Rev. 1.4

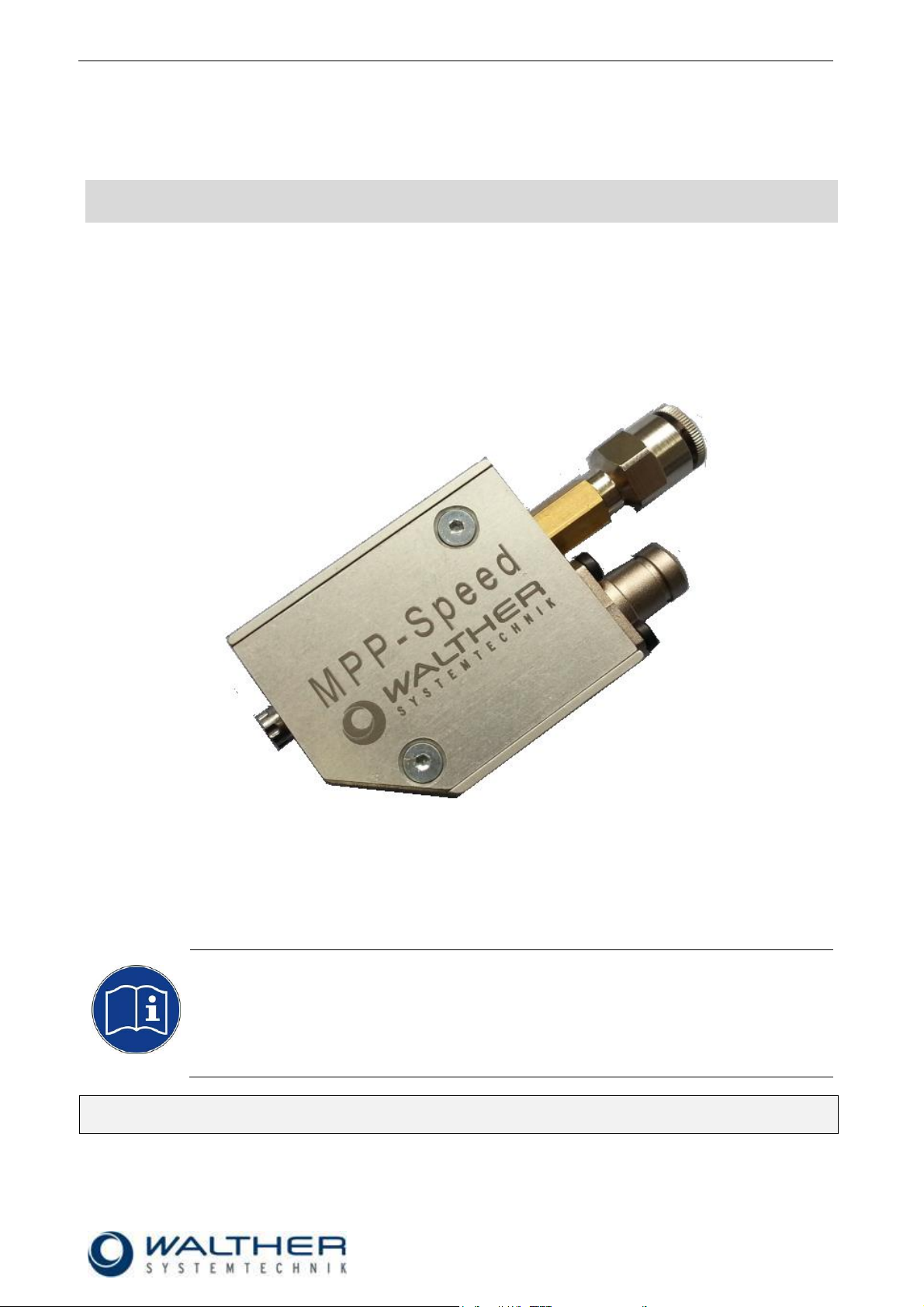

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 1 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

NOTE

Please read the Assembly Instructions carefully before first using the incomplete device and

strictly adhere to the instructions!

The incomplete device may only be worked with and worked on by persons who are familiar

with the assembly instructions and the current regulations for industrial safety and accident

prevention.

