This .pdf document is bookmarked

Operating Instructions and Parts Manual

Horizontal Band Saw

Models HBS-916W; HBS-1018W

WALTER MEIER (Manufacturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414468

Ph.: 800-274-6848 Revision G1 06/2010

www.waltermeier.com Copyright © 2010 Walter Meier (Manufacturing) Inc.

W arranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit waltermeier.com.

WARRANTY

JET products carry a limited warranty which varies in duratio n based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the e xceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME ST ATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERT Y, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

®

branded products are not sold in Canada by Walter Meier.

®

tools. For the name of an Authorized Service Center in

2

Table of Contents

Warra nty a nd Serv ice ......................................................................................................................2

Table of Contents.............................................................................................................................3

Warning ....................................................................................................................... ......................4

Introduction .................................................................................................................. .....................6

Specifications .....................................................................................................................................6

Uncrating and Cleanup........................................................................................................................7

Installation .................................................................................................................. .......................7

Assembly ...........................................................................................................................................7

Electrical Connections .........................................................................................................................8

Controls .............................................................................................................................................9

Prior to Operation ..............................................................................................................................9

Adjustments ..................................................................................................................................... 10

Adjusting Vise Square to the Blade ................................................................................................. 10

Changing Blade Speeds ......................................................................................................... ......... 10

Adjusting Feed Rate....................................................................................................................... 11

Changing Blades ............................................................................................................................ 11

Blade Tracking Adjustment ............................................................................................................ 12

Automatic Shut‐Off Adjustment ..................................................................................................... 13

Thrust Roller Adjustment ............................................................................................................... 13

Guide Roller Adjustment................................................................................................................ 13

Bow Weight Adjustment ................................................................................................................ 14

Vise Adjustment ............................................................................................................................ 14

Maintenance ................................................................................................................... ................. 15

Lubrication ....................................................................................................................................... 15

Replacement Parts............................................................................................................................ 15

Base and Bed Assembly ................................................................................................................. 16

Saw Arm Assembly – HBS‐916W..................................................................................................... 17

Saw Arm Assembly – HBS‐1018W ................................................................................................... 18

Parts List for HBS‐916W, HBS‐1018W ............................................................................................. 19

Gear Speed Reducing Box Assembly ............................................................................................... 26

Parts List for Gear Speed Reducing Box Assembly ............................................................................ 27

Electrical Connections – HBS‐916W ................................................................................................... 28

Electrical Connections – HBS‐1018W.................................................................................................. 29

3

Warning

1. Read and understand t he entire owner’s manual befor e attempting assembly or operation.

2. Read and understand the war nings post ed on the machine and in this manual. Fa ilure t o comply with

all of these warnings may cause serio us injury.

3. Replace the warning labels if they become obscured or removed.

4. This band saw is designed a nd intended for use by pr oper ly t r ai ned and experie nced per sonnel only.

If you are not familiar with the proper and safe operation of a band saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this band saw for other than its intended use. I f used for other p urposes, Walter Meier

(Manufacturing), Inc., disclaims any real or i mplied w ar r anty and holds itself harmless from any injury

that may result from that use.

6. Always wear appr oved saf ety glasses/ face s hields w hile using t his band saw . Everyday eyeglasses

only have impact resistant lens es; t hey are not safety glasses.

7. Before operating this ba nd saw, r emove tie, rings, wat ches and ot her jewelry , and roll sleeves up past

the elbows. Do not wear loose c lot hing. Confi ne long hair. No n-slip footw ear or anti-ski d floor st rips

are recommended. Do not w ear gloves.

8. Wear ear pr otect or s (plugs or muffs) duri ng exte nded periods of oper at io n.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals k nown to cause cancer, birt h def ec t s or ot her repr oducti ve har m. Some examples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium fr om chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make cer t ain the switch is in the OFF position before connecti ng the machine t o t he power supply.

12. Make cer t ain the machine is properly grounded.

13. Make all machine adjustme nts or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the mac hine before tur ning it on.

15. Keep belt guard, blade guards, and wheel co vers i n place and in working order.

16. Always keeps hands and fi ngers away f r om the blade when the machine is running.

17. Never hand hold the material. Alw ays use the vise and clamp it sec urely.

18. Always provide adequate supp or t f or long and heavy material.

19. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme cautio n and replace t he guards immed iately af t er maintenance is complet e.

20. Check damaged parts. Before further use of the machine, a guard or ot her part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignme nt of moving part s, binding of moving part s, break age of part s, mounting

and any other condit ions t hat may affect its oper ation. A guard or other part that is damaged s hould

be properly repaired or r eplaced.

