WALTHER PILOT PILOT TERRA Operating Instructions Manual

WALTHER PILOT

Betriebsanleitung / Operating Instructions

Mode d’emploi / Instrucciones de Servicio

Инструкция по эксплуатации / 使用说明书

Spritzpistole / Spray gun / Pistolet de pulvérisation

Pistola de pulverización / Пистолет-распылитель / 喷枪

PILOT TERRA

REV. 06/15

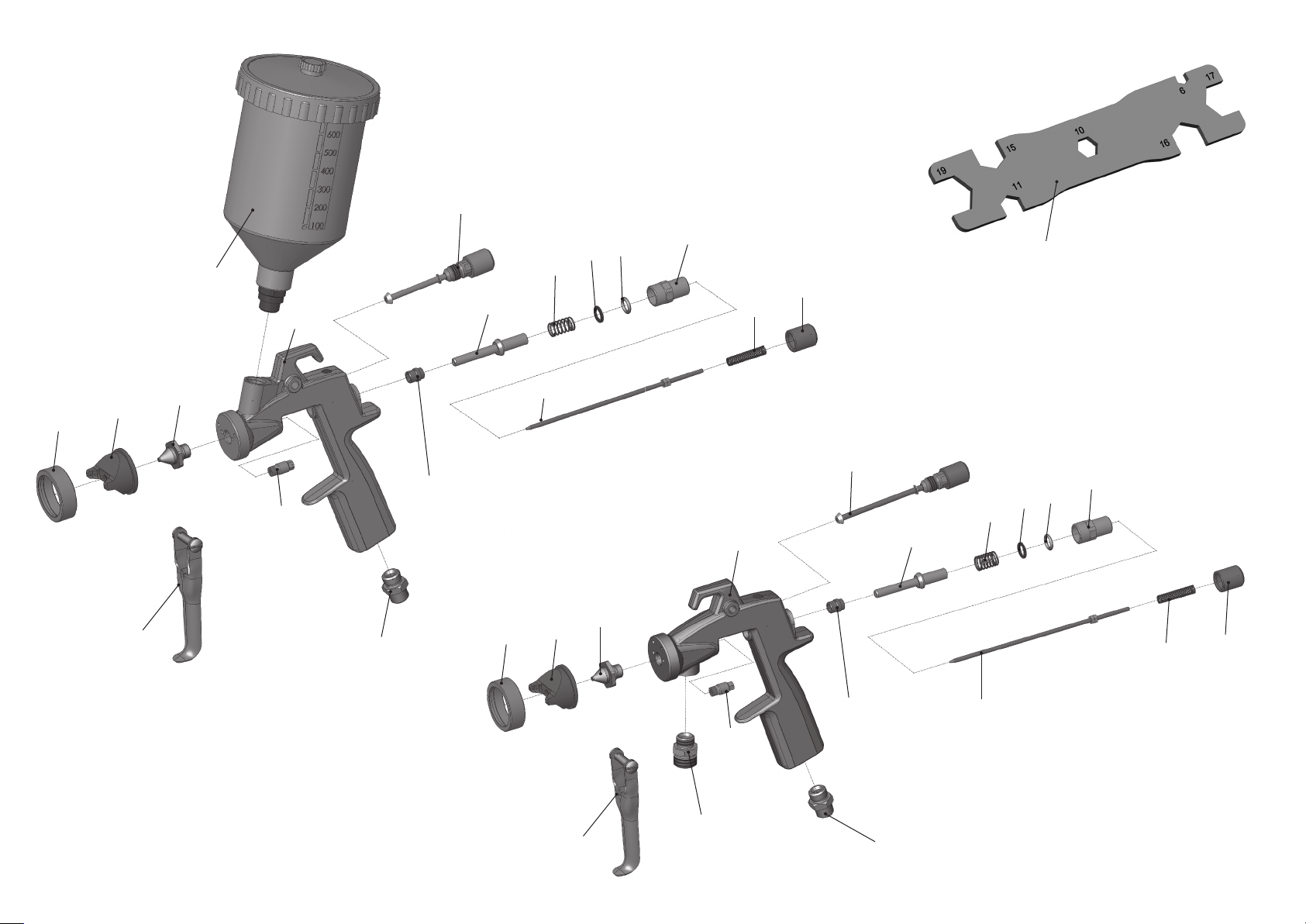

8

5.5

5.4

13

4

1

2

3.1

5.1

3.2

11

10

5.2

5.3

3.3

3.1

1

2

6

12

7

3.4

PILOT TERRA Materialanschluss / Material Connection /

raccordement matière / toma de material / Патрубок для

материала / 物料连接

8

6

5.5

5.4

5.3

4

5.2

3.4

7

PILOT TERRA Fließbecher / Gravity-Feed Cup /

à godet gravité / depósito de gravedad /

Наливной стаканчик / 喷壶

2

5.1

3.2

9

11

10

3.3

Stand: August 2014

3

Contents

Exploded Drawing 2

Declaration of CE-Conformity 21

Replacement parts 22

1 General 24

1.1 Model identification 24

1.2 Intended use 24

1.3 Inappropriate use 25

2 Technical description 25

3 Safety instructions 25

3.1 Identification of safety instructions 25

3.2 General Safety instructions 26

4 Supply line connection 27

5 Operational Handling 27

6 Spray pattern adjustments 28

6.1 Correcting spray pattern flaws 29

7 Troubleshooting and fault rectification 29

8 Conversion and repair 30

9 Cleaning 31

10 Waste disposal 32

11 Technical Data 32

20

Declaration of CE-Conformity

We, the manufacturers of the equipment, hereby declare under our sole responsibility that the product(s) described below conform to the essential safety requirements. This declaration will be rendered invalid if any changes are made to the equipment without prior consultation with us.

