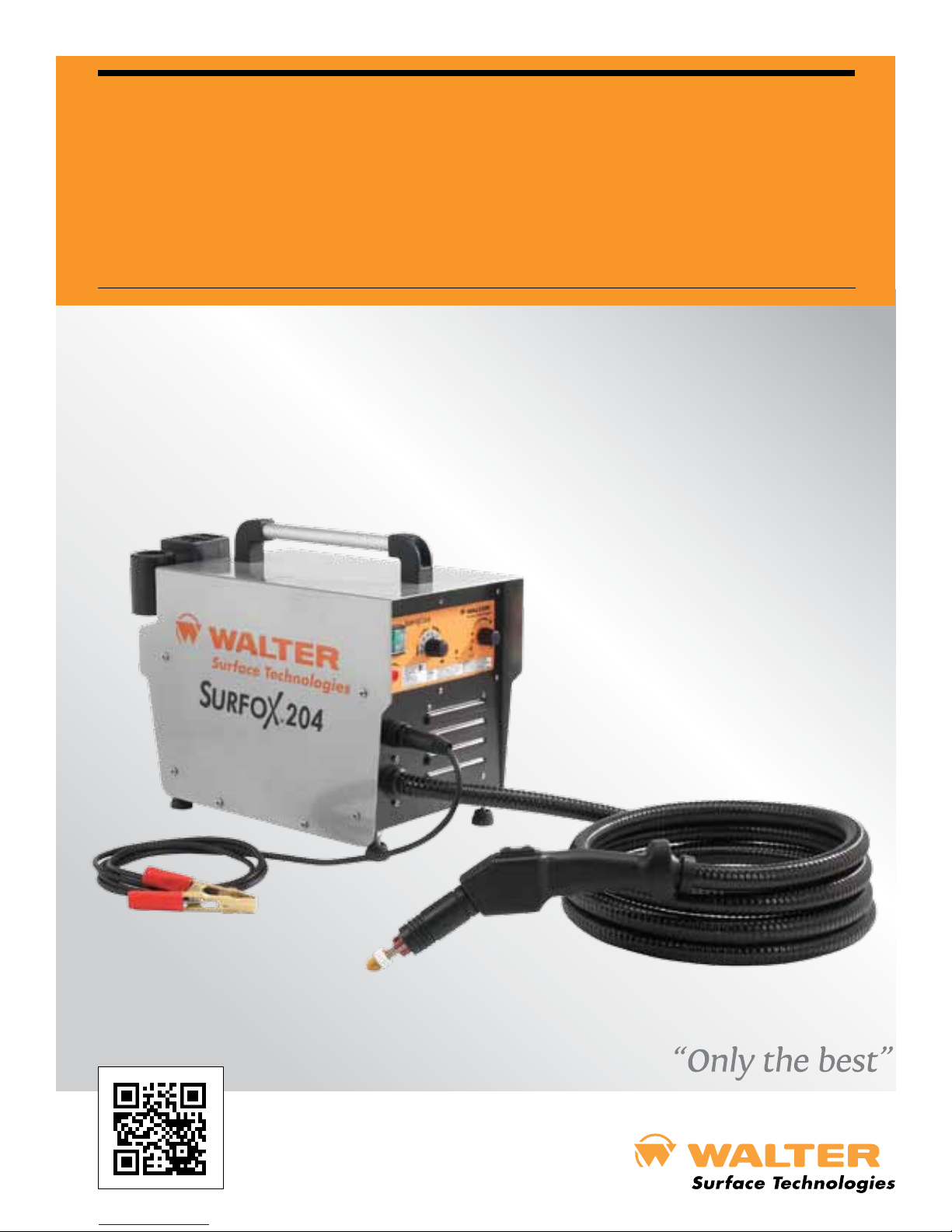

Walter SURFOX 204, SURFOX 104 User Manual

SURFOX 204

User’s guide

Manuel de l’utilisateur

Manual de usuario

Manual do Usuário

SURFOX website

(Link to surfox.com)

Table of contents

Table of contents

1 Introduction 2

2 Safety instructions 3

3 Equipment controls 4

A) Control panel pictograms 4

B) Front and back view of the machine 5

C) Wand control buttons 6

D) Fume elimination system 6

E) Tip repositioning (comfort for operator) 6

4 Control panel 7

A) Main power switch 7

B) Wand selector switch 7

C) Amperage regulating switch 7

D) Solution pump switch 7

E) Indicator lights 7

F) Accessory outlet 7

5 Start-up procedure 8

A) What is included in the box 8

B) Filling the reservoir 8

C) Connecting the air supply 8

D) Plugging in the power cord 8

E) Plugging in the ground clamp 8

6 Using the hand wand to electrochemically

clean, polish and passivate 9

A) Selecting the proper mode 9

B) Selecting the proper amperage type, AC or DC 9

C) Selecting the proper amperage setting 9

D) Selecting the proper pumping mode 9

E) Cleaning and passivating 9

F) Neutralizing 9

7 Using the mini wand (optional) to clean

and passivate 10

A) Selecting the proper mode 10

B) Selecting the amperage type, AC or DC 10

C) Selecting the proper amperage setting 10

D) Manual pumping mode 10

E) Cleaning and passivating 10

F) Neutralizing 10

G) List of supplies and part numbers 11

8 Using the marking/etching wand (optional) 12

A) Marking kits 12

B) Selecting the proper mode 12

C) SURFOX testing devices 12

9 Neutralizing 13

A) Directions for neutralizing SURFOX

electrolyte cleaning solutions 13

B) SURFOX WELD cleaning and neutralization

procedure 13

10 Accessories 14

A) Selection and mounting of the cleaning

pads and tips 14

B) PTFE clamp rings 16

C) SURFOX electrolyte solutions 16

D) Mounting a cleaning pad

11 Safety features 17

A) Sparks on the tip/work piece 17

B) Internal temperature 17

C) AC/DC current basics 17

D) AC/DC settings on the SURFOX machine 18

E) Welds that cannot be cleaned 18

12 Technical data 19

13 Warranty and service 19

A) Warranty policy 19

B) Repair and service 19

Version française 21

Versión española 41

Versão Portuguaise 61

SURFOX 204 User’s Guide 1

Introduction

1

Introduction

Congratulations on purchasing the nest electrochemical

weld cleaning and passivation equipment available today.

WALTER’s SURFOX

easily and cost effectively removes the heat tint from heat

affected zones while completely passivating the stainless

steel surface.

Our new generation of SURFOX machines are equipped

with self-regulating inverter boards, automatically monitoring

and adjusting the current so as to ensure maximum cleaning effectiveness without loss of productivity.

Before starting, please read the SURFOX

completely as we take you step-by-step through the startup, operating and maintenance procedures of your new

SURFOX

built with extra durability to stand up to the heavy demands

of industrial use. However, like any piece of electrical equipment, care and safety should always be taken when using

and maintaining this valuable investment. With proper care

and maintenance your SURFOX equipment will provide

years of dependable service.

To learn more about the other WALTER products, visit our

website: www.walter.com

equipment. Your new SURFOX machine has been

TM

weld cleaning equipment quickly,

owner’s manual

Operation

The SURFOX machine works by an electrochemical process

to clean and passivate welds on stainless steel. SURFOX

electrolyte solutions are phosphoric acid based, approved

for food industry, and are activated by an electrical current to clean welds. The process takes only a few seconds

without damaging or scratching the surface of the parts to

be cleaned.

Your SURFOX machine can clean:

u TIG welds

u Plasma welds

u Laser welds

u Spot welds

u MIG welds (with Pulse technology)

Basics of passivation:

u The cleaning of the welds is not only for aesthetic

purposes but most importantly for passivation.

u Passivation is the treatment of stainless steel surfaces

to remove contaminants and promote the formation of

a thick and durable protective chromium oxyde layer.

u This passive layer will insure the corrosion resistance of

stainless steel.

u If passivation is not done properly, stainless steel and

heat affected zones may start to rust.

2

Safety instructions

Safety instructions

2

WALTER weld cleaning machines are produced in accor-

dance with applicable standards governing the manufacture, performance and safety of industrial products.

WARNING: When using these machines, basic safety

precautions should always be observed to reduce the risk

of re, electrical shocks and personal injuries.

Before using this machine, read all Safety and

Operating Instructions carefully and save this owner’s

manual for future reference.

1. Read this owner’s manual to familiarize yourself with

this unit’s operation, its particular features, applications

and limitations.

2. This unit is equipped with a 3-conductor power cord

and 3-prong electrical plug, it must be connected to

a correspondingly grounded receptacle.

3. Allow a minimum of 8” clearance around the unit to

keep all air openings clear of any obstruction. Free

airow through the vent openings is required to

prevent the unit from overheating.

Keep work area clean and well lit. A cluttered environ-

4.

ment invites accidents. Remove any material that

may be ignited by sparks. Do not use this tool when

ammable liquids or gases are present. Keep handles

clean, dry and free from cleaning solution, oil and

grease. Do not use in rain, damp or wet locations.

5. Keep children and other persons at a safe distance

from the work. Make sure no one is under you when

working in high places. Do not let unqualied persons

handle this machine.

6. When working, always wear appropriate clothing

and safety gear, such as suitable and safety approved

chemical resistant gloves, overalls, safety shoes, etc.

7. Always wear approved safety goggles.

8. During the cleaning process, the wand tip and work

piece can reach very high temperatures, allow to cool

before coming in contact with exposed skin.

9. Avoid inhalation of fumes, use only in well ventilated

areas. Use a respirator, if necessary.

10. All electric shocks can be potentially dangerous.

11. Should you encounter an electrical problem, do not

use the unit until qualied personnel have inspected

the equipment.

12. Never operate the unit with its protective cover

removed.

13. Stay alert at all times when handling this unit. Watch

what you are doing. Use common sense. Do not

operate the tool when you are tired. Never leave it

running unattended.

14. Make sure the switch is in its OFF position before

plugging in or when moving the unit to avoid uninten tional starting.

15. Hold the wand rmly. Do not overreach, maintain good

footing and balance at all times.

16. Before use, all parts should be carefully examined to

determine that the unit will operate properly and

perform its intended function.

17. Parts that are damaged or defective should be properly

repaired or replaced by a WALTER Factory Service

Center or a WALTER Authorized Service Center.

18. Do not use the unit if the switch does not turn ON

and OFF.

19. Use only the accessories recommended for this

system. Always check accessories before starting to

work and do not use if damaged.

