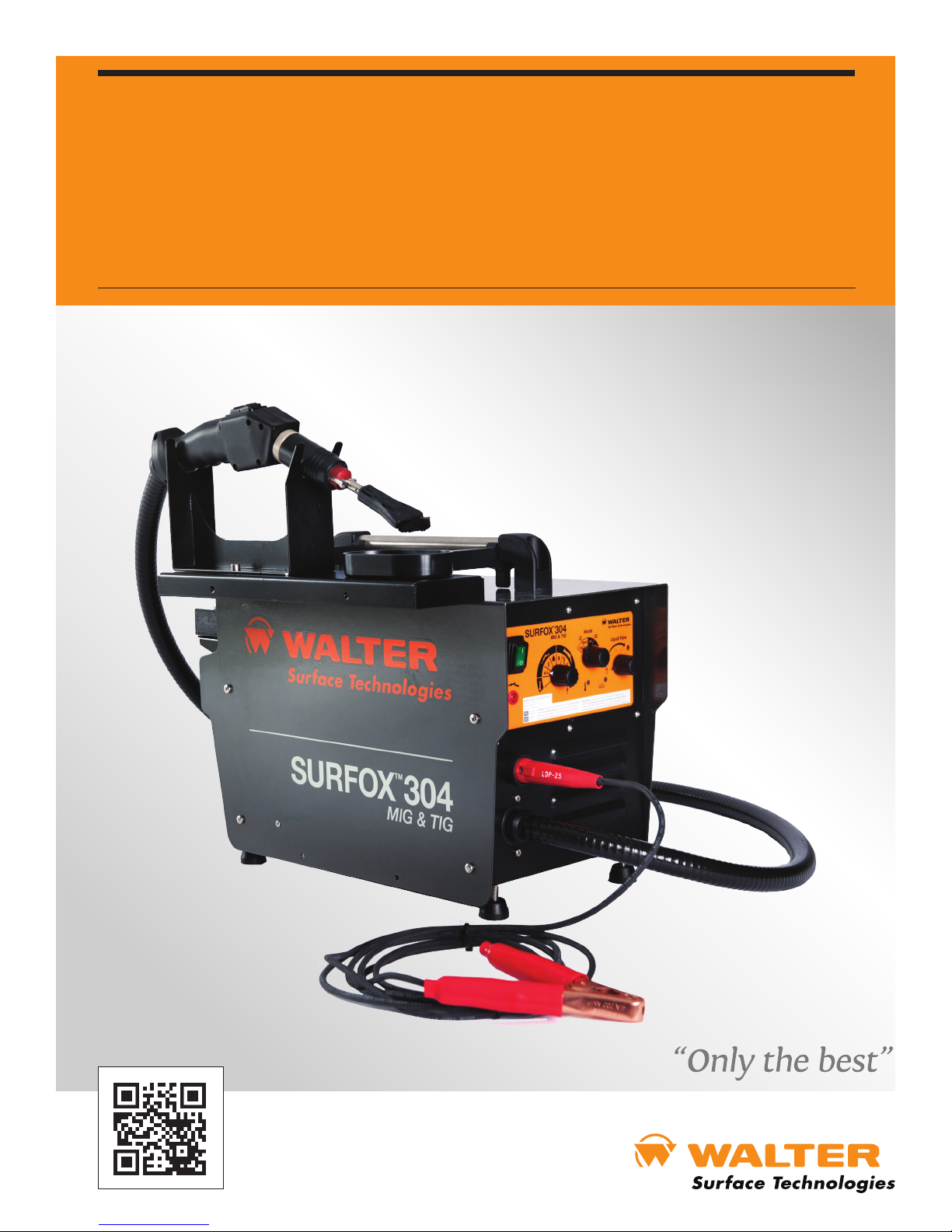

SURFOX 304

User’s guide

Manuel de l’utilisateur

Manual del usuario

Manual do Usuário

SURFOX website

(Link to surfox.com)

Table of contents

Table of contents

1 Introduction 2

2 Safety instructions 3

3 Equipment controls 4

A) Control panel pictograms 4

B) Front and back view of the machine 5

C) Wand control buttons 6

D) Fume elimination system 6

E) Tip repositioning (comfort for operator) 6

4 Control panel 7

A) Main power switch 7

B) Wand and accessory selector knob 7

C) Current mode selector knob 7

D) Solution pump switch 7

E) Indicator lights 7

F) Accessory outlet 7

5 Start-up procedure 8

A) What is included in the box 8

B) Filling the reservoir 8

C) Connecting air supply 8

D) Plugging in the power cord 8

E) Plugging in the ground clamp 8

6 Using the large wand to electrochemically

clean, polish and passivate 9

A) Selecting the proper wand and accessory 9

B) Selecting the proper current type, AC or DC and

proper current level, STD or MAX 9

C) Selecting the proper pumping mode 9

D) Cleaning and passivating 9

E) Neutralizing 9

7 Large wand accessories 10

A) Selection and mounting of the cleaning

pads and tips 10

B) PTFE clamp rings 12

C) SURFOX electrolyte solutions 12

D) Mounting a cleaning pad 12

8 Using the micro wand (optional) to clean, polish

and passivate 13

A) Selecting the proper wand and accessory 13

B) Selecting the proper current type, AC or DC and

proper curent level, STD or MAX 13

C) Manual pumping mode 13

D) Cleaning and passivating 13

E) Neutralizing 13

9 Using the marking/etching wand (optional) 14

A) Marking kits 14

B) Selecting the proper wand and accessory 14

C) Selecting the proper current type, AC or DC and

proper curent level, STD or MAX 14

10 Neutralizing 15

A) Directions for neutralizing SURFOX

electrolyte cleaning solutions 15

B) SURFOX weld cleaning and neutralization

procedure 15

11 Safety features 16

A) Sparks on the tip/work piece 16

B) Internal temperature 16

C) AC/DC current basics 16

D) AC/DC settings on the SURFOX machine 17

E) Welds that cannot be cleaned 17

12 Technical data 18

13 Warranty and service 18

A) Warranty policy 18

B) Repair and service 18

Version française 20

Versión española 39

Versão Português 58

SURFOX 304 User’s Guide 1

Introduction

1

Introduction

Congratulations on purchasing the finest electrochemical

weld cleaning and passivation equipment available today.

WALTER’s SURFOX

easily and cost effectively removes the heat tint from heat

affected zones while completely passivating the stainless

steel surface.

Our new generation of SURFOX machines are equipped

with self-regulating inverter boards, automatically monitoring

and adjusting the current so as to ensure maximum

cleaning effectiveness without loss of productivity.

Before starting, please read the SURFOX

completely as we take you step-by-step through the startup, operating and maintenance procedures of your new

SURFOX

built with extra durability to stand up to the heavy demands

of industrial use. However, like any piece of electrical

equipment, care and safety should always be taken when

using and maintaining this valuable investment. With proper

care and maintenance your SURFOX equipment will provide

years of dependable service.

To learn more about other WALTER products, visit our

website: www.walter.com

equipment. Your new SURFOX machine has been

TM

weld cleaning equipment quickly,

owner’s manual

1.1 General Information

This manual provides all the information required for a safe

installation, start-up and operation of the machine, along

with troubleshooting and maintenance instructions.

WALTER is not liable for any consequences of incorrect use

of its products, for example:

u Incorrect use of the machine or use by untrained

persons;

u Use in violation of the reference standards;

u Incorrect installation;

u Unsuitable main power supply;

u Incorrect maintenance;

u Incorrect maintenance;unauthorized modifications and

tampering;

u Incorrect maintenance;use of non-original spare parts

or spare parts not specified as suitable for the model in

question;

u Incorrect maintenance;partial or total failure to follow the

instructions;

u Unexpected events;

u And any other improper use.

Operation

The SURFOX machine works by an electrochemical

process to clean and passivate welds on stainless steel.

SURFOX electrolyte solutions are phosphoric acid based,

approved for food industry, and are activated by an electrical current to clean welds. The process takes only a few

seconds without damaging or scratching the surface of the

parts to be cleaned.

The manual is an integral part of the machine and must be

kept carefully with the machine until it is disposed of, to

allow for reference to future updates. Should your copy of

the manual be lost or unreadable, you can request a new

copy from: WALTER - walter.com or surfox.com

The present manual reflects the condition of the machine

at the time of manufacture and may not be deemed

inadequate in case of updates due to subsequent

experience.

WALTER reserves the right to update its products and

manuals without prior notification to users of previously

manufactured machines.

2

Your SURFOX 304 machine can clean:

u TIG welds

u Plasma welds

u Laser welds

u Spot welds

u MIG welds

Basics of passivation:

u The cleaning of the welds is not only for aesthetic

purposes but most importantly for passivation.

u Passivation is the treatment of stainless steel surfaces

to remove contaminants and promote the formation of

a thick and durable protective chromium oxyde layer.

u This passive layer will insure the corrosion resistance of

stainless steel.

u If passivation is not done properly, stainless steel and

heat affected zones may start to rust.

Safety instructions

Safety instructions

2

WALTER weld cleaning machines are produced in accor-

dance with applicable standards governing the manufacture, performance and safety of industrial products.

WARNING: When using these machines, basic safety

precautions should always be observed to reduce the risk

of fire, electrical shocks and personal injuries.

Before using this machine, read all Safety and

Operating Instructions carefully and save this owner’s

manual for future reference.

1. Read this owner’s manual to familiarize yourself with

this unit’s operation, its particular features, applications

and limitations.

2. This unit is equipped with a 3-conductor power cord

and 3-prong electrical plug, it must be connected to

a correspondingly grounded receptacle.

3. Allow a minimum of 8” clearance around the unit to

keep all air openings clear of any obstruction. Free

airflow through the vent openings is required to

prevent the unit from overheating.

Keep work area clean and well lit. A cluttered environ-

4.

ment invites accidents. Remove any material that

may be ignited by sparks. Do not use this tool when

flammable liquids or gases are present. Keep handles

clean, dry and free from cleaning solution, oil and

grease. Do not use in rain, damp or wet locations.

5. Keep children and other persons at a safe distance

from the work. Make sure no one is under you when

working in high places. Do not let unqualified persons

handle this machine.

6. When working, always wear appropriate clothing

and safety gear, such as suitable and safety approved

chemical resistant gloves, overalls, safety shoes, etc.

7. Always wear approved safety goggles.

8. During the cleaning process, the wand tip and work

piece can reach very high temperatures, allow to cool

before coming in contact with exposed skin.

9. Avoid inhalation of fumes, use only in well ventilated

areas. Use a respirator, if necessary.

10. All electric shocks can be potentially dangerous.

11. Should you encounter an electrical problem, do not

use the unit until qualified personnel have inspected

the equipment.

12. Never operate the unit without its protective cover.

13. Stay alert at all times when handling this unit. Watch

what you are doing. Use common sense. Do not

operate the tool when you are tired. Never leave it

running unattended.

14. Make sure the switch is in its OFF position before

plugging in or when moving the unit to avoid uninten tional starting.

15. Hold the wand firmly. Do not overreach, maintain good

footing and balance at all times.

16. Before use, all parts should be carefully examined to

determine that the unit will operate properly and

perform its intended function.

17. Parts that are damaged or defective should be repaired

or replaced by a WALTER Authorized Service Center.

18. Do not use the unit if the switch does not turn ON/OFF.

19. Use only the accessories recommended for this

system. Always check accessories before starting to

work and do not use if damaged.

20. CAUTION: WALTER SURFOX electrolyte weld cleaning

solutions contain phosphoric acid and may cause burns

when not handled properly. Avoid skin contact.

First aid Wash affected area with water.

Eye contact Flush with water for 15 minutes lifting

eyelids occasionally. Contact physician if necessary.

Ingestion DO NOT induce vomiting. Rinse mouth,

drink plenty of water and get medical attention.

Refer to WALTER product MSDS or SDS for complete

safety data information on walter.com or surfox.com.

21. Use only WALTER SURFOX electrolyte solutions with

this unit and NEVER mix it with any other products.

22. The use of the fume elimation system (page 6.) is highly

recommended when working in confided areas.

23. Do not use your SURFOX machine on the same struc-

ture when arc welding is in progress. Current could

ground back tot he SURFOX machine and cause irreparable damage.

24. Store solution in its original container and in a safe

place, out of the reach of children and other unquali fied persons. Keep container contents clean. Do not

reuse SURFOX electrolyte cleaning solutions.

25. Do not touch the wand tip or work piece while working

or immediately after use, they may be extremely hot

and could cause serious burns.

26. Do not abuse the power cord. Never pull or lift this unit

by its cord or yank to disconnect it from the receptacle.

Keep the cord away from heat, oil and sharp edges.

Inspect the cord periodically, if damaged, have it re placed by a WALTER Authorized Service Center.

27.

When not in use, switch OFF and unplug the electrical

cord and air hose (if connected). It must remain unplugged when replacing cleaning pads and accessories,

while performing maintenance and before servicing.

28.

Store the unit in a dry safe place, out of the reach of

children and other unqualified persons.

SURFOX 304 User’s Guide 3

Safety instructions

Equipment controls

2

Amperage

Before connecting this unit, check that the amperage

shown on the rating plate is the same as the power supply.

Operating this unit on an amperage other than specified on

its rating plate may result in personal injury to the user and

damage the unit.

Preventive maintenance

After use, allow the tip to cool and remove the cleaning pad

Neutralize with SURFOX-N and rinse the cleaning pad and

wand tip with water and dry. Clean dust and dirt deposits

from the exterior of the unit. Keep all airflow vent openings

free of any obstructions. Clean the power cord to prevent

deterioration and check for possible damage to cord and

plug.

Note: Damaged cords must be replaced immediately by

qualified personnel only. Refer to Spare Parts List for the

ordering number.

