LENGA

Installation, Servicing and User instructions

500 - 800 | Front, Bay and Corner

EN

v.1.0-112016

This appliance has been tested and certied for other counties (see technical data). However to install

appliance in other countries, modication of the appliance and its method of installation may be

necessary in order to use the appliance safely and correctly. The manual for the local language must be

obtained. Contact Wanders for further information.

2

© Copyright 2016 Wanders res & stoves

The information contained herein is subject to change without notice. Wanders res & stoves shall not be liable for technical or editorial errors or omissions contained herein.

1. General Notes 3

2. User instructions 4

2.1 First Time of Operation 4

2.2 Remote control 4

2.3 Wanders Eco Wave App control (optional) 4

2.4 Cleaning and Maintenance 4

3. Installation instructions. 4

3.1 Gas Connection 4

3.2 Ventilation 4

3.3 Appliance Fireplace Installation 4

3.3.1 Building the Fireplace 5

3.3.2 Built-In Fireplace Sizing 5

3.3.3 Mantel Clearances 6

3.4 Flue Connection 8

3.4.1. General Notes 8

3.4.2 Timber Frame Construction 8

3.4.3 Carport or Building Extension 8

3.4.4 Basements, Lightwells and Retaining walls 8

3.4.5 Terminal Locations 9

3.4.6 Horizontal Wall Vent Termination type C11 10

3.4.7 Vertical Roof Vent Termination type C31 10

3.4.8 Flue restrictors to be tted 10

3.4.9 Typical installations 11

3.5 Fuel Bed Media and Arrangements 12

Lenga 500 12

Lenga 800 17

3.6 Commissioning the Appliance 24

3.6.1 Pilot Ignition Check 24

3.6.2 Main Burner Check 24

3.6.3 Pressure Check 24

4. Servicing 24

4.1 Cleaning the Ceramics 25

4.2 Servicing the Burners 25

4.3 Opening the Glass 25

Terugplaatsen van de glasruit 25

5. Technical Information 26

5.1 Countries of use 26

5.2 Technical Data 27

5.2.1 Lenga 500 27

5.2.2. Lenga 800 27

5.3 Dimensions 28

5.3.1.a Lenga 500 A 28

5.3.1.b Lenga 500 AB 28

5.3.1.c Lenga 500 AE 29

5.3.1.d Lenga 500 ABE 29

5.3.2.a Lenga 800 A 30

5.3.2.b Lenga 800 AB 30

5.3.2.c Lenga 800 AE 31

5.3.2.d Lenga 800 ABE 31

Electrical diagram 32

3

Installation, Servicing and User Instructions | EN

1. General Notes

• This Wanders gas appliance is a High Eciency, Balanced Flue Live Fuel Eect appliance. It provides radiant

and convected heat using the latest burner technology. As well as having a variable heat output, these res

also utilise a special control system that allows the appliance to use two burners for high output or a single

burner for lower outputs.

• One of the burners will be designated as the “Main” Burner, this is the Front, the second burner will be

designated as the “Eect” Burner. The Eect burner can be switched ON or OFF whilst the appliance is alight.

• Before Installation, check that the local distribution conditions, nature of the gas and pressure, and adjustment

of the appliance are compatible.

• This appliance is intended for use on a gas installation with a governed meter.

• This Gas Installation may only be installed by a registered professional competent person (Gas Safe installer in

the UK). The installation must adhere to the requirements of the local and national Building regulations and

national standards. The installation manual must also be followed.

• Ensure that the Flue Terminal is not in any way obstructed and is clear of vegetation, i.e. trees, shrubs etc. and

that no objects are leant against the terminal or guard.

• Always clean the Window Panel before the re is ignited. Any nger prints must be removed, as these will be

burnt into the glass and will be un-removable.

• Do not operate this appliance if the glass panel has been broken (or cracked), removed or is open.

• The appliance is designed to t numerous installation situations as listed in these installation instructions.

However only ue approved by Wanders for this appliance may be used.

• This appliance is a balanced ue product and is room sealed and as such requires no additional ventilation for

operation. However an adequate supply of fresh air to maintain temperatures and a comfortable environment

is recommended.

• This appliance is designed as a heating appliance, and as such will get very hot in operation; all surfaces (except

the controls and access door) are considered to be working surfaces and as such should not be touched. The

front windows and surrounds are not considered to be fully secure guards against accidental contact. It is

recommended that an approved re screen be used if children, the elderly or persons with limited mobility

are to be present in the same area.

• Do not place curtains, laundry, furniture etc. within a safe distance of 300mm of this appliance.

• Do not attempt to burn rubbish on this appliance.

• If this appliance is extinguished, on purpose or other, no attempt to relight should be made within 3 minutes.

4

2. User instructions

2.1 First Time of Operation

Before igniting the appliance, ensure that all packaging, safety stickers and any protective wrapping have been

removed, and that the glass has been cleaned, including all ngerprints from the glass.

Ensure that the room is adequately ventilated the rst time that the appliance is ignited; we would recommend

opening windows if possible. Run the appliance at full setting for a few hours so that the paint gets an opportunity

to fully cure. During this period it is possible for some fumes and vapours to be given o. We would recommend

keeping children and pets out of the area at this time.

2.2 Remote control

Please refer to the separately added manual for the SYMAX remote control system.

2.3 Wanders Eco Wave App control (optional)

Please refer to the separately added manual for the Wanders Eco Wave control system.

2.4 Cleaning and Maintenance

This appliance should be inspected and serviced once a year by a qualied, competent and registered person.

The inspection and maintenance must at least ensure that the appliance is working correctly and safely. It is

advisable to clean the appliance of any dust and debris before regularly during the heating season and especially

if the appliance has not been used for some time. This can be done with a soft brush and a vacuum cleaner or a

damp cloth and if required a non-abrasive cleaning agent. Do not use corrosive or abrasive substances to clean

the appliance.

3. Installation instructions.

Before commencing Installation, conrm that the details on the appliance data plate correspond to the local

distribution conditions, gas type and pressure to which the appliance is to be installed.

Ensure that gas supply and supply pipe is capable of delivering the required volume and pressure of gas and is in

accordance with the rules in force.

3.1 Gas Connection

This appliance has a gas inlet connection of Ø 8mm.

3.2 Ventilation

This appliance is a Balanced Flue room sealed appliance, and as such needs no additional ventilation. However an

adequate supply of fresh air to maintain temperatures and a comfortable environment is recommended.

This appliance may be installed in a completely sealed or mechanically ventilated house.

3.3 Appliance Fireplace Installation

• Determine the position required for the appliance.

• Create a gas connection for the appliance in approximately the correct location for the gas controls.

• The gas controls are connected to the Burner of the appliance. These controls need to be located in the

control access box, so an appropriate position for the access box needs to be determined.

• This appliance has fully adjustable legs, these must me set to the desired length before the ue position is

nalised. Fine adjustment of the legs is available via the feet.

• Do not make any adjustments to the appliance, except the leg length.

• The appliance should be tted with a minimum clearance of 150mm from any combustible objects or

materials; this includes any combustible materials used for the replace construction. This clearance distance

can be reduced to 50mm if a Cement Board, of minimum thickness 12mm is used. This Cement Board will act

as a Thermal Break.

• The clearance distance of the Flue from combustibles must not be less than 75mm. This dimension can be

reduced to 25mm as the distance from the underside and the sides of Horizontal Flue runs.

5

Installation, Servicing and User Instructions | EN

• As this is a room sealed appliance and the appliance stands on appropriate legs, a hearth is not required for

this appliance.

