Page 1

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 1 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

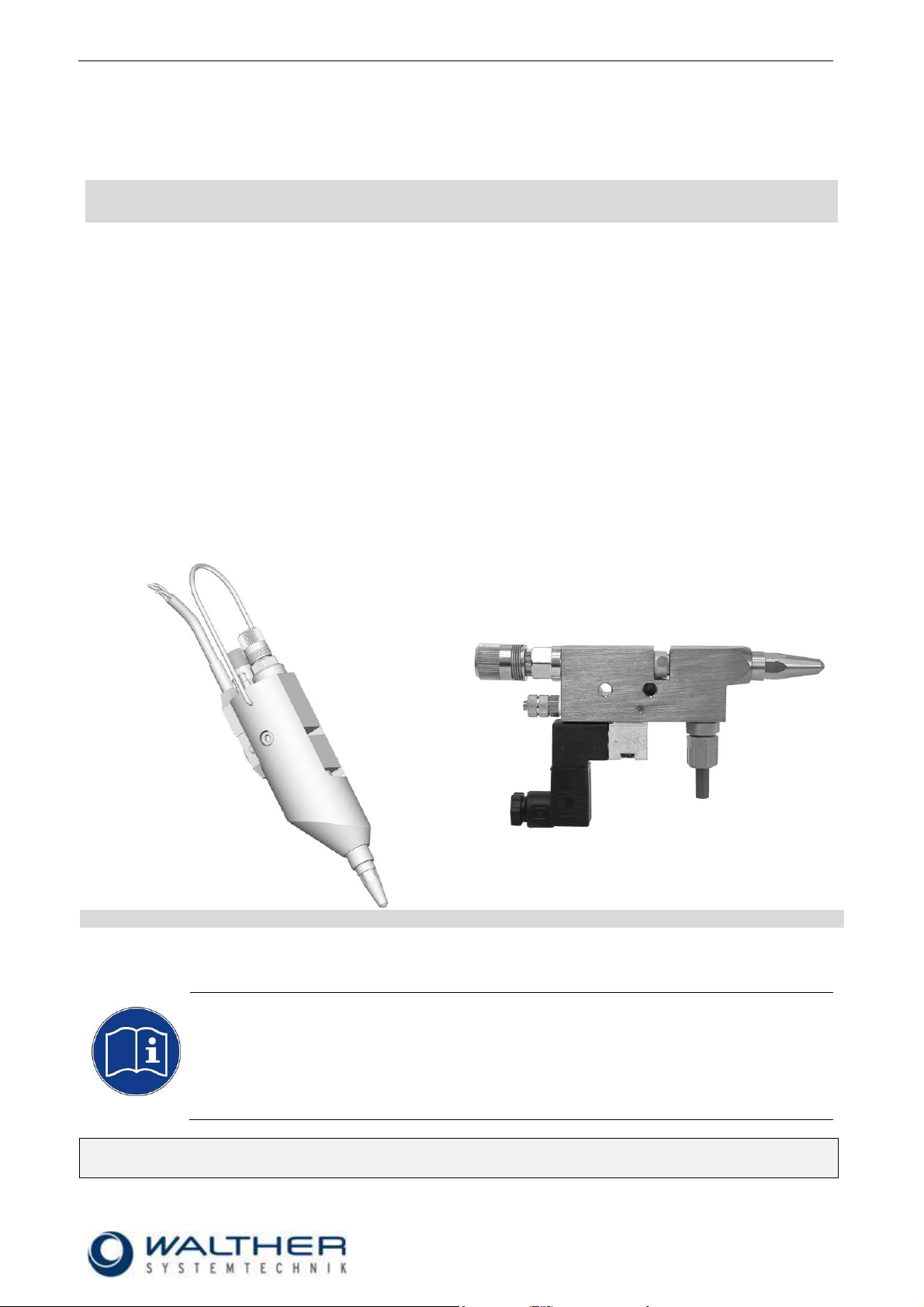

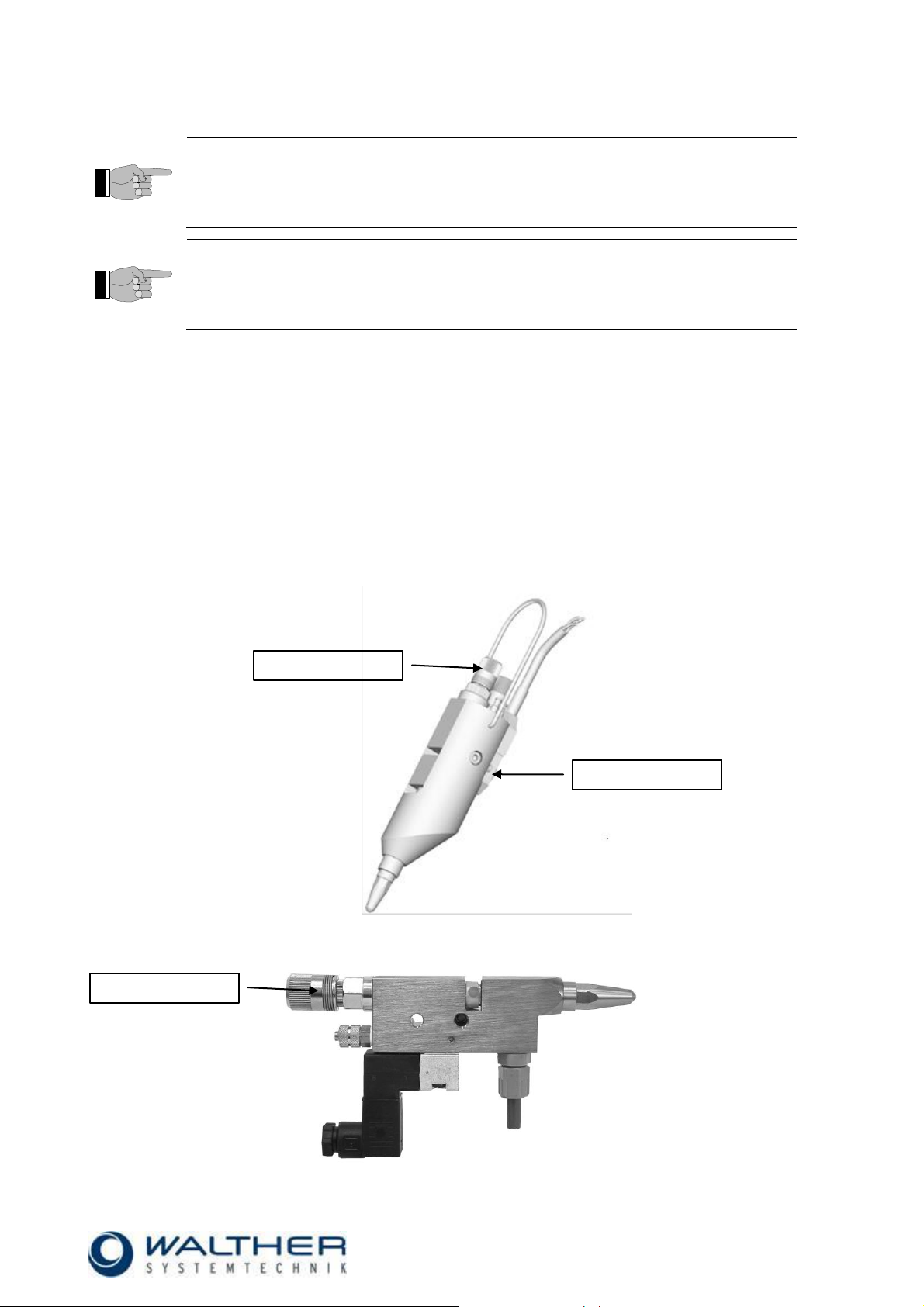

VMS-05 Standard

VMS-05 Special Design

NOTE

Please read the Assembly Instructions carefully before first using the incomplete device and

strictly adhere to the instructions!

