Page 1

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 1 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Assembly Instructions

Dosing Valves

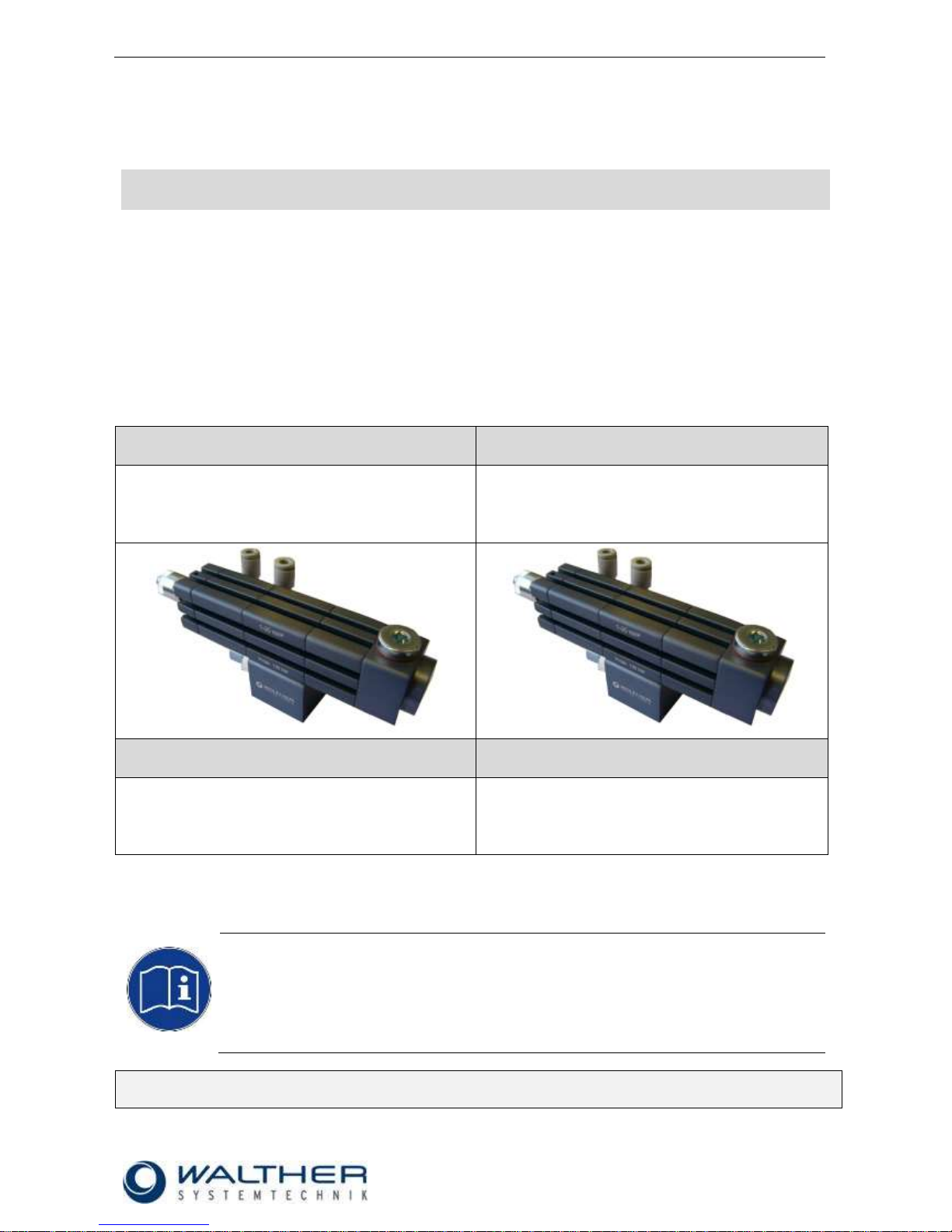

Article Numbers: WDV-01 Dosing volume 0.001 – 0.020 cm³

WDV-02 Dosing volume 0.010 – 0.200 cm³

WDV-03 Dosing volume 0.100 – 2.000 cm³

WDV-04 Dosing volume 1.000 – 6.000 cm³

WDV-01

WDV-02

WALTHER-Dosing Valve

0.001 – 0.020 cm³

(1 – 20 mm³)

WALTHER-Dosing Valve

0.010 – 0.200 cm³

(10 – 200 mm³)

WDV-03

WDV-04

WALTHER-Dosing Valve

0.100 – 2.000 cm³

(100 – 2000 mm³)

WALTHER-Dosing Valve

1.000 – 6.000 cm³

(1000 – 6000 mm³)

NOTE

Please read these Assembly Instructions carefully before first using the device and strictly

adhere to the instructions!

This device may only be worked with and worked on by persons who are familiar with the

Assembly Instructions and the current regulations for industrial safety and accident

prevention.

Always keep this translation of the “Original Assembly Instructions“ at the device!

The manual has to be available anytime!

Page 2

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 2 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Table of Contents

Page

EC DECLARATION OF INCORPORATION ....................................................................................................................... 4

1 INTRODUCTION ................................................................................................................................................. 5

1.1 TARGET GROUP OF THE ASSEMBLY INSTRUCTIONS ............................................................................................................ 5

1.2 LIST OF SIGNS AND SYMBOLS ....................................................................................................................................... 5

2 SAFETY............................................................................................................................................................... 5

2.1 GENERAL INFORMATION ............................................................................................................................................. 5

2.2 DANGERS FROM RESIDUAL ENERGIES ............................................................................................................................. 5

2.3 WARRANTY AND LIABILITY ........................................................................................................................................... 5

2.4 CORRECT USE ........................................................................................................................................................... 6

2.5 INCORRECT USE ........................................................................................................................................................ 6

2.6 QUALIFICATION OF PERSONNEL .................................................................................................................................... 6

3 TRANSPORT ....................................................................................................................................................... 7

3.1 PACKAGING .............................................................................................................................................................. 7

3.2 TASKS BEFORE TRANSPORT .......................................................................................................................................... 7

4 DESCRIPTION OF FUNCTION .............................................................................................................................. 7

4.1 DESIGNATED USE OF THE INCOMPLETE DEVICE ................................................................................................................ 7

4.2 TYPE LABEL OF THE INCOMPLETE DEVICE ........................................................................................................................ 7

4.3 FUNCTIONAL PRINCIPLE .............................................................................................................................................. 8

4.4 STEPS IN THE DOSING PROCESS WITH THE WDV .............................................................................................................. 9

4.5 TECHNICAL DATA ..................................................................................................................................................... 11

5 INITIAL START-UP ............................................................................................................................................. 12

5.1 MOUNTING AND INSTALLATION .................................................................................................................................. 12

5.2 ADJUSTING THE INCOMPLETE DEVICE .......................................................................................................................... 12

6 OPERATION ..................................................................................................................................................... 13

6.1 GENERAL INFORMATION ........................................................................................................................................... 13

6.2 OPERATING ELEMENTS ............................................................................................................................................. 13

6.3 ADJUSTING THE DOSED QUANTITY .............................................................................................................................. 13

7 TAKING OUT OF SERVICE ................................................................................................................................. 14

7.1 SHORT INTERRUPTION .............................................................................................................................................. 14

7.2 LONG-TERM INTERRUPTION ....................................................................................................................................... 14

7.3 SHUTDOWN OF DEVICE ............................................................................................................................................. 14

8 MAINTENANCE AND REPAIR ............................................................................................................................ 15

8.1 GENERAL INFORMATION ........................................................................................................................................... 15

8.2 ROUTINE TASKS ....................................................................................................................................................... 15