20. CAUTION: WALTER SURFOX electrolyte weld cleaning

solutions contain phosphoric acid and may cause burns

when not handled properly. Avoid skin contact.

First aid Wash affected area with water.

Eye contact Flush with water for 15 minutes lifting

eyelids occasionally. Contact physician if necessary.

Ingestion DO NOT induce vomiting. Rinse mouth,

drink plenty of water and get medical attention.

Refer to WALTER product MSDS for complete

safety data information.

21. Use only WALTER SURFOX electrolyte weld cleaning

solutions with this unit and NEVER mix it with any other

products.

22. Store solution in its original container and in a safe

place, out of the reach of children and other unquali-

ed persons. Keep container contents clean. Do not

reuse SURFOX electrolyte cleaning solutions.

23. Do not touch the wand tip or work piece while working

or immediately after use, they may be extremely hot

and could cause serious burns.

24. Do not abuse the power cord. Never pull or lift this unit

by its cord or yank to disconnect it from the receptacle.

Keep the cord away from heat, oil and sharp edges.

Inspect the cord periodically, if damaged, have it re placed by a WALTER Factory Service Center or a

WALTER Authorized Service Center.

25.

When not in use, switch OFF and unplug the electrical

cord and air hose (if connected). It must also remain

unplugged when replacing cleaning pads and other

accessories, while performing maintenance and before

servicing.

26.

Store the unit in a dry safe place, out of the reach of

children and other unqualied persons.

SURFOX 204 User’s Guide 3

Safety instructions

Equipment controls

2

Amperage

Before connecting this unit, check that the amperage

shown on the rating plate is the same as the power supply.

Operating this unit on an amperage other than specied on

its rating plate may result in personal injury to the user and

damage the unit.

Preventive maintenance

After use, allow the tip to cool and remove the cleaning pad

Neutralize with SURFOX-N and rinse the cleaning pad and

wand tip with water and dry. Clean dust and dirt deposits

from the exterior of the unit. Keep all airow vent openings

free of any obstructions. Clean the power cord to prevent

deterioration and check for possible damage to cord and

plug.

Note: Damaged cords must be replaced immediately by

qualied personnel only. Refer to Spare Parts List for the

ordering number.