Assembly Instructions

Micro Point Pulse Valve MPP-Speed

Article number: MPP-SPEED

Pic.: MPP- Speed with medium connector (high-pressure hose)

Always keep a translated version of the original Assembly Instructions at the incomplete device!

The assembly instructions have to be close at hand any time!

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 2 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Table of Contents

Page

EC DECLARATION OF INCORPORATION ....................................................................................................................... 3

1 INTRODUCTION ................................................................................................................................................. 4

1.1 TARGET GROUP OF THE ASSEMBLY INSTRUCTIONS ............................................................................................................. 4

1.2 LIST OF SIGNS AND SYMBOLS ........................................................................................................................................ 4

2 SAFETY............................................................................................................................................................... 4

2.1 GENERAL INFORMATION ............................................................................................................................................. 4

2.2 DANGERS FROM RESIDUAL ENERGY ............................................................................................................................... 4

2.3 WARRANTY .............................................................................................................................................................. 4

2.4 CORRECT USE ........................................................................................................................................................... 5

2.5 INCORRECT USE ........................................................................................................................................................ 5

2.6 QUALIFICATION OF PERSONNEL .................................................................................................................................... 5

3 TRANSPORT ....................................................................................................................................................... 6

3.1 PACKAGING .............................................................................................................................................................. 6

3.2 TASKS BEFORE TRANSPORT .......................................................................................................................................... 6

4 FUNCTIONAL DESCRIPTION ............................................................................................................................... 6

4.1 FUNCTIONAL PRINCIPLE .............................................................................................................................................. 6

4.2 TECHNICAL DATA OF INCOMPLETE DEVICE ...................................................................................................................... 7

4.3 STRESS TEST ............................................................................................................................................................. 7

4.4 TYPE LABEL .............................................................................................................................................................. 8

5 INSTALLATION AND INITIAL START-UP ................................................................................................................ 8

5.1 HOSE CONNECTION ................................................................................................................................................... 8

5.2 INTERFACES .............................................................................................................................................................. 8

5.3 ELECTRICAL INTERFACES .............................................................................................................................................. 9

6 OPERATION ....................................................................................................................................................... 9

6.1 GENERAL INFORMATION ............................................................................................................................................. 9

6.2 OPERATING INSTRUCTIONS / OPERATIONAL REQUIREMENTS .............................................................................................. 9

6.3 ELECTRICAL CONTROLS ............................................................................................................................................. 10

7 TAKING OUT OF OPERATION ............................................................................................................................ 11

7.1 SHORT INTERRUPTION .............................................................................................................................................. 11

7.2 LONG-TERM INTERRUPTION ....................................................................................................................................... 11

7.3 FINAL SHUTDOWN OF SYSTEM / DEVICE ...................................................................................................................... 11

8 MAINTENANCE AND REPAIR ............................................................................................................................ 11

8.1 GENERAL ............................................................................................................................................................... 11

8.2 CLEANING .............................................................................................................................................................. 12

8.3 REPLACING NOZZLE ................................................................................................................................................. 12

8.4 CUSTOMER SERVICE / SUPPORT .................................................................................................................................. 13

9 TROUBLESHOOTING ........................................................................................................................................ 13

9.1 GENERAL INFORMATION ............................................................................................................................................ 13

10 APPENDIX ........................................................................................................................................................ 14

10.1 TECHNICAL DRAWING .......................................................................................................................................... 14

10.1.1 Spare Parts Drawing ............................................................................................................................. 15

10.1.2 Spare Parts List ..................................................................................................................................... 15

10.2 POSSIBLE VERSIONS ............................................................................................................................................ 16

10.3 ACCESSORIES ..................................................................................................................................................... 16

10.3.1 WALTHER-Light barrier (WLS) ............................................................................................................... 17

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 3 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

EC Declaration of Incorporation

in accordance with EU Machinery Directive 2006/42/EU, dated 17 May 2006, Appendix II B

We herewith confirm that the below mentioned incomplete device meets the basic requirements for safety

and health as stated in EU Machinery Directive 2006/42/EU for its design and construction as well as for the

configuration released by us on the market. This machine component will not be operated before it has been

determined that the incomplete system where the machine component will be installed also meets the

requirements of the Directive (2006/42/EG).