8.3 CLEANING .............................................................................................................................................................. 15

8.4 SPARE PARTS .......................................................................................................................................................... 15

8.5 CUSTOMER SERVICE / SUPPORT .................................................................................................................................. 16

9 TROUBLESHOOTING ........................................................................................................................................ 16

9.1 GENERAL INFORMATION ........................................................................................................................................... 16

10 APPENDIX ........................................................................................................................................................ 17

10.1 DIMENSIONED DRAWING – DOSING VALVE WDV-01 ................................................................................................ 17

10.1.1 Spare Part Drawing – Dosing Valve WDV-01 ........................................................................................ 18

10.1.2 Spare Part List Dosing Valve WDV-01 up to batch no. 013078 ............................................................. 19

10.1.3 Spare Part List Dosing Valve WDV-01 from batch no. 018633 .............................................................. 20

10.1.4 Wear Part Kits ...................................................................................................................................... 20

10.2 DIMENSIONED DRAWING DOSING VALVE WDV-02 ................................................................................................... 21

10.2.1 Spare Part Drawing Dosing Valve WDV-02 ........................................................................................... 22

Page 3

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 3 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.2.2 Spare Part List Dosing Valve WDV-02 up to batch no. 014696 ............................................................. 23

10.2.3 Spare Part List Dosing Valve WDV-02 from batch no. 018322 ............................................................. 24

10.2.4 Wear Part Kits ...................................................................................................................................... 24

10.3 DIMENSIONED DRAWING DOSING VALVE WDV-03 ................................................................................................... 25

10.3.1 Spare Part Drawing Dosing Valve WDV-03 ........................................................................................... 26

10.3.2 Spare Part List Dosing Valve WDV-03 up to batch no. 011386 ............................................................ 27

10.3.3 Spare Part List Dosing Valve WDV-03 from batch no. 016056 ............................................................. 28

10.3.4 Wear Part Kits ...................................................................................................................................... 28

10.4 DIMENSIONED DRAWING DOSING VALVE WDV-04 ................................................................................................... 29

10.4.1 Spart Part Drawing Dosing Valve WDV-04 ........................................................................................... 30

10.4.2 Spare Part List Dosing Valve WDV-04 up to batch no. 011387 ............................................................ 31

10.4.3 Spare Part List Dosing Valve WDV-04 from batch no. 023000 ............................................................. 32

10.4.4 Wear Part Kits ...................................................................................................................................... 32

10.5 ACCESSORIES ..................................................................................................................................................... 33

10.5.1 Data Sheet – Dosing Piston Sensor (Article No. WDV-DS) .................................................................... 34

Page 4

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 4 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

EC Declaration of Incorporation

in accordance with EU Machinery Directive 2006/42/EU, dated 17 May 2006, Appendix II B

We herewith confirm that the below mentioned incomplete device meets the basic requirements for safety

and health as stated in EU Machinery Directive 2006/42/EU for its design and construction as well as for the

configuration released by us on the market. This machine component will not be operated before it has been

determined that the incomplete system where the machine component will be installed also meets the

requirements of the Directive (2006/42/EG).

Manufacturer

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D- 76726 Germersheim

Description

Dosing Valves, Article No. WDV-01 bis 04

We also declare the conformity with other, product-relevant directives/guidelines:

Mach. Direct. 2006/42/EU App. I, Clause: 1.1.2, 1.1.3, 1.1.5, 1.1.6, 1.3.2, 1.3.3,

1.3.4, 1.5.9

EMC- Directive 2014/30/EU, dated 26. February 2014

Applied harmonized standards, in particular:

DIN EN ISO 12100 Safety of Machinery – General Design Principles –

Risk Assessment and Risk Reduction (ISO

12100:2010)

In addition, we also confirm that the special documentation according to Appendix VII Part B has

been prepared.

The manufacturer, respectively his authorized representative obligates himself to submit this documentation

to the market surveillance authorities, if requested.

This EC Declaration of Incorporation becomes invalid if the incomplete device will be altered or changed

without consent of Walther Systemtechnik GmbH.

Authorized representative for Technical Documentation:

Stefan Hirl, Hockenheimer Straße 3, D- 76726 Germersheim

Germersheim, 09 August 2016

(Place, Date) (Stefan Hirl, Management)

Page 5

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 5 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

1 Introduction

1.1 Target Group of the Assembly Instructions

Operating Personnel

Maintenance Personnel

1.2 List of Signs and Symbols

Symbols are used to identify hazards and certain practices. Symbols are also used in the assembly

instructions. The below symbols for hazards and information describe circumstances which can result in

damages to persons, objects and environment if not observed.

The following terms and symbols are used in the assembly instructions to identify hazards:

DANGER

Describes a potentially dangerous situation.

Death, grievous bodily harm or severe material damage WILL occur if the respective

measures of precaution have not been taken.

WARNING

Describes a potentially dangerous situation.

Death, grievous bodily harm or severe material damage MAY occur if the respective

measures of precaution have not been taken.

CAUTION

Describes a potentially dangerous situation.

Slight injuries CAN occur if the respective measures of precaution have not been taken.

This signal word is also used to describe possible property damages.

IMPORTANT

Indicates tips for usage and other particularly useful information.

No dangerous situation.

2 Safety

2.1 General Information

The construction of this incomplete device is according to the latest technology and is absolutely reliable.

The individual components as well as the complete device are continuously checked by our quality management.

2.2 Dangers from Residual Energies

Please instruct the operating personnel on the respective measures to be taken against the occurrence of

mechanical, hydraulic, pneumatic and electric / electronic residual energies.

2.3 Warranty and Liability

According to the conditions laid down by the German Engineering Federation (VDMA), Walther Systemtechnik GmbH has a guarantee of 12 months under normal European operating conditions on its own parts

(spare parts are excluded); or according to the conditions of the manufacturer.

This guarantee can only be granted by Walther Systemtechnik GmbH, if:

the user has thorough knowledge of the content of these assembly instructions;

the user follows the instructions and notes contained in these assembly instructions;

the user does not rebuild or make changes on parts of the (incomplete) device without prior consent

of WST Systemtechnik GmbH.

Page 6

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 6 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

2.4 Correct Use

CAUTION

This device will not be operated under other than the described conditions.

It has solely been designed for the dosing of media in accordance with the detailed

information of this operating manual. Any other type of use or beyond is considered as

not intended. The manufacturer cannot be made liable for damages resulting from such

incorrect use

Correct use of the device also includes:

Observing and adhering to all operating instruction s stated in this manual.

Adherence to inspection and maintenance tasks.

2.5 Incorrect Use

The manufacturer cannot be made liable for damages resulting from such incorrect use; incorrect use

includes among others:

Processing aggressive media (such as acids, alkaline, cleaning agents, chemicals etc.) or media

which have not been approved in writing by the manufacturer;

Using corrosive and / or curable materials;

Operating the device with insufficient knowledge about the operation, maintenance and care of the

device.

Making changes, extensions or alterations on the device that may hamper its safety without the prior

consent of Walther Systemtechnik GmbH.

Operating the device with defective safety installations or not properly attached or malfunctioning

safety devices.

Handling the device while energized

2.6 Qualification of Personnel

Only trained and instructed personnel may conduct work on the equipment.

The responsibilities of the personnel for assembly work, operation, repair work or maintenance work must be

clearly assigned to individuals!

Persons in training may work with the equipment only under supervision of an experienced person.