This incomplete device may only be worked with and worked on by persons who are

familiar with the Assembly Instructions and the current regulations for industrial safety and

accident prevention.

Assembly Instructions

Hand Dosing Valve VMS-05

Article Numbers: Standard

V05-…

Special Design

V05-033040028012070

V05-253040028012070

V05-253080028012070

Always keep this translated version of the ‘original Assembly Instructions’ at the device!

The instructions have to be close at hand any time!

Page 2

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 2 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Table of Contents

Page

EC DECLARATION OF INCORPORATION ....................................................................................................................... 4

1 INTRODUCTION ................................................................................................................................................. 5

1.1 TARGET GROUP OF THE ASSEMBLY INSTRUCTIONS ............................................................................................................ 5

1.2 LIST OF SIGNS AND SYMBOLS ....................................................................................................................................... 5

2 SAFETY............................................................................................................................................................... 5

2.1 GENERAL INFORMATION ............................................................................................................................................. 5

2.2 DANGERS FROM RESIDUAL ENERGY ............................................................................................................................... 5

2.3 WARRANTY AND LIABILITY ........................................................................................................................................... 5

2.4 CORRECT USE ........................................................................................................................................................... 6

2.5 INCORRECT USE ........................................................................................................................................................ 6

2.6 QUALIFICATIONS OF PERSONNEL ................................................................................................................................... 6

3 TRANSPORT ....................................................................................................................................................... 7

3.1 PACKAGING .............................................................................................................................................................. 7

3.2 TASKS BEFORE TRANSPORT .......................................................................................................................................... 7

4 DESCRIPTION OF FUNCTION .............................................................................................................................. 7

4.1 DESIGNATED PURPOSE OF THE INCOMPLETE DEVICE ......................................................................................................... 7

4.2 TECHNICAL DATA ....................................................................................................................................................... 8

4.3 TYPE LABEL .............................................................................................................................................................. 8

5 INITIAL START-UP ............................................................................................................................................... 9

5.1 MOUNTING AND INSTALLATION .................................................................................................................................... 9

5.2 HOSE MOUNTING...................................................................................................................................................... 9

5.3 ADJUSTING THE INCOMPLETE DEVICE .......................................................................................................................... 10

5.4 OPERATING ELEMENTS STANDARD .............................................................................................................................. 10

5.5 OPERATING ELEMENTS SPECIAL DESIGN ....................................................................................................................... 10

6 OPERATION ..................................................................................................................................................... 11

6.1 GENERAL INFORMATION ........................................................................................................................................... 11

6.2 OPERATION INSTRUCTIONS / OPERATING CONDITIONS .................................................................................................... 11

7 TAKING OUT OF SERVICE ................................................................................................................................. 12

7.1 SHORT INTERRUPTION .............................................................................................................................................. 12

7.2 LONG-TERM INTERRUPTION ....................................................................................................................................... 12

7.3 SHUTDOWN OF DEVICE ............................................................................................................................................. 12

8 MAINTENANCE AND REPAIR ............................................................................................................................ 13

8.1 GENERAL INFORMATION ........................................................................................................................................... 13

8.2 CLEANING .............................................................................................................................................................. 13

8.3 REPLACING NEEDLE AND NOZZLE ................................................................................................................................ 13

8.4 REPLACING THE SEALING BUSHING .............................................................................................................................. 14

8.5 INSERTING SEALINGS AND O-RINGS............................................................................................................................. 14

8.6 SPARE PARTS .......................................................................................................................................................... 15

8.7 ROUTINE TASKS ....................................................................................................................................................... 15

8.8 CUSTOMER SERVICE / SUPPORT .................................................................................................................................. 15

9 TROUBLESHOOTING ........................................................................................................................................ 16

9.1 GENERAL INFORMATION ........................................................................................................................................... 16

9.2 MALFUNCTIONS ...................................................................................................................................................... 16

10 APPENDIX ........................................................................................................................................................ 17

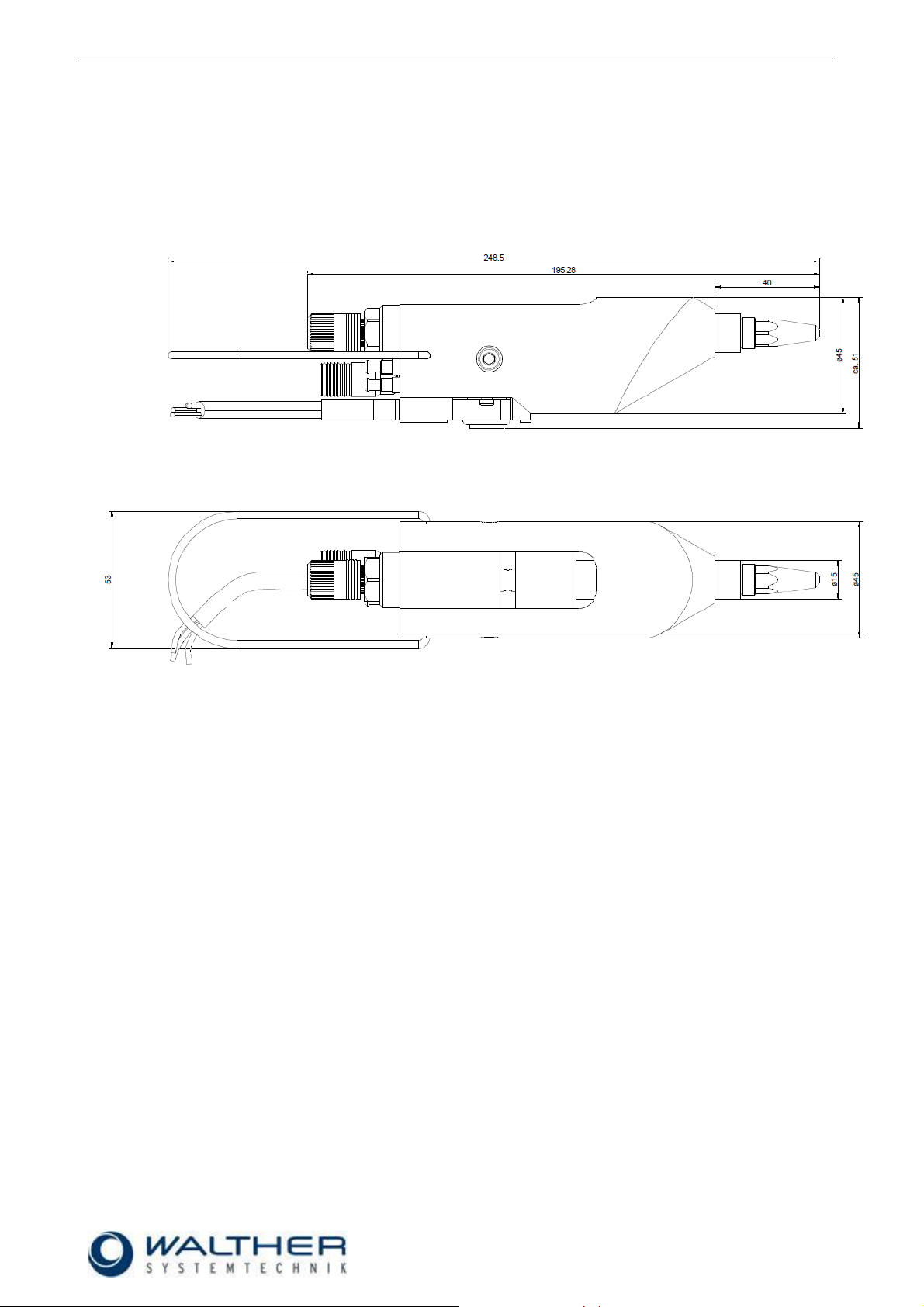

10.1 VMS-05 STANDARD ........................................................................................................................................... 17