• The Fireplace should be ventilated with openings giving a total free vent area of 200 cm².

• A gap of 50mm should be left all round the appliance.

• If a shelf is to be tted above the replace opening, a gap of 150mm minimum should be left between the

opening and the shelf.See section 3.3.3, Mantel Clearances.

• The brackets supplied may be used for securing the appliance to a rear wall.

3.3.1 Building the Fireplace

• Construct a studwork replace to the desired sizes, minimum sizes are shown in section 3.3.2. Any combustible

material used to construct the Fireplace must not be closer than the minimum dimensions quoted in section

3.3 above. Cement Board of minimum thickness 12mm, can be used as a Thermal Break and can be used

directly against the Frame Face on the appliance.

• Do not use insulation material (or other) to pack the void around or above the appliance.

• Provide ventilation from the replace to the minimum amount quoted in 3.3 above.

• Provide a cut-out for the Control Access Door.

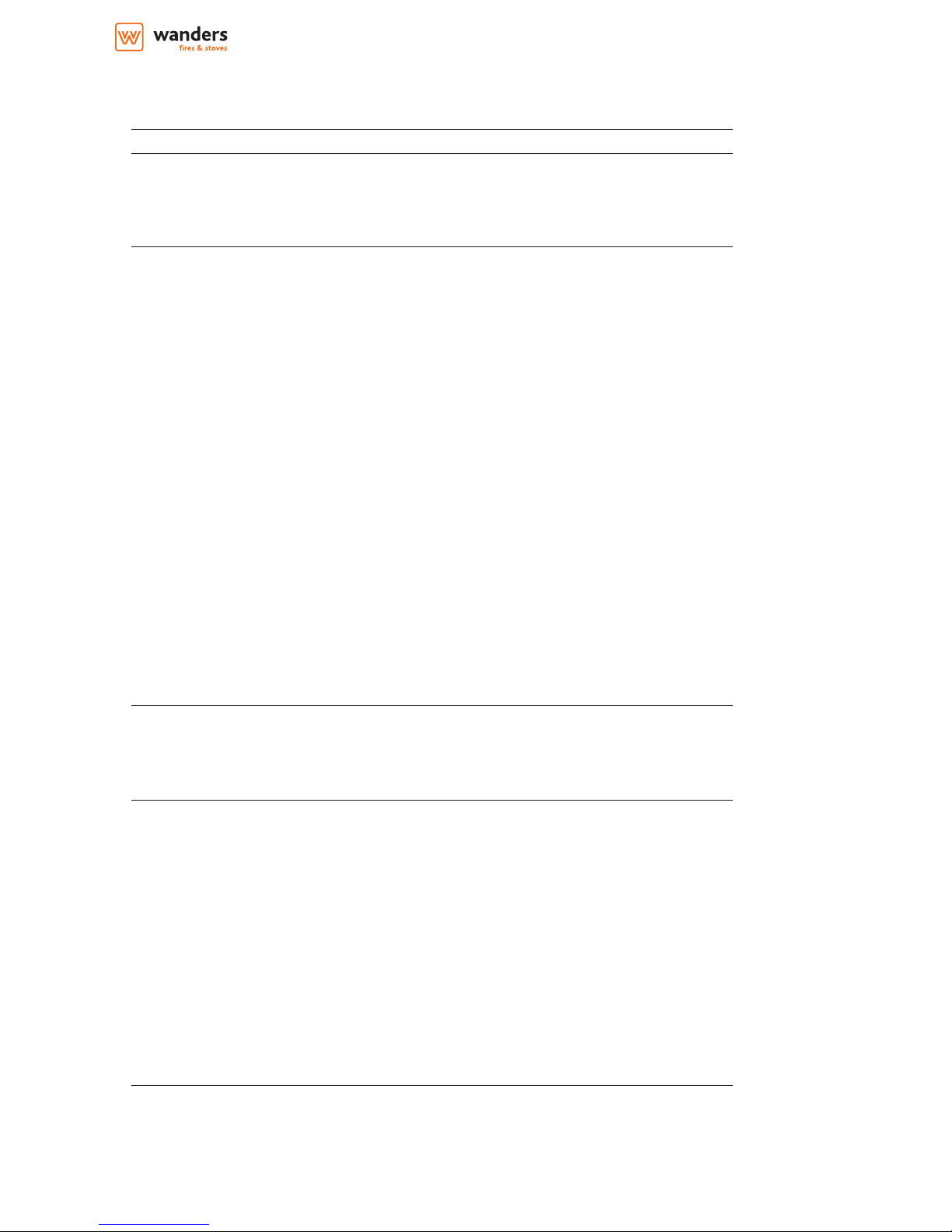

3.3.2 Built-In Fireplace Sizing

(assuming a Cement Board Lining is used)

