Page 1

TESTO ITC KORINNA 28mmAllargato

MONOBLOCK DIRECTIONAL

CONTROL VALVE

Page 2

SD5

Features

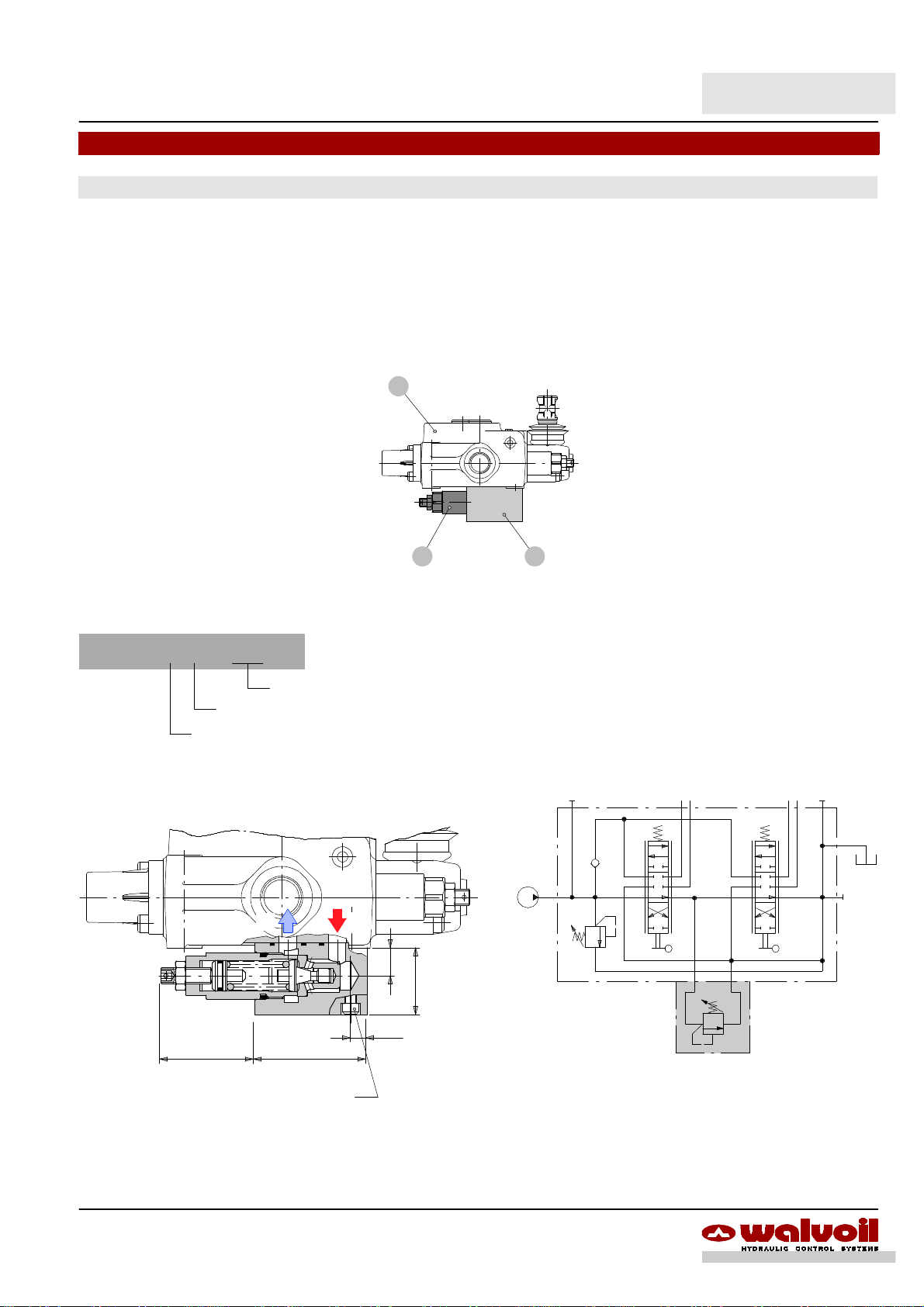

Simple , compact and heavy duty designed monoblock valves from 1 to 7 sections for open and closed center hydraulic systems..

H Fitted with a main pressure relief valve and a load check valve.

H Available with parallel, series or tandem circuit.

H Optional power beyond port (only for parallel or tandem circuit).

H Diameter 16 mm -- 0.63 in interchangeable spools.

H A wide variety of service port valve options.

H Actuation is manual, pneumatic, electro --pneumatic, hydraulic, electro--hydraulic, with solenoid and remote with flexible cables

spool control kits.

Additional information

This catalog shows the product in the most standard configurations.

Please contact Customer Service Dpt. for more detailed information or

special request.

WARNING!

All specifications of this catalog refer to the standard product at this date.

Walvoil, oriented to a continuous improvement, reserves the right to

discontinue, modify or revise the specifications, without notice.

WALVOIL IS NOT RESPONSIBLE FOR ANY DAMAGE CAUSED BY AN

INCORRECT USE OF THE PRODUCT.

5thedition November 2002:

This edition supercedes all prior documents.

2 DAT003A

Page 3

SD5

Contents

Contents

Working conditions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensional data 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic circuit 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance data 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ordering codes 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inlet relief options 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spool options 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

“A” side spool positioners 18. . . . . . . . . . . . . . . . . . . . . . . . . .

“B” side options 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Complete control kits 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outlet port options 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service valves

ordering codes 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

port relief valves 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

anti--shock valves 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pilot operated check valves 47. . . . . . . . . . . . . . . . . . . . . .

anti--shock and anti--cavitation valves 49. . . . . . . . . . . . .

flow regulator valves 50. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other execution

monoblock valve SD5/1 --N 54. . . . . . . . . . . . . . . . . . . . . . .

monoblock valve SD5/1 --D 55. . . . . . . . . . . . . . . . . . . . . . .

monoblock valve SD5 --S with series circuit 56. . . . . . . . .

monoblock valve SD5 --S with tandem circuit 58. . . . . . . .

Installation and maintenance 60. . . . . . . . . . . . . . . . . . . . . . . .

Accessories 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3DAT003A

Page 4

SD5

Working conditions

This catalog shows technical specifications and diagrams measured with mineral oil of 46 mm2/s -- 46 cSt viscosity at 40°C -- 104°F

temperature.

Nominal flow rating 45 l/min 12 US gpm

Operating pressure (maximum) parallel pr tandem circuit 315 bar 4600 psi

series circuit 250 bar 3600 psi

Max. back pressure on outlet port T 25 bar 360 psi

Internal leakage A(B)®T

Hydraulic fluid Mineral base oil

Fluid temperature range with NBR seals from --20° to 80°C from --4° to176°F

Viscosity operating range from 15 to 75 mm2/s from 15 to 75 cSt

Max. level of contamination 19/16 -- ISO 4406 NAS 1638 -- class10

Ambient temperature range from --40° to 60°C from --40° to 140°F

Dp=100 bar -- 1450psi

fluid and valve at 40°C -- 104°F

with FPM seals from --20° to 100°C from --4° to 212°F

minimum 12 mm2/s 12 cSt

maximum 400 mm2/s 400 cSt

3 cm3/min 0.18 in3/min

NOTE -- For different conditions please contact Customer Service.

4 DAT003A

Page 5

SD5

TYP

E

TYP

E

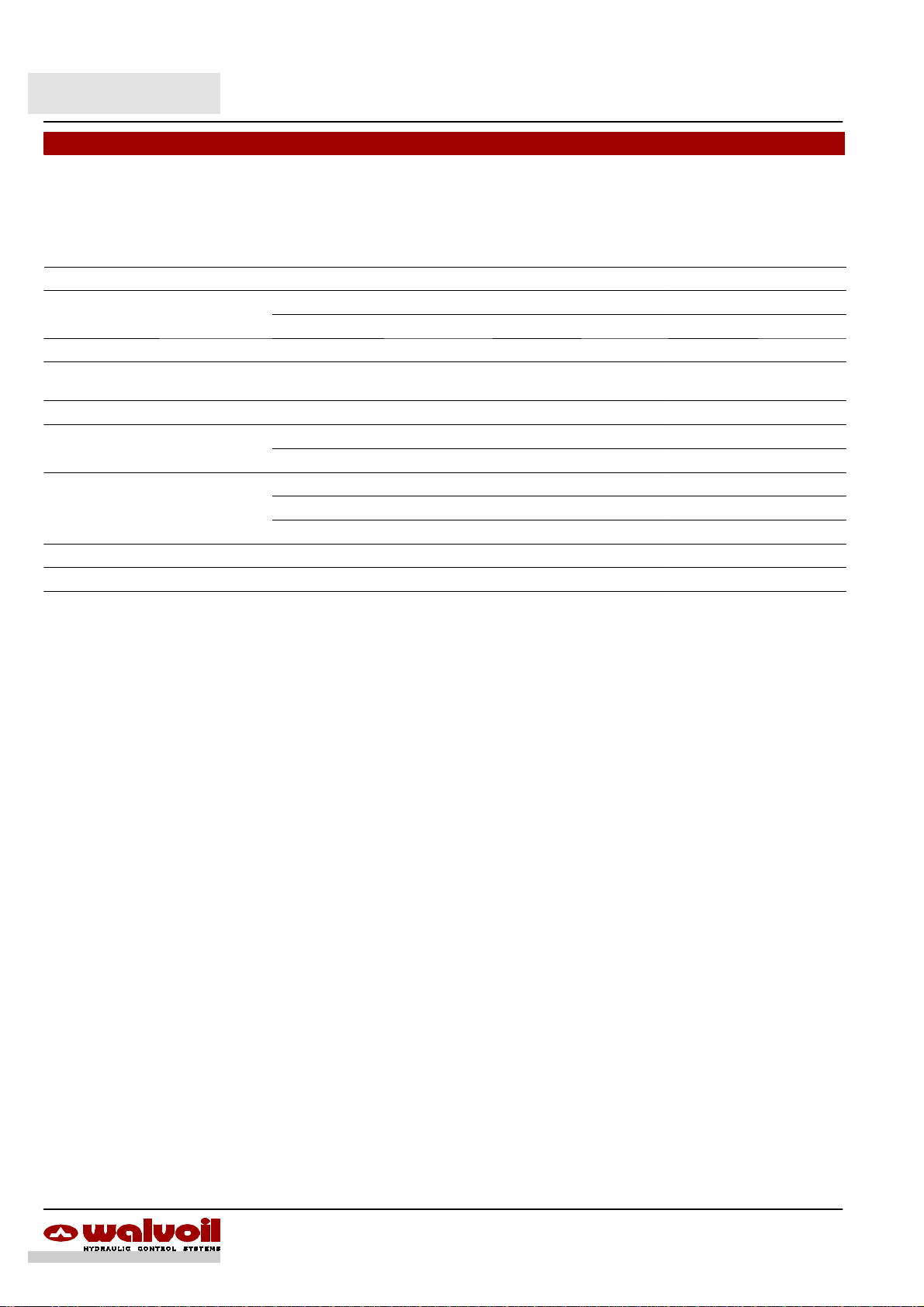

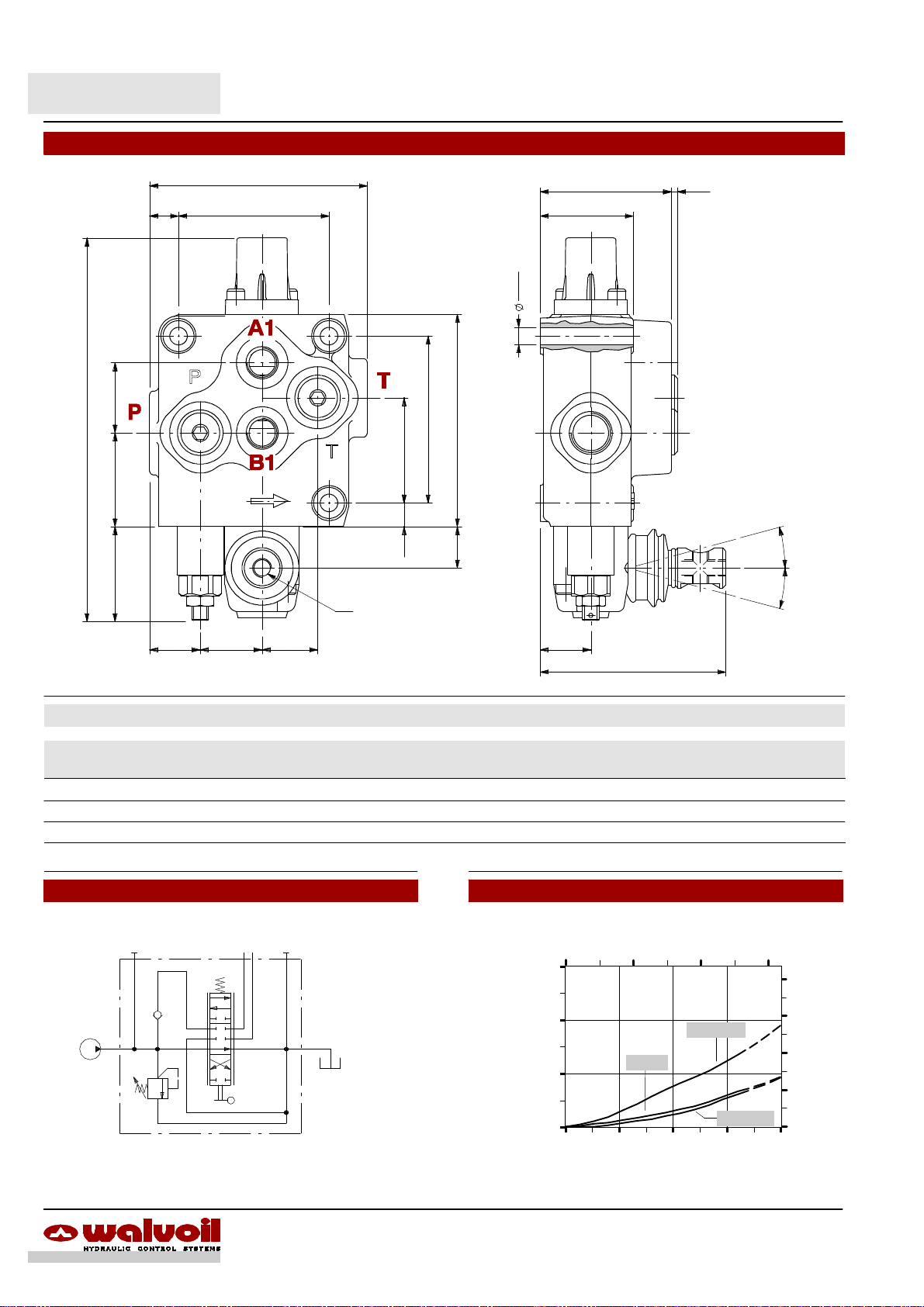

Dimensional data (parallel circuit)

E

12,5

0.06

34

1.34

186

7.32

45,5

1.791.77

45

F

Power beyond

M 8

63,5

21

0.81

8,5

0.33

81

103

4.06

3.19

51

2.01

2.50 0.12

45

1.77

3

spool out

3

11,5

0.45

20

0.79

1

24°

15°

0

15°

24°

2

23

0.91

30 37

1.18

1.46 1.06

27

WALVOIL

SD5/2--P

SD5/2--P

P0200001

WALVOIL

102219002

MADE IN ITALY

P0200001

102219002

24,5

0.96

90

3.54

Valve type

Production batch:

P02 = production year (2002)

00001 = progressive number

3

spool in

MADE IN ITALY

Valve code

SD5/1--P

SD5/2--P

SD5/3--P

SD5/4--P

E F Weight

mm in mm in kg lb

100.5 3.96 73 2.87 3.5 7.7

137.5 5.41 110 4.33 5.2 11.5

174.5 6.87 147 5.79 6.9 15.2

211.5 8.33 184 7.24 8.1 17.9

SD5/5--P

SD5/6--P

SD5/7--P

E F Weight

mm in mm in kg lb

248.5 9.78 221 8.70 10.1 22.3

285.5 11.24 258 10.16 11.7 25.8

322.5 12.70 295 11.61 13.2 29.1

Standard threads

PORTS

BSP

(ISO 228/1)

Inlet P and power beyond C G 3/8 3/4--16 UNF--2B (SAE 8) M18x1.5

A and B ports G 3/8 9/16 --18 UNF--2B (SAE 6) M18x1.5

Outlet T G 3/8 3/4--16 UNF--2B (SAE 8) M18x1.5

PILOT PORTS

Pneumatic NPTF 1/8--27 NPTF 1/8--27 NPTF 1/8--27

Hydraulic G 1/4 9/16--18 UNF--2B (SAE 6) G 1/4

5DAT003A

UN--UNF

(ISO 11926--1)

METRIC

(ISO 262)

