Page 1

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Operating Manual

WALTHER Temperature Controller Bundle (WTRB)

Article Number: WTRB-x-x

IMPORTANT

Please read this manual carefully before the actual start of operation.

The device will only be used, maintained and repaired by personnel who are familiar with the

operating manual and also with the guiding regulations on workplace safety and accident prevention.

When used in or with other machines, the kit will not be operated if the machine does not

comply with the Machine Directive.

Page 2

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 2 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

1 Table of Contents

1 Table of Contents ................................................................................................................... 2

2 General Information .............................................................................................................. 3

2.1 Scope of Delivery ................................................................................................................................... 3

2.2 Target Group of the Operating Manual .................................................................................................. 5

2.3 Contents of the Manual .......................................................................................................................... 5

2.4 List of Signs and Symbols ...................................................................................................................... 5

2.5 Warranty and Liability ............................................................................................................................. 5

2.6 Copyright ................................................................................................................................................ 5

3 Safety Information ................................................................................................................. 6

3.1 General Information ............................................................................................................................... 6

3.2 Basic Safety Instructions ........................................................................................................................ 6

3.3 Dangers from Using the Device ............................................................................................................. 6

3.4 Dangers from Residual Energy .............................................................................................................. 6

3.5 Correct Use ............................................................................................................................................ 7

3.6 Incorrect Use .......................................................................................................................................... 7

3.7 Personal Protective Equipment and Other Measures ............................................................................ 7

3.8 Required Qualification of Personnel....................................................................................................... 7

4 Transport ............................................................................................................................... 8

4.1 Packaging ............................................................................................................................................... 8

4.2 Transport ................................................................................................................................................ 8

4.3 Damages in Transport ............................................................................................................................ 8

4.4 Location of Set-up .................................................................................................................................. 8

5 Description of Product ............................................................................................................ 9

5.1 General Information ............................................................................................................................... 9

5.2 Electrical Installation / Start of Operation ............................................................................................. 11

5.3 Operation .............................................................................................................................................. 14

6 Technical Data / Installation Information ............................................................................. 16

6.1 Walther Temperature Controller WTR-x .............................................................................................. 16

6.2 Solid-state Relay WSSR-x-x ................................................................................................................ 22

7 Advanced Settings ............................................................................................................... 26

7.1 Concept of Levels................................................................................................................................. 26

7.2 Parameters ........................................................................................................................................... 28

7.3 Configuration (ConF) ............................................................................................................................ 29

7.4 Factory Configured Standard Parameters ........................................................................................... 37

8 Troubleshooting ................................................................................................................... 39

8.1 Error Messages .................................................................................................................................... 39

8.2 Self-Optimization .................................................................................................................................. 40

9 Service and Maintenance ..................................................................................................... 41

10 Spare Parts / Accessories .................................................................................................. 42

Page 3

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 3 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

2 General Information

This operating manual is provided for a safe use and start of operation of our product series „Walther Temperature Controller Bundle (WTRB-x-x)“. The operating manual contains safety instructions for a smooth operation

as well as information on the function principle of the temperature controller. Above that, you will find information

and instructions for the mechanical and electrical installation. Please refer to Table 1 for an overview of all

available types and ordering numbers of the Walther Temperature Controller Bundles (WTRB).

Walther Temperature Controller Bundle (WTRB)

Ordering key

Version for 230 [VAC] heating

230AC

Solid-state Relay 230 [VAC] 6000 [mA]

6000

Version for 24 [VDC] heating

24DC

Solid-state Relay 24 [VDC] 3500 [mA]

3500

Solid-state Relay 24 [VDC] 6000 [mA]

6000

Solid-state Relay 24 [VDC] 12000 [mA]

12000

WTRB

- x

- x

Table 1: Ordering keys for the different versions of the Walther Temperature Controller Bundle (WTRB)

2.1 Scope of Delivery

The Walther Systemtechnik Temperature Controllers will be delivered as bundles, consisting of the temperature

controller itself and a solid-state relay (SSR) for top hat rail mounting. The scope of delivery varies depending

on the selected temperature controller bundle and is shown in the below figures:

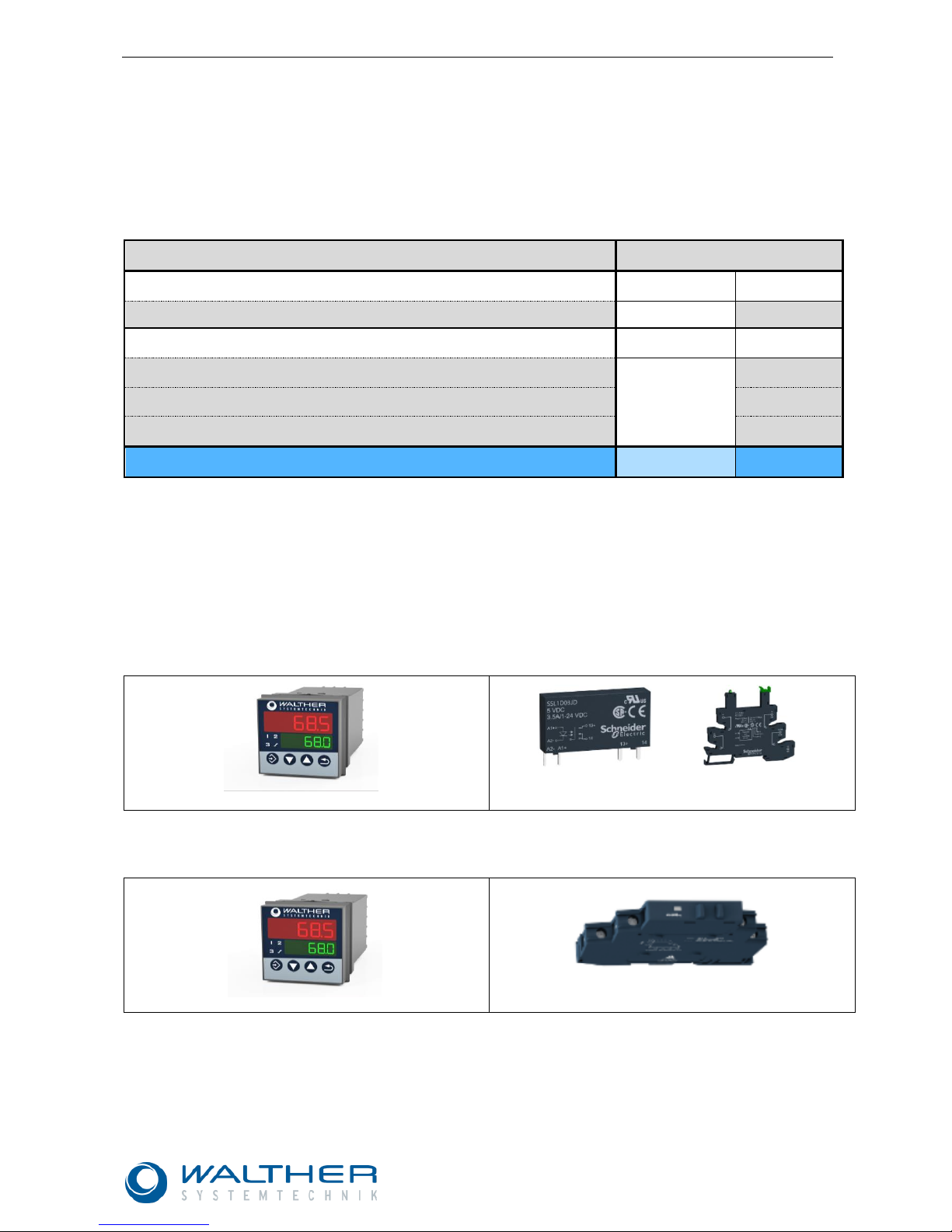

Scope of Delivery for WTRB-24DC-3500

➀

Temp.Controller WTR-24DC

➁ Solid-state relay 24 [VDC] 3500 [mA] incl. mounting

base (WSSR-24DC-3500)

Scope of Delivery for WTRB-24DC-6000

➀

Temp.Controller WTR-24DC

➁ Solid-state relay 24 [VDC] 6000 [mA]

(WSSR-24DC-6000)

Page 4

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 4 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Scope of Delivery for WTRB-24DC-12000

➀

Temp.Controller WTR-24DC

➁ Solid-state relay 24 [VDC] 12000 [mA]

(WSSR-24DC-12000)

Scope of Delivery for WTRB-230AC-6000

➀ Temp.Controller WTR-230AC

➁ Solid-state relay 230 [VAC] 6000 [mA]

(WSSR-230AC-6000)

Page 5

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 5 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

2.2 Target Group of the Operating Manual

➢ Operating personnel

➢ Maintenance personnel

2.3 Contents of the Manual

This Operating Manual contains information on:

➢ Safety

➢ Correct use

➢ Operation

➢ Service, maintenance and troubleshooting

2.4 List of Signs and Symbols

Symbols are used to indicate dangerous situations and specific behavior. These symbols are also used in this

operating manual. All warning, danger and information symbols describe situations which can be harmful to

persons, material or environment if rules are not followed.