10.1.1 Dimensioned Drawing VMS-05 Standard ............................................................................................. 17

Page 3

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 3 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

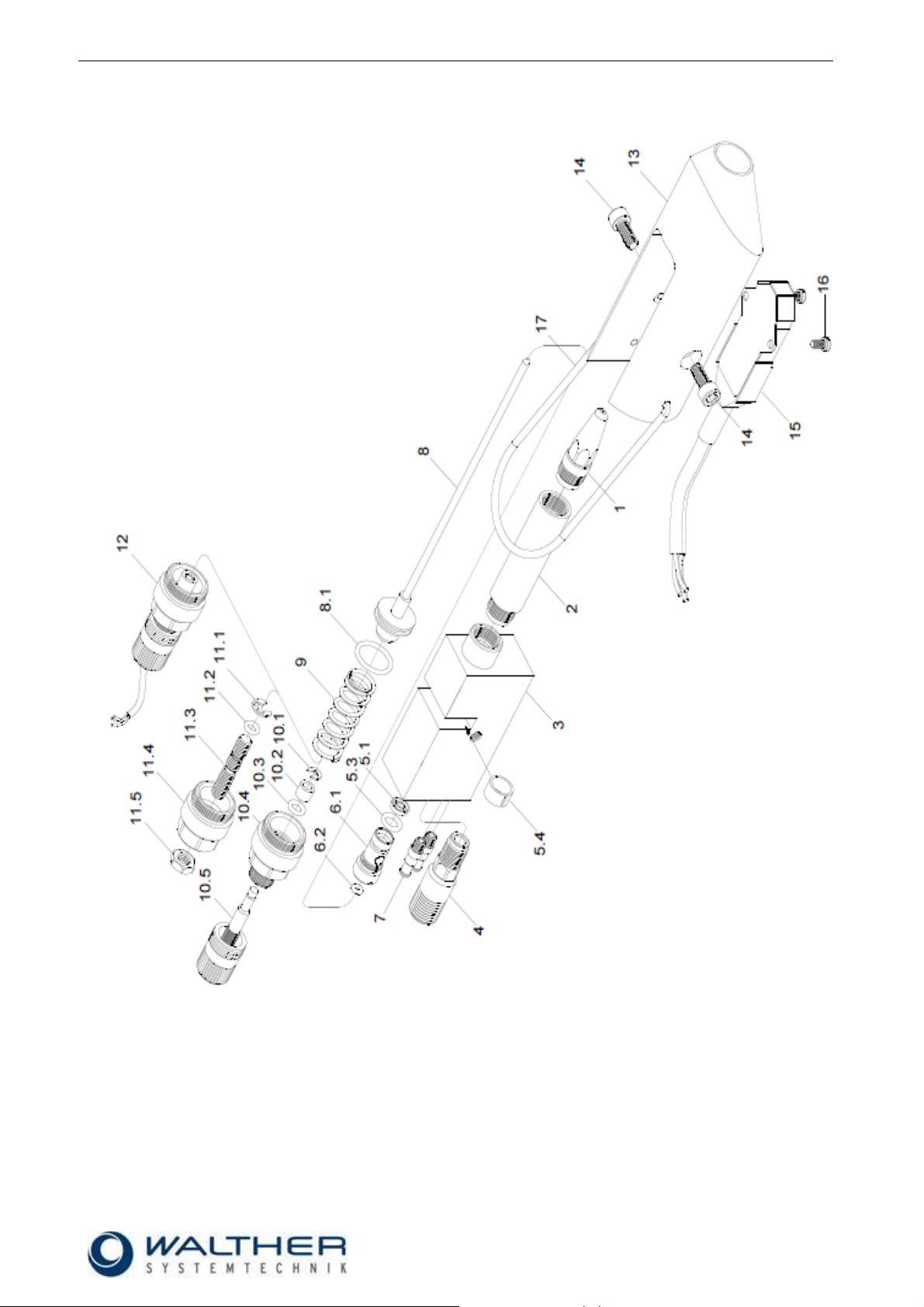

10.1.2 Spare Part Drawing VMS-05 Standard ................................................................................................. 18

10.1.3 Spare List VMS-05 Standard ................................................................................................................. 19

10.2 VMS-05 SPECIAL DESIGN .................................................................................................................................... 20

10.2.1 Dimensioned Drawing VMS-05 Special Design MV LV (long version) ................................................... 20

10.2.2 Dimensioned Drawing VMS-05 Special Design MV KV (short version) ................................................. 20

10.2.3 Spare Part Drawing VMS-05 Special Design ......................................................................................... 21

10.2.4 Spare Part List VMS-05 Special Design ................................................................................................. 22

10.3 ARTICLE NUMBERS FOR NOZZLES, NOZZLE NEEDLES AND MAGNETIC VALVES .................................................................. 23

10.4 ACCESSORIES ..................................................................................................................................................... 25

10.5 DATA SHEET MICRO SWITCH 97190003 ................................................................................................................ 25

Page 4

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 4 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

EC Declaration of Incorporation

in accordance with EU Machinery Directive 2006/42/EU, dated 17 May 2006, Appendix II B

We herewith confirm that the below mentioned incomplete device meets the basic requirements for safety

and health as stated in EU Machinery Directive 2006/42/EU for its design and construction as well as for the

configuration released by us on the market. This machine component will not be operated before it has been

determined that the incomplete system where the machine component will be installed also meets the

requirements of the Directive (2006/42/EG).

Manufacturer

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D- 76726 Germersheim

Description

VMS-05 Hand Dosing Valve, Article No. V05-…

We also declare the conformity with other, product-relevant directives/guidelines:

Mach. Direct. 2006/42/EU App. I, Clause: 1.1.2, 1.1.3, 1.1.5, 1.1.6, 1.3.2, 1.3.3,

1.3.4, 1.5.1, 1.5.9

EMC- Directive 2014/30/EU, dated 26. February 2014

Applied harmonized standards, in particular:

DIN EN ISO 12100 Safety of Machinery – General Design Principles –

Risk Assessment and Risk Reduction (ISO

12100:2010)

In addition, we also confirm that the special documentation according to Appendix VII Part B has

been prepared.

The manufacturer, respectively his authorized representative obligates himself to submit this documentation

to the market surveillance authorities, if requested.

This EC Declaration of Incorporation becomes invalid if the incomplete device will be altered or changed

without consent of Walther Systemtechnik GmbH.

Authorized representative for Technical Documentation:

Stefan Hirl, Hockenheimer Straße 3, D- 76726 Germersheim

Germersheim, 19 April 2016

(Place, Date) (Stefan Hirl, Management)

Page 5

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 5 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

DANGER

Describes a potentially dangerous situation.

Death, grievous bodily harm or severe material damage WILL occur if the respective

measures of precaution have not been taken

WARNING

Describes a potentially dangerous situation.