Page 6

SD5

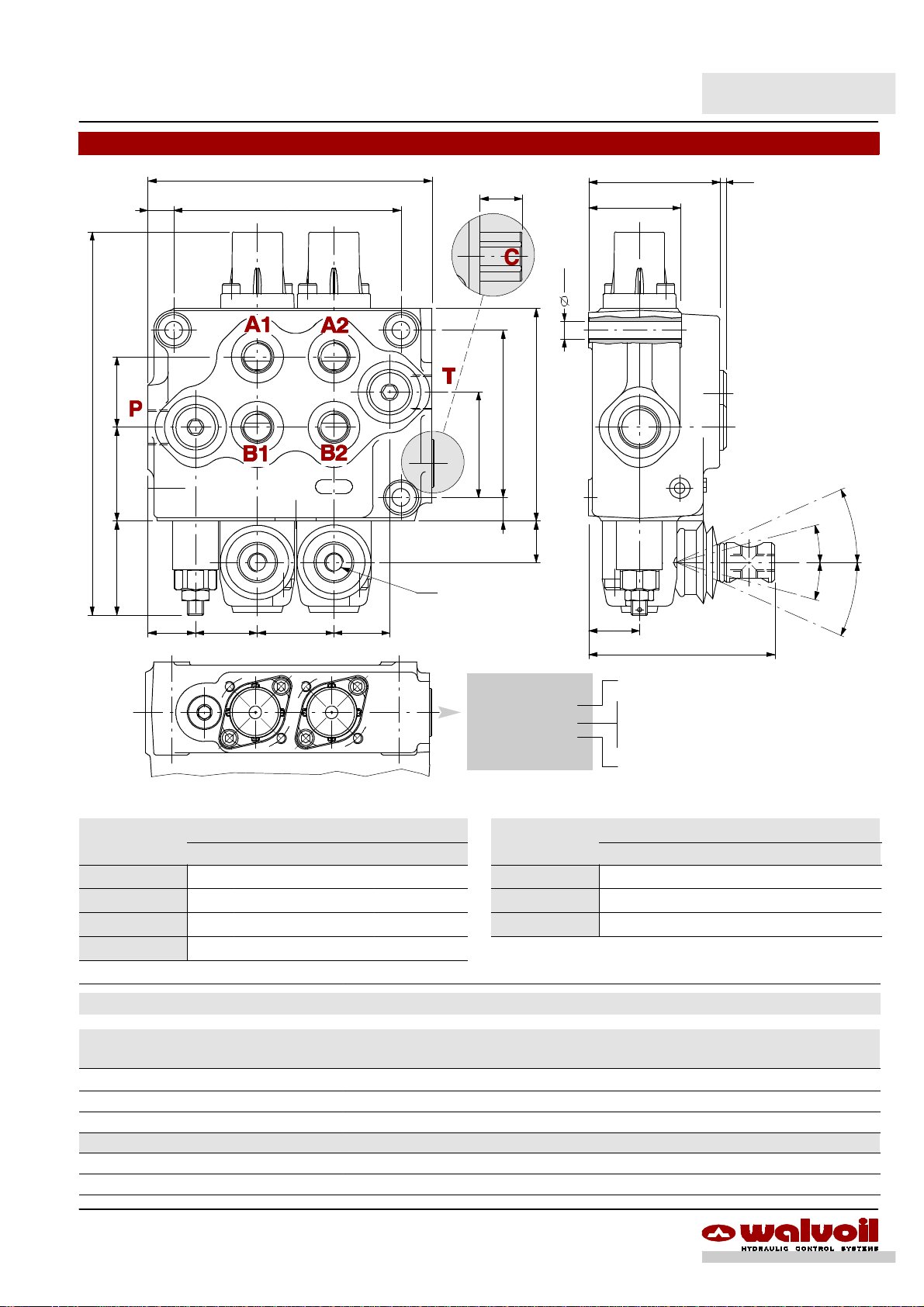

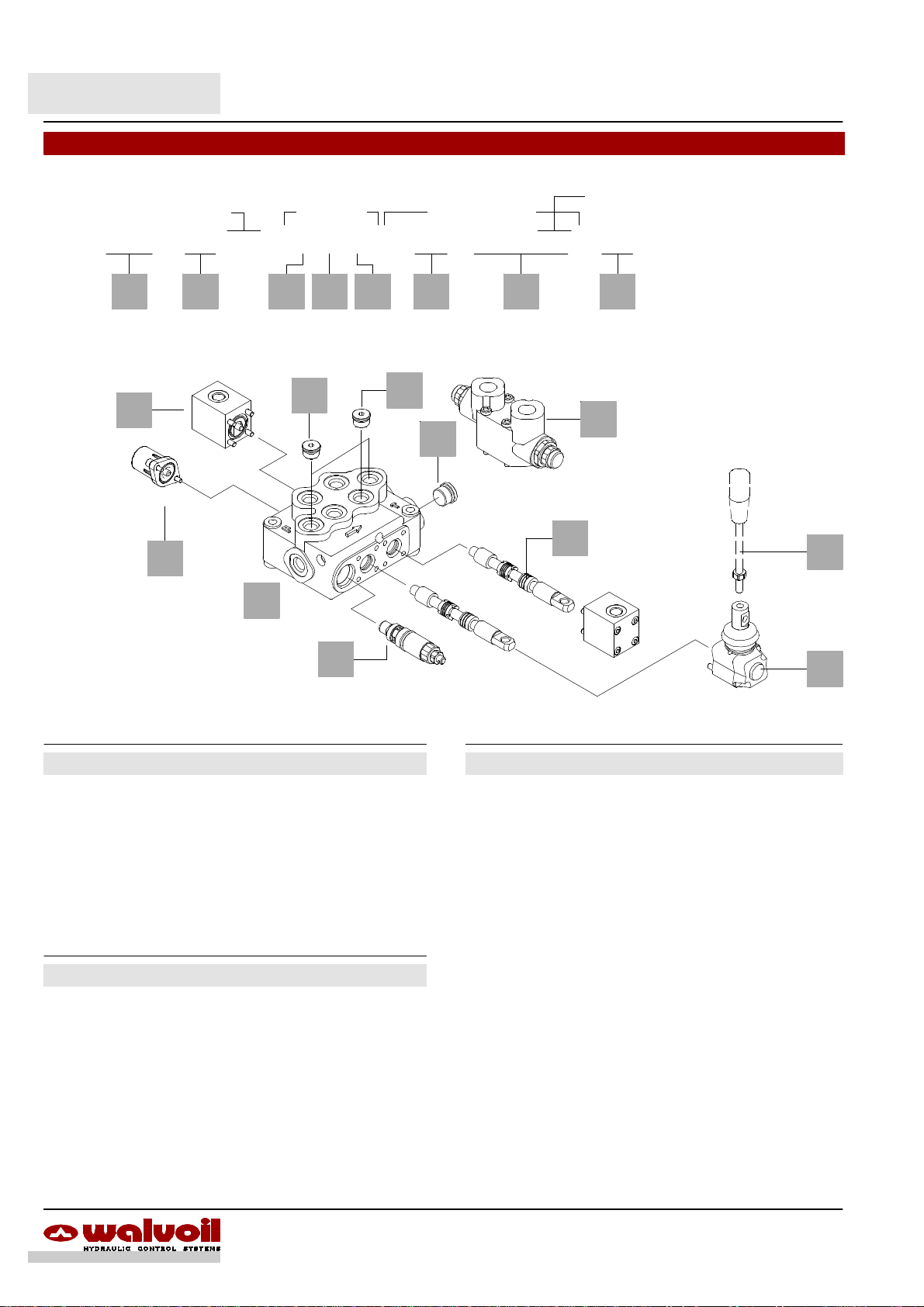

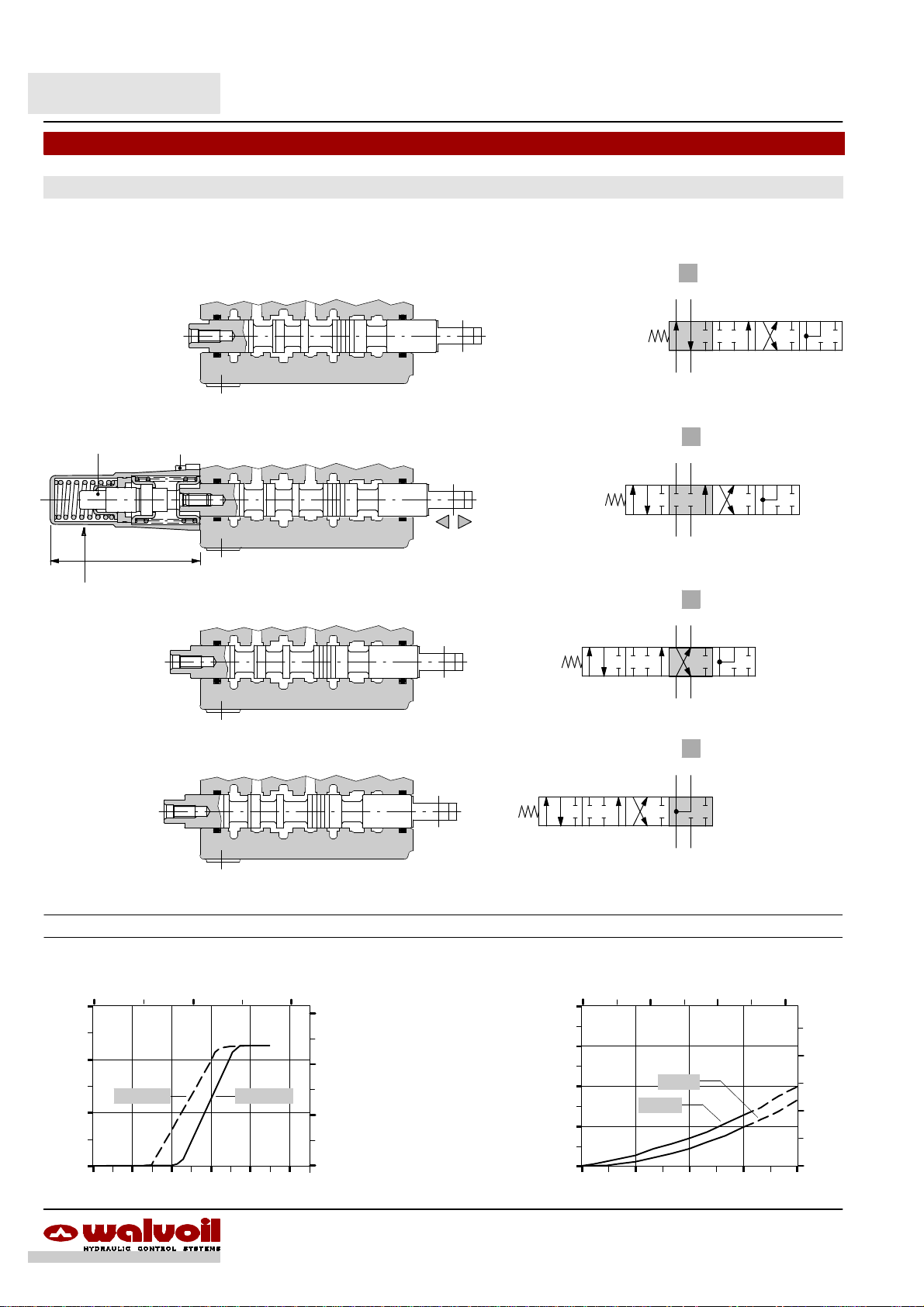

Hydraulic circuit

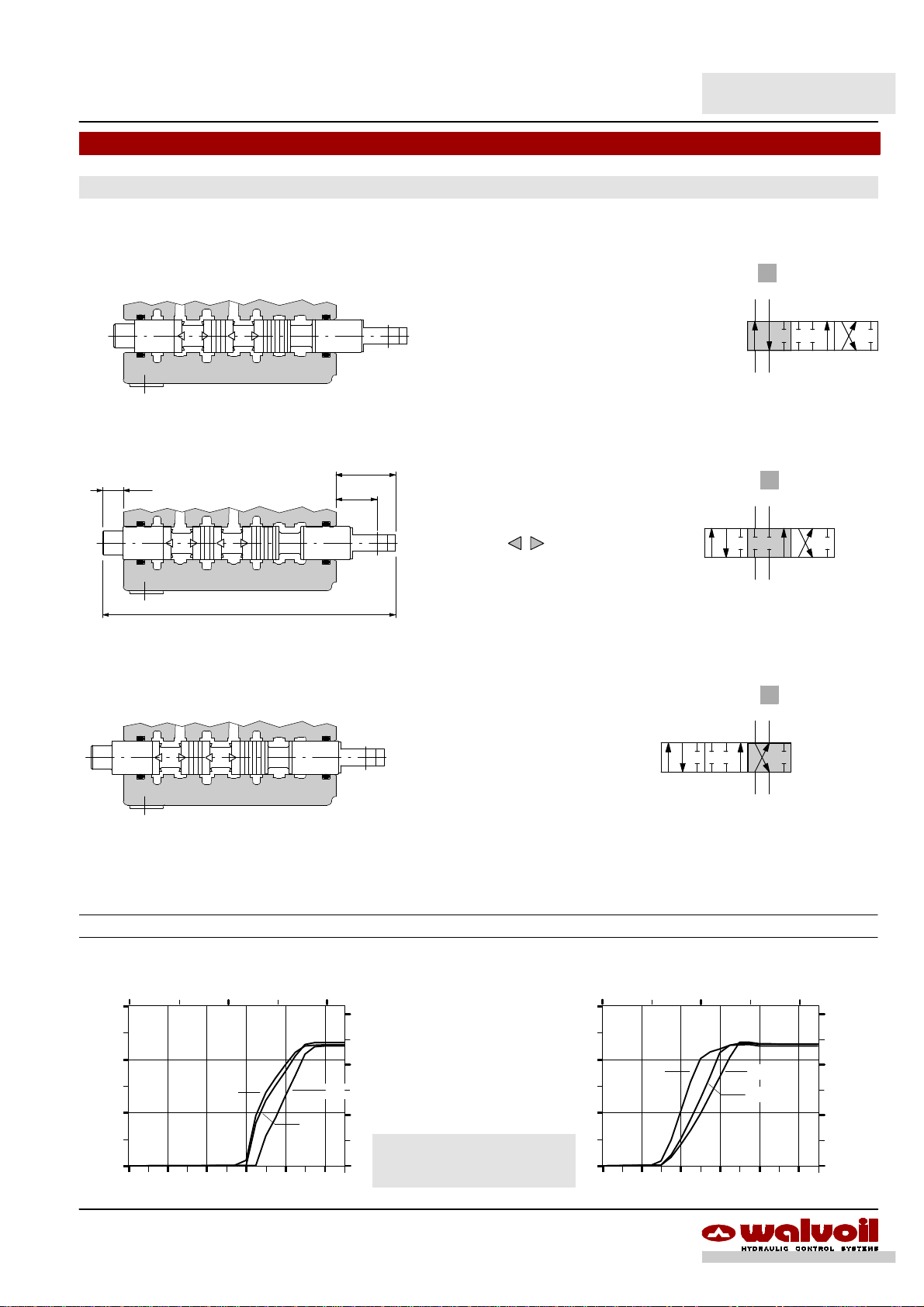

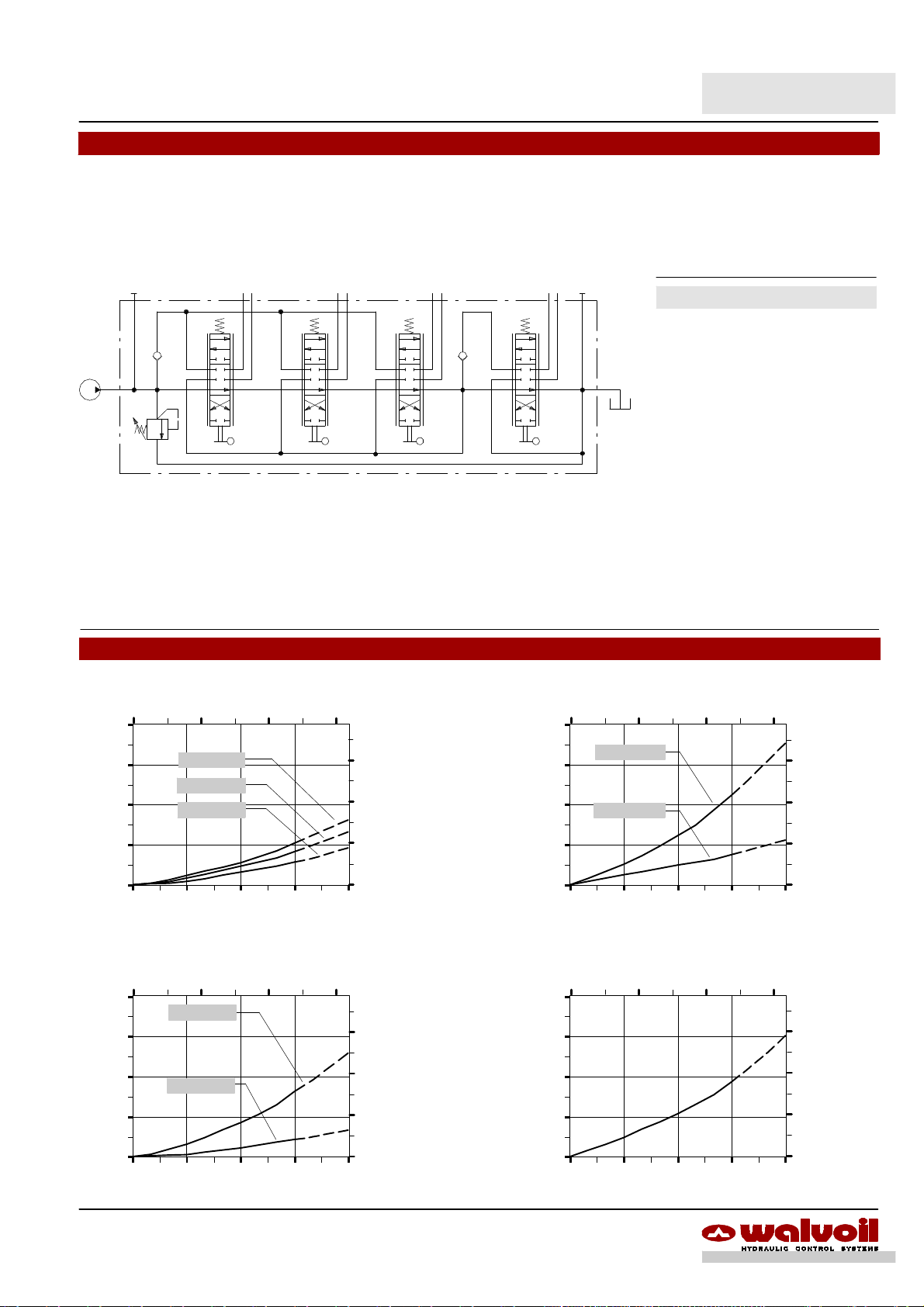

Parallel

Standard configuration with side inlet and outlet and open center (AET execution).