Manufacturer

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D- 76726 Germersheim

Description

Micro Point Pulse Valve MPP-Speed, article-No. MPP-SPEED

We also declare the conformity with other, product-relevant directives/guidelines:

Mach. Direct. 2006/42/EU App. I, Clause: 1.1.2, 1.1.3, 1.1.5, 1.1.6, 1.3.2, 1.3.3,

1.3.4, 1.5.1, 1.5.8, 1.5.9

EMC- Directive 2014/30/EU, dated 26. February 2014

Applied harmonized standards, in particular:

DIN EN ISO 12100 Safety of Machinery – General Design Principles –

Risk Assessment and Risk Reduction (ISO

12100:2010)

In addition, we also confirm that the special documentation according to Appendix VII Part B has

been prepared.

The manufacturer, respectively his authorized representative obligates himself to submit this documentation

to the market surveillance authorities, if requested.

This EC Declaration of Incorporation becomes invalid if the incomplete device will be altered or changed

without consent of Walther Systemtechnik GmbH.

Authorized representative for Technical Documentation:

Stefan Hirl, Hockenheimer Straße 3, D- 76726 Germersheim

Germersheim, 22 December 2018

(Place, Date) (Stefan Hirl, Management)

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 4 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

DANGER

Describes a potentially dangerous situation.

Death, grievous bodily harm or severe material damage WILL occur if the respective

measures of precaution have not been taken

WARNING

Describes a potentially dangerous situation.

Death, grievous bodily harm or severe material damage MAY occur if the respective

measures of precaution have not been taken

CAUTION

Describes a potentially dangerous situation.

Slight injuries CAN occur if the respective measures of precaution have not been

taken. This signal word is also used to describe possible property damages.

IMPORTANT

Indicates tips for usage and other particularly useful information.

No dangerous situation.

1 Introduction

1.1 Target group of the Assembly Instructions

Operating personal

Maintenance personal

1.2 List of signs and symbols

The assembly instructions warn users of operations which may put their health at risk. The warnings are

indicated by combinations of text and symbols as follows:

2 Safety

2.1 General Information

The construction of this device is according to the latest technology and is absolutely reliable. The individual

components as well as the complete device are continuously checked by our quality management.

2.2 Dangers from Residual Energy

Please note that there are residual energies from mechanical, hydraulic, pneumatic and electric/electronic

sources at the machine, and take appropriate measures when training the operating personnel.

2.3 Warranty

According to the conditions laid down by the German Engineering Federation (VDMA), Walther Systemtechnik GmbH has a guarantee of 12 months under normal European operating conditions on its own parts

(spare parts are excluded); or according to the conditions of the manufacturer.

This guarantee can only be granted by Walther Systemtechnik GmbH, if:

the user has thorough knowledge of the content of the assembly instructions;

the user follows the instructions and notes contained in the assembly instructions;

the user does not rebuild or make changes on parts of the device without prior consent of WST Sys-

temtechnik GmbH.

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 5 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

