Walthers Cornerstone, 933-2829 Series Manual

MODERN 130' TURNTABLE

HO Scale

Structure Built-up

933-2829

Thanks for purchasing this Cornerstone

Series

®

Built-up.

HISTORY OF THE TURNTABLE

Although we associate turntables with

steam locos, they’re still used in some

engine terminals. Requiring less space

than a wye or loop, they’re an economical way to reverse locos or cars. A

turntable is basically a large bridge

equipped with rails that can revolve in

a full circle. Around the turntable, a

series of radial tracks (other nicknames

were also used) run into roundhouse

stalls, open-air storage or service

tracks. So that all rails were at the

same height, the turntable was constructed in a large circular opening,

called a pit. Early pits were made of

earth or stone, while modern designs

used concrete.

The basic concept of the turntable

evolved before the railroad, when

crude examples were used to reverse

coal carts in mines. From the earliest

days, steam locos (as well as specialized equipment like snowplows and

observation cars) were built to operate

in one direction, and had to be turned

around for their return trip. By 1842, a

device we would recognize as a railroad turntable was in regular use in

England. Over the next century, the

turntable became a fixture of railroading around the world.

In America, three basic types developed. The first was the center-balance,

with a central pivot point and wheels

under each end of the bridge to support

the weight, but bigger and heavier

locos put too much strain on these

early turntables. The next was the

Articulated Design, with a central vertical hinge, which allowed the table to

tip in the direction of the greatest

weight. The final type (still seen today

and the prototype for this model) was

the Continuous Girder, which supports

the weight on a center pivot and on

load-

bearing wheels under each end.

Two styles of turntable bridges became

common. These included the Deck

Style, with most of the bridge below

ground level (requiring a deep pit) and

the Through Type, where a portion of

the bridge was above ground.

In order to swing the table end for end a

source of power was needed. In the

early days, men pushed the tables, and

they came to be called “armstrongs,” as

it took strong arms to do the job! In

later years steam and gasoline engines

were used to drive one set of the loadbearing wheels, but electric motors

were found to be the best choice for

most applications. Electricity was supplied to most tables by an arch over the

center, connected to overhead power

lines.

In most terminals, the turntable and

roundhouse were in constant use. For

easier and safer operation, turntables

had a small operator’s cabin at one end

of the bridge. This housed controls and

placed the operator in the best position

to align the rails. Many also sported an

old engine bell, which was rung to warn

that the table was being turned.

As was the case with most engine service facilities, new turntables were built

to accommodate the longest engines in

service on a division. For this reason,

some large engines were restricted to

one or two divisions where turntables

and facilities were big enough for them.

Railroads also went to extremes to utilize existing turntables. Some ordered

new steam locos with short wheelbases

so they would fit, others extended

turntable rails, and some resorted to

jacking up the end of the tender!

With the coming of diesels, the need for

turntables began to decline. Although F

units still had to be turned, the new

roadswitchers and Geeps could be run

in either direction. Today, the number of

turntables on active duty is declining,

but those in use can be found at major

shops and engine terminals. A few are

also in use at railroad museums.

ON YOUR LAYOUT

This 130' table is typical of units

installed by most roads from the 1920s

on at division point terminals, where

engines were changed and serviced. It

will easily accommodate large articulat

ed

steam locos and most diesels up to 18"

(45cm) long.

As bigger power came into service, bigger roundhouses were also required.

This can easily be modeled with the

Modern Roundhouse (933-2900) which

includes parts for three complete stalls.

It can be expanded up to a full circle

with the Modern Roundhouse Add-On

Stalls (933-2901) which includes

matching roof panels, doors and interior

truss work. Your new model will be

right at home alongside the Machine

Shop (933-2902), Modern Coaling

Tower (933-2903), Sanding Tower

(933-3182), Steel Water Tank (933-

3043), and Cinder Conveyor and Ash

Pit (933-3181) as well.