The operating manual uses the following signs and symbols for dangers:

WARNING

Signals a potentially dangerous situation.

Death or severe injuries can follow, if you do not avoid this situation.

CAUTION

Signals a potentially dangerous situation.

Slight or minor injuries can follow, if you do not avoid this situation. This sign is also used

where damage to property is possible.

IMPORTANT

Indicates tips for usage and other particularly useful information.

No dangerous situation.

2.5 Warranty and Liability

According to the conditions laid down by the German Engineering Federation (VDMA), Walther Systemtechnik

GmbH has a guarantee of 12 months under normal European operating conditions on its own parts (spare parts

are excluded); or according to the conditions of the manufacturer.

This guarantee can only be granted by Walther Systemtechnik GmbH, if:

• the user has thorough knowledge of the content of this operating manual;

• the user follows the instructions and notes contained in this operating manual;

• the user does not rebuild or make changes on parts of the device without prior consent of Walther

Systemtechnik GmbH.

2.6 Copyright

We reserve the copyright for this operating manual. This operating manual is exclusively designated for the

operator and his personnel.

➢ Any copying – also only in part – or processing, or distribution or other use is strictly prohibited.

Page 6

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 6 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

3 Safety Information

3.1 General Information

The construction of this device is according to the latest technology and is absolutely reliable. The individual

components as well as the complete device are continuously checked by our quality management team.

3.2 Basic Safety Instructions

Basic conditions for a safe handling and a failure-free operation of the device are:

Caution!!

• It is the customer’s responsibility that all relevant safety measures are followed.

• The device will only be used for the designated purpose.

• No changes will be made at the device. The customer carries the sole responsibility for

consequences resulting from failure to observe this guideline. Please contact Walther Systemtechnik GmbH for any desired modifications.

• Make sure that the device is always in a safe operational condition. Checks for proper

function or damages have to be performed by specialists on a regular basis. Dismounting

will only be made by authorized personnel and while using the operating manual. If requested, we will also offer trainings on the device in order to teach your personnel the

required knowledge.

• Disconnect the device from compressed air / grease supply for all maintenance tasks. All

lines and hoses have to be pressure-less.

• Check all lines, hoses and screwed joints regularly for leakages and apparent damages!

Repair damages immediately!

• Always make sure that the actual workstation and the device are clean and clearly arrange;

and this is routinely checked.

• Please observe the guiding rules and regulations for accident prevention at the workplace.

3.3 Dangers from Using the Device

The construction of this device and all assembly groups is according to the latest technology and is absolutely

reliable. However, there may be dangers for the user or third parties or other physical assets, if not used correctly.

Warning!! Use device only:

• for the designated purpose; and

• in a safe and operational condition.

• Immediately correct failures which can adversely affect safety and security!

3.4 Dangers from Residual Energy

Please instruct the operating personnel on the respective measures to be taken against the occurrence of mechanical, hydraulic, pneumatic and electric / electronic residual energies.

Page 7

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 7 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

3.5 Correct Use

CAUTION

The device will only be used under the designated operating conditions as outlined in the offer

and the confirmation of order. It was exclusively designed for certain media in accordance with

the detailed description. Any different or further use will be regarded as incorrect. The manufacturer cannot be made liable for damages resulting from incorrect use.

Correct use also includes:

• Observing and following all instructions of this manual;

• Performing the inspection and routine maintenance tasks.

3.6 Incorrect Use

• Operating the device with insufficient knowledge about the operation, maintenance and care of the

device.

• Making changes, extensions or alterations on the device that may hamper its safety without the prior

consent of Walther Systemtechnik GmbH.

• Operating the device with defective safety installations or not properly attached or malfunctioning

safety devices.

• Using unsuitable materials.

• Handling the device while energized.

• Processing aggressive media (e.g. acids, alkaline solutions, detergents, chemicals, etc.) or media which

have not been approved in writing by the manufacturer.

• Making changes in the software of the controls

3.7 Personal Protective Equipment and Other Measures

• The operator company is responsible for providing the required personal protective gear.

• All safety devices and installations should be checked at regular intervals.

3.8 Required Qualification of Personnel

Only trained and instructed personnel may conduct work on the equipment.

The responsibilities of the personnel for assembly work, operation, repair work or maintenance work must be

clearly assigned to individuals!

Persons in training may work with the equipment under supervision of an experienced person only.

Personnel

Task

Instructed personnel

Personnel with technical qualification

Specialist

Supervisor

Packaging, transport

X - - - Commissioning

X X - Operation

X - Troubleshooting, general

X X - Troubleshooting, mechanical

- X - - Troubleshooting, electrical

- - X - Setting up

- X - - Maintenance

- X - - Repair

- X X

-

Taking out of service, storage,

disposal

- X X

-

Page 8

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 8 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

4 Transport

4.1 Packaging

The device will be prepared by Walther Systemtechnik GmbH for a transport to the first destination.

The type of packaging depends on the individual mode of shipping. If not separately contracted, the packaging

is in accordance with the rules and regulations of Walther Systemtechnik GmbH. This rule is in accordance with

the Federal Association for Packaging HPE.

The packing unit will not be exposed to any additional strain. Packaging and contents will be protected against

any kind of humidity. The temperature for transport and storage will strictly range between –20°C and + 40°C.

4.2 Transport

The actual transport of the device and its individual parts requires special care in order to prevent damages from

external forceful impact or careless on- and off-loading. Depending on the mode of transportation, suitable

transport and load securing has to be selected. The device will be aligned and leveled by appropriate fastening

elements.

4.3 Damages in Transport

The following will be observed when the receiving checks reveal damages in transport:

• Contact the carrier (carrier, train etc.)

• Write a protocol of damages

• Contact the supplier

4.4 Location of Set-up

• All legal requirements for the mounting site should be clarified and fulfilled.

• Prior to installation of the equipment, the condition of the floor and the size of the surrounding space

should be checked to ensure safety of operation for both personnel and equipment. The installation must

be such that continuous operation at a high safety level is ensured.

• The installation of the equipment as well as commissioning or storage of the equipment must be conducted by specialists that are trained and made familiar with the equipment only.

• The equipment is designed for use in areas which are protected from climatic conditions.

• Operation or storage of the equipment in an aggressive or moist environment or outdoors may lead to

corrosion or other damage for which Walther Systemtechnik GmbH will not assume liability.

• All exposed parts and lines must be mounted as such that no injuries or damage can occur

• The minimum allowed space around the device will be closely observed.

Page 9

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 9 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5 Description of Product

5.1 General Information

Walther Temperature Controller Bundles (WTRB) are available for all heating plates and heating hoses from

Walther Systemtechnik GmbH. Based upon the selected heating technology product, Table 2 is your reference

guide for choosing the matching temperature controller bundle; the individual bundle contains a suitable temperature controller (WTR) and the adapted solid-state relay (WSSR). Please observe the following instructions

when using the Walther Temperature Controller Bundles (WTRB):

• The device is not suitable for installing in explosion-prone areas.

• Make sure that you follow the regulations of the DIN VDE 0100 "Construction of Low-Voltage Systems",

respectively the guiding state regulations (e.g. based upon the IEC 60364) when selecting the wiring

material, or during the installation, or for the electrical connection of the device.

• For maximum load, the lines have to be heat-resistant up to 80 °C.

• Only a trained and qualified technician will take care of the electrical connection.

• The device was designed for installation in switch cabinets or systems. The customer fuse protection

must not exceed 20 A. For all service / repair work, the device has to be completely disconnected from

current.

• Make sure that the load circuit will be protected for the maximum relay current; this will prevent a welding

of the output relay in case of a short circuit.

• The electromagnetic compatibility is accordance with standards and regulations mentioned under ‘tech-

nical data‘.