Appliance

A

minB minC minD min

E

min

F

minG minH min

Lenga 500 A 552 905 655 415 195 1235 n/a n/a

Lenga 500 ABC n/a 905 600 415 195 1235 290 n/a

Lenga 500 AB/AC n/a 905 640 415 195 1235 290 505

Lenga 800 A 852 755 955 415 195 1083 n/a n/a

Lenga 800 ABC n/a 755 900 415 195 1083 290 n/a

Lenga 800 AB/AC n/a 755 940 415 195 1083 290 805

6

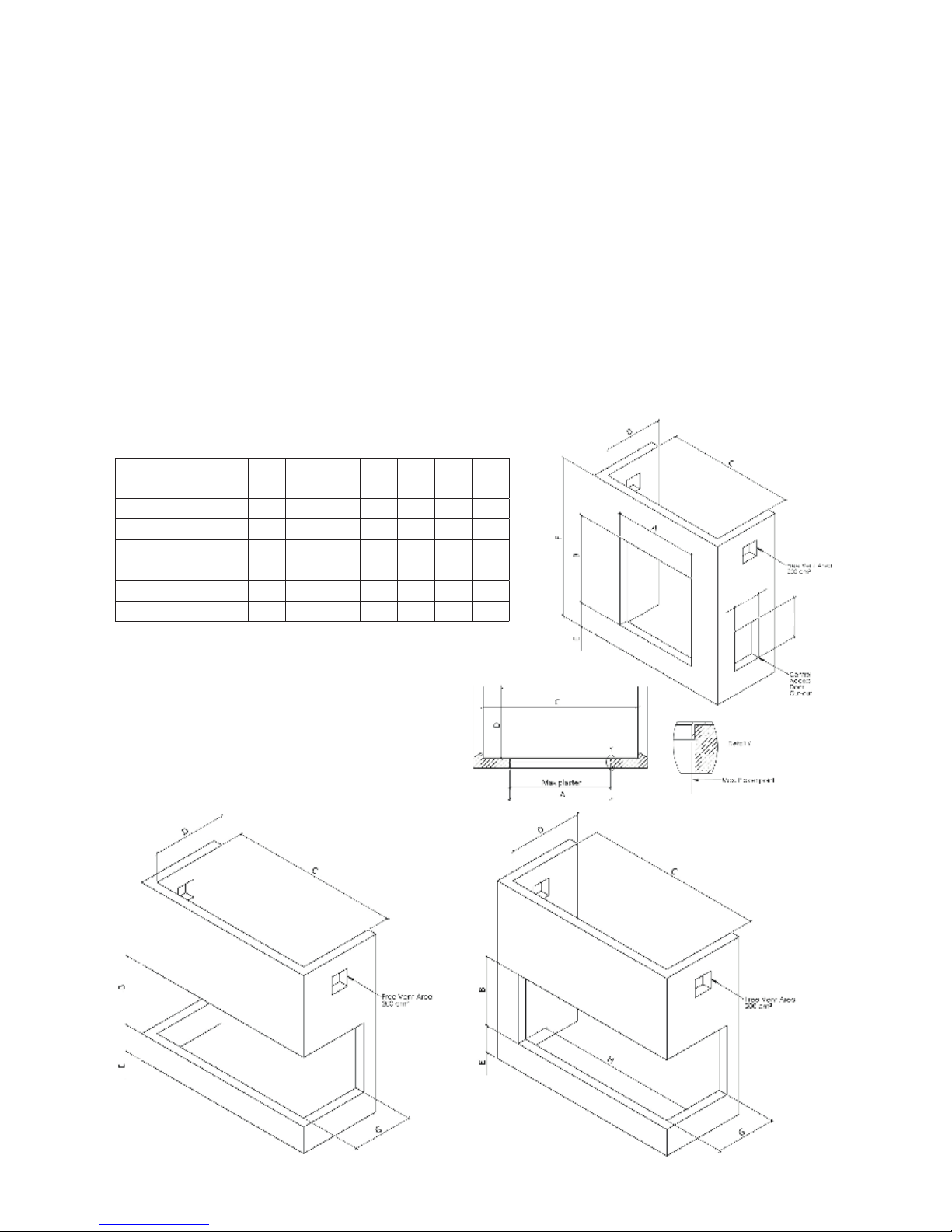

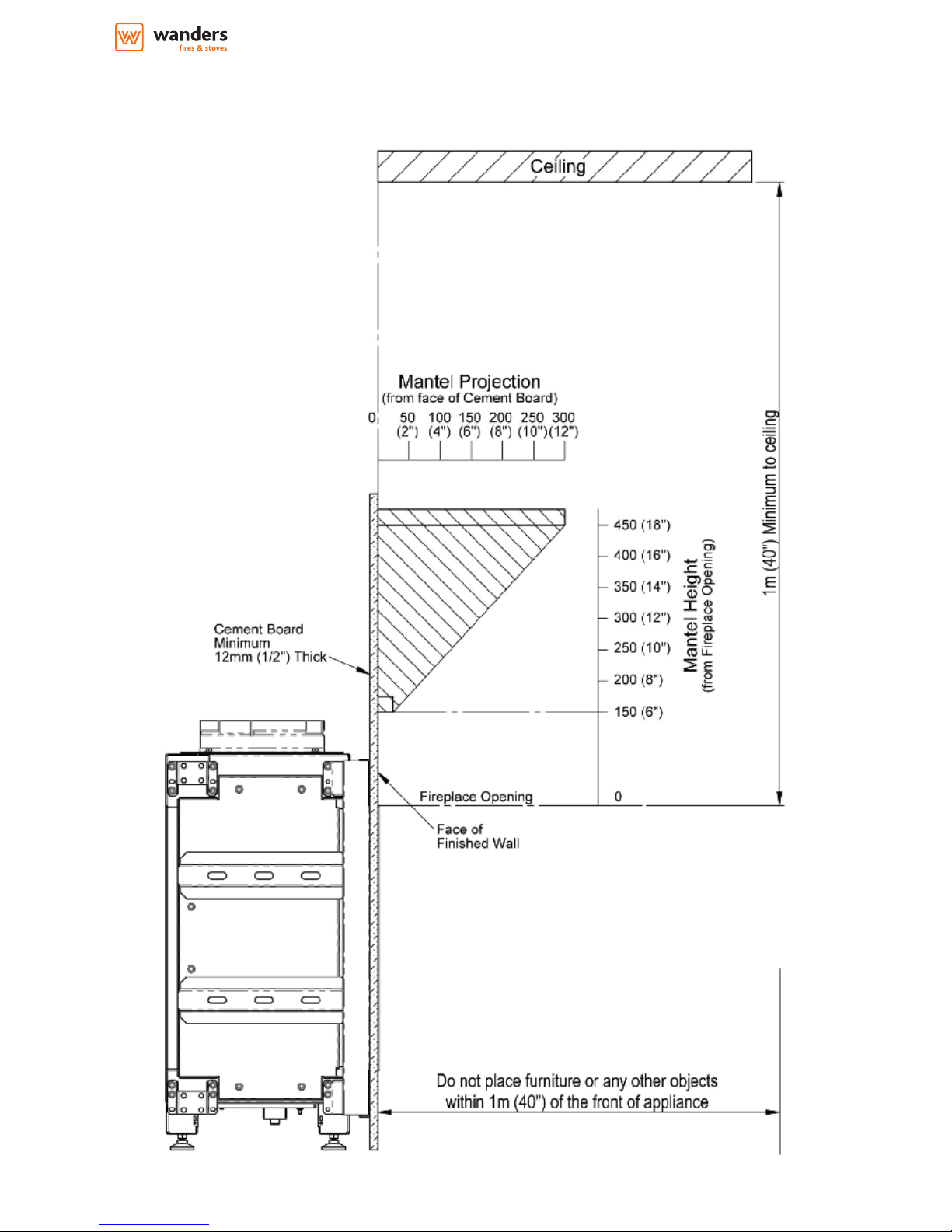

3.3.3 Mantel Clearances

3.3.3.a Combustible Mantel - side view

7

Installation, Servicing and User Instructions | EN

3.3.3.b Combustible Mantel/Side Wall - top view

8

3.4 Flue Connection

3.4.1. General Notes

This appliance may be installed with a roof terminal (C31) or a wall terminal (C11).

This appliance may only be used with Balanced Flue (otherwise known as Concentric Flue) parts as specied by

Wanders. The Wanders specied ue parts have been approved with the appliance. If the appliance is installed

on non-Wanders approved parts, Wanders cannot guarantee or accept and responsibility for the proper and safe

working of the appliance.

The ue system must be constructed from the appliance upwards, with all joints being fully locked and sealed

using the Wanders specied parts. Flue systems approved for this Appliance:

• Muelink & Grol (M&G) Concentric.

• Poujoulat PGI.

• Metaloterm US.

3.4.2 Timber Frame Construction

Whilst it is possible to install room-sealed appliances in timber frame properties, great care needs to be taken to

ensure that the ue assembly does not interfere with the weather proong qualities of any outer wall which it

may penetrate. Before attempting this work, further details need to be referenced, (e.g. “Gas Installations in Timber

Frame Buildings” from the CORGI installer series in the UK).

3.4.3 Carport or Building Extension

Where a ue terminal is sited within a carport or building extension, it should have at least two completely open

and unobstructed sides. The distance between the lowest part of the roof and the top of the terminal should be

at least 600mm.

Note: A covered passageway should not be treated as a carport. Flues should not be sited in a covered passageway

between properties.

3.4.4 Basements, Lightwells and Retaining walls

Flue terminals should not be sited within the connes of a basement area, light well or external space formed by a

retaining wall, unless steps are taken to ensure the products of combustion can disperse safely at all times. It may

be possible to install this Balanced Flue system in such a location provided that it is not sited lower than 1m from

the top level of that area to allow combustion products to disperse safely.

Flue terminals should be sited to ensure total clearance of the combustion products in accordance with the

included information.

When the products of combustion are discharged, they should not cause a nuisance to adjoining or adjacent

properties and they should be positioned so that damage cannot occur to other parts of the building. If the outer

wall surface is constructed of combustible material, a non-combustible plate should be tted behind the terminal

projecting 25mm beyond the external edges of the terminal.