3

Equipment controls

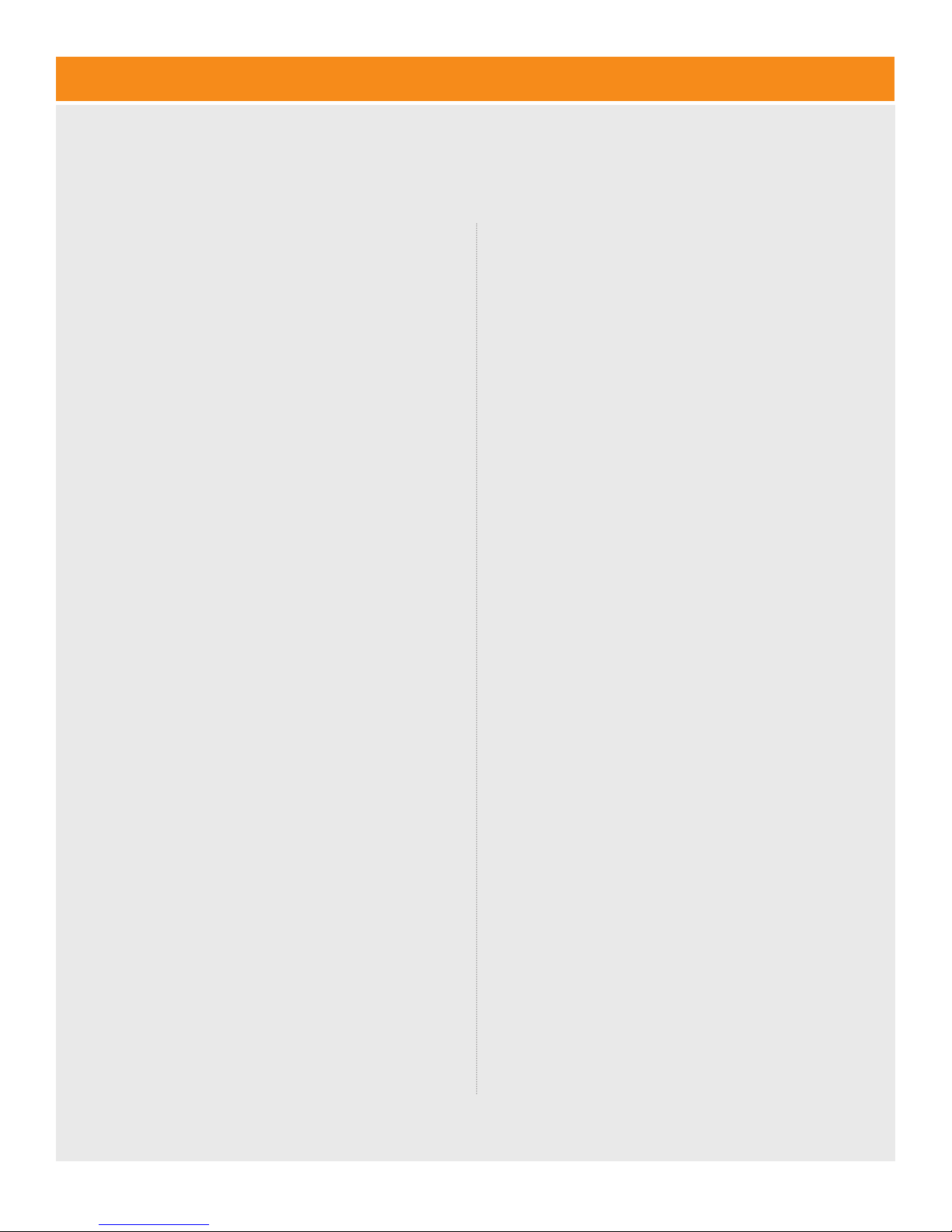

A) Control panel pictograms

.

Outlet for micro-wand

or marking wand

Indicator for wand tip

power ON

Transportation

Before transporting the machine, make sure the cleaning

solution reservoir and supply line are completely empty

and all connecting lines disconnected. The machine must

be carefully packed in a suitable container and properly

protected. WALTER will not be held responsible for any

damages resulting from leaked cleaning solution or rough

handling.

Storage

If the machine is to be stored for any length of time, the

cleaning solution reservoir and supply line must be emptied,

cleaning pad removed (neutralized, rinsed and left off) and

the tip neutralized, rinsed and dried. Store in a dry

safe place to avoid damage, especially to the electronic

components.

Waste disposal

Dispose of residual waste in compliance with Federal,

Provincial, State and local environmental regulations. Refer

to WALTER Material Safety Data Sheet of the SURFOX

electrolyte cleaning solutions on walter.com or surfox.com.

Extension cord

Indicator for high internal

temperature

Manual pumping mode Automatic pumping mode

Marking wand Micro-wand Large wand

MAX STD

STD MAX

Indicator for LOW

solution level

When an extension cord is needed, use wire size 14 (AWG)

for up to 50 feet (15 meters) and size 12 (AWG) for 50 to

100 feet (15 to 30 meters).

4

Current mode selector

Wand and Accessory

Selector Knob

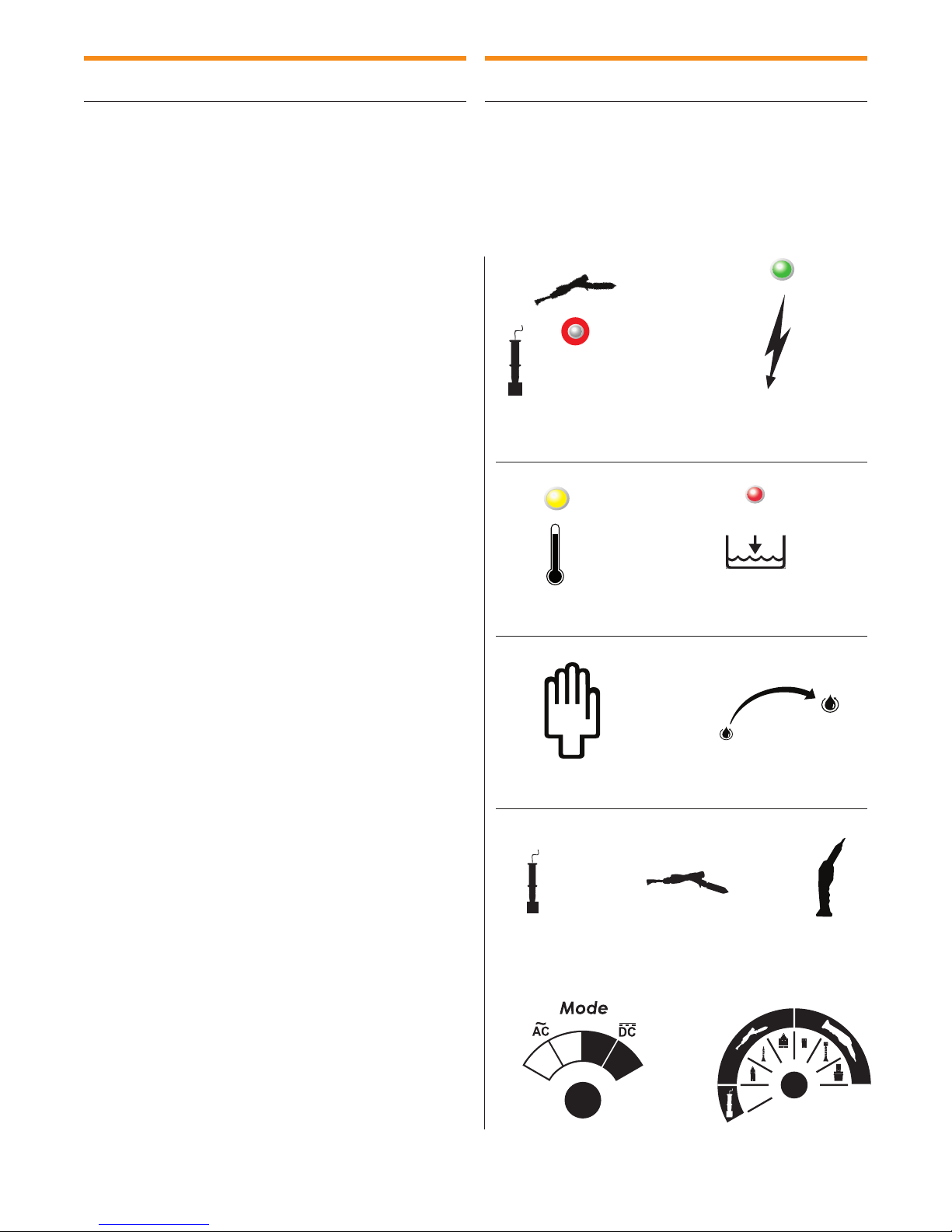

B) Front and back view of the machine

Equipment controls

3

ON/OFF button

Accessory outlet

Ground connector

Large wand hose

(electrical and solution

supply lines)

Control panel

SURFOX electrolyte solution

filling and reservoir

Cleaning pad mounting unit

Compressed air

connector (for fume

elimination system)

Power cord

SURFOX 304 User’s Guide 5

Equipment controls

3

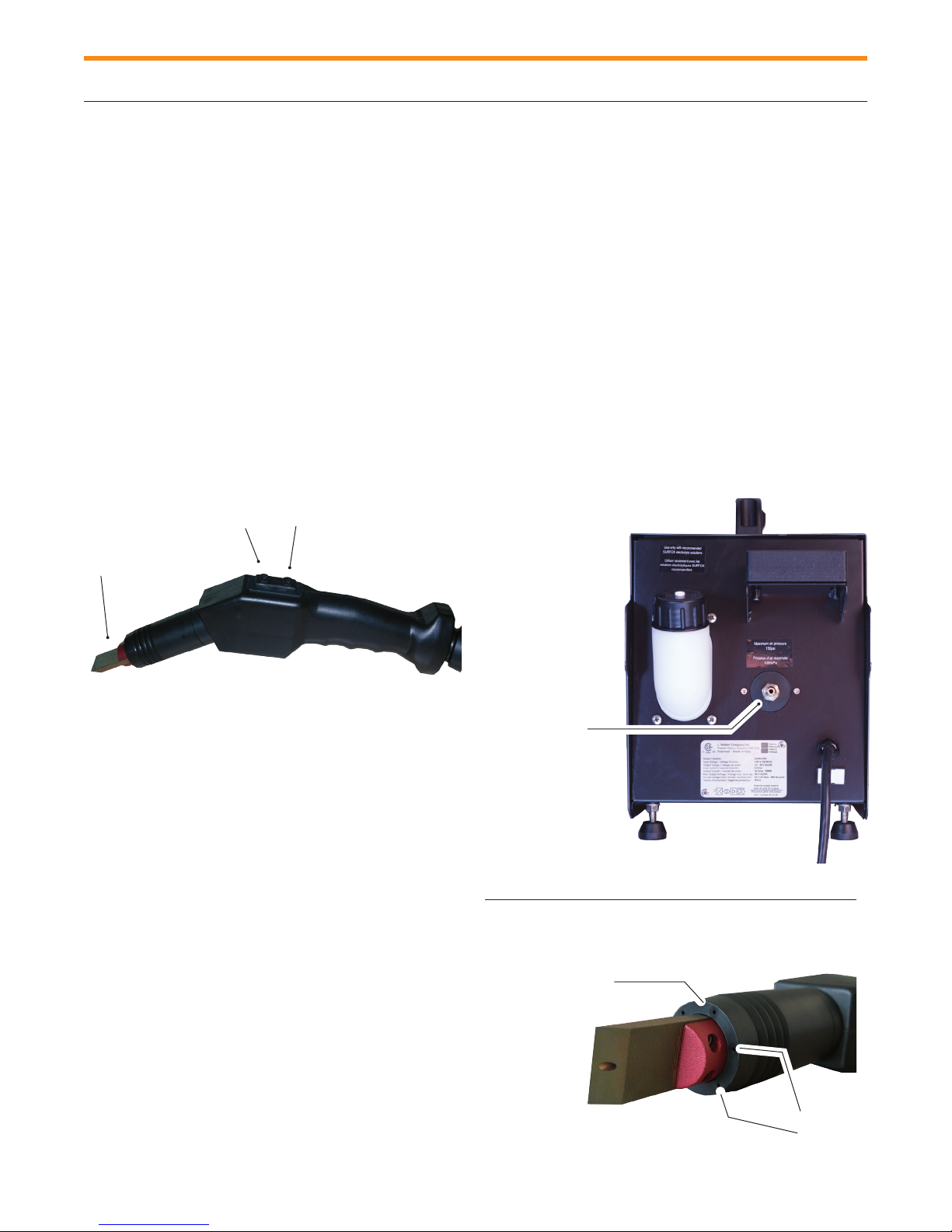

C) Large wand control buttons

The ON button is used to give power to the cleaning

accessory. When the pumping mode is set to Manual, press

the ON button to activate the pump. Press and keep the

button pressed to get continuous flow of liquid.

However, if the pumping mode is set to automatic, press

the ON button once to activate the pump. To stop the

pump, press the OFF button. When finished working

with the machine (in either mode) make sure to press

the OFF button.

Once the ON button is pressed, there will be continuous

power at the tip until the OFF button is pressed.

ON OFF

Cleaning

Accessory

E) Tip repositioning (comfort for operator)

The tungsten tip may be rotated from the standard horizontal position to a vertical position or anywhere in between to

make your cleaning as comfortable as possible. To loosen

the right hand threaded fume elimination sleeve, turn tip to

desired position and retighten sleeve.

Important: Always retighten fume elimination sleeve to

ensure a good electrical connection and avoid damaging

the contact points.

