voltage with the permissible supply voltage range have to be verified.

• The control monitors the working conditions within the electronic and within the

installation. Uncontrolled movements caused by unforeseen errors cannot be

prevented.

• Danger for persons has to be avoided by installing an emergency stop device

which cuts off the power to the system.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 7/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 8

Operating guide to Amplifier SD1X0

4 Construction and Function

Refer to the section "Block diagram SD1 " page 6

4.1 Introduction

• The Amplifier is constructed as an Eurocard

• The Eurocard is built into a housing made of alu

• All inputs and outputs have to be contacted trough the screw-on/plug-in connector strip

• The Version SD1102D20-AA has a RS232 (serial) interface, via which the parameterization and the

diagnostics can be made by using the multi-function terminal (MTG02) or PC-Terminalsoftware TESO

• The Version SD1302D20-AA has a RS232 (serial) interface, via which the parameterization and the

diagnostics can be made by using the PC-Parameterization software PASO

4.2 Description of the Function

The Amplifier serves for controlling proportional valves with one or two solenoids and includes constant

current control. Dither frequency and level are adjustable independently. Solenoid outputs are made short

circuit proof. Preset values can be connected in the range of 0 ... 10V or 0 ... ±10V. The analog inputs can be

used also as current inputs 0 ... 20mA or 4 ... 20mA. By that, the Amplifier can be adapted to all common

input signal types. By selecting one of the 4 operating modes, the Amplifier can be set in very universal.

Further, two independently working control loops are selectable.

Amended parameters can be stored in a non volatile memory to have them available when the control system

is switched on again.

4.3 Analog inputs

• The applied analog signal is digitalized in the 10-Bit A/D converter

Attention: By the input range 0 ... 8V, 0 ... 5v or 4 ... 20mA, the resolution is < 10-Bit!

• Differential inputs

Differential inputs must be used if the ground potential of the external preset value generator does not

agree with the analog ground on the Amplifier card.

If the differential input is intended to use like an analog input against analog ground, the - (minus)

connection of the differential input must be connected to the analog ground.

• Analog input with cable break detection

The preset value must be a current signal 4 ... +20mA or a voltage signal from a potentiometer. If a

potentiometer is used, its ground connection must be wired to the terminal "Analog ground with cable

break detection".

• Analog input 1 (for differential voltage signal)

Input voltage range: 0 ... +10V / 0 ... +8V / 0 ... +5V

• Analog input 2 (for differential current signal)

Input current range: 0 ... +20mA / 4 ... +20mA

• Analog input 3 (for voltage signal against analog ground)

Input voltage range: 0 ... ±10V / 0 ... ±8V / 0 ... ±5V

• Analog input 4 (for current signal against analog ground)

Input current range: 0 ... +20mA / 4 ... +20mA

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 8/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 9

Operating guide to Amplifier SD1X0

4.4 Digital inputs

• Digital inputs 1 and 2 are active-low (refer to section "Electrical specifications" page 4) and not galvanically

separated.

• Digital inputs 3 to 8 are acitve-high (refer to section (refer to section "Electrical specifications" page 4) and

galvanically separated via optical couplers.

Attention: Connect common optical coupler ground (14z)!

• Digital input 1 (Disable solenoid A)

If this input is set, solenoid output A is disabled.

• Digital input 2 (Disable solenoid B)

If this input is set, solenoid output B is disabled.

• Digital input 3 (Enable control)

If this input is set, the Amplifier is enabled. Without this enable, no movements can be made.

• Digital input 4 (Solenoid B active)

If this input is set, the solenoid B is acitve (only in the mode of operation 1).

• Digital input 5 (Ramp Off)

The ramp can be temporarily switched off by setting this input. If the ramp is never required, this input

needs not to be set since the ramp time is set to 0s.

• Digital input 6 - 8 (Fixed preset values)

7 fixed preset values, selectable in binary form, are available. When a fixed preset value is selected via

the digital inputs 6 - 8, the external preset value is ineffective.

The following inputs must be set to activate the corresponding fixed preset value:

Fixed preset value Digital input 6 Digital input 7 Digital input 8

External preset value

1

2

1

1

311

4

1

51 1

611

7111

Fixed preset values 1, 2 and 4 can be selected directly, i.e. without coding.

4.5 Outputs

• Proportional solenoid outputs A and B

The 2 solenoid outputs have a current output pulse-width-modulated at 1000Hz with superimposed dither.

The polarity of the connected solenoids is irrelevant. The outputs are short circuit proof and may be

loaded up to 1.8A.

• Digital output 1 (Error)

This output becomes active, when an error is present.

• Digital output 2 (Solenoid B active)

This output becomes acitve, when the solenoid B is active.

• Light emitting diodes LED green / yellow / red

LED green: Supply voltage is present

LED yellow: Solenoid B is acitve

LED red: Indicates an error

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 9/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 10

Operating guide to Amplifier SD1X0

4.6 Mode of operation

The following 4 mode of operation are possible:

• Mode of operation 1

With one analog input (voltage or current) and the digital input 4 (Solenoid B acitve), solenoid A and

solenoid B from a directional valve will be controlled.

0% ... 100% preset value, digital input 4 not active = Imin ... Imax solenoid A

0% ... 100% preset value, digital input 4 active = Imin ... Imax solenoid B

• Mode of operation 2

With one analog input (voltage or current), solenoid A and solenoid B from a directional valve will be

controlled.

0% ... 50% preset value = Imax ... Imin solenoid B

50% ... 100% preset value = Imin ... Imax solenoid A

• Mode of operation 3

With one voltage preset value from 0 ... ±100% at analog input 3, solenoid A and solenoid B from a

directional valve will be controlled.

-100% ... 0% preset value = Imax ... Imin solenoid B

0% ... +100% preset value = Imin ... Imax solenoid A

• Mode of operation 4

In this mode of operation, two solenoids can be controlled independently from each other. Each solenoid

is controlled by separate voltage or current input.