• Make sure that the lines for input, output and supply are physically separated and will not be laid paral-

lelly.

• Lines for sensors and interfaces will be twisted and shielded. Do not carry out near current-carrying

components or lines. Make sure that the shielding is grounded on one side.

• Do not connect other or additional users to the terminal plugs.

IMPORTANT

The WTR-x Temperature Controllers come with a standard configuration which matches most

of the heating elements of Walther Systemtechnik. The following chapters of this operating

manual refer to this standard configuration.

Page 10

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 10 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

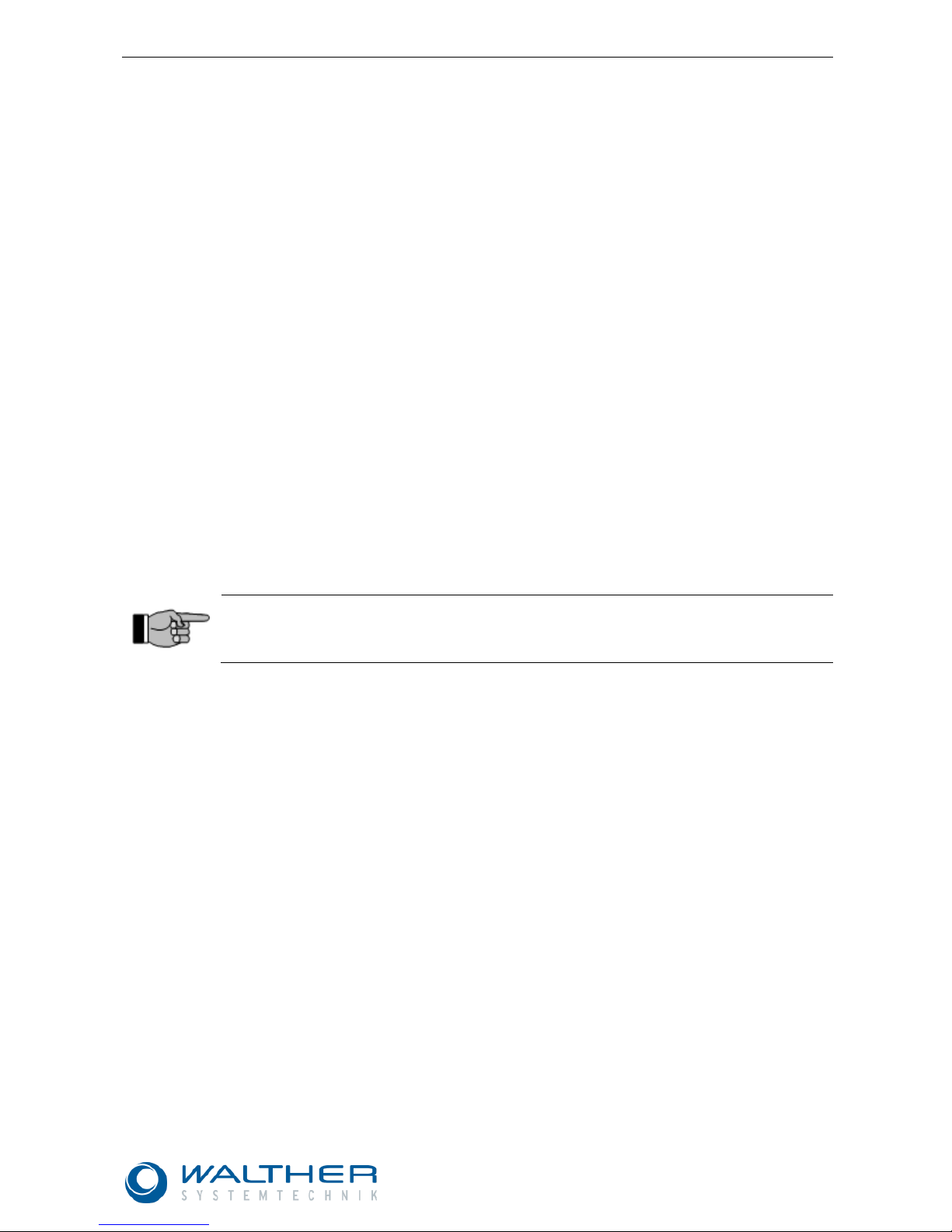

Product

Art.- No.

[V]

[A]

[W]

Temperature Cont. Bundle

Heating plates 24 [VDC]

HZP-x, etc.

24

1,0

25

WTRB-24DC-3500

Heating hoses 24 [VDC]

979524.001

24

2,5

60

WTRB-24DC-3500

979524.002

24

3,8

90

WTRB-24DC-6000

979524.003

24

1,9

45

WTRB-24DC-3500

979524.004

24

2,1

50

WTRB-24DC-3500

979524.007

24

7,5

180

WTRB-24DC-12000

979524.008

24

11,3

270

WTRB-24DC-12000

979524.009

24

5,0

120

WTRB-24DC-6000

979524.001M

24

2,5

60

WTRB-24DC-3500

979524.002M

24

3,8

90

WTRB-24DC-6000

979524.003M

24

1,9

45

WTRB-24DC-3500

979524.004M

24

2,1

50

WTRB-24DC-3500

979524.007M

24

7,5

180

WTRB-24DC-12000

979524.008M

24

11,3

270

WTRB-24DC-12000

979524.011M

24

3,2

76

WTRB-24DC-3500

979524.012M

24

5,6

135

WTRB-24DC-6000

979524.013M

24

5,6

135

WTRB-24DC-6000

Heating hoses 230 [VAC]

979524.102M

230

1,6

360

WTRB-230AC-6000

979524.103M

230

2,2

500

WTRB-230AC-6000

979524.104M

230

3,0

700

WTRB-230AC-6000

979524.100M

230

3,0

700

WTRB-230AC-6000

Heating pipes

979524.200

24

2,5

59

WTRB-24DC-3500

979524.201

24

2,5

59

WTRB-24DC-3500

Table 2: Reference guide for determining the correct Walther-Temperature Controller Bundle, based upon the selected heating technology

product.

Page 11

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 11 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5.2 Electrical Installation / Start of Operation