Positioner kit

Check valve

Allen wrench 4

24 Nm / 17.7 lbft

Port A line

Port B line

A

Pressure line

Tank line

T

B

Flow through

Main relief valve

Standard configuration

P

(LC)

Plug for open center

Allen wrench 8

24 Nm / 17.7 lbft

Lever pivot box

Configuration with upper inlet and outlet

T

A1 B1 A2 B2

A1 B1 A2 B2

P

T

P

120

1750

Ex.: SD5/2--P(JG3--120)/18L/18L/AET

120

1750

Ex.: SD5/2--P(JG3--120)/18L/18L/AET--PSA

6 DAT003A

Page 7

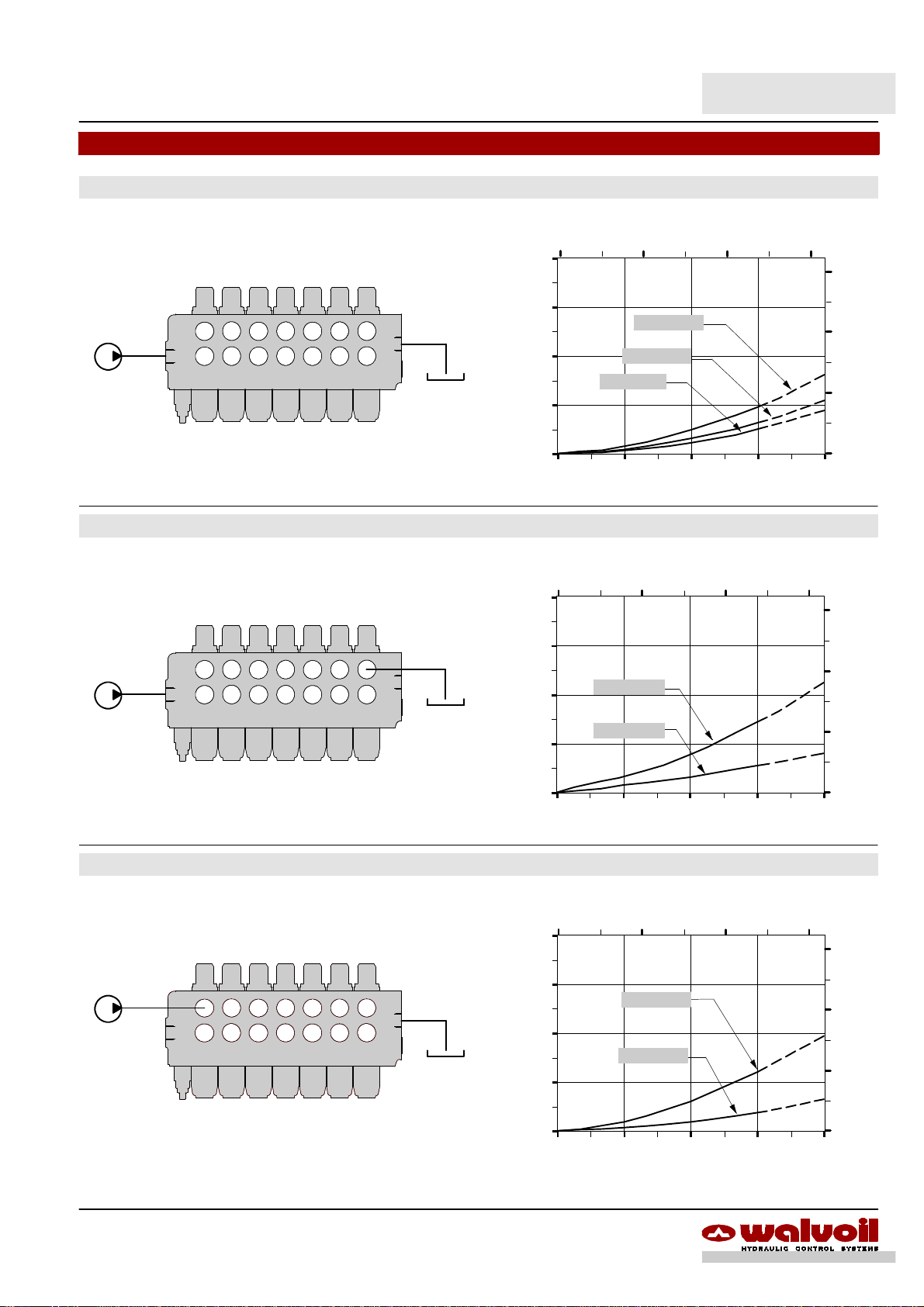

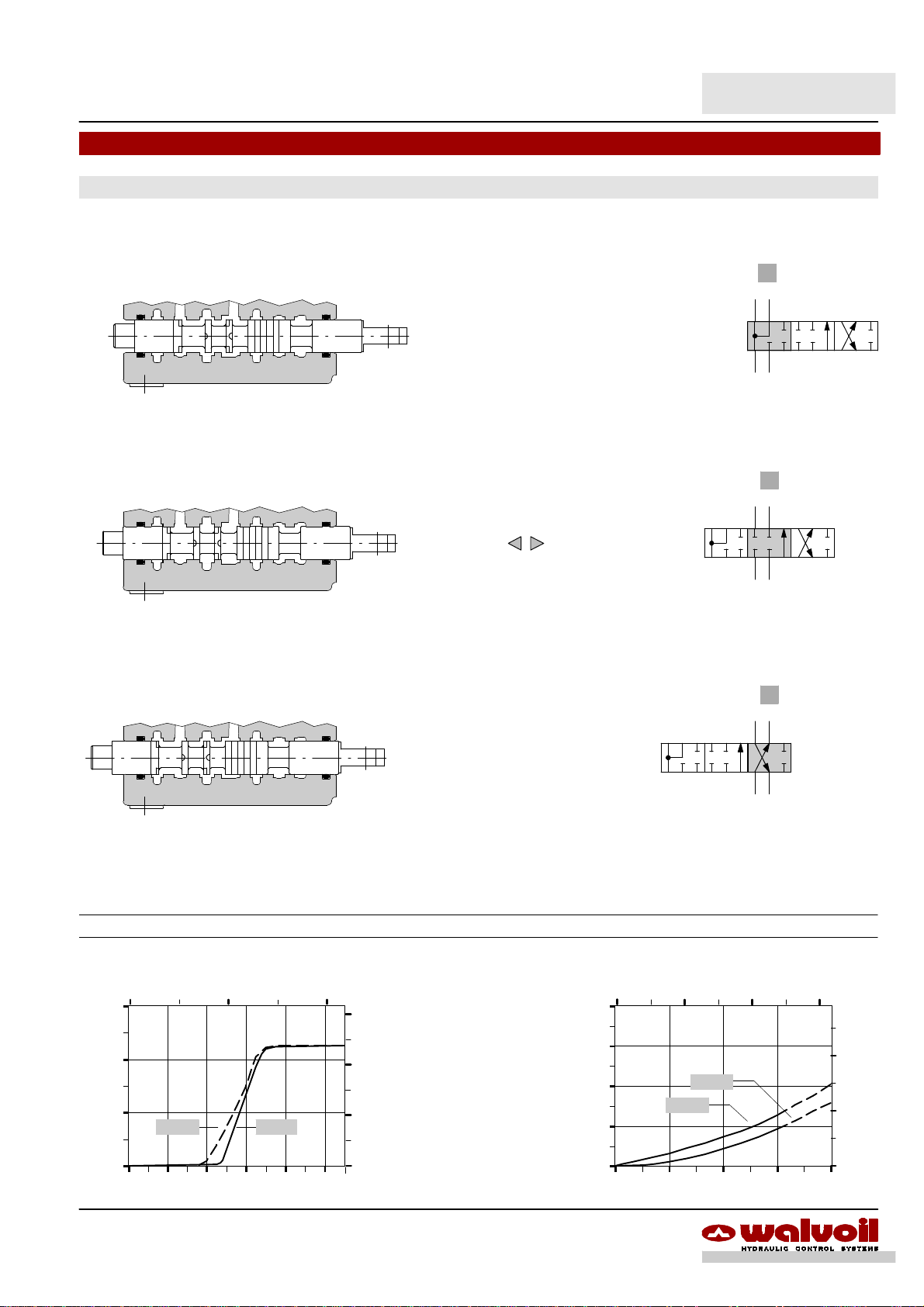

Open center

From side inlet to side outlet.

A1 A2 A3

P

B1 B2 B3

Inlet to work port

A4 A5 A6

A7

B4 B5 B6 B7

SD5

Performance data (pressure drop vs. flow)

5 10 15(US gpm)

40

(bar)

30

T

20

Pressure drop

10

0

0 15 30 45 60

7 sections

4 sections

2 sections

Flow

540

(psi)

360

180

(l/min)

From side inlet to A port (spool in position 1) or B port (spool in position 2).

40

(bar)

A1 A2 A3

P

B1 B2 B3

A4 A5 A6

A7

B4 B5 B6 B7

T

30

20

Pressure drop

10

Work port to outlet

From A port (spool in position 2) or B port (spool in position 1) to side outlet.

(bar)

A1 A2 A3

P

B1 B2 B3

A4 A5 A6

A7

B4 B5 B6 B7

T

Pressure drop

5 10 15

P®A7(B7)

P®A1(B1)

0

0 15 30 45 60

Flow

5 10 15(US gpm)

40

30

A1(B1)®T

20

A7(B7)®T

10

(US gpm)

540

(psi)

360

180

(l/min)

540

(psi)

360

180

NOTE -- Measured with spool type 1.

0

0 15 30 45 60

Flow

(l/min)

7DAT003A

Page 8

SD5

Ordering codes

Description example:

Valve setting (bar)

1stsection following section

Valve setting (bar)

SD5 / 2 -- P (JG3--120) / 1 8 L / 1 8IM . P3(G3--100) / AET -- SAE *

1.

2.

6.

3.

4. 5.

9.

6. 8.

7.

I

7.

8.

3.

4.

1.

II

2.

1. Body kits *

TYPE CODE DESCRIPTION

1--P 5KC1197000 Parallel, 1 section

2--P 5KC1227000 Parallel, 2 sections

3--P 5KC1247000 Parallel, 3 sections

4--P 5KC1277000 Parallel, 4 sections

5--P 5KC1317000 Parallel, 5 sections

6--P 5KC1357000 Parallel, 6 sections

7--P 5KC13E7000 Parallel, 7 sections

Include boby, seals and load check valve.

2. Inlet relief options page 10

TYPE CODE DESCRIPTION

VMD5 direct pressure relief valve type J

(JG2--80) 5KIT105412 Range 40 to 80 bar / 580 to 1150 psi

standard setting 80 bar / 1150 psi

(JG3--120) 5KIT105413 Range 63 to 200 bar / 900 to 2900 psi

standard setting 120 bar / 1750 psi

(JG4--220) 5KIT105414 Range160 to 315bar/ 2300 to4600psi

standard setting 220 bar / 3200 psi

Standard setting is referred to 10 l/min -- 2.64 US gpm flow.

SV XTAP623282 Relief valve blanking plug

5.

3. Spool options page 11

TYPE CODE DESCRIPTION

1 3CU1210130 Double acting, 3 positions, with A and B

closed in neutral position

1A 3CU1221130 Doubleacting, 3 positions, with A open to

tank in neutral position

1B 3CU1222130 Doubleacting, 3 positions, with B open to

tank in neutral position

2 3CU1225130 Double acting, 3 positions, with A and B

open to tank in neutral position

2H 3CU1225225 Double acting, 3 positions, with A e B

partially open to tank in neutral position

3 3CU1231130 Singleacting on A, 3 positions, Bplugged

requires G3/8 plug (see part I )

Special spools for particular positioner kits page 14. . . . . . . . . . . . . . .

5DY 3CU1242220 Double acting, 4 positions, floating circuit

in 4thposition with spool in

5PY 3CU1245620 Double acting, 4 positions, floating circuit

in 4thposition with spool out, fitted with

check valve

8 3CU1262120 Double acting, 4 positions, regenerative

circuit in 4thposition with spool in

Special spools for standard positioner kits page 17. . . . . . . . . . . . . . . .

8F 3CU1261100 Double acting, 3 positions, regenerative

circuit in 2ndposition with spool out

8 DAT003A

Page 9

SD5

Codici di ordinazione

4. “A” side spool positioners page 18

TYPE CODE DESCRIPTION

8 5V08105000 With spring return in neutral position

8D 5V08105200 With spring return in neutral position and

pin with M6 female thread for dual control

8D2 5V08105220 With spring return in neutral position and

pin with M8 male thread for dual control

8F2 5V08105101 With spring return in neutral position and

adjustable flow limiter

19 5V19105000 2 positions, with spring return in neutral

position from position 1

20 5V19105000 2 positions, with spring return in neutral

position from position 2

9 5V09105010 With detent in position 1 and springreturn

in neutral position

10 5V10105010 Withdetent in position 2 and spring return

in neutral position

11 5V11105000 Detent in positions neutral, 1 and 2

12 5V12105000 Detent in positions 1 and 2

15 5V15105000 2 positions, detent in positions 1 and

neutral

16 5V16105000 2 positions, detent in positions 2 and

neutral

9B 5V09202010 Withdetent in position 1 and spring return

in neutral position

10B 5V10202010 With detent in position 2 and spring return

in neutral position

11B 5V11202010 Detent in positions 1 and 2 and spring

return in neutral position

8MS3 5V08105553 With spring return in neutral position,

operation signalling in position 1 and 2,

prearranged for centralized microswitch

control

8MG1 5V08105670 With spring return in neutral position and

microswitch in position 1

8MG2 5V08105680 With spring return in neutral position and

microswitch in position 2

8MG3 5V08105660 With spring return in neutral position and

microswitch in positions 1 and 2

8M3 5V08105400 With spring return in neutral position and

external pin for microswitch control in

positions 1 and 2

8EM2 5V08105580 With spring return in neutral position and

12VDC electromagnetic detent in pos. 2

5V08105590 As previous, 24VDC

8MHE3(NC) 5V08105541 With spring return in neutral position and

spool postioning ON/OFF electric signal

circuit normally closed

8MHE3(NO) 5V08105540 As previous, with circuit normally open

8P 5V08105701 ON/OFF pneumatic kit

8EP3 5V08105735 ON/OFF 12 VDC electro--pneumatic kit

5V08105740 ON/OFF 24 VDC electro--pneumatic kit

8ED3 5V08105350 ON/OFF 12 VDC electro--hydraulic kit

5V08105351 ON/OFF 24 VDC electro--hydraulic kit

Particular positioner kits for special spools page 14. . . . . . . . . . . . . . .

13NZ 5V13305010....4 positions with spring return in neutral

pos.and detentin 4thpos.:for spool5DY

13QN 5V13405020 4 positions with spring return in neutral

pos. and detent in 4thpos.:for spool5PY

13FZ 5V13505400 4 positions with spring return in neutral

position: for spool 8

5. “B” side options page 30

TYPE CODE DESCRIPTION

L 5LEV105000 Standard lever box

LM10 5LEV205000 Lever box for M10 handlever

LF1 5LEV105102 Lever box with adjustable flow limiter

LEB 5LEV605000 Safety lever box, vertical configuration

LUP 5LEV805005 Safety lever box, horizontal configuration

SLP 5COP105000 Witout lever box, with dust--proof plate

SLC 5COP205000 Witout lever box, with endcap

TQ 5TEL105110 Flexible cable connection

LCB 5CLO205100 Joystick lever for 2 sections operation

6. Complete spool control kits page 34

Hydraulic proportional and ON/OFF electric spool controlkits.

7. Service valves page 42

Portrelief,anti--shock,pilot operatedcheckandflow regulation

valves.

8. Outlet port options pag. 40

TYPE CODE DESCRIPTION

AET XTAP623170 Open center plug

AEK 3XTAP522282 Closed center plug

AE 3XGIU527470* SAE8 power beyond sleeve

AET--L 5CAR405700* With hydraulic pilot unloader valve

AET--EL YCAR405305 With 12VDC electric control unloader

valve

YCAR405310 With 24VDC electric control unloader

valve

AET--LT XTAP523370 Prearranged for unloader valve, with

blanking plug

9. Inlet and outlet selection * page 6

TYPE CODE DESCRIPTION

PSL 3XTAP822150 Sideports; need n.2 SAE8 plugs, standard

configuration (omit in valve description)

PSA 3XTAP822150 Upper ports; need n.2 SAE8 plugs

I ”A” and “B” ports plugs *

TYPE CODE DESCRIPTION

SAE6 3XTAP817130 For single acting spool type 3

II Optional handlevers

TYPE CODE DESCRIPTION

AL01/M8x120 170011012 For lever L: height 120 mm / 4.72 in

AL01/M10x150 170012015 For lever LM10:

height 150 mm / 5.91 in

AL08/M12x150 170013115 For joystick LCB:

height 150 mm / 5.91 in

NOTE (*) -- Codes are referred to UN-UNF threads.