0% ... 100% analog input A = Imin ... Imax solenoid A

0% ... 100% analog input B = Imin ... Imax solenoid B

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 10/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 11

Operating guide to Amplifier SD1X0

5 Operating and Indicating elements

5.1 Introduction

The Amplifier is available as standard in two versions:

• The Version SD1102D20-AA has a RS232 (serial) interface, via which the parameterization and the

diagnostics can be made by using the multi-function terminal (MTG02) or PC-Terminalsoftware TESO

• The Version SD1302D20-AA has a RS232 (serial) interface, via which the parameterization and the

diagnostics can be made by using the PC-Parameterization software PASO

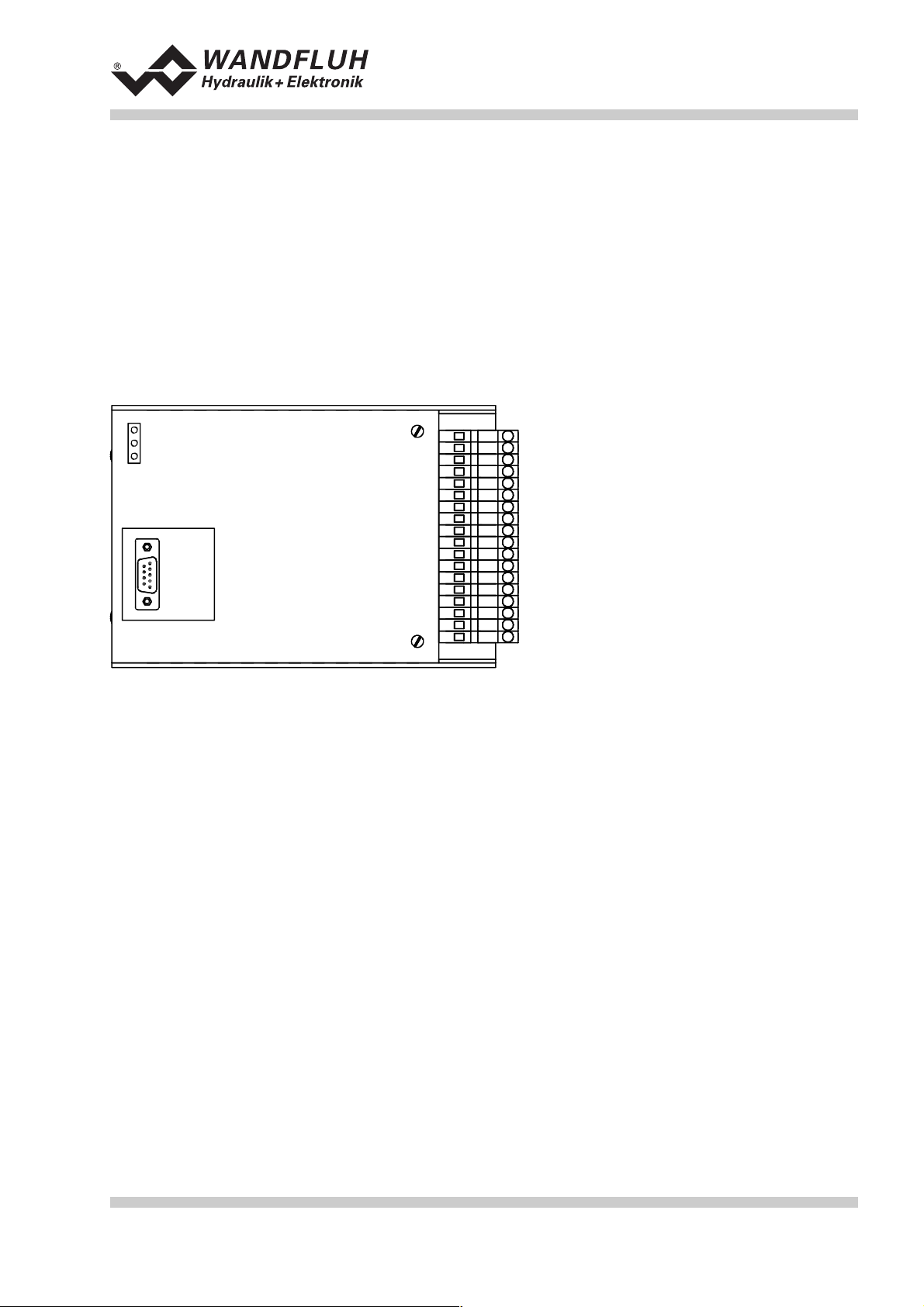

5.2 Top view

LED

grün

gelb

rot

9-pol

D-Sub

Schraub/

Steckleiste

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 11/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 12

Operating guide to Amplifier SD1X0

6 Commissioning

Please refer to the section "Safety rules" on page 7.

6.1 Installation / Connection

The Amplifier should preferably be installed in a switchboard cabinet.

For an installation / connection appropriate for EMC, the following points absolutely have to be observed:

• The housing has to be grounded on an electrically conducting sub-surface using a conductor strand with a

large cross section.

• The shielding connection (1) on the screw-on/plug-in connector strip has to be connected with the

switchboard cabinet with an as short as possible conductor with a strand cross section >= 1,5 mm

• The screening of the cable on the housing side must only be connected with the switchboard cabinet

using a large surface area and low Ohm connection (best by means of a clamp shackle).

• Solenoid- and signal cables must not be laid parallel to high voltage cables.

6.2 Connection instructions

The contact assignment of the following description refers to the section "Connection examples" page 15.

2.

6.2.1 Supply voltage

• For the dimensioning of the 24VDC power supply, the maximum power demand of the solenoid has to be

calculated (in case of directional valves, only the maximum power demand of one solenoid has to be

considered). This power then has to be increased by the no load power from the Amplifier (refer to the

section "Electrical specifications" page 4).

• The limit values of the supply voltage and its residual ripple indispensably have to be complied with (refer

to the section "Electrical specifications" page 4).

• The Amplifier has to be protected with a slow acting fuse. The rating of this fuse should correspond to

approx. 1.5 times the current calculated above.

6.2.2 Solenoid outputs

For the solenoid outputs, the polarity, with which the solenoids are connected, does not matter. The following,

however, has to be observed:

• The conductor strand cross section has to be adapted to the solenoid current

• Screened cables have to be used; the screen must be grounded only on the switchboard cabinet side.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 12/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 13

6.2.3 Digital inputs and outputs

• Digital inputs 1 and 2 are active-low and not galvanically separated.

• For activation, they have to be connected to 0V (ground)

Operating guide to Amplifier SD1X0

control extern control intern

0V

24V

• Digital inputs 3 - 8 are acitve-high and galvanically separated via optical couplers.

• In order to use the galvanically separation, the connection "Digital ground" (18) has to be connected to the

ground of the external digital signal transmitter.

• If no galvanically separation is necessary, the "Digital ground" (18) can be connected with the minus of the

24VDC power supply.

• For activation, they have to be connected to +24VDC.

control extern control intern

+24V

galvanically

separation

0V

18

• The digital outputs are "open collector" outputs.

control intern

galvanically

separation

control extern

+24V

18

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 13/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 14

6.2.4 Analog inputs 10-Bit

• There are two voltage and two current inputs available.

• One of each is a differential input.