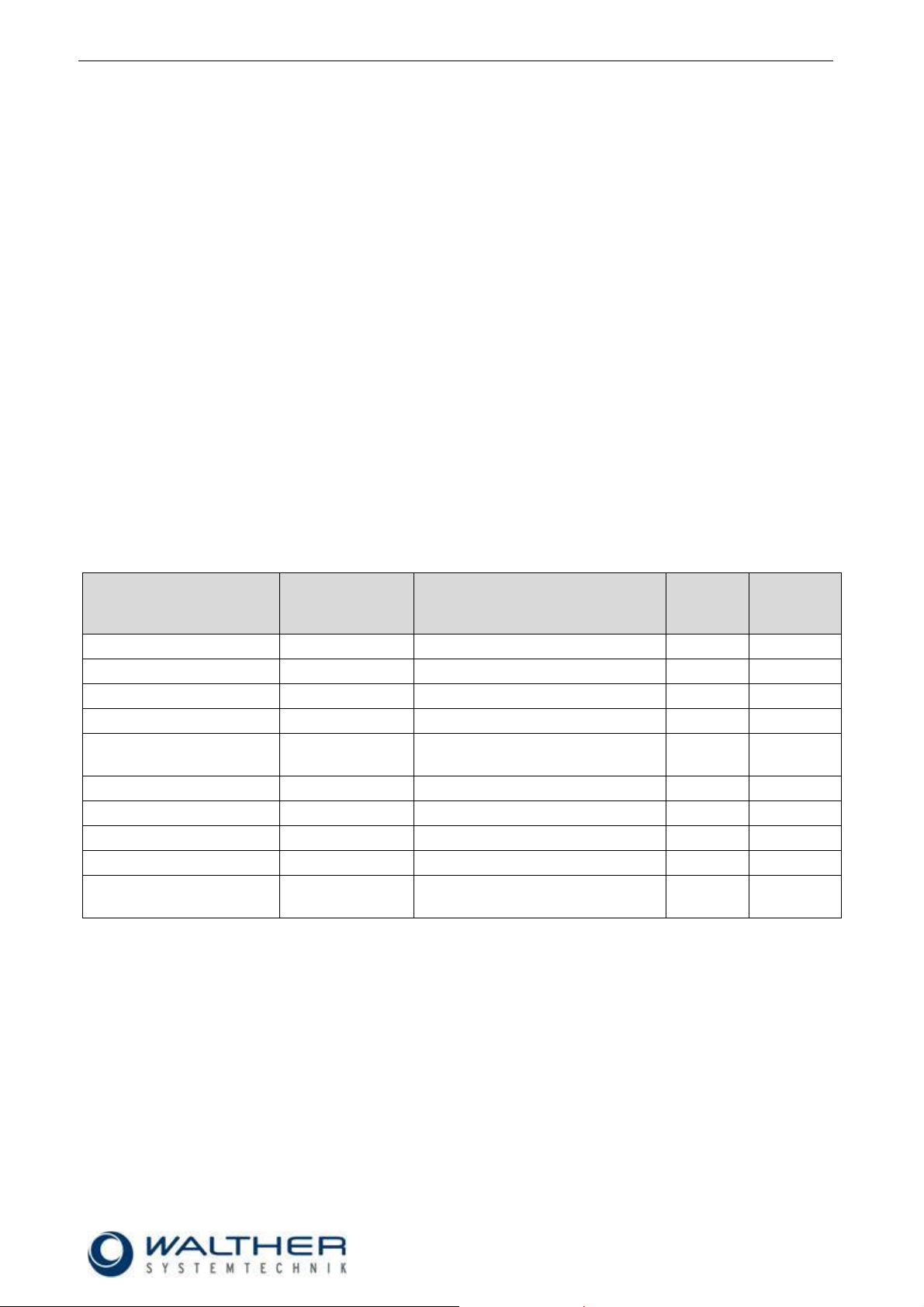

Personnel

Task

Trained

Personnel

Personnel with technical

qualification

Specialist

Supervisor

Packaging, Transport

X

-

-

-

Commissioning

X

X

-

Operation

X

-

Troubleshooting, general

X

X

-

Troubleshooting,

mechanical

-

X

-

-

Troubleshooting, electrical

-

-

X

-

Setting up

-

X

-

-

Maintenance

-

X

-

-

Repair

-

X

X

-

Taking out of service,

Storage

-

X

X

-

2.4 Correct Use

This device is a needle valve suitable for the processing of sprayable media in continuous as well as intermittent use. It is not suitable for spraying aggressive fluids such as acids, alkaline solutions, cleaning agents,

chemicals, etc. In case of doubt, please contact the manufacturer.

2.5 Incorrect Use

Operating the device with insufficient knowledge about the operation, maintenance and care of the

device.

Making changes, extensions or alterations on the device that may hamper its safety without the prior

consent of Walther Systemtechnik GmbH.

Operating the device with defective safety installations or not properly attached or malfunctioning

safety devices.

Using unsuitable materials.

Handling the device while energized.

2.6 Qualification of Personnel

Only trained and instructed personnel may conduct work on the equipment.

The responsibilities of the personnel for assembly work, operation, repair work or maintenance work must be

clearly assigned to individuals!