4

21. Provide for adequate space surrounding work area and non-glare, overhead lighti ng.

22. Keep the floor around t he machine clean and free of sc r ap material, oil and grease.

23. Keep visitors a saf e dist ance from the wor k ar ea. Keep children away.

24. Give your work undivided att ention. Looking aro und, carrying on a conversat ion and “horse-play” are

careless acts that can result i n serious injury.

25. Maintain a balanced stance at all times so that you do not fall or lean against the blade or other

moving parts. Do not overreac h or use excessive for c e t o perfor m any machine operation.

26. Use the right tool at t he correc t speed and feed rate. Do not force a tool or at t achment to do a jo b f or

which it was not designed. The r ight t o ol will do t he job b e tter a nd mor e s a fely.

27. Use recommended accessor ies; improper acc essor ies may be hazardous.

28. Maintain t ools with care. Ke ep blade sharp and clean for t he best and safes t performance. Foll ow

instructions for lubricat ing and changi ng accessori es.

29. Turn off t he mac hine and disconnect fr om power before cleaning. Use a br ush to remo ve c hips or

debris — do not use your ha nds.

30. Do not stand on the machine. Serio us injury co uld occur if the machine tips over.

31. Never lea ve the machine r unni ng unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

Familiarize yours elf with the f ollow ing saf et y not ices used in t his manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious or even fatal

injury.

‐ ‐ SAVE THESE INSTRUCTIONS ‐ ‐

5

Introduction

This manual is provided by Walter Meier (Manufacturing) Inc., covering the safe operation and

maintenance pr ocedures for a JET Model HBS-916W or HBS-1018W Ba nd Saw. This ma nual co ntains

instructions on installation, safety precautions, general operating procedures, maintenance instructions

and parts breakdow n. This machi ne has been designed a nd constructed to pr ovide years of t rouble free

operation if used in accorda nce wit h instructions set f orth in this ma nual. I f there are any q uestions or

comments, please contact either your loc al s uppli er or W alter M eier. Walter Meier c an also be reached at

our web site: www.waltermeier.com.

Specifications

Model Number ......................................................... HBS-916W......................................... HB S-1018W

Stock Number .............................................................. 414468................................................ 414473

Capacity (in.):

Round at 90° ..................................................................... 9........................................................ 10

Round at 45° ............................................................... 6-1/8.................................................... 7-3/4

Rectangle at 90° ............................................ 4 x 16 – 9 x 12.................................... 6 x 18 – 10 x 16

Rectangle at 45° .....................................................9 x 6-1/8...............................................9 x 7-3/4

Blade Size (in.) ............................................ 1 x 0.032 x 119-1/2..................................... 1 x 0.032 x 130

Blade Wheel Diameter ( in.).................................................... 13........................................................ 14

Blade Wheel Speed (SFPM) ............................82, 132, 170, 235..................................82, 132, 210, 330

Motor .......................................... TEFC 1.5HP, 1PH, 115/230V*.................... TEFC 2HP 1PH 230V only

*pre-w ired 115V

Lowered Height (in.).............................................................. 41........................................................ 43

Raised Height (in.) ................................................................ 65........................................................ 69

Bed Height (in.) .................................................................... 25........................................................ 25

Overall Dimensions (in.) ............................................65L x 28W............................................70L x 31W

Net Weight – approx. (lbs.) .................................................. 625...................................................... 776

Shipping Weight – approx. (lbs. ) .......................................... 704...................................................... 864

The above specificati ons were current at the time t his manual w as publis hed, but beca use of our policy of

continuo us impro vement, Walt er M eier r eser ves the right to change s pecificat ions at any time and without

prior notice, without incurring obligations.

6

Uncrating and Cleanup

Note: Read and understand the entire manual

before at t empting setup or operation.

1. Finish uncrating the saw and inspect for

damage. Should any have occ urred, contact

your local distrib utor.

2. Remove all bolts attaching machine to

shipping base.

3. Leave packing material between vise

clamps and saw head intact until band saw

has been lifted to it s final position.

4. Clean all rust protected surfaces with

kerosene or diesel oil to remove protective

coating. Do not use gasoline, paint thinner,

mineral spirits, etc. These may damage

painted surfaces.

5. Lubricate all slidewa y s with SAE 10W oil.

Installation

For best per formance, the band saw s hould be

located on a solid and level foundation. Allow

room for servicing and for moving large stock

around the ba nd s aw when decidi ng a locat ion

for the ma chine.