• Each input can be adjust for each solenoid output.

control extern control intern

Operating guide to Amplifier SD1X0

voltage

input

large surface

connection

current

input

large surface

connection

+

-

+

-

6.2.5 Configuration of the analog inputs 10-Bit

The analog inputs 10-Bit can be configured as follows:

Input signal Connector strip assignment Input range

Voltage input against analog ground + to 33 / ground to 23 0 ... +5/8/10V

0 ... ±5/8/10V

Voltage input against analog ground with cable

+ to 33 / ground to 21 0 ... +5/8/10V

break detection

Voltage differential input + to 27 / - to 25 0 ... +5/8/10V

Current input against analog ground + to 35 / ground to 23 0 ... +20mA

4 ... +20mA

Current differential input + to 31 / - to 29 0 ... +20mA

4 ... +20mA

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 14/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 15

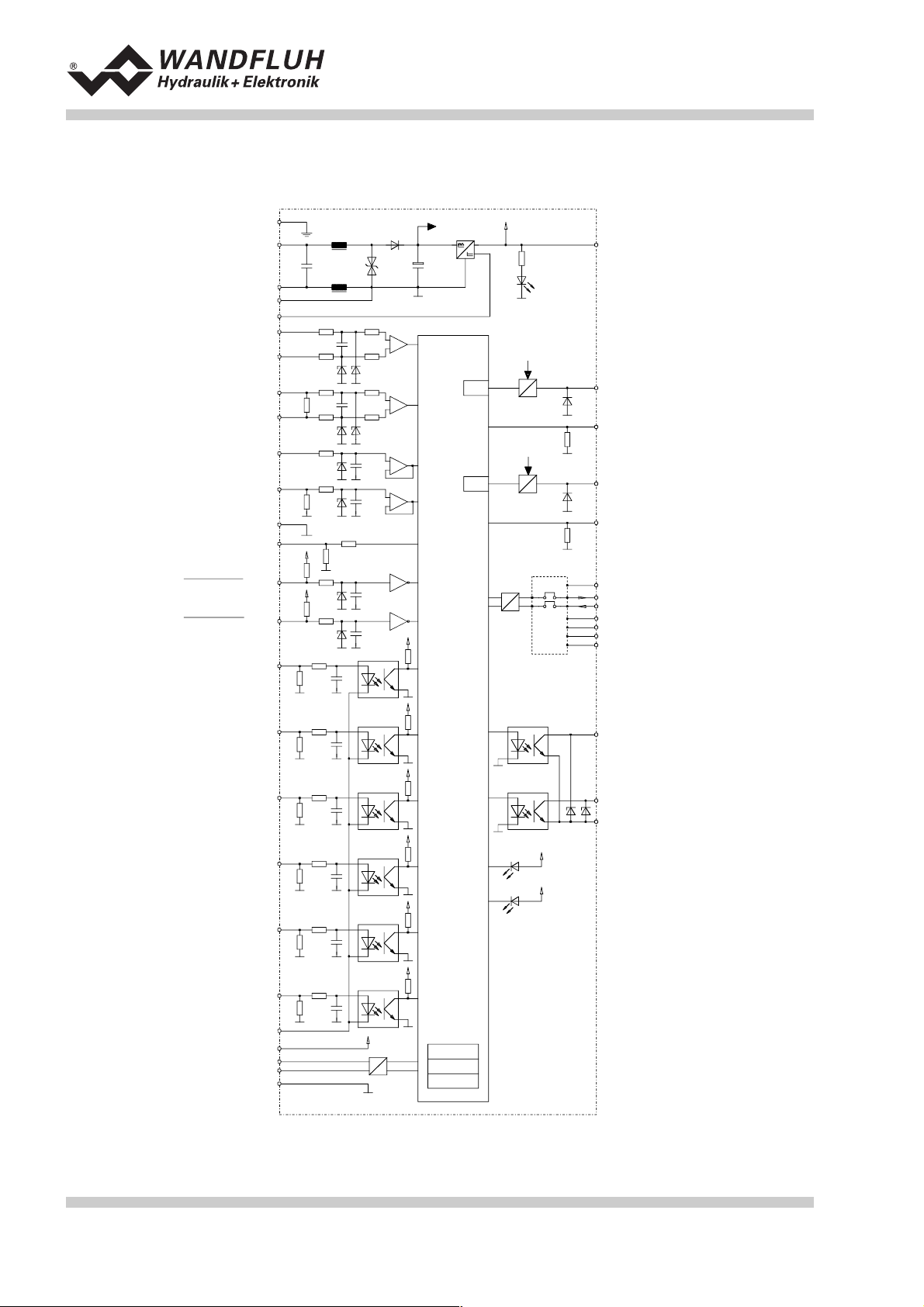

6.3 Connection examples

6.3.1 Mode of operation 1

• +10VDC voltage preset value with potentiometer

• digital inputs with switches without galvanically separation

Operating guide to Amplifier SD1X0

Supply

voltage 24VDC

Earth

Preset value from

potentiomete r

Common optical

coupler ground

Solenoid B aktive

Enable control

Ramp off

Fixed preset value 1

Fixed preset value 2

Fixed preset value 4

Disable solenoid A

Disable solenoid B

Fuse

+

-

Rack

5

SD1

3

1

19

33

23

18

8

6

10

12

14

16

2

4

6.3.2 Mode of operation 4

• +10VDC voltage preset value with potentiometer

• digital inputs with switches without galvanically separation

Directional valve

9

7

13

11

20

22

Rack

Rack

24V 24V

Error

active

Solenoid B

active

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 15/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 16

Operating guide to Amplifier SD1X0

Supply

voltage 24VDC

Earth

Preset value A

from potentiometer

Preset value B

from potentiometer

Common optical

coupler gro und

Enable control

Ramp off

Fixed preset value 1

Fixed preset value 2

Fixed preset value 4

Disable solenoid A

Disable solenoid B

Fuse

+

-

Rack

5

SD1

3

1

19

27

25

23

33

23

18

6

10

12

14

16

2

4

9

7

13

11

20

22

Rack

Rack

24V 24V

Error

active

Solenoid B

active

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 16/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 17

Operating guide to Amplifier SD1X0

7 Settings

Please refer to the section "Safety rules" on page 7.

7.1 Introduction

• The system- and parameter settings can be made it depends on the card version either via the RS232

interface with the multi-function terminal MTG02 resp. the PC-Terminal software TESO or the PCParameterization software PASO.

• For information about the operation via the multi-function terminal MTG02 resp. PC-Terminalsoftware

TESO please refer to section "Cyclic menu construction" page 28.