Manufacturer WALTHER Spritz- und Lackiersysteme GmbH

Kärntner Str. 18 - 30

D - 42327 Wuppertal

Tel.: +49(0)202 / 787 - 0

Fax: +49(0)202 / 787 - 2217

www.walther-pilot.de • e-mail: info@walther-pilot.de

Type Designation Manual Spray Guns PILOT TERRA

PILOT TERRA Gravity-Feed Cup V 11 801

PILOT TERRA Material Connection V 11 802

PILOT TERRA-LVLP Gravity-Feed Cup V 11 811

PILOT TERRA-LVLP Material Connection V 11 812

Intended purpose Processing of sprayable media

Applied Standards and Directives

EU-Mechanical Engineering Directives 2006 / 42 / EC

94 / 9 EC (ATEX Directives)

DIN EN ISO 12100-1

DIN EN ISO 12100-2 DIN EN 1953

EN 1127-1 DIN EN 13463-1

Specification according 94 / 9 / EC

Category 2 Part marking II 2 G c T 6

Tech.File,Ref.:

2417

Authorized with the compilation of the technical file:

Nico Kowalski, WALTHER Spritz- und Lackiersysteme GmbH, Kärntner Str. 18 - 30

D- 42327 Wuppertal

Special remarks :

The named product is intended for installation in other equipment. Commissioning is

prohibited until such time as the end product has been proved to conform to the

provision of the Directives 2006 / 42 / EC.

Wuppertal, the 1st of April 2014

p.p.

Name: Torsten Bröker

Position: Manager, Design and Development

This Declaration does not give assurance of properties in the sense of product liability. The safety instructions provided in the product documentation must be observed at all times.

