WWAALLTTHHEERR PPIILLOOTT

Betriebsanleitung / Operating Instructions

Signierpistole / Marking Gun

PPIILLOOTT SSiiggnniieerr 2200 335577

Membranausführung / Diaphragm - Version

Das WALTHER PILOTProgramm

• Hand-Spritzpistolen

• Automatik-Spritzpistolen

• Niederdruck-Spritzpistolen (System HVLP)

• Zweikomponenten-Spritzpistolen

• Materialdruckbehälter

• Drucklose Behälter

• Rührwerk-Systeme

• Airless-Geräte und Flüssigkeitspumpen

• Materialumlaufsysteme

• Kombinierte Spritz- und Trockenboxen

• Absaugsysteme mit Trockenabscheidung

• Absaugsysteme mit Naßabscheidung

• Pulversprühstände

• Trockner

• Zuluft-Systeme

• Atemschutzsysteme und Zubehör

The WALTHER PILOTProgramme

• Manual spray guns

• Automatic spray guns

• HVLP spray guns

• Two-component spray guns

• Pressure pots

• Pressureless containers

• Agitator systems

• Airless equipment and fluid pumps

• Material circulation systems

• Combined spraying and drying booths

• Exhaust extraction systems with dry filtering

• Exhaust extraction systems with wet filtering

• Powder spraying stands

• Dryers

• Air supply systems

• Breathing masks, breathing equipment and

accessories

WALTHER Spritz- und Lackiersysteme

Kärntner Str. 18-30 • 42327 Wuppertal

D-42306 Wuppertal

Telefon: 0202 / 787-0 • Telefax: 0202 / 787-217

www.walter-pilot.de • Email:info@walther-pilot.de

DISTRIBUTED BY COATING EQUIPMENT TECHNOLOGY, INC

PHONE: 586-210-0555

WEB: www.cetinc.com

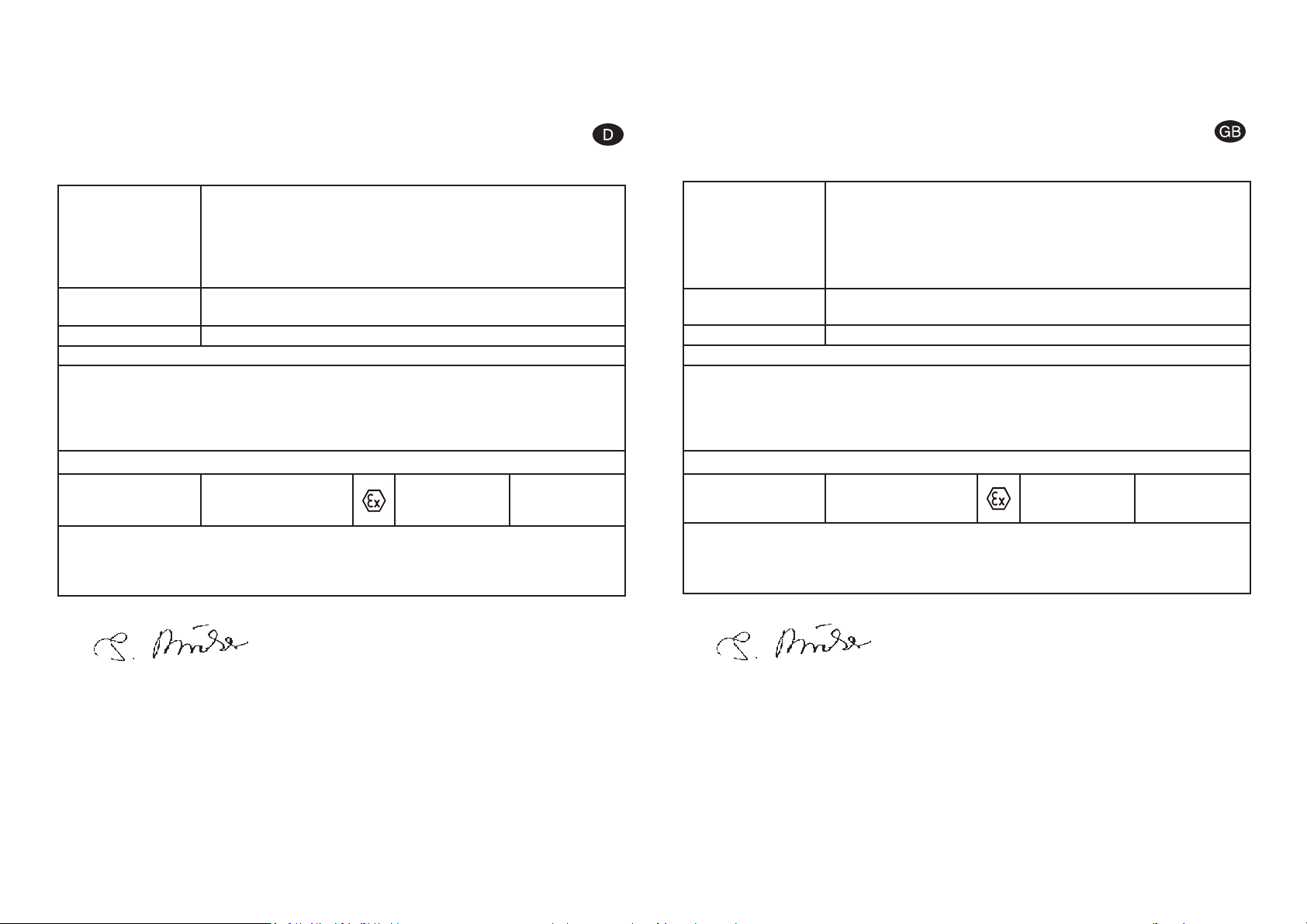

EG-Konformitätserklärung

Wir, der Gerätehersteller, erklären in alleiniger Verantwortung, daß das Produkt in der

untenstehenden Beschreibung den einschlägigen grundlegenden Sicherheits- und

Gesundheitsanforderungen entspricht. Bei einer nicht mit uns abgestimmten Änderung an dem Gerät oder bei einer unsachgemäßen Verwendung verliert diese

Erklärung ihre Gültigkeit.

Wuppertal,den 7. Juli 2003

Name: Torsten Bröker

Stellung im Betrieb: Leiter der Konstruktion und Entwicklung

Diese Erklärung ist keine Zusicherung von Eigenschaften im Sinne der Produkthaftung. Die Sicherheitshinweise der

Produktdokumentation sind zu beachten.

i.V.

Declaration of CE-Conformity