D) Fume elimination system (patented)

The SURFOX 304 machine comes with the integrated fume

elimination system. This system provides for better working conditions. Although the fumes are non-toxic and non

hazardous, they can be uncomfortable when working in

confined areas.

To activate this feature simply connect a compressed air line

(150 PSI max., 80 PSI min.) to the fitting at the back of the

machine. The fume elimination system is automatically activated when the ON button is pressed on the large wand.

The fume elimination system is turned OFF when the OFF

button on the large wand is pressed. If the fume elimination

system is not wanted, simply disconnect the compressed

air line.

The working principle is quite simple and highly effective;

the air comes out through the small openings behind the

cleaning accessory. This preset regulated air pressure condenses the vapors out of the air.

6

Compressed

air line fitting

Cleaning accessory close up

Small openings

Control panel

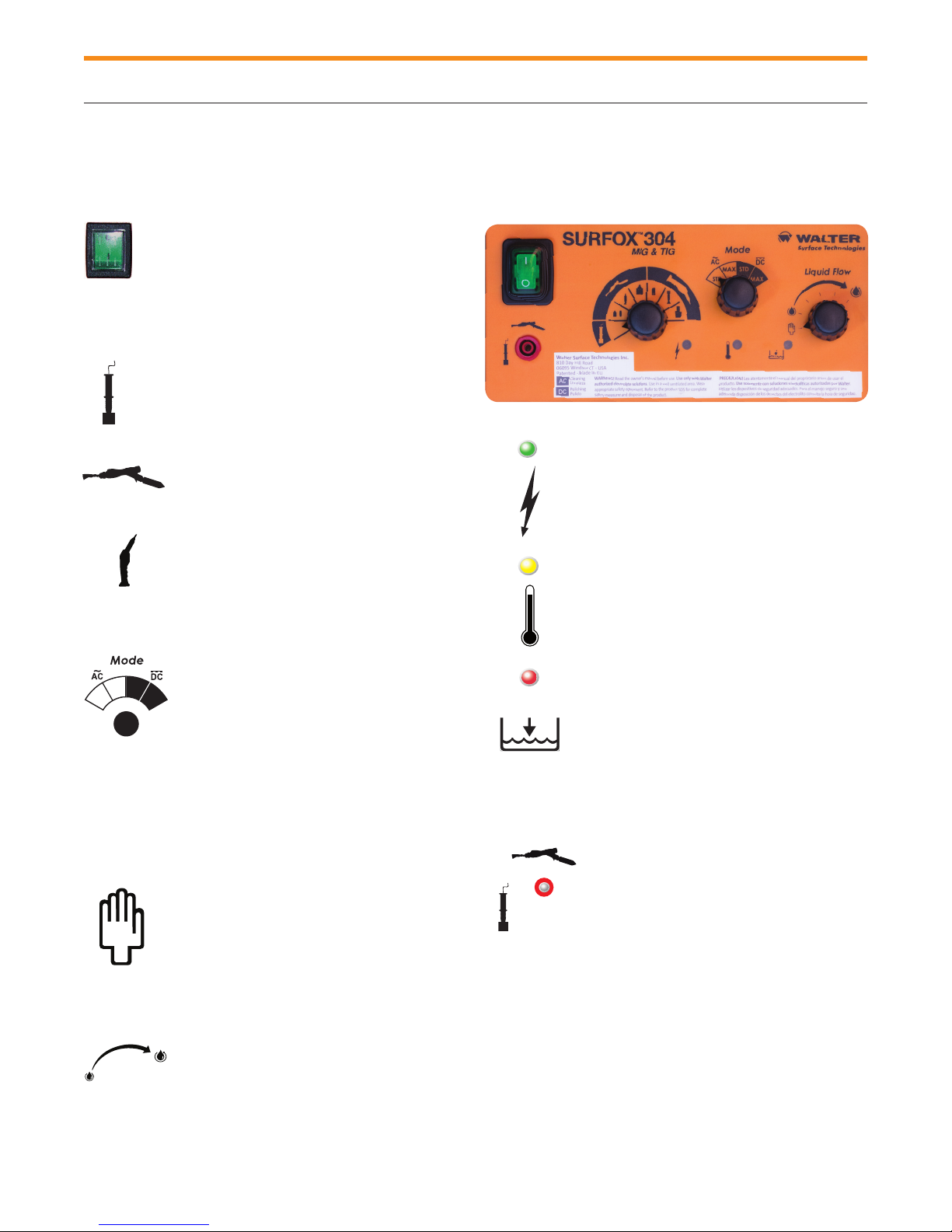

A) Main power switch

Control panel

4

MAX STD

STD MAX

Turns the main power to the unit ON

and OFF.

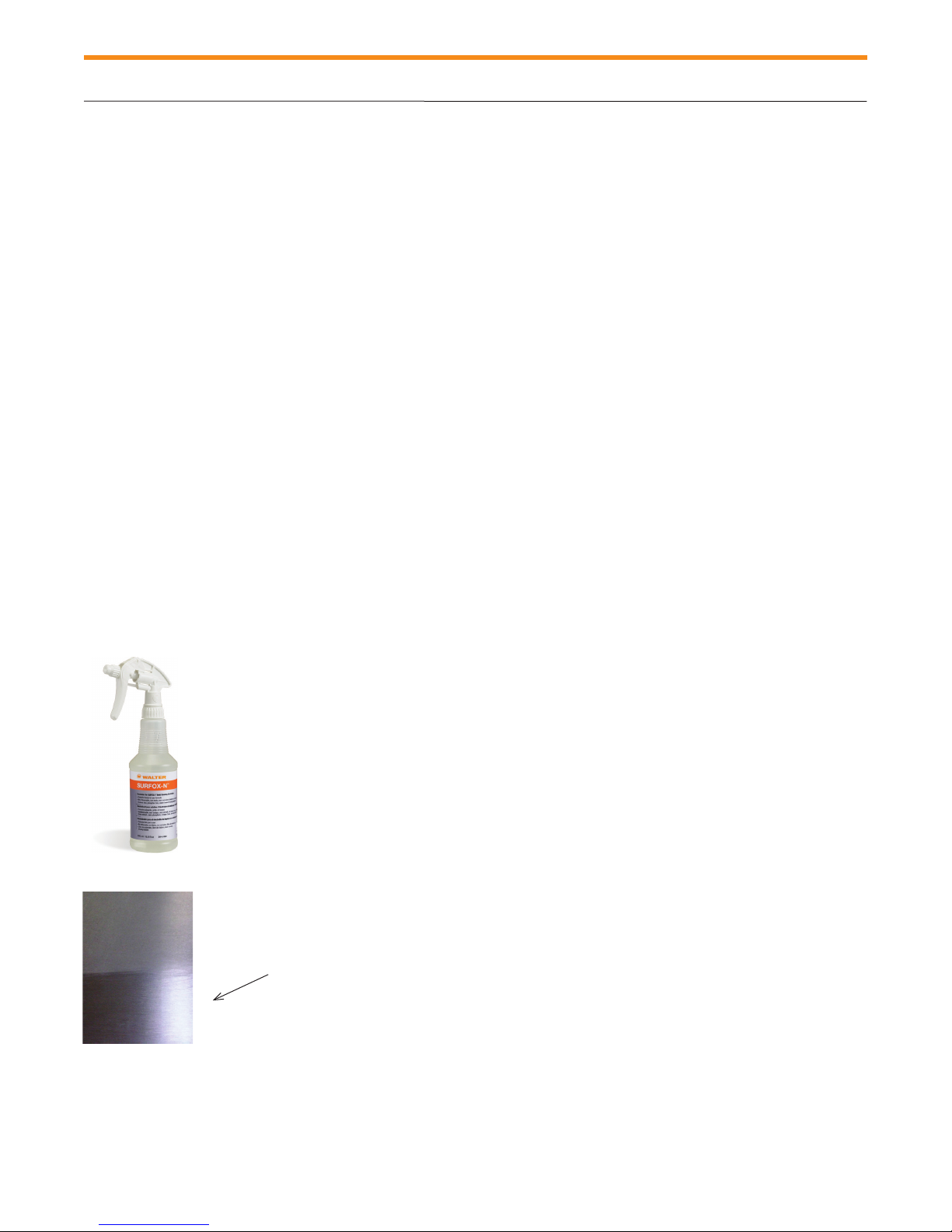

B) Wand and accessory selector

knob

Marking and etching wand. Select this

icon when using a marking/etching wand

which has been plugged into the accessory

outlet.

Micro wand. Select this icon when using

the micro wand which has been plugged

into the accessory outlet. Select the right

accessory, either the tungsten insert, the

brush or the large insert.

Large wand. Select this icon when using

the large wand attached to the SURFOX

unit.

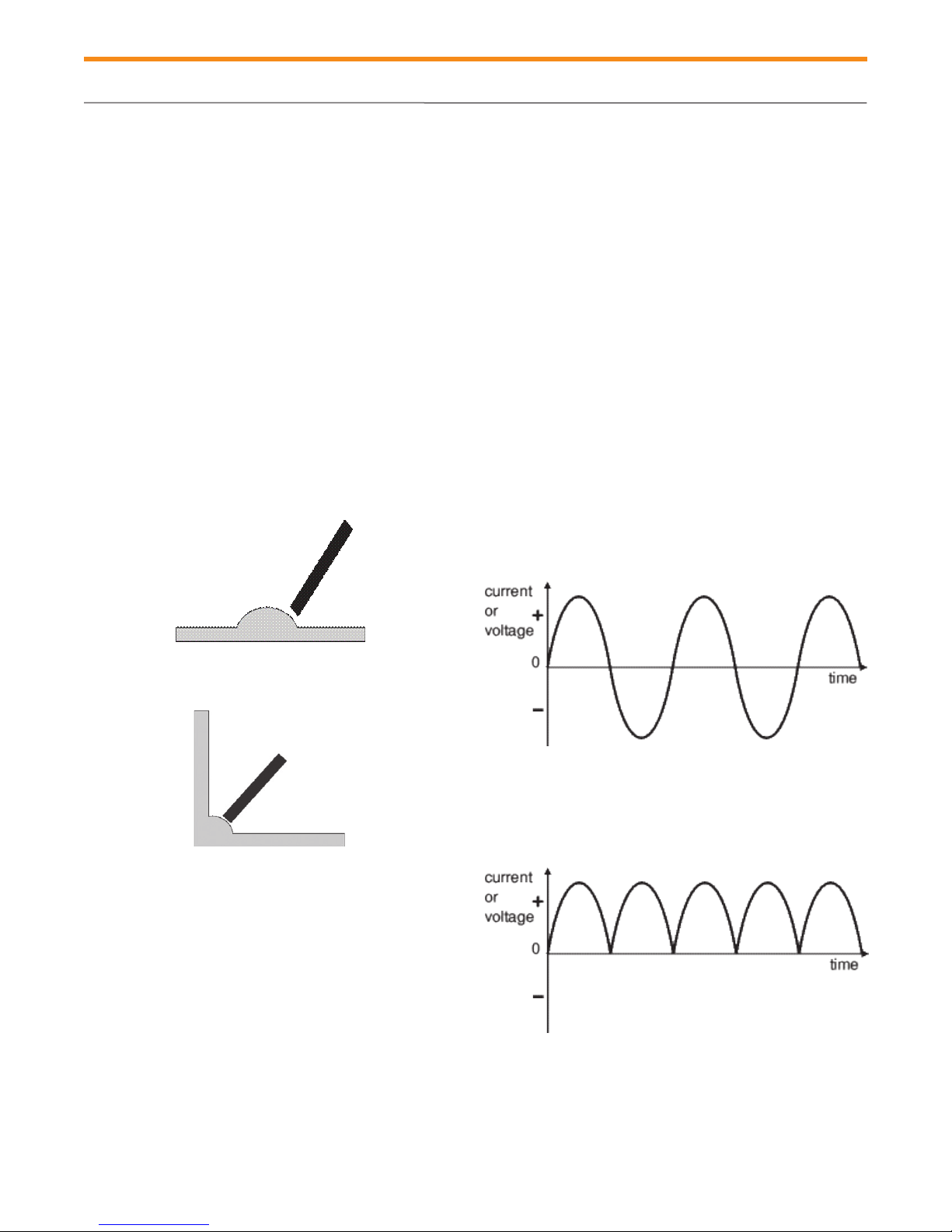

C) Current mode selector

Selecting the proper current type, AC

or DC, STD or MAX. AC for cleaning

and passivating the weld. DC for cleaning,

passivating and polishing the weld. STD is

recommended when using the tungsten

inserts and pads, MAX is recommended

when using the brush or the large graphite

insert.

A

F

C

B

D

E

E) Indicator lights

Large wand power ON indicator. The

green light goes ON when the large wand

ON button is pressed and there is power

to the tip. Power to the tip is OFF when the

large wand OFF button is pressed.

If the operating temperature is too high, the

yellow light goes on and the machine will

shut down and restart by itself when the

temperature reaches an acceptable level.

Low solution level indicator. When

solution level is low, the red indicator light

will go on.

D) Solution pump switch

Manual pumping mode. Choose the man-

ual pumping mode to control the amount of

solution pumping to the tip. Hold the large

wand ON button down to pump solution to

the tip. Release the ON button to stop the

pumping cycle. Always use enough solution

to keep the cleaning pad wet. Too little solution will reduce the cleaning accessory's life.

Automatic pumping mode. To start the

automatic pumping mode, press the ON

button on the wand. Once it is activated,

it will automatically pump the liquid. The

quantity of liquid can be selected from less

to more. Pumping will continue in this mode

until the OFF button is pressed.

F) Accessory outlet

Outlet for optional micro wand or

marking/etching wand. The marking/

etching wand is used to permanently etch/

mark your company name, logo, part

number or other desired information onto

stainless steel surfaces. The micro-wand

is used to access hard to reach areas for

cleaning and passivating, which are too

small for the large wand.