21

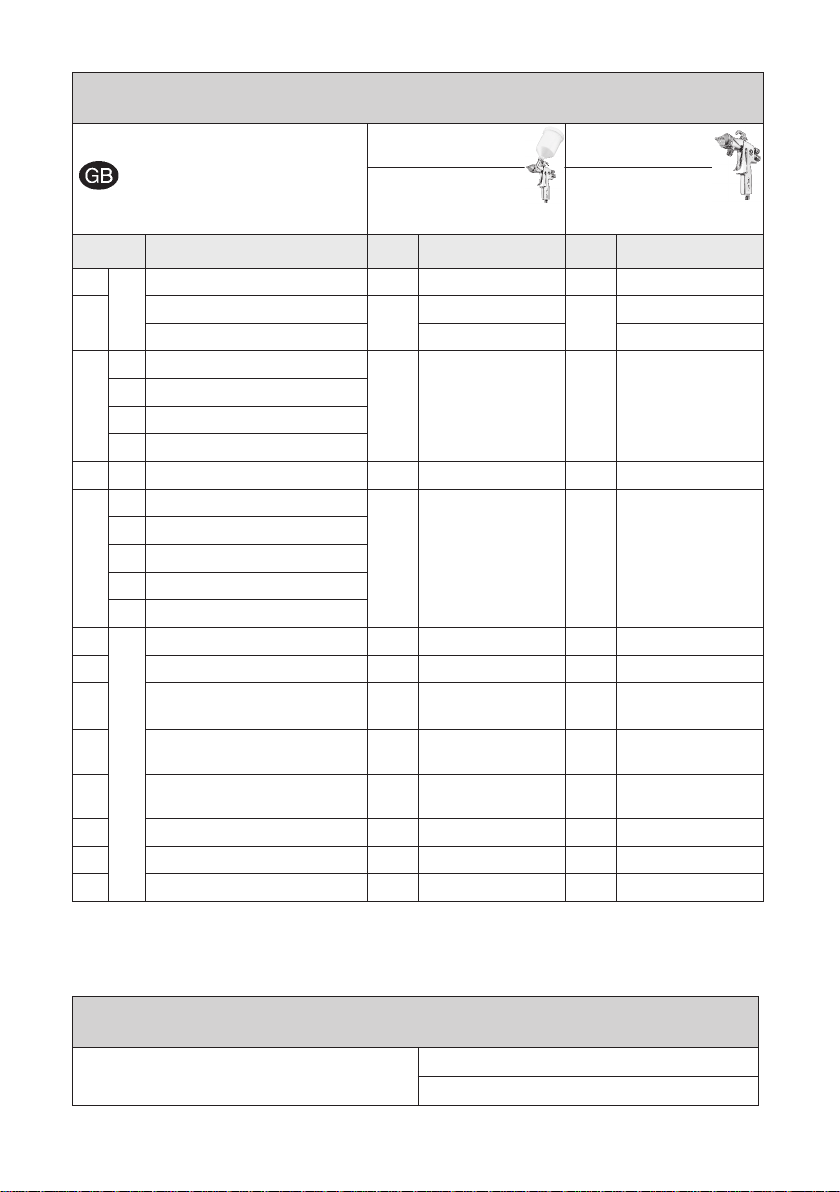

Replacement Parts

PILOT TERRA

Gravity-feed cup

V 11 801 03 XX3

V 11 811 03 XX3 (LVLP)

PILOT TERRA

Material Connection

V 11 802 03 XX3

V 11 812 03 XX3 (LVLP)

N° Description Qty. Article-No. Qty. Article-No.

1 Air cap nut compl. 1 2337082 1 2337082

2

3

Air cap

Air cap (LVLP) V 11 801 45 1MP V 11 801 45 1MP

3.1

Material nozzle*

3.2

Needle seal Packing comp.

3.3

Material needle compl.*

3.4

Needle spring

V 11 801 40 006

1

V 11 801 40 006

1

1 V 15 118 03 XX3* 1 V 15 118 13 XX3*

4 Gun body compl. 1 2337094 1 2337105

5.1

Valve shaft seal

5.2

Valve cone compl.

5.3

5

5.4

5.5

Valve spring

Washer

O-Ring

1 V 17 118 01 000 1 V 17 118 02 000

6 Spring bushing 1 2337086 1 2337086

7 Adjusting screw 1 2337087 1 2337087

8 Round/ wide jet adjustment

compl.

9 Double nipple

(Material connection)

10 Double nipple

(Air connection)

1 V 11 801 05 000 1 V 11 802 05 000

- - 1 V 00 101 04 000

1 V 00 101 01 000 1 V 00 101 01 000

11 Trigger compl. 1 V 11 801 07 000 1 V 11 801 07 000

12 Gun key 1 2342434 1 2342434

13 Gravity-feed cup compl. 1 V 00 130 00 100 - -

* When ordering replacements please quote the respective sizes.