We, the manufacturers of the equipment, hereby declare under our sole responsibility

that the product(s) described below conform to the essential safety requirements.

This declaration will be rendered invalid if any changes are made to the equipment

without prior consultation with us.

Wuppertal, the 7th of July 2003

Name: Torsten Bröker

Position: Manager, Design and Development

This Declaration does not give assurance of properties in the sense of product liability. The safety instructions provided in the product documentation must be observed at all times.

Manufacturer WALTHER Spritz-und Lackiersysteme GmbH

Kärntner Str. 18-30

D-42327 Wuppertal

Tel.: 0202 / 787-0

Fax: 0202 / 787-217

www.walther-pilot.de • Email: info@walther-pilot.de

Type Designation Automatic Spray Gun PILOT Signier

PILOT Signier 20 357 (Marking - Diaphragm - Version) V 20 357

Intended purpose Processing of sprayable media

Applied Standards and Directives

EU-Machinery Directive 98 / 37 CE

94 / 9 EC (ATEX Directives)

DIN EN 292 Part 1

DIN EN 292 Part 2

DIN EN 1953

Specification according 94 / 9 / CE

Category 2 Part marking II 2 G c T 5

Tech.File,Ref.:

2408

Special remarks :

The named product is intended for installation in other equipment. Commissioning is prohibited until such time as the end product has been proved to conform to the provision of

the Directives 98 / 37 / CE.

i.V.

Hersteller WALTHER Spritz-und Lackiersysteme GmbH

Kärntner Str. 18-30

D-42327 Wuppertal

Tel.: 0202 / 787-0

Fax: 0202 / 787-217

www.walther-pilot.de • Email: info@walther-pilot.de

Typenbezeichnung Automatische Spritzpistole PILOT Signier

PILOT Signier 20357 (Signier - Membranausführung) V 20 357

Verwendungszweck Verarbeitung spritzbarer Materialien

Angewandte Normen und Richtlinien

EG-Maschinenrichtlinien 98 / 37 EG

94 / 9 EG (ATEX Richtlinien)

DIN EN 292 Teil 1

DIN EN 292 Teil 2

DIN EN 1953

Spezifikation im Sinne der Richtlinie 94 / 9 / EG

Kategorie 2 Gerätebezeichnung II 2 G c T 5

Tech.File,Ref.:

2408

Besondere Hinweise :

Das Produkt ist zum Einbau in ein anderes Gerät bestimmt. Die Inbetriebnahme ist so

lange untersagt, bis die Konformität des Endproduktes mit der Richtlinie 98 / 37 / EG

festgestellt ist.

