Das WALTHER PILOT-Programm

• Hand-Spritzpistolen

• Automatik-Spritzpistolen

• Niederdruck-Spritzpistolen (System HVLP)

• Zweikomponenten-Spritzpistolen

• Pulverbeschichtungs-Systeme

• Materialdruckbehälter

• Drucklose Behälter

• Rührwerk-Systeme

• Airless-Geräte und Flüssigkeitspumpen

• Materialumlaufsysteme

• Kombinierte Spritz- und Trockenboxen

• Absaugsysteme mit Trockenabscheidung

• Absaugsysteme mit Naßabscheidung

• Pulversprühstände

• Trockner

• Zuluft-Systeme

• Atemschutzsysteme und Zubehör

WALTHER Spritz- und Lackiersysteme

Kärntner Str. 18-30 • 42327 Wuppertal

Telefon: 0202 / 787-0 • Telefax: 0202 / 787-217

www.walther-pilotde • E-Mail: info@walther-pilot.de

WWAALLTTHHEERR PPIILLOOTT

Operating Manual

PPIILLOOTT

Extrusionspistole

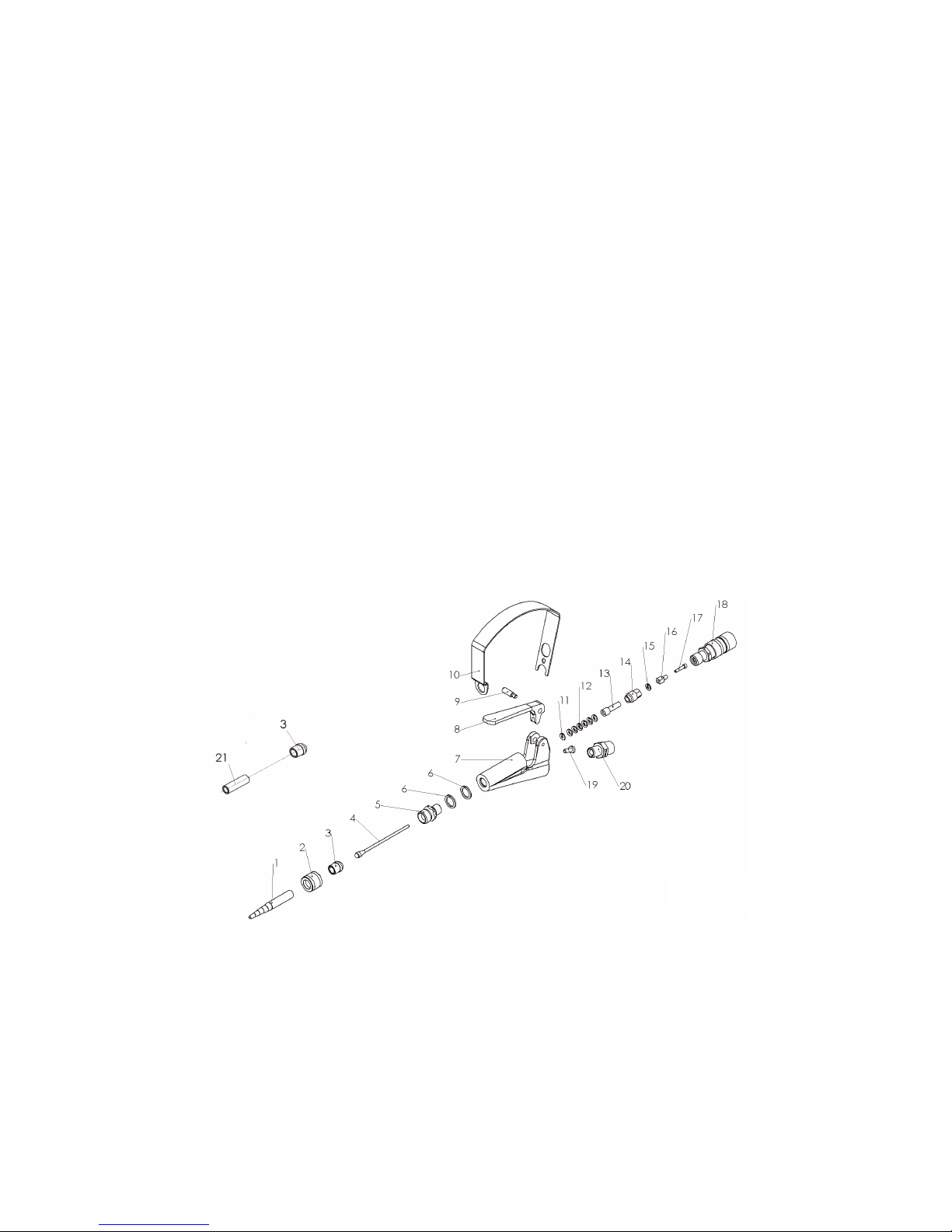

13

14

15

16

17

18

19

20

21

1

2

3

4

5

6

7

8

9

10

11

12

V 10 250 19 000

V 10 250 22 000

V 10 250 13 000

V 10 250 21 000