Personnel

Task

Instructed

Personnel

Personnel with Technical

Qualification

Specialist

Supervisor

Packaging, Transport

X

-

-

-

Commissioning

X

X

-

Operation

X

-

Troubleshooting, general

X

X

-

Troubleshooting

mechanical

-

X

-

-

Troubleshooting electrical

-

-

X

-

Setting up

-

X

-

-

Maintenance

-

X

-

-

Repair

-

X

X

-

Taking out of service,

Storage

-

X

X

-

Page 7

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 7 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

3 Transport

3.1 Packaging

The type of packaging depends on the individual mode of shipping. If not separately contracted, the

packaging is in accordance with the rules and regulations of Walther Systemtechnik GmbH. This rule is in

accordance with the Federal Association for Packaging HPE.

3.2 Tasks before Transport

The following has to be done before transport:

Disconnect all power lines.

The actual transport of the device and its individual parts requires special care in order to prevent damages

from external forceful impact or careless on- and off-loading. Depending on the mode of transportation,

suitable transport and load securing has to be selected. The device will be aligned and leveled by

appropriate fastening elements.

4 Description of Function

4.1 Designated Use of the Incomplete Device

Dosing valves are used for the application of a pre-defined quantity of medium on certain selected parts. A

special drive technology (pneumatic/electric) will define and control the application time. The Dosing Valves

are also suitable for use with oil.

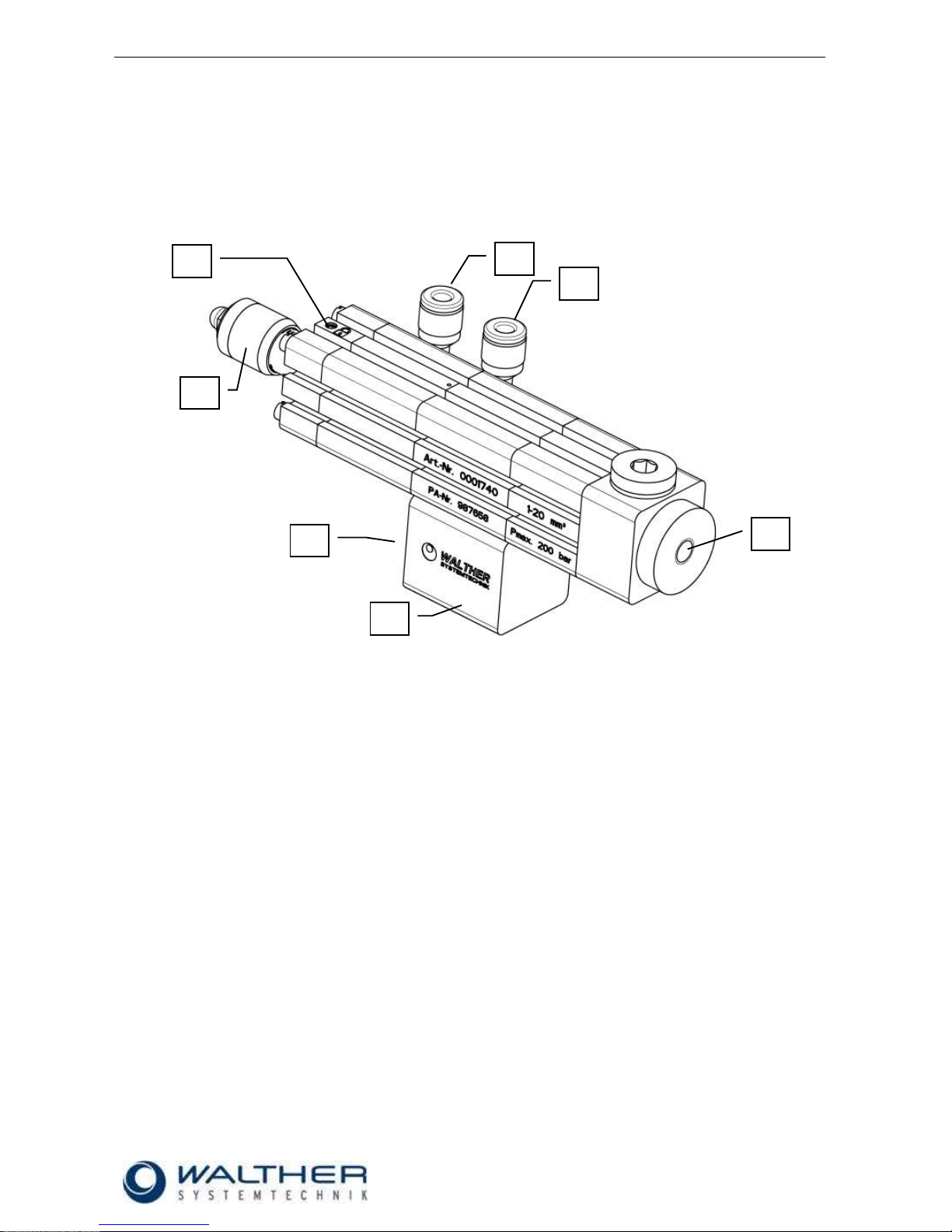

4.2 Type Label of the Incomplete Device

The Dosing Valve is marked on the side of the

housing by an engraving that contains the

production number, the article number, the max.

operating pressure and the dosing volume.

IMPORTANT

Please indicate the product information shown on the type label when ordering spare

parts or requesting technical support.

Page 8

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 8 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

4.3 Functional Principle

The pneumatic part of the dosing valve is controlled by a 5/2-way valve. This initiates the grease dosing. The

dosing pressure depends on the lubricant feed pressure (medium).

In order to obtain a high quality and repeatability of the dosing process, the complete cycle must be completed. This means that the control piston must be driven from the starting position to the dosing position and

then back to the starting position.

LEGEND

Pos. Description

1 Support bracket

2 Connection for medium G 1/8“ (in the back of the support frame)

3 Connection for air ø4 mm

4 Regulating screw

5 Dosing output

6 Fastening screw

5 3 3 4 1

2

6

Page 9

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 9 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