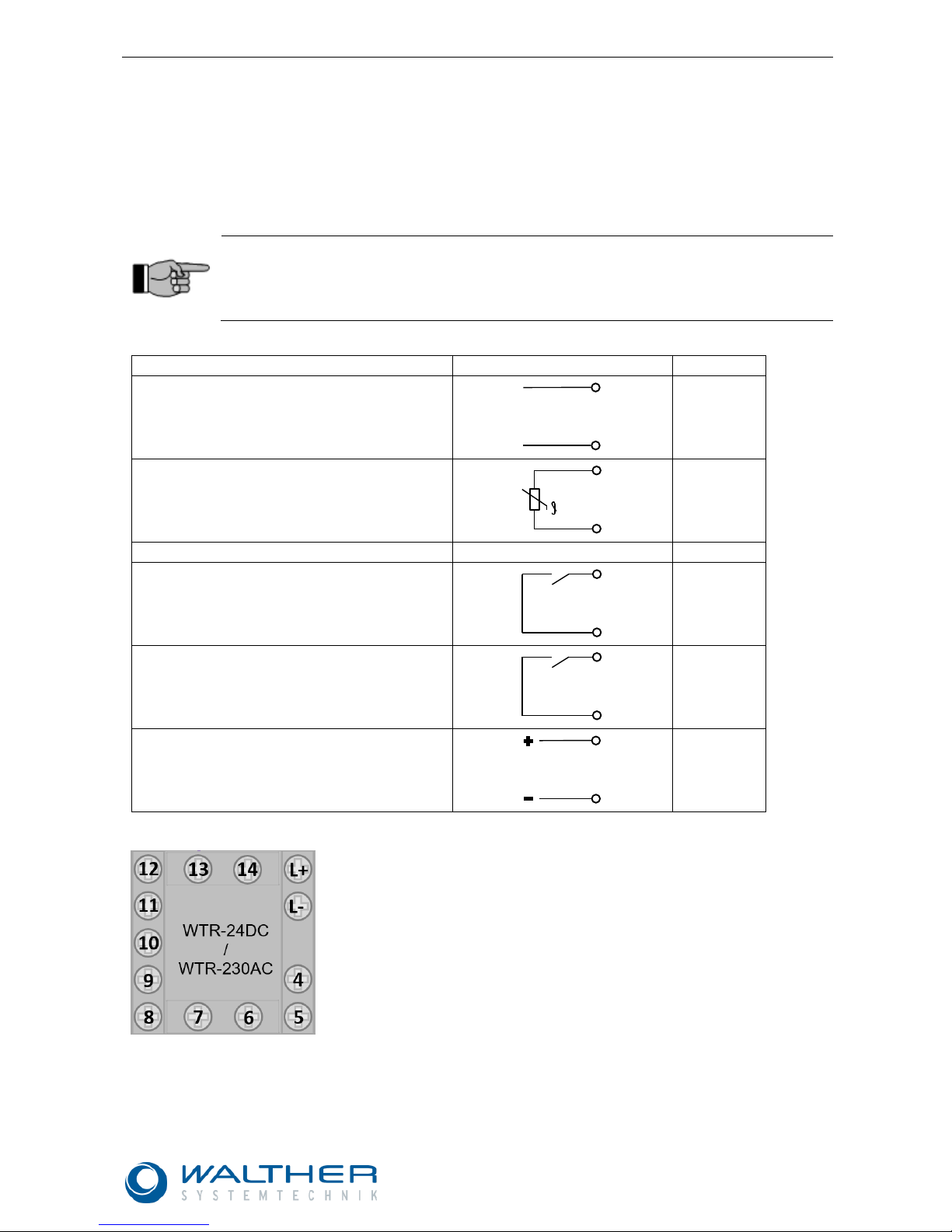

The Walther Temperature Controllers WTR-x have inlets and outlets, as listed in Table 3. Please refer to Figure

1 for the numbering of the connections. Please refer to model WTR-24DC or WTR-230AC for the voltage supply

at the marked pins (L+ / L- resp. L1 / N).

Pins 10 and 8 were configured as analog inputs for a PT100 2-wire resistance thermometer. The alarm outlets

for insufficient or excess temperature errors are integrated as make contacts at the pins 4 and 5, resp. 6 and 7.

The solid-state relay WSSR-x-x will be connected at the pins 13 and 14 of the logic output.

IMPORTANT

In order to also detect sensor errors and cable breaks at the alarm outputs, the make-contact

relays are permanently locked within the valid temperature range. If the preset temperature is

exceeded or fallen below, the contact will be interrupted (see also chapter 5.3.2 Limit Monitoring ).

Input

Symbol

Pin

Voltage supply

WTR-24DC: 24V DC

WTR-230AC: 230V AC

L1 (L+)

N (L-)

Analog input

Resistance thermometer PT100 2-wire

10

8

Output

Relay output (make contact) 1

Alarm output – error insufficient temperature

4

5

Relay outlet (make contact) 2

Alarm output - excess temperature error

6

7

Logic output (DC 0/12V)

Solid-state relay

13

14

Table 3: Overview of the inputs and outputs for the WTR-x and the pin assignment

Figure 1: View of back with terminal assignment for the WTR-24DC and WTR-230AC

AC/DC

Ux

Page 12

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 12 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5.2.1 Circuit Example

Figure 2 below shows you an example of connecting a 24 [VDC] heating device (e.g. a heating plate HZP-x)

to the components of a Walther Temperature Controller Bundle „WTRB-24DC-3500“.

CAUTION

This connection example only refers to the 24 [VDC] versions of the WTRB-x-x. Connecting

the 230 [VAC] models will not be similar. Pay special attention to the intended use and the

connection of the alarm outputs.

WTRB-24DC-3500

Figure 2: Sample connection for a WTRB-24DC-3500.

IMPORTANT

The Walther Systemtechnik heating elements come with a status LED which indicates the

heating operation. Pay close attention to a correct polarity of the heating elements in order to

guarantee a proper function.

Page 13

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 13 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5.2.2 Circuit Diagram

Figure 3: Circuit Diagram WTRB-24DC-3500

Page 14

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 14 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5.3 Operation

The Walther Systemtechnik Temperature Controllers come with a standard configuration which will only allow

changes in the preset temperature (SP1). The parameters of the analog input were pre-configured for a PT100

2-wire resistance thermometer. Please refer to chapter 5.3.2 for the pre-settings of the limit monitoring. Table 5

in section 7.4 provides an overview of the parameters of the standard configuration.

The controller parameters of the PID controller were pre-configured for the classic use with 24 [VDC]-heating

elements of Walther Systemtechnik GmbH.

IMPORTANT

If you are not satisfied with the control performance when using a heating element with the

pre-configured control parameters, you should change/adapt the PID control parameters.

Please refer to chapter 7 “Advanced Settings“ and 8.2 “Self-Optimization “.

5.3.1 Display and Operating Elements in the Standard Configuration

Use the buttons (B) and (C) for decreasing or increasing the desired temperature. The system will automatically accept and apply the set value.

(A) Change in level

(B) Decrease set value / previous parameter

(C) Increase set value / next parameter

(D) Function key / leave level

(E) Red 7-segment-display:

actual value

(F) Green 7-segment-display:

set value

(G) LED 1 ... 3: switch position for binary output (LED

lights up = output active)

Figure 4: Display and operating elements of the WTR-x-x.

When changing into the operating level OPr, you can switch between the following parameters with the buttons

(B) and (C) :

Symbol

Description

SP 1

Set value 1 (editable)

SP 2

Set value 2 (not used)

InP 1

Measured value at analog input resistance thermometer

Y

Current output level (0-100 [%])

Table 4: Available parameters in the operator level OPr

69.5

70

(A)

(B)

(C)

(D)

(G)

(E)

(F)

Page 15

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 15 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5.3.2 Limit Monitoring

One alarm output for excess and one alarm output for insufficient temperature have been pre-configured. They

were set at ± 1 [°C] from the currently set desired value (SP1). In order to prevent malfunctions from broken

cables, a permanent signal is transferred to the superordinate control unit. If the preset value at the WTR is

exceeded or fallen short by 1°C, the individual alarm output drops as a signal for the superordinate control unit

(Signal at LOW). The alarm signal is turned off (Signal at HIGH) once the set value range has been reached

again. If the currently measured, actual temperature is within the preset tolerance range of ± 1 [°C], HIGH will

be indicated for both alarm outputs.

The hysteresis (HySt) for error signal is factory-set at ±1 [°C] symmetrically to the limit value of the insufficient

temperature (UT) or excess temperature (OT). If the temperature rises or falls back into these limits, the respective signal will be given. Please refer to Figure 5 for the signal curves of the two alarm outlets of the WTR-x.

Signal at alarm output 1

Used for issuing an error signal

for insufficient temperature (deviation AL -1°C to set value SP1)

Signal at alarm output 2

Used for issuing an error signal

for excess temperature (deviation

AL +1°C to set value SP1)

Figure 5: Signal curves of the alarm outlets of the WTR-x.

1

0

SP1

Temp.

AL

HySt

UT

1

0

SP1

Temp.

AL

HySt

OT

Page 16

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 16 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

6 Technical Data / Installation Information

Section 6.1 below provides installation instructions and dimensions for the mechanical mounting of the Walther

Temperature Controllers WTR-24DC and WTR-230AC, as well as the applying technical data. Please refer to

section 6.2 for the technical data and dimensions of the solid-state relay WSSR-x-x.

6.1 Walther Temperature Controller WTR-x

Both types (WTR-24DC and WTR-230AC) have the same dimensions and identical steps for mounting. Figure

6 shows the outside dimensions. For mounting on a switchboard, a square cut with 45

+0,6

[mm] side length is

required.

Figure 6: Dimensions of the WTR-x

Figure 7 shows you how to mount. Insert the device from the

front into the opening in the switchboard, and make sure that

the gasket fits properly (1). From the back of the switchboard,

place the fastening frame on the device and push the springs

against the back of the switchboard (2) until the latches click

into the designated grooves and the device is properly fixed.

Figure 7: Mounting the WTR

Switchboard cut 45

+0,6

x 45

+0,6

Units [mm]

Page 17

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 17 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

6.1.1 Technical Information for WTR-24DC

Input Resistance Thermometer (Pins 8; 9; 10)

Description

Measured range

Measuring

accuracy

Ambient temperature influence

PT100 2-wire connection according to

DIN EN 60751

-200 … +650 [°C]

≤ 0,4 [%]

≤ 100 [ppm/K]

Sensor line resistance: max. 30 [Ω] per line with a three-wire circuit

Measured current: PT100 ca. 1 [mA]

Line balancing:

For a two-wire circuit, a line balancing can be performed through a correction of the actual value (see

chapter 7.3 Configuration (ConF)).