Death, grievous bodily harm or severe material damage MAY occur if the respective

measures of precaution have not been taken.

CAUTION

Describes a potentially dangerous situation.

Slight injuries CAN occur if the respective measures of precaution have not been

taken. This signal word is also used to describe possible property damages.

IMPORTANT

Indicates tips for usage and other particularly useful information.

No dangerous situation.

1 Introduction

1.1 Target Group of the Assembly Instructions

Operating Personnel

Maintenance Personnel

1.2 List of Signs and Symbols

The assembly instructions warn users of operations which may put their health at risk.

The warnings are indicated by combinations of text and symbols as follows:

2 Safety

2.1 General Information

The construction of this incomplete device is according to the latest technology and is absolutely reliable.

The individual components as well as the complete device are continuously checked by our quality management.

2.2 Dangers from Residual Energy

Please instruct the operating personnel on the respective measures to be taken against the occurrence of

mechanical, hydraulic, pneumatic and electric / electronic residual energies.

2.3 Warranty and Liability

According to the conditions laid down by the German Engineering Association (VDMA), Walther Systemtechnik GmbH has a guarantee of 12 months under normal European operating conditions on its own

parts (spare parts are excluded); or according to the conditions of the manufacturer.

This guarantee can only be granted by Walther Systemtechnik GmbH, if:

the user has thorough knowledge of the content of the assembly instructions;

the user follows the instructions and notes contained in the assembly instructions;

the user does not rebuild or make changes on parts of the device without prior consent of WST Sys-

temtechnik GmbH.

Page 6

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 6 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

WARNING

Do not use solvents or cleaners from the chlorinated hydrocarbon group; for example,

1.1.1 trichloromethane or methylene chloride can react explosively with aluminum or

galvanized parts.

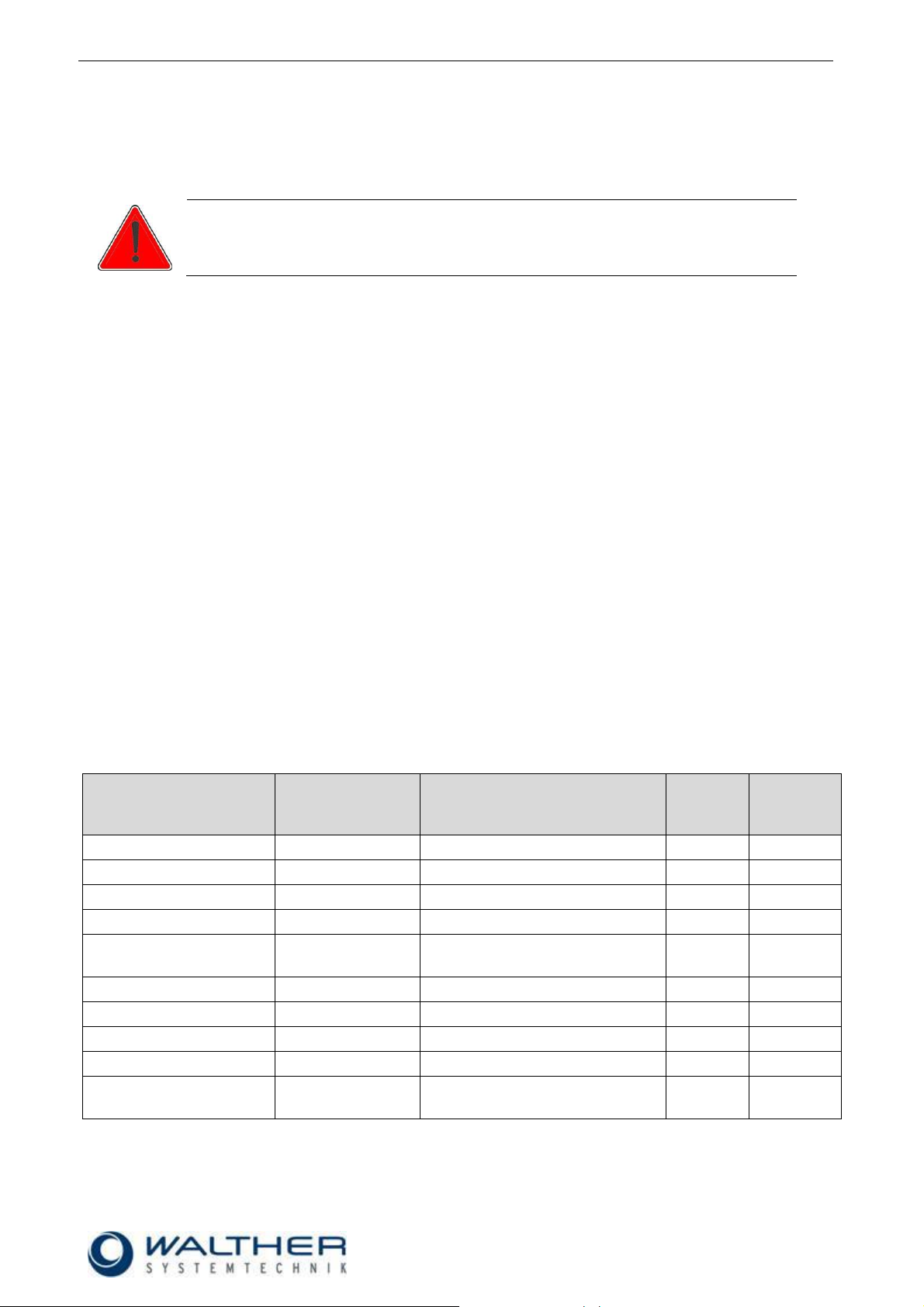

Personnel

Task

Instructed

Personnel

Personnel with Technical

Qualification

Specialist

Supervisor

Packaging, Transport

X

-

-

-

Commissioning

X

X

-

Operation

X

-

Troubleshooting, general

X

X

-

Troubleshooting

mechanical

-

X

-

-

Troubleshooting electrical

-

-

X

-

Setting up

-

X

-

-

Maintenance

-

X

-

-

Repair

-

X

X

-

Taking out of service,

Storage

-

X

X

-

2.4 Correct Use

The VMS-05 Hand Dosing Valve is suitable for the application of media such as sealants, adhesives, greases, pastes and oils. Under no circumstance will aggressive media be processed! In case of doubt, please

contact the manufacturer if a certain medium is suitable for this device.

The VMS-05 Special Design valve is a needle valve and will be used for processing materials which can be

sprayed in continuous or intermitting operation. Under no circumstances shall aggressive media such as

acids, alkaline solutions, detergents, chemicals or others be sprayed. If you are not sure, please contact the

manufacturer if a certain spray medium is suitable for this device.

2.5 Incorrect Use

Operating the incomplete device with insufficient knowledge about the operation, maintenance and care

of the device.

Making changes, extensions or alterations on the incomplete device that may hamper its safety without

the prior consent of Walther Systemtechnik GmbH.

Operating the incomplete device with defective safety installations or not properly attached or malfunc-

tioning safety devices.

Using unsuitable materials.

Handling the incomplete device while energized

2.6 Qualifications of Personnel

Only trained and instructed personnel may conduct work on the equipment.

The responsibilities of the personnel for assembly work, operation, repair work or maintenance work must be

clearly assigned to individuals!

Persons in training may work with the equipment only under supervision of an experienced person.

Page 7

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 7 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

CAUTION

The use of other media can cause functional failures, damages or even the destruction

of the device.

3 Transport

3.1 Packaging

The type of packaging depends on the individual mode of shipping. If not separately contracted, the

packaging is in accordance with the rules and regulations of Walther Systemtechnik GmbH. This rule is in

accordance with the Federal Association for Packaging HPE.