SURFOX 304 User’s Guide 7

Start-up procedure

5

Start-up procedure

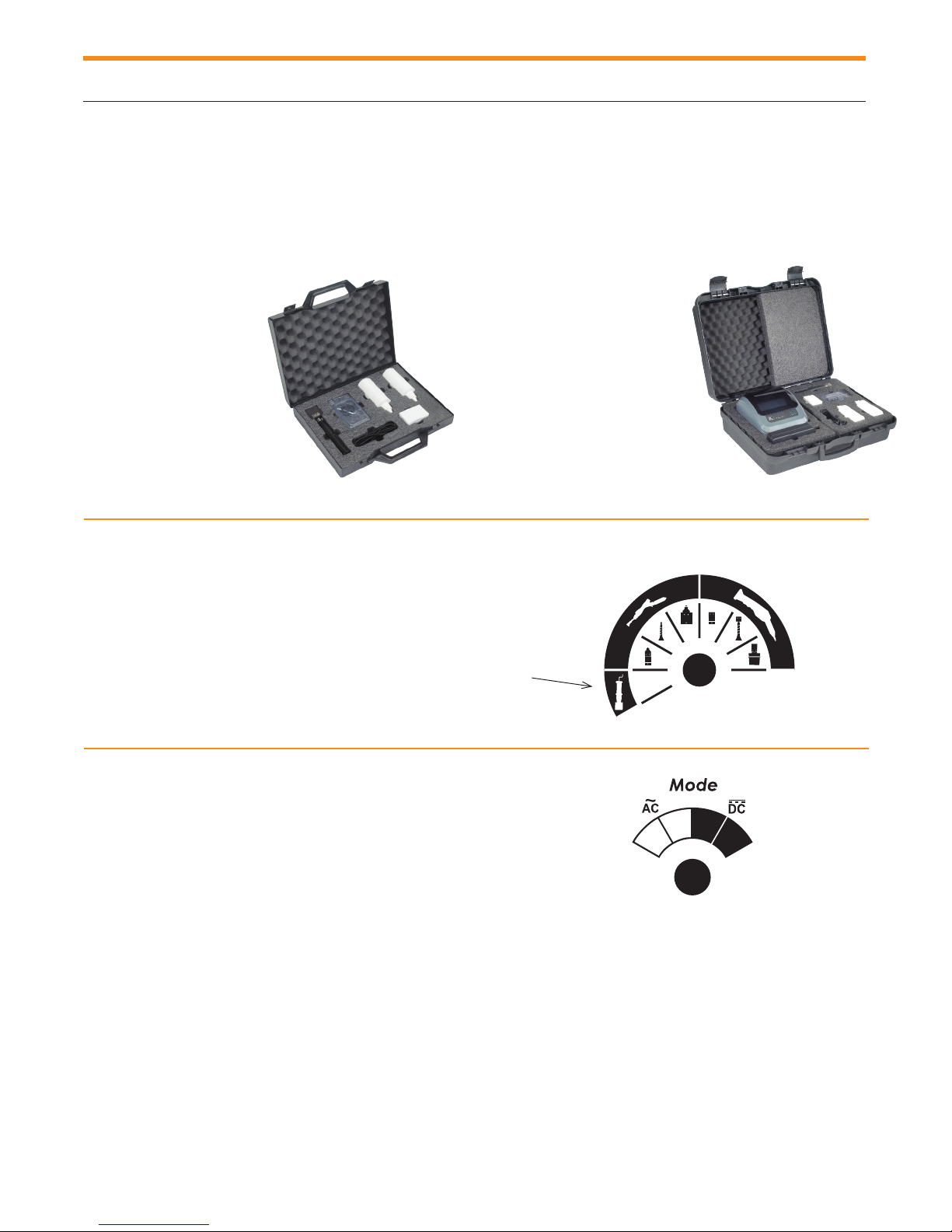

A) What is included in the box

u 1 x Large wand and connecting hose

u 1 x 48-R 136 Ground clamp

u 1 x 54-B 094 Wand Holder for Surfox 204/304

u Accessory kit containing:

• 1 x 54-B 095 Carbon Fiber Brush for Large Wand

• 1 x 54-B 099 Large Wand Brush Adaptor

• 1 x 54-B 101 Triangular Sleeve

• 1 x 54-B 102 Cylindrical Sleeve

• 1 x 48-R 133 Tungsten Insert

(Already mounted on the large wand)

• 3 x 54-B 026 High Conductivity Standard

Cleaning Pads

• 1 x 54-B 002 PTFE Clamping Ring

• 1 x 2.5 mm hexagonal key for changing tungsten insert

• 1 x 5.0 mm hexagonal key for mounting the

wand holder

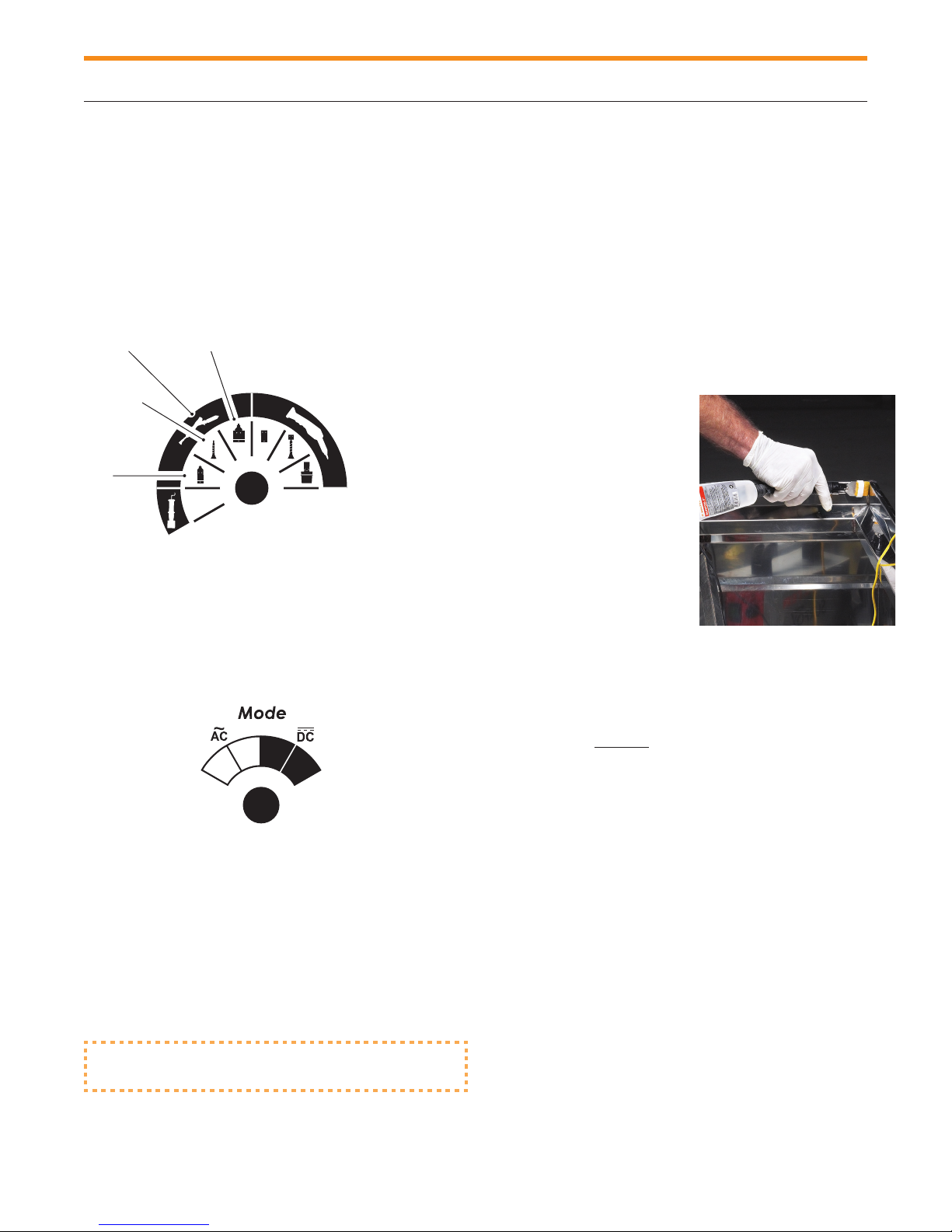

B) Filling the reservoir

Fill the reservoir in the back of the machine with SURFOX

electrolyte solution. The reservoir holds 1.9 L of SURFOX

electrolyte solution.

C) Connecting air supply

Connect the air supply at the back of the machine. Note

that the maximum allowed pressure is 150 PSI max.,

80 PSI min. (1000 KPa). If the air supply is not plugged into

the machine, the machine will still work but there will not be

any fume elimination.

D) Plugging in the power cord

When an extension cord is needed, use wire size 14 (AWG)

for up to 50 feet (15 meters) and size 12 (AWG) for 50 to

100 feet (15 to 30 meters).

Reservoir

Ground

clamp

Air supply

connector

E) Plugging in the ground clamp

Plug the ground clamp at the front of the unit. Attach the

clamp to the work piece being cleaned. The cleaning and

passivating process will not work if the part is not properly

grounded.

8

Using the large wand to electrochemically clean, polish and passivate

Using the large wand to electrochemically clean, polish

and passivate

6

A) Selecting the proper wand and accessory

Tungsten

insert

Brush

Large

wand

Large

graphite

insert

B) Selecting the proper current type, AC or DC

and proper current level, STD or MAX

MAX STD

STD MAX

AC for cleaning and passivating the weld.

DC for cleaning, passivating and polishing the weld.

STD is recommended when using the tungsten inserts and

pads, MAX is recommended when using the brush or the

large graphite insert.

WARNING! DC mode is used to polish the weld bead to

match the mirror finish of the parent material.

TIP! When using the polishing mode (DC), use plenty

of SURFOX electrolyte solution.

Note: When using DC setting, the SURFOX electrolyte

solution will become slightly yellow or will darken.

C) Selecting the proper pumping mode

Automatic

mode

Manual

mode

Manual pumping mode. Choose the manual pumping

mode to control the amount of solution pumping to the tip.

Hold the large wand ON button down to pump solution to

the tip. Release the ON button to stop the pumping cycle.

Always use enough solution to keep the cleaning pad wet.

Automatic pumping mode. To start the automatic

pumping mode, press the ON button on the wand. Once

it is activated, it will automatically pump the liquid. The

quantity of liquid can be selected from less to more.

D) Cleaning and passivating

To clean and passivate, press the large wand ON button.

Make sure the cleaning accessory is saturated with

SURFOX electrolyte cleaning solution before starting to

work. If the cleaning accessory is too dry, it will wear

prematurely. Start working when solution drips from the

cleaning pad.

Do not press hard, let the electrochemical process do the

work. Do not use the cleaning accessory like an abrasive

pad.

WARNING! When using the machine for the first time, there

could be water in the system from factory testing. Adjust

the liquid pump setting to automatic at maximum speed

and let the liquid drip into a disposal cup for 2 minutes

(amount of time required to empty the hose from the tank

to the wand). Then, adjust the liquid pump setting back to

desired pumping speed.

E) Neutralizing

1. Remove any excess of SURFOX electrolyte cleaning

solution using a soft clean cloth.

2. Spray SURFOX-N on the surface.

3. Wipe dry with another soft clean cloth to avoid cross

contamination.

Refer to neutralization procedure in neutralization section for

instructions on how to properly neutralize (page 15).

SURFOX 304 User’s Guide 9

Large wand accessories

7

Large Wand Accessories

A) Selection and mounting

of the cleaning pads and tips

Tungsten tips are made from high quality tungsten alloy

material. Other materials will not resist the harsh environment created by the electrochemical process.

WARNING! When the insert is too worn, it can

cause damage to the cleaning pads.

In this example of a worn insert, there are only two

contact points. All the current comes out of these

two points. Because of the lower available cross

section, the temperature will be higher at the two

points and the cleaning pads may become damaged or wear out prematurely.

O-Ring

Inserts

Tungsten insert 90°

No: 48-R 133

Use with cleaning pads 54-B 026

or 54-B 040 and clamp ring

54-B 002 or boot 54-B 005

Tungsten insert 60°

No: 54-B 016

Use with cleaning pad 54-B 027

and clamp ring 54-B 002 or boot

54-B 006

TIP! Resurface the insert using a bench grinding wheel

or angle grinder.

Note: Be sure to install the O-Ring located at the back of

the insert whenever they are changed.

Tungsten insert kit for

SURFOX 104, 204 and 304

Order No.: 54-B 012

Includes:

1 x 48-R 133

1 X 54-B 017

1 X 54-B 016

1 X 54-B 018

Narrow tungsten insert 90°

No: 54-B 017

Use with cleaning pad 54-B 028

or 54-B 041 and clamp ring

54-B 020 or boot 54-B 007.

Large graphite insert for

SURFOX 204 and 304

Order No.: 54-B 009

45 mm W - Ideal for surface

renewing or restoring, and to

clean the back of MIG welds

Carbon fiber brush for large

wand on SURFOX 304

Order No.: 54-B 095

Without adaptor - Pack of 5

Triangular sleeve for large

wand carbon fiber brush

Order No.: 54-B 101

10

Narrow tungsten insert 60°

No: 54-B 018

Use with cleaning pad 54-B 028

and clamp ring 54-B 020 or boot

54-B 008.