In many bigger cities, the terminal was

part of the railroad’s shop complex,

which can be modeled with the

Backshop (933-3039) and Car Shop

(933-3040).

For more ideas to detail your scene, ask

your dealer, visit walthers.com or see

the latest Walthers HO Scale Model

Railroad Reference Book.

For additional prototype history and

information on turntables, see “The

Locomotive Merry-Go-Round” by

James Alexander Jr. in the July 1995

issue of Trains magazine. Your local

library may also have copies of older

Railroad Maintenance Cyclopedias,

which provided basic information on

turntables and other facilities.

©2004 Wm. K. Walthers, Inc.

Milwaukee WI, 53218

933-2829 I sheet 12/2/04 10:22AM Page 1

INSTALLATION ON YOUR

LAYOUT

Your new turntable has been carefully assembled and tested to provide years of enjoyable operation.

Please take a few minutes to look

over the parts, read these instruc

tions

and study the drawings before

starting.

Your new turntable drive should be

powered from its own power pack,

sold separately. Check the output

of the transformer with a voltmeter

before making any electrical con-

nections. The drive operates best at

15 Volts AC or DC, 500mA; a

minimum of 12 Volts is required,

but total output must not exceed 19

Vo lts AC (RMS) or DC.

INSTALLING THE PIT

Your new turntable automatically

reverses track polarity when

turned. As a result, the unit has two

electrically insulated areas where

the track on the bridge is not powered. These are identified on the

underside of the lip by the “NO

TRACK” lettering (also shown on

the mounting template). Working

approach and fan tracks must be

installed away from these areas –

we suggest placing them at 90° to

the approach tracks. You can, however, add an unpowered display

track at these points if desired.

The opening in the wall of the pit

houses the optical sensor used as

the “zero point.”

For the indexing to work properly,

this area, along with the small gear

teeth and ring rail molded in the

bottom of the pit, must be clean

and open at all times. If you plan

to paint or weather the pit further,

mask off these areas before starting.

Befor

e installing the pit, cover

the center pivot hole with tape to

keep out dust and debris.

For best results your new turntable

must be installed on a flat, level

surface. Determine the location for

your pit; use the enclosed template

to cut the mounting hole in your

benchwork. Allow at least 2-1/4"

(5.7cm) of clearance below the pit.

The zero reader is mounted directly below a mounting boss; be sure

to provide clearance in your bench-

work for the reader too.

If your pit will be mounted on a

wooden surface, drill out the areas

for the mounting bosses as shown

on the template with a 5/16"

(8mm) bit. Secure the pit in place

using the eight screws and washers

— if the thickness of your wood

surface is less than 1/2", use additional washers (not included) for

correct spacing — do not over

tighten as this could cause the pit

to warp.

If you are using foam for the surface of your layout, open the areas

for the mounting bosses slightly

and push the pit into place.

Make sure the pit is level, secure

and properly supported before

proceeding.