9DAT003A

Page 10

SD5

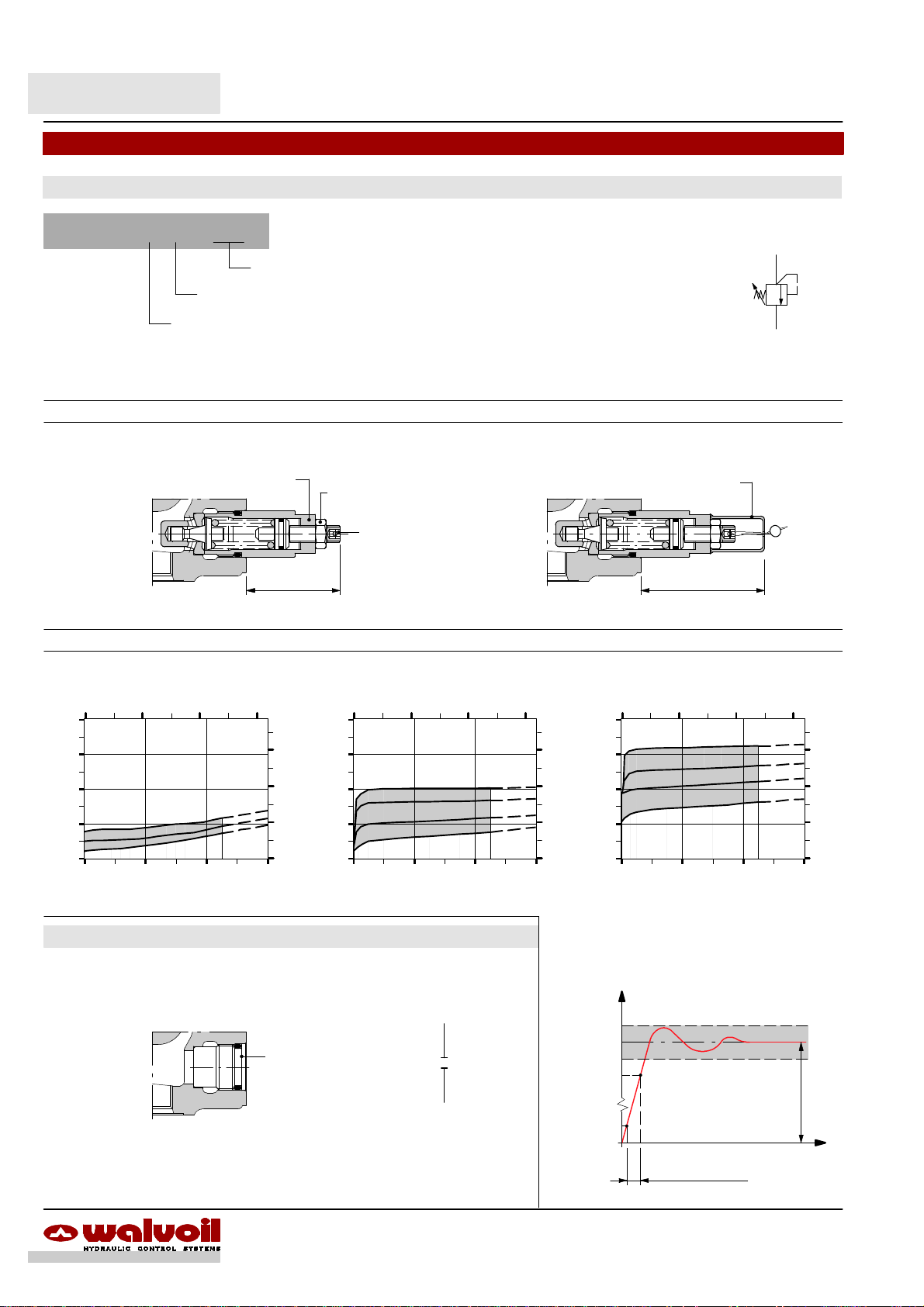

Inlet relief options

Direct pressure relief vave

VMD5 ( J G 3 -- 120 )

Standard setting in bar (for value see page 8)

Adjustable spring type (2, 3, 4).

Adjustment type (G, H)

Adjustment type

G: with screw H: valve set and locked

Wrench 19

42 Nm / 31 lbft

Wrench 13

24 Nm / 17.7 lbft

Allen wrench 4

Cap code: 3COP117260

Performance data

5 10 15

400

(bar)

300

200

Pressure

100

0

0 20 40 60

Flow

(US gpm)

(psi)

4500

3000

1500

(l/min)

SV : relief valve blanking plug

Allen wrench 10

42 Nm / 31 lbft

2.03 2.34

59.5max. 51.5

Spring nr. 4 (red band)Spring nr. 3 (blue band)Spring nr. 2 (green band)

5 10 15

400

(bar)

300

200

Pressure

100

0

0 20 40 60

Flow

(l/min)

(US gpm)

(psi)

4500

3000

1500

400

(bar)

300

200

Pressure

100

0

0 20 40 60

5 10 15

Flow

Response time

(% DP)

105%

95%

90%

(US gpm)

(psi)

4500

3000

1500

(l/min)

Pressure

10%

0,02”

RESPONSE TIME

100 bar

1450 psi

Time (”)

10 DAT003A

Page 11

SD5

Spool options

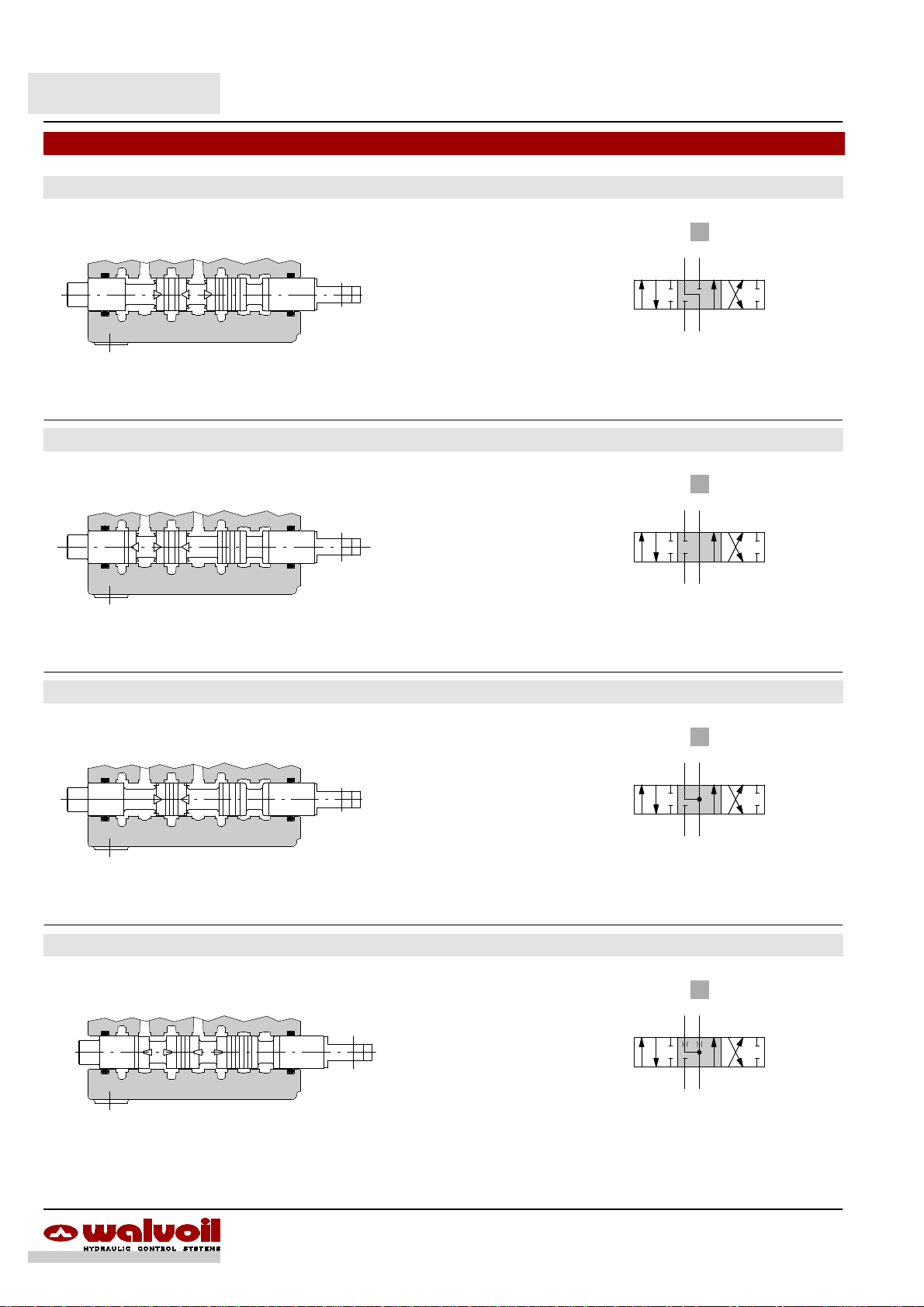

Type 1

For special requirement, spool 1CS code 3CU1210200 suggested for flow from 15 to 30 l/min -- 4 to 7.9 US gpm and spool 1CEX

code 3CU1210230 suggested for flow up to 15 l/min -- 4 US gpm, are available.

A B

T P LCT

P ® A B ® T

29

10

0.39

A B

0.35

20

0.79

T P LCT

142

5.59

P--A--B--T closed, with flow through line (LC) open

A B

"

stroke

201

A B

+ 5.5 mm

+ 0.22 in

P T

201

A B

P T

201

A B

T P LCT

P® B A ® T

Performance data

60

(l/min )

40

Flow

20

0

0.0 1.0 2.0 3.0 4.0 5.0

0.1 0.2

F

Stroke

stroke

-- 5.5 mm

-- 0.22 in

A

Spool metering A(B)®TSpool metering P®A(B)

(in)

15

(US gpm)

10

J

5

Y

5.5 5.5

(mm)

Qin = 45 l/min -- 12 US gpm

F

Y

J

P

(on ports)

P

(on ports)

P

(on ports)

= 63bar / 900 psi

= 100bar / 1450 psi

= 250bar / 3600 psi

60

(l/min )

40

Flow

20

0

0.0 1.0 2.0 3.0 4.0 5.0

0.1 0.2

J

Stroke (mm)

P T

F

Y

(in)

15

(US gpm)

10

5

11DAT003A

Page 12

SD5

Spool options

Type 1A

A B

T P LCT

P--B closed, A®T, flow through line (LC) open

Type 1B

A B

T P LCT

P--A closed, B®T, flow through line (LC) open

201

A B

P T

201

A B

P T

Type 2

A B

T P LCT

P closed, A --B®T, flow through line (LC) open

Type 2H

A B

T P LCT

P closed, A --B partially open to tank,

flow through line (LC) open

201

A B

P T

201

A B

P T

12 DAT003A

Page 13

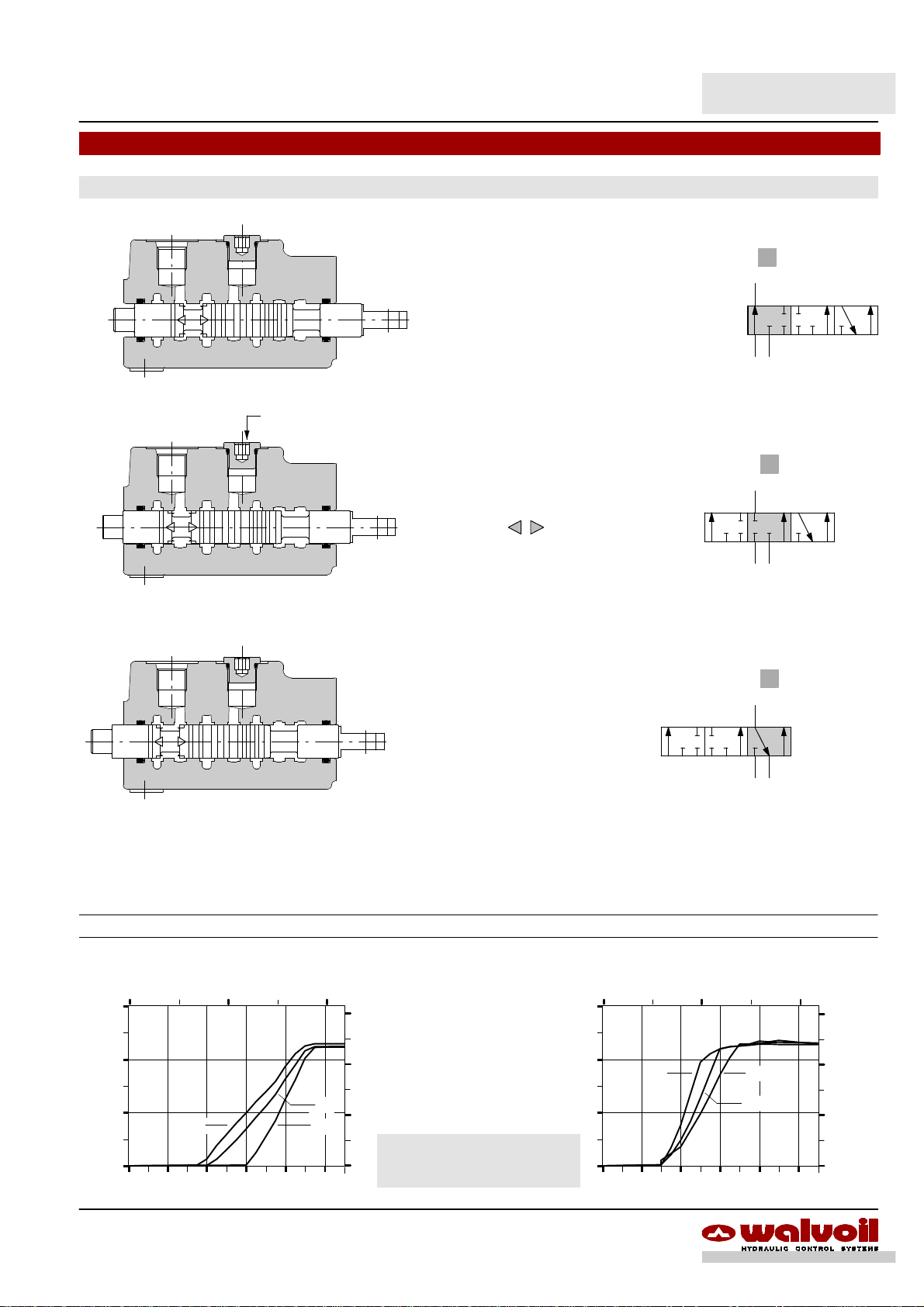

Type 3

SD5

Spool options

A

201

A

+ 5.5 mm

stroke

"

+ 0.22 in

T P LCT

P ® A

Port B plugged

A

Allen wrench 6 -- 24 Nm / 17.7 lbft

T P LCT

P--A--T closed, flow through line (LC) open

A

T P LCT

A

stroke

P T

201

A

P T

201

A

-- 5.5 mm

-- 0.22 in

P T

A ® T

Performance data

0.1 0.2

60

(l/min )

40

Flow

20

F

0

0.0 1.0 2.0 3.0 4.0 5.0

Stroke

J

Y

(mm)

(in)

15

(US gpm)

10

5

5.5

Qin = 45 l/min -- 12 US gpm

F

P

Y

P

P

J

(on ports)

(on ports)

(on ports)

= 63bar / 900 psi

= 100bar / 1450 psi

= 250bar / 3600 psi

13DAT003A

Spool metering A®TSpool metering P®A

0.1 0.2

60

(l/min)

40

J

Flow

20

0

0.0 1.0 2.0 3.0 4.0 5.0

Stroke (mm)

(in)

15

(US gpm)

F

Y

10

5

5.5

Page 14

SD5

Spool options

Type 5DY

It needsspecial body with extramachining: for information pleasecontact Customer Service. Thisspool must becoupled withpositioner type 13NZ.

Also available spool with check valve on A port; type 5WY code 3CU1242320.

201

3

3

Allen wrench 4

6.6 Nm / 4.9 lbft

Wrench 6

9,8 Nm / 7.2 lbft

A B

T P LCT

P® A , B ® T

A B

"

stroke

+ 4.5 mm

+ 0.18 in

A B

P T

201

A B

72.5

2.85

Positioner kit 13NZ

Locking force:

280 N / 63 lbf ±10%

Unlocking force:

300 N / 67.4 lbf ±10%

Performance data

Spool metering

Qin = 45 l/min -- 12 US gpm / P

0.1 0.2

60

(l/min )

40

P®A A®T

Flow

20

T P LCT

P--A--B--T closed

flow through line (LC) open

A B

T P LCT

P® B , A ® T

A B

T P LCT

A--B ® T (float in lock position)

(on ports)

= 100 bar -- 1450 psi

(in)

15

(US gpm)

10

5

A

stroke

AA

stroke

-- 4.5 mm

-- 0.18 in

-- 9 mm

-- 0.35 in

(bar)

Pressure

P T

201

A B

P T

201 3

A B

P T

Pressure drop in position 3

20

15

10

5

(last section)

5 10 15

A®T

B®T

3

(US gpm)

(psi)

200

100

0

0.0 1.0 2.0 3.0 4.0 5.0

Stroke (mm)

5.5

0

0 15 30 45 60

Flow (l/min)

14 DAT003A

Page 15

SD5

Spool options

Type 5PY

It needsspecial body with extramachining: for information pleasecontact Customer Service. Thisspool must becoupled withpositioner type 13QN.