Large pads for large

graphite insert

Order No.: 54-B 043

90 mm L X 50 mm W X 2 mm H

Pack of 10 with O-ring

Spare brush adaptor for large

wand on SURFOX 304

Order No.: 54-B 099

Cylindrical sleeve for large

wand carbon fiber brush

Order No.: 54-B 102

Large pad for graphite

insert for SURFOX 304

Order No.: 54-B 052

Pack of 5

Wand holder for

SURFOX 304 and 204

Order No.: 54-B 094

Large wand accessories

7

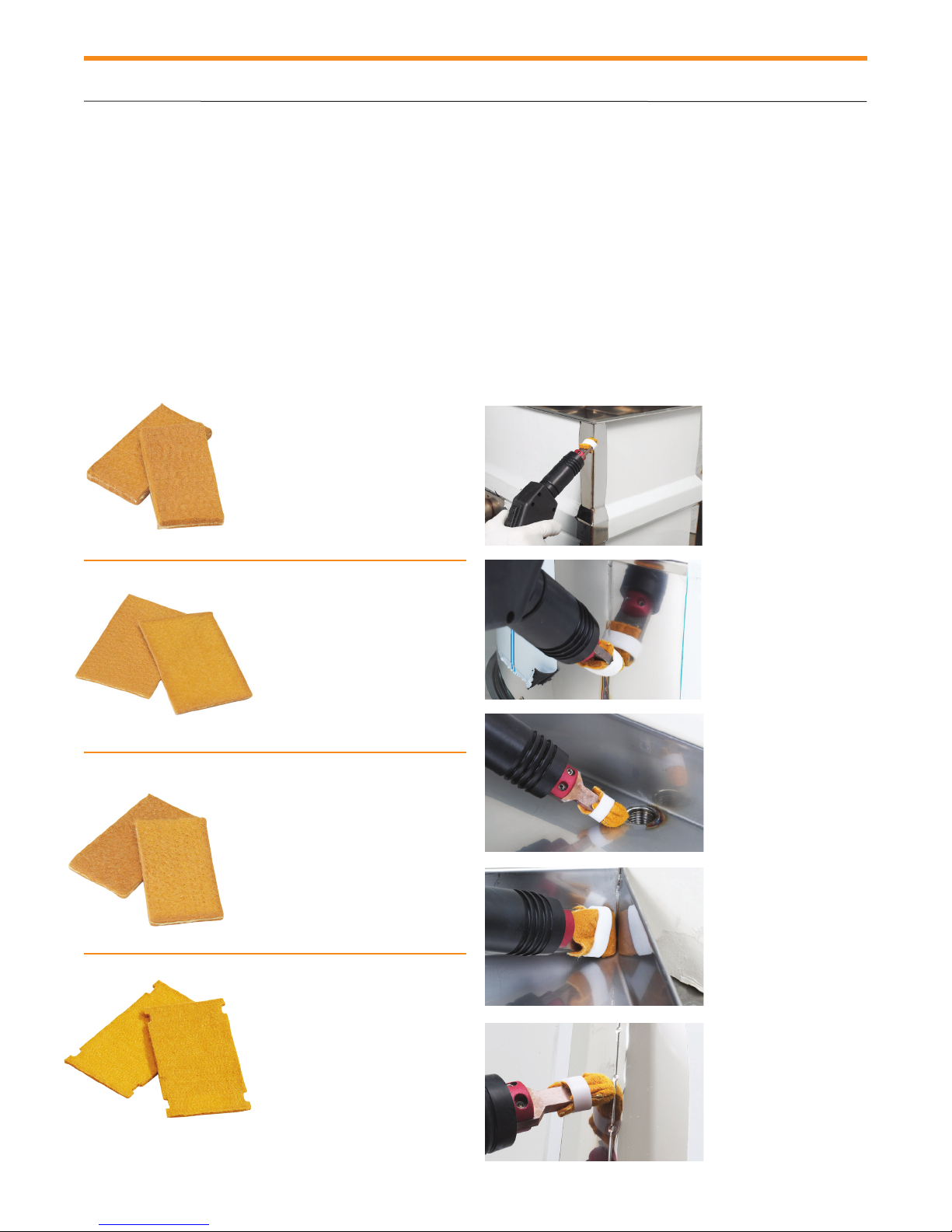

High conductivity cleaning pads

Cleaning pads are made of a complex blend of highly

conductive synthetic polymer which is very resistant to wear

and which offers excellent thermal stability. For longer life,

remove the cleaning pad and neutralize with SURFOX-N at

the end of each working day.

Cleaning pads are available in four types:

Standard cleaning pad

No: 54-B 026

Use with insert 48-R 133

Inside corners cleaning pad

No: 54-B 027

Use with insert 54-B 016

Features

• Flexible: Can be folded many ways

• Soft on surfaces

• Can be used both sides

• Long lasting

• Highly conductive (4x more conductive than previous

generation)

Narrow cleaning pad

No: 54-B 028

Use with inserts 54-B 017

and 54-B 018

Large cleaning pad

No: 54-B 043

Use with large graphite insert

54-B 009

SURFOX 304 User’s Guide 11

Large wand accessories

7

B) PTFE clamp rings

PTFE clamp rings are designed to hold the cleaning pads

on the tungsten inserts.

They are available in two sizes:

Narrow clamp ring for narrow pads

No: 54-B 020

Use with narrow inserts. 10 per package.

Clamp ring for standard cleaning pads

No: 54-B 002

Use with standard inserts. 10 per package.

C) SURFOX electrolyte solutions

Surfox electrolyte solutions are specially formulated phosphoric acid cleaning solutions designed to be used only in

Walter SURFOX systems.

SURFOX-G

Electrolyte Cleaning Solution

Cleans up to 3-5 feet per minute.

1.5 L/50.7 oz. No: 54-A 065

STD Pack: 1 STD Carton: 4

5 L/1.3 gal. No: 54-A 066

1 STD Pack: 1 STD Carton: 1

20 L/5.2 gal. No: 54-A 067

STD Pack: 1 STD Carton: 1

208 L/55 gal. No: 54-A 068

STD Pack: 1 STD Carton: 1

D) Mounting a cleaning pad

1. Squeeze and insert clamp ring.

2. Insert cleaning pad.

3. Firmly press in tungsten tip.

SURFOX-T

Heavy-Duty

Cleans up to 3-5 feet per minute.

1.5 L/50.7 oz. No: 54-A 005

STD Pack: 1 STD Carton: 4

5 L/1.3 gal No: 54-A 006

1 STD Pack: 1 STD Carton: 1

20 L/5.2 gal. No: 54-A 007

STD Pack: 1 STD Carton: 1

208 L/55 gal. No: 54-A 008

STD Pack: 1 STD Carton: 1

12

Electrolyte Cleaning Solution

4. Remove tip with installed pad and clamp ring.

Note: When mounting classic pads, ensure the Ω sign

is facing up on step 2.

Using the micro wand (optional) to clean and passivate

8

Using the micro-wand (optional) to clean, polish and passivate.

54-B 033 and 54-B 133

Use the micro-wand to get into tight places where the large

wand cannot go. Plug the micro wand into the accessory

outlet on the front panel.

A) Selecting the proper wand and accessory

Microwand

Brush

Tungsten

insert

When this mode is selected, it automatically cuts the power

to the large wand, stops the solution pump and the fume

elimination system (if connected) from operating. Only

power is provided to the micro wand/marking wand outlet.

Be sure work piece is grounded.

Large

graphite

insert

B) Selecting the proper current type, AC or DC

and proper current level, STD or MAX

C) Manual pumping mode

The micro-wand uses a manual pumping mode only. One (1)

press equals one (1) stroke. To pump more liquid, press repeatedly. See micro wand instructions for more information.

D) Cleaning and passivating

Screw in SURFOX electrolyte solution 100 ml tube onto the

micro-wand. Make sure the cleaning pad is saturated with

solution before starting to work.

If the cleaning pad is too dry,

it will wear prematurely. Start

working when solution drips

from the cleaning pad.

Do not press hard, let the

electrochemical process do

the work. The cleaning pad is

a bridge between the machine

and the weld. Do not use the

cleaning pad like an abrasive

pad.

E) Neutralizing

1. Remove any excess of SURFOX electrolyte cleaning

solution using a soft clean cloth.

MAX STD

STD MAX

AC for cleaning and passivating the weld.

DC for cleaning, passivating and polishing the weld.

STD is recommended when using the tungsten inserts and

pads, MAX is recommended when using the brush or the

large graphite insert.

WARNING! DC mode is used to polish the weld bead to

match the mirror finish of the parent material.

TIP! When using the polishing mode (DC), use plenty

of SURFOX electrolyte solution.

Note: When using DC setting, the SURFOX electrolyte solution will become slightly yellow or will darken.

2. Spray SURFOX-N on the surface.

3. Wipe dry with another soft clean cloth to avoid cross

contamination.

Refer to neutralization procedure in neutralization section for

instructions on how to properly neutralize.

SURFOX 304 User’s Guide 13

Using the marking/etching wand (optional)

9

Using the marking/etching wand (optional)

A) Marking kits

Standard kit (54-B 080) includes:

• 1 marking/etching wand with

graphite insert

• 35 mm X 10 mm

and connecting cable

• 20 marking pads

• 5 O-Rings

• 1 SURFOX-M, 100 ml

solution

• 1 SURFOX-E, 100 ml

solution

B) Selecting the proper wand and accesssory

Turn the selector knob to the marking/etching wand icon.

Use the marking/etching wand to permanently mark or etch

your company name, logo, part number or other desired

information onto the surface of stainless steel, using permanent or disposable stencils. Plug the marking/etching wand

into the accessory outlet on the front panel.

PRO kit (54-B 081) includes:

• 1 marking/etching wand with

graphite insert

• 35 mm X 10 mm

and connecting cable

• 20 marking pads

• 5 O-Rings

• 1 SURFOX-M, 100 ml solution

• 1 SURFOX-E, 100 ml solution

• 1 Stencil printer and software

• 1 Stencil paper roll 100 mm (W) X 20 m (L)

Marking/etching

wand

C) Selecting the proper current type, AC or DC

and proper current level, STD or MAX

AC for marking using Surfox-M.

DC for etching using Surfox-E.

STD current level is recommended for marking or etching.

14

MAX STD

STD MAX

TECHNICAL BULLETINS AVAILABLE ON OUR WEB SITE.

Neutralizing

Neutralizing

10

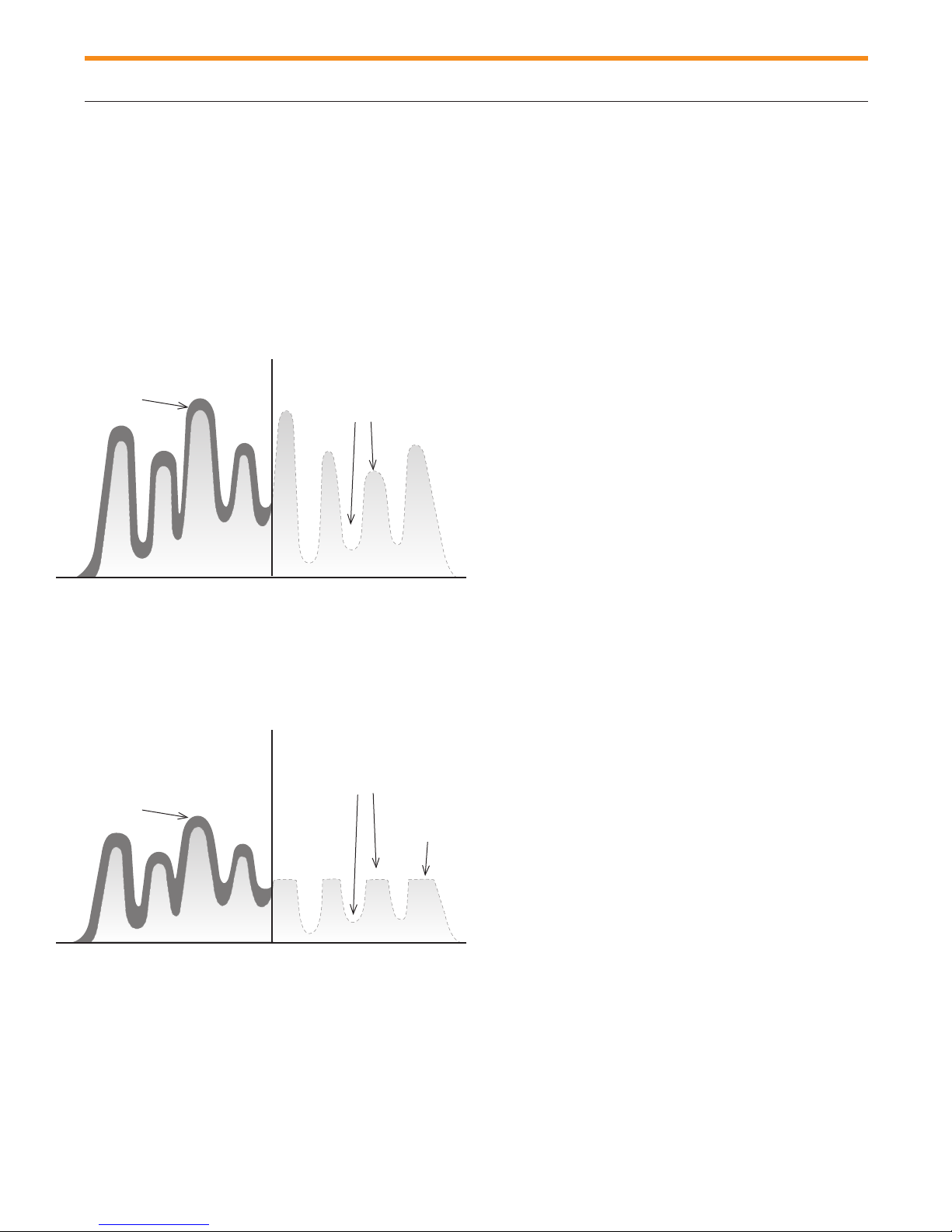

The SURFOX-N liquid is a specially formulated neutralizer for the SURFOX electrolyte solutions. It is a powerful

ready-to-use formula which leaves no residue, is non-toxic,

solvent free, water-based and biodegradable.