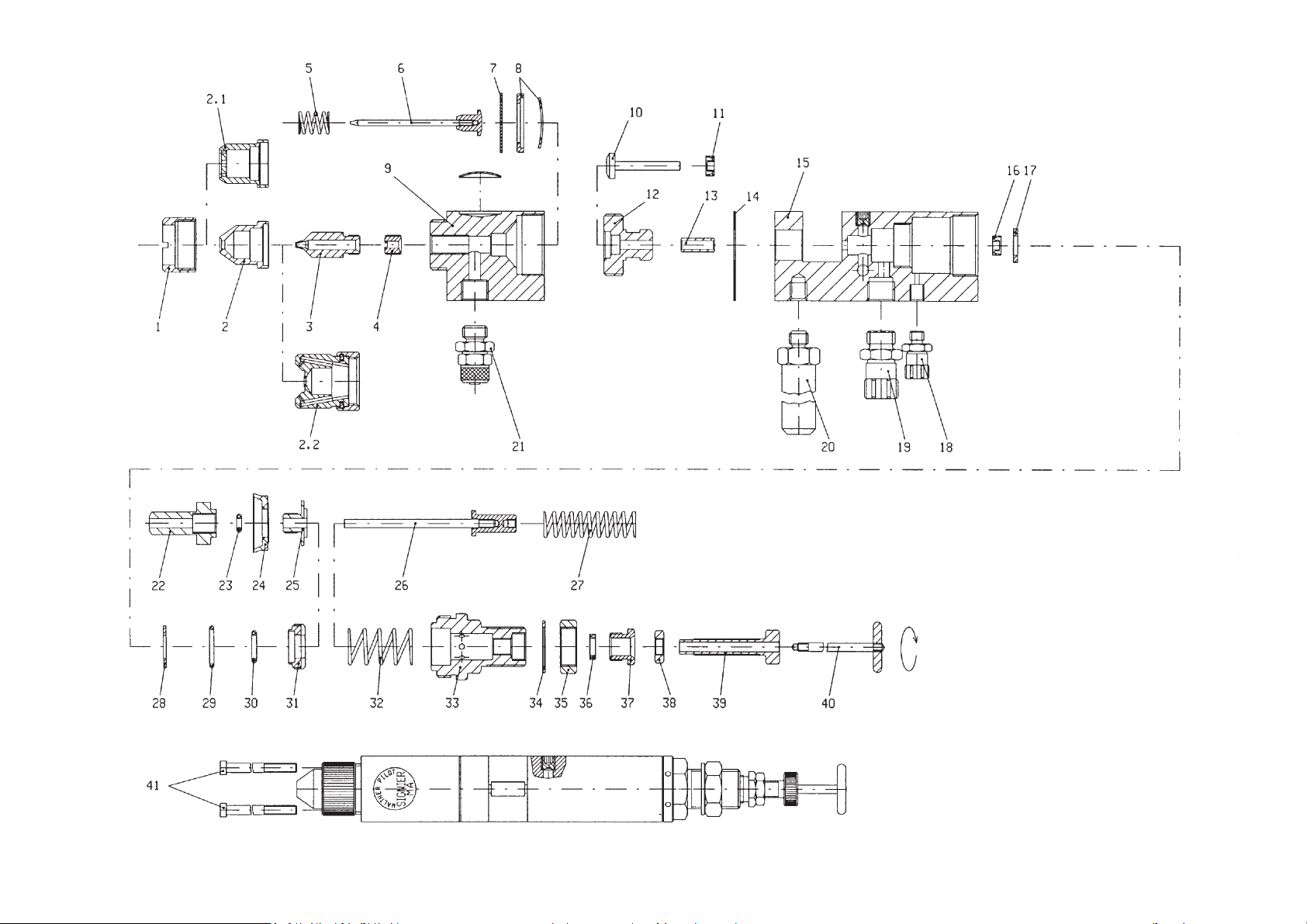

Parts list PILOT 20 357

Item Part number Description

1 V 20 335 15 . . 5 Air cap nut

2 V 20 336 34 . . 5* Round fan cap

2.1 V 20 336 44 . . 5* Small wide fan cap

2.2 V 20 336 50 . . 5* Large wide fan cap

3 V 20 336 23 . . 3* Material nozzle

4 V 20 355 25 004 Needle guide

5 V 20 355 17 003 Pressure spring

6 V 20 355 11 . . 3 Material needle

7 V 09 230 03 000 Diaphragm

8 V 20 355 15 000 Support washer

9 V 20 357 02 005 Front part

10 V 20 355 12 003 Pressure bar

11 V 09 220 25 000 Lip seal

12 V 20 355 03 004 Clamping sleeve

13 V 20 355 05 005 Coupling

14 V 09 002 44 000 Seal

15 V 20 357 01 005 Housing

16 V 09 220 25 000 Lip seal

17 V 09 230 04 000 Piston cylinder seal

18 V 66 100 03 561 Control air connection

19 V 66 100 02 027 Atomising air connection

20 V 20 357 03 003 Fastening bolt

21 V 66 100 02 127 Material connection

22 V 20 355 06 004 Piston

23 V 09 102 08 000 O - ring

24 V 09 210 11 000 Rubber packing ring

25 V 20 355 07 004 Piston screw

26 V 20 355 08 000 Piston rod

27 V 20 355 18 003 Needle spring

28 V 20 355 14 004 Washer

29 V 09 103 36 001 O - ring

30 V 09 102 09 001 O - ring

31 V 02 355 13 004 Piston guide

32 V 20 355 19 003 Piston spring

33 V 20 357 04 005 Spring bushing

34 V 20 666 06 000 Plain washer

35 V 20 660 04 003 Hexagonal nut

36 V 20 336 36 000 Clamping ring

37 V 10 501 06 000 Plug bushing

38 V 20 336 45 000 Locknut

39 V 20 355 20 005 Adjusting screw

40 V 20 336 38 390 Tension bar

41 V 20 355 21 003 Screw

* When ordering parts, please state the corresponding dimensions. We recommend that all

parts printed in bold type (wearing parts) are kept in stock.

Contents

1 General

1.1 Identification of Model Version

1.2 Proper use

1.3 Improper use

2 Technical description

3 Safety instructions

4 Using the spray gun

4.1 Connections for control air, atomising air and material

4.2 Spraying a test pattern

4.3 Changing the spray pattern