V 10 250 02 000

V 10 250 10 000

V 10 250 03 000

V 10 250 14 000

V 10 250 15 0SP

V 10 250 15 000

V 10 250 17 000

V 10 250 16 000

V 10 250 11 000

V 10 250 12 000

V 10 250 24 000

V 10 250 01 000

V 10 250 23 000

V 10 250 18 000

V 10 250 25 000

V 10 250 20 000

V 10 250 26 000

Packing Pressure Pin

Packing Screw

Washer

Adjusting Nut

Cylinder Head Screw

Back Bushing

Screw

Double Nipple

Special Nozzle

Step Nozzle

Cap Nut

Adapter

Material Needle Complete

Valve

Gasket (2 pieces)

Gun Body

Trigger

Bolt Screw

Safety Guard

Packing support washer

V - Packing (6 Stück)

Additional Nozzle Option

We recommend that you keep all the bold parts (wearing parts) in stock.

Repair Kit : V 16 250 00 000

Pos.Nr.

Part Number Part Name

Pos.Nr.

Part Number Part Name

PILOT Extrusionspistole (Teflon®-coated)

Art.-Nr. V 10 250 40 000

DIffering Part:

7 V 10 250 01 Tef

Gun Body

Spare Parts List

Part.-No. V 10 250 00 000 (350 bar)