Outputs

Relay (make contact)

(Pins 4/5 and 6/7)

Switch capacity/

Contact lifetime

max. 3 [A[ at 230 [VAC[ resistive load

150.000 switches at nominal load

350.000 switches at 1 [A[

310.000 switches at 1 [A[ and cos ϕ > 0,7

Logic output for SSR

(Pins 13/14)

0/14 [V] 20 [mA] max.

Controller

Controller type

Two-point controller, three-point controller, permanent controller

Controller structure

P/PI/PD/PID

Scan time

250 [ms]

A/D convertor

Resolution 16 Bit

Timer

Accuracy

0,8 [%] ± [ppm/K] ± 250 [ms]

Electrical Data

Voltage supply (power supply)

AC/DC 20 … 30 [V], 48 … 63 [Hz]

Electrical safety

According to DIN EN 61010, Part 1

Overvoltage Category III, Degree of Contamination 2

Power consumption

max. 14 VA

Electrical connection /

Wire diameter /

Tightening torque

From back with screw terminal; with wire

end ferrule (pipe shape), open cable lug or

terminal pin, fine-stranded wire 0,25 ... 1,5

[mm²] 0,5 [Nm]

Electromagnetic compatibility – emitted interference – interference immunity

According to DIN EN 61326-1 Class A – for

industrial use only – industrial requirement

Setup interface

USB socket, type Mini-B 5-poles

Page 18

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 18 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Requirements for wire end ferrules and cable lug

Type of housing

Plastic housing for mounting in switchboard

according to DIN IEC 61554 (use indoors)

Dimensions (Front)

48 [mm[ x 48 [mm[

Switchboard cut/opening

45 [mm] x 45 [mm]

Minimum distance horizontal / vertical

11 [mm] / 30 [mm] (65 [mm] with USB cable

Mounting depth

max. 95

[mm]

Mounting

depth

max. 95 [mm]

Ambient / storage temperature range

Climate resistance

rel. humidity <

90[%]

annual

average

without

condensation

Climate

resistance

rel. humidity < 90[%] annual average without

condensation

Set-up altitude

max. 2000 [m] above NN

Operating position

Any

Protection type

According to DIN EN 60529, front IP 65,

back IP 20

Weight (fully equipped)

ca. 150 [g]

Type of housing

Plastic housing for mounting in switchboard

according to DIN IEC 61554 (use indoors)

Dimensions (Front)

48 [mm[ x 48 [mm[

Switchboard cut/opening

45 [mm] x 45 [mm]

Minimum distance horizontal / vertical

11 [mm] / 30 [mm] (65 [mm] with USB cable

Mounting depth

max. 95 [mm]

Ambient / storage temperature range

-5 ... +55 [°C] / -40 ... +70 [°C]

Climate resistance

rel. humidity < 90[%] annual average without

condensation

Certification / Mark of Conformity

Mark of conformity c UL us of the verifying authority Underwriters Laboratories with certificate number

E201387 based upon test principles UL 61010-1 CAN/CSA C22.2 No. 61010-1

Page 19

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 19 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

6.1.2 Technical Information for WTR-230AC

Input Resistance Thermometer

Description

Measured range

Measuring

accuracy

Ambient temperature influence

PT100 2-wire connection

according to DIN EN

60751

-200 … +650 [°C]

≤ 0,4 [%]

≤ 100 [ppm/K]

Sensor line resistance: max. 30 [Ω] per line with a three-wire circuit

Measured current: PT100 ca. 1 [mA]

Line balancing:

For a two-wire circuit, a line balancing can be performed through a correction of the actual value (see

chapter 7.3 Configuration (ConF)).

Outputs

Relay (make contact)

(Pins 4/5 and 6/7)

Switch capacity/

Contact lifetime

max. 3 [A[ at 230 [VAC[ resistive load

150.000 switches at nominal load

350.000 switches at 1 [A[

310.000 switches at 1 [A[ and cos ϕ > 0,7

Logic output for SSR (Pins

13/14)

0/14 [V] 20 [mA] max.

Controller

Controller type

Two-point controller, three-point controller, permanent controller

Controller structure

P/PI/PD/PID

Scan time

250 [ms]

A/D convertor

Resolution 16 Bit

Timer

Accuracy

0,8 % ± [ppm/K] ± 250 [ms]

Electrical Data

Voltage supply (power supply)

AC 110 … 240 [V] +10/-15 [%], 48 … 63

[Hz]

Electrical safety

According to DIN EN 61010, Part 1

Overvoltage Category III, Degree of Contamination 2

Power consumption

max. 14 VA

Electrical connection /

Wire diameter /

Tightening torque

From back with screw terminal; with wire

end ferrule (pipe shape), open cable lug or

terminal pin, fine-stranded wire 0,25 ... 1,5

[mm²] 0,5 [Nm]

Electromagnetic compatibility – emitted interference – interference immunity

According to DIN EN 61326-1 Class A – for

industrial use only – industrial requirement

Setup interface

USB socket, type Mini-B 5-poles

Page 20

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 20 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Requirements for wire end ferrules and cable lug

Wire end ferrule

Pie shape, without plastic sleeve according

to DIN 46228 Part 1,

with plastic sleeve according to DIN 46228

Part 4

Cable lug

Open crimp terminal, similar to DIN 46237

for closed crimp terminal

Pin terminal

According to DIN 46231

For UL applications

Use of cable lugs and wire end ferrules according to

UL 486A-B (UL listed or recognized)

Housing

Type of housing

Plastic housing for mounting in switchboard

according to DIN IEC 61554 (use indoors)

Dimensions (Front)

48 [mm[ x 48 [mm[

Switchboard cut/opening

45 [mm] x 45 [mm]

Minimum distance horizontal / vertical

11 [mm] / 30 [mm] (65 [mm] with USB cable

Mounting depth

max. 95 [mm]

Ambient / storage temperature range

-5 ... +55 [°C] / -40 ... +70 [°C]

Climate resistance

rel. humidity < 90[%] annual average without

condensation

Set-up altitude

max. 2000 [m] above NN

Operating position

Any

Protection type

According to DIN EN 60529, front IP 65,

back IP 20

Weight (fully equipped)

ca. 150 [g]

Certification/Mark of Conformity

Mark of conformity c UL us of the verifying authority Underwriters Laboratories with certificate number

E201387 based upon test principles UL 61010-1 CAN/CSA C22.2 No. 61010-1

Page 21

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 21 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

6.1.3 Galvanic Isolation WTR-x

Figure 8 shows you the galvanic isolation for Walther Temperature Controllers.

(1) Analog input

(2) Binary input

(3) Setup interface (USB)

(4) Supply voltage

(5) RS485 – interface

(6) Analog output

(7) Relay outputs

(8) Logic outputs

Figure 8: Galvanic isolation of the WTR-x

2300V

AC

30 V AC

50 V DC

2300 V

AC

30 V AC

50 V DC

(7)

(1)

(3)

(2)

(6)

(5)

(4)

(8)

Page 22

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 22 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

6.2 Solid-state Relay WSSR-x-x

6.2.1 Technical Information for WSSR-24DC-3500

Main Features

Product or type of component

Solid-state relay

Number of channels

1

Number of mains phases

1 phase

Additional Characteristics

Mounting bracket

Base

Rated current [In]

3,5 [A]

Outlet voltage

1...24 [VDC]

Control circuit voltage

3...12 [VDC]

Setup and type of connection

1 S

Capacity unbalance

<= 1,5 [pF] for inlet / outlet

Minimal switch voltage

3 [VDC] turn-on

Maximum switch voltage

1 [VDC] turn-off

Inlet current limits

10 [mA]

Solid shaft outlet type

DC contactor / Mosfet output

Load current

0,001...3,5 [A]

Absolute maximum voltage

30 [V]

Surge current

<= 9 [A] for 10 [ms]

Drop in voltage

<= 0,5 [V] turned on

Leakage current

<= 0,001 [mA] turned off

Reaction time

0,12 [ms] turning on

0,1 [ms] turning off

Overvoltage category

III

Width

5 [mm[

Height

28 [mm]

Depth

15 [mm]

Product weight

0,0041 [kg]

SSL1D03JD

13+

A1+

LOAD 1…24VDC/3,5A

INPUT 3…12VDC

A2-

14

1 2 4

3

Solid-state relay

Base

Page 23

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 23 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