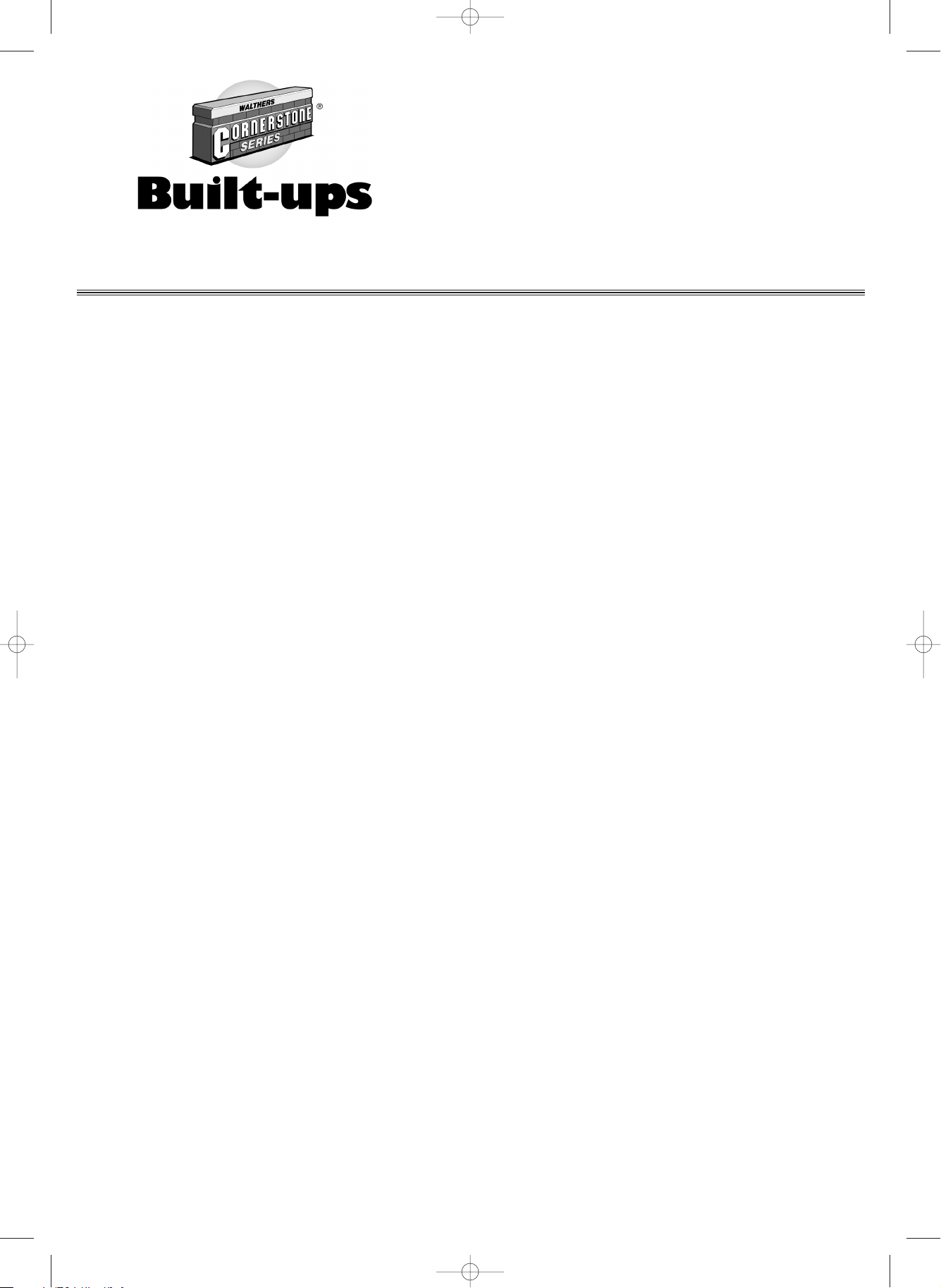

POS: Red LED comes on

when the turntable is in a

programmed position.

POWER: Red LED stays

lit when power is on.

RIGHT/LEFT ARROW: Use to move

and stop the bridge.

ZERO: Use to locate the zero point.

SET: Use to program

the stopping points.

INSTALLING THE CONTROL

BOX

This unit is used to program and

operate your turntable. As noted

above, we suggest a dedicated

power pack be used as a power

supply. Do not attempt to run the

turntable at this time.

The control box can be used as-is,

or flush-mounted on the surface or

side of your layout. Simply remove

the four screws from the back to

remove the front panel. Cut a

mounting hole with the template,

place the front panel in the opening

and reattach the back.