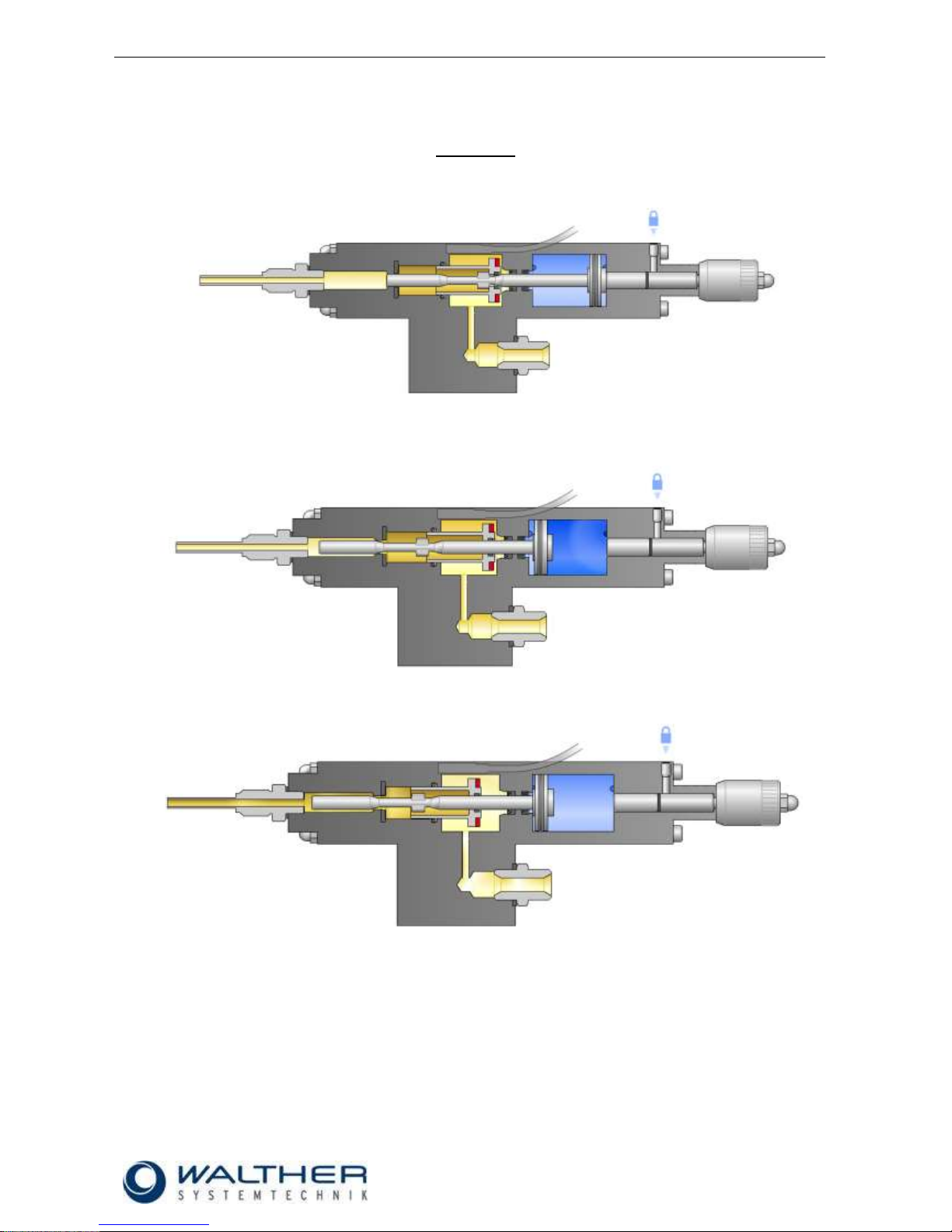

4.4 Steps in the Dosing Process with the WDV

I Dosing lift

1. The dosing chamber is filled with medium before the actual dosing

Controlled via an external 5/2-way valve, the air piston first moves to the front end position

2. After having reached the end position, the dosing piston moves and the dosing chamber is emptied

Page 10

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 10 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

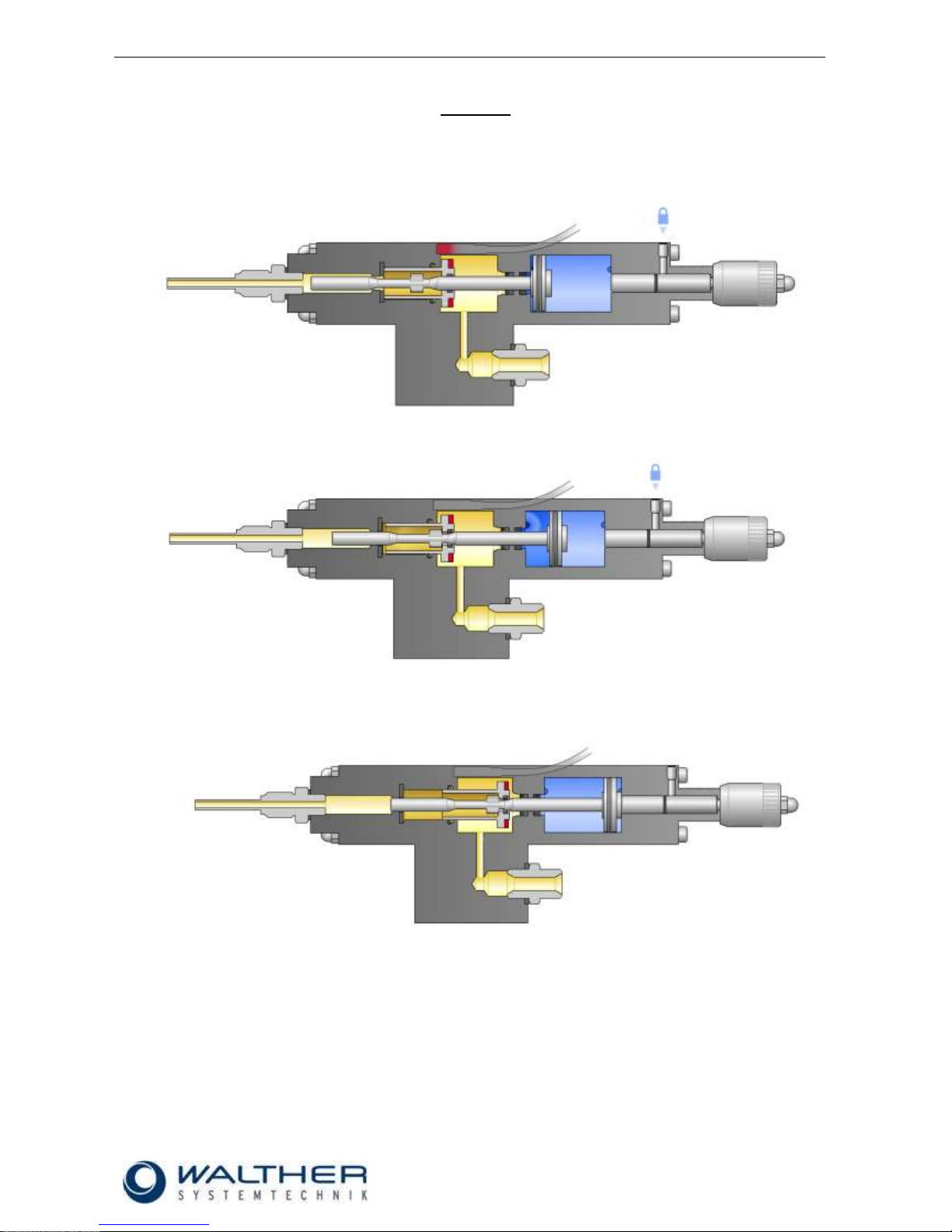

II Refill lift

3. Once the dosing piston reaches the end position, the dosing piston sensor sends a signal, if

applicable. The volume has been completely dosed.

4. Controlled by the external 5/2-way valve, the air piston is moved back into the basic position.

5. Also the dosing piston will be moved hereby and the dosing chamber is refilled by in-flowing medium.

Both pistons have returned into the basic position.