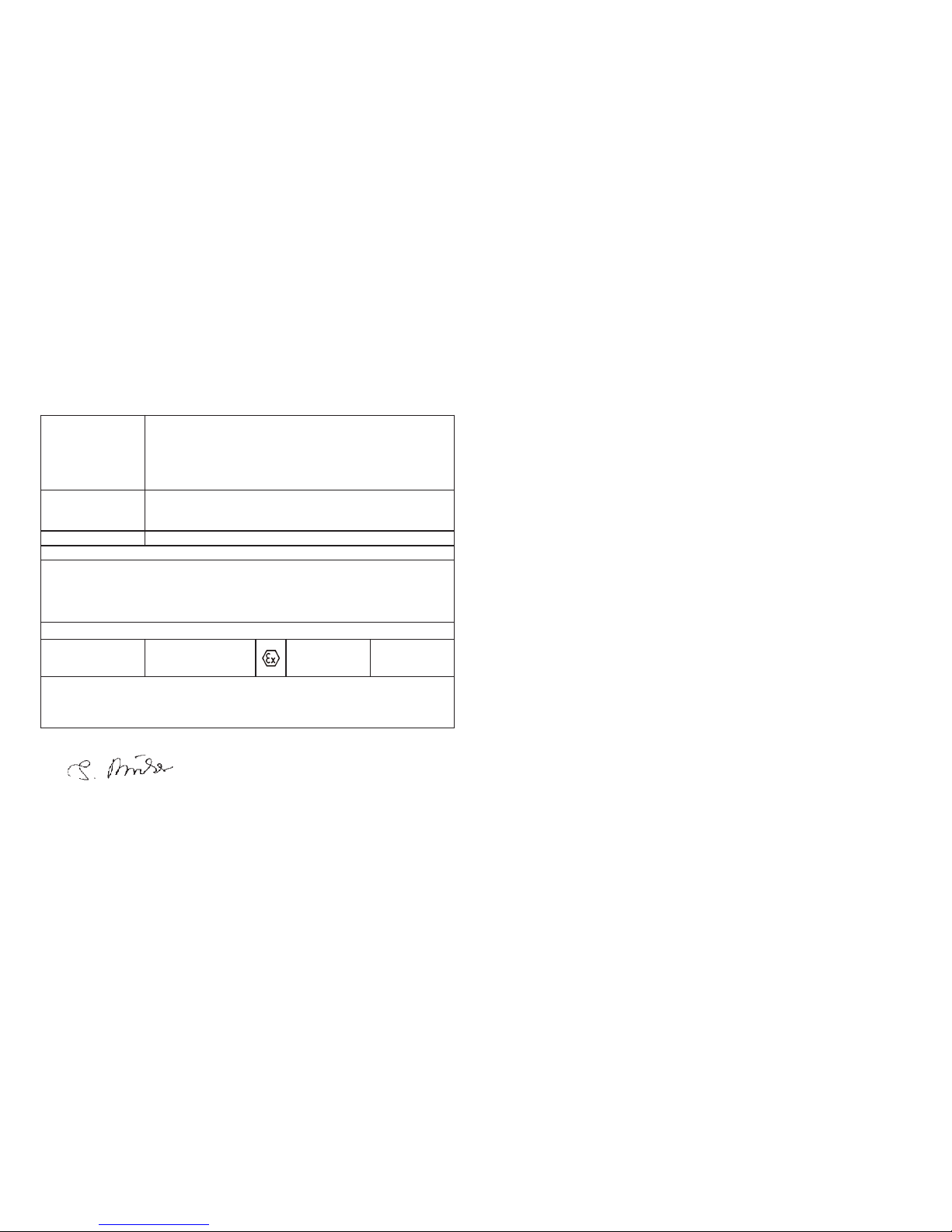

EC Declaration of Conformity

We, the equipment manufacturer, declare under our sole responsibility that the

product in the description below corresponds to the relevant basic safety and

health requirements. Any unauthorized modifications are made to the equipment or

improper use of this declaration loses its validity.

Wuppertal, den 7. Juli 2003

Name: Torsten Bröker

Stellung im Betrieb: Leiter der Konstruktion und Entwicklung

Diese Erklärung ist keine Zusicherung von Eigenschaften im Sinne der Produkthaftung. Die Sicherheitshinweise der

Produktdokumentation sind zu beachten.

1

1.1

1.2

1.3

General

Model Identification

Intended Use

Inappropriate Use

2

Technical Description

3

3.1

3.2

Safety Instructions

Identification of Safety Instructions

General Safety Instructions

4

4.1

Assembly

Supply Line Connection

5

5.1

5.2

5.3

5.4

5.5

Operation

Safety Information

Start-up and Shut-down

Setting Material Flow Rate

Regulating Material Pressure

Retooling Extrusion Gun

6

6.1

6.2

6.3

Cleaning and Maintenance

Safety

Basic Cleaning

Routine Cleaning

7

7.1

7.2

7.3

Repair

Replace Leaking Valve Seat

Replace Leaking Gasket

Replace Leaking Material Needle

8

Troubleshooting and Solutions

9

Disposal

10

Technical Data

Contents

1

i.V.