Persons in training may work with the equipment under supervision of an experienced person only.

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 6 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

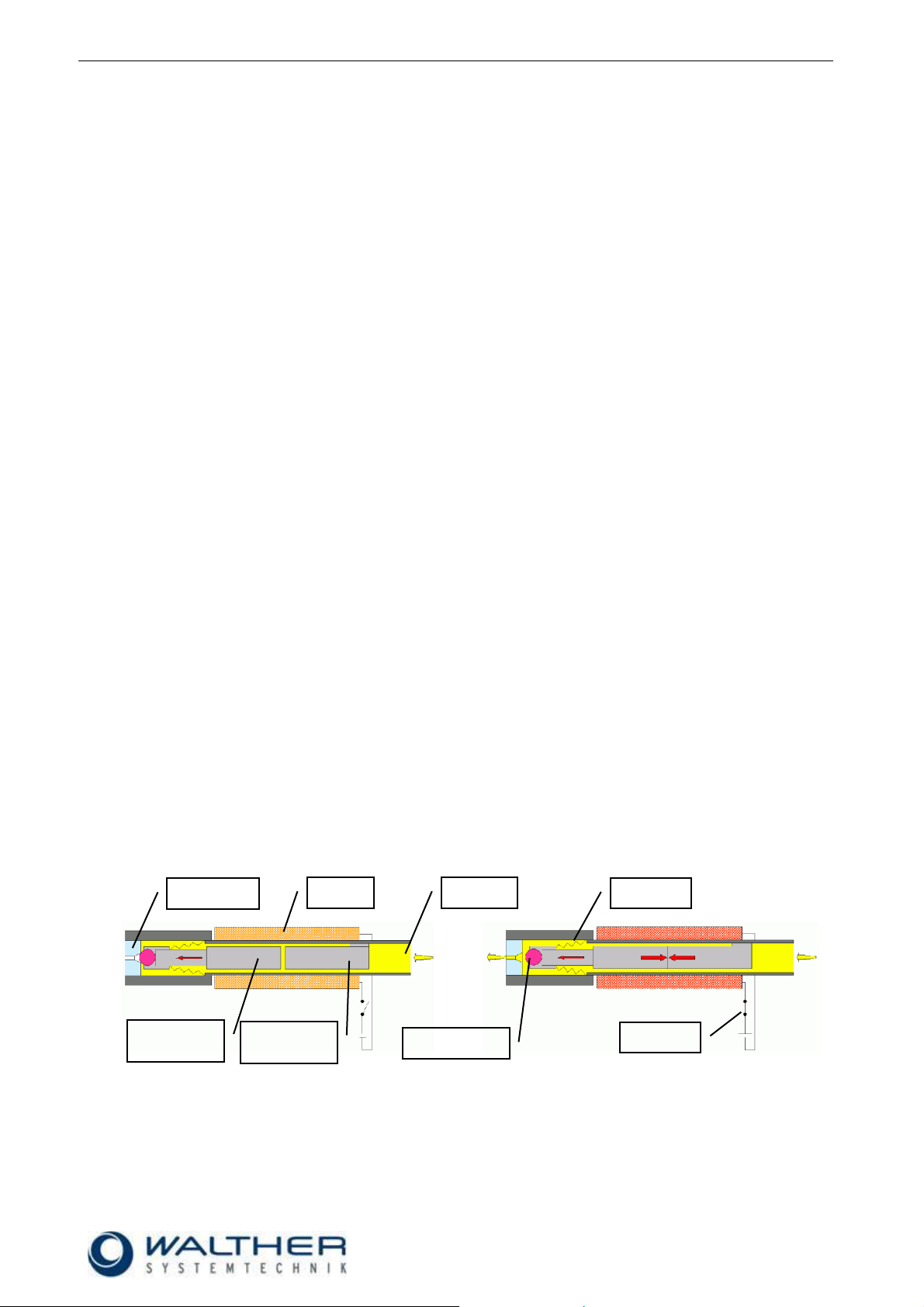

Coil without current (valve closed)

Coil with current (valve open)

Medium

Switch

Coil

Mobile

anchor

Spring

Valve seat

Stationary

anchor

Valve ball

3 Transport

3.1 Packaging

The type of packaging will be selected according to the mode of transport. If not separately negotiated, the

packaging will be made in accordance with the packaging directive of company Walther Systemtechnik

GmbH. This directive complies with HPE Packaging Regulations.