6. The cycle can start again.

Page 11

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 11 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

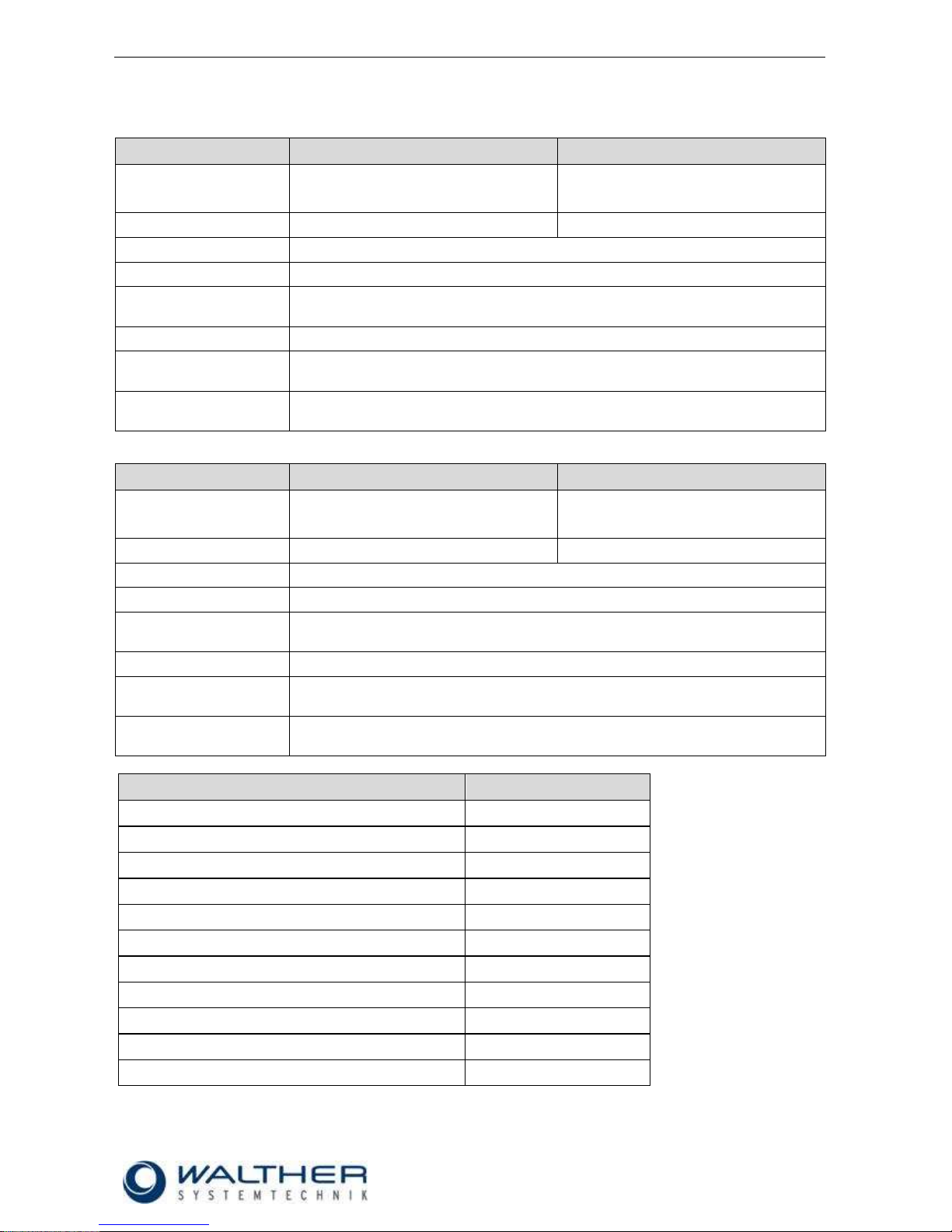

4.5 Technical Data

WALTHER-Dosing Valve WDV-01

WALTHER-Dosing Valve WDV-02

Dosing range [cm³] / [mm³]

0.001 – 0.020

1 – 20

0.010 – 0.200

10 – 200

Weight [kg]

0.180

0.182

Material inlet [mm]

External thread G 1/8

Material outlet [mm]

Internal thread M61

Compressed air supply

[mm]

Swivel-type angles M 3 for hose 4/2

Fixture [mm]

2 x M 4

min. / max. material inlet

pressure [bar]

20 / 200

min. / max. pneumatic

operating pressure [bar]

5 / 7

1

Do not exceed the max. screw-in depth!

WALTHER-Dosing Valve WDV-03

WALTHER-Dosing Valve WDV-04

Dosing range [cm³] / [mm³]

0.100 – 2.000

100 – 2000

1.000 – 6.000

1000 – 6000

Weight [kg]

0.773

0.802

Material inlet [mm]

External thread G 1/4

Material outlet [mm]

Internal thread G 1/8

Compressed air supply

[mm]

Swivel-type angles M 3 for hose 4/2

Fixture [mm]

2 x M 4

min. / max. material inlet

pressure [bar]

20 / 160

min. / max. pneumatic

operating pressure [bar]

5 / 7

Article Number

WDV-DS

Construction type

2.9 x 16.8 x 4.5

Switching output

PNP

Switching function

NO switch

Electrical version

DC voltage

Rated operating voltage [V DC]

24

Rated normal current [mA]

100

Ambient temperature min. [C°]

-25

Ambient temperature max. [C°]

+85

Connection

cable with plug connector

Protection type according to DIN 40050

IP 67

Housing material

PA 12

Page 12

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 12 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5 Initial Start-up

5.1 Mounting and Installation

IMPORTANT

We recommend adding a maintenance unit to the control air.

5.2 Adjusting the Incomplete Device

IMPORTANT

In order to ensure optimal operation of the valves, make sure that the air supply

pressure is set to approx. 6 bar.

The lubricant feed pressure should not exceed 200 bar at the input. To ensure this,

check the pressure conversion ratio of the lubricant feed pump. The feed pressure may

be reduced by means of an air pressure control valve (The use of an air pressure

control valve may be advantageous, although it is not imperative as long as the 200

bar are not exceeded).

IMPORTANT

All dosing valves are tested by the manufacturer prior to shipping. Due to testing, residues of test liquid may be found inside the valve.

1) Make sure that the lubricant feed hose is filled with lubricant and all air is removed. Then connect

feed hose and air connectors according to drawing.

2) For first operation, set valve to maximum dosage (i.e. turn adjustment screw to outmost position).

3) If the adjustment screw cannot be turned, change position of change-over-valve. The adjustment

screw should now be unlocked.

4) Execute a first shot of lubricant. Then set the adjustment screw to the desired grease quantity.

5) Keep the distance from the metering valve to the greasing point short. This allows for improved

metering precision and repeatability.

6) The minimum cycle time depends on the viscosity of the lubricant, as well as on the lubricant feed

pressure.

7) The dosing valves with support bracket can be fastened with four M5 screws.

8) The dosing amount can be adjusted via the dosing screw.

9) When installing the (optional) dosing sensors, please consider that there are 2 switching points per

magnetic field.

5/2-way valve

Page 13

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 13 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

6 Operation

6.1 General Information

This incomplete device may only be operated if the safety-related equipment is permanently effective and

not suspended during operation or altered in its intended effectiveness.

6.2 Operating Elements

6.3 Adjusting the Dosed Quantity

Loosen fastening screw.

Activate and hold external way-valve or dosing trigger.

Use regulating screw to adjust the desired volume/quantity.

Let the dosing trigger go.

Tighten fastening screw.

Regulating

screw

Fastening

screw

Page 14

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 14 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

7 Taking out of Service

7.1 Short Interruption

A short interruption (15 min or more) has to be followed by a fine dosing

IMPORTANT

Please follow the maintenance instructions!

7.2 Long-term Interruption

The following has to be observed for a long-term interruption of the device:

Make sure that system is depressurized (check all displays).

IMPORTANT

Please follow the maintenance instructions!

7.3 Shutdown of Device

Please observe the following for a shutdown of the device:

Disconnect mains plug.

Depressurize complete systems (check all displays).

Grease / oil have to be disposed of properly.

Clean dosing valve with special thinner

CAUTION

Danger of accidents and to environment. Do not spill grease / oil. Grease / oil have to

be properly disposed of (hazardous material).

IMPORTANT

Please follow the maintenance instructions!

Page 15

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 15 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

8 Maintenance and Repair

8.1 General Information

CAUTION

Before starting any maintenance or repair work, ensure that all air-operated tools are

depressurized and disconnected from the air supply.

Before opening the dosing valve it must be disconnected from the air and fluid supply.