Locking force:

370 N / 83.2 lbf ±10%

Unlocking force:

390 N / 87.7 lbf ±10%

Allen wrench 4

6.6 Nm / 4.9 lbft

Wrench 6

9,8 Nm / 7.2 lbft

72,5

Positioner kit 13QN

Wrench 12

9,8 Nm / 7.2 lbft

A B

T P LCT

A--B ® T (float in lock position)

A B

T P LCT

P® A , B ® T

A B

T P LCT

P--A--B--T closed

flow through line (LC) open

A B

""

stroke

"

stroke

+ 9 mm

+ 0.35 in

+ 4.5 mm

+ 0.18 in

013 2

A B

P T

013 2

A B

P T

013 2

A B

P T

013 2

A B

Performance data

Spool metering

Qin = 45 l/min -- 12 US gpm / P

0.1 0.2

60

(l/min)

40

Flow

20

0

0.0 1.0 2.0 3.0 4.0 5.0

Stroke (mm)

T P LCT

P® B , A ® T

(on ports)

= 100 bar -- 1450 psi

P®BB®T

(in)

15

(US gpm)

10

5

5.5

A

stroke

15DAT003A

-- 4.5 mm

-- 0.18 in

P T

Pressure drop in position 3

(last section)

5 10 15

20

(bar)

15

10

Pressione

5

0

0 15 30 45 60

A(B)®T

Portata (l/min)

(US gpm)

(psi)

200

100

Page 16

SD5

Spool options

Type 8

It needsspecial body with extramachining: for information pleasecontact Customer Service. Thisspool must becoupled withpositioner type 13FZ.

201

3

Allen wrench 5

9.8 Nm / 7.2 lbft

Allen wrench 4

6.6 Nm / 4.9 lbft

A B

T P LCT

P® A , B ® T

A B

"

stroke

+ 4.5 mm

+ 0.18 in

A B

P T

201 3

A B

72.5

2.85

Positioner kit 13FZ

Performance data

Spool metering

Qin = 45 l/min -- 12 US gpm / P

0.1 0.2

60

(l/min )

40

Flow

20

T P LCT

P--A--B--T closed

flow through line (LC) open

A B

T P LCT

P® B , A ® T

A B

T P LCT

P ® A--B (regenerative)

= 100 bar -- 1450 psi

(on ports)

(in)

15

(US gpm)

10

P®A(B)A(B)®T

5

A

stroke

AA

stroke

-- 4.5 mm

-- 0.18 in

-- 7.5 mm

-- 0.29 in

(bar)

Pressure

P T

201

A B

P T

201 3

A B

P T

Pressure drop in positione 3

20

15

10

5

(last section)

5 10 15

A®B

P®B

3

(US gpm)

(psi)

200

100

0

0.0 1.0 2.0 3.0 4.0 5.0

Stroke

(mm)

(mm)

5.5

0

0 15 30 45 60

Flow (l/min)

16 DAT003A

Page 17

Type 8F

It needs special body with extra machining: for information please contact Customer Service.

SD5

Spool options

A B

T P LCT

P ® A--B (regenerative)

A B

T P LCT

P--A--B--T closed, flow through line (LC) open

A B

"

stroke

201

A B

+ 5.5 mm

+ 0.22 in

P T

201

A B

P T

201

A B

T P LCT

P® B , A ® T

Performance data

Spool metering

Qin = 45 l/min -- 12 US gpm / P

0.1 0.2

60

(l/min)

40

Flow

20

0

0.0 1.0 2.0 3.0 4.0 5.0

Stroke (mm)

(on ports)

P®BA®T

= 100 bar -- 1450 psi

(in)

15

(US gpm)

10

5

5.5

A

stroke

-- 5.5 mm

-- 0.22 in

P T

Pressure drop in position 1

(last section)

5 10 15

20

(bar)

15

10

Pressure

5

0

0 15 30 45 60

B®A

P®A

Flow (l/min)

(US gpm)

(psi)

200

100

17DAT003A

Page 18

SD5

”A” side spool positioners

With spring return in neutral position

8 kit

It’ssuppliedwithstandard springtypeD(see force--strokediagram)andavailablewithlighterspringtype C(8MCcode:5V08205000)

or heavier type E (8ME code: 5V08405000).

Force--stroke diagram

(in)

E

D

C

(mm)

(lbf)

60

40

20

--20

--40

--60

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen rench 5

9.8 Nm / 7.2 lbft

36.5

1.44

201

300

(N)

200

100

0

Force

C

--100

D

--200

E

--300

--6 --5 --4 --3 --2 --1 0 1 2 3 4 5 6

--0.1--0.2 0

Stroke

0.1 0.2

0

8D kit

8D2 kit

Allen wrench 4

6.6 Nm / 4.9 lbft

Wrench 9

9.8 Nm / 7.2 lbft

12

0.47

M6

Allen wrench 4

6.6 Nm / 4.9 lbft

Wrench 9

9.8 Nm / 7.2 lbft

201

36.5

1.44

44

1.73

201

M8

40

1.57 1.44

84

3.31

36.5

18 DAT003A

Page 19

With spring return in neutral position

8F2 kit

SD5

“A” side spool positioners

Allen wrench 5

9.8 Nm / 7.2 lbft

Wrench 13

24 Nm / 17.7 lbft

Allen wrench 4

M8x1

19 kit

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen wrench 5

9.8 Nm / 7.2 lbft

51.5

2.03

36.5

1.44

36.5

1.44

Allen wrench 4

6.6 Nm / 4.9 lbft

01

Force--stroke diagram

300

(N)

200

100

0

Force

--100

--200

--300

0 1 2 3 4 5 6

0.1 0.2

Stroke

(in)

(mm)

201

(lbf)

60

40

20

0

--20

--40

--60

20 kit

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen wrench 5

9.8 Nm / 7.2 lbft

36.5

1.44

20

(N)

Force

--100

--200

--300

Force--stroke diagram

--0.1--0.2

300

200

100

0

--6 --5 --4 --3 --2 --1 0

Stroke

(in)

(mm)

(lbf)

60

40

20

0

--20

--40

--60

19DAT003A

Page 20

SD5

”A” side spool positioners

With detent

9 kit

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen wrench 5

9.8 Nm / 7.2 lbft

45,545.5

1.79

Operating features

Locking force (from pos. 0 to 1) :150 N /33.7 lbf ±10%. . .

Unlocking force (from pos. 1 to 0) : 140 N /31.5 lbf ±10%.

11 kit

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen wrench 5

9.8 Nm / 7.2 lbft

10 kit

201201

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen wrench 5

9.8 Nm / 7.2 lbft

41

1.61

Operating features

Locking force (from pos. 0 to 2) :150 N /33.7 lbf ±10%. . .

Unlocking force (from pos. 2 to 0) : 140 N /31.5 lbf ±10%.

12 kit

201

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen wrench 5

9.8 Nm / 7.2 lbft

201

36.5

1.44

Operating features

Locking and unlocking force : 120 N / 27 lbf ±10%. . . . . .

15 kit

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen wrench 5

9.8 Nm / 7.2 lbft

36.5

1.44

Operating features

Locking and unlocking force : 100 N /22.5 lbf ±10%. . . . . .

36.5

36,5

1.44

Operating features

Locking and unlocking force : 100 N /22.5 lbf ±10%. . . . . .

16 kit

01

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen wrench 5

9.8 Nm / 7.2 lbft

36.5

1.44

Operating features

Locking and unlocking force : 100 N /22.5 lbf ±10%. . . . . .

20

20 DAT003A

Page 21

“A” side spool positioners

With detent and sprimg return to neutral position from either directions

9B kit

SD5

Allen wrench 4

6.6 Nm / 4.9 lbft

10B kit

Allen wrench 4

6.6 Nm / 4.9 lbft

72.5

2.85

Allen wrench 5

9.8 Nm / 7.2 lbft

72.5

2.85

Allen wrench 5

9.8 Nm / 7.2 lbft

201

300

(N)

200

Force

--100

--200

--300

100

0

Fromposition2 to 0

From position 0to 2

--6 --5 --4 --3 --2 --1 0 1 2 3 4 5 6

Locking--unlocking area

Ulocking force: 200 N / 45 lbf ±10%:

201

300

(N)

200

100

Force

--100

--200

--300

:

0

--6 --5 --4 --3 --2 --1 0 1 2 3 4 5 6

Locking--unlocking area

Ulocking force: 200 N / 45 lbf ±10%:

Force--stroke diagram

--0.1--0.2 0

Stroke

Force--stroke diagram

--0.1--0.2 0

Fromposition2 to 0

From position 0to 2

Stroke

0.1 0.2

Fromposition0 to 1

From position 1to 0

0.1 0.2

Fromposition0 to 1

From position 1to 0

(in)

(lbf)

60

40

20

0

--20

(mm)

(in)

(mm)

--40

--60

(lbf)

60

40

20

0

--20

--40

--60

:

11B kit

Allen wrench 4

6.6 Nm / 4.9 lbft

72.5

2.85

Allen wrench 5

9.8 Nm / 7.2 lbft

201

300

(N)

200

100

Force

--100

--200

--300

:

0

--6 --5 --4 --3 --2 --1 0 1 2 3 4 5 6

Locking--unlocking area

Ulocking force: 200 N / 45 lbf ±10%:

Force--stroke diagram

--0.1--0.2 0

Fromposition2 to 0

From position 0to 2

Stroke

0.1 0.2

Fromposition0 to 1

From position 1to 0

(in)

(lbf)

60

40

20

0

--20

:

--40

--60

(mm)

21DAT003A

Page 22

SD5

”A” side spool positioners

8MS3 kit: with centralized control for microswitch

Example of a two section valve assembly

Microswitch on

request (see page 25)

58

Rocker arm to

actuate microswitch

2.28

M3

n.2 threads

25.4

1

0.04

1

Bracket for 5MIC100

microswitch

8

0.32

Allen wrench 2.5

6.6 Nm / 4.9 lbft

Allen wrench 2.5

6.6 Nm / 4.9 lbft

A1 B1 A2 B2

P

120

1750

Es.: SD5/2--P(JG3--120)/18MS3L/18MS3L/AET -- KM 2 S 51

Assembling kit

Nr. of working sections

22 DAT003A

T

51 = with bracket for M51 (IP51) microswitch fixing

67 = with bracket for M67 (IP67) microswitch fixing

S = bracket placed on left

D = bracket placed on right

Page 23

8MS3 kit: with centralized control for microswitch

201

Allen wrench 2.5

6.6 Nm / 4.9 lbft

Allen wrench 4

6.6 Nm / 4.9 lbft

58.3

2.29

Notch 1.5 mm / 0.06 in

9.8 Nm / 7.2 lbft

SD5

“A” side spool positioners

Other configurations

8MS1 kit

microswitch operation in

position 1

201

8MS2 kit

microswitch operation in

position 2

201

Microswitches for 8MS kits

Complete with rubber cover and mounting screws.

M51 code: 5MIC100 M67 code: 5MIC200

Dedicated bracket is needed for the assembly

code: 3FLA225052

55.5M42.19

18 4

0.7140.16

Operating features

Max. current / voltage : 5 A / 250 VAC. . . . . . . . . . . . .

Weather protection : IP67. . . . . . . . . . . . . . .

64

2.52

0.83

M3

21 4

0.16

Operating features

Max. current / voltage : 15 A / 480 VAC. . . . . . . . . . . . .

Weather protection : IP51. . . . . . . . . . . . . . .

6

Æ

0.24

25.5 14

1.00

30.2

1.19

Stroke

2.5

0.10

68

2.68

: 0.25 A / 250 VDC

0.55

58.2

7

0.28

Æ

27.1

1.07

1.5

0.06

2.29

33 6

1.30

Stroke

: 0.25 A / 230VDC

0.24

23DAT003A

Page 24

SD5

“A” side spool positioners

With microswitch and spring return in neutral position

8MG3 kit

Microswitch kit with

PACKARD male connector

Wrench 22

42 Nm / 31 lbft

Wrench 10

9.8 Nm / 7.2 lbft

Allen wrench 4

6.6 Nm / 4.9 lbft

103

4.06

8MG3 kit

microswitch operation in

positions 1 and 2

201

Other configuration

8MG1 kit

microswitch operation in

position 1

66,5

Allen wrench 5

9.8 Nm / 7.2 lbft

Allen wrench 4

6.6 Nm / 4.9 lbft

Microswitch operating features

Mechanical life : 5x105operations. . . . . . . . . . .

Electrical life (resistive load) : 105operations -- 7A / 13,5VDC

: 5x104operations -- 10A / 12VDC

Microswitches ordering codes

Thekit consisting ofmicroswitchandconnector,canbeorderedseparately (normally closed NC version is available on request).

CODE DESCRIPTION

4MIC730 Normally open (NO) microswitch kit with PACKARD

male connector: needs C07 female connector

4MIC740 Normally closed (NC) microswitch kit with PACKARD

female connector: nedds C17 male connector

For connection see page NO TAG.

201

8MG2 kit

microswitch operation in

position 2

201

24 DAT003A

Page 25

With microswitch and spring return in neutral position

8M3 kit

SD5

“A” side spool positioners

Allen wrench 4

6.6 Nm / 4.9 lbft

notch 1.5 mm / 0.06 in

9.8 Nm / 7.2 lbft

Allen wrench 2.5

6.6 Nm / 4.9 lbft

36.5

1.44

74

2.91

8EM2: with electromagnetic detent

With spring return in neutral position and electromagnetic detent in position2.

Solenoid kit with DEUTSCH male connector

(need connector type C..., see page

NO TAG)

201

201

Allen wrench 4

6.6 Nm / 4.9 lbft

Notch 1.2 mm / 0.047 in

6.6 Nm / 4.9 lbft

600

23.6

88

3.46

111

4.37

Wrench 10 -- 9.8 Nm / 7.2 lbft

Operating features

Nominal voltage : 12/ 24VDC ± 10%. .. . . .. . . .. . . ..

Power rating : 4 W.. . . . . . . . . . . . . . . . .

Resistance (20 °C) : 36 / 144 Ohm. . . . . . . . . . . . .

Min. release force : 145 N. . . . . . . . . . . . . .

Duty cycle : 100%. . . . . . . . . . . . . . . . . . . .

Solenoid ordering codes

With male DEUTSCH connector

CODE DESCRIPTION

YSOL528465 12 VDC solenoid

YSOL528466 24 VDC solenoid

25DAT003A

Page 26

SD5

“A” side spool positioners

8MHE3 kit: with spring return in neutral position and spool positioning ON/OFF signal

This module supplies two different ON/OFF signals, related to the direction of the spool.

It has two separate contacts which can be normallyopen or normally closed.

Connection DIN43650/C

(needs connector type C11, see page 62)

Notch -- 6.6 Nm / 4.9 lbft

Wrench 5

6.6 Nm / 4.9 lbft

Wrench 10

9.8 Nm / 7.2 lbft

Connector wiring

Position 1 signal

38.5

1.52

Wrench 5

9.8 Nm / 7.2 lbft

44.5

1.75

81

3.19

Vedi particolare A

Position 2 signal

32

4 1

8MHE3(NC) kit 8MHE3(NO) kit

1 2 34

Configuration with

normally closed circuit

View A View A

Configuration with

normally open circuit

Operating features

Power supply range : from 3 da 28 VDC

Max. output current : 500 mA.

Weather protection : IP65.

1 2 34

201201

Ouput signal with NC circuit

Tolerance range

(VDC)

100%

--0.2

12

Voltage

0

--6 --5 --4 --3 --2 --1 0 1 2 3 4 5 6

--0.1

Stroke

0.1

Mobile contact

Fixed contact

0.2 (in)0

(mm)

Mobile contact

Fixed contact

Ouput signal with NO circuit

Tolerance range

(VDC)

100%

--0.2

12

Voltage

0

--6 --5 --4 --3 --2 --1 0 1 2 3 4 5 6

--0.1

Stroke

0.1

0.20

(mm)

26 DAT003A

Page 27

8P: ON/OFF pneumatic kit

SD5

“A” side spool positioners

201

Wrench 1 1

9.8 Nm / 7.2 lbft

Allen wrench 4

6.6 Nm / 4.9 lbft

23

0.91

NPT 1/8” -- nr.2 thread

51,5

V2

V1

118

Wrench 10

9.8 Nm / 7.2 lbft

4.64

Allen wrench 4

6.6 Nm / 4.9 lbft

8EP3: ON/OFF electro-- pneumatic kit

Wrench 14

9.8 Nm / 7.2 lbft

Pg9

43

1.69 2.24

57

V1 V2

Operating features

Pilot pressure : min. 5.5 bar / 80 psi. . . . . . . . . . . . . . . . . . .