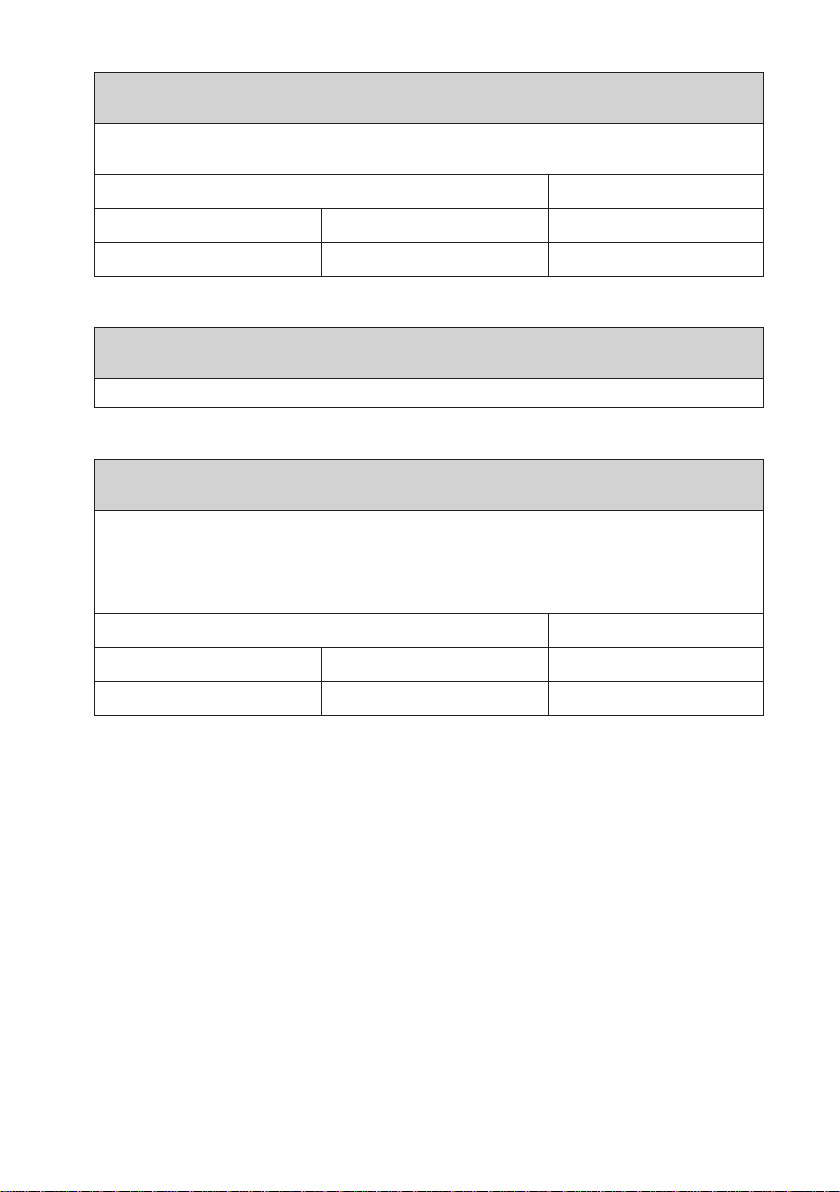

Accessories

Walther Pilot gun grease

(Pads 8 - 10 g)

22

Article-No.

V 00 000 00 001

Nozzle / needle sets

The nozzle / needle sets consist material nozzle, needle seal packing comp., material needle compl. and needle spring (No 3).

Article-No.

PILOT TERRA Gravity-feed cup V 15 118 03 XX3*

PILOT TERRA Material Connection V 15 118 13 XX3*

Nozzle sizes optional:

▪ 1,0 ▪ 1,4 ▪ 1,8 mm ø

Air valve sets

WALTHER has PILOT TERRA Gravity-feed cup and PILOT TERRA material

connection air valve sets available for the manual spray guns containing the following items:

Valve shaft seal, valve cone compl., valve spring, washer and O-Ring (No 5).

Article-No.

PILOT TERRA Gravity-feed cup V 17 118 01 000

PILOT TERRA Material Connection V 17 118 02 000

23

1 General

1.1 Model Identification

Model: Manual Spray Gun PILOT TERRA

Type: PILOT TERRA Gravity-Feed Cup V 11 801

PILOT TERRA Material Connection V 11 802

PILOT TERRA-LVLP Gravity-Feed Cup V 11 811

PILOT TERRA-LVLP Material Connection V 11 812

Manufacturer: WALTHER Spritz- und Lackiersysteme GmbH

Kärntner Str. 18-30

D-42327 Wuppertal

Tel.: +202 / 787-0

Fax: +202 / 787-2217

www.walther-pilot.de • Email: info@walther-pilot.de

1.2 Intended use

The manual spray guns PILOT TERRA Gravity-Feed Cup and PILOT TERRA

Material Connection are designed to be used exclusively for sprayable media, such

as:

• paints and lacquers

• greases, oils and corrosion preventives

• ceramic glazes

Aggressive materials must not be sprayed.

If the material you intend to spray is not included in the above list, please contact

WALTHER Spritz- und Lackiersysteme GmbH, Wuppertal, for further information.

Please note that sprayable materials may only be applied to workpieces and /or

similar objects.

The temperature of the spraying material must not exceed 43°C.