Otherwise, ejected components can cause injuries.

IMPORTANT

This chapter does not explain how to repair damage of the device. Repair work shall be

executed exclusively by skilled and trained experts, or by staff of the manufacturer`s

customer service.

8.2 Routine Tasks

The maintenance intervals stated below are valid for single-shift operation of the equipment. In case of

multiple-shift or very intensive operation, maintenance intervals must be shortened accordingly. Also take

into account other influences on maintenance need, such as dirty environment.

WHEN

WHAT

HOW

WHO

Weekly

Check dosing valve for

leak-tightness and

damage

Visual inspection

Expert

Weekly

Check all screw

connections and

connections of

mountings for tightness

Visual inspection

Expert

Monthly

Check electrical

conducts for damage

Visual inspection

Expert

CAUTION

After maintenance tasks are completed, check all functions and safety devices.

8.3 Cleaning

IMPORTANT

Only use soft brushes for outside cleaning of the nozzle tips. Never use metal tools

with sharp edges.

8.4 Spare Parts

IMPORTANT

Only use original spare parts from the manufacturer!

Wrong or defective spare parts from other manufacturers can damage the device. If

other than original spare parts of the manufacturer will be used, all obligations from the

manufacturer or his sales partners, such as guarantees, service contracts etc will be

forfeited without further notice.

Page 16

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 16 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

8.5 Customer Service / Support

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D-76726 Germersheim

Germany

Phone ++49(0)7274-7022-0

Fax ++49(0)7274-7022-91

Email info@walther-2000.de

Internet www.walther-2000.de

9 Troubleshooting

9.1 General Information

IMPORTANT

First check all supply lines for connection and serviceability.

Only a trained technician will take care of the below described malfunctions.

In case of serious problems that cannot be resolved, please contact the Walther Systemtechnik GmbH

customer service.

Malfunction

Possible cause

Action

Valve is actuated, but

no lubricant is ejected.

Is no lubricant fed by

the feed pump?

Check feed pump.

See operating manual of feed pump.

Check venting screw of feed pump.

See operating manual of feed pump.

Leakage

Check dosing valve.

Leakage at bore hole

Seals defective

Exchange seals

Permanent signal from

sensor

Sensor defective

Exchange sensor

Dosing volume too

small

Check dosing valve; check setting of dosing

volume and increase, if necessary; check position

of sensors

Feed pressure of

grease too high

Reduce pump pressure to max. operating

pressure of dosing valve; possibly employ a

material pressure regulator

No signal from sensor

Broken cable

Exchange cable

Sensor defective

Exchange sensor

Dosing piston in starting

position

Check pump pressure; check bore hole of grease

supply for contaminants

Air pockets in grease

system.

Air pockets in grease

container.

Air pockets in tubing.

Disconnect tubing to dosing valve. Drain a quantum of grease. Restart with dosage adjustment

screw set to maximum.

Page 17

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 17 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10 Appendix

10.1 Dimensioned Drawing – Dosing Valve WDV-01

Page 18

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 18 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.1.1 Spare Part Drawing – Dosing Valve WDV-01

Page 19

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 19 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.1.2 Spare Part List Dosing Valve WDV-01 up to batch no. 013078

Pos.

Artikelnummer

Bezeichnung

Description

Menge/Qty

1

970001739

Anschlussblock

Connecting block

1

2

970001224

O-ring

O-ring

1

3

978460002

Spiral Spannstift S

Spiral pin S

1

4

970001734

Fettzylinder

Grease cylinder

1

5

978423904

Zyl. Schraube

Socket head screw

2

6

970001525

Nutenstein

Slot nut

2

7

970001735

Anschlussstück

Connecting piece

1

8

978227800

O-ring

O-ring

1

9

978223401

O-ring

O-ring

5

10

970001038

Kolben

Piston

1

11

978221401

Glydring Stange 3x2 hydr.

Glydring rog 3x2 hydr.

2

12

970001738

Luftzylinder

Air cylinder

1

13

970001737

Endstück

End piece

1

14

970001045

Anschlag

Stop

1

15

970001043

Kolben

Piston

1

16

970001039

Nadel

Needle

1

17

970001041

Hülse

Sleeve

1

18

978353502

Nutring

Slot ring

1

19

970001042

Buchse

Socket

1

20

978411400

Hutmutter

Cap nut

1

21

970001226

Zylinderschraube

Socket head screw

1

22

978221400

O-ring

O-ring

1

23

978221600

O-ring

O-ring

1

24

978220400

O-ring

O-ring

1

25

970001106

X-ring

X-ring

1

26

978225600

O-ring

O-ring

1

27

970001044

Magnet

Magnet

1

28

970001227

Stift

Pin 1 29

978510101

Gewindestift

Set screw

1

30

970001228

Schraube

Screw

4

31

978634201

Einschraubwinkel M3 – ø4

Male elbow M3 – ø4

2

32

970001733

Adapter

Adapter

1

33

978026600

Flachdichtung

Gasket

1

34

978430001

Verschlussschraube

Lock screw

1

Page 20

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 20 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.1.3 Spare Part List Dosing Valve WDV-01 from batch no. 018633

Pos.

Artikelnummer

Bezeichnung

Description

Menge/Qty

1

970001739

Anschlussblock

Connecting block

1

2

970001224

O-ring

O-ring

1

3

978460002

Spiral Spannstift S

Spiral pin S

1

4

970002730

Fettzylinder

Grease cylinder

1

5

978423904

Zyl. Schraube

Socket head screw

2

6

970002213

Nutenstein

Slot nut

2

7

970002731

Anschlussstück

Connecting piece

1

8

978227800

O-ring

O-ring

1

9

978223401

O-ring

O-ring

5

10

970001038

Kolben

Piston

1

11

978221401

Glydring Stange 3x2 hydr.

Glyd-ring rod 3x2 hydr.

2

12

970002735

Luftzylinder

Air cylinder

1

13

970002733

Endstück

End piece

1

14

970001045

Anschlag

Stop

1

15

970001043

Kolben

Piston

1

16

970001039

Nadel

Needle

1

17

970001041

Hülse

Sleeve

1

18

978353502

Nutring

Slot ring

1

19

970001042

Buchse

Socket

1

20

978411400

Hutmutter

Cap nut

1

21

970001226

Zylinderschraube

Socket head screw

1

22

978221400

O-ring

O-ring

1

23

978221600

O-ring

O-ring

1

24

978220400

O-ring

O-ring

1

25

970001106

X-ring

X-ring

1

26

978225600

O-ring

O-ring

1

27

970001044

Magnet

Magnet

1

28

970001227

Stift

Pin 1 29

978510101

Gewindestift

Set screw

1

30

970001228

Schraube

Screw

4

31

970002633

Einschraubwinkel M2,5 – ø4

Male elbow M2,5 – ø4

2

32

970001733

Adapter

Adapter

1

33

978026600

Flachdichtung

Gasket

1

34

978430001

Verschlussschraube

Lock screw

1

10.1.4 Wear Part Kits

Wear parts kit complete for WDV-01

Consisting of:

# Pos. 2,8,9,22,23,24 / O-ring

# Pos. 11 / Glyd-ring

# Pos. 17 / Sleeve

# Pos. 18 / Slot ring

# Pos. 25 / X-Ring

# Pos. Gasket

Artikel-Nr.

Description

974191850

Wear part kit for WDV-01, VITON1

1 Wear part kits are compatible with batch numbers

Page 21

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 21 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.2 Dimensioned Drawing Dosing Valve WDV-02

Page 22

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 22 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.2.1 Spare Part Drawing Dosing Valve WDV-02

Page 23

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 23 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.2.2 Spare Part List Dosing Valve WDV-02 up to batch no. 014696

Pos.