3

Equipment controls

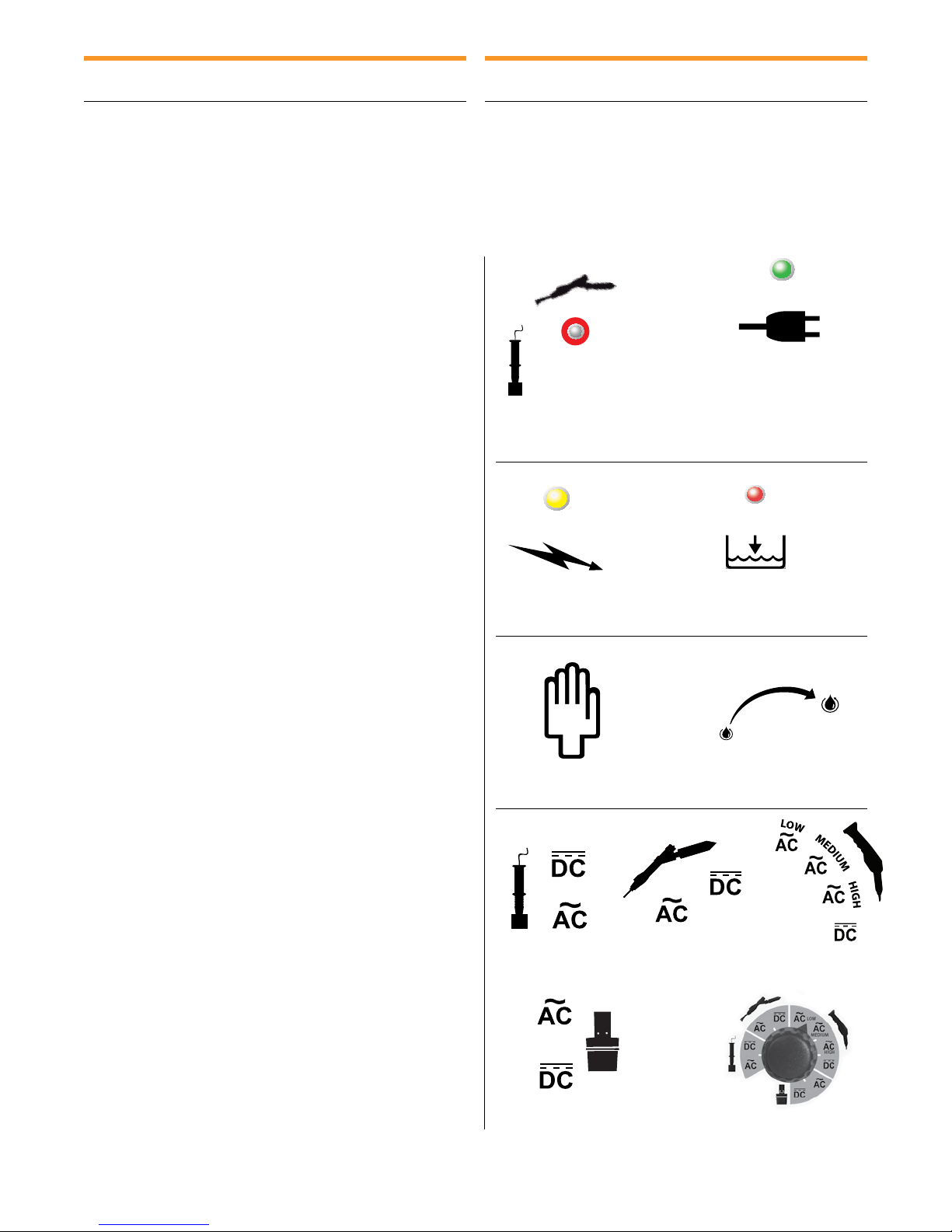

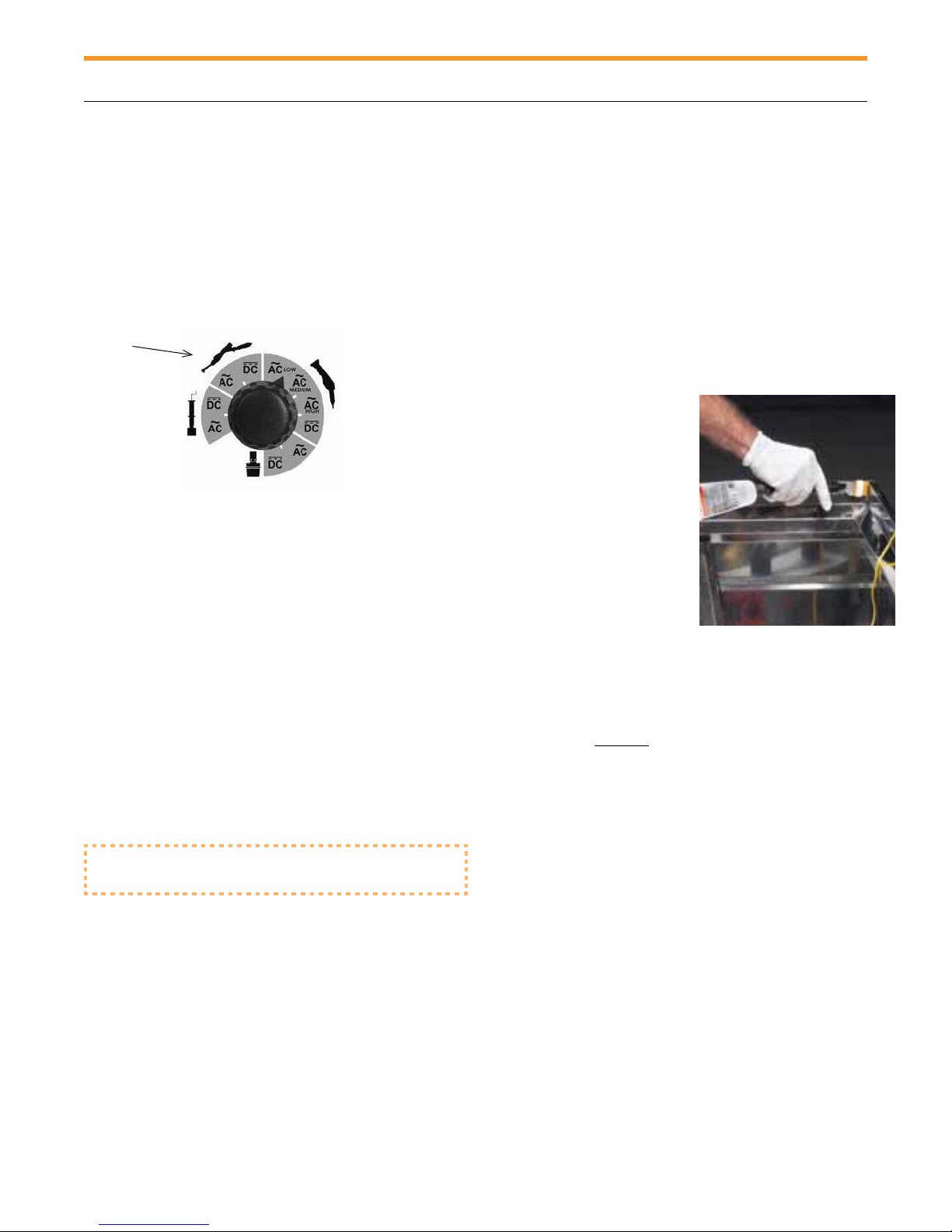

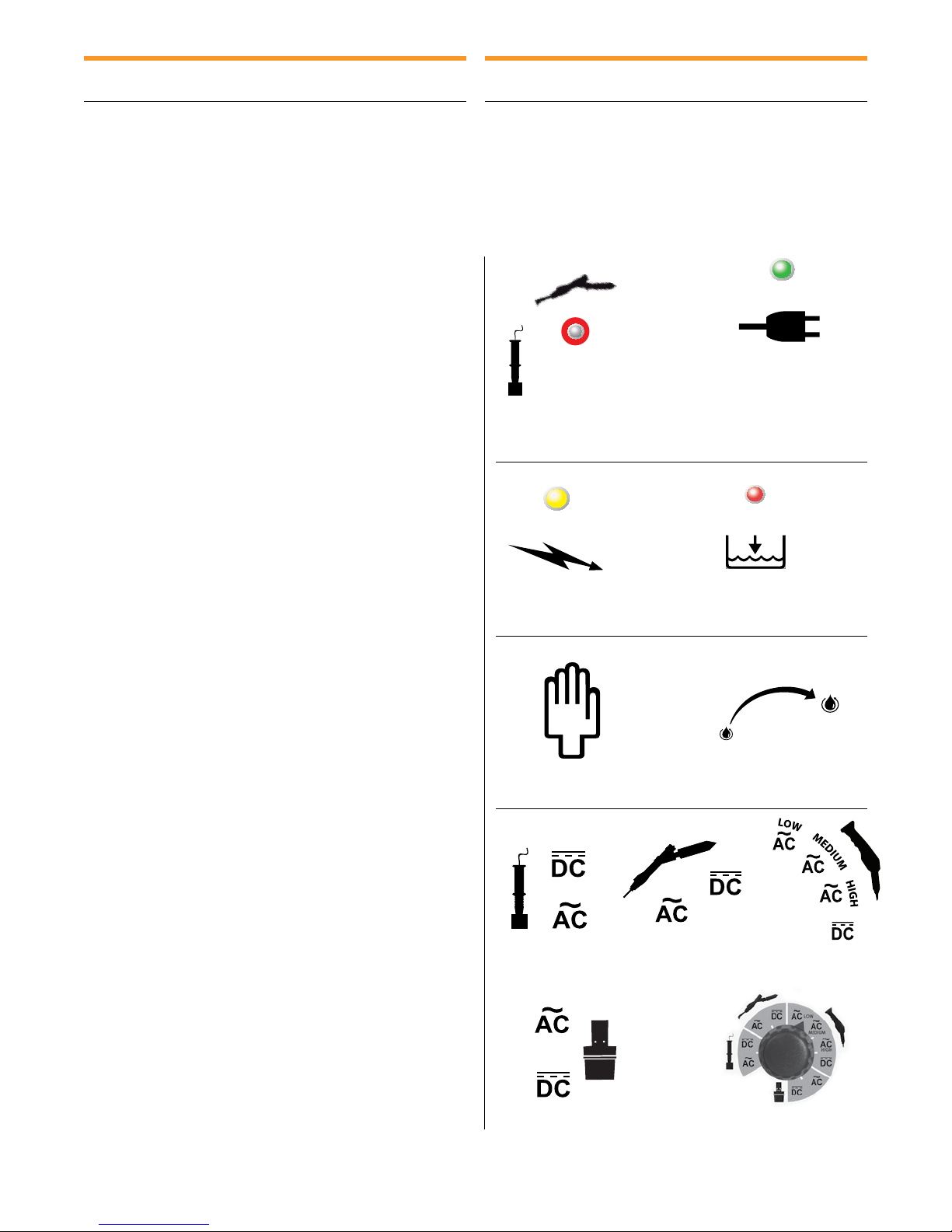

A) Control panel pictograms

.

Outlet for mini wand

or marking wand

Indicator for unit

power ON

Transportation

Before transporting the machine, make sure the cleaning

solution reservoir and supply line are completely empty

and all connecting lines disconnected. The machine must

be carefully packed in a suitable container and properly

protected. WALTER will not be held responsible for any

damages resulting from leaked cleaning solution or rough

handling.

Storage

If the machine is to be stored for any length of time, the

cleaning solution reservoir and supply line must be emptied,

cleaning pad removed (neutralized, rinsed and left off) and

the tip neutralized, rinsed and dried. Store in a dry

safe place to avoid damage, especially to the electronic

components.

Waste disposal

Dispose of residual waste in compliance with Federal,

Provincial, State and local environmental regulations. Refer

to WALTER Material Safety Data Sheet of the SURFOX

electrolyte cleaning solutions.

Indicator for wand tip

power ON

Manual pumping mode Automatic pumping mode

Marking wand selector Mini wand selector

Indicator for LOW

solution level

Cleaning or polishing

wand selector

Extension cord

When an extension cord is needed, use wire size 14 (AWG)

for up to 50 feet (15 meters) and size 12 (AWG) for 50 to

100 feet (15 to 30 meters).

4

Large insert selector

Mode selector

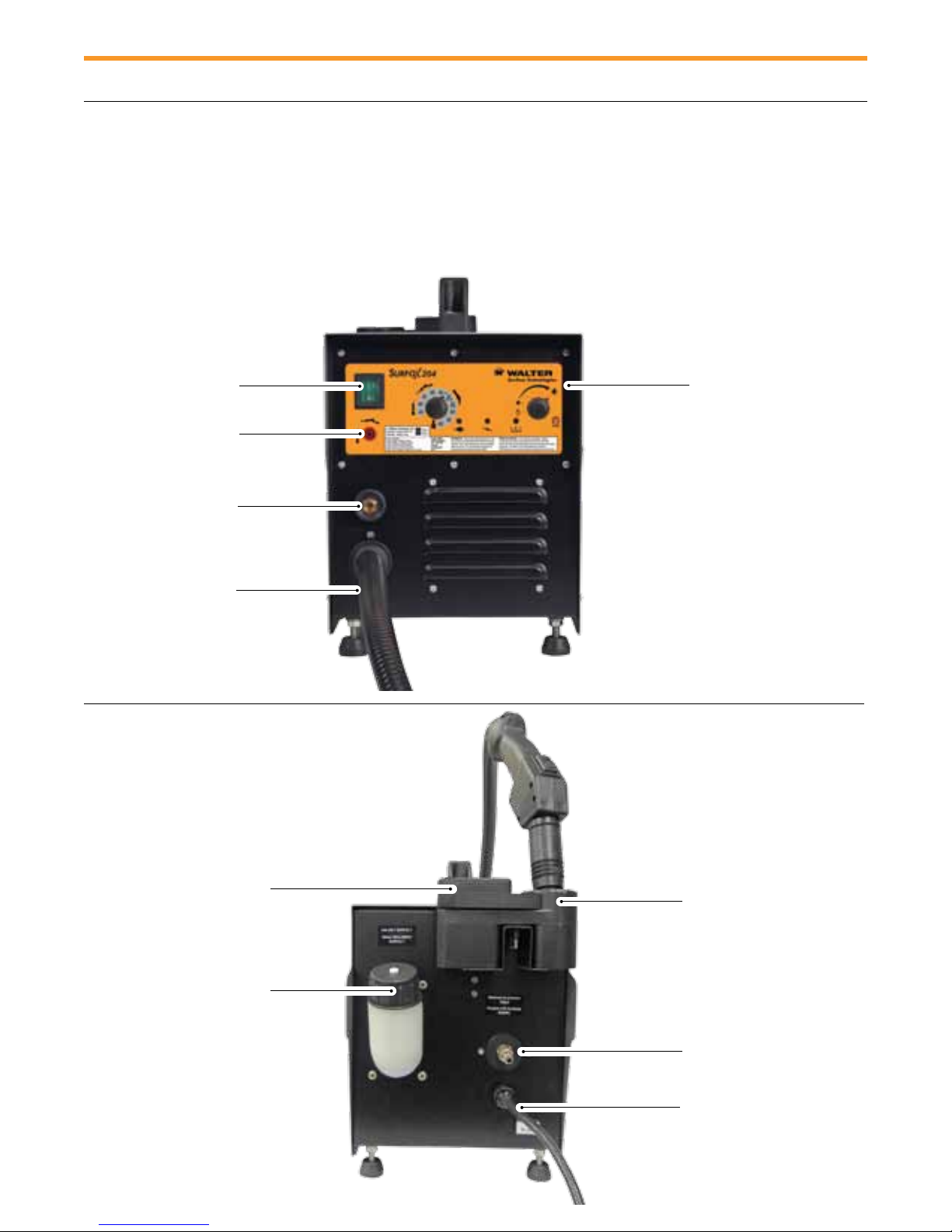

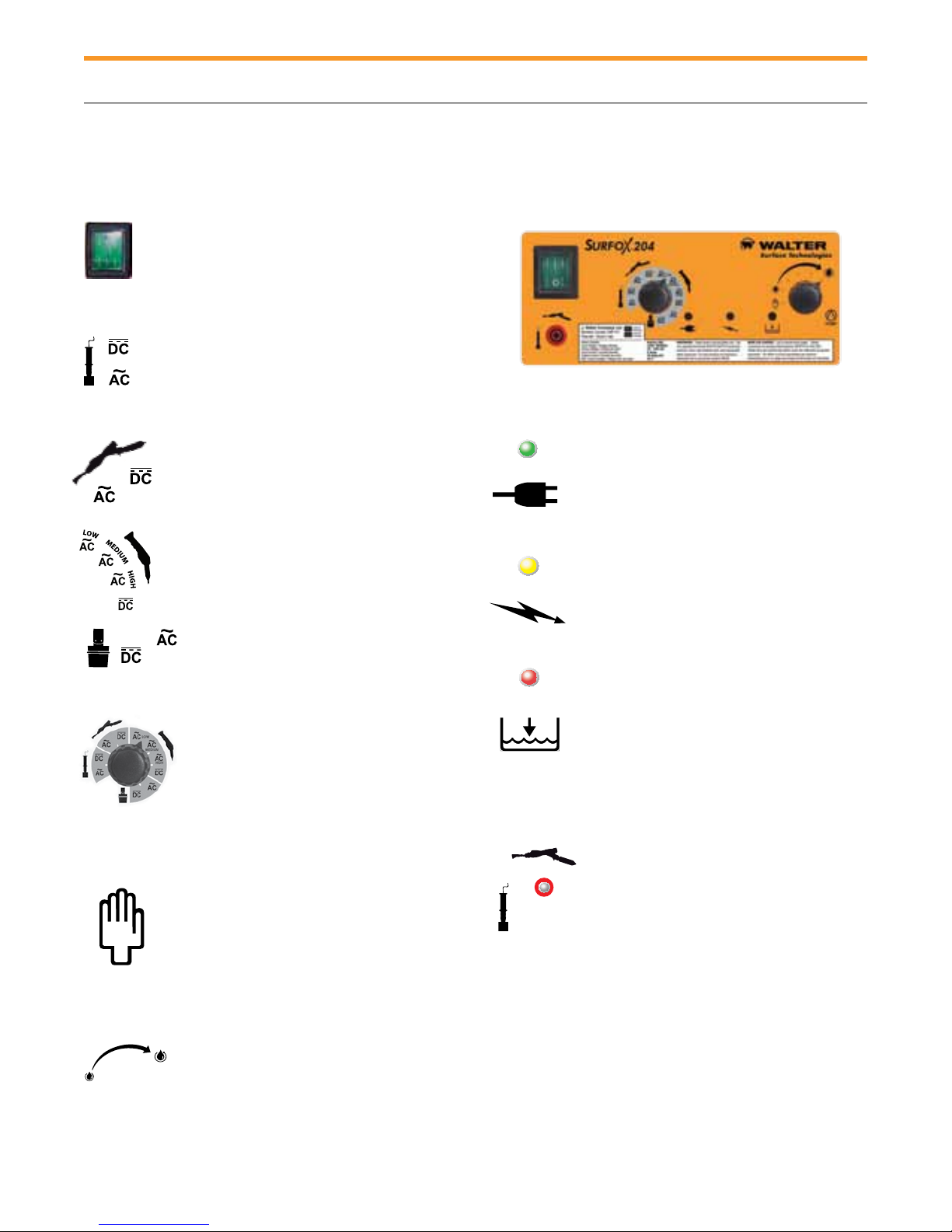

B) Front and back view of the machine

Equipment controls

3

ON/OFF button

Accessory outlet

Ground connector

Hand wand hose

(electrical and solution

supply lines)