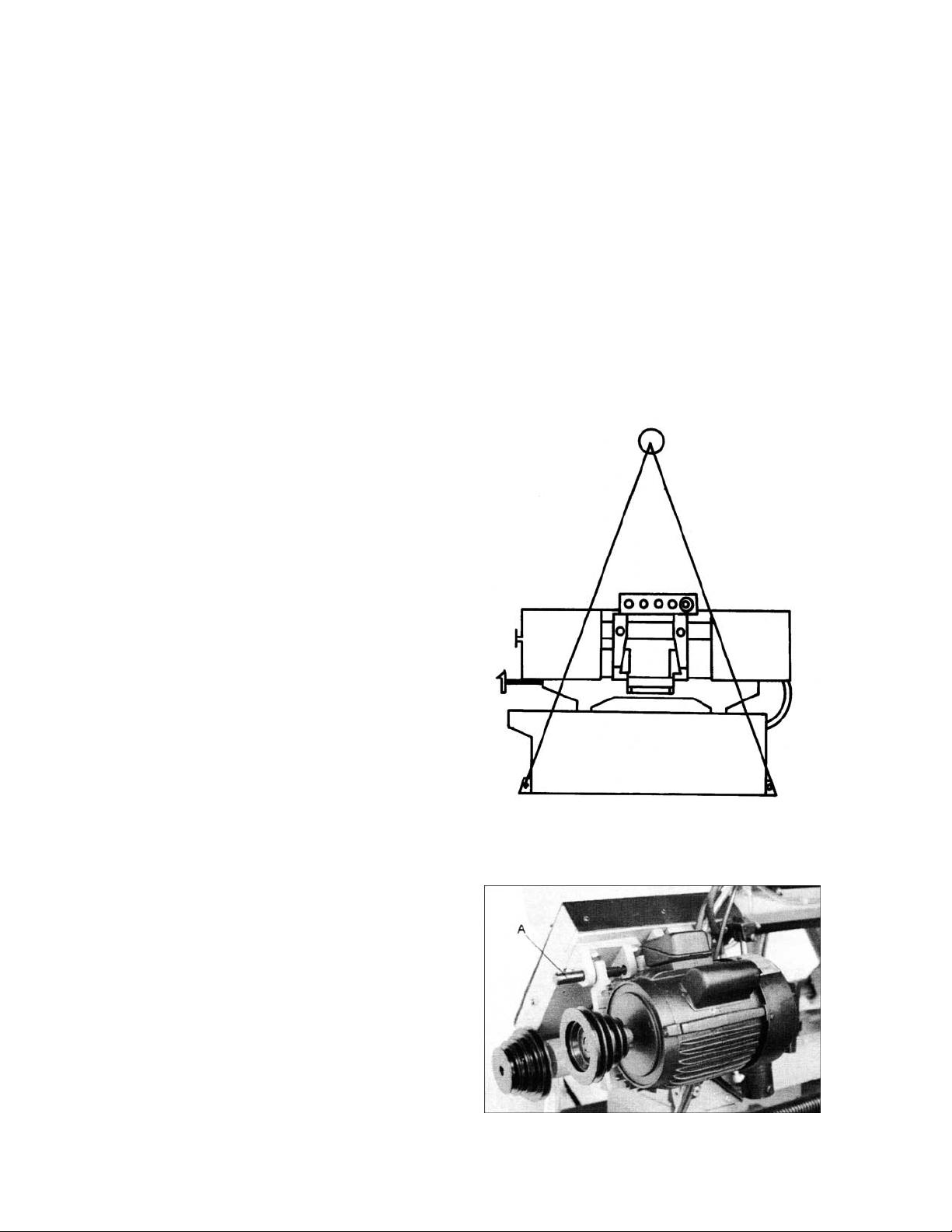

1. Using lifti ng straps that are isolat ed f r om the

band saw’s finished surfaces, lift machine

and place in desired locatio n. See Fig ure 1

for strap placeme nt.

2. Install four leveling bolts with lock nuts on

both sides of t he base as shown in the parts

breakdown on page 16, items 2 and 3.

3. Place a level on t he tabl e surface and check

side-to-s ide and front-to- back .

4. Adjust le veli ng scr ew s unt il m ac hine is le vel

in both directions and tighte n locking nuts.

Assembly

1. Unbolt the motor assembly from the

shipping crat e bottom.

2. Remove nut and washer from the motor

support shaft .

3. Remove s haft ( A, Figure 2) from t he motor

mount bracket.

Figure 1

7

4. Carefully lift motor and line up holes in the

motor mounting plate a nd the motor br acket.

5. Slide motor support shaft into motor mount

bracket to hold the motor in place.

6. Fasten shaft w it h nut and washer.

7. Loosen strain relief nut on the motor

junction box. Remove the junction box

cover. Insert wire through strain relief and

connect to the terminal strip using the

diagram o n t he j unction bo x cover. Tig hte n

the strain relief nut and replace the junction

box cover.

8. Remove tw o hex cap bolt s and washers (A,

Figure 3) fr om the right side of the saw arm.