Artikelnummer

Bezeichnung

Description

Menge/Qty

1

970001739

Anschlussblock

Connecting block

1

2

970001224

O-ring

O-ring

1

3

978460002

Spiral Spannstift S

Spiral pin S

1

4

970001734

Fettzylinder

Grease cylinder

1

5

978423904

Zyl. Schraube

Socket head screw

2

6

970001525

Nutenstein

Slot nut

2

7

970001736

Anschlussstück

Connecting piece

1

8

970001628

O-ring

O-ring

1

9

978223401

O-ring

O-ring

5

10

970001629

Kolben

Piston

1

11

978221401

Glydring Stange 3x2 hydr.

Glydring rog 3x2 hydr.

2

12

970001738

Luftzylinder

Air cylinder

1

13

970001737

Endstück

End piece

1

14

970001045

Anschlag

Stop

1

15

970001043

Kolben

Piston

1

16

970001039

Nadel

Needle

1

17

970001041

Hülse

Sleeve

1

18

978353502

Nutring

Slot ring

1

19

970001042

Buchse

Socket

1

20

978411400

Hutmutter

Cap nut

1

21

970001226

Zylinderschraube

Socket head screw

1

22

978221400

O-ring

O-ring

1

23

978221600

O-ring

O-ring

1

24

978220400

O-ring

O-ring

1

25

970001106

X-ring

X-ring

1

26

978225600

O-ring

O-ring

1

27

970001044

Magnet

Magnet

1

28

970001227

Stift

Pin 1 29

978510101

Gewindestift

Set screw

1

30

970001228

Schraube

Screw

4

31

978634201

Einschraubwinkel M3 – ø4

Male elbow M3 – ø4

2

32

970001733

Adapter

Adapter

1

33

978026600

Flachdichtung

Gasket

1

34

978430001

Verschlussschraube

Lock screw

1

Page 24

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 24 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.2.3 Spare Part List Dosing Valve WDV-02 from batch no. 018322

Pos.

Artikelnummer

Bezeichnung

Description

Menge/Qty

1

970001739

Anschlussblock

Connecting block

1

2

970001224

O-ring

O-ring

1

3

978460002

Spiral Spannstift S

Spiral pin S

1

4

970002730

Fettzylinder

Grease cylinder

1

5

978423904

Zyl. Schraube

Socket head screw

2

6

970002213

Nutenstein

Slot nut

2

7

970002732

Anschlussstück

Connecting piece

1

8

970001628

O-ring

O-ring

1

9

978223401

O-ring

O-ring

5

10

970001629

Kolben

Piston

1

11

978221401

Glydring Stange 3x2 hydr.

Glydring rog 3x2 hydr.

2

12

970002735

Luftzylinder

Air cylinder

1

13

970002733

Endstück

End piece

1

14

970001045

Anschlag

Stop

1

15

970001043

Kolben

Piston

1

16

970001039

Nadel

Needle

1

17

970001041

Hülse

Sleeve

1

18

978353502

Nutring

Slot ring

1

19

970001042

Buchse

Socket

1

20

978411400

Hutmutter

Cap nut

1

21

970001226

Zylinderschraube

Socket head screw

1

22

978221400

O-ring

O-ring

1

23

978221600

O-ring

O-ring

1

24

978220400

O-ring

O-ring

1

25

970001106

X-ring

X-ring

1

26

978225600

O-ring

O-ring

1

27

970001044

Magnet

Magnet

1

28

970001227

Stift

Pin 1 29

978510101

Gewindestift

Set screw

1

30

970001228

Schraube

Screw

4

31

970002633

Einschraubwinkel M2,5 – ø4

Male elbow M2,5 – ø4

2

32

970001733

Adapter

Adapter

1

33

978026600

Flachdichtung

Gasket

1

34

978430001

Verschlussschraube

Lock screw

1

10.2.4 Wear Part Kits

Wear parts kit complete for WDV-02

Consisting of:

# Pos. 2,8,9,22,23,24 / O-ring

# Pos. 11 / Glydring

# Pos. 17 / Sleeve

# Pos. 18 / Slot ring

# Pos. 25 / X-Ring

# Pos. Gasket

Artikel-Nr.

Description

974191850

Wear Part Kit for WDV-02, VITON1

1 Wear part kits are compatible with all batch numbers

Page 25

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 25 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.3 Dimensioned Drawing Dosing Valve WDV-03

Page 26

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 26 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.3.1 Spare Part Drawing Dosing Valve WDV-03

Page 27

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 27 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.3.2 Spare Part List Dosing Valve WDV-03 up to batch no. 011386

Pos.

Artikelnummer

Bezeichnung

Description

Menge/Qty

1

970002157

Anschlussblock

Connecting block

1

2

978460002

Spiral Spannstift S

Spiral pin S

1

3

970002159

Fettzylinder

Grease cylinder

1

4

970001595

Scheibe

Washer

1

5

970002158

Anschlussstück

Connecting piece

1

6

970002161

Luftzylinder

Air cylinder

1

7

970002162

Endstück

End piece

1

8

970001582

Zwischenstück

Intermediate unit

1

9

970001584

Kolben

Piston

1

10

978331100

L-Cup_6x3.5

L-Cup_6x3.5

1

11

978365000

Stangendichtung ARUP ø6

Stepseal ARUP ø6

1

12

978223201

Glydring Stange 5.7x2 hydr.

Glydring rod 5.7x2 hydr.

2

13

970001591

Kolben

Piston

1

14

970001586

Ventilstange

Valve rod

1

15

970001590

O-Ring

O-ring

1

16

970001587

Dosierschraube

Metering screw

1

17

970001588

Regulierhülse

Metering sleeve

1

18

978424105

Zyl. Schraube

Socket head screw

1

19

978223200

O-Ring

O-ring

1

20

978411000

Hutmutter

Cap nut

1

21

970001596

Schraube

Screw

4

22

978232100

O-Ring

O-ring

4

23

970001528

Magnet

Magnet

1

24

978227302

O-Ring

O-ring

1

25

978227700

O-Ring

O-ring

1

26

978221400

O-Ring

O-ring

1

27

978222500

O-Ring

O-ring

1

28

970001589

Stift

Pin 1 29

978512700

Gewindestift

Set screw

1

30

970001525

Nutenstein

Slot nut

4

31

970001593

Zylinderschraube

Socket head screw

4

32

970002163

Anschlussstück

Connecting piece

1

33

978233000

O-Ring

O-ring

1

34

978026600

Flachdichtung

Gasket

1

35

978430001

Verschlussschraube

Lock screw

1

36

978634201

Einschraubwinkel M3 – ø4

Male elbow M3 – ø4

2

Page 28

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 28 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.3.3 Spare Part List Dosing Valve WDV-03 from batch no. 016056

Pos.

Artikelnummer

Bezeichnung

Description

Menge/Qty

1

970002157

Anschlussblock

Connecting block

1

2

978460002

Spiral Spannstift S

Spiral pin S

1

3

970002746

Fettzylinder

Grease cylinder

1

4

970001595

Scheibe

Washer

1

5

970002745

Anschlussstück

Connecting piece

1

6

970002749

Luftzylinder

Air cylinder

1

7

970002750

Endstück

End piece

1

8

970001582

Zwischenstück

Intermediate unit

1

9

970001584

Kolben

Piston

1

10

978331100

L-Cup_6x3.5

L-Cup_6x3.5

1

11

978365000

Stangendichtung ARUP ø6

Stepseal ARUP ø6

1

12

978223201

Glydring Stange 5.7x2 hydr.