9

Installation, Servicing and User Instructions | EN

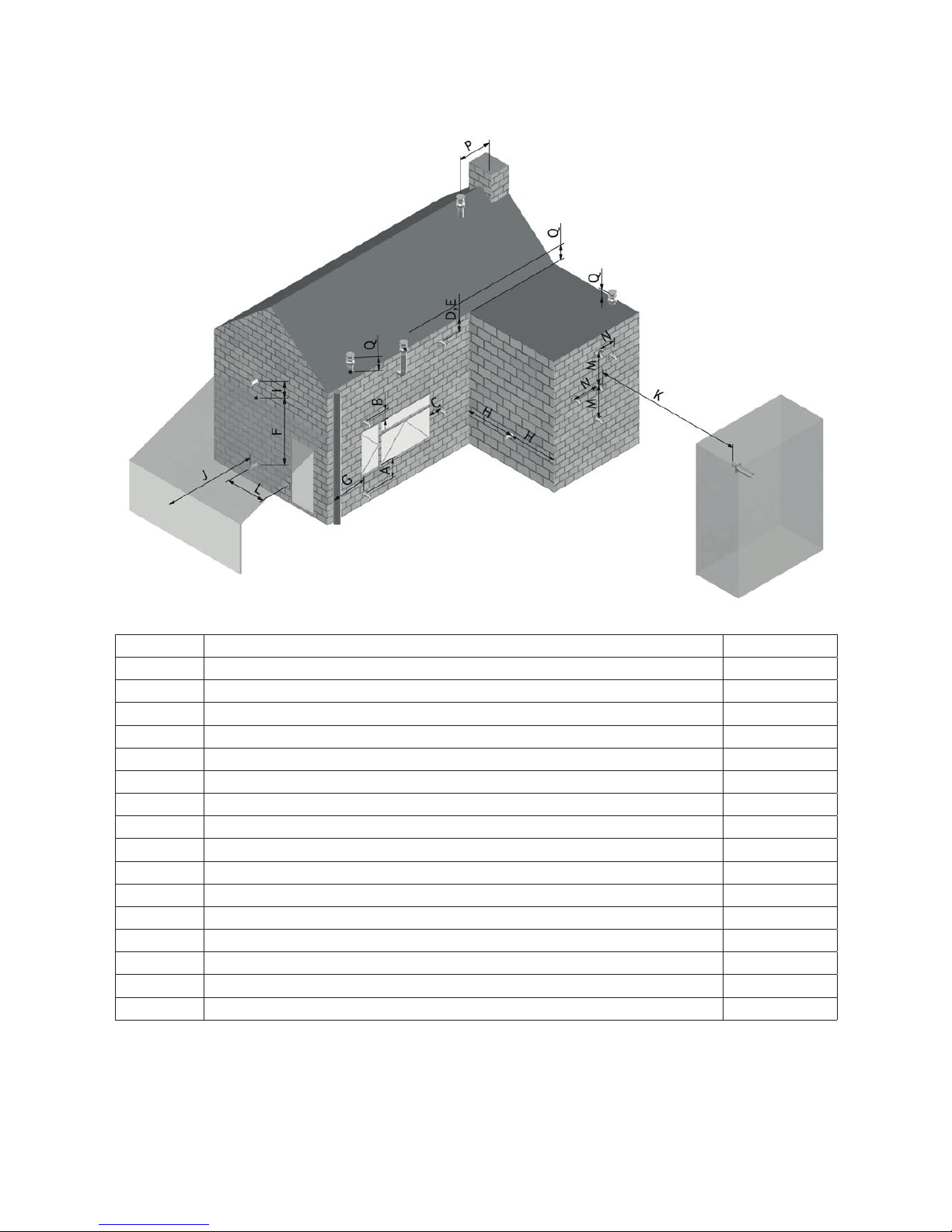

3.4.5 Terminal Locations

Dimension Terminal Position Distance (mm)

A* Directly below an opening, air brick, opening window etc. 600

B Above an opening, air brick, opening window etc. 300

C Adjacent to an opening, air brick, opening window etc. 400

D Below gutters, soil pipes or drain pipes 300

E Below eaves 300

F Below balconies or car port roof 600

G From a vertical drain pipe or soil pipe 300

H From an internal or external corner 600

I Above ground roof or balcony level 300

J From a surface facing the terminal 600

K From a terminal facing the terminal 600

L From an opening in the car port (e.g. door, window into the dwelling) 1200

M Vertically from a terminal on the same wall 1500

N Horizontally from a terminal on the same wall 300

P From a vertical structure on the roof 600

Q Above intersection with roof 150

* In addition, the terminal should not be nearer than 300mm to an opening in the building fabric

formed for the purpose of accommodating a built in element such as a window frame.

10

3.4.6 Horizontal Wall Vent Termination type C11

Flue sizing and regulations.

Lenga 500

• Ø100/150 Connector on appliance.

• Ø100/150 to be used throughout.

• Maximum horizontal length is 3 meters.

• Minimum vertical length directly on appliance is 1 meter.

• Maximum pipe extension for outside wall (H) is 2 x vertical pipe rise (V).

• Maximum length of the entire system (excl. outlet terminal) is 10 meters.

• Flue Terminal: Ø100/150 Part No. INK.4330

Lenga 800

• Ø130/200 Connector on appliance.

• Ø130/200 to be used throughout.

• Do NOT reduce to 100/150.

• Maximum horizontal length is 3 meters.

• Minimum vertical length directly on appliance is 1 meter.

• Maximum pipe extension for outside wall (H) is 4 x vertical pipe rise (V).

• Maximum length of the entire system (excl. outlet terminal) is 10 meters.

• Flue Terminal: Ø130/200 Part No. INK.4430

3.4.7 Vertical Roof Vent Termination type C31

Flue sizing and regulations.

Lenga 500

• Ø100/150 Connector on appliance.

• Ø100/150 to be used throughout.

• Maximum horizontal length is 3 meters.

• Minimum vertical length directly on appliance is 1 meter.

• Maximum length of the entire system (excl. outlet terminal) is 10 meters.

• Flue Terminal: Ø100/150 Part No. INK.4335

Lenga 800

• Ø130/200 Connector on appliance.

• Ø130/200 to be used throughout.

• Reducing to 100/150 is allowed if the ue run is entirely vertical with a maximum length of 10 meters. The rst

meter needs to be 130/200.

• Reducing to 100/150 is allowed when the ue run has elbows in it, but only at the very last moment just

before the roof outlet.

• Maximum horizontal length is 3 meters.

• Minimum vertical length directly on appliance is 1 meter.

• Maximum length of the entire system (excl. outlet terminal) is 10 meters.