3.2 Tasks before Transport

The following has to be done before transport:

Disconnect all power lines.

The actual transport of the incomplete device and its individual parts requires special care in order to prevent

damages from external forceful impact or careless on- and off-loading. Depending on the mode of

transportation, suitable transport and load securing has to be selected. The incomplete device will be aligned

and leveled by appropriate fastening elements.

4 Description of Function

4.1 Designated Purpose of the Incomplete Device

Standard

The VMS-05 Hand Dosing Valve was designed for the application of sealants, adhesives, greases, pastes

and oils. The selected nozzle defines the actual application. Depending on the viscosity of the medium to be

applied, the application result can be individually adjusted through the nozzle size, the material supply

pressure and the needle stroke. The medium will be supplied via a material connection. The VMS-05 hand

dosing valve is a high-precision device which will be a long-term reliable tool if the following notes are

observed.

Operating the micro-switch (15) sends an electric impulse to a pilot valve (not included in scope of delivery).

This pilot valve will then send an air impulse to the Dosing Valve which will start the spraying process.

A pilot valve can come as magnetic valve. Is this the case, the Dosing Valve will spray as long as the microswitch is pushed.

A pilot valve can also come as a time-control. In this case, the Dosing Valve will spray according to the preset time, and the micro-switch does not have to be pushed constantly.

Special Design

Due to their low weight and a very compact design, the valves of the VMS-05 Special Design series MV

LV/KV are ideally suitable for all applications with only little space for installation in machines or robots.

Using LV-nozzles (long versions) allows you to install the devices with an incline towards each other, but not

much more mounting space is required. The valves are predominantly used for the application of sealants,

adhesives and oils. Depending on the nozzle size, media with different viscosities can be processed. The

VMS-05 Special Design MV LV/KV valves are high-precision devices which will be a long-term reliable tool

if the following notes are observed.

The valve is a pneumatically controlled application device for processing materials such as sealants,

adhesives, greases, paints, oils etc. A mutual application of air on the working piston results in opening and

closing of the nozzle needle. When the control air is turned off or fails, the spring closes the nozzle needle.

The spraying medium is supplied from a pressured container or a pump. The valve operates with a full jet.

Page 8

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 8 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

4.2 Technical Data

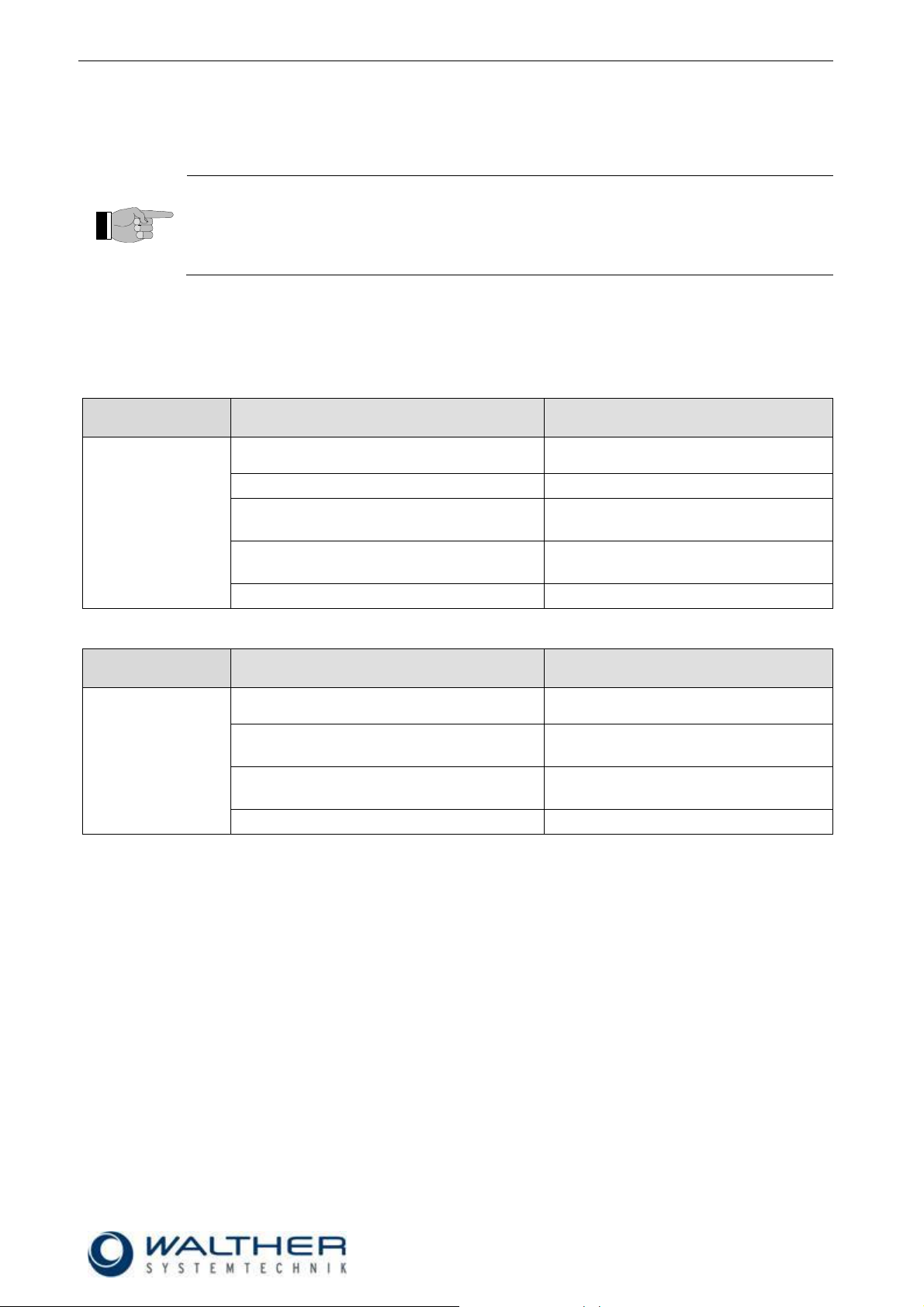

Dimensions [mm] KV-type

ca. 45 x 250

Weight [g]

ca. 700

Sealing material

Viton

Control air pressure [bar]

min. 6

Material pressure [bar]

max. 100

Dimensions [mm] KV-type

ca. 122 x 15 x 75 (see Appendix!)

Dimensions [mm] LV-type

ca. 142 x 15 x 75 (see Appendix!)

Weight [g]

ca. 265

Sealing material

Viton

Control air pressure [bar]

min. 6

Material pressure [bar]

max. 30

General Data - Standard

Energy Supply

General Data - Special Design

Energy Supply

4.3 Type Label

The type label has been etched in near the material connection. The serial number will be hammered into

the type label.

Page 9

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 9 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Control air

Material

Control air

open

Material

Control air

close

5 Initial Start-up

5.1 Mounting and Installation

Connect the VMS-05 Hand Dosing Valve with a pressured container or a pump via the material connection

(4). Connect the micro-switch (15) with a pilot valve (magnetic valve or time control or other). Adjust material

pressure at the pressured container or the pump (max. 20bar). When you now operate the micro-switch,

material will be discharged from the nozzle.

The VMS-05 Special Design valves can be installed in any position. The distance to the application area

depends on the desired application image.

