Page 1

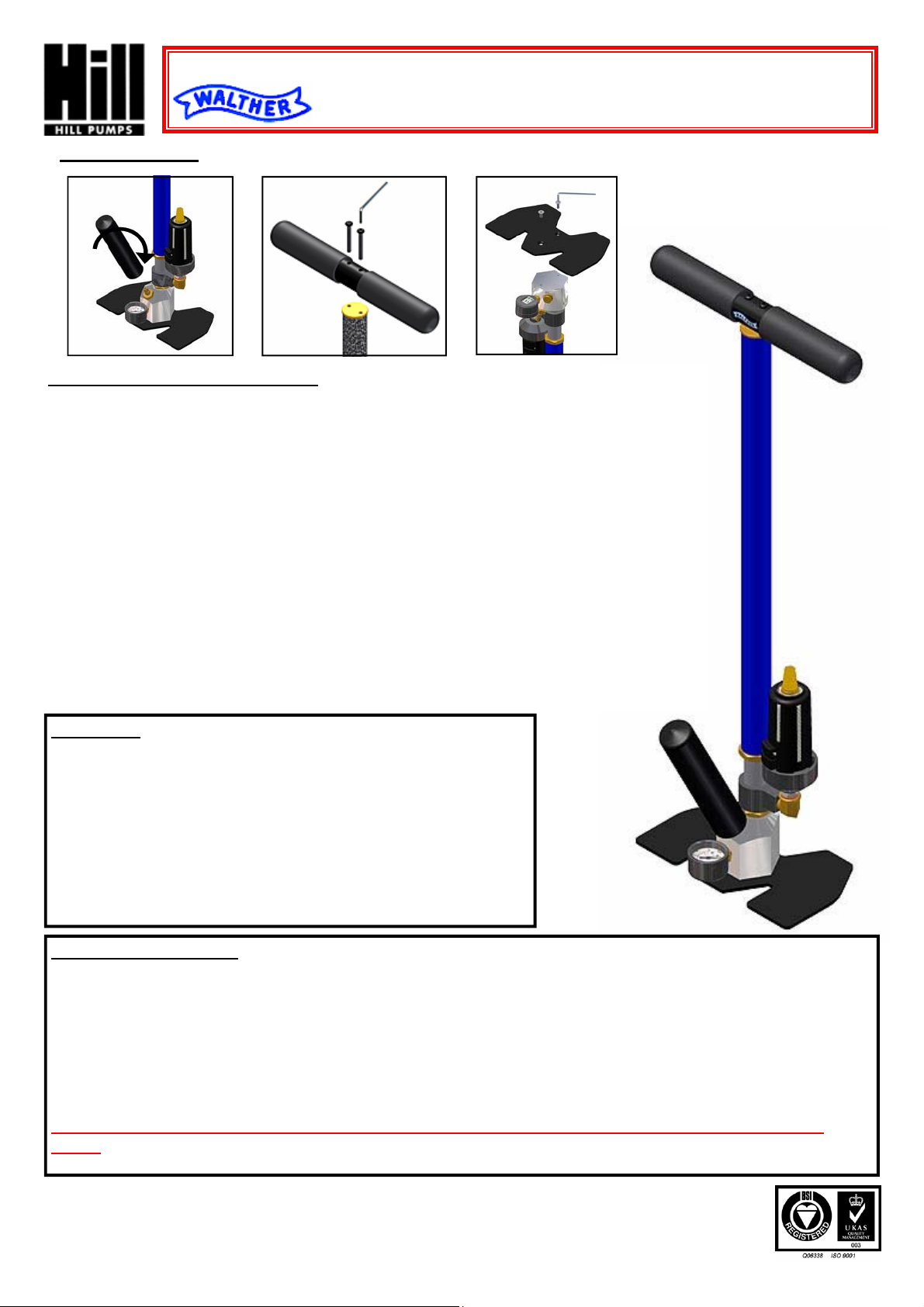

Model 2128 AIR COMPRESSOR PUMP

Operating Instructions

Assembly of pump

Connection to cylinder and charging

1) Connect the air cylinder to the pump. Do not over tighten.

2) Close the knurled brass bleed screw by turning it fully clockwise. Finger tightness is all that is

required. Do not use tools to tighten.

3) The pump is now ready to charge the cylinder. Use a full stroke for efficiency.

4) The gauge will show a rapid rise in pressure upon initial pumping, gradually rising at a slower

rate until the pressure in the pump and the pressure within the cylinder are equalised. The

indicated gauge pressure at this point will give a guide to the residual pressure in the cylinder.

Continue pumping until the required pressure is indicated. Do not exceed 230 bar (3300 psi).

5) When working pressure has been achieved (refer to your gun manufacturers specification)

open the bleed valve at the bottom of the pump to release the residual air pressure. A built in

safety device which controls the rate of air discharge enables the bleed valve to be opened

quickly without risk of injury. Disconnect the air hose from the cylinder.

6) We recommend pausing pumping after approximately 50 continuous strokes or when the pump

body tube feels excessively warm at any time. Failure to do so could shorten the life of the

internal seals. Whilst pausing, pumps without the Dry Pac option fitted should also have the

bleed valve opened to allow excess moisture to be expelled. It is not necessary to bleed

pumps that have the Dry Pac option fitted. Consult the separate Dry Pac instructions on how to

maintain moisture free charging.

Precautions

Only use the pump to fill compressed air cylinders used in modern pneumatic

air weapons. Do not use for any other purpose.

The maximum recommended air pressure for this pump is 230 bar (3300 psi)

Do not exceed the manufacturers recommended filling pressure rating of the

cylinder. This could result in injury to yourself or others. Never attempt to

recharge a damaged air cylinder

Always use the pump on firm, non slip surfaces.

Do not use the pump without a fully working pressure gauge fitted. Gauges

are robust but can be damaged (particularly the face) by careless handling.

Ensure correct posture for pumping.

Maintenance of the pump

After prolonged use the pump may become harder to operate. This can be caused by a blocked filter; lack of lubrication; or a build up

of previously applied lubricant causing stiction of seals and rod. The pump has a specially designed integral micron filter to prevent

excess moisture, oil grease or contaminants from entering the cylinder when charging. This filter is easily replaceable and should be

changed when it becomes clogged or after extensive use.

Spare filter kits are readily available. Product Code Z2128-100

It is recommended that the pump is occasionally cleaned and lubricated for long life and ease of use. Lubrication should be applied

sraringly onto the pump rod and then pumped for a few strokes. Only silicone grease should be used as a lubricant for this pump.

Do not over lubricate. The pump is factory lubricated using our own brand of NLGI 2 Silicone grease.

To order quote Product Code 06R50011.

DO NOTUSE PETROLEUM/OIL OR PROPELLANT BASED PRODUCTS AS A LUBRICANT FOR THIS

PUMP.

ERNEST H HILL LTD

10–12 MEADOWBROOK PARK, STATION RD, HALFWAY, SHEFFIELD S20 3PJ ENGLAND

http://www.airriflepump.com e-mail: sales@hillpumps.com

Loading...

Loading...