Hersteller WALTHER Spritz-und Lackiersysteme GmbH

Kärntner Str. 18-30

D-42327 Wuppertal

Tel.: 0202 / 787-0

Fax: 0202 / 787-217

www.walther-pilot.de • Email: info@walther-pilot.de

Typenbezeichnung PILOT Extrusionspistole

V 10 250 00 000

V 10 250 40 000 (Teflon

®

-beschichtet)

Verwendungszweck Verarbeitung spritzbarer Materialien

Angewandte Normen und Richtlinien

EG-Maschinenrichtlinien 98 / 37 EG

94 / 9 EG (ATEX Richtlinien)

DIN EN 292 Teil 1

DIN EN 292 Teil 2

DIN EN 1953

Spezifikation im Sinne der Richtlinie 94 / 9 / EG

Kategorie 2 Gerätebezeichnung II 2 G c T 6

Tech.File,Ref.:

2409

Besondere Hinweise :

Das Produkt ist zum Einbau in ein anderes Gerät bestimmt. Die Inbetriebnahme ist so

lange untersagt, bis die Konformität des Endproduktes mit der Richtlinie 98 / 37 / EG

festgestellt ist.

1

1.1

General

Model Identification

Models:

PILOT Extrusion Gun

(350 bar)

Type:

Part.-Nr.

V 10

250 00

000

V

10 250

40 000

(Teflon®-

coated)

Manufacturer:

WALTHER Spritz-und Lackiersysteme GmbH

Kärntner Str. 18-30

D-42327 Wuppertal

Tel.: 0202 / 787-0 • Fax: 0202 / 787-217

www.walther-pilot.de • Email:info@walther-pilot.de

1.2 Intended Use

The PILOT Extrusion guns are for the processing of sprayable media, such as:

•

Pasty Materials

•

Greases, oils, and corrosion inhibitors

•

Adhesives and glues

•

Waxes, Bitumen, Silicones, and Kit

Using the device in potentially explosive atmospheres. The device complies with the

ATEX requirements of the directive 94/9 EC (ATEX 100a) for explosion group,

category and temperature class marked on the rating plate. When operating the

device, the specifications of this manual must be followed.

The prescribed inspection and maintenance intervals are required.

The information on the equipment rating plates or the information in the chapter

technical data must be maintained and must not be exceeded. An overloading of

equipment must be ruled.

The device may be used in potentially explosive atmospheres only with the

competent supervisory authority.

The competent authority or the operator is responsible for determining

the

explosion hazard (zone classification).

It is operator must check and ensure that all technical data and the marking according

to ATEX conform to the required standards. Applications in which the failure of the

device could be a danger to persons intro-duced are operator must provide

appropriate security measures. Grounding / potential equalization

It must be ensured that the extrusion gun is properly grounded

(m

aximum resistance 106 Ω).

2

If abnormalities are detected during operation, the unit must be shut down

immediately and it is to keep up with WALTHER PILOT consultation.

1.3

Improper Use

The extrusion gun shall not be used otherwise than 1.2 Intended use is wr

itten in

the

section.

Any other use is improper.

To inappropriate use include, for example:

•

spraying of material on people and animals

•

the spraying of liquid nitrogen.

2

Technical Description

The WALTHER PILOT extrusion gun is a gun that can be processed by the

existing material pressure of the pump extrudable materials. The max. Operating

pressure is 350 bar .

The gun body is made of cast aluminum and the model V 10 250 40 000 is for

easy cleaning Teflon ® coated. The medium to be processed is supplied to the

extruding gun of a piston or diaphragm pump under pressure. When you press the

trigger , the medium is pressed out of the stage nozzle ( extruded) .