6.2.2 Technical Information for WSSR-24DC-6000

Main Features

Product or type of component

Solid-state relay

Number of channels

1

Number of mains phases

1 phase

Additional Characteristics

Mounting bracket

Symmetrical DIN rail

Rated current [In]

6 A

Outlet voltage

1...60 [VDC]

Control circuit voltage

4...32 [VDC]

Setup and type of connection

1 S

Starting torque

Inlets : 0,5...0,8 [N]

Outlets : 0,5...0,8 [N]

Connections – clamps

Screw terminal : 1 x 0,3...1 x 1,5 [mm²],

(AWG 22...AWG 16) for inputs

Screw terminal : 1 x 0,3...1 x 2,5 [mm²],

(AWG 22-AWG 14) for outputs

Capacity unbalance

<= 10 [pF] for inlet / outlet

Insulation resistance

1000 [MΩ] at 500 [VDC]

Local signaling

LED green for input status

Minimum switch voltage

4 [VDC] turn-on

Maximum switch voltage

10 [VDC] turn-off

Inlet current limits

8...11 [mA]

Solid shaft outlet type

Mosfet outlet / DC contactor

Load current

0,0025...6 [A]

Absolute maximum voltage

60 [V]

Surge current

<= 60 [A] for 10 [ms]

Drop in voltage

<= 0,6 [V] turned on

Resistance

0,1 [Ω] turned on

Leakage current

<= 0,1 [mA] turned off

Reaction time

0,6 [ms] turning on

0,3 [ms] turning off

Overvoltage category

III

Width

11 [mm]

Height

90,3 [mm]

Depth

83,7 [mm]

Product weight

0,05 [kg]

SSM1D26BD

11/13+

A2

LOAD 1…60VDC/6A

INPUT 4…32VDC

A1

14

1 2 4

3

Page 24

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 24 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

6.2.3 Technical Information for WSSR-24DC-12000

Main Features

Product or type of component

Solid-state relay

Number of channels

1

Number of mains phases

1 phase

Additional Characteristics

Mounting bracket

Symmetrical DIN rail

Rated current [In]

12 [A]

Outlet voltage

1...60 [VDC]

Control circuit voltage

4...32 [VDC]

Setup and type of connection

1 S

Starting torque

Inlets : 0,5...0,8 [N]

Outlets : 0,5...0,8 [N]

Connections – clamps

Screw terminals : 1 x 0,3...1 x 1,5 [mm²],

(AWG 22...AWG 16) for inputs

Screw terminals : 1 x 0,3...1 x 2,5 [mm²],

(AWG 22-AWG 14) for outputs

Capacity unbalance

<= 10 [pF] for inlet / outlet

Insulation resistance

1000 [MΩ] at 500 [VDC]

Local signaling

LED green for input status

Minimum switch voltage

4 [VDC] turn-on

Maximum switch voltage

1 [VDC] turn-off

Inlet current limits

9...11 [mA]

Solid shaft outlet type

DC contactor / Mosfet outlet

Load current

0,0025…12 [A]

Absolute maximum voltage

60 [V]

Surge current

<= 100 [A] for 10 [ms]

Drop in voltage

<= 0,5 [V] turned on

Resistance

0,045 [Ω] turned on

Leakage current

<= 0,1 [mA] turned off

Reaction time

0,6 [ms] turning on

0,3 [ms] turning off

Overvoltage category

III

Width

18 [mm]

Height

90,3 [mm]

Depth

83,7 [mm]

Product weight

0,09 [kg]

SSM1D212BD

11/13+

A2

LOAD 1…60VDC/12A

INPUT 4…32VDC

A1

14

1 2 4

3

Page 25

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 25 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

6.2.4 Technical Information for WSSR-230AC-6000

Main Features

Product or type of component

Solid-state relay

Number of channels

1

Number of mains phases

1 phase

Additional Characteristics

Mounting bracket

Symmetrical DIN rail

Rated current [In]

6 [A]

Outlet voltage

24...280 [VAC]

Control circuit voltage

4...32 [VDC]

Setup and type of connection

1 S

Starting torque

Inlets : 0,5...0,8 [N]

Outlets : 0,5...0,8 [N]

Connections – clamps

Screw terminals : 1 x 0,3...1 x 1,5 [mm²],

(AWG 22...AWG 16) for inputs

Screw terminals : 1 x 0,3...1 x 2,5 [mm²],

(AWG 22-AWG 14) for outputs

Capacity unbalance

<= 10 [pF] for inlet / outlet

Insulation resistance

1000 [MΩ] at 500 [VDC]

Local signaling

LED green for input status

Minimum switch voltage

4 [VDC] turn-on

Maximum switch voltage

1 [VDC] turn-off

Inlet current limits

8...11 [mA]

Solid shaft outlet type

Zero-voltage switching, thyristor output

Load current

0,00015...6 [A]

Absolute maximum voltage

600 [V]

Surge current

<= 285 [A] for 16.6 [ms]

<= 300 [A] for 20 [ms]

Motor performance (HP)

0,16 [hp] at 40 [°C] 240 [VAC]

Drop in voltage

<= 1,3 [V] turned on

Leakage current

<= 0,1 [mA] turned off

Reaction time

0,5 cycles turning on

0,5 cycles turning off

Overvoltage category

III

Width

11 [mm]

Height

90,3 [mm]

Depth

83,7 [mm]

Product weight

0,05 [kg]

SSM1A16BD

-K17

L1

A1+

LOAD 24…280VAC/6A

INPUT 4…32VDC

A2

T1

1 2 4

3

Page 26

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 26 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

7 Advanced Settings

IMPORTANT NOTE!

Only make changes in the “Advanced Settings“ if the standard factory settings do not produce

satisfactory controlling results. As a rule, changes in the “Advanced Settings” should only be

made by trained and qualified technicians with experience in control technology.

7.1 Concept of Levels

Locking of Levels

(the factory settings only allow access to the operating level)

1. Press (A) and (B) at the same time (>5 s)

2. Press (A) (display is blinking)

3. Enter code with (B) or (C)

4. Press (D) for returning to normal display

Code

Operator level

Parameter level

Configuration level

0

Free

Free

Free

1

Free

Free

Locked

2

Free

Locked

Locked

3

Locked

Locked

Locked

(H) Programming / one level lower

(I) Decrease value / previous parameter

(J) Increase value / next parameter

(K) Function key / leave level

(L) Red 7-segment-display (factory set: actual value);

four digits, configurable decimal place (automatic

adjustment when display capacity is reached)

(M) Green 7-segment-display (factory set: desired

value);

four digits, configurable decimal place; also showing level and parameter symbols

(N) LED 1 ... 3: switch position binary output (LED

lights up = outlet active)

(1) Changing from normal display into levels

(2) Changing between levels

(3) Change within operator level (desired values, process val-

ues, timer value and times)

(4) Change to parameter level (control parameters)

(5) Change to configuration level (analog input, controller,

ramp function, limit value monitoring, timer, outputs, binary

functions, display and operation, interface)

(6) Return to normal display

(10) Navigation principle:

(11) – one level lower

(12) – next parameter / increase value

(13) – previous parameter / decrease value

(14) – go one level back

24.98

54.32

(2)

(1)

(3)

(4)

(5)

(6)

OPr

PArA

ConF

>2s

(11)

(14)

(12)

(13)

(10)

If you do not press a button for 10 [s] (factory set), the device returns to normal display. This duration can be configured.

.

69.5

70

(A)

(B)

(C)

(D)

(H)

(G)

(E)

(F)

Page 27

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 27 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Entering values

When entering values in the actual levels, the lower display shows you the symbol of the parameter,

(1) Select parameter (lower display -

green)

(2) Change value (upper display - red)

(3) Parameter blinking

Entering times

Time values are displayed with a decimal point in the middle and to the right. Time units can be configured.

(1) Select parameter (lower display -

green)

(2) Change value (upper display - red)

(3) Parameter blinking

Procedure

1.

Select parameter with button (B) or (C)

2.

Change into entering mode with button (A): lower display is blinking.

3.

Change value with button (B) or (C). The longer you press the button, the faster the value changes,

4.

Accept settings with button (A) (will be automatically saved after 2 [s] ) - or use button (D) for canceling input (value will not be saved)

0

Pd 1

1

PD 1

(C)

(B)

(A)

(1)

(3)

(2)

(B)

(C)

88.88.

tO

00.28.

tO

(C)

(B)

(A)

(1)

(3)

(B)

(C)

Page 28

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 28 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

7.2 Parameters

IMPORTANT

Certain parameter will not be shown, if the device does not have the respective equipment.