• For information about the operation via the PC-Parameterization software PASO please refer to section

"PASO Installation and Operation" page 29.

• The following instructions refer to the Menu order of the PC-Parameterization software PASO. To look for

the corresponding points in the version with multi-function terminal MTG02 resp. PC-Terminal software

TESO, the corresponding cyclic menu construction is also displayed.

• Depending on the software version and connecting card type, certain settings may be blocked.

7.2 General

In order for some of the menus resp. sub-menus listed below to be able to be selected, first a parameter set

must be present int the memory or else a new one has to be established. To do this, one of the following

commands has to be executed:

• File_New

• File_Open

• Start PASO with the connection to the Amplifier (in this case, the data are loaded from the Amplifier)

7.3 Tips for the first commissioning

• Connect the power supply, leave the Amplifier still switched off

• Switch off the hydraulic drive (hydraulics switched off)

• Carefully check the connections

• Switch on the power supply

• Establish the communication with PASO (connect the PC and the Amplifier with an RS232 cable and start

PASO)

• In the menu "Configuration", define the correct input for the preset value

• In the menu "Parameters_Valves", set the desired current for the solenoids

7.4 File - Menu (only PASO - Version)

Contained in the File menu are the menu points, which concern the file handling and the printing of the

parameters. In the "On Line Mode", some of these menu points are blocked..

7.4.1 File_New

This menu point is active only in the "Off Line Mode".

With this command, a new file can be opened. A selection window will be displayed. In this window, the

desired function from the PASO can be selected. The selected function should correspond to the function of

the connected digital card. All parameter values are set to standard values. The required values can now be

entered.

7.4.2 File_Open...

This menu point is only active in the "Off Line Mode".

With this command, an existing file from a storage medium is opened. First the file selection window appears.

In this window the required file can now be selected and opened with ”OK”. If the function of the selected file

does not correspond to the current function of the PASO, a message will be displayed. A selection is now

possible, if the event should be cancelled or if the current function from the PASO should change over to the

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 17/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 18

Operating guide to Amplifier SD1X0

new function of the selected file. The parameter values can now be edited and changed as required under

the menu points “Configuration” or “Parameters”.

7.4.3 File_Save

With this command, the parameters are saved on a data storage medium. All parameter values of all input

windows are saved under the current file name. If no file name has been defined yet, then first the file

selection window appears (refer to File_Save as...).

7.4.4 File_Save as...

With this command, the parameters are saved on a data storage medium. All parameter values of all input

windows are saved under the file name entered.

First the file selection window appears (see File_Open). In this window the desired file name can now be

entered. If the file name is entered without an extension, then the extension “.par” is automatically assigned

to it. After actuating the key “Save”, the file information window appears (see File_File-Info). In this window

the required entries can now be made. With the key “Save”, the file is then finally saved under the selected

file name. With the key “Cancel”, one changes back to the file window.

7.4.5 File_Print...

With this command, the current parameters are printed in ASCII text format. The File_Print window is

opened. In this window one can now select, whether the printing process is to be to a printer or to a file.

If the output is to be to a printer, then the Windows printer selection window is opened.. In this window,

please do not select “Print to File”. If you do, a new program start might possibly be required and you

could lose any data not yet saved.

If the output is to be to a file, then the file selection window appears. In this window the desired file name can

now be entered. If the file name is entered without an extension, then automatically the extension “.txt” is

assigned to it.

7.4.6 File-Info

With this command, the file information of an existing file is displayed. The file information consists of the

following parts:

Date, time Date, time of saving.

File name: The file name, under which the file has been saved.

Card type: The type of digital control card at the moment of saving. If no card is connected, then this

indication remains empty. In case of saving during “On Line Operation”, this indication is

updated.

Operator: The name of the originating person.

Remarks: Possibility to enter remarks concerning the file.

When the File_Info window appears during the execution of the command “File_Save”, then the

corresponding entries can be made in the various fields (with the exception of “Date”, “Time”, “File name” and

“Card type”, which cannot be edited). When the File_Info window appears during the execution of the

command “File_File-Info”, then the various fields cannot be edited.

7.4.7 File_Off Line (On Line)

Off Line

With this command, the connection with the Amplifier is interrupted. All menu points, which call for a

communication with the Amplifier, are blocked. The PASO software now runs in the “Off Line Mode”. The

loading, saving and the editing of parameter files is possible in this mode.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 18/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 19

Operating guide to Amplifier SD1X0

On Line

With this command, the connection with the Amplifier is established. The communication with the Amplifier is

briefly tested. If the connection works, then the user has the option of taking over the parameters from the

Amplifier or of transferring the parameters to the Amplifier. During the transfer of the parameters, the user

has the possibility of aborting the operation.

Before parameters are transfered to the Amplifier, a verification is carried out as to whether the version of the

Amplifier supports the parameter values. If this is not the case, then a message is issued and a transfer to

the controller is not possible.

If the parameters have been taken over by the Amplifier, then they are briefly checked. If one or several of

the parameters are outside the tolerance, standard values are assigned instead and a message is issued. If

the transfer was successful and the verification check was also successful, then the software subsequently

runs in the On Line Mode”. The loading of parameter files is not possible in this mode.

7.4.8 File_Exit

With this command, the parameterization program PASO is terminated. If parameter data have been

changed and have not yet been saved, then the question appears, as to whether these data should be saved.

When terminating, the current data from the configuration window are also saved.

7.5 Fixed preset value - Menu

SD1x02D2 Ver. E

<MODE>

Language:english

+-<±> ok<E>

....: <M>

Select: <E>

System: <M>

Select: <E>

Parameters <M>

Select: <E>

fixed preset:<M>

Select: <E>

When one of the fixed preset values 1 - 7 is selected, the external preset value is ineffective.

7.5.1 Generator

In this window, all adjustments according to the fixed preset values will be made.

Field Parameter description Range / Step

Fixed preset value X Desired value of the corresponding fixed preset value. The

adjusted %-value refer to the adjusted solenoid current

range (0% = Imin, 100% = Imax). A positive %-value will

activate the solenoid A, a negative %-value will activate the

solenoid B.

Parameters: <M>

Select: <E>

....: <M>

Select: <E>

Service: <M>

Select: <E>

0 ... 100%

0.1%

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 19/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 20

7.6 Parameters - Menu

Operating guide to Amplifier SD1X0

SD1x02D2 Ver. E

<MODE>

Language:english

+-<±> ok<E>

System: <M>

Select: <E>

Parameters: <M>

Select: <E>

Service: <M>

Select: <E>

In this window, all parameter values of the Amplifier will be made.