In the PILOT extrusion gun , the material pressure is controlled by the pump and

the amount of material can then be finely adjusted by an additional 18 of the

securing bushing Pos . The scope of the extrusion gun consists of the airless ,

caterpillar -shaped dispensing of pasty materials. It can thermoplastics,

elastomers , silicones , greases , adhesives, glues , waxes , etc. , depending on

the consistency of workable materials are extruded . The stage nozzle has

different diameter sizes . By severing at the respective notch you can the change

required nozzle diameter maximum.

3

3.1

Safety

Identification of Safety Instructions

Warning

This picture and the accompanying warning note "Warning" indicate possible risk

and dangers to yourself.

Caution

This picture and the accompanying note "Caution" indicate possible damage to

equipment, workpieces, etc.

Notice

This picture and the accompanyingnote "Notice" indicate additional and useful

information to help you in handling the spray gun with even greater confidence

and efficiency.

l

l

3

3.2

General Applicable Safety Precautions

All applicable accident prevention rules and regulations as well as other

recognized industrial safety and health rules and regulations must be observed

at all times

Use the spray gun only in well-ventilated rooms. Fires, naked light and smoking are

strictly prohibited in the working area. WARNING - during the spraying of flammable

materials (e.g. lacquers, adhesives, cleaning agents, etc), there is an increased risk to

health as well as an

increased risk of explosion and fire.

An adequate grounding of the extrusion gun is to ensure, for example, through the

fluid hose (maximum resistance 106Ω).

Before carrying out any maintenence or service work, always ensure that the air and

material feed to the spray gun have been de-pressurized. The extremely high pressure

at the gun or pump outlet can cause serious injury.Risk of injury!

When spraying make sure your hands and other body parts are clear from the

pressurized nozzle of the extrusion

gun - the extremely high injection pressure can

cause serious injury.

Use diaphragm or piston pumps only in the context of a fluid regulator to prevent the

maximum allowable operating pressure of 350 bar can not be exceeded.

Do not point the extrusion gun towards people or animals - risk of injury.

Always observe the spraying and

safety instructions given by the manufacturers of

the spraying material and the cleaning agent. Aggressive and corrosive materials in

particular can be harmful to health.

Exhaust air containing particles (overspray) must be kept away from the working

area and presonnel. In spite of these measures, always wear the regulation

breathing masks and protective overalls

when using the gun. Airborne particles

represent a serious health hazard!

After carrying out assembly or maintenance work, always ensure that all nuts, bolts

and screw connections have been fully tightened before the gun is used.

Use only original replacement parts, since WALTHER canonly guarantee safe and

fault-free operation for original

parts.

For further information on the safe use of the spray gun and the spraying

materials, please contact WALTHER Spritz- und Lackiersysteme GmbH, D-42327

Wuppertal.

4

4

Assembly

Warning

Material lines that are attached with a hose must additionally be secured by a

hose clamp.

Warning

Risk of Injection. Spray from the dispensing valve, leaks, or ruptured components can

inject material into the

body and cause serious injury, including the need for

amputation.

•

Although material injected into the skin may look like an ordinary injury, these are

extremely serious

injuries. If injection occurs, get immediate medical attention.

•

Nozzle valve should never be pointed at people of body parts

•

Do not put your hands or fingers over the nozzle valve.

•

Never use the Extrusion gun without the trigger guard.

•

Before each use, make sure that the gun trigger safely operates the valve.

•

Always lock the trigger safety valve when not in use.

•

Before performing any cleaning, checking or servicing the equipment or clogged

valve nozzle following the steps given in 5.2 Starting and shutting down.

•

All fluid connections must be checked and tightened before start-up.

•

Inspect hoses, tubes, and couplings daily. Replace worn, damaged, or loose

parts immediately. Damaged hoses should not be repaired. In this case, the

entire hose

should be replaced.

4.1

Supply Line Connection

Warning

Us

e the pump only in the context of a fluid regulator to prevent the maximum

allowable operating pressure of 350 bar can not be exceeded.

Material connection:

Attach the supply line at the connection item 20 of the extrusion gun. Maintain a

tight screw.