Please see the following table for the factory settings which are in bold print.

Parameterization (PArA)

Control parameters will be entered here.

PArA ->

Parameter

Value

Description

Proportional range

Pb1

0…9999

Size of the proportional range: The larger the P-range, the smaller

the gain of the controller. For Pb = 0, there is no efficient controller

structure (same behavior as for limit value monitoring). For a steady

controller, Pb > 0 is required.

Derivative time

Dt

0 ...

80 ...

9999 [s]

Influences the differential portion of the controller output signal. The

influence of the D-portion increases with an increasing derivative

time.

0 = derivative time turned off (no D-portion)

Reset time

rt

0 ...

350

... 9999 [s]

Influences the integral portion of the controller output signal. The

influence of the I-portion becomes smaller with an increasing reset

time.

0 = reset time turned off (no I-portion)

Cycle time

Cy1

0.0 ...

20.0 ...

999.9 [s]

For a switching outlet, select the cycle time as follows: the energy

supply for the process should be almost continuous, and at the same

time, the switching elements should not be overstrained.

Contact distance

db

0.0 ...

999.9

Distance between the two controlling contacts in a three-point controller

Switching differential

HyS1, HyS2 1

0.0 ...

1.0 ...

999.9

Switching differential for a switching controller with proportional

range Pb = 0 (same behavior as for limit value monitoring)

Operating point

y0

-100 ...

0 ...

+100

Output level for P- and PD-controller (for x = w, then y = y0)

Output level limiting

y1, y2

0 ...

100 [%]

y1: Maximum output level limiting

-100 ...

+100 [%]

y2: Minimum output level limiting (only working for Pb > 0)

The type of controller determines the display of parameters. For some parameters, the decimal places depend

upon the equipment of the device. Factory settings are shown in bold print.

Page 29

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 29 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

7.3 Configuration (ConF)

Analog Selector

For some parameters in the configuration level, the user can select from a number of analog values. The below list shows you all available signals.

Value

Description

Value

Description

0

Turned off

7

Desired value 2

1

Analog input

8

Display output level

(-100 % ... +100 [%])

2

Actual value

9

Controller outlet 1 (e.g. heating,

output level 0 ... +100 [%])

3

Current desired value

10

Controller outlet 2 (e.g. cooling,

output level 0 ... -100 [%])

4

Ramp end value

11

Timer runtime (time unit of timer)

5

(reserved)

12

Timer remaining time (unit of timer)

6

Desired value 1

Analog Input (InP)

ConF -> InP ->

Parameter

Value

Description

Value

Description

Type of sensor

SEnS

Resistance thermometer:

Thermal elements:

0

PT100 3-conductor

9

NiCr-Ni K

1

PT1000 3-conductor

10

Pt10Rh-Pt S

2

PT100 2-conductor

11

Pt13Rh-Pt R

3

PT1000 2-conductor

12

NiCrSi-NiSi N

4

KTY 2-conductor

13

NiCr-CuNi E

5

Cu-50 3-conductor

Standard signals:

Thermal elements:

14

0 ... 20 [mA]

6

Cu-CuNi T

15

4 ... 20 [mA]

7

Fe-CuNi J

16

0 ... 10 [V]

8

Fe-CuNi L

When you select „0 ... 10 [V]“, the binary outlet bin1 is inactive.

Parameter

Value

Description

Correction of measured value

OFFS

-1999 ...

0 ...

+9999

The measured valued is corrected by this value (Offset)

before it is used as controller input value and in the analog sector.

Display start

SCL

-1999 ...

0 ...

+9999

When using a detector with standard signal, a display

value will be correlated to a physical signal here. Example: 0 … 20 mA = 0 … 1500 °C

Display end

SCH

-1999 ...

100 ...

+9999

Filter time constant

dF

0.0 ...

0.6 ...

100.0 [s]

Adaptation of the digital inlet filter (0 = filter off)

Temperature unit

Unit

1

Degree

2

Fahrenheit

(Setup program: you can set the resistance of the KTY at 25 [°C].)

Page 30

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 30 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Controller (Cntr)

The controller receives the actual value from the analog input.

ConF -> Cntr ->

Parameter

Value

Description

Type of controller

CtyP

1

Two-point controller

2

Three-point controller

3

Steady controller

Control direction

CACt

0

Direct (the output level of the controller will be > 0, if the

actual value is large than the desired value; e.g. cooling)

1

Inverse (the output level of the controller will be > 0, if the

actual value is smaller than the desired value, e.g. heating)

Manual output level

HAnd

-100...

0 ...

+101

Output level after switching into manual operation 101 =

last output level

Output level for Out-of-Range

rOut

-100... 0 ...

+100

Output level for exceeding or falling short of the measuring range

Limit for desired value – start

SPL

-1999 ...

+9999

A limit for the desired value will prevent entering values

which are outside the determined range. The limits for

desired values do work if the desired value will be input

via the interface. The correction value will be limited for

an external desired value with correction.

Limit for desired value- end

SPH

-1999 ...

+9999

(Setup program: manual operation and self-optimization can be locked.)

Ramp Function / Firing Curve (rAFC)

The device can be used as a fixed value controller with or without ramp function. A firing curve is supported

additionally.

ConF -> rAFC ->

Parameter

Value

Description

Function

FnCt

0

Ramp function/ firing curve turned off

1

Ramp function Kelvin/ minute

2

Ramp function Kelvin/ hour

3

Ramp function Kelvin/ day

4

Firing curve Kelvin/ minute

5

Firing curve Kelvin/ hour

6

Firing curve Kelvin/ day

Ramp gradient

rASL

0 …

999

Value of ramp gradient (only for function = 1 to 6)

(Setup program: you can set the time value, time unit and desired values for the firing curve here.)

Page 31

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 31 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Limit Monitoring (Li1, Li2)

The device has two functions for limit value monitoring (Li 1, Li 2) with eight different alarm functions (AF1 to

AF8) each. Both outlet signals are available in the binary functions.

ConF -> L1,L2 ->

Parameter

Value

Description

Alarm function

FnCt

0

Limit value monitoring turned off

1

AF1: limit value above and below the desired value (monitoring tape); symmetrical or unbalanced

2

AF2: as AF1, outlet signal inverted

3

AF3: limit value below desired value

4

AF4: as AF3, outlet signal inverted

5

AF5: limit value above desired value

6

AF6: as AF5, outlet signal inverted

7

AF7: fixed limit value (separate from desired value)

8

AF8: as AF7, outlet signal inverted

Limit value

AL, AL2

-1999 ...

0 ...

+9999

Limit value to be monitored when limit value is unbalanced: AL is below desired value, AL2 above desired

value. Limit value range for AF1 and AF2: 0 ... 9999

Switch differential

HySt

0 ... 1 ...

9999

Switch differential for limit value

Behavior for Out-of-Range / Symmetry of limit value

ACrA

0

Off / symmetrical (only AL active)

Behavior for Out-of-Range / Symmetry of limit value

ACrA

Turn-on delay

tOn

1

On / symmetrical (only AL active)

2

Off / unbalanced (AL and AL2 active)

3

On / unbalanced (AL and AL2 active)

Switching status for exceeding or falling short is measuring range (Out-of-Range) / Symmetry for alarm functions

AF1, AF2

0 … 9999

Turn-on delay of outlet signal (in seconds)

Actual value

AFPr

2

Signal to be monitored; 2 = actual value "Analog Selector", page 15

Desired value

AFSP

3

Desired value for limit value monitoring (reference signal

for AF1 to AF6); 3 = current desired value

Page 32

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 32 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

The below figures show you the functions of the limit value (AL, AL2) for the different alarm functions AF1 to

AF8. The switch differential (HySt) will always be symmetrical to the limit value.

Limit value in relation to the desired value w

AF1 symmetrical

AF2 symmetrical

AF1 unbalanced

AF2 unbalanced

AF3

AF4

AF5

AF6

1

0

W

X

AL

HySt

AL

1

0

W

X

AL

HySt

AL

1

0

W

X

AL2

HySt

AL

1

0

W

X

AL2

HySt

AL

1

0

W

X

HySt

AL

1

0

W

X

HySt

AL

1

0

W

X

AL

HySt

1

0

W

X

AL

HySt

Page 33

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 33 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Fixed limit value

AF7

AF8

Timer (tFCt)

The timer issues an outlet signal which is available for the binary functions. This will help you realize e.g. a

time-limited controlling or a time-dependent switching of the desired value. The timer value will not be saved

during a power outage. The time remains inactive after the return of current.