A) Directions for neutralizing SURFOX

electrolyte cleaning solutions

1. Remove any excess SURFOX electrolyte solution using a

soft clean cloth.

2. Spray SURFOX-N on the surface.

3. Wipe dry with another soft clean cloth.

For more information about this product, refer to product

MSDS or SDS on walter.com or surfox.com.

WARNING! Be sure to wipe off all excess SURFOX electrolyte solution from the surface and neutralize otherwise the

inorganic salt from the phosphoric acid will adhere to the

surface and cause deposits.

B) SURFOX weld cleaning and neutralization

procedure

Clean the weld using the SURFOX machine and SURFOX

electrolyte solutions. Work only 2 feet at a time.

Note: The cleaning pad should be kept moist – not

dripping.

1. After weld cleaning, use a clean cloth or paper towel

and wipe the affected area in a squeegee action from left

to right. Then discard the cloth or paper towel.

After cleaning the weld with the SURFOX weld cleaning

machine, the electrolyte solution must be neutralized.

1. Spray the affected area with SURFOX-N neutralizer.

Allow to sit for 15 seconds on the surface.

2. Use a clean cloth or paper towel and wipe the affected

area in a squeegee action from left to right. Then discard

the cloth or paper towel.

Note: Failure to neutralize or neutralize properly will result in

clouding, hazing and dulling of the surface.

SURFOX-N neutralizer Part No.

500 ml 54-A 023

5 L 54-A 026

20 L 54-A 027

208 L 54-A 028

Salt deposits due to unproper

neutralization and rinsing.

SURFOX 304 User’s Guide 15

Safety features

11

Safety features

A) Sparks on the tip/work piece

To avoid short circuits (arcing), the machine automatically

stops when the insert touches the work piece (metal to

metal contact). There is an inverter board that monitors the

voltage every millisecond. If the voltage sharply increases

creating a short, the system will automatically cut the power

to the tip to avoid any damage to the equipment.

To restart the machine, simply press the large wand ON

button.

WARNING! To avoid drawing too much amperage and

automatically stopping the power to the tip, make sure that

you touch only one surface at a time. The machine is set

to work at a maximum of 30 amps. If the amperage goes

above 30 amps, the machine automatically shuts down.

Example: On a flat surface, the amperage is around

24 amps. The contact surface area is relatively small.

B) Internal temperature

To protect the internal components of the machine, there

are temperature sensors inside the machine. If the operating

temperature is too high, the machine will shut down and restart by itself when the temperature reaches an acceptable

level. There is an internal fan inside the machine to keep all

the components cool.

WARNING! The inside temperature can increase for many

reasons: high ambient temperature, lack of proper air circulation around the machine, fluctuations in voltage, electrical

set-up in the shop, etc.

C) AC/DC current basics

Alternating Current (AC) flows one way, then the other

way, continually reversing direction. An AC voltage is continually changing between positive (+) and negative (-).

Example: An internal angle, which if you touch 2 sides

simultaneously, the contact surface area is doubled, amperage goes above 30 amps and the machine stops.

Note: Automatic shut off if ground is not detected within

20 seconds.

16

Direct Current (DC) always flows in the same direction, but

it may increase and decrease. A DC voltage is always positive, but may increase and decrease.

Safety features

11

D) AC/DC settings on the SURFOX machine

Example of cleaning and passivation with SURFOX in AC

mode:

Microscopic view of the material

BEFORE

Oxide

layer to be

removed

Example of cleaning and passivation with SURFOX in DC

mode:

Microscopic view of the material

AFTER

Cleaning and passivation is

perfect. Cleans every crack in

the material.

E) Welds that cannot be cleaned

If the area around the weld is black (not blue) from contamination, this is a problem of high heat generated during the

welding process. The contaminated areas do not conduct

electricity. If there is no conductivity in the material, the

SURFOX system cannot work.

If there are two welds on top of the other, the structure of

the material has been seriously altered. These areas may

not be cleaned.

The quality of the weld is critical. The better the weld, the

easier it will be to clean.

Oxide

layer to be

removed

BEFORE

AFTER

Cleaning and passivation is

perfect. Cleans every crack in

the material.

Alteration of the

material due to

the DC setting

SURFOX 304 User’s Guide 17

Warranty and serviceTechnical data

1312

Technical data

MODEL: SURFOX 304

PART NUMBER: 54-D 314

INPUT VOLTAGE: 120 V, 50/60 Hz

OUTPUT VOLTAGE: 30 V, AC/DC

INPUT CURRENT: 7.5 Amps

OUTPUT CURRENT: 30 Amps Max, AC/DC

MAX. OUTPUT VOLTAGE: 33 V, AC/DC

DIMENSIONS: 525 mm x 370 mm x 250 mm

(20-2/3” x 9.84” x 14.57”)

RESERVOIR CAPACITY: 1.9 L

WEIGHT: 22 kg (48.5 lbs.)

INPUT AIR PRESSURE: 150 PSI max., 80 PSI min.

Warranty and service

A) Warranty policy

All WALTER SURFOX cleaning systems and accessories

are inspected and tested before shipment and are warranted to be free from any defect in material and faulty

workmanship. Should any malfunction occur within six (6)

months from the date of original purchase, return the complete system prepaid with proof of purchase, to the nearest WALTER Authorized Service Center. If an examination

shows that the malfunction was caused by defective material or faulty workmanship, WALTER will repair (or at our

option, replace the unit) without charge. This warranty does

not apply when; normal maintenance is required, repairs or

replacements have been made or were attempted by anyone other than WALTER authorized service personnel, and

does not cover any damage caused by accidents, modifications, use of improper accessories, abuse or misuse, which

also includes overloading the tool beyond its rated capacity

as well as its continued use after partial failure. No other

warranty, written or verbal, is authorized.

In no event shall WALTER be liable for any indirect, inciden-

tal or consequential damages from the sale of the product.

This disclaimer applies both during and after the term of this

warranty.

This warranty gives you specific rights. The provisions

contained in this warranty are not intended to limit, modify,

take away from, disclaim or exclude any warranties set forth

in any Provincial or State legislation. To the extent required

by law, the provisions in any Provincial, State or Federal

legislation with respect to warranties take precedence over

the provisions in this warranty.

B) Repair and service

When shipping:

• Drain the SURFOX electrolyte solution from the reservoir

• Use original shipping case

• Use sufficient packing

• Ship on a small pallet

• Give detailed description of the problem as well as

company name, address, phone and fax numbers and

contact person

18

SURFOX 304 User’s Guide 19

Table des matières

Table des matières

1 Introduction 21

2 Directives de sécurité 22

3 Commandes de l’équipement 23

A) Pictogrammes du panneau de commande 23

B) Vue de l’appareil – avant et arrière 24

C) Boutons de contrôle de la baguette 25

D) Système d’élimination des fumées 25

E) Positionnement de la buse (confort de l’opérateur) 25

4 Panneau de commande 26

A) Interrupteur d’alimentation principal 26

B) Bouton de sélection de baguette et d'accessoires 26

C) Bouton de sélection du type de courant 26

D) Interrupteur de la pompe de solution 26

E) Témoins lumineux 26

F) Sortie pour les accessoires 26

5 Procédure de démarrage 27

A) Contenu de la boîte 27

B) Remplissage du réservoir 27

C) Raccordement de l’alimentation d’air 27

D) Branchement du cordon d’alimentation 27

E) Branchement du collier de mise à la terre 27

6 Utilisation de la baguette large pour

le nettoyage, le polissage et la passivation

électrochimique 28

A) Sélectionner la baguette et l'accessoire de

nettoyage 28

B) Choisir le bon type de courant AC ou DC et

la bonne intensité STD ou MAX 28

C) Sélectionner le mode de pompage adéquat 28

D) Nettoyage et passivation 28

E) Neutralisation 28

7 Accessoires pour baguette large 29

A) Sélection et assemblage des buses et tampons de

nettoyage 29

B) Bagues de serrage en PTFE 31

C) Solutions électrolytiques SURFOX 31

D) Assemblage d’un tampon nettoyeur 31

8 Utilisation de la micro-baguette pour le nettoyage,

le polissage et la passivation (facultatif) 32

A) Sélectionner la baguette et l'accessoire de

nettoyage 32

B) Choisir le bon type de courant AC ou DC et

la bonne intensité STD ou MAX 32

C) Mode de pompage manuel 32

D) Nettoyage et passivation 32

E) Neutralisation 32

9 Utilisation de la baguette de marquage/gravure

(facultatif) 33

A) Trousses de marquage 33

B) Sélectionner la baguette et l'accessoire de

nettoyage 33

C) Choisir le bon type de courant AC ou DC et

la bonne intensité STD ou MAX 33

10 Neutralisation 34

A) Directives pour la neutralisation des solutions

de nettoyage électrolytiques SURFOX 34

B) Procédure de neutralisation et de nettoyage

des soudures SURFOX 34

11 Éléments de sécurité 35

A) Étincelles sur la buse ou la pièce de travail 35

B) Température interne 35

C) Rudiments du courant CA/CC 35

D) Réglages CA/CC pour l’appareil SURFOX 36

E) Les soudures qui ne peuvent pas être nettoyées 36

12 Données techniques 37

13 Garantie et service 37

A) Politique de garantie 37

B) Réparation et service 37

20

Introduction

Introduction

1

Félicitations! Vous avez acheté le meilleur équipement de

nettoyage de soudures et de passivation électrochimique

sur le marché. L’équipement de nettoyage de soudures

SURFOX

la teinte de chaleur sur les zones affectées rapidement,

facilement et de manière rentable, tout en permettant une

passivation totale de la surface en acier inoxydable.

Notre nouvelle génération d’appareils SURFOX est équipée

de panneaux convertisseurs à régulation automatique qui

surveillent l’intensité du courant et le règlent automatiquement de manière optimale afin d’assurer une efficacité de

nettoyage maximum sans perte de productivité.

Avant de commencer vos travaux, nous vous demandons

de lire ce manuel du propriétaire SURFOX en entier; nous

vous guiderons, étape par étape, du démarrage aux procédures de maintenance, en passant par la mise en œuvre de

votre nouvel équipement SURFOX. Votre nouvel appareil

SURFOX possède une durabilité accrue pour résister aux

exigences élevées d’une utilisation industrielle. Toutefois,

comme c’est le cas pour toute pièce d’équipement électrique, son utilisation exige des soins et la sécurité nécessaires à la protection de cet important investissement.

En y apportant les soins et l’entretien appropriés, vous

pourrez compter sur votre équipement SURFOX pendant

des années.

MC

fabriqué par WALTER permet de supprimer

u Alimentation principale inadéquate ;

u Mauvais entretien ;

u Modifications et manipulations non autorisées ;

u L'utilisation de pièces de rechange non originales ou des

pièces de rechange non spécifiées comme appropriées

pour le modèle en question ;

u Respect partiel ou l'échec total du respecter des con-

signes ;

u Événements inattendus ;

u Et toute autre mauvaise utilisation de la machine.

Opérations

L’appareil SURFOX utilise un procédé électrochimique

pour nettoyer et passiver les soudures faites sur l’acier

inoxy dable. Les solutions électrolytiques utilisées par les

appareils SURFOX sont à base d’acide phosphorique. Elles

sont approuvées par l’industrie alimentaire et sont activées

par un courant électrique pour nettoyer les soudures. Le

traitement ne prend que quelques secondes et ne provoque

aucun dommage ou égratignure à la surface des pièces

nettoyées.

Pour obtenir des informations sur les autres produits

WALTER, visitez notre site Web : walter.com ou

surfox.com

1.1 Informations générales

Ce manuel fournit toutes les informations nécessaires

pour une installation sécuritaire, le démarrage et le fonctionnement de la machine, ainsi que des instructions de

dépannage et de maintenance . Le manuel est une partie

intégrante de la machine et doit être conservé avec la machine. Si votre copie du manuel est perdue ou illisible , vous

pouvez demander une nouvelle copie à: WALTER - www.

walter.com Le présent manuel reflète l'état de la machine au

moment de la fabrication et ne peut être jugé insuffisant en

cas de mises à jour en raison de d'expériences ultérieures .

WALTER se réserve le droit de mettre à jour ses produits et

ses manuels sans notification préalable aux utilisateurs de

machines fabriquées antérieurement . WALTER n'est pas

responsable des conséquences d' une mauvaise utilisation

de ses produits, par exemple :

u Mauvaise utilisation de la machine ou l'utilisation par des

personnes non qualifiées ;

u Utiliser en violation des normes de référence ;

u Installation incorrecte ;

Votre appareil SURFOX peut nettoyer :

u les soudures TIG;

u les soudures plasma;

u les soudures laser;

u les soudures par points;

u les soudures MIG

Rudiments de la passivation :

u Le nettoyage des soudures se fait non seulement à des

fins esthétiques, mais surtout pour les besoins de

passivation.

u La passivation est un traitement des surfaces en acier

inoxydable qui élimine les contaminants et favorise la

formation d’une couche de protection en oxyde de

chrome épaisse et durable.

u Cette « couche passive » permet une meilleure résistance

de l’acier inoxydable à la corrosion.

u Si la passivation n’est pas correctement réalisée, l’acier

inoxydable et les zones touchées par la chaleur peuvent

commencer à rouiller.

SURFOX 304 Manuel de l’utilisateur 21

Directives de sécurité

2

Directives de sécurité

Les appareils de nettoyage de soudure WALTER sont produits

conformément aux normes en vigueur pour la fabrication, le

rendement et la sécurité des produits industriels.