Control panel

Cleaning pad mounting unit

SURFOX electrolyte solutions

lling and reservoir

Wand holder

Compressed air

connector (for fume

elimination system)

Power cord

SURFOX 204 User’s Guide 5

Equipment controls

3

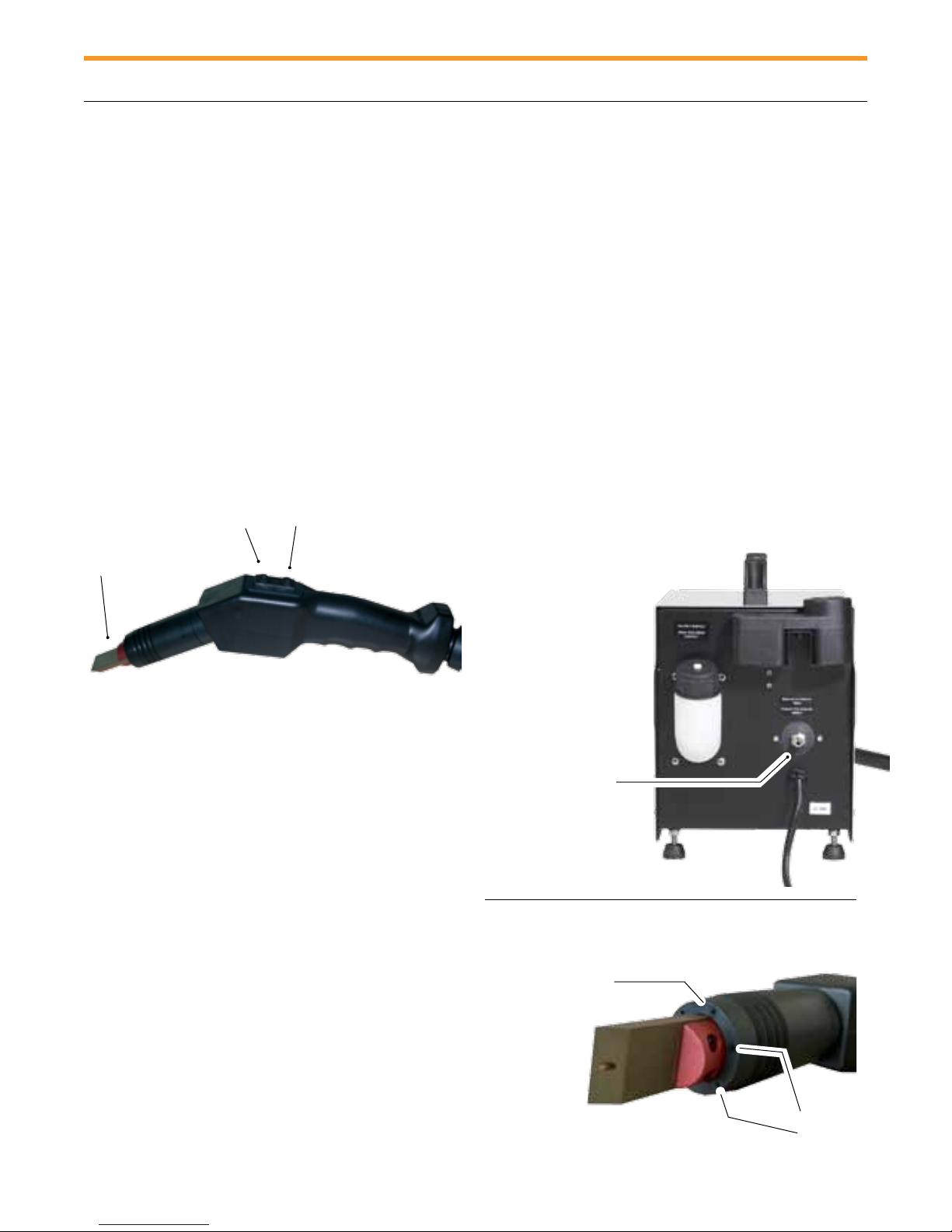

C) Wand control buttons

The ON button is used to give power to the tungsten tip.

When the pumping mode is set to manual, press the ON

button to activate the pump. Press and keep the button

pressed to get continuous ow of liquid.

However, if the pumping mode is set to automatic, press

the ON button once to activate the pump. To stop the

pump, press the OFF button. When nished working

with the machine (in either mode) make sure to press

the OFF button.

Once the ON button is pressed, there will be continuous

power at the tip until the OFF button is pressed.

ON OFF

Tungsten tip

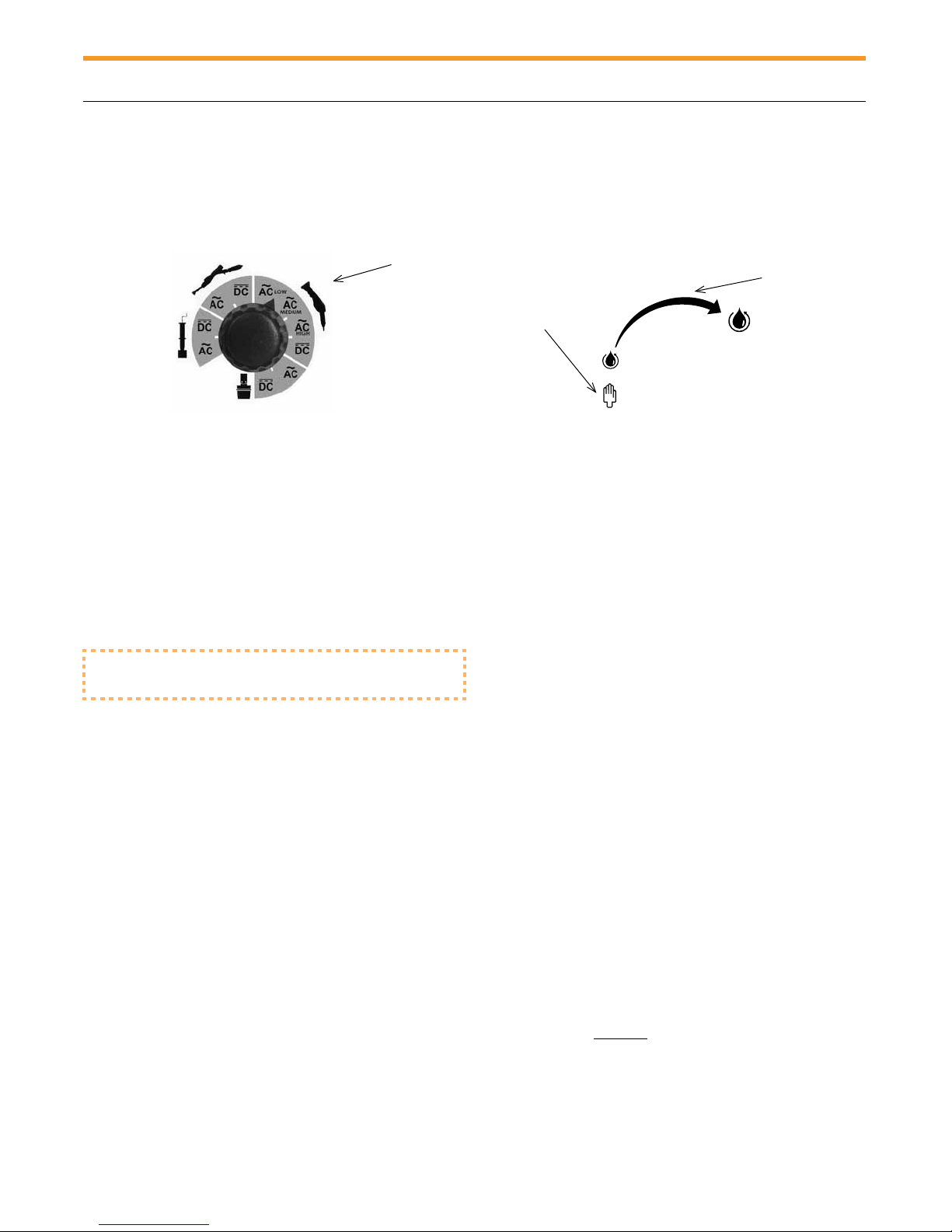

E) Tip repositioning (comfort for operator)

The tungsten tip may be rotated from the standard horizontal position to a vertical position or anywhere in between to

make your cleaning as comfortable as possible. To loosen

the right hand threaded fume elimination sleeve, turn tip to

desired position and retighten sleeve.

Important: Always retighten fume elimination sleeve to

ensure a good electrical connection and avoid damaging

the contact points.

D) Fume elimination system (patented)

The SURFOX 204 machine comes with the integrated fume

elimination system. This system provides for better working conditions. Although the fumes are non-toxic and non

hazardous, they can be uncomfortable when working in

conned areas.

To activate this feature simply connect a compressed air line

(150 PSI max., 80 PSI min.) to the tting at the back of the

machine. The fume elimination system is automatically activated when the ON button is pressed on the Hand Wand.

The fume elimination system is turned OFF when the OFF

button on the Hand Wand is pressed. If the fume elimination

system is not wanted, simply disconnect the compressed

air line.

The working principle is quite simple and highly effective;

the air comes out through the small openings behind the

tungsten tip. This preset regulated air pressure condenses

the vapors out of the air.