7.6.1 Parameters_Valves

Parameters: <M>

Select: <E>

....: <M>

Select: <E>

current A/B: <M>

Select: <E>

....: <M>

Select: <E>

dither: <M>

Select: <E>

In this window, all settings specific to the valves will be made.

Field Parameter description Range / Step

Preset value internal

(only PASO-Version)

If this switch is selected, an internal preset value from 0%

resp. 100% will be active during the setting of the Imin resp.

Imax. If this switch is not selected, the external preset value

will be active.

Prop. Valve settings The minimum and the maximum solenoid current can be

set separately for each solenoid output, corresponding to

0% resp. 100% preset value.

In the "Off Line Mode", the displayed current value is the

theoretical preset current. This makes it possible to set the

Imin/Imax values without a solenoid or a valve is connected

to the Amplifier (only PASO-Version).

In the "On Line Mode", if the Imin setting is active, a preset

value of 0% resp. if the Imax setting is active, a preset

value of 100% is automatically applied internally (with the

PASO-Version only if the switch "Preset value internal" is

selected).

As a result of the digitalisation, the numbers entered max

be modified to less "rounded-off" number.

Imin A Set minimum solenoid current A.

(= solenoid current by 0% preset value)

Imax A Set maximum solenoid current A.

(= solenoid current by 1000% preset value)

Imin B Set minimum solenoid current B.

(= solenoid current by 0% preset value)

Imax B Set maximum solenoid current B.

(= solenoid current by 1000% preset value)

0 ... 950mA

2mA

0 ... 1800mA

2mA

0 ... 950mA

2mA

0 ... 1800mA

2mA

Frequency The dither frequency can be set in steps. 20, 40, 60, 70, 80, 90,

100, 110, 125, 140,

165, 200, 250Hz

Level Level of the superimposed AC signal 0 ... 199mA

2mA

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 20/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 21

7.6.2 Parameters_Analog inputs

Parameters: <M>

Select: <E>

Operating guide to Amplifier SD1X0

analogInput: <M>

Select: <E>

....: <M>

Select: <E>

...: <M>

Select: <E>

Dependent of the settings from the menu "Configuration_System", certain settings may be blocked.

Field Parameter description Range / Step

Analog inputs Dependent of the selected mode of operation and the

selected analog inputs, the settings of the parameter

"Offset" and "Window" can be made here (refer to the

below figure)

Offset This parameter can be set only in the mode of operation 2.

Dependent of the selected signal type, the setting is in V or

mA.

Voltage:

Current:

0 ... ±1.24V

0 ... ±2.48mA

Window X Window width for each analog input. Dependent of the

selected mode of operation are one or two settings

possible. Dependent of the selected signal type, the setting

is in V or mA.

Voltage:

0 ... ±4.96mA

Current:

Solenoid current [%]

100

0.01V

0.02mA

0 ... 2.48V

0.02V

0.04mA

Window

0

Preset value [%]0100

Offset

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 21/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 22

7.6.3 Parameter_Ramps

Parameters: <M>

Select: <E>

Operating guide to Amplifier SD1X0

....: <M>

Select: <E>

ramps A/B: <M>

Select: <E>

....: <M>

Select: <E>

In this window, all adjustments according to the ramp function will be made.

Field Parameter description Range / Step

Solenoid A

Solenoid B

After a preset value jump, the new preset value is

approached via a linear ramp (with the set ramp time). A

ramp time up and ramp time down can be set separately

for each solenoid.

Ramp up The set ramp time refer to a preset value jump from 0% to

100%

Ramp down The set ramp time refer to a preset value jump from 100%

to 0%

0 ... 51s

0.05s

0 ... 51s

0.05s

7.6.4 Parameters_Store (not PASO-Version)

Parameters: <M>

Select: <E>

....: <M>

Select: <E>

....: <M>

Select: <E>

store: <M>

Select: <E>

With this command, the set parameters can be stored in the non volatile memory (EEPROM) on the

Amplifier. With the PASO-Version, this will be made automatically by leaving a input window with the key

"OK".

7.7 Configuration - Menu

SD1x02D2 Ver. E

<MODE>

Language:english

+-<±> ok<E>

System: <M>

Select: <E>

In this window, the settings of the function of the Amplifier will be made.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 22/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Parameters: <M>

Select: <E>

Service: <M>

Select: <E>

Page 23

Operating guide to Amplifier SD1X0

7.7.1 Configuration_System

In this window, the basic function of the Amplifier will be adjust.

In the version with multi-function terminal resp. PC-Terminalsoftware TESO, a password question appears.

Press the + and - keys in succession as the password.

Field Parameter description Range / Step

Mode of operation Select the desired mode of operation 1 / 2 / 3 / 4

Cablebreak Switch on/off the cablebreak detection of the analog inputs no

yes

Input Signal In the mode of operation 4, the selection is possible, if the

following settings should be for the analog input for the

Input A

Input B

solenoid A or for the solenoid B.

Signal type Select the desired signal type. Dependent of the selected

mode of operation, not all signal types are available.

0-5V

0-8V

0-10V

0-20mA

4-20mA

Used input A selection can be made between voltage and current

inputs. Only the corresponding inputs to the selected signal

type are available.

AnaInp1 [V]

AnaInp2 [mA]

AnaInp3 [V]

AnaInp4 [mA]

Inversion The preset value can be inverted.

0% preset value = 100% solenoid current

no

yes

100% preset value = 0% solenoid current

With leaving the window with the key "OK", a check will be made, if for the input A and input B the used input

is different. If not, a message will be displayed and the window cannot be left.

7.7.2 Configuration_Digital I/O

SD1x02D2 Ver. E

<MODE>

Language:english

+-<±> ok<E>

datas: <M>

Select: <E>

System: <M>

Select: <E>

Service: <M>

Select: <E>

diagnostics: <M>

Select: <E>

Parameters: <M>

Select: <E>

SetDigInputs:<M>

Select: <E>

Service: <M>

Select: <E>

With this command, the digital inputs of the connected Amplifier can be set to active, not active or released.

Field Parameter description Range / Step

Digital Inputs Set digital input with software

Reset digital input with software

Read in the external digital input

1

0

X

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 23/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 24

7.7.3 Configuration_Default setting

ED1x02D2 Ver. E

<MODE>

Operating guide to Amplifier SD1X0

Language:english

+-<±> ok<E>

System: <M>

Select: <E>

Parameters: <M>

Select: <E>

Service: <M>

Select: <E>

With this command, the default settings in the EPROM on the connected Amplifier will be loaded and read to

the PC in the PASO-Version.