: max. 10bar / 145psi

Scheme

V1 V2

4.47

113.5

Allen wrench 4

6.6 Nm / 4.9 lbft

V1 V2

42

1.65

Wrench 13

24 Nm / 17.7 lbft

119

4.68

Wrench 9

8

0.32

Ø

Pneumatic solenoid valves codes (with connector)

CODE DESCRIPTION

2X4001012 Nominal voltage 12VDC

2X4001024 Nominal voltage 24VDC

Connector C01 inclded

code: 2X1001020

(see page 62)

Allen wrench 4 -- 6.6 Nm / 4.9 lbft

Special wrench -- 9.8 Nm / 7.2 lbft

Operating features

Pilot pressure : 6 bar / 87 psi. . . . . . . . . . . . . . . . . .

Solenoid operating features

Nominal voltage tolerance : ±10%. . . . . . . . .

Power rating : 8 W. . . . . . . . . . . . . . . . . . . .

Duty Cycle : 100%. . . . . . . . . . . . . . . . . . . . . .

201

Scheme ISO 1219

201

V1 V2

: (max.10 bar / 145psi)

27DAT003A

Page 28

SD5

”A” side spool positioners

8ED3: ON/OFF electro-- hydraulic kit

With external pilot and drain.

Coil

5.24

133 /

Collector

Wrench 10

Allen wrench 4 -- 6.6 Nm / 4.9 lbft

1.65

133

5.24

Allen wrench 4 -- 6.6 Nm / 4.9 lbft

139

5.47

116

4.57

5942

2.32

6.6 Nm

4.9 lbft

Connection ISO4400

(needs C02 connector,

see page 62)

Solenoid valve:

wrench 24 -- 9.8 Nm / 7.2 lbft

Wrench 10

24 Nm / 17.7 lbft

Special wrench

9.8 Nm / 7.2 lbft

Scheme

1

L

V

201

Scheme ISO 1219

201

V L

Operating features

Pilot pressure : min. 10 bar / 145 psi. . . . . . . . . . . . . . . . . .

: max. 50 bar / 725 psi

Max. backpressure on drain L : 25 bar / 360 psi. . . . .

Solenoid operating features

Nominal voltage tolerance : ±10%. . . . . . . .

Power rating : 21 W. . . . . . . . . . . . . . . . . . .

Duty cycle : 100%. . . . . . . . . . . . . . . . . . . . .

Ordering codes

CODE DESCRIPTION

2S0EJ08002013 3--way solenoid valve

2X4350012 12VDC coil

2X4350024 24VDC coil

Collector kit for external pilot and drain

Wrench 22

24 Nm / 17.7 lbft

SAE 6

V

20 bar

290 psi

Collector

P

Ex: SD5/2--P(JG3--120)/18ED3L/18ED3L/AET--SAE--KE2S0--24VDC

L

149.5

5.89

T

A1 B1 A2 B2

V

P

120

1750

Ordering codes (UN--UNF thread)

TYPE CODE DESCRIPTION

KE1S0 5KE1S00070 Kit for 1 section

KE2S0 5KE2S00270 Kit for 2 sections

KE3S0 5KE3S00270 Kit for 3 sections

KE4S0 5KE4S00270 Kit for 4 sections

KE5S0 5KE5S00270 Kit for 5 sections

KE6S0 5KE6S00270 Kit for 6 sections

KE7S0 5KE7S00270 kit for 7 sections

L

T

28 DAT003A

Page 29

8ED3: ON/OFF electro-- hydraulic kit

Collector kit with pilot and drain lines

The kit consists of a collector with VRP pressure reducing valve and relative pipes.

SD5

“A” side spool positioners

13628

Allen wrench 6

24 Nm / 17.7 lbft

VRP Code:

2S100808VAL21

Wrench 17

Inlet line

P

Wrench 24

24 Nm / 17.7 lbft

1.10

5.35

Collector

1.38

Wrench 19

24 Nm / 17.7 lbft

Drain

Wrench 24

42 Nm / 31 lbft

T

VRC back pressure

35

valve (not included)

Ex: SD5/2--P(JG3--120)/18ED3L/18ED3L/VRC--SAE--

KE2R3--24VDC

VRP valve operating features

Outlet pressure : 20 bar / 290 psi. . . . . . . . . . . . . . . . . .

Max. flow : 8 l/min. . . . . . . . . . . . . . . . . . . . . . .

Filtering : 80 m. . . . . . . . . . . . . . . . . . . . . . . .

VRP

A1 B1 A2 B2

5.89

149.5

T

P

VRC

120

1750

Ordering codes (UN--UNF thread)

TYPE CODE DESCRIPTION

KE1R3 5KE1R30270 Kit for 1 section

KE2R3 5KE2R30270 Kit for 2 sections

KE3R3 5KE3R30270 Kit for 3 sections

KE4R3 5KE4R30270 Kit for 4 sections

KE5R3 5KE5R30270 Kit for 5 sections

KE6R3 5KE6R30270 Kit for 6 sections

VRC valve : code X003600010

Valve assembled on flow through passage provides pilot pressure to the actuator.

Wrench 22

42 Nm / 31 lbft

20

0.79

Wrench 22

24 Nm / 17.7 lbft

29DAT003A

40

(bar)

30

20

Pressure

10

0

Pressure drop P®T

4 8

0 15 30 45

Flow

12

(l/min)

(US gpm)

(psi)

400

200

Page 30

SD5

”B” side options

Lever controls

L type

Alluminium with protection boot lever pivot box; it can be rotated 180° (execution L180).

(**) (*)

Vertical handlever

assembly

M8

20

0.79

44

1.73

Horizontal handlever

assembly

65.5

53.7

2.11

20

0.79

5

Allen wrench 4

6.6 Nm / 4.9 lbft

2.580.96

24.

NOTE (*) -- With spool type 5DY (see page 14)

(**) -- With spool type 5PY (see page 15)

LM10 type LF1 type

201

Execution L180

29.2411.15

1.61

M10

20

44

M 10

201

54

2.13

20

0.79

Allen wrench 4

6.6 Nm / 4.9 lbft

201

M8

M8

Allen wrench 2.5

71.5

2.82

20

24.5

0.96

20

0.79

44

1.73

max

66

2.60

Allen wrench 4 -- 6.6 Nm / 4.9 lbft

Wrench 13

24 Nm / 17.7 lbft

65.5

2.58

53.7

2.11

0.79

24.5

0.96

30 DAT003A

Page 31

Special lever controls

Safety levers with lock in neutral complete with handlever; lift handlever knob to operate.

LEB type

5

Stroke to ulocking

Locking bush

Wrench 13

24 Nm / 17.7 lbft

236.5

9.31

SD5

“B” side options

201

51.5

2.03

0.79

24.5 20

0.96

20

0.79

44

1.73

Allen wrench 4

6.6 Nm / 4.9 lbft

LUP type

Available as LUP(R150) configuration, with lenght L = 150 mm / 5.91 in and red knob:

code 5LEV805010.

219

20

0.79

M8

Wrench 13

24 Nm / 17.7 lbft

Allen wrench 4

6.6 Nm / 4.9 lbft

52.8

2.08

8.62

53.7

2.11

Locking bush

65

2.56

12

Stroke to ulocking

0.47

21

0.83

Standard black knob

201

31DAT003A

Page 32

SD5

“B” side options

Controls prearrangement

SL type SLC type

201

22

0.35

9H8

+0.00866

0

0.87

9

0.35

15

0.59

SLP type

201

Allen wrench 4

6.6 Nm / 4.9 lbft

8

0.32

Mechanical control with dust--proof

plate.

Protection cap usable with pneumatic,

electro--pneumatic, and electro--hydraulic spool positioners.

TQ cable remote control kit

201

Allen wrench 8

3 Nm / 2.2 lbft

68.5

2.70

Allen wrench 4 -- 6.6 Nm / 4.9 lbft

Waterproof cap prearranged for remote control with flexible cable.

Allen wrench 4 -- 6.6 Nm / 4.9 lbft

Wrench 10 -- 9.8 Nm / 7.2 lbft

Wrench 24 -- 24 Nm / 17.7 lbft

81

3.19

Flexible cable

NOTE -- For more information about remote cable control,

require appropriate documentation.

201

Example of cable control

TQ kit

SCF030 remote

control

CD flexible cables

SD5/2 directional control

valve without lever boxes

32 DAT003A

Page 33

LCB mechanical joystick for two sections control

SD5

Kit comandi lato “B”

Execution LCB4

2ndsection spool

Wrench 13

1stsection spool

Allen wrench 4 -- 6.6 Nm / 4.9 lbft

Allen wrench 4 -- 6.6 Nm / 4.9 lbft

Wrench 13 -- 24 Nm / 17.7 lbft

Wrench 13 -- 24 Nm / 17.7 lbft

Wrench 10 -- 9.8 Nm / 7.2 lbft

24 Nm / 17.7 lbft

Wrench 10

NOTE -- The handlever must be ordered separately (see page 9).

Dimensions and movement scheme

Execution LCB1

pivot placed down on the left

1stsection axis

Execution LCB2

pivot placed down on the right

201

Pivot

201

Allen wrench 5

9.8 Nm / 7.2 lbft

2ndsection axis

B1

B1--A2 B1--B2

A2

A1--A2 A1--B2

A1

Execution LCB3

pivot placed above to the left

A1

A1--A2 A1--B2

A2

B1--A2 B1--B2

B1

NOTE -- Don’t use with spool type 5DY.

B2

B2

B2

B1

A2--B1

M12

10 27

0.39 1.06

A2

Exection LCB4

pivot placed above on the right

A2

B1

B2--B1

B2

B2--A1B2--B1

A2--A1

A2--A1A2--B1

B2--A1

A1

A1

spool axis

72

2.83

36

21.5

0.85

76

2.99

1.5

0.06

1.42

36

1.42

33DAT003A

Page 34

SD5

Complete controls

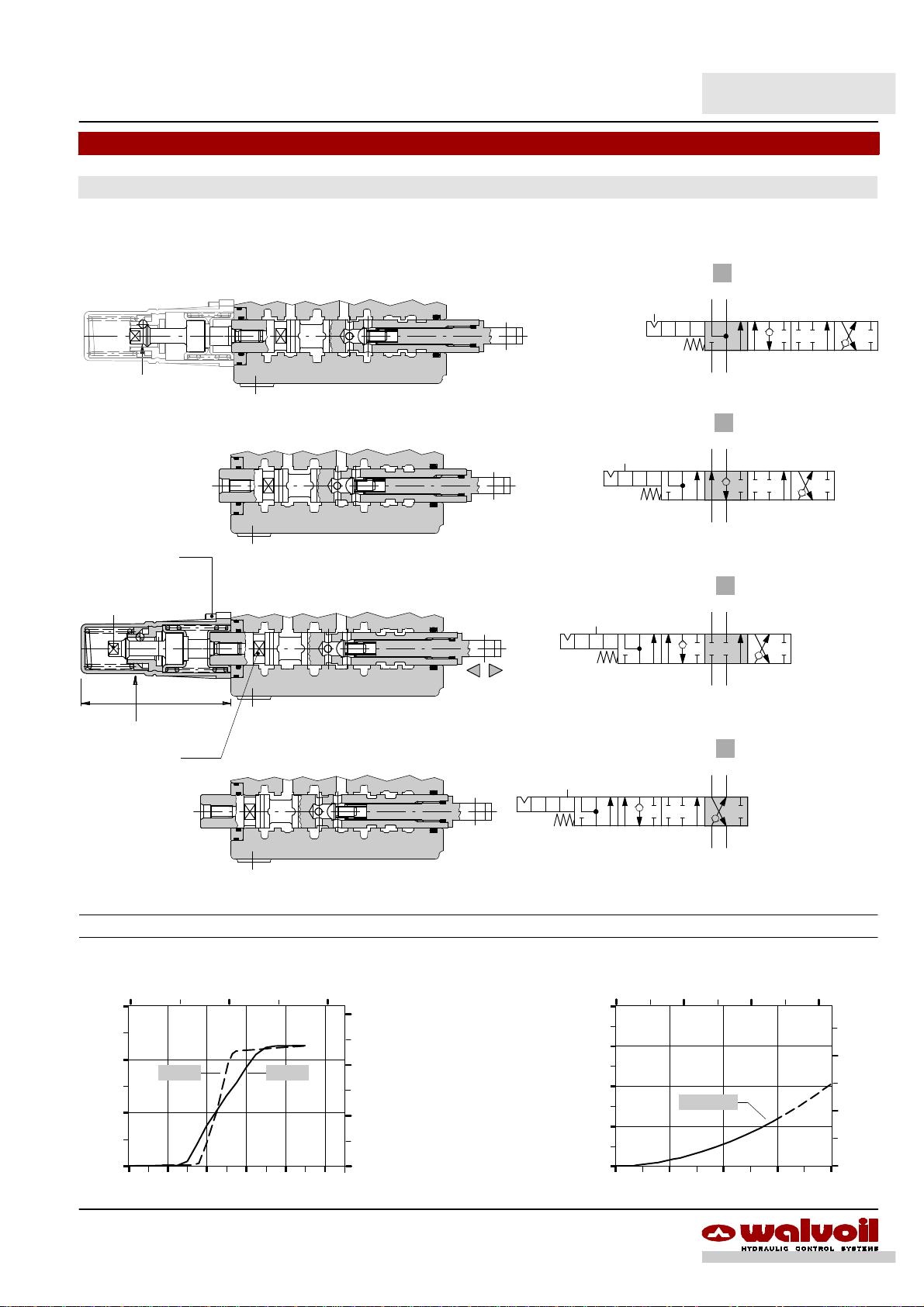

8IM: proportional hydraulic control code 5IDR205071

It can be used with standard spools and body (body kit without seals on spool).

Coupling suggested with type 1CS spool (see page 11).

38

VA VB

Allen wrench 5

9.8 Nm / 7.2 lbft

1.50

28

1.10

201

VA VB

SAE6

Allen wrench 4

6.6 Nm / 4.9 lbft

52

2.05

197

7.76

Pilot pressure -- stroke diagram

Max. pilot pressure 50 bar -- 720 psi

Port B Port A

2 0 1

20

(bar)

16

15

10

5

Pilot pressure

0

--6 --4 --2 0 2 4 6

--0.1--0.2

Stroke (mm)

0.1 0.2

5.5--5.5

Spool

42

1.65

(in)

(psi)

200

100

Spool overlap area

Metering area

34 DAT003A

Page 35

8IM: proportional hydraulic control code 5IDR205021

Connection example

Hydraulic pilot control valve series SV01

with curve type 026

Curve 026

30

0.1 0.2

(bar)

0.3

(in)

(psi)

400

SD5

Complete controls

20

14

10

Pilot pressure

6.5

0

1

0 3 6 9

Stroke (mm)

VA1 VA2

A1 A2

P

8.5

T

300

200

100

1 4 3 2T P

VA1 VB1 VA2 VB2

A1 B1 A2 B2

T

P

B1 B2

VB1 VB2

120

1750

Ex:

SD5/2--P(JG3--125)/1CS8IM/1CS8IM/AET--SAE+

SV01--S/01W--026Ax4

35DAT003A

Page 36

SD5

Complete controls

8ESN solenoid control

Direct control by double solenoid with spring return to neutral position, available with emergency manual override.

It’s necessary special spool and standard body (body kit without spool seals).

Due to the large dimension, it’s not possible to assembly more than one control consecutively,except SD5/2--P and SD5/3--P that

have special bodies with bigger centre --to--centre.

Description example:

SD5 / 1 -- P (JG3--120) / 1 8ESN LES / AET -- SAE -- 24VDC

2. 3.

4.1.

3.

5.

1.

1. Body kit *

TYPE CODE DESCRIPTION

SD5/1--P 5KC1193100 1 section, standard body

SD5/2--PS 5KC1223003 2 sections, special body

SD5/3--PS 5KC1243006 3 sections, special body

2. Spool options

TYPE CODE DESCRIPTION

1(ES) 3CU1210036 Double acting, 3 positions, with A and B

closed in neutral position

2(ES) 3CU1225036 Double acting, 3 positions, with A and B

open to tank in neutral position

3. Connection kit

TYPE CODE DESCRIPTION

8ESN 5V08009 For solenoid joint, with spring return in

neutral position

5.

4.

LES

2.

CAE

4. “B” side options

TYPE CODE DESCRIPTION

LES 5LEV105410 Safety lever pivot box for manual

operation

CAE 5COP205100 Endcap

5. Solenoid

TYPE CODE DESCRIPTION

10.5VDC XSOL314310 Nominal voltage 10.5VDC

12VDC XSOL314312 Nominal voltage 12VDC

24VDC XSOL314024 Nominal voltage 24VDC

192VDC XSOL314192 Nominal voltage 192VDC;

(for 220 VAC supply)

NOTE (*) -- Codes are referred to UN-UNF threads.

36 DAT003A

Page 37

8ESN solenoid control

SD5

Complete controls

Electric wiring example

2

3

1

Connector

To battery

Operating features

Internal leakage A(B)®T

(Dp = 100 bar -- 1450 psi

T = 40°C -- 104°F) : 10 cm3/min -- 0.61 in3/min. . . . . . . . . . . . . . . .

Solenoid operating features

Nominal voltage tolerance : ±10%. . . . . . . . .

Power rating : 65 W. . . . . . . . . . . . . . . . . . . .

Coil insulance : class H. . . . . . . . . . . . . . . . . . .

Duty cycle : 100%. . . . . . . . . . . . . . . . . . . . . .