• Reducer Ø130/200 > 100/150 Part No. INK.4490

• Flue Terminal: Ø100/150 Part No. INK.4430

3.4.8 Flue restrictors to be tted

The restrictor can be installed with the pre-installed M5x20 bolts

Lenga 500

Wall terminal:

• Ø100/150, vertical rise 1 meter, no restrictor

• Ø100/150, vertical rise > 1 meter, 35 mm restrictor

Roof terminal:

• Ø100/150, vertical rise < 2 meter, 35 mm restrictor

• Ø100/150, vertical rise > 2 meter, 60 mm restrictor

11

Installation, Servicing and User Instructions | EN

Lenga 800

Wall terminal:

• Ø130/200, vertical rise 1 meter, no restrictor

• Ø130/200, vertical rise 1-2 meter, 35 mm restrictor

• Ø130/200, vertical rise > 2 meter, 50 mm restrictor

Roof terminal:

• Ø130/200, vertical rise < 1 meter, no restrictor

• Ø130/200, vertical rise 1-2 meter, 35 mm restrictor

• Ø130/200, vertical rise 2-4 meter, 50 mm restrictor

• Ø130/200, vertical rise > 4 meter, 60 mm restrictor

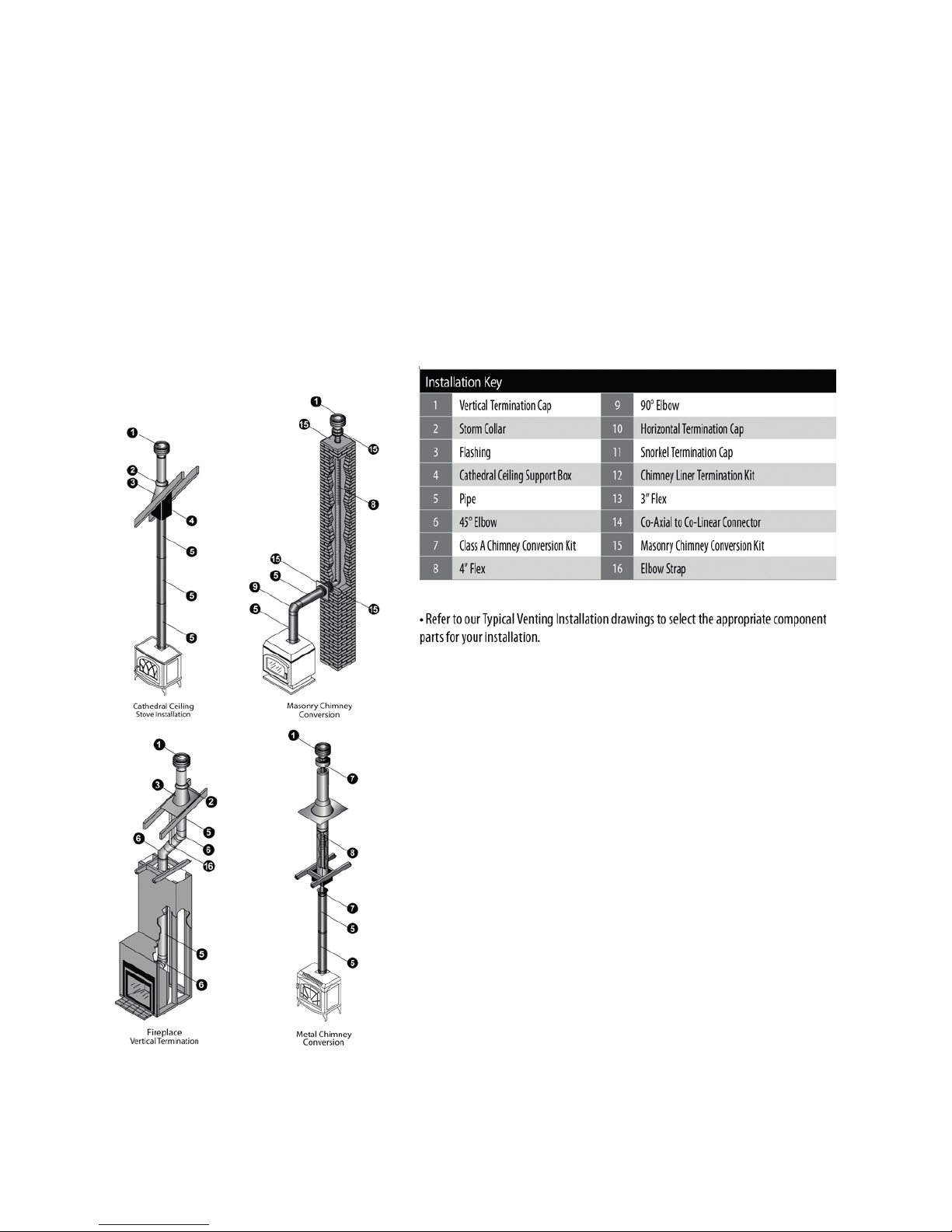

3.4.9 Typical installations

12

3.5 Fuel Bed Media and Arrangements

Please note that all arrangements are viewed from the front of the appliance, with the main burner at the front

(e ect burner at the rear).

01 - 02 -

03 - 04 -

05 - 06 -

07 - 08 -

09 - 10 - 11 -

Lenga 500

13

Installation, Servicing and User Instructions | EN

Place log 03 on the burner plate as

shown on the image.

Place log 02 on burner port BP 1 as

shown on the image.

Make absolutely sure the log slides all

the way over the connection.

When arranging the media in the re, it is always important to keep the mainburner (MAIN) clear from

media unless otherwise instructed. The main burner needs to have an uninterupted connection with the

pilot burner (PILOT) and with with logs of the eff ectburner that are connected to burner port 1 and 2 (BP

1 and BP 2)

14

Place log 04 on the burner plate as

shown on the image. The log leans on

log 03 and against log 02.

Place log 01 on burner port BP 2 as

shown on the image. The log leans

against log 02 at the top.

Make absolutely sure the log slides all

the way over the connection.

Place log 05 on the left-back side of

the burner. The log rests on log 03.

15

Installation, Servicing and User Instructions | EN

Place log 08 in the left front corner on

the burner as shown on the image.

Place log 06 on the right side of the

burner as shown on the image.

Place log 07 in front left of the middle

as shown on the image.

Make absolutely sure the log doesn’t

block the main burner (MAIN).

16

Place the ceramic bers (10). on the

main burner (MAIN) and secure them

with some small embers (09).

Make absolutely sure the ember don’t

block the main burner (MAIN).

Scatter the remaining embers (09)

evenly on the burnerplate.

Make absolutely sure the embers don’t

block the main burner (MAIN).

Scatter the vermiculite grains (11)

evenly over the burnerplate.

Make absolutely sure the grains don’t

block the main burner (MAIN).

At this last step also ensure that the

front of the burner plate, as marked on

the image, is free of decoration. The

glass is installed in that area.

17

Installation, Servicing and User Instructions | EN

Lenga 800

11 - 12 -

09 - 10 -

01 - 02 -

03 - 04 -

05 - 06 -

07 - 08 -

18

13 - 14 - 15 -

When arranging the media in the re, it is always important to keep the mainburner (MAIN) clear from

media unless otherwise instructed. The main burner needs to have an uninterupted connection with the

pilot burner (PILOT) and with with logs of the eff ectburner that are connected to burner port 1, 2 and 3 (BP

1, BP 2 and BP 3)

Place log 04 on the burner plate as shown on the image.

19

Installation, Servicing and User Instructions | EN

Place log 06 on the burner plate as shown on the image.

Place log 09 on the left side of the burner plate as shown on the image.

Place log 08 on the right side of the burner plate as shown on the image. The log leans against log 04.

20

Place log 05 on the back of the burner plate as shown on the image.

Place log 07 on the left of the burner plate as shown on the image.

Place log 01 on burner port BP 3 as shown on the image. The log leans against log 04.

Make absolutely sure the log slides all the way over the connection.

21

Installation, Servicing and User Instructions | EN

Place log 02 on burner port BP 2 as shown on the image. The log leans against log 01.

Make absolutely sure the log slides all the way over the connection.

Place log 03 on burner port BP 1 as shown on the image. The log leans against log 02.

Make absolutely sure the log slides all the way over the connection.

Place the ceramic bers (14). on the main burner (MAIN) and secure them with some small embers (13).

Make absolutely sure the ember don’t block the main burner (MAIN).

22

Scatter the remaining embers (13) evenly on the burnerplate.

Make absolutely sure the embers don’t block the main burner (MAIN).