7.7.4 Configuration_Interface (only PASO-Version)

With this command, the serial output port for the communication with the connected control card can be

selected. This setting is automatically saved in the file “konfig.kon” and taken over with a new start.

If the software is in the "On Line Mode", then the communication is broken off when the “OK” key is pushed.

If the software is in the "Off Line Mode", then a confirmation window appears with the question, as to whether

the communication with the axis controller is to be tested. If the communication works, a corresponding

message is issued and a connection with the axis controller can be established via the menu point File_On

Line.

If no communication can be established (transmission interference or no axis controller card connected), then

an error message appears. All menu points and keys, which contain an action in connection with the

communication, are then blocked.

Field Parameter description Range / Step

Output port The serial port of the PC can be selected. COM1

COM2

COM3

COM4

7.7.5 Configuration_Language

SD1x02D2 Ver. E

<MODE>

Language:english

+-<±> ok<E>

System: <M>

Select: <E>

Parameters: <M>

Select: <E>

Service: <M>

Select: <E>

In this window, the language can be selected, with which the menu will be inscribed. In the version with multifunction terminal MTG02 resp. PC-Terminalsoftware TESO, the menu language question appears after the

card is switched on for the first time. During the execution, the language can be changed at any time in menu

"System". In the PASO-Version, this setting is automatically saved in the file "konfig.kon" and taken over with

a new start.

Field Parameter description Range / Step

Language Field, from which the desired language can be selected. deutsch

english

français

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 24/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 25

7.8 Analysis - Menu

Operating guide to Amplifier SD1X0

SD1x02D2 Ver. E

<MODE>

Language:english

+-<±> ok<E>

System: <M>

Select: <E>

Parameters: <M>

Select: <E>

Service: <M>

Select: <E>

In the Analysis menu, measured values can be displayed on-line and various process signals can be

recorded and correspondingly displayed.

7.8.1 Analysis_Values

Service: <M>

Select: <E>

datas: <M>

Select: <E>

diagnostics: <M>

Select: <E>

SetDigInputs:<M>

Select: <E>

This menu point is active only in the "On Line Mode".

With this command, all relevant data of the connected axis controller are read-in and displayed. The values

are continually updated (on-line).

Field Description Unit

Supply voltage Power supply voltage of the card V

Analog input X Voltage- resp. current value of the analog input for the

solenoid A

Analog input X Voltage- resp. current value of the analog input for the

solenoid B

V

mA

V

mA

Control voltage A Control signal before solenoid output A V

Solenoid current A Solenoid current of solenoid A mA

Control voltage B Control signal before solenoid output B V

Solenoid current B Solenoid current of solenoid B mA

Digital inputs 1 - 8 Logical conditions of the digital inputs

When the inputs are set

When the inputs are not set

1

0

Digital outputs 1 - 2 Logical conditions of the digital outputs

When the outputs are set

When the outputs are not set

1

0

7.8.2 Analysis_Diagnostic

Service: <M>

Select: <E>

datas: <M>

Select: <E>

diagnostics: <M>

Select: <E>

SetDigInputs:<M>

Select: <E>

With this command, possibly present errors on the connected Amplifier are indicated. The error is read in

once. In the version with multi-function terminal MTG02 resp. PC-Terminalsoftware TESO, only the text in the

column "Diagnostics" will be displayed. For making an exact analysis of the error, this operating guide has to

be contacted. In the PASO-Version, a complete description of the error will be displayed.

Diagnostics: Error Error remedy

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 25/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 26

Operating guide to Amplifier SD1X0

Power supply fault If the supplied voltage < 18VDC. the

Disable and reenable the control

solenoid outputs are blocked.

Cable break supply This error is only detected, if the

Disable and reenable the control

parameter "cablebreak" is set to "yes".

The power supply and/or the ground of

the preset generator is interrupted. The

solenoid outputs are blocked.

Cable break input X This error is only detected, if the

Disable and reenable the control

parameter "cablebreak" is set to "yes".

The preset value signal to the controller

is interrupted. The corresponding

solenoid output is blocked.

Solenoid output X The connection to the solenoid is

Disable and reenable the control

interrupted. The corresponding solenoid

output is blocked. This fault is only

detected if the solenoid current should

be > 100mA.

Memory: XX Error in verifying EEPROM-RAM data.

The solenoid outputs are blocked.

Switch off and on the control or resave

the parameters

7.9 Help - Menu (only PASO-Version)

The PASO-Help based on the standard Windows-Help construction.

7.9.1 Help_Description of the function

A general information about the function of the Amplifier will be displayed.

7.9.2 Help_Contents

The list of contents of the PASO-Help will be displayed.

7.9.3 Help_Index

The list of index of the PASO-Help will be displayed.

7.9.4 Help_Card Identification

This menu point is only active in the "On Line Mode".

Here the current version of the hardware and the software from the connected Amplifier will be read and

displayed.

7.9.5 Help_Info

Information about PASO and its version.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 26/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 27

Operating guide to Amplifier SD1X0

8 The system does not work

In this section, the generally possible errors and the procedures for eliminating them are listed and explained.

8.1 Procedure

The following check list can be used to help, if a problem is arised.

Question: Action: Possible errors and causes

Green LED off Analysis_Values ● The 24VDC supply is not switched on

● The 24VDC supply is wrongly or not connected

● If the supply voltage value is between 21VDC and 30VDC, the

supply is correct

Red LED on Analysis_Values

Power supply error

Analysis_Diagnostic

Cablebreak supply

Analysis_Diagnostic

Cable break input X

Analysis_Diagnostic

Solenoid output X

Analysis_Diagnostic

Memory XX

● The supplied voltage is under 18VDC. The error is also displayed

if a supplied voltage interruption occurred (t > 250ms).

● Is the supplied power enough?

● Is the AC voltage too high (refer to section "Electrical

specifications" page 4)

● When the error is cleared, disable the controller for a short period

and re-enable (DigInp 3)

● If the preset value encoder is a potentiometer, the supply is

absent

● The ground connection of the potentiometer is not connected to

the connector strip.

● Check connections to the potentiometer

● If the cablebreak detection is not desired, switch off the

cablebreak function in the menu "Configuration".

● When the error is cleared, disable the controller for a short period

and re-enable (DigInp 3)

● The cable break detection functions only with potentiometer or 4

... 20mA preset value.

● The preset value signal is absent or is smaller than 4mA.

● Check the preset value signal connections between the preset

value encoder and card.

● If the cablebreak detection is not desired, switch off the

cablebreak function in the menu "Configuration".

● When the error is cleared, disable the controller for a short period

and re-enable (DigInp 3).

● The connections to the solenoid is interrupted.

● Check the connections to the solenoids.