3.2 Tasks before Transport

The following tasks have to be fulfilled before the actual transport.

Disconnect energy supply lines

Extreme care has to be applied when transporting the incomplete machine and its individual parts in order to

avoid damages from external impacts or careless on- and off-loading. Depending on type and duration of

transport, appropriate transport securing devices have to be used. The incomplete device itself will be adjusted and leveled by appropriate fastening elements.

4 Functional Description

The MPP-Speed Micro Point Pulse Valve is an incomplete, electrically controlled application device designed for the application of materials such as greases, paints, oils, etc. If the power supply is cut off or fails,

the spring closes the needle. The medium is transported to the valve either out of a pressure tank or a pump.

4.1 Functional Principle

By using hard materials it is possible to achieve little opening strokes of only a few hundredths of a millimeter

in size. Also, an extremely high repeatability in the range of thousandths millimeters can be realized.

The MPP-Speed is electromagnetically operated. The medium flows around the nozzle sphere. The closing

spring acts on the mobile anchor with a valve ball. When there is a current feed through the valve coil, the

mobile anchor with the valve ball is magnetically pulled by the magnetic field of the stationary anchor. The

micro valve opens and the medium emerges. After pulsing, the nozzle is closed again by the closing spring.

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 7 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

4.2 Technical Data of Incomplete Device

Dimensions (length x width x height) [mm]

39 x 20 x 75,5

Weight [g]

approx. 87g

Pressure range [bar]

up to 50

Viscosity range [mPa.s]

1-1000 / optional / heated: higher depending on medium

Valve stroke [mm]

0,1(Standard) 0,03/0,06/0,15

Life expectancy

up to 500 mio. cycles

Max. allowed coil temperature [°C]

90

Max. dosing frequency [Hz]

up to 400

Min. control time [µs]

400

Repetition accuracy [CV]

< 5%

Minimal grid width [mm]

6

Dosable media

greases, oils, paint, UV glue / others upon request

Voltage [VDC]

24

Power consumption heating [W]

14,4

Current consumption heating [mA]

600

Nominal current [A]

1

Holding current [mA]

100-200

Coil resistance [Ohm]

6

Coil inductance [mH] (valve coil mounted on

MPP)

0,8

Electrical connection

Soldering pins/300mm strand, tin-coated or with plug 2poles Molex Type 70066-176

Recommended peak current [VDC]

24 during 400 µs (current limitation required for higher voltages)

Recommended hold current

0,2-0,3A / 1,2-2 VDC no time limit

Hold-Voltage

Peak-Time 500µs

Peak-Time 800µs

Peak-Time 1000µs

10%

15%

20%

25%

30%

40%

50%

60%

70%

80%

85%

90%

95%

General Data

Energy supply

4.3 Stress Test

Parameters:

- Shot Number: 3000

- Duration: 167sek.

- Temperature: 90°

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 8 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

The connection for the material will be determined with the actual order (screw connection can be ordered separately as accessories)

Connection for material hose

Connection for material hose

Connection for electronic

plug

Fastening thread (see

technical drawing)

4.4 Type Label

The type designation has been lasered near the material connection. Also the serial number has been

marked in this area.

5 Installation and Initial Start-up

The valves can be installed in any position. The distance to the surface to be applied with the medium

depends on the spray pattern.

Vibrations of the valve caused by fast intermitting cycles require solid and tight installation. Machine vibrations to the valves should be avoided.

5.1 Hose Connection

The material hose will be connected as follows:

5.2 Interfaces

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 9 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5.3 Electrical Interfaces

CAUTION

Do not point the jet at people. The wearing of eye protection is strongly recommended.

The valve must not be operated without a nozzle – it could be destroyed!

WARNING

Danger caused by flammable, harmful fluid. Always follow the safety instructions on the

container or the safety data sheet for the fluid.

IMPORTANT

A plant-specific setting is required for an optimal adjustment of the application pattern.