An intermittent operation of the device will cause certain vibrations. Therefore make sure that the device is

safely and securely fixed and installed. The device comes with two borings of 5mm diameter in the valve

body which can be used for a solid installation. Try to avoid extremely large vibrations (transfer from

machines to valve).

5.2 Hose Mounting

Standard

Three functional hoses will connected as follows:

1. Control air (black) to plug-in nipple (open 7 SA)

2. Control air (black) to plug-in nipple (close 7 SZ)

3. Material (transparent) to 1/4"-connection (4)

Special Design

Two functional hoses will be connected as follows:

1. Control air to M5-connection (21.0.0)

2. Material to 1/4"-connection (21.20)

Page 10

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 10 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

IMPORTANT

Do not turn the raster-needle locking screw any further counter-clockwise if no more

stops are noticeable while turning it! The maximum needle stroke adjustment has been

reached already.

Further turning will cause the raster-needle locking screw to jump out!!

IMPORTANT

Nozzle and needle can be damaged by wrong handling. Only decrease the material

flow (by a right turn of the regulating screw) if material spills out. Do not turn the regulating screw further to the right after the nozzle is closed!

Regulating screw

Regulating screw

Release button

5.3 Adjusting the Incomplete Device

Standard

The individual material quantity can be adjusted with the needle-stroke regulation (10, 11 or 12).

Functional Principle:

Turn the raster head/regulating spindle to the right: decrease the material quantity

Turn the raster head/regulating spindle to the left: increase the material quantity

Special Design

The amount of material can be regulated via the stroke adjustment of the needle. A left turn of the locking

screw increases the material amount. A fine precision thread affects a needle rise that results in an adjustment of 0.5 mm with each turn of the adjusting knob

5.4 Operating Elements Standard

5.5 Operating Elements Special Design

Page 11

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 11 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

CAUTION

Never point the jet at people. The wearing of eye protection is strongly recommended.

The spraying process can create noise depending on the air and fluid pressures used.

Ear protection should be worn, if required.

WARNING

Danger caused by flammable, harmful fluid. Always follow the safety instructions on the

container or the safety data sheet for the fluid.

IMPORTANT

Accident prevention directions will be strictly followed when applying high material

pressures. Please strictly follow the following instructions when planning and

constructing application systems.

IMPORTANT

The base for an optimum setting of the application image is a device-specific

adjustment. Basic values from lab tests can be used as references. However these

have to be adjusted individually. Parameters such as nozzle size, opening time,

opening stroke, material pressure and maybe also temperature have to be combined.

6 Operation

6.1 General Information

This device will only be operated if the safety-related equipment is permanently effective and not suspended

during operation or altered in its intended effectiveness.

6.2 Operation Instructions / Operating Conditions

The valves of the VMS-05 Special Design series generally operate with a control air pressure of 6 bar and

material pressures of up to 30 bar.

The valves are able to perform contact-applications or also contact-free applications. The valves can be

controlled for intermittent or continuous use. According to the individual application, the control air must be

adjusted to the operating cycles and to the higher or lower material pressures. 40 tacts per second can be

reached under appropriate operating conditions (material pressure, control air pressure, needle stroke, and

short conductions).

The amount of material can be regulated via the stroke adjustment of the needle. A left turn of the locking

screw increases the material amount. A fine precision thread affects a needle rise that results in an adjustment of 0.5 mm with each turn of the adjusting knob.

For longer times of standstill, the material can remain in the valve, if it remains under pressure (no contact to

outside air).

Page 12

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 12 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

IMPORTANT

Please follow the Operating Manual!

IMPORTANT

Please follow the maintenance guidelines!

IMPORTANT

Please follow the maintenance guidelines!

7 Taking out of Service

7.1 Short Interruption

A short interruption (15 min or more) has to be followed by a clean spraying.

7.2 Long-term Interruption

The following has to be observed for a long-term interruption of the device/machine:

Depressurize material supply lines

Remove air cap and clean nozzle with a special thinner and a soft cloth. Make sure that no cloth fibers

are left on the nozzle tip.

7.3 Shutdown of Device

The following is important for a shutdown of the machine / device:

Clean full-jet valve with a special thinner.

Page 13

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 13 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

CAUTION

Before starting any maintenance or repair work, ensure that all air-operated tools are

depressurized and disconnected from the air supply.

Before opening the dosing pen it must be disconnected from the air and fluid supply.

Otherwise, ejected components can cause injuries.

IMPORTANT

Only use soft brushes for outside cleaning of the nozzle tips. Never use metal tools

with sharp edges.

CAUTION

First depressurize all connections.

8 Maintenance and Repair

8.1 General Information

The valves of the VMS-05 series are high-quality precision devices which will not fail if treated correctly and

will operate almost maintenance-free. Always keep clean and observe minimum instructions to maintain a

long life of the valve. Always use clean and filtered material only. The control air must also be clean and

should be slightly oiled, if necessary. Maintenance also depends on the individual operating conditions and

the type of media used.

8.2 Cleaning

Wash equipment thoroughly after use to remove residues and dirt, especially if nozzle needle, sealing

bushing or nozzle have to be exchanged.

Use the thinner for sprayable media as detergent. A daily cleansing rinse will remove residues of the

sprayable medium and clean almost all parts and channels which have been in contact with the sprayable

medium.

8.3 Replacing Needle and Nozzle

Standard Needle (8) and Nozzle (1)

First unscrew screws (14) and then remove valve from device body (13). Completely unscrew needle lock

(10, 11 or 12). Unscrew nozzle (1). From the nozzle side, carefully push out needle (8) to the back. Reassemble with slightly greased new parts in reverse order. We do not recommend reusing old needles.

Piercing of slightly dirty needles through the needle gaskets (pos. 5.1) can cause leakages.

Special Design Needle (7.10) and Nozzle (2.10)

Completely unscrew raster-needle lock (pos. 9.02) and nozzle (pos. 2.10). Remove needle spring (8.10) and

carefully push out the needle (pos. 7.10) towards the nozzle end. Re-assemble with slightly greased new

parts in reverse order. We do not recommend reusing old needles. Piercing of slightly dirty needles through

the needle gaskets (pos. 5.50) can cause leakages.

Page 14

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 14 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

IMPORTANT

Gaskets and gasket holders can be damaged.

Do not use any sharp or pointed metallic implements for inserting the sealings!

8.4 Replacing the Sealing Bushing

Standard Sealing Bushing (6)

Unscrew screws (14) and remove valve from device body (13). Completely unscrew needle lock (pos. 10, 11

or 12) and nozzle (pos. 1). Carefully push out the needle (pos. 8) towards the nozzle end. Then unscrew the

sealing sleeve (pos. 6.0.0) from the thread with a screwdriver. Since the outer O-ring (pos. 5.3) prevents the

sealing sleeve from falling through the mounting thread of the valve body (pos. 3), it is necessary to push the

sealing sleeve together with O-ring (pos. 5.3) carefully backwards through the thread using a thin strip of

metal (0.5 – 1.0 mm) which you push between the recess in the body and flat in front of the front end of the

sealing sleeve. You can then take the sealing sleeve out of the enclosure.

Special Design Sealing Bushing (6.00)

Completely unscrew raster-needle lock (pos. 9.02) and nozzle (pos. 2.10). Carefully push out the needle

(pos. 7.10) towards the nozzle end. Then unscrew the sealing sleeve (pos. 6.00) from the thread with a

screwdriver. Since the outer O-ring (pos. 5.30) prevents the sealing sleeve from falling through the mounting

thread of the valve body (pos. 4.10), it is necessary to push the sealing sleeve together with O-ring (pos.