P Þ B

A Þ T

8ESNLES kit

with safety lever pivot box

201

8ESNCAE kit

with encadp

201

P Þ A

B Þ T

+--

Manual operation:

lift the bush to lever

unlocking

LES

Wrench 24

24 Nm / 17.7 lbft

Connection ISO4400

(needs C03 connector for VDC supply or C05 connector for VAC supply; see page 62)

Wrench 14

9.8 Nm / 7.2 lbft

3112

WW

172.5

6.79

Allen wrench 4

9.8 Nm / 7.2 lbft

Spool: wrench 13

37DAT003A

Allen wrench 4

6.6 Nm / 4.9 lbft

Allen wrench

6.6 Nm / 4.9 lbft

68.5

2.70

CAE

32

1.26

Allen wrench 4

6.6 Nm / 4.9 lbft

Page 38

SD5

Complete controls

8ES solenoid control

Solenoid direct control with spring return to neutral position.

It needs special spools and standard body (body kit without seals on spool).

Description example:

SD5 / 1 -- P (JG3--120) / 1 8ES3 / AET -- SAE -- 24VDC

1. 2.

3.

8ES3

8ES1

8ES2

4.

3.

3. 4.

I

2.

1.

3.

8ES1

8ES3

8ES2

3.

4.

1. Body kit *

TYPE CODE DESCRIPTION

SD5/1--P 5KC1193100 1 section

SD5/2--P 5KC1223100 2 sections

SD5/3--P 5KC1243100 3 sections

SD5/4--P 5KC1273100 4 sections

SD5/5--P 5KC1313100 5 sections

SD5/6--P 5KC1353100 6 sections

SD5/7--P 5KC3E3100 7 sections

2. Spool options

TYPE CODE DESCRIPTION

1(ES) 3CU1210011 Double acting, 3 positions, with A and B

closed in neutral position

2(ES) 3CU1225010 Double acting, 3 positions, with A and B

open to tank in neutral position

NOTE (*) -- Codes are referred to UN-UNF threads.

3. Control kit

TYPE CODE DESCRIPTION

8ES1 5V08024 Single acting P®A, with spring return to

neutral position

8ES2 5V08024 Single acting P®B, with spring return to

neutral position

8ES3 5V08025 Doubleacting, with springreturntoneutral

position

4. Coil

TYPE CODE DESCRIPTION

10.5VDC 4SOL512011 Nominal voltage 10.5VDC

12VDC 4SOL512012 Nominal voltage 12VDC

24VDC 4SOL512024 Nominal voltage 24VDC

I ”A” and “B” ports plugs *

TYPE CODE DESCRIPTION

SAE6 3XTAP817130 For single acting controls type 8ES1 and

8ES2

38 DAT003A

Page 39

8ES solenoid control

SD5

Complete control

Electric wiring example

1

2

Connector 1 Connector 2

P Þ A

B Þ T

P Þ B

A Þ T

+--

To battery

Operating features

Internal leakage A(B)®T

(Dp = 100 bar -- 1450 psi

T = 40°C -- 104°F) : 10 cm3/min -- 0.61 in3/min. . . . . . . . . . . . . . . .

Coil operating features

Nominal voltage tolerance : ±10%. . . . . . . . .

Power rating : 36 W. . . . . . . . . . . . . . . . . . . .

Coil insulance : class H. . . . . . . . . . . . . . . . . . .

Duty cycle : 100%. . . . . . . . . . . . . . . . . . . . . .

8ES3 kit

double acting

201

1

2

8ES1 kit

single acting on A

01

8ES2 kit

single acting on B

20

Operating condition diagram

400

(bar)

300

200

Pressure

100

0

0 15 30 45

4 8

Operation area

Flow

12

(l/min)

(US gpm)

(psi)

4500

3000

1500

24 Nm / 17.7 lbft

Allen wrench 4

6.6 Nm / 4.9 lbft

7 Nm

5.2 lbft

Wrench 22

Connection ISO4400

(needs C02 connector,

23.5

0.93

Conn. 1 Conn. 2

Spool

Wrench 13

24 Nm / 17.7 lbft

93.8

3.69

see page. 62)

39DAT003A

Emergency

manual override

Page 40

SD5

Outlet port options

It’s possible to have open center, closed center and power beyond.

Unloader valves are available: these valves need special bodies with appropriate cavity on lateral outlet port, the tank connection

T must be on top.

AET: open center (standard)

See page 6

AE: with power beyond

23.5

0.93

A1 B1 A2 B2

P

Wrench 27 --42 Nm / 31 lbft

C

SAE8

T

C

AEK: closed center

Allen wrench 8 --42 Nm / 31 lbft

4

0.16

A1 B1 A2 B2

T

P

120

1750

Ex: SD5/2--P(KG3--120)/18L/18L/AE--SAE

L: hydraulic pilot unloader valve

For safety reasons it’s provided with pilot port plugged.

Pressure drop curve

31

1.22

SAE6

X

Wrench 22

24 Nm / 17.7 lbft

Wrench 24

42 Nm / 31 lbft

Operating features

Internal leakage : 10 cm3/min a 100 bar. . . . . . . . . . . . . . . . .

12

(bar)

9

6

Pressure

3

0

0 10 20 30 40

: 0.61 in3/min at 1450 psi

4 8

Flow

40 DAT003A

120

1750

Ex: SD5/2--P(KG3--120)/18L/18L/AEK

A2 B2

12

(US gpm)

(psi)

150

100

50

45

(l/min)

Ex.: SD5/2--P(JG3--120)/18L/18L/AET--L--SAE

T

X

Page 41

EL: electric control unloader valve

123

4.84

Wrench 27

42 Nm / 31 lbft

SD5

Outlet port options

T

A2 B2

Wrench 24

42 Nm / 31 lbft

Wrench 30

42 Nm / 31 lbft

Push and twist push--button

ISO4400 connection

(needs C02 connector, see

page 62)

Operating features

Internal leakage (excited position) : 75 cm3/minat 100 bar. .

:4.6in3/minat1450psi

Solenoid operating features

Nominal voltage : 12 VDC 24 VDC. . . . . . . . . . . . . . . . .

Nominal voltage tolerance : ±10%. . . . . . . . .

Power rating : 19 W. . . . . . . . . . . . . . . . . . . .

Nominal current : 1,58 A 0,81 A. . . . . . . . . . . . . . . . . .

Resistance : 7,6 W 29,5 W. . . . . . . . . . . . . . . . . . . . .

Coil insulation : Class F. . . . . . . . . . . . . . . . . . .

Duty cycle : 100%. . . . . . . . . . . . . . . . . . . . . .

Coils ordering codes

CODE DESCRIPTION

2X4311012 Nominal voltage 12VDC

2X4311024 Nominal voltage 24VDC

for manual override

Ex.: SD5/2--P(JG3--120)/18L/18L/AET--EL--12VDC

Pressure drop curve

4 8

25

(bar)

20

15

10

Pressure

5

0

0 10 20 30 40

Flow

12

45

(l/min)

(US gpm)

(psi)

300

200

100

LT: unloader valve prearrangement

Allen wrench 6

24 Nm / 17.7 lbft

A2 B2

T

Ex.:SD5/2--P(JG3--120)/18L/18L/AET--LT

41DAT003A

Page 42

SD5

Service valves1.

All service valves need special body: contact Customer Service.

BP

BPS

P

2.

1.

VSC(JG...)

VSCT

VS

3.

Kit VS

4.

6.

VD11

Kit VD1

5.

VM(...)

VMT

VD12

Kit VM

VD13

VM(...)

VMT

42 DAT003A

Page 43

SD5

Service valves

1. Relief valve page 44

TYPE CODE DESCRIPTION

VS(G3--100) 3XCAR505113 Range 40 to 200 bar / 580 to 2900 psi

standard setting 100 bar / 1450 psi

VST 3XTAP419300 Valve blanking plug

2. Flange mounted relief valve page 45

TYPE CODE DESCRIPTION

VSC(JG2--60) 5KIT105412 Range 40 to 80 bar / 580 to 1150 psi

standard setting 60 bar / 870 psi

VSC(JG3--100) 5KIT105413 Range 63 to 200 bar / 900 to 2900 psi

standard setting 100 bar / 1450 psi

VSC(JG4--200) 5KIT105414 Range 160to250 bar /2300to 3600psi

standard setting 200 bar / 2900 psi

VSCT XTAP623282 Valve blanking plug

Kit VS 5CO2420000Mounting block kit

3. Antishock valves page 46

Cross return type, fitted with mounting block

TYPE CODE DESCRIPTION

P1(G3--100) 602001007* Block with valve on port A

P2(G3--100) 602001007* Block with valve on port B

P3(G3--100) 602001101* Block with valves on ports A and B

P(G2--60) 5CAR211 112 Single valve:range 40to 100bar /580 to

1450psi,standard setting 60bar/ 870 psi

P(G3--100) 5CAR211113 Single valve: range 80 to 200 bar / 1150

to 2900 psi, standard setting 100 bar /

1450 psi

P(G4--200) 5CAR211113 Single valve:range 180to 315 bar/ 2600

to 4600 psi, standard setting 200 bar /

2900 psi

PT XTAP526430 Valve blanking plug(forconfigurationP1,

P2)

4. Pilot check valves page 47

Fitted with mounting block

TYPE CODE DESCRIPTION

Directv type

BP1 602002020* Block with valve on port A

BP2 602002020* Block with valve on port B

BP3 602002101* Block with valves on ports A and B

BP XCAR605110 Single valve

With pre--opening

BPS1 602003005* Block with valve on port A

BPS2 602003005* Block with valve on port B

BPS3 602003105* Block with valves on ports A and B

BPS XACR605210 Single valve

BPT XTAP627300 BP and BPS valves blanking plug

5. Anti--schock+anti--cavitation valve page 49

Flange mounted type with fixed setting

(setting is referred to Q = 10 l/min -- 2.64 US gpm flow)

TYPE CODE DESCRIPTION

VM(50) 5KIT326050 Setting 50 bar / 720 psi

VM(60) 5KIT326060 Setting 60 bar / 870 psi

VM(70) 5KIT326070 Setting 70 bar / 1010 psi

VM(80) 5KIT326080 Setting 80 bar / 1150 psi

VM(90) 5KIT326090 Setting 90 bar / 1300 psi

VM(100) 5KIT326100 Setting 100 bar / 1450 psi

VM(125) 5KIT326125 Setting 125 bar / 1800 psi

VM(140) 5KIT326140 Setting 140 bar / 2050 psi

VM(160) 5KIT326160 Setting 160 bar / 2300 psi

VM(175) 5KIT326175 Setting 175 bar / 2550 psi

VM(190) 5KIT326190 Setting 190 bar / 2750 psi

VM(210) 5KIT326210 Setting 210 bar / 3050 psi

VM(230) 5KIT326230 Setting 230 bar / 3350 psi

VM(250) 5KIT326250 Setting 250 bar / 3600 psi

VM(260) 5KIT326260 Setting 260 bar / 3750 psi

VM(280) 5KIT326280 Setting 280 bar / 4050 psi

VM(300) 5KIT326300 Setting 300 bar / 4350 psi

VMT XTAP221340 Valve blanking plug

Kit VM 5CO2820020 Mounting block kit

6. Flow control valves page 50

Flow control on every section; with auxiliary inlet

TYPE CODE DESCRIPTION

VD11 2S0PP10002000 Fine regulation from 3 to 30 l/min

VD12 2S163602021 1 As VD11, one turn with detent

VD13 2S0PP10002002 12VDC proportional solenoid valve

Kit VD1 5CO2822015* Mounting block kit

NOTE -- Valve setting at points 1--2--3 are referred to 10 l/min -- 2.64 US gpm flow.

NOTE -- (*) Codes are referred to UN-UNF threads.

43DAT003A

Page 44

SD5

Services valves

VS relief valve

It’s suggested for flow up to 25 l/min -- 6.6 US gpm, and it’s mounted on parallel body to limitate the pressure, at lower value than

main relief valve (min. gap 20 bar -- 290 psi ), on downstream section.

It’s in parallel with flow trough and it works only with single operation.

VS5 ( G 3 -- 100 )

Adjustment type (G, H)

Adjustment type

G: with screw H: valve set and locked

Wrench 10

9.8 Nm / 7.2 lbft

Wrench 17

24 Nm / 17.7 lbft

Wrench 19

24 Nm / 17.7 lbft

Pressure setting in bar

(standard 100 bar / 1450 psi)

Allen wrench 3

32.5

1.28

Max.

A1 B1 A2 B2

T

P

100

120

1750

1450

Performance data

Spring nr. 3 (blue band)

2 4 6

400

(bar)

300

200

Pressure

100

0

0 10 20 30

Flow

(US gpm)

(l/min)

VST: valve blanking plug

Allen wrench 6

42 Nm / 31 lbft

(psi)

4500

3000

1500

4

0.16

(% DP)

105%

95%

90%

Pressure

10%

Response time

0,08”

RESPONSE TIME

100 bar

1450 psi

Time (”)

44 DAT003A

Page 45

SD5

\

Service valves

VSC relief valve

It’sflange mounted onparallel body onthe oppositeside of workingports, the functionto limitthe pressure, atlower value thanmain

relief valve (min. gap 20 bar -- 290 psi) on downstream sections.

It’s in parallel with flow through line and it works only with single operation.

It needs a dedicated body with extra machining: for production requirements, the block (2) is flanged (1) before the final honing of

spool hole, while the valve (3) is mounted during final assembling phase.

For information contact Customer Service.

1

23

VSC ( J G 3 -- 100 )

Adjustable spring type (2, 3, 4).

Adjustment type (G, H)

T

max. 51.5

2.03

Standard setting in bar (for value see page 43)

LC

13.5

0.53

32

1.26

7.5

54.5

2.15

Allen wrench 4

6.6 Nm / 4.9 lbft

0.30

A1 B1 A2 B2

P

120

1750

100

1450

Ex.: SD5/2--P(JG3--120)/18L/VSC(JG3--100)/18L/AET

T

NOTE -- For valve performance see page 10.

45DAT003A

Page 46

SD5

Service valves

P anti--shock valves with cross return

Cast iron block with antishock valves.

P 1 ( D 3 -- 100 ) -- SAE

Standard setting in bar

(for value see page 43)

Spring type (2, 3, 4).

Adjustment with blind nut (D).

1 mounted on port A.

2 rmounted on port B.

3 mounted on ports A and B.

P1 P2 P3

A B A B A B

100

1450

100

1450

100

1450

100

1450

P1 configuration

Example of pressure on port A and port B to tank

A B A B

Allen wrench 8

42 Nm / 31 lbft

P T PT

Performance data

Spring nr. 2 (green band)

5 10 15

400

(bar)

300

200

Pressure

100

(US gpm)

(psi)

4500

3000

1500

Wrench 27

42 Nm / 31 lbft

Allen wrench 5

Wrench 21

24 Nm / 17.7 lbft

(bar)

Pressure

P3 configuration

Example of pressure on port B and port A to tank

Spring nr. 3 (blue band)

5 10 15

400

300

200

100

(US gpm)

(psi)

4500

3000

1500

0

0 20 40 60

Flow

Spring nr. 4 (red band)

5 10 15

400

(bar)

300

200

Pressure

100

0

0 20 40 60

Flow

(l/min)

(l/min)

(US gpm)

(psi)

4500

3000

1500

0

0 20 40 60

Flow

(l/min)

Time response

(% DP)

105%

95%

90%

Pressure

10%

0,12”

TIME RESPONSE

120 bar

1750 psi

Time (”)

46 DAT003A

Page 47

BP, BPS pilot check valves

Cast iron block with pilot check valves.

SD5

Service valves

BP1 BP2 BP3

BPS 1 -- SAE

1 mounted on port A.

2 mounted on port B.

3 mounted on ports A and B.

BP direct type

BPS with pre--opening

BP1 configuration

Example of pressure on port A and port B to tank

A B

Wrench 27

42 Nm / 31 lbft

P T

Example of pressure on port B and port A to tank

A B

BPS1 BPS2 BPS3

A B

Example of pressure on port A and port B to tank

Wrench 27

42 Nm / 31 lbft

Wrench 19

42 Nm / 31 lbft

Example of pressure on port B and port A to tank

A B A B

BP3 configuration

A B

P T

BA

Performance data

BP valve pressure drop

5 10 15

40

(bar)

30

20

Pressure

10

0

0 20 40 60

Flow

PT

(l/min)

(US gpm)

(psi)

450

300

150

Type

BP

BPS 1 : 16

With

pre-- opening

Pilot ratio

/

47DAT003A

Main

1 : 5.3

1 : 3.2

BPS valve pressure drop

5 10 15

40

(bar)

30

20

Pressure

10

0

0 20 40 60

Flow

PT

(US gpm)

(psi)

450

300

150

(l/min)

Page 48

SD5

Service valves

P antishock valves with cross return

36

P3 configuration

valve block

14

14

0.55

19

0.75

50

1.97

26

1.02

1.42

BP3 configuration

valve block

0

58

2.28

30

1.18

19

0.75

16.521

0.652.360.83

60

128

3.46

5.04

20 88

0.79

21.5

0.85

56.5

2.22

97

93

3.66

= =

14.3

0.56

4.79

3.82

121.6

= =

= =

0.91

L1 special lever box

code: 5LEV105050

1.18 1.46 1.06 0.22

37 273023 5.5

Standard lever box

Example of extra machining on directional valve body

2828 9 18.5

0.73

16.5

0.65

2737.5

1.06

Milled surface with

fixing threaded holes

1.10

0.35

1.10

P3 configuration BP3, BPS3 configuration

62.5

2.46

1.6

M5

1.48

10

0.39

13

0.51

48 DAT003A

Page 49

SD5

Service valves

VM anti--shock and anti--cavitation

They are flange mounted on the opposite side of working ports, connected in parallel with A and B ports and with outlet on T port.