9. Slide belt cover ( B, Figure 3) ar ound pulley

shafts and attach to saw with two hex cap

bolts and two was hers.

10. Lift motor and place v-belt around both

pulleys. Lower motor .

11. Tensio n the v-be lt by pushi ng dow n on t he

motor and tig htening the lock handle o n the

motor tilt plate. Correct tension is achieved

when finger pressure between the two

pulleys causes approximately a 1/2”

deflectio n. See Fig ure 4.

Figure 2

Figure 3

12. Close pulley cover door and f ast en with lock

knob.

13. Fasten work st op rod (#17, page 16) to saw

bed (#11) by i nser ting into bed a nd t ur ning

clockwise until tight. Place work stop

bracket (#16) onto stop rod (#17) and

tighten lock handle (#20). Attac h stop screw

(#19) t o stop brack et (#16) with lock handle

(#18) and tighten.

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be proper ly grounded to help

prevent electrical shock and possible fatal

injury.

Disconnect machine from power source

before changin g any voltage components!

The HBS-916W Ba nd Saw is rated at 115/ 230V

single phase, and is pr e-wired 115 volt from the

factor y. The HBS-1018W is rat ed at 230V only,

single phase. Confirm that power available at

the saw’s location matches that for which the

saw is wired.

Figure 4

8

To convert t he HBS-916W from 115V to 2 30V,

the f ollo wing it ems w ill have t o be c hanged:

Main Motor – follow diagram i nside j unctio n box

cover.

Coolant Pu mp – Remove c hip pa n on front of

saw, remove junctio n box co ver o n pump, and

follow diagram inside junctio n box co ver.

Control Transformer – Open electrical panel

on rear of base and cha nge the fuse from 115V

to 230V.

Machine must always be cor r ectly grounded.

NOTE: The power cord end will have to be

changed to one rated 230V when changing to

the higher voltage.

Controls

Refer to Figure 5.

Power Indicator Light (A) – lit whenever

machine is running.

Start Button (B) – press to start band saw.

Emergency Stop Button (C) – press to

immediately stop all machine functio ns.

Coolant S witch (D) – Tur n arrow to “I” to turn

on coolant flow. Turn arrow to “O” to stop

coolant flow.

Cutting Pressure C ontrol (E) – turn clockwise

to decrease cutting pressure. Turn counterclockwise to increase c utting press ure.

Hydraulic On-Off Valve (F) – turns hydraulic

cylinder on and off.

Pri or to Operation

1. Check that blade tooth direction matches

diagram on blade guides.

2. Check to see that blade is properly seated

on wheels after applying correct tension

(approximately 25,000 lbs. ) .

3. Set blade holder guides for approximately

.003” t o . 005” c learance bet ween the g uides

and blade.

4. C heck for slight cleara nce between back up

rollers and back of blade.

5. Positio n blade guides as close t o workpiece

as possible.

6. Select proper speed and feed rate for

material being cut. See speed selection

chart found in the enclosed “Guide to Band

Sawing” booklet supplied with this saw.

Figure 5

9

7. Mater ial to be cut must be sec urely held i n

vise.

8. C heck to see t hat cool ant le vel is ad equate

and turn on coolant pump if material to be

cut requires it. M achine should be filled w it h

four gallons of the proper coolant mixture.

Follow t he directio ns on the product maker ’s

label and fill the coolant tank through the

chip tray ar ea.

9. Do not start cut on a sharp edge.

10. Keep machine l ubricated. See “L ubr ication”

section.

Adjustments

Adjusting Vise Square to the Blade

1. Disconnect the machine from the power

source.

2. Place a machinist’s square on the table

against the blade a nd t he vise. The square

should lie along t he entire length of the vise

and blade without a gap.

3. If adjustment is necessary, loosen bolts

holding the vise and adjust vise so square

lines up properly. Tig hte n bolts.

4. Connect machine to t he power source.

Changing Blade Speeds

Disconnect machine from

the power source before changing blade

speeds. Failure t o comp ly may cause seriou s

injury.

1. Disconnect machi ne from the power s ource.

2. Open pulley cover by supporting the belt

cover with one hand while rem oving the bel t

cover lock knob with the other. Low er guard

gently to its full open position.

3. Support motor with one hand while

loosening lock handle (A, Figure 6). Lower

motor gently.

4. Position belt in grooves according to the

speed selection c hart.

5. Tension t he v-be lt by p us hing down on the

motor and tig htening the lock handle o n the

motor tilt plate. Correct tension is achieved

when finger pressure on the belt between

the two pulleys causes approximately a 1/ 2"

deflection.

6. Close pulley cover and fasten.

Figure 6

7. Connect machine to t he power source.

10

Loading...

Loading...