Place log 10 on the front of the burner plate as shown on the image.

Place log 11 on the embers between log 02 and 09 as shown on the image.

23

Installation, Servicing and User Instructions | EN

Place log 12 on the embers in the left back corner as shown on the image.

Scatter the vermiculite grains (15) evenly over the burnerplate.

Make absolutely sure the grains don’t block the main burner (MAIN).

At this last step also ensure that the front of the burner plate, as marked on the image, is free of decoration. The glass

is installed in that area.

24

3.6 Commissioning the Appliance

3.6.1 Pilot Ignition Check

1. Ignite the pilot light as described in the User Instructions

2. Check that the pilot ame stays alight

3. Extinguish the pilot light

3.6.2 Main Burner Check

1. Ignite the pilot light as described in the User Instructions

2. Turn on the main burner as described in the User Instructions

3. Check that the pilot smoothly cross-lights to the main burner and that the main burner and pilot stay alight

4. Check the operation of the second “eect” burner as described in the User Instructions

5. Extinguish the appliance fully

3.6.3 Pressure Check

The appliance is preset to give the correct heat inputs as listed in the technical details. No further adjustment is

necessary. Always check the inlet pressure and burner pressure.

1. Turn o the gas valve on the appliance

2. Release the screw on the Inlet Pressure test point on the gas valve and connect a manometer

3. Check that the measured pressure is as the prescribed supply pressure

4. Perform the test when the appliance is burning on full (inc. “eect” burner) and with only the pilot alight

5. If the pressure is low, check the gas supply pipes are too a correct sizing

6. If the pressure is too high (more than 5 mbar over) the appliance may be installed, but the gas supply company

should be contacted

7. Release the screw on the Burner Pressure test point on the gas valve and connect a manometer

8. Check that the measured pressure is as detailed in the Technical details

9. The measured value should be within +/- 10% of the described value. If this is not the case, please contact the

supplier.

Note: After checking the pressures and removing the manometers, the screws in the Pressure

Test points must be closed, and the system must be checked for gas-tightness.

4. Servicing

Turn the appliance OFF and isolate the gas supply. Ensure the appliance is fully cold before attempting to start

servicing the appliance. No liability can be accepted by Wanders for injury caused by burning or scolding by a hot

appliance.

A suggested procedure for servicing is listed below.

A. Lay out dust sheet on ooring, mask o any special replace materials.

B. Remove Side Window Trims

C. Remove Bottom Window Trim

D. Remove Window Assembly

E. Carefully remove the Ceramic components (including Embers) or Gravels

F. Use a Vacuum cleaner to clean the top of the burners and grate

G. Remove Grate

H. Remove all 3 Burner Top assemblies, there are 3 M6 ange bolts holding each in

I. Using a vacuum cleaner, fully clean both Burner Top.

J. With the Burner Tops now removed, the Pilot and the heads of the injectors are clearly visible. Use the

vacuum cleaner and a soft brush to clean the pilot assembly and both Injectors. Never modify or bend the

Thermocouple

K. Replace the burner top assemblies and x in with the xings

L. Turn on the gas supply and check for leaks, check the burners and Pilot for good condition and operation

25

Installation, Servicing and User Instructions | EN

M. Replace Grate

N. Replace the Firebed arrangements

O. Replace Window Assembly and Trims

P. Check the ue system and terminal, making sure that the terminal vent is fully clear

Q. Light the appliance and test setting pressures

R. Check the safe operation of the appliance.

4.1 Cleaning the Ceramics

Remove the ceramics as detailed in A - E above.

Gently clean the ceramics in the open air, using a soft brush and a vacuum cleaner. Where necessary replace

damaged components only with genuine Wanders speci ed parts. Seal any scrap ceramics in plastic bags and

dispose at proper refuse sites. When using a vacuum cleaner, it is recommended that one with a HEPA ltering

system is used.

Re- t the Firebed arrangement, re-seal the appliance and check the safe operation of the appliance.

4.2 Servicing the Burners

Remove the Burner Top Assemblies as detailed in A - H above.

The pilot is now clearly visible, the pilot, including the Thermocouple, can be replaced/serviced by removing

raising the pilot assembly from its mounting. This is done by removing the two screws on the surface of the pilot.

The ttings on the under-side of the pilot can be un-done using a 10mm spanner where appropriate.

To access the Main Burner Injectors, the Burner base units must be removed. This is done by removing the six

bolts (M6, 10mm spanner) holding the burner in. With these six bolts removed, the Burner base can be raised up

through the Firebox, and the Injectors can be easily accessed.

When replacing any parts use only original Wanders speci ed parts.

4.3 Opening the Glass

• Place the suction lifter on the middle of the glass. Make sure the glass is not hot.

• Open the glass clamps with the enclosed hook.

• Pull the glass slightly towards you.

• Lift the glass slightly and pull to bottom towards you.

• Put the glass aside carefully.

Terugplaatsen van de glasruit

• Place the glass at the base of the mainburner. Make sure the area is clear of any media covering the burner.

• Push the top of the glass in its place. Make sure the 2 steel tabs lock in the frame of the appliance.

• Pull the glass clamps down to lock the glass.

• Remove the suction lifter.

26

5. Technical Information

5.1 Countries of use

Code Country Natural LPG

AT Austria I2H, G20 at 20 mbar I3P(50), G31 at 50 mbar; I3B/P(50), G30/G31 at 50 mbar

BE Belgium I2E+, G20/G25 at 20/25 mbar

I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar;

I3B/P(30), G30/G31 at 30 mbar

BG Bulgaria I2H, G20 at 20 mbar I3B/P(30), G30/G31 at 30 mbar

CH Switzerland I2H, G20 at 20 mbar

I3P(50), G31 at 50 mbar; I3+, G31/G31 at 28/37 mbar;

I3P(37), G31 at 37 mbar; I3B/P(50), G30/G31 at 50 mbar

CY Cyprus I2H, G20 at 20 mbar

I3+, G31/G31 at 28/37 mbar; I3B/P(30), G30/G31 at 30

mbar

CZ Czech Republic I2H, G20 at 20 mbar

I3P(50), G31 at 50 mbar; I3+, G31/G31 at 28/37 mbar;

I3P(37), G31 at 37 mbar; I3B/P(50), G30/G31 at 50 mbar

DE Germany I2ELL, G25 at 20 mbar¹; I2E, G20 at 20 mbar I3P(50), G31 at 50 mbar; I3B/P(50), G30/G31 at 50 mbar

DK Denmark I2H, G20 at 20 mbar I3B/P(30),G30/G31 at 30 mbar

EE Estonia I2H, G20 at 20 mbar I3B/P(30),G30/G31 at 30 mbar

ES Spain I2H, G20 at 20 mbar I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar

FI Finland I2H, G20 at 20 mbar I3P(30), G31 at 30 mbar; I3B/P(30), G30/G31 at 30 mbar

FR France I2E+, G20/G25 at 20/25 mbar

I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar;

I3B/P(30), G30/G31 at 30 mbar; I3B/P(50), G30/G31 at 50

mbar

GB United Kingdom I2H, G20 at 20 mbar

I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar;

I3B/P(30), G30/G31 at 30 mbar

GR Greece I2H, G20 at 20 mbar

I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar;

I3B/P(30), G30/G31 at 30 mbar

HU Hungary I3B/P(30), G30/G31 at 30 mbar

HR Croatia I2H, G20 at 20 mbar I3P(37), G31 at 37 mbar; I3B/P(30), G30/G31 at 30 mbar

IE Ireland I2H, G20 at 20 mbar I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar

IS Iceland

IT Italy I2H, G20 at 20 mbar

I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar;

I3B/P(30), G30/G31 at 30 mbar

LT Lithuania I2H, G20 at 20 mbar

I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar;

I3B/P(30), G30/G31 at 30 mbar

LU Luxembourg I2E, G20 at 20 mbar

LV Latvia I2H, G20 at 20 mbar

MT Malta I3B/P(30), G30/G31 at 30 mbar

NL The Netherlands I2L/ I2EK, G25/G25.3 at 25 mbar

I3P(50), G31 at 50 mbar; I3P(30), G31 at 30 mbar; I3P(37),

G31 at 37 mbar; I3B/P(30), G30/G31 at 30 mbar

NO Norway I2H, G20 at 20 mbar I3B/P(30), G30/G31 at 30 mbar

PL Poland I2E, G20 at 20 mbar I3P(37), G31 at 37 mbar

PT Portugal I2H, G20 at 20 mbar I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar

RO Romania I2E, G20 at 20 mbar I3P(30), G31 at 30 mbar; I3B/P(30), G30/G31 at 30 mbar

SE Sweden I2H, G20 at 20 mbar I3B/P(30), G30/G31 at 30 mbar

SL Slovenia I2H, G20 at 20 mbar

I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar;

I3B/P(30), G30/G31 at 30 mbar

SK Slovakia I2H, G20 at 20 mbar

I3P(50), G31 at 50 mbar; I3+, G31/G31 at 28/37 mbar;

I3P(37), G31 at 37 mbar; I3B/P(30), G30/G31 at 30 mbar;

I3B/P(50), G30/G31 at 50

TR Turkey I2H, G20 at 20 mbar

I3+, G31/G31 at 28/37 mbar; I3P(37), G31 at 37 mbar;

I3B/P(30), G30/G31 at 30 mbar

27

Installation, Servicing and User Instructions | EN

5.2 Technical Data

Product Identication Number: 0359CO0001254

5.2.1 Lenga 500

Gas type

G20 G20/G25 G25/G25.3 G20/G25* G30/G31 G31

I2H, I2E I2E+ I2L/I2K I2ELL

I3B/P

(30/50)

I3+

I3P

(37/50)

I3P (30)

Supply Pressure mbar 20 20/25 25 20 30/50 28-30/37 37/50 30

Nominal Heat Input Gross (Hs) kW 10,5 10,5 10,3 10,5 11,5 11,5 11,5 9,7

Nominal Heat Input Nett (Hi) kW 9,5 9,5 9,3 9,5 10,6 10,6 10,6 9,0

Consumption m

3

/hr 1,022

1,022 /

1,103

1,117 1,117 0,204 0,204 0,403 0,341

Burner Pressure (hot) mbar 18,8 18,8 23,7 18,8 28,3 28,3 35,0 29,0

Injector Code 120 (middle), 320 (right), 220 (left) 100 (middle), 120 (right), 100 (left)

Pilot 440-1350-xx (31.2 inj) 440-1350-xx (27.1 inj)

Eciency Class 2

Nox Class 5

Type C11/C31

*) I2ELL Injectors: 120 (middle), 380 (right), 360 (left)

5.2.2. Lenga 800

Gas type

G20 G20/G25 G25/G25.3 G20/G25* G30/G31 G31

I2H, I2E I2E+ I2L/I2K I2ELL

I3B/P

(30/50)

I3+

I3P

(37/50)

I3P

(30)

Supply Pressure mbar 20 20/25 25 20 30/50 28-30/37 37/50 30

Nominal Heat Input Gross (Hs) kW 14,5 14,5 13,7 14,5 14,0 14,0 14,0 12,0

Nominal Heat Input Nett (Hi) kW 13,1 13,1 12,3 13,1 12,9 12,9 12,9 11,1

Consumption m

3

/hr 1,388

1,388 /

1,482

1,490 1,482 0,398 0,398 0,517 0,444

Burner Pressure (hot) mbar 17,8

17,8 /

22,3

22,5 18,0 28,4 28,4 36,4 28,9

Injector Code

160 (middle), 320 (right), 320 (front left), 280

(back left)

100 (middle), 120 (right), 120 (front left),

100 (back left)

Pilot 440-1350-xx (31.2 inj) 440-1350-xx (27.1 inj)

Eciency Class 2

Nox Class 5

Type C11/C31

*) I2ELL Injectors: 160 (middle), 360 (right), 360 (front left), 320 (back left)

28

5.3 Dimensions

5.3.1.a Lenga 500 A

5.3.1.b Lenga 500 AB

388,30

366,00

1061,70

1170,93

118,40

893,50

469,00

554,00

100/150

M&G

103,43

94,00

488,00

120,40

488,00

575,00

894,50

254,80

894,50

479,00

100/150

M&G

368,00

1061,70

1170,93

93,00

103

,43

388,30

29

Installation, Servicing and User Instructions | EN

5.3.1.c Lenga 500 AE

5.3.1.d Lenga 500 ABE

120,40

488,00

575,00

100/150

M&G

388,30

894,50

254,80

894,50

479,00

1061,70

1170,93

93,00

,43

376,00

488,00

600,00

100/150

M&G

894,50

500,00

894,50

254,80

1067,50

1170,93

120,40

93,00

103,43

288,50

192,43

1229,93

898,50

554,00

554,00

30

5.3.2.a Lenga 800 A

5.3.2.b Lenga 800 AB

120,40

788,00

875,00

130/200

M&G

368,00

388,30

744,50

254,80

744,50

779,00

912,00

1020,93

93,00

,43

120,40

788,00

854,00

130/200

M&G

743,50

769,00

94,00

103

,43

368,00

390,30

911,70

1020,93

31

Installation, Servicing and User Instructions | EN

5.3.2.c Lenga 800 AE

5.3.2.d Lenga 800 ABE

120,40

788,00

875,00

130/200

M&G

368,00

744,50

779,00

743,99

254,80

912,00

1020,93

103

,43

93,00

390,30

854,00

120,40

900,00

130/200

M&G

376,00

744,50

254,80

917,50

1020,93

93,00

744,50

800,00

32

“myfire” App for Android/iOS

Handset

B6R-H8(9)…P…

Light

Fan

Ignition Cable G60-ZKIS…

Interrupter Block

G60-ZUS…

Combination Control

GV60…

Mains Power

(115/230 V; AC)

V Module

G6R-BU(E)…

Cable

G6R-CBV…

Home Network

NOTE:

Components are not actual size.

OPTIONAL WiFi/APP (excl. tablet and router)

OPTIONAL MODULE (INK.3255)

Electrical diagram

33

Installation, Servicing and User Instructions | EN

34

garantiebewijs / guarantee certicate / certicat de garantie / garantieschein

Wanders res & stoves

Amtweg 4

7077 AL Netterden

The Netherlands

T: +31 (0) 315 - 386 414

F: +31 (0) 315 - 386 201

E: service@wanders.nl

I: www.wanders.com

model / model / modèle / modell

serienummer / serial number

nr. de série / seriennummer

aankoop datum / date of purchase

date de láchat / kaufdatum

s'il vous plaît joindre copie de la preuve d'achatplease enclose copy of proof of purchase bitte kopie vom kaufbeleg beifügenkopie aankoopbewijs bijvoegen aub

/ / /

naam / name / nom / name

adres / address / adresse / adresse

postcode - plaats / postal code - town

code postal - lieu / postleitzahl - ort

land / country / pays / land

naam / name / nom / name

adres / address / adresse / adresse

postcode - plaats / postal code - town

code postal - lieu / postleitzahl - ort

land / country / pays / land

dealer gegevens / dealer information / l'information revendeur / händler informationen

Onder de garantie vallen alle gebreken die te herleiden zijn

tot materiaal- en constructiefouten. In die gevallen ontvangt

u gratis nieuwe onderdelen. Arbeidsloon en andere kosten

vallen niet onder de garantie. Defecte onderdelen kunt

franco toezenden aan WANDERS Metaalproducten B.V.,

Amtweg 4, 7077 AL, Netterden.