Notice

Use only grounded fluid hoses with a maxim

um total length of 150 m in order to

ensure a continuous ground and they must be resilient enough for an operating

pressure of 350 bar. Check the electrical resistance of the fluid hoses at least once

a week. If the hose does not have a label, on which the maximum electrical

resistance is specified, the maximum resistance values can be obtained from the

manufacturer. If the resistance exceeds the recommended limits, replace the hose

immediately concerned.

The gun is now ready for operation.

5

l

l

l

Shut-down

1.

Release the trigger lever fully and screw in the safety button (back bushing item 18)

until it stops.

2.

Turn off material supply to the pump.

3.

Place the trigger guard Item 10 firmly to a grounded metal pail, turn on the

safety button and pull the trigger lever to relieve the pressure.

4.

Open the pressure relief valve (on site) on the pump to increase the pressure

from the pump, the valve and out of the hoses. The pressure relief valve

should remain

open until work resumes. Triggering the gun may not be

sufficient to relieve the pressure. Keep a container handy to collect any

leaking material.

Warning

The entire extrusion line must be always depressurized after work. The

pressurized

pipes can burst and injure persons close by the outflowing material.

5.3

Setting the Material Flow Rate

The setting of the material flow rate - and thus the spray jet width - shall be

initially based on the selection of a suitable nozzle size. Setting the material

pressure regulator on the material and on the safety button of the back bushing

(Item 18) may also be affect the flow rate.

5.4

Regulating Material Pressure

The suitable material pressure you place on the pump (air

pressure regulator on

site) and the material pressure regulator. Pay attention to the instructions and

safety of the manufacturer.

7

5

5.1

Operation

Safety

Observe the operation of the extrusion gun in accordance with the follow-the safety

instructions!

•

When work is interrupted, the extrusion system must be depressurized.

•

Wear proper respiratory protection and work clothes when you extrude the

extrusion gun materials. Airborne particles hazardous to your health.

•

In the workspace, Fire, naked flame and sm

oking is prohibited. Spraying of highly

flammable materials (eg glue) th

ere is an increased ris

k of explosion and fire.

5.2

Start-up and Shut-down

Notice

Before first using the extrusion gun, flush it out with solvent to ensure that it is

clean.

Warning

Turn power off before refitting the extrusion pressure from the system and check

the gauge, otherwise there is

a risk of injury.

Before you can set the extrusion gun in operation, the fluid pressure must be

available at the extrusion gun.

Caution

The material pressure must not be set higher than:

- 350 bar

Start-up

1.

Before first use, the trigger lock is locked by screwing in the safety button until it

stops at the back bushing Item 18.

2.

Set the pump to minimum speed required to extrude the material with a

satisfactory discharge rate.

3.

Slowly unscrew the safety button (back bushing Item 18) and press the trigger

Item 8 to achieve the

desired discharge rate. If there is not enough speed, then

the appropriate discharge rate can be further tuned alternating between safety

button and pump (on site air pressure regulator).

4.

If the settings are correct, you can start with the extrusion process.

6

l

l

l

5.5

Retooling Extrusion Gun

Warning

Turn off pressure retooling the extrusion gun from the system and check the

gauge, otherwise there is a risk of injury.

Warning

Disconnect all supply lines before retrofitting any supply of material to the

extrusion gun-injury.

Notice

To carry out the operations listed below, please use the drawing at the beginning

of this manual.

Change Fluid Nozzle

1.

Remove the Cap Nut (Item 2)

2.

Remove the fluid nozzle (Item 1), together with adapter (Item 3) from the valve (Item 5)

•

Now you can unscrew the step nozzle from the adapter, look for the notch

indicating the appropriate diameter (see

drawing) and cut it off at the notch.

•

But you can also use our special nozzle (Item 21).

Assemble in reverse order.

Replacement of Material Filter

For appropriate filtering of the material, you can use coarse-and fine-mesh filter.