5 Retooling the spray gun

5.1 Changing the air cap

5.2 Changing the material nozzle

5.3 Changing the material needle

5.4 Changing the needle seal

6 Cleaning and maintenance

7 Troubleshooting

8 Technical data

1 General

1.1 Identification of Model Version

Model: Automatic Spray Gun PILOT Signier

Type: Marking Gun PILOT Signier 20 357 Diaphragm Version V 20 357

Manufacturer: WALTHER Spritz-und Lackiersysteme GmbH

Kärntner Str. 18-30

D-42327 Wuppertal

Tel.: 0202 / 787-0

Fax: 0202 / 787-217

www.walther-pilot.de • Email: info@walther-pilot.de

1.2 Proper use

The automatic spray gun PILOT Signier 20 357 must be used only for processing sprayable

materials, in particular:

• lacquers and paints

• grease, oil and anti-corrosion agents

• adhesives, grease, oil and anti-corrosion agents

• ceramic glazes

• stains

If you intend to spray materials that are not listed here, please contact WALTHER Spritz- und

Lackiersysteme GmbH, Wuppertal.

The sprayable materials must be sprayed only on workpieces or objects. The temperature of

the material to be sprayed must not exceed 80°C. The model PILOT WA 20 357 is not a

hand-held spray gun and must therefore be mounted in a suitable bracket.

Proper use of the spray gun also includes the fact that you have read, understood and

observed all information, advice and safety requirements presented in this instruction

manual.

This equipment complies with the explosion protection requirements of Directive 94 / 9 / EC

(ATEX 100a) for the explosion group, equipment category and temperature class indicated

on the type plate. When using the equipment, the requirements specified in these Operating

Instructions must be observed at all times. The technical data indicated on the equipment

rating plates and the specifications in the chapter "Technical Data" must be complied with at

all times and must not be exceeded. An overloading of the equipment must be ruled out.