● When the error is cleared, disable the controller for a short period

and re-enable (DigInp 3) or disable the corresponding solenoid

only a for short period and re-enable.

● Error in verifying EPROM-RAM data.

● Error has occurred while writing to or reading from the EPROM.

● If fault occurred while storing, store again, then switch card off

and on.

● If fault occurred when card was switched on, store parameter,

then switch card off and on.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 27/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 28

Operating guide to Amplifier SD1X0

9 Cyclic menu construction

The operation via the display/keys or the multi-function terminal MTG02 resp. the PC-Terminalsoftware

TESO is in the form of a cyclic menu structure.

Carte

Identification

Parameters: <M>

Select: <E>

System: <M>

Select: <E>

Service: <M>

Select: <E>

To move through the cyclic menu, press the key "MODE". All existing menu items are listed in the section

"Settings" page 17 with the number 7.x.

To enter a program branch, press the key "ENTER":

Parameters: <M>

Select: <E>

current A/B: <M>

Select: <E>

regulator: <M>

Select: <E>

dither: <M>

Select: <E>

to move through the sub cycle menu, press the key "MODE". All existing menu items are listed in the section

"Settings" page 17 with the number 7.x.x.

To enter a parameter branch, press the key "ENTER":

current A/B: <M>

Select: <E>

Imin A: 150mA

+-<±> ok<E>

more Parameters

+-<+> ok<E>

With the keys "+" and "-", the desired value can be adjusted. With the key "ENTER", the next parameter

value will be displayed. All existing parameters are listed in the section "Settings" page 17 with the column

"Field".

The detailed description of all commands and parameters is located in the section "Settings" page 17 of this

operating guides.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 28/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 29

Operating guide to Amplifier SD1X0

10 PASO Installation and Operation

The parameterisation software PASO serves for the parameterising and diagnosing of digital control cards of

the WANDFLUH AG company. The software provides a user interface, through which by means of a

keyboard or a mouse all adjustments and settings can easily be carried out. The communication with the

digital control card takes place through a serial RS 232 interface.

The parameterisation software PASO can only be utilised in connection with a digital control card of

the WANDFLUH AG company. It is necessary to carefully study the operating instructions of the

connected digital control card beforehand.

10.1 PASO system requirements

A description of the different PASO versions is located in the file "history.pdf". This file is located in the

directory where the PASO will be installed.

In order to be able to correctly utilise the PASO, an IBM-compatible PC with the following requirements has to

be available:

• Processor 486 or higher, min. 33MHz, min. 8MB RAM

Recommended: 80586 66MHz or higher, 16 MB RAM or more

• Free harddisk storage space of minimum 4MB, plus storage space for program files

• Operating system MS-WINDOWS 95/98, NT 4.0 or higher

• Standard VGA or higher graphics card, recommended resolution 800x600

• At least one serial RS 232 interface (with Laptops resp. Notebooks without a serial interface, this can be

realised with a PCMCIA-card)

• Serial RS232 cable 1:1 (RxD and TxD not crossed)

10.2 PASO installation

The PASO software can be downloaded via the Internet free of charge (www.wandfluh.com/Download =>

PASO ED1/SD1 => Download Program files) or on request delivered on an installation-CD.

The installation of the PASO is then carried out by executing the file "setupPasoEd1vxxxx.exe", where "xxxx"

means the current version (e.g. setupPasoEd1v3000.exe, see also version index). An installation program

takes over the complete installation of PASO. To them, the Windows Installer must be installed. This is

normally a part of the Windows Environment. If not, please download it from the Microsoft Website.

If there is already a version of the PASO software installed on the PC, one can select if the existing version

should be overwritten or removed.

For all standard cards (Amplifier, Position controller, Pressure/Flow controller and Position controller PLUS),

the helpfiles are included in the setup and are installed automatically. For the special cards ED1AE, ED1AF,

ED1AG, ED1AP, SD1AY and SD1BA the helpfiles can be downloaded separate via the internet

(www.wandfluh.com/Download => PASO ED1/SD1 => Download Helpfiles for Special types)

10.3 PASO connection to the digital card

The connection between the PC, on which the parameterisation software PASO is installed and the axis

controller takes place through the serial RS 232 interface. To do this, a 1:1 cable (RxD and TxD not crossed)

has to be connected with the desired output port on the PC and with the RS 232 socket on the axis controller.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 29/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 30

Operating guide to Amplifier SD1X0

The parameterisation software PASO runs in one of two modes:

• In the "Off Line"-mode, the processing of the parameter files is possible. The communication with the axis

controller is not active. A connection is not necessary.

• In the "On Line"-mode, there is active communication with the axis controller card. Every change becomes

immediately effective in the axis controller. In this mode, the loading and processing of files is not

possible. Solely the saving of the currently active parameters into a file is possible.

The change between the two modes takes place through the menu point “File_On Line / Off Line”. In case of

an interference in the communication, the controlling of the axis controller is not assured anymore. An error

message follows and the PASO software automatically changes over to the "Off Line"-mode.

When the parameterisation software PASO is started up, a check takes place, as to whether a

communication with the axis controller is possible. If no communication can be established, an error

message appears. The reason for this message is either a not connected - or a not switched on axis

controller, or else on the PASO side not the same interface has been selected as the one used for the

connection cable to the axis controller. In the latter case, one must reply with “No” and after the PASO start

has taken place one changes the interface port setting in the menu "Configuration_Interface (only PASOVersion)" page 24.

If one replies with “No”, then an additional message appears. The PASO software is set to the "Off Line"mode. All menu points and keys, which involve an action in connection with the communication, are then

blocked. All other functions of the parameterisation software PASO, such as the processing of parameter

files, can be utilised without any limitation.

If one replies with “Yes”, then it is once again checked, whether now a communication with the digital

controller card is possible.

If the interruption of the communication occurs during the operation of the parameterisation software PASO,

then an error message appears and the PASO software is set to the "Off Line"-mode. All menu points and

keys, which involve an action in connection with the communication, are now blocked.

In order to re-establish a communication, the menu point "File_Activate On Line" has to be selected.

If a communication with the connected card is possible, a check will be made, if the current function from the

PASO correspond to the function of the connected card type. If yes, the parameters will be transfered. If no,

in case of "Take over", a question will be displayed if the current function from the PASO should be changed

or not. In case of "Reprogram", an error message will be displayed and the parameters can not be transfered.

10.4 PASO program description

In the following section, you will find a detailed description of the function from the parameterisation software

PASO.

10.4.1 Description of the keys

TAB Transfer to the next input element

SHIFT-TAB Transfer to the previous input element

ENTER Execution of the active input element or conclusion of an input.