1.

Make sure the complete extrusion system is depressurized

2.

Remove the hose material / material hoses.

3.

Remove the material filter.

Assemble in reverse order.

8

Change Material Needle

1.

Remove the cap nut (Item 2)

2.

Remove the fluid nozzle (Item 1), together with adapter (Item 3) from the valve (Item 5)

3.

Unscrew the needle securing (Item 18) from the gun body (Item 7)

4.

Twist out bolt screw (Item 9) to remove the trigger.

5.

Loosen the cylinder screw (Item 17) turn the adjusting nut (Item 16) of the fluid

needle (Item 4) and take the washer (Item 15).

6.

Turn the valve (Item 5) out of the gun body (Item 7).

7.

Pull the fluid needle (Item 4) from the gun body.

The assembly is done in reverse order, with needle valve and back bushing

applied with a high-strength adhesive.

Notice

An exact setting dimension does not exist. The adjustment nut is screwed as long

until the trigger play is approximately 5 mm and is secured to the cylinder screw

against rotation.

6

6.1

Cleaning and Maintenance

Safety

•

Turn power off before servicing the extrusion pressure from the system - risk

of injury.

•

Disconnect all material pressure before performing any maintenance to the extrusion gun.

•

In the workspace, Fire, naked flame and smoking is prohibited. Spraying of

highly flammable materials (eg cleaning agents) there is an increased risk of

explosion and fire.

•

Notice. the safety precautions of the detergent manufacturer's warnings.

Aggressive and corrosive cleaning agents can cause health damage.

6.2

Basic Cleaning

In order for the service life and function of the extrusion gun to be maximized,

the extrusion gun must be cleaned and lubr

icated.

Caution

Never place the extrusion gun in solvent or

other cleaning agents. The proper

function of the extrusion gun can not otherwise be guaranteed.

Caution

When cleaning any hard or sharp objects. Pr

ecision parts, extrusion gun may

be damaged and deteriorate the extrusion result.

9

l

l

l

l

To clean the extrusion gun cleaning solutions that are specified by the manufacturer

of the extrusion material and do not contain the following ingredients:

•

halogenated hydrocarbons

(eg 1,1,1, trichloroethane, methylene chloride, etc.)

•

Acids and acidic detergents

•

regenerated solvents (so-called cleaning dilutions)

•

Paint stripper.

The above-mentioned Constituents cause electroplated components, chemical

reactions and lead to

corrosion damage.

For damages resulting from such treatment, WALTHER PILOT makes no warranty.

Clean the extrusion gun

•

before any material change

•

at least once a week

•

depending on material and depending on the degree several times a week.

This will give you the safe function of the extrusion gun.

Warning

Turn off the extrusion pressure before cleaning the system (see 5.2 Starting and

shutting down).

1.

Disassemble the pistol as described in 5.5 extrusion gun retooling.

2.

Clean the fluid tip with a brush and cleaning agent.

3.

Clean all remaining parts and the gun body with a cloth and detergent.

4.

Lubricate the following parts with a thin film of grease:

•

material needle

•

valve

•

all moving parts and bearings

•

The internal moving parts must be lubricated at least once a week.

•

The springs should be constantly provided with a thin layer of grease.

Use an acid-free, non-resinous grease and a brush or enter a drop of oil from a

dosage bottle.

Then, the extrusion gun is set together in reverse order.

6.3

Routine Cleaning

When changing material or after work, you c

an also clean the extrusion gun, without

having

to

disassemble it.

W

arning

Tur

n off the extrusion pressure from the system before cleaning (see 5.2 Starting

a

nd shutting down).

10

Before you perform the Routine maintenance, the following condition must be met:

•

Make sure that the cleaning agent used to the process fits the material. Perform the

following steps:

1.

Place the extrusion gun into operation (see 5.2 putting into operation).

2.

Flush the gun with the lowest possible pressure.