5.30) carefully backwards through the thread using a thin strip of metal (0.5 – 1.0 mm) which you push

between the recess in the body and flat in front of the front end of the sealing sleeve. You can then take the

sealing sleeve out of the enclosure.

8.5 Inserting Sealings and O-Rings

Standard

If a complete packing sleeve (pos. 6) is not available as a replacement, the old gaskets must be removed

and replaced with new ones. In order to do so, the sealing sleeve must be thoroughly cleaned so that no

particles of the previous spraying fluid impair the installation of the new gaskets. The O-ring seats should be

lightly greased with a lubricant (technical Vaseline). First insert O-ring (pos. 6.2) into the rear hole of the

sealing sleeve until it reaches the end. Then insert O-ring (pos. 5.3) into the outer groove. Insert the special

form gasket (pos. 5.1) into the front seat. Since this form gasket is not symmetrical, the side with the larger

boring must be inserted facing forwards, i.e. it must point in the direction of the nozzle after the complete

sealing sleeve has been installed. Lightly grease the sealing sleeve (pos. 6) and insert it back into the valve

body (pos. 3). Use a screwdriver to carefully push it through the mounting thread together with the outer Oring (pos. 5.3) without twisting it. Then screw the sealing sleeve into the thread (gently tighten).

Do not use any metallic or sharp-edged aids or tools when you insert the O-rings and the form gasket. Despite all its outstanding sealing qualities, the form gasket is a sensitive precision component, which cannot

tolerate impacts or pressure.

Special Design

If a complete packing sleeve (pos. 6.00) with integrated material sealing set (5.00) is not available as a replacement, the old gaskets must be removed and replaced with new ones. In order to do so, the sealing

sleeve must be thoroughly cleaned so that no particles of the previous spraying fluid impair the installation of

the new gaskets. The O-ring seats should be lightly greased with a lubricant (technical Vaseline). First insert

O-ring (pos. 6.20) into the rear hole of the packing sleeve until it reaches the end. Then insert O-ring (pos.

5.30) into the outer groove. Insert the special form gasket (pos. 5.50) into the front seat. Since this form gasket is not symmetrical, the side with the larger boring must be inserted facing forwards, i.e. it must point in

the direction of the nozzle after the complete packing sleeve has been installed. Lightly grease the sealing

sleeve (pos. 6.00) and insert it back into the valve body (pos. 4.10). Use a screwdriver to carefully push it

through the mounting thread together with the outer O-ring (pos. 5.3.0) without twisting it. Then screw the

sealing sleeve into the thread (gently tighten).

Do not use any metallic or sharp-edged aids or tools when you insert the O-rings and the special form

gasket. Despite all its outstanding sealing qualities, the special form gasket is a sensitive precision

component, which cannot tolerate impacts or pressure.

Page 15

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 15 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

IMPORTANT

Only use original spare parts from the manufacturer!

Wrong or defective spare parts from other manufacturers can damage the device. If

other than original spare parts of the manufacturer will be used, all obligations from the

manufacturer or his sales partners, such as guarantees, service contracts etc will be

forfeited without further notice.

No.

Description

Cleaning

Lubricating

Inspecting

Additional tasks

Frequency

1.

connections

(tightness)

X

monthly

2.

nozzle

X X

exchange if

damaged

monthly

3.

complete valve

X

check for wear

after 10 mio.

switching

operations

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D-76726 Germersheim

Germany

Phone ++49(0)7274-7022-0

Telefax ++49(0)7274-7022-91

Email info@walther-2000.de

Internet www.walther-2000.de

8.6 Spare Parts

8.7 Routine Tasks

8.8 Customer Service / Support

Page 16

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 16 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

IMPORTANT

First check all supply lines for connection and serviceability.

Fault

Possible Cause

Action

Nozzle needle does

not open

Not enough control air supplied

Check if enough control air available (5 6 bar).

Valve does not activate

Check if micro-switch is defective

Leakages

Check if O-Rings (6.2 and 8.1) are

defective.

Nozzle needle (8) is sticky within the

sealing screw (6).

Disassemble and clean.

Needle stroke is set too low.

Check if needle stroke is correctly set.

Fault

Possible Cause

Action

Nozzle needle does

not open

Not enough control air supplied

Check if enough control air available (5 6 bar).

Leakages

Check if O-Rings (6.20 and 7.40) are

defective.

Needle (7.10) is sticky within the sealing

screw (6.10).

Disassemble and clean.

Needle stroke is set too low.

Check if needle stroke is correctly set.

9 Troubleshooting

9.1 General Information

In case of serious problems that cannot be resolved, please contact the Walther Systemtechnik GmbH customer service.

9.2 Malfunctions

Standard

Special Design

Page 17

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 17 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10 Appendix

10.1 VMS-05 Standard

10.1.1 Dimensioned Drawing VMS-05 Standard

Page 18

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 18 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.1.2 Spare Part Drawing VMS-05 Standard

Page 19

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 19 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.1.3 Spare List VMS-05 Standard

Dwg No.

Art.-No.

Qty

Description

1 * 1

Nozzle, stainless

1.1

97320005

1

Needle guide

1.2

97410053

1

Hexagon retaining ring

Pos. 1.1 and 1.2 are not part of the drawing

2 * 1

Nozzle tube

3

97510158

1

Main body VMS-05 Standard

4

97220139

1

Reduction screw-joint, stainless steel 1/4"AG - 1/8"AG

5

97640102

1

Material sealings

5.1

97640004

1

Variseal

5.3

97640021

1

O-Ring Viton

5.4

97640101

1

Plastic protection sleeve

6

97810014

1

Sealing screw, complete

6.1

97810013

1

Sealing screw

6.2

97640026

1

O-Ring

7

97220288

2

Plug-in nipple, brass M5

8 * 1

Nozzle needle, complete

8.1

97640007

1

O-Ring Viton

9

97820044

1

Pressure spring

10

97900021

1

Raster-needle lock

10.1

97620017

1

Safety washer

10.2

97320098

1

Stop sleeve

10.3

97640027

1

O-Ring Viton

10.4

97220291

1

Raster-needle locking screw (incl. 10.3)

10.5

97610093

1

Needle stroke raster head

11

97900013

1

Normal lock

11.1

97620007

1

Safety washer

11.2

97640032

1

O-Ring Viton

11.3

97610107

1

Regulating spindle

11.4

97220115

1

Locking screw

11.5

97410007

1

Nut

12

97900044

1

Raster-needle lock with electric needle sensor

13

97510159

1

Device body – handle

14

97610011

2

Cylinder screw with inner hex

15

97190003

1

Micro-switch

16

97610005

2

Cylinder screw with slot

17

97910340

1

Hanging clamp

IMPORTANT

Always indicate the inscribed serial numbers when ordering spare parts!

* Article numbers can be found on the following pages.

Please indicate the required size when ordering spare parts for nozzle sets.

Available sizes: 0.3/0.5/0.7/1.0/1.5/2.0mm

Nozzle set = Nozzle needle and nozzle (should always be replaced together)

Page 20

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 20 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.2 VMS-05 Special Design

10.2.1 Dimensioned Drawing VMS-05 Special Design MV LV (long version)

10.2.2 Dimensioned Drawing VMS-05 Special Design MV KV (short version)

Page 21

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 21 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.2.3 Spare Part Drawing VMS-05 Special Design

Page 22

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 22 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Dwg No.

Art.-No.