6

Compressed

air line tting

Tungsten tip close up

Small openings

Control panel

A) Main power switch

Control panel

4

Turns the main power to the unit ON

and OFF.

B) Wand selector switch

Marking and etching wand selector.

Select this icon when using a marking/

etching wand which has been plugged into

the accessory outlet. Select AC for marking

and DC for etching. Preset at 6 amps.

Mini wand selector. Select this icon

when using the mini wand which has been

plugged into the accessory outlet. Select

AC for cleaning and DC for polishing. Preset

at 12 amps.

Hand wand selector. Select this icon

when using the hand wand attached to the

SURFOX unit. Select AC for cleaning and

DC for polishing.

Large insert selector. Select this icon

when using the large insert which has been

plugged into the accessory outlet. Preset at

15 amps.

The electrochemical cleaning AC mode

has 3 settings: Low (6 amps), Medium

(9 amps), High (12 amps)

A

F

C

B

D

E

D) Indicator lights

Power ON indicator. Green light is on

when the unit is plugged in and the main

power switch is turned on.

Hand wand power ON indicator. The

yellow light goes ON when the hand wand

ON button is pressed and there is power

to the tip. Power to the tip is OFF when the

hand wand OFF button is pressed.

Low solution level indicator. When

solution level is low, the red indicator light

will go on.

C) Solution pump switch

Manual pumping mode. Choose the man-

ual pumping mode to control the amount of

solution pumping to the tip. Hold the hand

wand ON button down to pump solution to

the tip. Release the ON button to stop the

pumping cycle. Always use enough solution

to keep the cleaning pad wet. Too little solution will reduce the cleaning pad life.

Automatic pumping mode. To start the

automatic pumping mode, press the ON

button on the wand. Once it is activated,

it will automatically pump the liquid. The

quantity of liquid can be selected from less

to more. Pumping will continue in this mode

until the OFF button is pressed.

E) Accessory outlet

Outlet for optional mini wand or

marking/etching wand. The marking/etch-

ing wand is used to permanently etch/mark

your company name, logo, part

number or other desired information onto

stainless steel surfaces. The mini wand

is used to access hard to reach areas for

cleaning and passivating, which are too

small for the hand wand.

SURFOX 204 User’s Guide 7

Start-up procedure

5

Start-up procedure

A) What is included in the box

u SURFOX machine

u Hand wand and connecting hose

u Ground clamp

u Accessory kit containing:

• 1 90° tungsten tip (already installed on the hand wand)

• 3 high conductivity standard cleaning pads

• 1 PTFE clamping ring

• 1 x 2.5 mm hexagonal key for changing tungsten

cleaning tips

B) Filling the reservoir

Fill the reservoir in the back of the machine with SURFOX

electrolyte solution. The reservoir holds 1.9 L of SURFOX

electrolyte solution.

C) Connecting air supply

Connect the air supply at the back of the machine. Note

that the maximum allowed pressure is 150 PSI max.,

80 PSI min. (1000 KPa). If the air supply is not plugged into

the machine, the machine will still work but there will not be

any fume elimination.

D) Plugging in the power cord

When an extension cord is needed, use wire size 14 (AWG)

for up to 50 feet (15 meters) and size 12 (AWG) for 50 to

100 feet (15 to 30 meters).

E) Plugging in the ground clamp

Plug the ground clamp at the front of the unit. Attach the

clamp to the work piece being cleaned. The cleaning and

passivating process will not work if the part is not properly

grounded.

Reservoir

Ground

clamp

Air supply

connector

8

Using the hand wand to electro chemically clean, polish and passivate

Using the hand wand to electrochemically clean, polish

and passivate

6

A) Selecting the proper mode

Hand

wand

B) Selecting the proper current type, AC or DC

AC for cleaning and passivating the weld.

DC for cleaning, passivating and polishing the weld. The

cleaning and passivating process takes longer in DC mode

than AC mode and requires more electrolyte cleaning solution to prevent premature wear of the cleaning pads and

tips as well as preventing white haloes on the parent material.

WARNING! DC mode is used to polish the weld bead to

match the mirror nish of the material.

TIP! When using the polishing mode (DC), use plenty

of SURFOX electrolyte solution.

C) Selecting the proper pumping mode

Automatic

mode

Manual

mode

Manual pumping mode. Choose the manual pumping

mode to control the amount of solution pumping to the tip.

Hold the hand wand ON button down to pump solution to

the tip. Release the ON button to stop the pumping cycle.

Always use enough solution to keep the cleaning pad wet.

Automatic pumping mode. To start the automatic pumping mode, press the ON button on the wand. Once it is

activated, it will automatically pump the liquid. The quantity

of liquid can be selected from less to more.

D) Cleaning and passivating

To clean and passivate, press the hand wand ON button.

Make sure the cleaning pad is saturated with SURFOX

electrolyte cleaning solution before starting to work. If the

cleaning pad is too dry, it will wear prematurely. Start working when solution drips from the cleaning pad.

Note: When using DC setting, the SURFOX electrolyte solution will become slightly yellow or will darken.

Do not press hard, let the electrochemical process do the

work. Do not use the cleaning pad like an abrasive pad.

WARNING! When using the machine for the rst time, there

could be water in the system from factory testing. Adjust the

liquid pump setting to automatic at maximum speed and let

the liquid drip into a disposal cup for 2 minutes (amount of

time required to empty the hose from the tank to the wand).

Then, adjust the liquid pump setting back to desired pumping speed.

E) Neutralizing

1. Remove any excess of SURFOX electrolyte cleaning

solution using a soft clean cloth.

2. Spray SURFOX-N on the surface.

3. Wipe dry with another soft clean cloth to avoid cross

contamination.

Refer to neutralization procedure in neutralization section for

instructions on how to properly neutralize.

SURFOX 204 User’s Guide 9

Using the mini wand (optional) to clean and passivate

7

Using the mini wand (optional) to clean and passivate

Use the mini wand to get into tight places where the hand

wand cannot go. Plug the mini wand into the accessory

outlet on the front panel.

A) Selecting the proper mode

Mini

wand

When this mode is selected, it automatically cuts the power

to the hand wand, stops the solution pump and the fume

elimination system (if connected) from operating. Only

power is provided to the mini wand/marking wand outlet.

Be sure work piece is grounded.

B) Selecting the proper current type, AC or DC

AC for cleaning and passivating the weld.

DC for cleaning, passivating and polishing the weld:

The cleaning and passivating process takes longer in the

DC mode than in the AC mode and requires more electrolyte cleaning solution to prevent premature wear of the

cleaning pads and tips as well as preventing white haloes

on the parent material.

WARNING! DC mode is used to polish the weld bead to

match the mirror nish of the material.

C) Manual pumping mode

The mini wand uses a manual pumping mode only. One

(1) press equals one (1) pump. To pump more liquid, press

repeatedly. See mini wand instructions for more information.

D) Cleaning and passivating

Screw in SURFOX electrolyte solution 100 ml tube onto the

mini wand. Make sure the cleaning pad is saturated with

solution before starting to work.

If the cleaning pad is too dry,

it will wear prematurely. Start

working when solution drips

from the cleaning pad.

Do not press hard, let the

electrochemical process do

the work. The cleaning pad is

a bridge between the machine

and the weld. Do not use the

cleaning pad like an abrasive

pad.

E) Neutralizing

1. Remove any excess of SURFOX electrolyte cleaning

solution using a soft clean cloth.

2. Spray SURFOX-N on the surface.

3. Wipe dry with another soft clean cloth to avoid cross

contamination.

Refer to neutralization procedure in neutralization section for

instructions on how to properly neutralize.

TIP! When using the polishing mode (DC), use plenty

of SURFOX electrolyte solution.

Note: When using DC setting, the SURFOX electrolyte solution will become slightly yellow or will darken.

10

F) List of supplies and part numbers

The mini wand kit (part no.: 54-B 133) includes:

• 1 mini wand

• 2 carbon ber ow-through brushes

• 1 black power cord

• 1 x 2.5 mm hex key to change cleaning tips

SURFOX-T electrolyte

cleaning solution 100 ml

Part no: 54-A 001

6 per package

Using the mini wand (optional) to clean and passivate

7

SURFOX-H electrolyte

cleaning solution 100 ml

Part no: 54-A 011

6 per package

Carbon fiber brush

Part no: 54-B 029

To be mounted on the mini-wand

54-B 133, use with SURFOX-H electrolyte

solution only in 100 ml cartridges

5 per package

Ideal for tight corners, narrow surfaces

and intricate areas

SURFOX 204 User’s Guide 11

Using the marking/etching wand (optional)

8

Using the marking/etching wand (optional)

A) Marking kits

Standard kit (54-B 080) includes:

• 1 marking/etching wand with

graphite insert

• 35 mm X 10 mm

and connecting cable

• 20 marking pads

• 5 O-Rings

• 1 SURFOX-M, 100 ml

solution

• 1 SURFOX-E, 100 ml

solution

B) Selecting the proper mode

Turn the selector knob to the marking/etching wand icon.

Use the marking/etching wand to permanently mark or etch

your company name, logo, part number or other desired

information onto the surface of stainless steel, using permanent or disposable stencils. Plug the marking/etching wand

into the accessory outlet on the front panel.

PRO kit (54-B 081) includes:

• 1 marking/etching wand with

graphite insert

• 35 mm X 10 mm

and connecting cable

• 20 marking pads

• 5 O-Rings

• 1 SURFOX-M, 100 ml solution

• SURFOX solution, 100 ml

• 1 Stencil printer and software

• 1 Stencil paper roll 100 mm (W) X 20 m (L)

Marking/etching

wand

C) SURFOX testing devices

Stainless steel Passivation Testing Device

(54-T 010)

To monitor the state of corrosion protection and to ensure

proper passivation of the

workpiece.

Corrosion resistance of

stainless steel is signicantly

reduced near welds as a result of the heating cycle. Visually, this can be seen as a darkened zone next to the weld.

When electro-chemical cleaning is performed on the weld,

corrosion risk is reduced but the treated zone still has to be

passivated for 24-48 hours before the corrosion protection

is fully restored.

12

Stainless steel Grade Identication Testing

Device (54-T 001)

Informs you on the type of stainless steel you are really working

with.

Because it is visually impossible

to differentiate 200, 300 and 400

grade stainless steel, the test-

ing device instantly identies the

grade of stainless steel.

TECHNICAL BULLETINS AVAILABLE ON OUR WEB SITE.