3.

To maintain grounding continuity when flushing must ensure the gun to be

pressed firmly

against one side of a grounded metal pail, then trigger the

gun.

4.

Spray the extrusion gun until only a clear detergent is sprayed from the gun.

The entire extrusion line should now be depressurized until the next use.

7

Repair

Warning

Turn power the extrusion pressure from the entire system before servicing (see

5.2 Starting and shutting down).

Warning

Disconnect all

power before any repairs, the material feed to the extrusion

gun - risk of injury.

Notice

To carry out the operations listed below, please use the drawing at the

beginning of this manual.

7.1

Replace Leaking Valve Seat

1.

Remove the fluid nozzle in accordance with 5.5 retooling extrusion gun.

2.

Turn the valve (Item 5) out of the gun body (Item 7).

3.

Replace the two seals (Item 6) with new ones.

4.

Before beginning turn the valve again, you should secure the thread with a highstrength adhesive coat to achieve optimum sealing.

The assembly of the remaining components is carried out in reverse or

der.

7.2

Replace Leaking Gasket

1.

Remove the fluid nozzle and needle material as described in 5.5 extrusion gun

retooling.

2.

Turn the pack screw (Item 14) with the packing pressure pin (Item 13) from the gun

body.

11

l

l

l

l

8

Troubleshooting and Solutions

W

arning

Make

sure

the

entire

extrusion system is depressurized before servicing.

W

arning

Prior

to

any

repair

material supply must be shut off - risk of injury.

9

Disposal

The costs incurred in cleaning and maintenance materials should be disposed

of in accordance with the laws and regulations properly and professionally.

Warning

Pay

particular attention to the instructions of the manufacturer of extrusion and

detergent. Risk to the health of humans and animals.

10

Technical Data

Net Weight

Nozzle equipment of your choice:

570 g

Stage Nozzle (Item 1)

Special Nozzle (Item 21)

350 bar

Pressure Range

max. pressure.

Operating Temp:

42°C

Subject to technical changes.

13

3.

Remove the V-pack (Item 12) and the packing support plate (Item 11) out of the

gun body. To do this, use a solid wire whose end is bent into a small hook.

4.

Now replace the new packing support washer and new V-pack in the gun body.

To do this, use a special tool that has the shape of the packing pressure pin. With

the difference that the tool

has a pin at the front the inner diameter of the V-pack.

Install the components individually.

5.

Now turn the screw pack with pushpins in again.

6.

Before the packing bolt is tightened, slide in the material needle from the front.

After tightening, the material needle should still be movable.

The assembly of the remaining components is carried out in reverse order.

Notice

The parts taken from the gun use parts should not be re-used, otherwise a

functionally reliable sealing effect is not guaranteed.

7.3

Replace Leaking Material Needle

Disassemble the pistol as described in 5.5 extrusion gun retooling.

Assemble in reverse order.

Notice

All moving and sliding parts must be greased before installation in the gun body

with an acid-free, non-gumming grease.

Repair Kit:

WALTHER PILOT repair kit available that contains all wearing parts for the PILOT

EXTRUSION GUN (350 bar).

Part. No.: V 16 250 00 000

Consisting of: material needle assy. (Item 4), valve (item 5), seal 2x (item 6),

packing support washer (item 11), V-Pack 6x (key 12), packing pressure pin (item

13), washer (item . 15).

12

Problem Cause Remedy

Leak at the nozzle •Material needle (Item 4) Check settings

or Replace material

needle

Too little material

•

Dirty filter

•

Nozzle too small or

clogged

•

Fluid pressure too low

-Clean

-Choose larger diameter

or clean

Valve seat leak

•

Worn seals

•

Worn valve

-Increase fluid pressure

-Replace seals

-

Replace valve

Fluid leaks fromgun

body

•

Packing (Item 12) leaking -Repl

ace packing

l

l

l

Loading...

Loading...