Glydring rod 5.7x2 hydr.

2

13

970001591

Kolben

Piston

1

14

970001586

Ventilstange

Valve rod

1

15

970001590

O-Ring

O-ring

1

16

970001587

Dosierschraube

Metering screw

1

17

970001588

Regulierhülse

Metering sleeve

1

18

978424105

Zyl. Schraube

Socket head screw

1

19

978223200

O-Ring

O-ring

1

20

978411000

Hutmutter

Cap nut

1

21

970001596

Schraube

Screw

4

22

978232100

O-Ring

O-ring

4

23

970001528

Magnet

Magnet

1

24

978227302

O-Ring

O-ring

1

25

978227700

O-Ring

O-ring

1

26

978221400

O-Ring

O-ring

1

27

978222500

O-Ring

O-ring

1

28

970001589

Stift

Pin 1 29

978512700

Gewindestift

Set screw

1

30

970002213

Nutenstein

Slot nut

4

31

970001593

Zylinderschraube

Socket head screw

4

32

970002163

Anschlussstück

Connecting piece

1

33

978233000

O-Ring

O-ring

1

34

978026600

Flachdichtung

Gasket

1

35

978430001

Verschlussschraube

Lock screw

1

36

978634201

Einschraubwinkel M3 – ø4

Male elbow M3 – ø4

2

10.3.4 Wear Part Kits

Wear parts kit complete for WDV-03

Consisting of:

# Pos.15,19,22,24,26,27 / O-ring

# Pos. 4 / Washer

# Pos. 8 / Intermediate unit

# Pos. 10 / L-Cup

# Pos. 11 / Rod seal

# Pos. 12 / Glydring

# Pos. Gasket

Artikel-Nr.

Description

970001746

Wear Part Kit for WDV-03, VITON1

1 Wear part kits are compatible with all batch numbers

Page 29

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 29 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.4 Dimensioned Drawing Dosing Valve WDV-04

Page 30

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 30 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.4.1 Spare Part Drawing Dosing Valve WDV-04

Page 31

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 31 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.4.2 Spare Part List Dosing Valve WDV-04 up to batch no. 011387

Pos.

Artikelnummer

Bezeichnung

Description

Menge/Qty

1

970002157

Anschlussblock

Connecting block

1

2

978460002

Spiral Spannstift S

Spiral pin S

1

3

970002160

Fettzylinder

Grease cylinder

1

4

970001595

Scheibe

Washer

1

5

970002158

Anschlussstück

Connecting piece

1

6

970002161

Luftzylinder

Air cylinder

1

7

970002162

Endstück

End piece

1

8

970001582

Zwischenstück

Intermediate unit

1

9

970001583

Kolben

Piston

1

10

978331100

L-Cup_6x3.5

L-Cup_6x3.5

1

11

978365000

Stangendichtung ARUP ø6

Stepseal ARUP ø6

1

12

978223201

Glydring Stange 5.7x2 hydr.

Glydring rod 5.7x2 hydr.

2

13

970001591

Kolben

Piston

1

14

970001586

Ventilstange

Valve rod

1

15

970001590

O-Ring

O-ring

1

16

970001587

Dosierschraube

Metering screw

1

17

970001588

Regulierhülse

Metering sleeve

1

18

978424105

Zyl. Schraube

Socket head screw

1

19

978223200

O-Ring

O-ring

1

20

978411000

Hutmutter

Cap nut

1

21

970001596

Schraube

Screw

4

22

978232100

O-Ring

O-ring

4

23

970001528

Magnet

Magnet

1

24

978227700

O-Ring

O-ring

1

25

978221400

O-Ring

O-ring

1

26

978222500

O-Ring

O-ring

1

27

970001589

Stift

Pin 1 28

978512700

Gewindestift

Set screw

1

29

970001525

Nutenstein

Slot nut

4

30

970001593

Zylinderschraube

Socket head screw

4

31

970002163

Anschlussstück

Connecting piece

1

32

978233000

O-Ring

O-ring

1

33

978026600

Flachdichtung

Gasket

1

34

978430001

Verschlussschraube

Lock screw

1

35

978634201

Einschraubwinkel M3 – ø4

Male elbow M3 – ø4

2

Page 32

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 32 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.4.3 Spare Part List Dosing Valve WDV-04 from batch no. 023000

Pos.

Artikelnummer

Bezeichnung

Description

Menge/Qty

1

970002157

Anschlussblock

Connecting block

1

2

978460002

Spiral Spannstift S

Spiral pin S

1

3

970002746

Fettzylinder

Grease cylinder

1

4

970001595

Scheibe

Washer

1

5

970002745

Anschlussstück

Connecting piece

1

6

970002749

Luftzylinder

Air cylinder

1

7

970002750

Endstück

End piece

1

8

970001582

Zwischenstück

Intermediate unit

1

9

970001583

Kolben

Piston

1

10

978331100

L-Cup_6x3.5

L-Cup_6x3.5

1

11

978365000

Stangendichtung ARUP ø6

Stepseal ARUP ø6

1

12

978223201

Glydring Stange 5.7x2 hydr.

Glydring rod 5.7x2 hydr.

2

13

970001591

Kolben

Piston

1

14

970001586

Ventilstange

Valve rod

1

15

970001590

O-Ring

O-ring

1

16

970001587

Dosierschraube

Metering screw

1

17

970001588

Regulierhülse

Metering sleeve

1

18

978424105

Zyl. Schraube

Socket head screw

1

19

978223200

O-Ring

O-ring

1

20

978411000

Hutmutter

Cap nut

1

21

970001596

Schraube

Screw

4

22

978232100

O-Ring

O-ring

4

23

970001528

Magnet

Magnet

1

24

978227700

O-Ring

O-ring

1

25

978221400

O-Ring

O-ring

1

26

978222500

O-Ring

O-ring

1

27

970001589

Stift

Pin 1 28

978512700

Gewindestift

Set screw

1

29

970002213

Nutenstein

Slot nut

4

30

970001593

Zylinderschraube

Socket head screw

4

31

970002163

Anschlussstück

Connecting piece

1

32

978233000

O-Ring

O-ring

1

33

978026600

Flachdichtung

Gasket

1

34

978430001

Verschlussschraube

Lock screw

1

35

978634201

Einschraubwinkel M3 – ø4

Male elbow M3 – ø4

2

10.4.4 Wear Part Kits

Wear parts kit complete for WDV-04

Consisting of:

# Pos.15,19,22,24,26,27 / O-ring

# Pos. 4 / Washer

# Pos. 8 / Intermediate unit

# Pos. 10 / L-Cup

# Pos. 11 / Rod seal

# Pos. 12 / Glydring

# Pos. Gasket

Artikel-Nr.

Description

970001746

Wear Part Kit for WDV-04, VITON1

1 Wear part kits are compatible with all batch numbers

Page 33

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 33 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.5 Accessories

Picture

Article Number

Description

WDV-DS

Dosing piston sensor

(see also Product Catalog DOSING)

97PA21X-XX

Pressure sensor

(see also Product Catalog „Checking“)

979450-M6

Luer-Lock adapter, male, thread M6 for WDV-

01/02

979450-G1/8

Luer-Lock adapter, male, thread G1/8 for WDV-

03/04

Page 34

Rev. 1.2

Assembly Instructions – Dosing Valves WDV-0x

Page 34 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.5.1 Data Sheet – Dosing Piston Sensor (Article No. WDV-DS)

Loading...

Loading...