Neutralizing

Neutralizing

9

The SURFOX-N liquid is a specially formulated neutralizer for the SURFOX electrolyte solutions. It is a powerful

ready-to-use formula which leaves no residue, is non-toxic,

solvent free, water-based and biodegradable.

A) Directions for neutralizing SURFOX

electrolyte cleaning solutions

1. Remove any excess SURFOX electrolyte solution using a

soft clean cloth.

2. Spray SURFOX-N on the surface.

3. Wipe dry with another soft clean cloth.

For more information about this product, refer to product

MSDS.

WARNING! Be sure to wipe off all excess SURFOX electrolyte solution from the surface and neutralize otherwise the

inorganic salt from the phosphoric acid will adhere to the

surface and cause deposits.

B) SURFOX WELD cleaning and neutralization

procedure

Clean the weld using the SURFOX machine and SURFOX

electrolyte solutions. Work only 2 feet at a time.

Note: The cleaning pad should be kept moist – not

dripping.

1. After weld cleaning, use a clean cloth or paper towel

and wipe the affected area in a squeegee action from left

to right. Then discard the cloth or paper towel.

After cleaning the weld with the SURFOX weld cleaning

machine, the electrolyte solution must be neutralized.

1. Spray the affected area with SURFOX-N neutralizer.

Allow to sit for 15 seconds on the surface.

2. Use a clean cloth or paper towel and wipe the affected

area in a squeegee action from left to right. Then discard

the cloth or paper towel.

Note: Failure to neutralize or neutralize properly will result in

clouding, hazing and dulling of the surface.

SURFOX-N neutralizer Part No.

500 ml 54-A 023

20 L 54-A 027

208 L 54-A 028

Salt deposits due to unproper

neutralization and rinsing.

SURFOX 204 User’s Guide 13

Accessories

10

Accessories

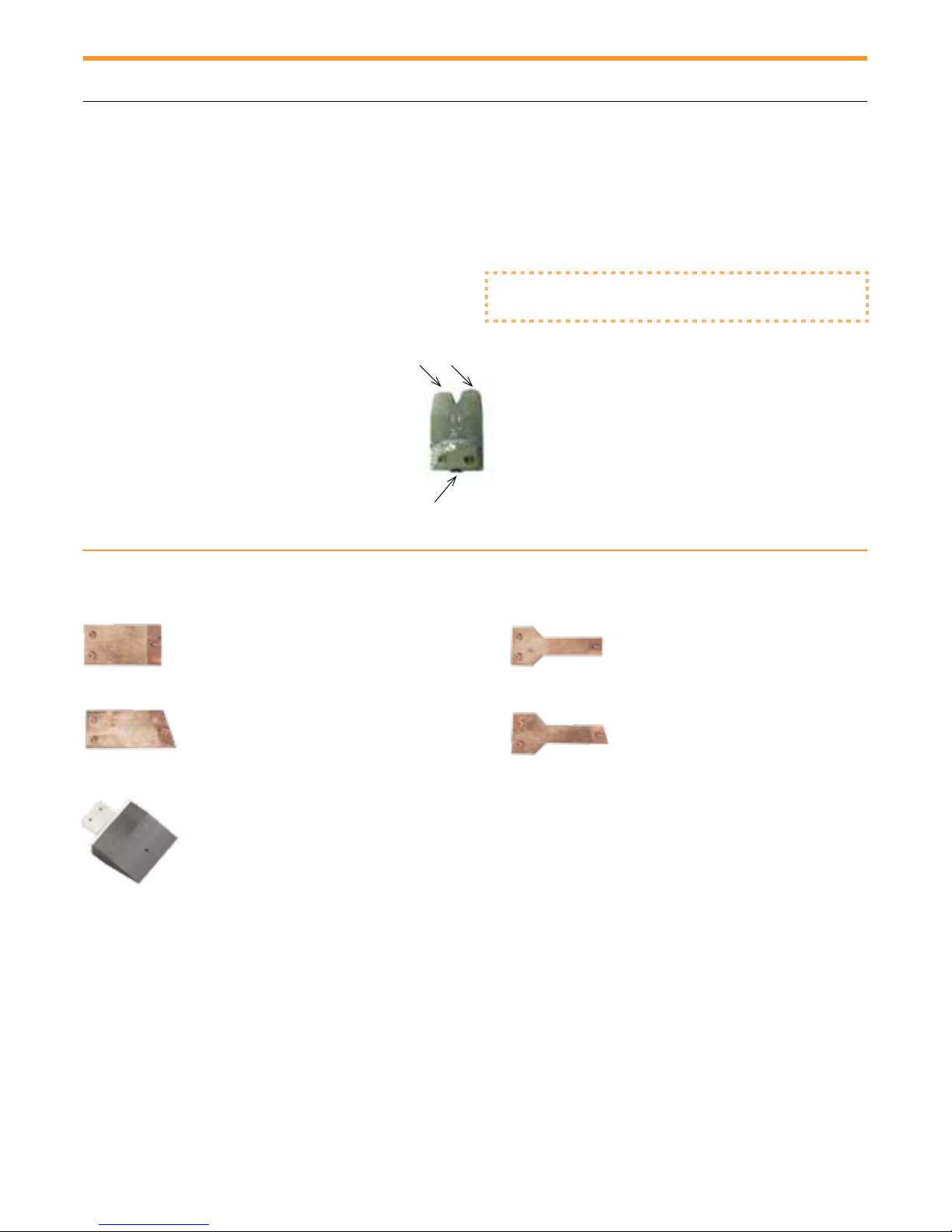

A) Selection and mounting

of the cleaning pads and tips

Tungsten tips are made from high quality tungsten alloy

material. Other materials will not resist the harsh environment created by the electrochemical process.

WARNING! When the insert is too worn, it can

cause damage to the cleaning pads.

In this example of a worn insert, there are only two

contact points. All the current comes out of these

two points. Because of the lower available cross

section, the temperature will be higher at the two

points and the cleaning pads may become damaged or wear out prematurely.

O-Ring

Inserts

Tungsten insert 90°

No: 48-R 133

Use with cleaning pad 54-B 026 or 54-B 040 and

clamp ring 54-B 002 or boot 54-B 005.

Tungsten insert 60°

No: 54-B 016

Use with cleaning pad 54-B 027 and clamp ring

54-B 002 or boot 54-B 006.

TIP! Resurface the insert using a bench grinding wheel

or angle grinder.

Note: Be sure to install the O-Ring located at the back of

the insert whenever they are changed.

Narrow tungsten insert 90°

No: 54-B 017

Use with cleaning pad 54-B 028 or 54-B 041

and clamp ring 54-B 020 or boot 54-B 007.

Narrow tungsten insert 60°

No: 54-B 018

Use with cleaning pad 54-B 028 and clamp

ring 54-B 020 or boot 54-B 008.

Large graphite insert

No: 54-B 009

Use with large cleaning pad 54-B 043

Ideal for large welded areas and for

surface renovation

14

Accessories

10

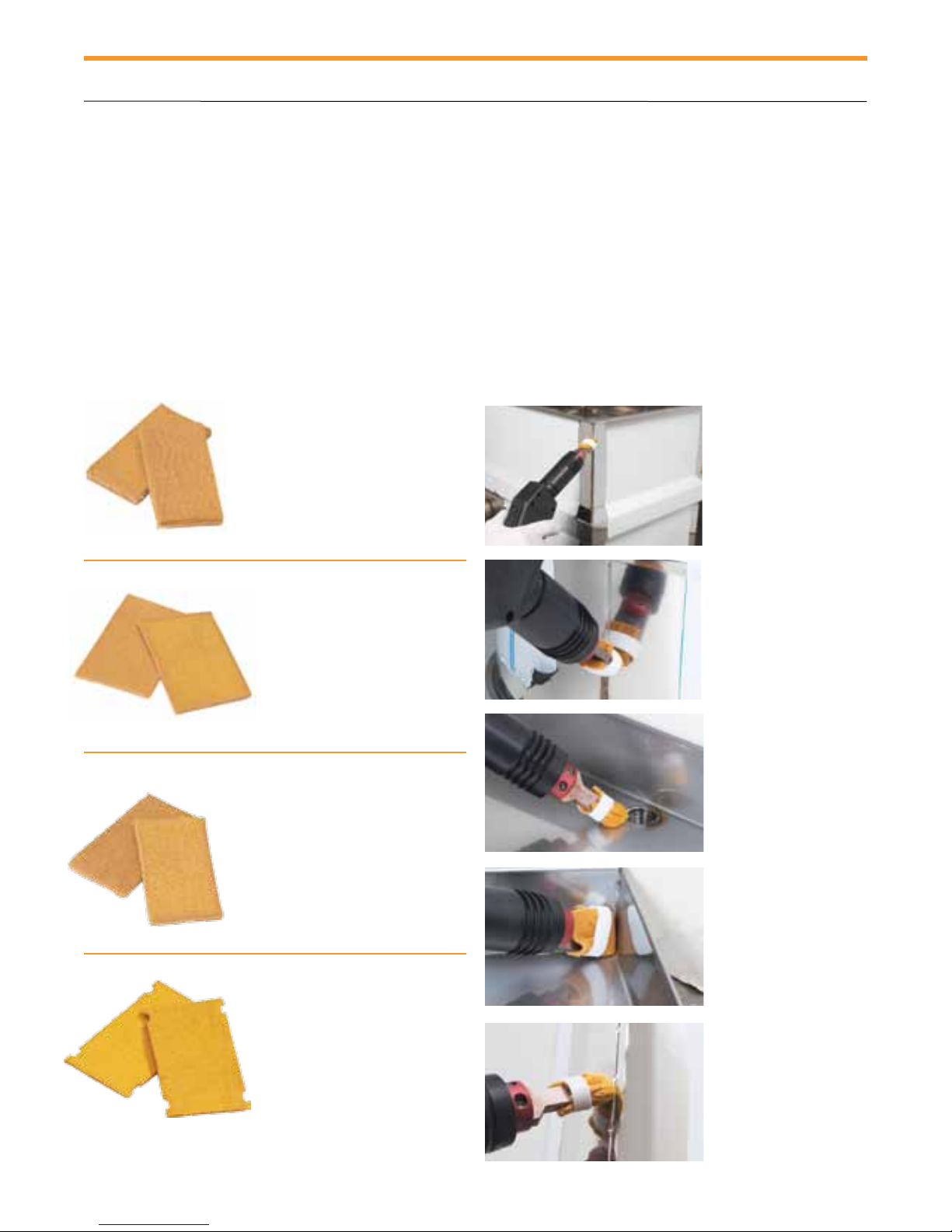

High conductivity cleaning pads

Cleaning pads are made of a complex blend of highly

conductive synthetic polymer which is very resistant to wear

and which offers excellent thermal stability. For longer life,

remove the cleaning pad and neutralize with SURFOX-N at

the end of each working day.