Qty

Description

2.10 * 1

Nozzle, stainless steel

4.10

97510036

1

Main body VMS-05 MV, complete

5.00

97640107

1

Material sealing set

5.30

97640021

1

O-Ring Viton

5.40

97640101

1

Plastic protection sleeve

5.50

97640004

1

Variseal

6.00

97810014

1

Sealing screw, complete

6.10

97810013

1

Sealing screw

6.20

97640026

1

O-Ring

7.10 * 1

Nozzle needle, complete

7.40

97640007

1

O-Ring Viton

8.10

97820020

1

Pressure spring

9.02

97900008

1

Raster-needle lock

9.12

97610093

1

Needle stroke raster head

9.22

97220104

1

Raster locking screw SW 13

9.32

97640027

1

O-Ring Viton

9.42

97320022

1

Cylinder pin DIN 6325

9.52

97820000

1

Pressure spring

9.62

97610017

1

Threaded pin DIN 913

9.72

97320098

1

Stop sleeve

15.00 * 1

Magnetic valve

21.00

97220089

1

Screw joint, complete, SW 8

21.20

97220114

1

Double nipple, stainless steel, 1/4"AG-1/8"AG

IMPORTANT

Always indicate the inscribed serial numbers when ordering spare parts!

10.2.4 Spare Part List VMS-05 Special Design

* Article numbers can be found on the following pages.

Please indicate the required size when ordering spare parts for nozzle sets.

Available sizes: 0.2/0.3/0.4/0.5/0.6/0.7/0.8/1.0/1.2/1.5/2.0mm

Nozzle set = Nozzle needle and nozzle (should always be replaced together)

Page 23

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 23 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

*Nozzle, LV, stainless steel Standard

Dwg No

Article No.

Description

1

97210139

Nozzle, LV, 1.0 mm, Stainless steel

1

97210141

Nozzle, LV, 1.5 mm, Stainless steel

1

97210142

Nozzle, LV, 2.0 mm, Stainless steel

1

97210210

MG-Adapter, 0.8mm, M13 x 0.75

*Nozzle, LV, stainless steel Special Design

Dwg No

Article No.

Description

2.10

97210132

Nozzle, LV, 0.2 mm, Stainless steel

2.10

97210133

Nozzle, LV, 0.3 mm, Stainless steel

2.10

97210134

Nozzle, LV, 0.4 mm, Stainless steel

2.10

97210102

Nozzle, LV, 0.5 mm, Stainless steel

2.10

97210136

Nozzle, LV, 0.6 mm, Stainless steel

2.10

97210137

Nozzle, LV, 0.7 mm, Stainless steel

2.10

97210138

Nozzle, LV, 0.8 mm, Stainless steel

2.10

97210139

Nozzle, LV, 1.0 mm, Stainless steel

2.10

97210140

Nozzle, LV, 1.2 mm, Stainless steel

2.10

97210141

Nozzle, LV, 1.5 mm, Stainless steel

2.10

97210142

Nozzle, LV, 2.0 mm, Stainless steel

*Nozzle, KV, stainless steel Standard

Dwg No

Article No.

Description

1

97210144

Nozzle, KV, 0.3 mm, Stainless steel

1

97210146

Nozzle, KV, 0.5 mm, Stainless steel

1

97210148

Nozzle, KV, 0.7 mm, Stainless steel

1

97210153

Nozzle, KV, 2.0 mm, Stainless steel

1

97210210

MG-Adapter, 0.8mm, M13 x 0.75

*Nozzle, KV, stainless steel Special Design

Dwg No

Article No.

Description

2.10

97210143

Nozzle, KV, 0.2 mm, Stainless steel

2.10

97210144

Nozzle, KV, 0.3 mm, Stainless steel

2.10

97210145

Nozzle, KV, 0.4 mm, Stainless steel

2.10

97210146

Nozzle, KV, 0.5 mm, Stainless steel

2.10

97210147

Nozzle, KV, 0.6 mm, Stainless steel

2.10

97210148

Nozzle, KV, 0.7 mm, Stainless steel

2.10

97210149

Nozzle, KV, 0.8 mm, Stainless steel

2.10

97210150

Nozzle, KV, 1.0 mm, Stainless steel

2.10

97210151

Nozzle, KV, 1.2 mm, Stainless steel

2.10

97210152

Nozzle, KV, 1.5 mm, Stainless steel

2.10

97210153

Nozzle, KV, 2.0 mm, Stainless steel

10.3 Article Numbers for Nozzles, Nozzle Needles and Magnetic Valves

Page 24

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 24 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

*Nozzle tube, Standard

Dwg No

Article No.

Description

2

97850139

Nozzle tube, 60mm, Standard

2

97220813

Nozzle tube, 50mm

2

97851597

Nozzle tube, 1000mm, extension

*Nozzle needle, Standard stainless steel

Dwg No

Article No.

Description

8

97110425

Nozzle needle, KV 0.3mm, complete

8

97110449

Nozzle needle, KV 0.5mm, complete

8

97111835

Nozzle needle, KV 0.5mm, complete for 1000mm ext.

8

97112012

Nozzle needle, KV MG-Adapter 0.8mm, complete for 1000mm ext.

8

97110388

Nozzle needle, KV 0.7mm, complete

8

97111857

Nozzle needle, KV 2.0mm, complete

*Nozzle needle, Standard stainless steel

Dwg No

Article No.

Description

8

97111682

Nozzle needle, LV 1.0mm, complete for 50mm ext.

8

97111995

Nozzle needle, LV 1.5mm, complete for 50mm ext.

8

97111720

Nozzle needle, LV 2.0mm, complete for 50mm ext.

*Nozzle needle, LV, carbide

Dwg No

Article No.

Description

7.10

97110221

Carbide -Nozzle needle, LV 0.2/0.3mm, complete

7.10

97110222

Carbide -Nozzle needle, LV 0.4mm, complete

7.10

97110223

Carbide -Nozzle needle, LV 0.5mm, complete

7.10

97110224

Carbide -Nozzle needle, LV 0.6/0.7mm, complete

7.10

97110225

Carbide -Nozzle needle, LV 0.8/1.0mm, complete

7.10

97110227

Carbide -Nozzle needle, LV 1.2mm, complete

7.10

97110228

Carbide -Nozzle needle, LV 1.5mm, complete

7.10

97110229

Carbide -Nozzle needle, LV 2.0mm, complete

*Nozzle needle, KV, carbide

Dwg No

Article No.

Description

7.10

97110230

Carbide -Nozzle needle, KV 0.2/0.3mm, complete

7.10

97110231

Carbide -Nozzle needle, KV 0.4mm, complete

7.10

97110232

Carbide -Nozzle needle, KV 0.5mm, complete

7.10

97110233

Carbide -Nozzle needle, KV 0.6/0.7mm, complete

7.10

97110234

Carbide -Nozzle needle, KV 0.8/1.0mm, complete

7.10

97110235

Carbide -Nozzle needle, KV 1.2mm, complete

7.10

97110236

Carbide -Nozzle needle, KV 1.5mm, complete

7.10

97110237

Carbide -Nozzle needle, KV 2.0mm, complete

Page 25

Rev. 1.1

Assembly Instructions - Full-Jet Valve VMS-05

Page 25 of 25

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

*Magnetic valve 3/2-way

Dwg No

Article No.

Description

15.00

97150018

Magnetventil 24V / DC / 2,5W

15.00

97150019

Magnetventil 110V / 50Hz / 1,5W

15.00

97150020

Magnetventil 220V / 50Hz / 1,5W

10.4 Accessories

Picture

Article Number

Description

979444

Cleaning Kit

10.5 Data Sheet Micro Switch 97190003

Loading...

Loading...