AVERTISSEMENT : Lorsque vous utilisez ces appareils, vous

devez toujours prendre des précautions pour réduire les risques

d’incendie, de décharges électriques et de blessures personnelles.

Avant d’utiliser cet appareil, lisez attentivement toutes les

consignes de fonctionnement et de sécurité; assurez-vous de

conserver ce manuel pour pouvoir vous y référer dans le futur.

1. Lisez ce manuel du propriétaire pour vous familiariser avec le

fonctionnement de cet appareil, ses particularités, son champ

d’application et ses limites.

2. Cet appareil est muni d’un cordon d’alimentation à 3 con ducteurs et de prises électriques enfichables doubles avec

terre (3 fiches); il doit être branché à une prise adéquate avec

mise à la terre.

3. Prévoyez un dégagement minimum de 8 pouces autour

de l’appareil afin de maintenir les ouvertures de ventilation

libres de toute obstruction. Un débit d’air libre à travers les

ouvertures de ventilation est nécessaire pour empêcher la

surchauffe de l’appareil.

4. Gardez la zone de travail propre et bien éclairée. Un envi ronnement encombré peut provoquer des accidents. Enlevez

tout matériel qui pourrait s’enflammer au contact d’étincelles.

N’utilisez pas cet outil lorsque des liquides inflammables ou

des gaz sont présents dans l’environnement. Gardez les

poignées propres, sèches et sans souillure de solution

nettoyante, d’huile ou de graisses. N’utilisez pas cet appareil

sous la pluie et dans des endroits humides ou mouillés.

5. Gardez les enfants et les autres personnes à une distance

sécuritaire des travaux. Veillez à ce que personne ne soit placé

en dessous de vous lorsque vous travaillez en hauteur. Ne

laissez personne sans formation adéquate utiliser cet appareil.

6. Portez toujours des vêtements appropriés et l’équipement de

sécurité nécessaire lorsque vous travaillez, des gants de

protection certifiés pour résister aux produits chimiques par

exemple, des combinaisons ou chaussures de sécurité, etc.

7. Portez toujours des lunettes de protection approuvées.

8. Pendant le processus de nettoyage, la buse de la baguette et

la pièce de travail peuvent atteindre des températures extrême ment élevées; assurez-vous que ces pièces refroidissent avant

de les mettre en contact avec une surface cutanée.

9. Évitez d’inhaler des fumées; n’utilisez l’appareil que dans un

environnement bien ventilé. Utilisez un masque filtrant au

besoin.

10. Toute décharge électrique peut être dangereuse.

11. Si vous éprouvez des problèmes d’ordre électrique,

n’utilisez pas l’appareil avant qu’une personne qualifiée ait

vérifié l’équipement.

12. N’utilisez jamais l’appareil lorsque le couvercle de protection

est retiré.

13. Restez vigilant en tout temps lorsque vous utilisez cet

appareil. Prenez garde à ce que vous faites. Utilisez votre bon

sens. N’utilisez pas l’appareil lorsque vous êtes fatigué. Ne

laissez jamais l’appareil en marche sans surveillance.

14. Assurez-vous que l’appareil est à l’arrêt (position OFF) avant

de le brancher ou lors d’un déplacement afin d’éviter un

démarrage intempestif.

22

15. Tenez la baguette fermement. Ne travaillez pas à bout de bras

afin de maintenir un bon équilibre en tout temps.

16. Avant l’utilisation, toutes les pièces devraient être examinées

soigneusement pour vous assurer que l’appareil fonctionne

correctement et remplisse sa fonction.

17. Les pièces endommagées ou défectueuses doivent être

réparées ou remplacées par un centre de service agréé par

WALTER.

18. N’utilisez pas l’appareil s’il est impossible de faire passer

l’interrupteur de l’arrêt à la mise en marche ou le contraire (ON

et OFF).

19. N’utilisez que les accessoires recommandés pour ce système.

Faites toujours une vérification des accessoires avant de com mencer le travail et ne les utilisez pas s’ils sont endommagés.

20. ATTENTION : Les solutions électrolytiques de nettoyage

SURFOX de WALTER contiennent de l’acide phosphorique

pouvant causer des brûlures lorsqu’elles ne sont pas

manipulées correctement. Évitez tout contact avec la peau.

Premiers soins : laver la zone affectée avec de l’eau.

Contact avec les yeux : rincez à l’eau pendant 15 minutes

en soulevant les paupières de temps en temps. Appelez

unmédecin au besoin. Ingestion : NE PAS PROVOQUER le

vomissement. Rincez votre bouche, buvez beaucoup d’eau

et recherchez une aide médicale. Reportez-vous aux fiches

signalétiques ou aux fiches de données de sécurité des

produits WALTER pour obtenir des informations de sécurité

exhaustives. Disonibles au walter.com ou surfox.com

21. N’utilisez que les solutions électrolytiques de nettoyage de

soudures SURFOX de WALTER avec cet appareil; ne les

mélangez JAMAIS avec d’autres solutions.

22. L'utilisation du système d'élimination des fumées (page 25)

est fortement recommandé lors de travaux dans des endroits

confinés.

23. N'utilisez pas votre machine SURFOX sur la même structure

lorsque vous soudez à l'arc. Le courant pourrait endomamger

irréparablement motre machine SURFOX. pourrait terre retour

tot il SURFOX machine et causer des dommages irréparables .

24. Entreposez la solution dans son contenant original et dans

un endroit sûr se trouvant hors de portée des enfants et des

personnes non qualifiées. Gardez le contenu du récipient

propre. Ne réutilisez jamais les solutions électrolytiques de

nettoyage SURFOX.

25. Ne touchez pas la buse de la baguette ou la pièce de travail

lorsque vous utilisez l’appareil ou immédiatement après l’avoir

utilisé; ils peuvent être extrêmement chauds et pourraient vous

causer de graves brûlures.

26. Ne maltraitez pas le cordon d’alimentation. Ne tirez jamais cet

appareil en utilisant le cordon et ne tirez pas brusquement sur

celui-ci pour débrancher l’appareil. Gardez le cordon électrique

loin de la chaleur, de l’huile et des rebords tranchants.

Inspectez régulièrement le cordon et, s’il est endommagé,

faites-le remplacer par un centre de service agréé par

WALTER.

27. Lorsqu’il n’est pas utilisé, il faut mettre l’appareil en arrêt (OFF)

et débrancher le cordon électrique ainsi que le boyau pour l’air

(s’il est branché). L’appareil doit également demeurer débran ché pour le remplacement de tampons de nettoyage ou

d’autres accessoires ainsi que pendant les périodes d’entretien

et de réparation.

28. Entreposez l’équipement dans un endroit sûr et sec se

trouvant hors de portée des enfants et des personnes qui ne

possèdent pas la formation appropriée.

Directives de sécurité

Commandes de l’équipement

2

Tension électrique

Avant de brancher cet appareil, vérifiez que l’intensité du courant (ampérage) indiqué sur la plaque signalétique est la même

que sur le bloc d’alimentation.

L’utilisation de cet appareil avec une intensité de courant

différente de celle affichée sur la plaque signalétique pourrait

provoquer des blessures à l’utilisateur et des dommages à

l’appareil.

Entretien préventif

Après une utilisation, donnez à la buse le temps de refroidir,

puis enlevez le tampon de nettoyage. Faites une neutralisation

avec le SURFOX-N, puis rincez le tampon de nettoyage et la

buse de la baguette avec de l’eau; laissez sécher. Nettoyez la

poussière et les dépôts qui se sont formés sur la partie exté

rieure de l’appareil. Gardez les ouvertures de ventilation libres

de toute obstruction. Nettoyez le cordon d’alimentation pour

prévenir sa détérioration et cherchez d’éventuels dommages

qui auraient pu survenir au cordon ou à la fiche d’alimentation.

Remarque : Les cordons électriques endommagés doivent

être remplacés immédiatement par du personnel qualifié

uniquement. Reportez-vous à la liste des pièces de rechange

pour obtenir le numéro de commande.

Transport

Avant de transporter l’appareil, assurez-vous que le réservoir de la solution de nettoyage et sa conduite d’alimentation

sont complètement vides et que tous les raccordements sont

débranchés. L’appareil doit être emballé soigneusement dans

un contenant approprié et doit être convenablement protégé.

WALTER ne pourra être tenu responsable des dommages

résultant d’une fuite de solution de nettoyage ou d’une manipulation brusque.

Entreposage

Si vous devez entreposer l’appareil, peu importe la durée de

l’entreposage, le réservoir de la solution de nettoyage et sa

conduite d’alimentation doivent être complètement vidés; le

tampon de nettoyage enlevé (neutralisé, rincé et laissé de

côté); la buse doit être neutralisée, rincée et séchée. Entreposez l’appareil dans un endroit sec et sécuritaire pour éviter

les dommages qui pourraient survenir, particulièrement aux

composantes électroniques.

Élimination des déchets

Éliminez les déchets résiduels en conformité avec les réglementations environnementales en vigueur (fédérales, provinciales, territoriales ou locales). Consultez les fiches signalétiques

ou les fiches de données de sécurités du matériel de WALTER

qui traitent des solutions électrolytiques de nettoyage SURFOX.

Cordon de rallonge

Lorsque l’ajout d’un cordon de rallonge est nécessaire, utilisez

la taille 14 (AWG) pour les cordons ayant une longueur maximum de 50 pieds (15 mètres) et la taille 12 (AWG) pour les

cordons de 50 à 100 pieds (15 à 30 mètres).

-

3

Commandes de l’équipement

A) Pictogrammes du panneau de commande

Sortie pour la micro-baguette ou

baguette de marquage

Indicateur de haute température interne

Mode pompage manuel Mode pompage automatique

Bbaguette de marquage Micro-baguette

MAX STD

STD MAX

Bouton de sélection du type et

du niveau de courant

Indicateur de mise en marche pour

la buse de la baguette

Indicateur de bas niveau

de la solution

Baguette large

Bouton de sélection de

baguette et d'accessoires

SURFOX 304 Manuel de l’utilisateur 23

Commandes de l’équipement

3

B) Vue de l’appareil – avant et arrière

Bouton

EN MARCHE/ARRÊT (ON/OFF)

Sortie pour accessoires

Raccord de mise à la terre

Boyau de la baguette

large (alimentation

de la solution et

alimentation électrique)

Unité d’assemblage pour les

tampons de nettoyage

Panneau

de commande

Réservoir et unité de

remplissage de la solution

électrolytique SURFOX

24

Support à baguette

Cordon d’alimentation

Connexion d’air compressé (système

d’élimination des fumées)

Cordon d’alimentation

Commandes de l’équipement

3

C) Boutons de contrôle de la baguette

Le bouton EN MARCHE (ON) est utilisé pour alimenter les

accesoires de nettoyage. Lorsque le pompage est réglé en

mode Manuel, appuyez sur le bouton EN MARCHE (ON)

pour activer la pompe. Appuyez sur le bouton et gardez-le

enfoncé pour obtenir une arrivée continue de liquide.

Toutefois, si le pompage est en mode automatique, appuyez sur le bouton EN MARCHE (ON) une seule fois pour

activer la pompe. Pour arrêter le pompage, appuyez sur le

bouton ARRÊT (OFF). Lorsque votre travail est terminé (peu

importe le mode), assurez-vous d’appuyer sur le bouton

ARRÊT (OFF).

Une fois que le bouton EN MARCHE (ON) est activé, il

y aura une arrivée continuelle de courant à la buse de la

baguette jusqu’au moment où vous appuierez sur le bouton

ARRÊT (OFF).

ON OFF

Accessoire de

nettoyage

E) Positionnement de la buse (confort de

l’opérateur)

La position normale de la buse de tungstène est à

l’horizontale, mais elle peut être placée en position verticale – ou tout autre positon entre les deux – pour faire

votre nettoyage de la manière la plus confortable possible.

Desserrez le manchon fileté d’élimination des fumées vers

la droite; placez la buse dans la position désirée; resserrez

le manchon.

Important : Resserrez toujours le manchon d’élimination

des fumées pour assurer une bonne connexion électrique

et prévenir les dommages aux points de contact.

D) Système d’élimination des fumées (breveté)

L’appareil SURFOX 204 est muni d’un système intégré

d’élimination des fumées. Ce système permet d’obtenir

un meilleur environnement de travail. Bien que les fumées

dégagées par l’appareil ne soient pas toxiques ou

dangereuses, elles peuvent vous rendre inconfortable si

vous travaillez dans un espace clos.

Pour activer cette fonctionnalité, il suffit de brancher une

conduite d’air comprimé (150 lb/po

min) au raccord situé à l’arrière de l’appareil. Le système

d’élimination des fumées est activé automatiquement

lorsque vous appuyez sur le bouton EN MARCHE (ON)

de la baguette large. Le système se ferme lorsque vous

appuyez sur le bouton ARRÊT (OFF) de la baguette large.

Si vous ne désirez pas utiliser ce système, il suffit de

débrancher la conduite d’air.

Le fonctionnement est très efficace et fort simple : l’air

sort par les petites ouvertures derrière l'accessoire de

nettoyage. Cette pression d’air préréglée agit de manière

constante. Elle condense les vapeurs pour les expulser hors

de l’air ambiant.

2

max., 80 lb/po2

Raccord de la

conduite d’aire

comprimé

Gros plan sur les

accessoires de nettoyage

Petites

ouvertures

SURFOX 304 Manuel de l’utilisateur 25

Panneau de commande

4

Panneau de commande

A) Interrupteur d’alimentation

principal

Permet de mettre l’appareil en marche ou à

l’arrêt (ON et OFF).