Cleaning pads are available in three sizes:

Standard cleaning pad

No: 54-B 026

Use with insert 48-R 133

Inside corners cleaning pad

No: 54-B 027

Use with insert 54-B 016

Features

• Flexible: Can be folded many ways

• Soft on surfaces

• Can be used both sides

• Long lasting

• Highly conductive (4x more conductive than previous

generation)

Narrow cleaning pad

No: 54-B 028

Use with inserts 54-B 017

and 54-B 018

Large cleaning pad

No: 54-B 043

Use with large graphite insert

54-B 009

SURFOX 204 User’s Guide 15

Accessories

10

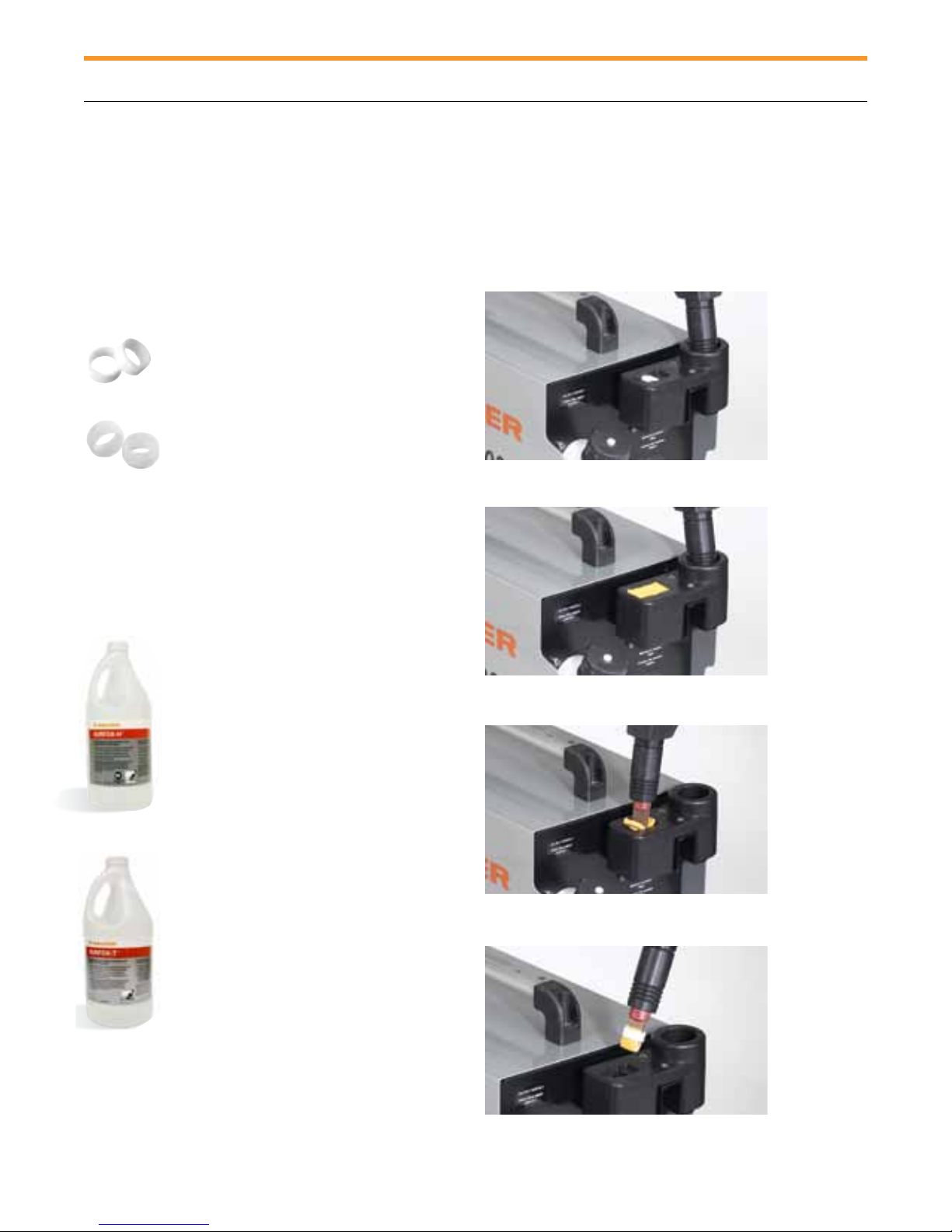

B) PTFE clamp rings

PTFE clamp rings are designed to hold the cleaning pads

on the tungsten inserts.

They are available in two sizes:

Narrow clamp ring for narrow pads

No: 54-B 020

Use with narrow inserts. 10 per package.

Clamp ring for standard cleaning pads

No: 54-B 002

Use with standard inserts. 10 per package.

C) SURFOX electrolyte solutions

Surfox electrolyte solutions are specially formulated phosphoric acid cleaning solutions designed to be used only in

Walter SURFOX electro cleaning systems.

SURFOX-H

Electrolyte Cleaning Solution

D) Mounting a cleaning pad

1. Squeeze and insert clamp ring.

2. Insert cleaning pad.

Cleans up to 3-5 feet per minute.

1.5 L/50.7 oz. No: 54-A 015

STD Pack: 1 STD Carton: 4

20 L/5.2 gal. No: 54-A 017

STD Pack: 1 STD Carton: 1

208 L/55 gal. No: 54-A 018

STD Pack: 1 STD Carton: 1

SURFOX-T

Heavy-Duty

Cleans up to 3-5 feet per minute.

1.5 L/50.7 oz. No: 54-A 005

STD Pack: 1 STD Carton: 4

20 L/5.2 gal. No: 54-A 007

STD Pack: 1 STD Carton: 1

208 L/55 gal. No: 54-A 008

STD Pack: 1 STD Carton: 1

Electrolyte Cleaning Solution

3. Firmly press in tungsten tip.

4. Remove tip with installed pad and clamp ring.

16

Note: When mounting classic pads, ensure the Ω sign

is facing up on step 2.

Safety features

Safety features

11

A) Sparks on the tip/work piece

To avoid short circuits (arcing), the machine automatically

stops when the insert touches the work piece (metal to

metal contact). There is an inverter board that monitors the

voltage every millisecond. If the voltage sharply increases

creating a short, the system will automatically cut the power

to the tip to avoid any damage to the equipment.

To restart the machine, simply press the hand wand ON

button.

WARNING! To avoid drawing too much amperage and

automatically stopping the power to the tip, make sure that

you touch only one surface at a time. The machine is set

to work at a maximum of 15 amps. If the amperage goes

above 15 amps, the machine automatically shuts down.

Example: On a at surface, the amperage is around

12 amps. The contact surface area is relatively small.

B) Internal temperature

To protect the internal components of the machine, there

are temperature sensors inside the machine. If the operating

temperature is too high, the machine will shut down and restart by itself when the temperature reaches an acceptable

level. There is an internal fan inside the machine to keep all

the components cool.

WARNING! The inside temperature can increase for many

reasons: high ambient temperature, lack of proper air circu-

lation around the machine, uctuations in voltage, electrical

set-up in the shop, etc.

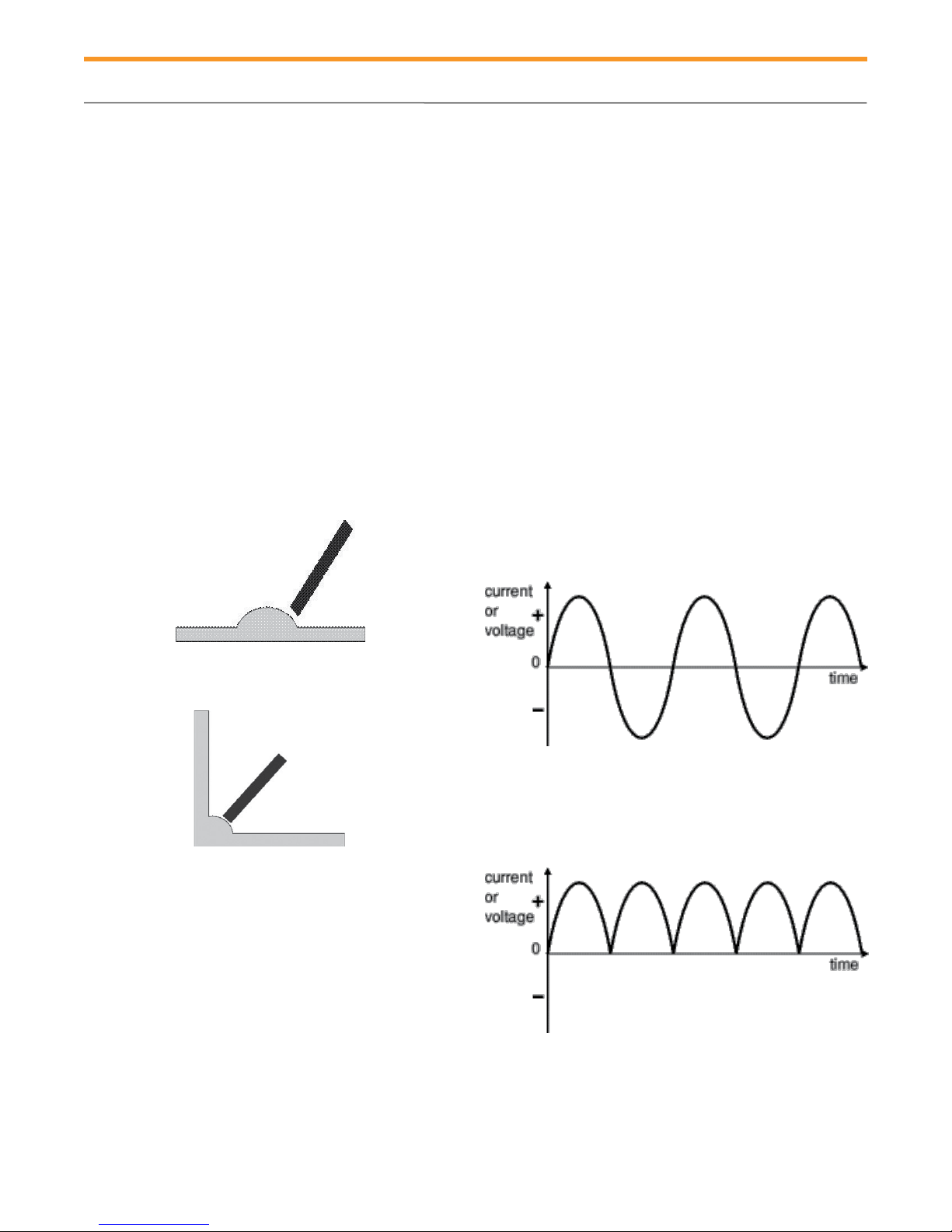

C) AC/DC current basics

Alternating Current (AC) ows one way, then the other

way, continually reversing direction. An AC voltage is continually changing between positive (+) and negative (-).