Starting values from laboratory tests can be used as a basis. However, these may

need to be adjusted for the specific plant. A combination of the following parameters is

necessary: nozzle size, opening time, opening stroke, material pressure and temperature (if applicable).

6 Operation

6.1 General Information

This device may only be operated if the safety-related equipment is permanently effective and not suspended during operation or altered in its intended effectiveness.

6.2 Operating Instructions / Operational Requirements

According to the individual application, up to 400 tacts per second can be reached under appropriate

operating conditions (material pressure, medium, length of hoses). The valve works starting with an opening

time from 400µs upwards. The opening time (in real time) must correspond with the theoretical value, in

order to enable constant opening and closing.

It is harmless to leave fluid in the valve during longer standstills if system stays under pressure (no

connection to outside air).

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 10 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Important

If high material pressures are required, the safety regulations of the trade association

must always be observed.

CAUTION

The “Peak- and Hold-Function“ must be used for all MPP-Speed valves. Otherwise, the

valve coil overheats and is destroyed.

(Impulse time = 400µs Holding voltage in % = 12)

6.3 Electrical Controls

The MPP-Speed pulsing valve works with a voltage of 24V DC and a material pressure of up to 50 bar. The

pulse valve is controlled via a control module (WLVC) (available as an accessory). ). To obtain a consistent

application pattern, the material supply must be kept constant.

In order to keep the heat development for the little opening times of the MPP Speed at a minimum and to

avoid overheating of the solenoid coil, controlling is done via the “Peak- and Hold-“procedure. The pulsing

valve is precisely opened with a temporarily increased peak current. After opening, a low holding current is

enough to keep the valve open. Due to the very small opening times and the “Peak- and Hold-Function“, it is

necessary to additionally integrate the WLVC control (if the existing control cannot fulfill this function).

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 11 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

IMPORTANT

Please follow operating instructions!

IMPORTANT

Please follow maintenance instructions!

IMPORTANT

Please follow maintenance instructions!

CAUTION

Before starting any maintenance or repair work, ensure that all air-operated tools are

depressurized and disconnected from the air supply.

Before opening the spray valve it must be disconnected from the air and fluid supply.

Otherwise, ejected components can cause injuries.

7 Taking out of Operation

7.1 Short Interruption

A short interruption (15 min and more) requires a clear-spraying.

7.2 Long-term Interruption

The following has to be observed for a long-term interruption of the system / device:

Disconnect material connection from pressure

7.3 Final Shutdown of System / Device

The following will be observed for a final shutdown of the system / device:

Clean pulse valve with a special thinner.

8 Maintenance and Repair

8.1 General

The MPP-Speed Micro Point Pulse Valves are high precision tools. Always keep clean and observe minimum instructions to maintain a long life of the valve. We recommend lubricating moveable parts regularly

and greasing threads, especially the nozzle threads, when replacing or cleaning the nozzle. Always use

clean and filtered material only. Maintenance also depends on the individual operating conditions and the

type of media used.

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 12 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

IMPORTANT

Only use soft brushes for outside cleaning of the nozzle tips. Never use metal tools

with sharp edges; see also Article No. 979444.

CAUTION

There is the potential of seriously damaging or destroying the nozzle.

CAUTION

Ensure that the valve is depressurized and disconnected from the air supply. Unscrew nozzle and deposit it in solvent if contaminated. Reinsert and screw tight cleaned nozzle.

.

IMPORTANT

Make sure that the O-ring at the upper part of the valve is not lost or damaged. If

necessary, slightly grease the nozzle shaft. The sealing ring is inserted below the

material connection.

8.2 Cleaning

Wash device thoroughly after use to remove residues and dirt.

Free-Spraying of Nozzle

Should the nozzle of the MPP-Speed be clogged by dirt or changes in the medium, there are several options

for re-enabling proper functions.

Increase the pulse frequency

Increasing the pulse frequency can remove solids and particles from the nozzle which can then be pulsed

off.

Example: opening time valve = 500µs, break time valve = 3000µs, number of shots 50

Rinsing with solvents

Rinsing with solvents will remove dried contamination from the nozzle. The effect can be enhanced by

simultaneously increasing the pulse frequency.