The term "normal use” also implies that all safety warnings, operating handling

details, etc., as stated in these operating instructions are carefully read, understood

and duly complied with.

This equipment complies with the explosion protection requirements of Directive

94/9/EC (ATEX) for the explosion group, equipment category and temperature class

indicated on the type plate. When using the equipment, the requirements specified

in these Operating Instructions must be observed at all times.

The technical data indicated on the equipment rating plates and the specifications in

the chapter "Technical Data" must be complied with at all times and must not be

exceeded. An overloading of the equipment must be ruled out.

The equipment may be used in potentially explosive atmospheres only with the

authorisation of the relevant supervisory authority.

The relevant supervisory authority or the operator of the equipment are

responsible for determining the explosion hazard (zone classification).

The operator must check and ensure that all technical data and the marking of the

24

equipment in accordance with ATEX are compliant with the necessary requirements.

The operator must provide corresponding safety measures for all applications in

which the breakdown of the equipment might lead to danger to persons.

If any irregularities are observed while the equipment is in operation, the equipment

must be put out of operation immediately and WALTHER Spritz- und Lackiersysteme

must be consulted.

Grounding / Equipotential Bonding

Measures must be taken to ensure that the spray gun is sufficiently grounded

(earthed) by means of a conductive air hose (maximum resistance 106 Ω).

1.3 Inappropriate use

The spray gun can’t be used for any application not included in the instructions. Any

other use is improper. Some sample of improper use:

• Spray in direction of people or animals

• Spray liquid nitrogen

2 Technical Description

PILOT TERRA: Manual spray gun for conventional atomisation

PILOT TERRA-LVLP: Manual spray gun vapour-reduced

Model versions: • with gravity-feed cup

• with material connection

When pulling the trigger (No 11) the valve cone opens first (No 5.2) (pre-air) and the

material needle (No 3.3) is pulled back only after this. Closing takes place in reverse

order.

The material flow rate is dependent on the diameter of the nozzle and the adjustment

of the material pressure at the pressure tank or material pressure regulator. In addition, the material flow rate can be controlled by screwing the adjusting screw (N° 7)

in or out.

3 Safety instructions

3.1 Identification of safety instructions

Warning

The pictogram and the urgency level “Warning“ identify a possible danger to

persons.

Possible consequences: Slight to severe injuries.

Attention

The pictogram and the urgency level “Attention“ identify a possible danger to

material assets.

Possible consequences: Damage to material assets.

25

Note

The pictogram and the urgency level “Note“ identify additional information for the

safe and efficient operation of the spray gun.

3.2 General Safety instructions

► All applicable accident prevention rules and regulations as well as other recog-

nised industrial safety and health rules and regulations must be observed at all

times.

► Use the spray gun only in well-ventilated rooms. Fire, naked flames and smo-

king are strictly prohibited within the working area. WARNING – during the

spraying of flammable materials (e.g. lacquers, adhesives, cleaning agents,

etc.), there is an increased risk to health as well as an increased risk of explosion and fire.

► You must ensure that the spray gun is properly earthed (grounded) either sepa-

rately or in connection with the equipment with which it is being used (max.

resistance 106 Ω).

► Before carrying out maintenance or servicing work, always ensure that the air

and material feed to the spray gun have been de-pressurised. Risk of injury!

► When spraying materials, do not place your hands or other parts of the body in

front of the pressurised nozzle or the spray gun.

Risk of injury!

► Never point the spray gun at persons or animals. Risk of injury!

► Always observe the spraying and safety instructions given by the manufacturers

of the spraying material and the cleaning agent. Aggressive and corrosive materials in particular can be harmful to health.

► Always wear hearing protection when using the gun or when in the vicinity of a

gun that is in use. The noise level generated by the spray gun is approx. 86

dB(A).

► Exhaust air containing particles (overspray) must be kept away from the working

area and personnel. In spite of these measures, always wear the regulation

breathing masks and protective overalls when using the gun. Airborne particles

represent a serious health hazard!

► After carrying out assembly or maintenance work, always ensure that all nuts,

bolts and screw connections have been fully tightened before the gun is used.

► Use only original replacement parts, since WALTHER can only guarantee safe

and fault-free operation for original parts.

► For further information on the safe use of the spray gun and the spraying mate-

rials, please contact WALTHER Spritz- und Lackiersysteme GmbH, D-42327

Wuppertal, Germany.

26

Loading...

Loading...