ESC Abort, undoing of an action.

In many cases corresponds to the key "Cancel".

F1 Activation the key "Help"

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 30/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 31

Operating guide to Amplifier SD1X0

10.4.2 Input elements

Key A key executes the action, with which it is inscribed.

Actuation of a key through the keyboard:

● Push the key TAB, until the key becomes active.

● Push the key ENTER. The action is now carried out.

● Push the key ALT and the underlined letter of the key inscription: The action is

carried out immediately.

Actuation of a key with the mouse:

● Click on the corresponding key. The action is now carried out.

Switch By means of a switch, a selection between two possibilities is possible. A switch is

either switched on or - off.

Actuation of a switch through the keyboard:

● Push the keys UP or HOME to switch on the switch.

● Push the keys DOWN or END to switch off the switch.

● Push the SPACE key for changing over (switching over).

Actuation of a switch with the mouse:

● Click on the switch for changing over (switching over).

Input field The input fields enable the entering of numbers or text. All applicable keys of the

keyboard are allowed, including the keys HOME, END, LEFT, RIGHT. In certain

cases when taking it over, the input is checked and if necessary an error message

is issued.

Actuation of an input field through the keyboard:

● Push the key ENTER or TAB to finish with the input field.

● In the case of input fields with ARROW keys UP and DOWN: Actuation of the

UP-/DOWN - keys for the step by step changing of the values.

Actuation of an input field with the mouse:

● Click within the input field, in order to position the cursor in it.

● In the case of input fields with ARROW keys UP and DOWN: Click on the

corresponding arrow for the step by step changing of the values.

Selection field The selection fields enable the selection from various possibilities.

Actuation of a selection field through the keyboard:

● Push the SPACE key to open all selection possibilities. With the help of the

keys UP, DOWN, HOME, END, make the required selection. Subsequently

push the ENTER key to confirm the required selection, or else the ESC key to

undo the selection.

● Push the key UP to cyclically select the previous selection.

● Push the key DOWN to cyclically select the next selection.

● Push the key HOME to select the first item of the selection list.

● Push the key END to select the last item of the selection list.

Actuation of a selection field with the mouse:

● Click inside the selection field so that all selection possibilities are displayed

and then click on the required selection.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 31/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 32

Operating guide to Amplifier SD1X0

10.4.3 Starting of PASO

Following the successful installation, the parameterisation software PASO can be started by double-clicking

on the PASO - icon. Certain settings of the PASO software, e.g., the selected interface port, are saved in the

file “konfig.kon”. When PASO is started for the first time, the configuration values int this file are set to

standard values. During the course of running the program, these values can be corrected.

After the start-up, the Start window appears:

Header line

Menu line

Icon list

Status line

During the start-up, the parameterisation software PASO checks, whether a digital controller card is

connected. If no communication can be established (communication interference or no axis controller

connected), an error message appears. All menu points and keys, which involve an action in connection with

the communication, are then blocked. All other functions of the parameterisation software PASO can be

utilised without any limitation.

If the communication works without any interference, the software PASO checks, if the current function of the

PASO correspond with the function of the connected digital controller card. If no, a question will be displayed

if the current function from the PASO should be changed or not.

If the function is ok or will be changed, the parameters are loaded from the card and subsequently a

verification of the axis controller values takes place. If one or several parameters are outside the

corresponding tolerance, they are replaced with standard values and a message is issued (refer to section

"Limiting value error" page 33). In this case the communication is set to the "Off Line"-mode. The user now

has the possibility to check the parameters and if necessary to correct them. The communication is resumed

again via the menu point “File_On Line”. Subsequently one has to select the option “Re-program the axis

controller”, in order for the corrected values to be made active on the axis controller.

The menu points in the menu line can be selected in the following manner:

• by clicking on them with the mouse

• by actuating the key "ALT" and the underlined letter of the required menu point

• if a menu point has been selected, then by means of the keys "Arrow left" and "Arrow right" one can

change to the next menu point and with the keys "Arrow up" and "Arrow down" one can change to the next

sub-menu point within the menu selection field.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 32/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 33

Operating guide to Amplifier SD1X0

In the header line of the window, the name of the current file is always displayed. If no existing file has been

loaded or if the data have not been saved to a file, then this line reads ”noname”. Also the current function of

the PASO is displayed.

The following states will be displayed in the status line:

• 1. field: Selected RS232 interface

• 2. field: Current mode (On line or Off Line)

10.4.4 Store parameter on the controller card

Each new input value is immediately transferred to the connected controller card after the completion of the

input field (either by pushing the key ENTER or by activating another input field).

If the window is closed with the key "OK", the values are stored in the connected controller card so that they

are available after the controller card is switched on again (non-volatile memory).

If the window is closed with the key "Cancel", the previous current values are active again. All inputs made in

the current window are cancelled.

10.4.5 Limiting value error

Each incoming parameter (either transferred via the serial interface or loaded from a file) is checked against

the limiting value. If a parameter is smaller or bigger than its limiting value (= limiting value error), it is set

automatically to the default value and the following window appears:

Parameter: Name of the parameter with the limiting value error

Current value: Current value of the parameter

Min. value: Minimum allowed value of the parameter

Max. value: Maximum allowed value of the parameter

Default value: Default value of the parameter

After pressing the key "OK", the current value is overwritten by the default value.

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 33/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 34

Operating guide to Amplifier SD1X0

Normally, a limiting value error does not happen. However, in the following cases it can happen:

• loading a file, in which parameter values have been changed from outside

• reading parameter values from a connected controller card with another configuration than the current

configuration in the PASO (only if the controller card was changed while in the "On Line"-mode)

• if the transmission of the parameter values is wrong

10.5 Description of Commands

The description of the individual commands and parameters is contained in section "Settings" page 17.

11 Disposal

• The electronics card has to be disposed of in accordance with the generally applicable regulations of that

country, in which it is being used.

• Electronics cards are recycled by companies specialised in this field.

12 Additional information

You can find additional information in the following Wandfluh documentations:

Wandfluh-Electronics general Documentation A Register 1.13

Accessories Documentation A Register 1.13

Proportional directional control valves Documentation A Register 1.10

Proportional pressure control valves Documentation A Register 2.3

Proportional flow control valves Documentation A Register 2.6

Wandfluh AG Tel. ++41 33 672 72 72 E-mail: sales@wandfluh.com Page 34/35

Postfach 134 Fax ++41 33 672 72 12 Internet: www.wandfluh.com Edition 03 38

CH-3714 Frutigen sd1x0bae.doc

Page 35

Operating guide to Amplifier SD1X0