It needs a dedicated body with extra machining: for production requirements, the block (2) is flanged (1) before the final honing of

spool hole, while the valve (3) is mounted during final assembling phase.

For information contact Customer Service.

1

23

VM 1 (100)

1 mounted on port A

2 mounted on port B

3 mounted on ports A and B

28.5

1.12

41.5

1.63

2 75

0.08

Allen wrench 10

24 Nm / 17.7 lbft

Valve setting in bar

VM1 configuration

2.95

Allen wrench 6

24 Nm / 17.7 lbft

Allen wrench 4

6.6 Nm / 4.9 lbft

VM1 VM2 VM3

100

1450

100

12

45

(l/min)

A B

(US gpm)

(psi)

4500

3000

1500

A BA B

T

1450

100

1450

TT

100

1450

Pressure--flow diagram

4 8

350

(bar)

300

250

200

150

14.5

0.57

Pressure

100

50

0

0 10 20 30 40

Flow

49DAT003A

Page 50

SD5

Service valves

VD1 flow control valves

Block with pressure compensated 3--way flow control valve, to be flange mounted on body with parallel circuit.

The cavity is oriented toward lever side.

The flow is regulated on every working section while the exceeding flow goes to tank: max. regulated flow 30 l/min -- 7.9 US gpm

(with inlet on P1 port).

It needs a dedicated body with extra machining: for production requirements, the block (2) is flanged (1) before the final honing of

spool hole, while the valve (3) is mounted during final assembling phase.

For information contact Customer Service.

1

T

3

P1

2

Manual control

VD11: continuous fine regulation

13.5

0.53

33.5

1.32

447711.5

0.45

Ex.: SD5/2--P(JG3--120)VD11/18L/18L/AET--SAE

3.03

1.73

VD12: one turn with detent handknob regulated

P1

Hydraulic circuit

A1 B1

P

120

1750

C

R

Ex.: SD5/2--P(JG3--120)VD12/18L/18L/AET--SAE

94.5

3.72

50 DAT003A

Page 51

VD1 flow control valves

VD13 with proportional solenoid control

SD5

Service valves

ISO4400 connection

(needs C02 connector,

see page. 62)

13.5

0.53

33.5

0.14

94.57711.5

0.45 3.03

3.72

Ex.: SD5/2--P(JG3--120)VD13/18L/18L/AET

VD13 proprtional solenoid flow control valve connection

It’s shows a configuration with push--button panel type UPA.

For information contact Customer Service.

Emergency

push--button

Potentiometer for

valve adjustment

Hydraulic circuit

P

120

1750

P1

C

R

Solenoid operating feautures

Nominal voltage : 12 VDC. .. . . .. . .

Power rating : 28 W. . . . . . . . . . . .

Duty cycle : 100%. . . . . . . . . . . . . .

A1 B1

STOP

Push--button panel type:

UPA12/100/SC01B22

Performance data

Pressure--flow diagram

Qin = 45 l/min

1000 2000 3000

40

(l/min)

30

20

10

Priority flow

0

30 90 150 210 270

Pressure (bar)

(psi)

(US gpm)

9

6

3

To battery

ISO4400

connector

Flow regulation diagram

Qin = 45 l/min (12 US gpm) -- P = 100 bar (1450 psi)

0,3 0,6 0,9 1,2 Current (A)0

40

(l/min)

30

20

Priority flow

10

0

F

0,0 0,5 1,0 1,5 2,0 2,5

3 6 9 12 15 18

0

Y

(US gpm)

9

J

6

3

(n.of turn)

(n.of clicks)

F

VD11 flow control valve

Y

VD12 flow control valve

J

VD13 flow control valve

51DAT003A

Page 52

SD5

52 DAT003A

Page 53

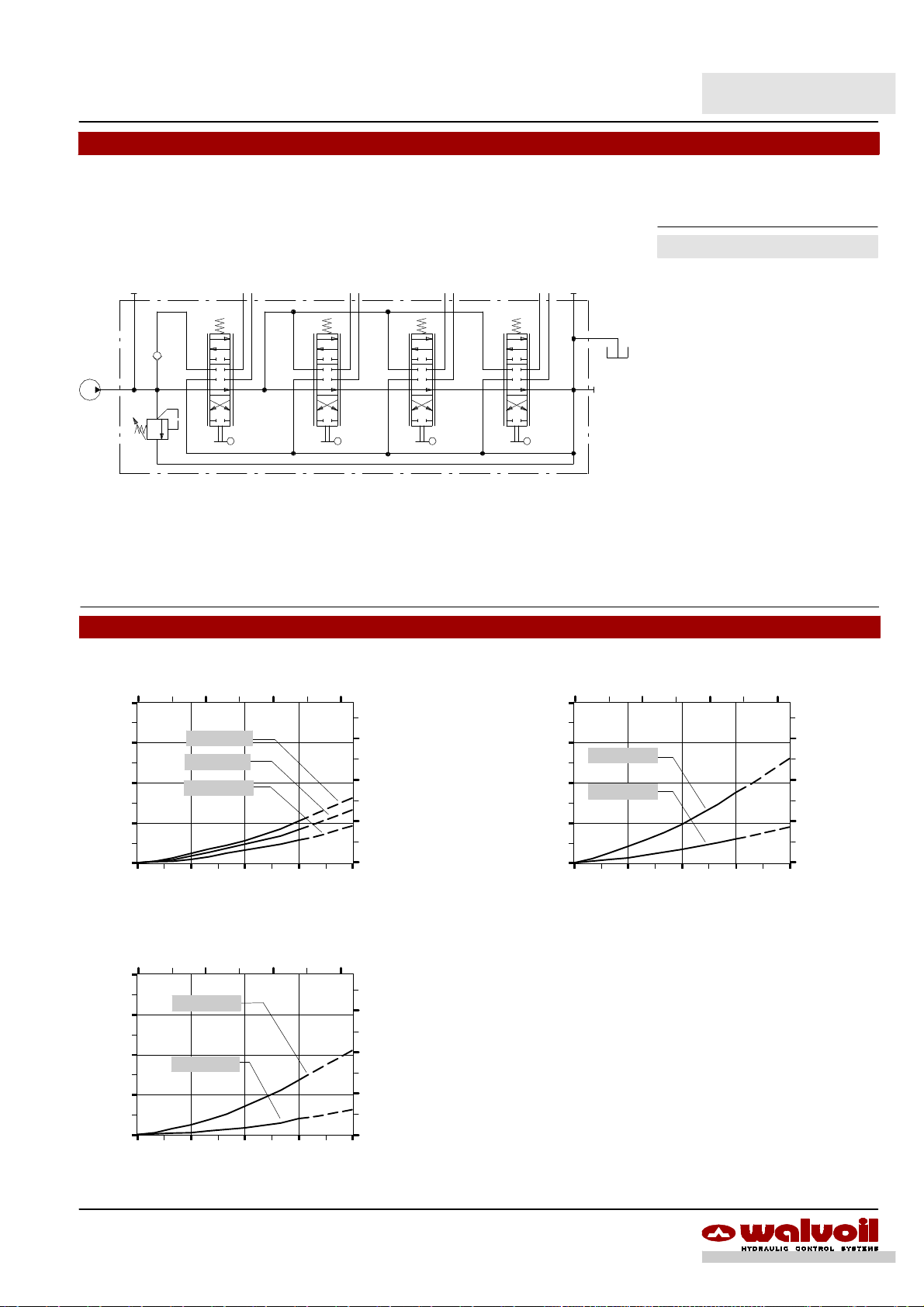

Other executions

SD5/1-N page 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

It’s available only with one working section and it can be used in hydraulic circuits where power beyond doesn’t required.

SD5/1-D page 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

It’s available only with one working section and it can be used in hydraulic circuits where power beyond is required.

SD5

SD5-S: with series circuit page 56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Availablefrom 2 to 6 sections,it can be used in systems wich onedownstream

sectionfrom seriesconnection mustwork withupstream onesatthe sametime.

It’s not available the power beyond circuit.

On the same body are possible more than one connection.

SD5-SP: with tandem circuit pag. 58.. . . . . . . . . . . . . . . . . . . . . . . .

Available from 2 to 6 sections, for security reasons it can be used in systems

which isrequired to prohibit engagementof downstream sections from tandem

connection when the upstream sections are working.

On the same body are possible more than one connection.

53DAT003A

Page 54

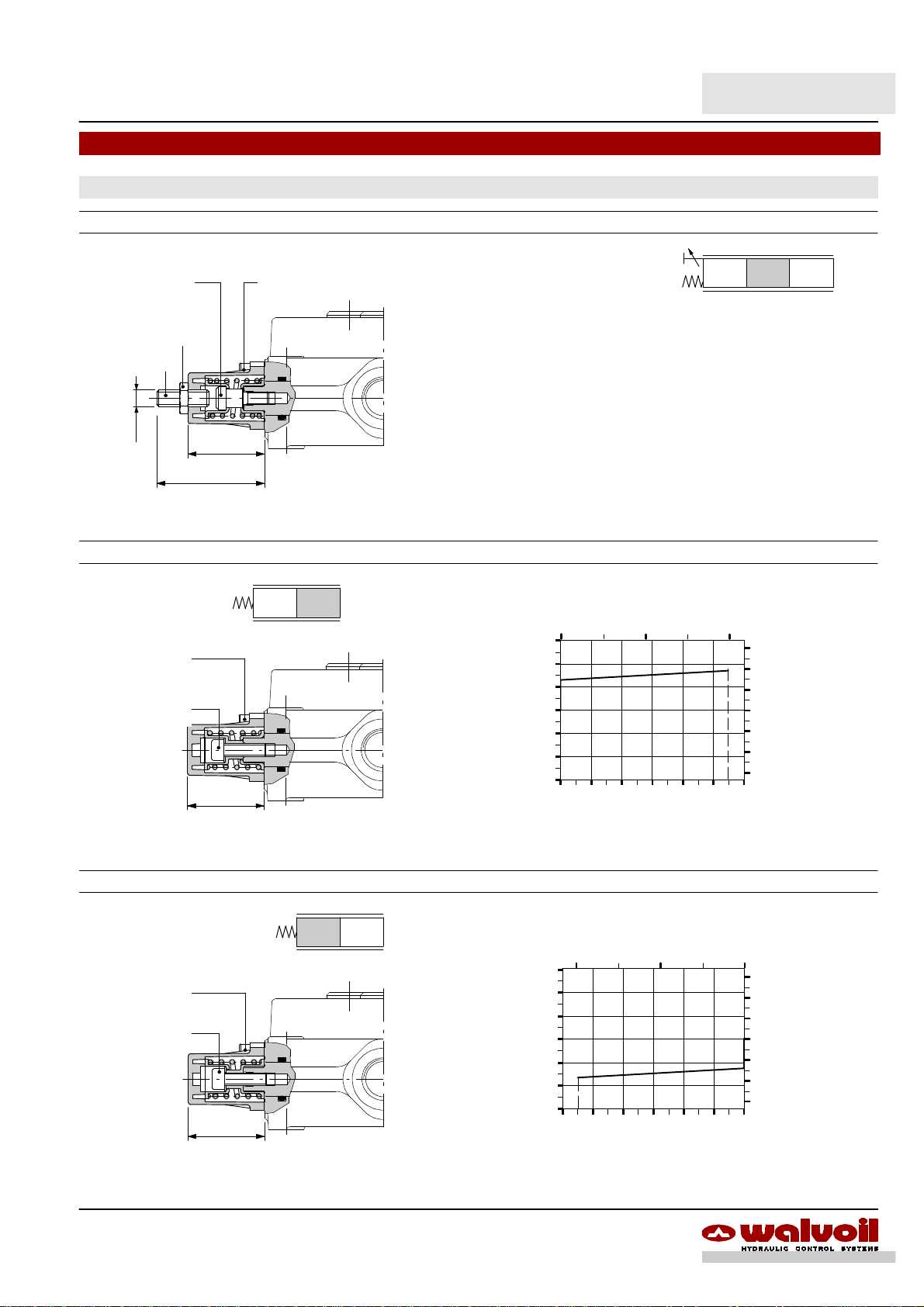

SD5/1-- N

Dimensional data

105.5

4.15

14 73

0.55

1.341.79

186

7.32

45.5 34

46

1.81

0.96

2.87

273024.5

1.18 1.06

M8

8.5

0.33

81

103

3.19

4.06

51

2.01

20

11.5

0.45

0.79

63.5 3

2.50 0.12

45

1.77

24.5

0.96

Position 1

15°

Pos. 0

15°

Position 2

90

3.54

Standard threads

PORTS

BSP

(ISO228/1)

Inlet P G 3/8 3/4--16 UNF--2B (SAE 8) M18x1.5

Ports A and B G 3/8 9/16 --18 UNF--2B (SAE 6) M18x1.5

Outlet T G 3/8 3/4--16 UNF--2B (SAE 8) M18x1.5

UN--UNF

(ISO 11926--1)

METRIC

(ISO 262)

Hydraulic circuit Performance data

A1 B1

P

120

1750

Ex.: SD5/1--N(JG3--120)/18L--SAE

Code: 102110118

15

(bar)

10

T

5

Pressure

0

Pressure drop curve

5 10 15

P®A(B)

P®T

A(B)®T

0 15 30 45 60

Flow

(l/min)

(US gpm)

200

(psi)

150

100

50

54 DAT003A

Page 55

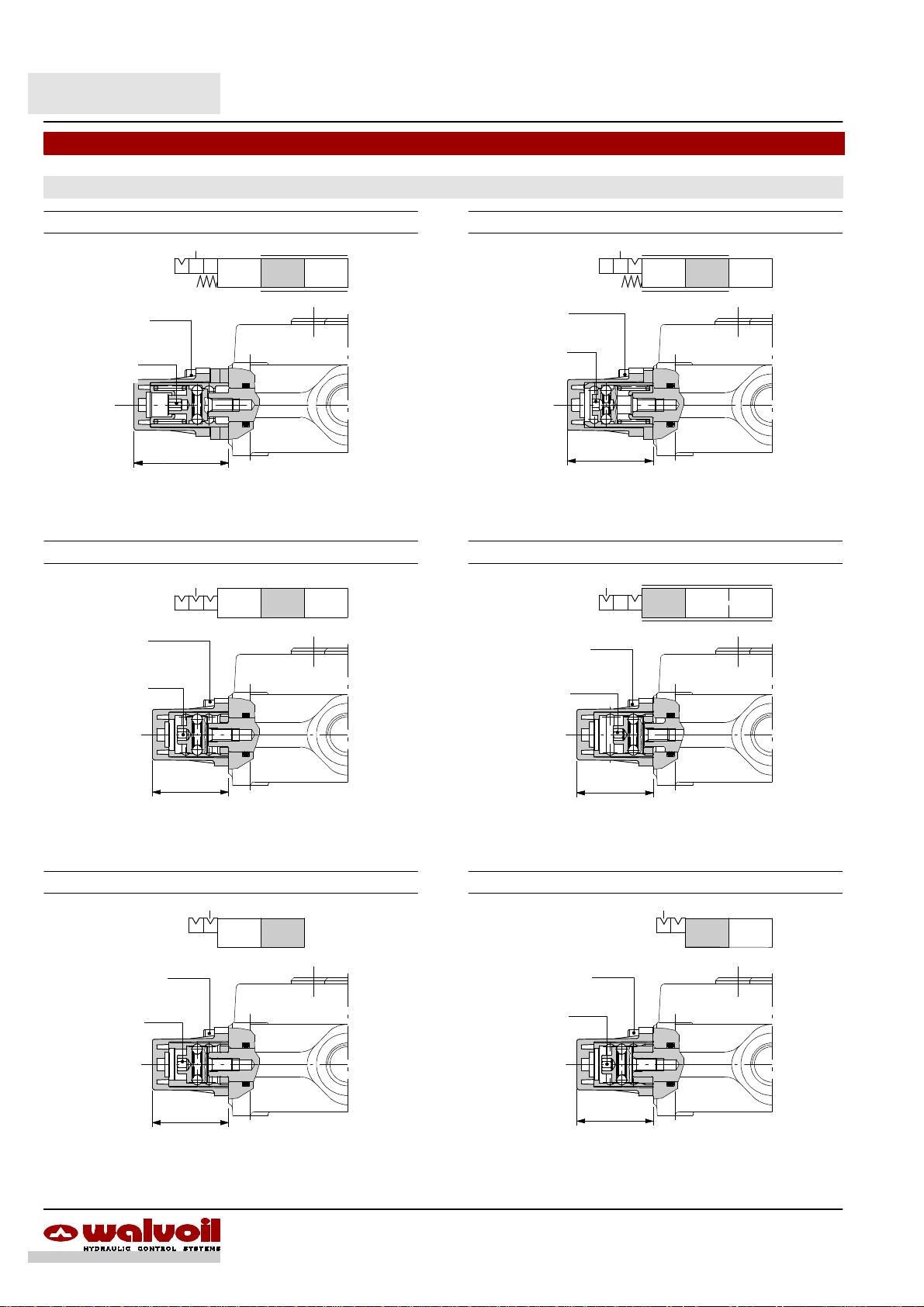

SD5/1-- D

Dimensional data

102

13 73

0.51

1.341.79

186

7.32

45.5 34

46

1.81