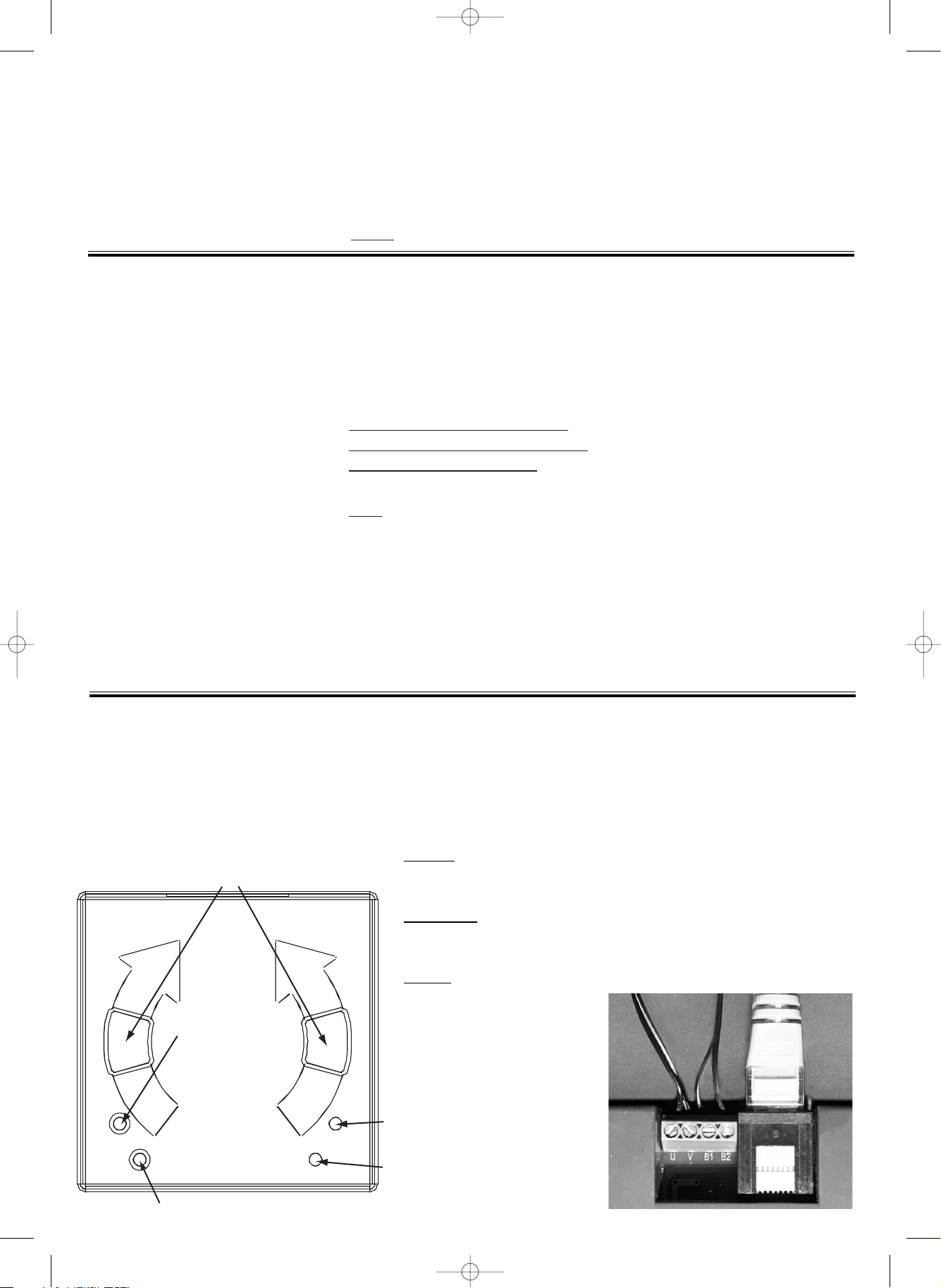

Wiring

Connection points are marked

on the underside as follows:

B1 and B2

= connect to rail

power supply; powers bridge

rails.

U &

V = connect to AC terminals on power pack; powers

drive mechanism.

All wires are secured using the

small screw terminals.

Plug in the large gray cable

from the indexing unit (located

beneath the pit) into the port

on the side of the control box.

933-2829 I sheet 12/2/04 10:23AM Page 2

Loading...

Loading...