Ultra-sonic bath

Heavy contamination in the nozzle can be removed by placing the nozzle itself in an ultra-sonic bath. For this

purpose, the system has to be depressurized so that there is no more media pressure at the pulse valve.

Then unscrew the nozzle from the valve body and place it in the ultra-sonic bath.

Cleaning with a cleaning needle

You have to be extremely careful when cleaning with the cleaning needle (part of the cleaning kit). Carefully

and slowly insert the needle into the boring of the nozzle until you can feel a slight resistance.

8.3 Replacing Nozzle

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 13 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D-76726 Germersheim

Germany

Telephone ++49(0)7274-7022-0

Telefax ++49(0)7274-7022-91

E-Mail info@walther-2000.de

Internet www.walther-2000.de

IMPORTANT

First check all supply lines for connection and serviceability.

IMPORTANT

When clogged by cured medium, the nozzle can be cleared again by changing the Peek

time (normally 400µs, change to 600µs), or respectively the Hold voltage (from 12% to

20%). Additionally select several sequences with increased frequency in the selection field

WLVC “Folgeschuss/sequence shots”.

The nozzle can be also bathed in Acetone for several hours to clear clogging or in cases of

undefined dosing.

8.4 Customer Service / Support

9 Troubleshooting

9.1 General information

In case of serious problems that cannot be resolved, please contact the Walther Systemtechnik GmbH customer service.

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 14 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10 Appendix

10.1 Technical Drawing

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 15 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.1.1 Spare Parts Drawing

Pos.

Article No.

Qty

Description

1.01

979617–E01-001

1

Valve casing

1.02

979617–E01-002

1

Lid

1.03 4

Cylinder head stud (screw)

1.04

979617–E01-003

1

Sticker

1.05 4

Counter-sunk screw

1.06 1

Heating foil

1.07 * 1

Coil

1.08 1

Foil thermometer

1.09 1

Plug

1.10 1

O-ring

1.11 2

Cylinder screw

1.12 1

Threaded pin

1.13

979617–E02-001

1

Valve basic part

1.14

979617–E02-002

1

Valve top part

1.15

979617–E02-003

1

Connecting adapter

Pos.

Article No.

Description

1.07

979617-0,10

Nozzle Ø 0.1 mm

1.07

979617-0,15

Nozzle Ø 0.15 mm

1.07

979617-0,30

Nozzle Ø 0.3 mm

1.07

979617-0,45

Nozzle Ø 0.45 mm

1.07

979617-0,60

Nozzle Ø 0.6 mm

10.1.2 Spare Parts List

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 16 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.2 Possible Versions

Device type

Characteristic

MPP-Speed

Nozzle diameter

0.10 mm

x 0.15 mm

x

0.20 mm

x

0.30 mm

x 0.45 mm

x 0.60 mm

x

Material connection

Straight screw – Plug-in connection (high pressure)

x

Straight screw – Plug-in connection (PA 6/4)

x Cartridge connection with Luer-Lock-adapter

x

Cable length

5 m x

ohne Kabel / without cable

x

Picture

Article number

Description

97619400

Ring wrench for changing the MPP-Speed-Nozzle

(see Product Catalog ACCESSORIES)

979444

Cleaning set

(see also Product catalog ACCESSORIES)

979617-Kabel_5m

Connection cable for MPP-Speed length 5m

WLS-SPEED-V-R-

01Z001

Holder with fiber optic cables

for WLS-SPEED-V-R-01

Please note!! The use of Walther Light Barriers requires

centering recesses on the valves.

10.3 Accessories

Rev. 1.4

Assembly Instructions - Micro Point Pulse Valve MPP-SPEED

Page 17 of 17

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

WLS-SPEED-H-R-

01Z001

Holder with fiber optic cables

for WLS-SPEED-H-R-01

Please note!! The use of Walther Light Barriers requires

centering recesses on the valves.

10.3.1 WALTHER-Light barrier (WLS)

Figure 1 – Mounting a WLS-SPEED-H-R-01 with horizontal optical axis on a pulse valve MPP-SPEED

Figure 2 – Mounting a WLS-SPEED-V-R-01 with vertical optical axis on a pulse valve MPP-SPEED

Loading...

Loading...