A

B

C

D

MAX STD

STD MAX

26

B) Bouton de sélection de

baguette et d'accessoires

Baguette de marquage et gravure. Sé-

lectionnez ce réglage lorsque vous utilisez

la baguette de marquage/gravure qui a été

branchée dans la sortie d’accessoires.

Micro-baguette. Sélectionnez ce réglage

lorsque vous utilisez la micro-baguette qui a

été branchée dans la sortie d’accessoires.

Sélectionnez le bon accessoire de nettoyage

soit la buse en tungstène, la brosse ou la buse

large en graphite.

Baguette large. Sélectionnez ce réglage

lorsque vous utilisez la baguette rattachée à

l’appareil SURFOX.

C) Bouton de sélection du type et

du niveau de courant

Choisir le bon type de courant AC ou DC

et la bonne intensité STD ou MAX AC

est pour le nettoyage et la passivation des

soudures. DC est pour le nettoyage, la passivation et le polissage des soudures STD est

recommandé pour l'utilisation avec buse en

tungstène et les tampons.

MAX est recommandé pour l'utilisation avec

les brosses et les embouts large en graphite.

D) Interrupteur de la pompe

de solution

Mode pompage manuel. Choisissez le mode

de pompage manuel pour contrôler la quantité

de solution à envoyer vers la buse. Gardez le

bouton EN MARCHE (ON) de la baguette large

enfoncé pour pomper la solution vers la buse.

Relâchez le bouton EN MARCHE (ON) pour

arrêter le cycle de pompage. Utilisez toujours

la quantité de solution adéquate pour garder le

tampon de nettoyage humide. Une trop petite

quantité de solution réduira la durabilité du

tampon de nettoyage.

Mode pompage automatique. Pour lancer

le mode de pompage automatique, appuyez

sur le bouton EN MARCHE (ON) de la baguette. Une fois activé, le pompage du liquide

se fera automatiquement. La quantité de

liquide utilisée peut être réglée de « moins » à

« plus ». Le pompage de solution se poursuivra

jusqu’au moment où le bouton ARRÊT (OFF)

sera enfoncé.

E

F

E) Témoins lumineux

Indicateur de mise en marche (ON) de

la baguette large. Le témoin lumineux vert

s’allume lorsque le bouton de la microbaguette EN MARCHE (ON) est enfoncé

et que du courant passe jusqu’à la buse.

La buse n’est plus alimentée en courant

lorsque le bouton ARRÊT (OFF) de la

baguette large est enfoncé.

Lorsque la température opérationnelle

devient trop élevée, le témoin lumineux

jaune s'allume et l’appareil se met à l’arrêt

et redémarre automatiquement

lorsque la température redevient

acceptable.

Indicateur de bas niveau pour la

solution. Lorsque le niveau de la solution

devient trop bas, le témoin lumineux

passera au rouge.

F) Sortie pour les accessoires

Sortie pour la micro-baguette ou

la baguette de marquage/gravure

en option. La baguette de marquage/

gravure est utilisée pour créer une gravure

permanente sur les surfaces en acier

inoxydable, que ce soit votre nom, logo,

numéro de pièce ou toute autre information

que vous souhaiteriez inscrire. La microbaguette permet d’accéder à des zones qui

sont difficiles à atteindre ou trop petites pour

la baguette large lorsque vous procédez à

un nettoyage et une passivation.

Procédure de démarrage

A) Contenu de la boîte

u 1 x Baguette large et boyau de raccordement

u 1 x 48-R 136 Collier de mise à la terre

u 1 x 54-B 094 Support à baguette pour Surfox 204/304

u La trousse d’accessoires comprend :

• 1 x 54-B 095 Brosse en carbone pour baguette large

• 1 x 54-B 099 Adaptateur pour brosse de

baguette large

• 1 x 54-B 101 Guide triangulaire

• 1 x 54-B 103 Guide cylindrique

• 1 x 48-R 133 Buse en tungstène (déjà installée sur

la baguette large)

• 3 x 54-B 026 Tampons standards de nettoyage à

haute conductivité

Procédure de démarrage

5

• 1 x 54-B 002 1 anneau de serrage en PTFE

• 1 x clé hexagonale (clé Allen) de 2.5 mm pour le

changement des accessoires de nettoyage.

• 1 x clé hexagonale (clé Allen) de 5.0 mm pour

l'assemblage du support de la baguette large

B) Remplissage du réservoir

Remplissez le réservoir situé à l’arrière de l’appareil avec la

solution de nettoyage électrolytique SURFOX. Le réservoir

peut contenir 1,9 L de solution électrolytique SURFOX.

C) Raccordement de l’alimentation d’air

Raccordez l’alimentation d’air à l’arrière de l’appareil. Notez

que la pression maximum tolérée est de 150 lb/po

mum de 80 lb/po

rectement sans alimentation d’air, mais il n’y aura aucune

élimination des fumées.

2

(1000 kPa). L’appareil fonctionnera cor-

2

; mini-

D) Branchement du cordon d’alimentation

Lorsque l’ajout d’un cordon de rallonge est nécessaire,

utilisez la taille 14 (AWG) pour les cordons ayant une

longueur maximum de 50 pieds (15 mètres) et la taille

12 (AWG) pour les cordons de 50 à 100 pieds (15 à 30

mètres).

Réservoir

Collier de

mise à la

terre

Connexion de

l’alimentation

d’air

E) Branchement du collier de mise à la terre

Branchez le collier de mise à la terre sur le devant de

l’appareil. Attachez le collier à la pièce de travail qui doit

être nettoyée. Vous ne pourrez pas nettoyer et passiver une

pièce si elle n’est pas mise à la terre correctement.

SURFOX 304 Manuel de l’utilisateur 27

Utilisation de la baguette large pour le nettoyage, le polissage et la passivation électrochimique

6

Utilisation de la baguette large pour le nettoyage,

le polissage et la passivation électrochimique

A) Sélectionner la baguette et l'accessoire de

nettoyage

Embout en

Tungsten

Brosse

Baguette

large

Embout

large en

graphite

B) Choisir le bon type de courant AC ou DC et

la bonne intensité STD ou MAX

Mode pompage manuel. Choisissez le mode de pompage

manuel pour contrôler la quantité de solution à envoyer vers

la buse. Gardez le bouton EN MARCHE (ON) de la baguette

large appuyé pour pomper la solution vers la buse. Relâchez le bouton EN MARCHE (ON) pour arrêter le cycle de

pompage. Utilisez toujours la quantité de solution nécessaire pour garder le tampon de nettoyage humide.

Mode pompage automatique. Pour lancer le mode

de pompage automatique, appuyez sur le bouton EN

MARCHE (ON) de la baguette. Une fois activé, le pompage

du liquide se fera automatiquement. La quantité de liquide

utilisée peut être réglée de « moins » à « plus ».

D) Nettoyage et passivation

MAX STD

STD MAX

AC est pour le nettoyage et la passivation des soudures.

DC est pour le nettoyage, la passivation et le polissage

des soudures. STD est recommandé pour l'utilisation avec

buse en tungstène et les tampons. MAX est recommandé

pour l'utilisation avec les brosses et les embouts large en

graphite.

AVERTISSEMENT! Le mode DC est utilisé pour polir la

tête de soudure afin de la faire correspondre au fini miroir du

matériel.

TRUC ! Lorsque vous utilisez le mode polissage (DC),

utilisez une grande quantité de solution

électrolytique SURFOX.

Remarque : Lorsque vous utilisez le réglage DC, la solution

électrolytique SURFOX prendra une teinte jaunâtre ou plus

foncée.

Pour nettoyer et passiver, appuyez sur le bouton EN

MARCHE (ON) de la baguette large. Assurez-vous que

l'accessoire de nettoyage est saturé de solution nettoyante

électrolytique SURFOX avant de commencer le travail. Si

l'accessoire de nettoyage est trop sec, il s’usera prématurément. Commencez à travailler au moment où des gouttes

de solution commencent à tomber du tampon de nettoyage.

N’appliquez pas une pression trop forte; laissez le traitement électrochimique faire le travail. N’utilisez pas le tampon de nettoyage comme un tampon abrasif.

AVERTISSEMENT ! À la première utilisation de l’appareil,

de l’eau provenant des tests de fabrication pourrait subsister à l’intérieur du système. Réglez la pompe à liquide

en mode automatique à la vitesse maximale et laissez le

liquide s’égoutter pendant deux minutes dans un récipient

à déchets (le temps nécessaire pour vider le tuyau entre le

réservoir et la baguette), puis ramenez les réglages de la

pompe à la vitesse de pompage désirée.

E) Neutralisation

1. Enlevez le surplus de solution électrolytique SURFOX à

l’aide d’un chiffon souple et propre.

C) Sélectionner le mode de pompage adéquat

Mode

manuel

28

Mode

automatique

2. Vaporisez du SURFOX-N sur la surface.

3. Asséchez en utilisant un nouveau chiffon souple et

propre pour éviter une contamination croisée.

Reportez-vous à la procédure de neutralisation dans la

section portant sur la neutralisation pour obtenir les directives appropriées (page 34).

Accessoires pour baguette large

A) Sélection et assemblage des buses

et tampons de nettoyage

Accessoires pour baguette large

7

Les buses de tungstène sont fabriquées avec un alliage de

tungstène de haute qualité. D’autres matériaux pourraient

ne pas résister à l’environnement hostile créé par un traitement électrochimique.

AVERTISSEMENT ! Des embouts trop usés

peuvent endommager les tampons de nettoyage.

Dans cet exemple d’embout trop usé, il ne subsiste que deux points de contact. Tout le courant

passe par ces deux points. En raison de la section

transversale inférieure, la température deviendra

plus élevée sur les deux points et les tampons de

nettoyage pourraient s’endommager ou s’user

prématurément.

O-Ring

Embouts

Embout en tungstène 90°

No de comm. : 48-R 133

S’utilise avec tampon 54-B 026

ou 54-B 040 et bague de serrage

54-B 002 ou chausson 54-B 005

Embout en tungstène

étroit 90°

No de comm. : 54-B 017

S’utilise avec tampon 54-B 028

ou 54-B 041 et bague de serrage

54-B 020 ou chausson 54-B 007

TRUC ! Rectifiez l’embout à l‘aide d’une meuleuse

d’établi ou une meuleuse angulaire.

Remarque : Assurez-vous d’installer le joint torique (O-Ring)

à l’arrière des embouts chaque fois que vous les changez.

Embout en tungstène 60°

No de comm. : 54-B 016

S’utilise avec tampon 54-B 027

et bague de serrage 54-B 002

ou chausson 54-B 006

Embout en tungstène

étroit 60°

No de comm. : 54-B 018

S’utilise avec tampon 54-B 028

et bague de serrage 54-B 020

ou chausson 54-B 00854-B 008.

Ensemble d’embouts

en tungstène

No de comm. : 54-B 012

Comprend :

1 x 48-R 133

1 X 54-B 017

1 X 54-B 016

1 X 54-B 018

Tampon grand format

pour SURFOX 304

No de comm. : 54-B 052

(paquet de 5)

Embout en graphite large

pour 204 et 304

No de comm. : 54-B 009

1,8 Larg. (45 mm Larg.) Idéal pour

les grandes zones soudées et la

restauration de surface et le nettoyage

de l’arrière de soudures au MIG.

Brosse en fibre de

carbone pour grand

applicateur SURFOX 304

No de comm. : 54-B 095

Sans adaptateur. (paquet de 5)

Manchon triangulaire

pour brosse en fibre de

carbone s’adaptant au

grand applicateur

No de comm. : 54-B 101

Tampon large pour embout

en graphite large

No de comm. : 54-B 043

90 mm L X 50 mm W X 2 mm H

Paquet de 10 avec joint

d’etancheite

Adaptateur de brosse

de rechange pour grand

applicateur SURFOX 304.

No de comm. : 54-B 099

Manchon cylindrique pour

brosse en fibre de carbone

s’adaptant au grand

applicateur

No de comm. : 54-B 102

Support d’applicateur pour

Surfox 304 et 204.

No de comm. : 54-B 094

SURFOX 304 Manuel de l’utilisateur 29

Accessoires pour baguette large

7

Tampons de nettoyage à haute conductivité

Les tampons de nettoyage sont faits d’un mélange complexe de polymères synthétiques extrêmement conductifs.

Ces polymères sont très résistants à l’usure et offrent une

excellente stabilité thermique. Pour obtenir un cycle de

vie plus long, enlevez le tampon de nettoyage à la fin de

chaque journée de travail et faites une neutralisation en

utilisant le SURFOX-N.

Les tampons de nettoyage sont offerts en quatre formats :

Tampons de nettoyage

standards

No : 54-B 026

Utilisez avec l’embout

48-R 133.

Tampons de nettoyage

pour coins intérieurs

No : 54-B 027

Utilisez avec l’embout 54-B 016.

Caractéristiques

• Flexibilité; ils peuvent être pliés de plusieurs manières.

• Doux pour les surfaces.

• Utilisable sur les deux côtés.

• Durée prolongée.

• Conductivité élevée (4x plus conducteurs que la

génération précédente).

Tampons de nettoyage

étroits

No : 54-B 028

Utilisez avec les embouts 54-B 017

et 54-B 018.

Tampons de nettoyage

larges

No : 54-B 043

Utilisez avec l’embout large

en graphite 54-B 009.

30

Accessoires pour baguette large

7

B) Bagues de serrage en PTFE

Les bagues de serrage en PTFE sont conçues pour

maintenir en place les tampons de nettoyage sur les

embouts de tungstène.

Elles sont offertes en deux formats :

Bague étroite pour les tampons étroits

o

: 54-B 020

N

Utilisez avec des embouts étroits. 10 par paquet.

Bague de serrage pour les tampons

de nettoyage standards

o

: 54-B 002

N