ConF -> tFCt->

Parameter

Value

Description

Function

FnCt

0

Timer turned off

1

Timer signal is “high“ while timer is running

2

Timer signal is “low“ while timer is running

Start condition

Strt

0

Manual start through function key or binary signal (no restart after power outage)

1

Automatic start after ‘power on‘ (restart after power outage); manual start also possible

Time unit

Unit

0

mm:ss

1

h:mm

2

hhh.h

Timer value

t1

00.00. ...

999.9.

Runtime of timer (in the preset time unit)

Tolerance band

toLt

0 ... 9999

Tolerance band for the start of the timer. The timer will not

start before the actual value hasn’t reached the tolerance

band. 0 = start without tolerance band

1

0

X

AL

HySt

1

0

X

AL

HySt

Page 34

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 34 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Outputs (OutL, OutA)

The configuration of the device outputs is divided into binary outlets (OutL) and analog outlets (OutA). Switching statuses of the binary outlets 1 to 3 (5) will be indicated by the LEDs K1 to K3 (K5) (LED on = outlet active).

Binary Outputs

As a standard, the device comes with a relay output (make contact; output 1); optionally, it can be equipped

with two (four) additional binary outlets (relay or logic output; outlets 2 to 5).

ConF -> OutL->

Parameter

Value

Description

Output 1 ... 5

Out1

Out2

Out3

Out4

Out5

0

Output not active (factory set for Out2 ... Out5)

1

Controller output 1 (factory set at Out1)

2

Controller output 2

3

Binary input

4

Limit value monitoring 1

5

Limit value monitoring 2

6

Timer signal

(Setup program: the output signal can be inverted.)

Analog Output

Optionally, the device can be equipped with an analog output (outlet 2).

ConF -> OutA->

Parameter

Value

Description

Function

FnCt

9

Function of output; 9 = controller outlet 1

Type of signal

SiGn

Physical output signal

0

0 ... 20 [mA]

1

4 ... 20 [mA]

2

0 ... 10 [V]

Value for Out-of-Range

rOut

0 ... 101

Signal (as percentage) for exceeding or falling short of

measuring range 101 = last output signal

Zero point

0Pnt

-1999 ... 0

... +9999

Value range of the basic value for the physical output signal

Final value

End

-1999 ...

100 ...

+9999

Page 35

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 35 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Binary Functions (binF)

The binary input, the limit value monitoring and the timer have binary signals with which you can activate different functions.

The binary functions for starting and cancelling respond to the ascending rising edge of the initiating signal; all

other binary functions are controlled by the status and are High-active.

ConF -> binF->

Parameter

Value

Description

Binary input

bin1

Limit value monitoring 1 and 2

LiI, Li2

Timer signal

tF1

0

Signal without function

1

Start self-optimization

2

Cancel/stop self-optimization

3

Switch into manual operation

4

Turn off controller (controller outlets inactive)

5

Turn on controller

6

Lock manual operation

7

Pause ramp/firing curve

8

Cancel ramp/firing curve

9

Restart ramp, start/cancel firing curve

10

Switching from desired value 1 to desired value 2

11

Lock keyboard

12

Lock parameter and configuration level; lock start of selfoptimization

13

Turn off display

14

Start timer

15

Cancel timer

16

Pause timer

17

Start/cancel timer

Display and Operation (diSP)

Both displays as well as the function key can be individually adapted to the respective requirements.

ConF -> diSP->

Parameter

Value

Description

Upper display

diSU

2

Display value for upper display; 2 = actual value

Lower display

diSL

3

Display value for lower display; 3 = current desired

value

Display change for timer start

diSt

Time indication on lower display after timer-start

0

No change in display

1

Timer remaining time

2

Timer runtime

Time-out

tout

0 ...

180 ...

255

Duration in seconds after which the device will automatically switch into normal display (when no button is

pressed) 0 = function turned off

Decimal places

dECP

0

No decimal place

1

One decimal place

2

Two decimal places

Function key short (< 2 s)

tAS

0

Without function

1

Start timer/firing curve

2

Cancel timer/firing curve

Page 36

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 36 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

3

Pause/continue timer/firing curve

4

Start/cancel timer/firing curve

5

Display timer (timer runtime or timer remaining time)

(Setup program: you can also configure for a longer activation of the function key (> 2 s))

Interface (IntF)

An optional RS485 interface can be provided for integrating the device into a data network. When communication is made via the setup interface, the RS485 interface will be inactive.

ConF -> IntF->

Parameter

Value

Description

Baud rate

bdrt

0

9600 Baud

1

19200 Baud

Device address

Adr

0 ...

1 ...

254

Address in data network

Page 37

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 37 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

7.4 Factory Configured Standard Parameters

Hardware:

Optional slot 1:

Logic output

Optional slot 2:

Relay (make contact)

Analog Input:

Temperature unit

Temperature unit (Unit):

[°C]

Analog input 1

Sensor (SEnS):

PT100 2-wire

Measured value correction (OFFS):

0.000 [°C]

Filter time constant (dF):

0.6 [s]

Controller:

Controller type (CtYP):

Two-point controller

Control direction (CACt):

Inverse

Manual output level (HAnd):

101 [%]

Output level for Out of Range (rOut):

0 [%]

Desired value limit, start (SPL):

0.000 [°C]

Desired value limit, end (SPH):

100.0 [°C]

Manual operation (InHA):

Free

Self-optimization:

Free

Controller Parameters:

Proportional range 1 (Pb1):

3.500

Derivate time (dt):

3.000 [s]

Reset time (rt):

13.000 [s]

Cycle time 1 (CY1):

2.0 [s]

Switch differential 1 (HYS1):

1.000

Operating point (Y0):

0 [%]

Output level limit max (Y1):

100 [%]

Output level limit min (Y2):

-100 [%]

Desired Values:

Desired value (SP1)

60.00

Desired value (SP2)

60.00

Ramp Function / Firing Curve:

Function (FnCt):

Turned off

Limit Value Monitoring:

Limit value monitoring 1

Alarm function (FnCt):

Alarm function 3

Symmetry of limit value (ACrA):

Symmetrical

Limit value (AL):

1.000

Limit value 2 (AL2):

61.00

Switch differential (HYSt):

1.000

Behavior for Out of Range (ACrA):

Alarm function on

Alarm function – actual value (AFPr):

Analog input 1

Alarm function – desired value (AFSP):

Current desired value

Turn-on delay (tOn):

0 s

Limit value monitoring 2

Alarm function (FnCt):

Alarm function 5

Symmetry of limit value (ACrA):

Symmetrical

Limit value (AL):

1.000

Limit value 2 (AL2):

61.00

Switch differential (HYSt):

1.000

Behavior for Out of Range (ACrA):

Alarm function on

Page 38

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 38 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Alarm function – actual value (AFPr):

Analog input 1

Alarm function – desired value (AFSP):

Current desired value

Turn-on delay (tOn):

0 s

Timer:

Function (Fnct):

No function

Outputs:

Analog output:

Not existing

Binary outputs:

Function binary output 1:

Limit value monitoring 1

Function binary output 2:

Controller outlet 1

Function binary output 3:

Limit value monitoring 2

Binary Function:

Binary input:

Function:

Locking levels

Limit value monitoring:

1.Limit value monitoring:

Function:

None

2.Limit value monitoring:

Function:

None

Timer :

Function:

None

Display / Operation:

Display

Upper display (diSU):

Actual value

Lower display (diSL):

Current desired value

Change display for timer start (diSt):

No change in display

Decimal place (dECP):

XXX .X

Operation

Timeout (tout):

180 [s]

Locking levels (CodE):

Parameter and configuration level

Function key short (tAS):

No function

Function key >2 sec (tASt):

Switch to manual operation

Interface:

Baud rate (bdrt):

9600 Baud

Device address (Adr):

1

Table 5: Parameters of the WTR-x in the standard configuration

Page 39

Rev. 1.0

WALTHER Temperature Controller Bundle WTRB-x-x

Page 39 of 42

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

8 Troubleshooting

8.1 Error Messages

Display

Reason/cause

Action

- 1999

(blinking!)

Displayed value falls under measuring range

• Is the medium to be measured

within the measuring range (too

hot – too cold?)

• Check sensor for sensor break

or sensor short circuit