The equipment may be used in potentially explosive atmospheres only with the authorisation

of the relevant supervisory authority.

The relevant supervisory authority or the operator of the equipment are responsible

for determining the explosion hazard (zone classification).

The operator must check and ensure that all technical data and the marking of the equipment in accordance with ATEX are compliant with the necessary requirements.

The operator must provide corresponding safety measures for all applications in which the

breakdown of the equipment might lead to danger to persons.

If any irregularities are observed while the equipment is in operation, the equipment must be

put out of operation immediately and WALTHER PILOT must be consulted.

Grounding / Equipotential Bonding

You must ensure that the spray gun is properly earthed (grounded) either separately or in

connection with the equipment with which it is being used (maximum resistance 10

6

Ω).

1.3 Improper use

The spray gun must not be used in any other way than as described above in the section

Proper use. Any other use is improper.

Improper use includes:

• spraying materials onto persons or animals.

• spraying liquid nitrogen.

2

1

2 Technical Description

The model PILOT WA 20 357 is operated automatically by compressed air and is controlled via a 3/2-way control valve. Hand-operated, foot-operated or solenoid-valve-operated

valves can be used for this purpose.

After actuating the 3/2-way control valve, the compressed air required for controlling enters

the cylinder chamber of the spray gun and opens the spraying air and material feed.

If the control air is interrupted by the 3/2-way valve, the compressed air in the cylinder

chamber is allowed to escape. The spring pressure of the piston and needle spring shuts

off the material feed to the material nozzle and then the spraying air feed.

The automatic spray gun as a recirculating version, e.g. for strongly settling materials, can

be integrated into a material circulation system. In addition, several automatic spray guns

can be supplied with the spraying material by the ring-shaped arrangement of the circulation piping.

3 Safety instructions

• The spray gun must be used only by trained and qualified persons.

• All relevant rules of safety and workers' safety regulations applicable in the country or

area of use must be fully observed.

• Observe the instructions given by the manufacturers of the spraying material and the

cleaning agents with regard to safety and proper use.

• Use the spray gun only in well-ventilated rooms. Fire, naked flames and smoking are prohibited within the working area.

• Always wear the regulation breathing masks, protective clothing and hearing protection

when using the spray gun.

• Exhaust air which contains particles must be kept away from the working area and operating personnel. Make sure that adequate exhaust extraction is provided.

• When spraying materials, keep your hands and other parts of the body away from the

pressurised nozzle of the spray gun.

• Do not direct the spray gun at persons or animals.

• Before carrying out maintenance or servicing, ensure that the air and material feed to the

spray gun have been de-pressurised.

•You must ensure that the spray gun is properly earthed (grounded) either separately or in

connection with the equipment with which it is being used (maximum resistance 10

6

Ω).

• After carrying out assembly and maintenance work, ensure that all nuts, bolts and screw

connections have been fully tightened.

• Use only original spare parts, since WALTHER can only guarantee safe and fault-free

operation for original parts.

For further information on the safe use of spraying equipment, please contact WALTHER

Spritz- und Lackiersysteme GmbH, Wuppertal

4 Using the spray gun

Before using the spray gun, ensure that the following conditions apply:

• The control air pressure is applied to the spray gun.

• The atomising air pressure is applied to the spray gun.

• The material pressure is applied to the spray gun.

4.1 Connections for control air, atomising air and material

• Connect the control air connector (via the 3/2-way valve) to the spray gun Item 18 and

set the control air pressure (min. 4.5 bar).

• Connect the atomising air connector to the air hose (filtered compressed air supply) and

to the atomising air connection of the spray gun Item 19.

• Switch on the compressed air and set the required atomising air pressure at the reducing

valve (max. 6 bar).

• Fill the pressure pot with the material to be sprayed and close the lid.

• Connect the material feed hose to the pressure pot or the pump and to the material

connection Item 21. Set the required material pressure (max. 6 bar).

• Open the material valve on the pressure pot.

4.2 Spraying a test pattern

A test spray pattern should always be made whenever:

• the spray gun is used for the first time.

• the spraying material is changed.

• the spray gun has been disassembled for maintenance or servicing.

The test pattern can be sprayed on a test workpiece, panel, cardboard or paper.