Voordat de haard geplaatst wordt, moet u controleren of er

zichtbare schade is aan het toestel.

In dat geval moet u het toestel niet accepteren, maar contact

opnemen met uw leverancier.

Buiten de garantie vallen: het glas, storingen ontstaan

door onoordeelkundig gebruik; niet juiste naleving van de

landelijke voorschriften en de bijgevoegde installatie- en

bedieningsvoorschrif-ten; installatie door een niet door

WANDERS erkend installateur of dealer; verwaarlozing van

het toestel en bij wisseling van eigenaar. De garantie vervalt

ook bij gebruik van een verkeerde brandstof.

WANDERS is niet verantwoordelijk voor eventuele

scheuren in sierpleisterwerk en verkleuringen van wanden,

plafonds en/of roosters na het stoken van de haard.

Verkleuringen kunnen ontstaan doordat stofdeeltjes

verbranden in de convectiemantel. Om de kans op

scheuren in sierpleisterwerk en eventuele verkleuringen te

minimaliseren verwijzen wij naar het advies dat gegeven

wordt in de sfeerhaardenbranche. Uw installateur kan u

hierover informeren.

Klachten worden in behandeling genomen nadat de

verkooprma/installateur of het gasbedrijf een klacht

heeft ingediend, vergezeld van de aankoopdatum en een

kopie van de aankoopbon. Reparaties geven geen recht op

verlenging van de garantietermijn.

Alle gevolgschade wordt uitgesloten.

The guarantee includes all defects which can be reduced

to aws in material and construction, in which case you

will receive the new parts free of charge. Labour costs

or other expenses are not covered by the guarantee.

You can send defect parts (shipping paid) to WANDERS

Metaalproducten B.V., Amtweg 4, 7077 AL in Netterden

[The Netherlands].

Before installing your stove you must check if there is any

visible damage to the unit. If there is, do not accept the

unit and contact your supplier.

The guarantee does not include: the glass, failure due

to improper use; non-compliance with the national

regulations and enclosed installation and operating

instructions; installation by an installer of dealer who is

not acknowledged by WANDERS, negligence of the unit

and change of owner. The guarantee is also disclaimed

when a wrong fuel is used.

WANDERS disclaims responsibility for any cracks in

stuccoed walls or discolouration of walls, ceilings and/

or grates after burning the replace. Discolouration can

be caused when dust particles burn in the convection

cover. To minimize the chance of cracks in stucco and

discolouration we refer to the advice given for decorative

hearths. Your installer can give you more information.

Any complaints will be dealt with after the sales rm,

the installer has led a complaint and sent a copy of the

purchase receipt with purchase date. Any repairs do not

entitle you to extend the guarantee term.

All consequential damages or loss are excluded.

La garantie couvre tous les défauts qui résulteraient des vices

de matière et de construction. Dans ces cas, vous recevrez des

pièces nouvelles gratuitement. Les frais de salaire et les autres frais

n’entrent pas dans le champ de la garantie. Les pièces défectueuses

peuvent être expédiées franco à WANDERS Metaalproducten B.V.,

Amtweg 4, 7077 AL, Netterden, Pays-Bas .

Avant de procéder à la pose de l’appareil vous devrez vérifier si

le poêle ne présente pas des dommages visibles. Dans ce cas, il

ne faut pas accepter l’appareil en prendre contact avec votre

fournisseur.

La garantie ne couvre pas la vitre et ne s’applique pas aux

dérangements provenant d’une mauvaise utilisation, d’un

manque de respect de la réglementation nationale et des

instructions d’installation et d’emploi fournis avec l’appareil, d’une

installation effectuée par un installateur ou revendeur non-agréé

par WANDERS , d’un défaut d’entretien et en cas où le poêle serait

passé en d’autres mains. La garantie ne s’applique pas non plus si

un combustible non approprié a été utilisé.

WANDERS n’est pas responsable des éventuelles fissures au

plâtrage de parement et des décolorations des parois, plafonds et/

ou grilles après le chauffage du poêle. Les décolorations peuvent

être causées par la combustion des grains de poussière dans le

manteau de convection. Pour réduire au maximum les fissures au

plâtrage et les décolorations éventuelles, veuillez vous reporter

aux consignes généralement données dans le commerce sur les

poêles d’ambiance. Votre installateur vous renseignera.

Les plaintes sont examinées après qu’elles ont été présentées

par l’établissement de vente, par l’installateur, accompagnées

d’une copie de la facture d’achat indiquant la date d’achat. Les

réparations ne donnent pas droit à une prorogation de la durée

de garantie.

Les dommages conséquents sont exclus.

Unter diese Garantie fallen alle Mängel die auf Materialoder Konstruktionsfehler zurückzuführen sind. In

diesen Fällen erhalten Sie gratis neue Ersatzteile. Der

Arbeitslohn und andere Kosten fallen nicht unter die

Garantie. Fehlerhafte Teile können Sie franco an WANDERS

Metaalproducten B.V. Amtweg 4, 7077 AL Netterden

(Holland) schicken.

Vor Montage des Ofens müssen Sie kontrollieren ob das

Gerät keine sichtbaren Schäden aufweist. In dem Fall

müssen Sie das Gerät nicht akzeptieren, müssen aber mit

Ihren Lieferanten Kontakt aufnehmen.

Nicht unter die Garantie fallen: Störungen die durch nicht

sachgemäßen Gebrauch entstanden sind; nicht strikte

Befolgung der Installations- und Bedienungsvorschriften;

Montage durch einen nicht von WANDERS anerkannten

Installateur, Vernachlässigung des Ofens und bei einem

Wechsel des Besitzers. Die Garantie verfällt auch, wenn

verkehrtes Heizmaterial benützt wurde.

Wanders ist nicht verantwortlich für eventuelle Risse im

Feinputz und Verfärbungen der Wände, Decken und/

oder Roste nach Heizen des Ofens. Verfärbungen können

entstehen weil Staubteilchen im Konvektionsmantel

verbrennen. Um eventuelle Risse im Feinputz und

Verfärbungen zu minimalisieren, verweisen Sie auf den

Rat der von der Branche für Kaminöfen gegeben wird. Ihr

Installateur kann Sie darüber informieren.

Reklamationen werden erst dann behandelt, wenn

die Verkaufsrma, der Installateur eine Reklamation,

zusammen mit einer Kopie des Kassenzettels mit

Kaufdatum, eingereicht hat. Reparaturen berechtigen

nicht zu einer Verlängerung der Garantie.

Alle Folgeschäden sind ausgeschlossen.

Wanders res & stoves

Amtweg 4

7077 AL NETTERDEN

Nederland

Tel: +31 (0)315 - 386 414

Fax: +31 (0)315 - 386 201

info@wanders.nl

www.wanders.nl

@Wanders_ res

www.facebook.com/Wanders resstoves

Type- en zetfouten voorbehouden. Wanders res & stoves is een onderdeel van de Wanders Groep

© 2014 Wanders Metaalproducten B.V. - All rights reserved

wanders res

wandersnetterden

Loading...

Loading...