4.3 Changing the spray pattern

• Round-fan or wide-fan air caps are available

• The fan width can be varied by changing the atomising air

• The material flow rate is determined by the material pressure and the diameter of the

adjusting screw Item 33.

3

4

6 Troubleshooting5 Retooling the spray gun

Before retooling the spray gun, always ensure that the air supply and material supply to

the spray gun have been interrupted.

The combination of air cap, material nozzle and needle for a certain spraying material

forms a specially matched unit - the nozzle assembly. Always exchange the complete

nozzle assembly in order to maintain the desired spray pattern quality.

5.1 Changing the air cap

1. Unscrew the air cap nut and remove the air cap.

2. Installation takes place in reverse order.

5.2 Changing the material nozzle

1. Unscrew the air cap nut.

2. Remove the air cap.

3. Unscrew the material nozzle from the spray gun head.

4. Installation takes place in reverse order.

5.3 Changing the material needle

1. Unscrew the spray gun head from the body.

2. Release the front part and unscrew the clamping sleeve.

3. Remove the support washer and the diaphragm.

4. Withdraw the material needle together with the pressure spring.

5. Installation takes place in reverse order.

5.4 Changing the diaphragm

1. Unscrew the spray gun head from the body.

2. Release the front part and unscrew the clamping sleeve.

3. Remove the support washer and the diaphragm.

4. Installation takes place in reverse order.

5. When reinstalling the diaphragm, ensure that the teflon-coated side is pointing towards

the material channel.

Fault Cause Remedy

Gun drips

Gun does not open

Irregular or splattering spray

Gun sprays when switched off

Material leaks from the leakage hole

Material bubbling in material

container

Spray fan one-sided

Material needle or nozzle

dirty

Material needle or nozzle

damaged

Control air pressure too

low

Insufficient material in container

rubber packing ring Item

24 damaged

Diaphragm damaged

Atomising air is entering

the material container via

the material channel.

Material nozzle or air cap

not properly tightened

Air cap horn bore dirty

Remove and clean

Replace

Increase control air pressure

to min. 4.5 bar

Fill up with material (see

instructions from material

manufacturer)

Replace

Replace

Clean the parts, tighten or

replace

Remove and clean

5

6

Spray pattern test Fault Necessary adjustment

Swollen centre • Spray jet should be flatter

Swollen ends • Spray jet should be rounder

Coarse pearl effect • Increase atomising air pressure

Unduly thin paint

layer in centre

• Decrease atomising air pressure

Split centre

• Increase nozzle diameter

• Reduce atomising air pressure

• Increase material pressure

Split centre

• Decrease material pressure

• Increase atomising air pressure

7 Cleaning and maintenance

• To ensure that the spray gun functions properly and to maximise its service life, the spray

gun must be maintained, cleaned and lubricated regularly.

• Before carrying out any maintenance, ensure that the control air and atomising air as well

as the material feed are de-pressurised.

• Cleaning should be carried out after every colour and material change or according to the

degree of contamination.

• For cleaning the spray gun, use only those cleaning agents that are specified by the mate-

rial manufacturer and ensure that they do not contain any of the following components:

- halogenated hydrocarbons, e.g. 1,1,1-trichloroethane,

- methylene chloride,

- acids or acidic cleaning agents,

- paint strippers,

- regenerated solvents (cleaning thinners).

• Never immerse the whole spray gun in solvent or cleaning agent, as this could harm the

correct functioning of the gun.

• Do not use sharp or hard objects to clean the spray gun, as this might cause damage to

precision parts and impair the spraying result.

• WALTHER PILOT cannot accept any liability for damage caused by improper treatment of

the spray gun.

8 Technical data

Weight: 500 Gramm

Connections:

Atomising air: G 1/8 "

Control air: M 5

Material feed: G 1/8 "

Pressure range:

Control air pressure: min. 4,5 bar

Material pressure: max. 2 bar

Atomising air pressure: max. 6 bar

The noise level

is 83 dB (A)

Air consumption at:

1 bar Atomising air 1,2 m

3

/h

2 bar Atomising air 1,8 m3/h

3 bar Atomising air 2,4 m3/h

4 bar Atomising air 3,0 m3/h

5 bar Atomising air 3,6 m

3

/h

6 bar Atomising air 4,8 m3/h

Right to effect technical changes reserved.

7

Loading...

Loading...