Example: An internal angle, which if you touch 2 sides

simultaneously, the contact surface area is doubled, amperage goes above 15 amps and the machine stops.

Note: Automatic shut off if ground is not detected within

20 seconds.

Direct Current (DC) always ows in the same direction, but

it may increase and decrease. A DC voltage is always positive, but may increase and decrease.

SURFOX 204 User’s Guide 17

Safety features

11

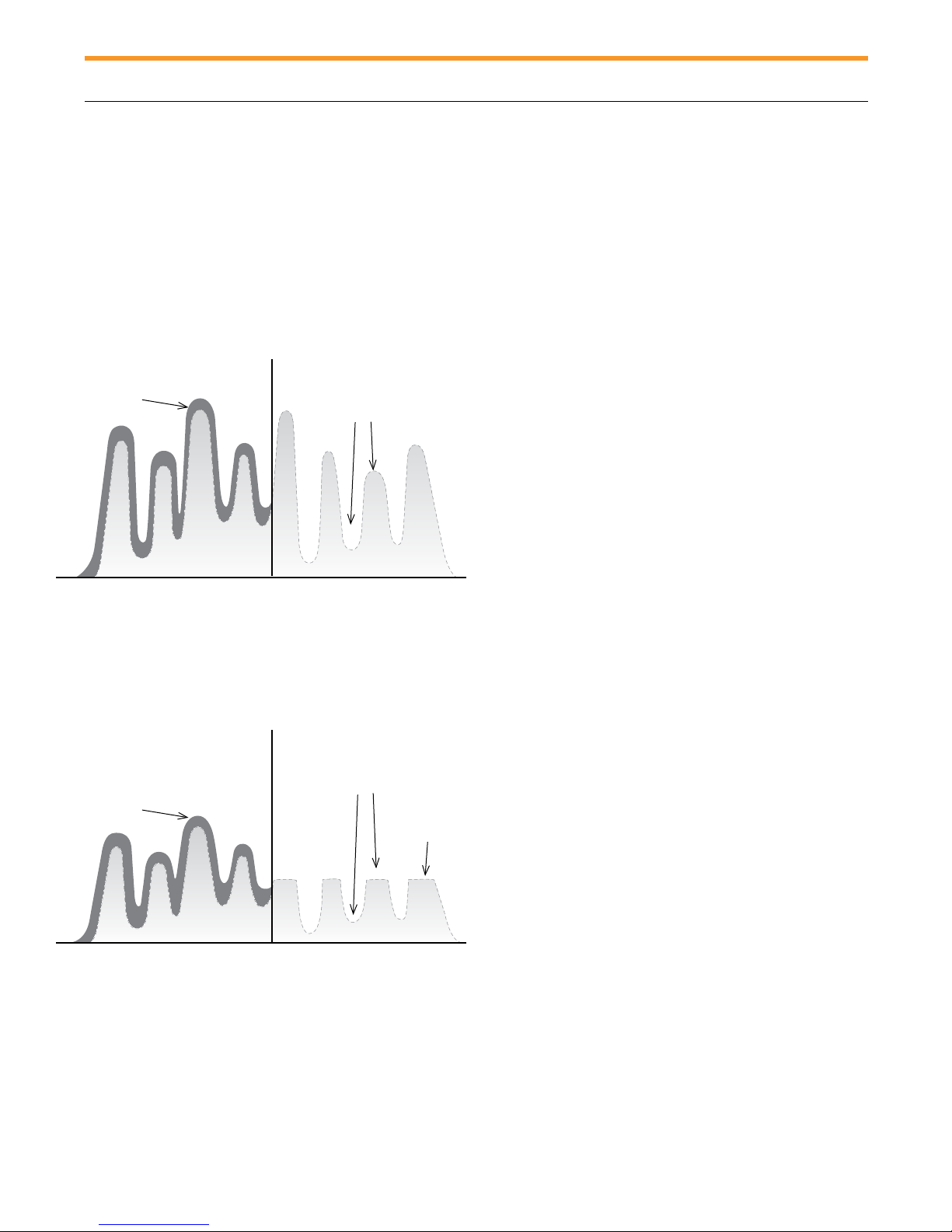

D) AC/DC settings on the SURFOX machine

Example of cleaning and passivation with SURFOX in AC

mode:

Microscopic view of the material

BEFORE

Oxide

layer to be

removed

Example of cleaning and passivation with SURFOX in DC

mode:

Microscopic view of the material

AFTER

Cleaning and passivation is

perfect. Cleans every crack in

the material.

E) Welds that cannot be cleaned

If the area around the weld is black (not blue) from contamination, this is a problem of high heat generated during the

welding process. The contaminated areas do not conduct

electricity. If there is no conductivity in the material, the

SURFOX system cannot work.

If there are two welds on top of the other, the structure of

the material has been seriously altered. These areas may

not be cleaned.

The quality of the weld is critical. The better the weld, the

easier it will be to clean.

18

Oxide

layer to be

removed

BEFORE

AFTER

Cleaning and passivation is

perfect. Cleans every crack in

the material.

Alteration of the

material due to

the DC setting

Warranty and serviceTechnical data

1312

Technical data

MODEL: SURFOX 204

PART NUMBER: 54-D 214

INPUT VOLTAGE: 120 V, 50/60 Hz

OUTPUT VOLTAGE: 10-30 V, AC/DC

INPUT CURRENT: 6 Amps

OUTPUT CURRENT: 15 Amps, AC/DC

MAX. OUTPUT VOLTAGE: 33 V, AC/DC

DIMENSIONS: 470 mm x 380 mm x 250 mm

(18.5” x 15” x 9.75”)

RESERVOIR CAPACITY: 1.9 L

WEIGHT: 16.8 kg (37 lbs.)

INPUT AIR PRESSURE: 150 PSI max., 80 PSI min.

Warranty and service

A) Warranty policy

All WALTER SURFOX cleaning systems and accessories

are inspected and tested before shipment and are warranted to be free from any defect in material and faulty

workmanship. Should any malfunction occur within six (6)

months from the date of original purchase, return the complete system prepaid with proof of purchase, to the nearest

WALTER Factory or Authorized Service Center. If an examination shows that the malfunction was caused by defective

material or faulty workmanship, WALTER will repair (or at

our option, replace the unit) without charge. This warranty

does not apply when; normal maintenance is required,

repairs or replacements have been made or were attempted

by anyone other than WALTER authorized service person-

nel, and does not cover any damage caused by accidents,

modications, use of improper accessories, abuse or

misuse, which also includes overloading the tool beyond

its rated capacity as well as its continued use after partial

failure. No other warranty, written or verbal, is authorized.

In no event shall WALTER be liable for any indirect, inciden-

tal or consequential damages from the sale of the product.

This disclaimer applies both during and after the term of this

warranty.

This warranty gives you specic rights. The provisions

contained in this warranty are not intended to limit, modify,

take away from, disclaim or exclude any warranties set forth

in any Provincial or State legislation. To the extent required

by law, the provisions in any Provincial, State or Federal

legislation with respect to warranties take precedence over

the provisions in this warranty.

B) Repair and service

When shipping:

• Drain the SURFOX electrolyte solution from the reservoir

• Use original shipping case

• Use sufcient packing

• Ship on a small pallet

• Give detailed description of the problem as well as

company name, address, phone and fax numbers and

contact person

SURFOX 204 User’s Guide 19

Table des matières

Table des matières

1 Introduction 22

2 Directives de sécurité 23

3 Commandes de l’équipement 24

A) Pictogrammes du panneau de commande 24

B) Vue de l’appareil – avant et arrière 25

C) Boutons de contrôle de la baguette 26

D) Système d’élimination des fumées 26

E) Positionnement de la buse (confort de l’opérateur) 26

4 Panneau de commande 27

A) Interrupteur d’alimentation principal 27

B) Sélecteur de fonction de la baguette 27

C) Interrupteur de la pompe de solution 27

D) Témoins lumineux 27

E) Sortie pour les accessoires 27

5 Procédure de démarrage 28

A) Contenu de la boîte 28

B) Remplissage du réservoir 28

C) Raccordement de l’alimentation d’air 28

D) Branchement du cordon d’alimentation 28

E) Branchement du collier de mise à la terre 28

6 Utilisation de la baguette à main pour

le nettoyage, le polissage et la passivation

électrochimique 29

A) Sélectionner le mode adéquat 29

B) Sélectionner l’intensité de courant adéquate;

CA ou CC 29

C) Sélectionner le mode de pompage adéquat 29

D) Nettoyage et passivation 29

E) Neutralisation 29

7 Utilisation de la mini-baguette pour le

nettoyage et la passivation (facultatif) 30

A) Sélectionner le mode adéquat 30

B) Sélectionner le type d’intensité de courant;

CA ou CC 30

C) Mode de pompage manuel 30

D) Nettoyage et passivation 30

E) Neutralisation 30

F) Liste des fournitures et numéros de pièces 31

8 Utilisation de la baguette de marquage/gravure

(facultatif) 32

A) Trousses de marquage 32

B) Sélectionner le mode adéquat 32

C) Appareils de test SURFOX 32

9 Neutralisation 33

A) Directives pour la neutralisation des solutions

de nettoyage électrolytiques SURFOX 33

B) Procédure de neutralisation et de nettoyage

des SOUDURES SURFOX 33

10 Accessoires 34

A) Sélection et assemblage des tampons et

buses de nettoyage 34

B) Bagues de serrage en PTFE 36

C) Solutions électrolytiques SURFOX 36

D) Assemblage d’un tampon nettoyeur 36

11 Éléments de sécurité 37

A) Étincelles sur la buse ou la pièce de travail 37

B) Température interne 37

C) Rudiments du courant CA/CC 37

D) Réglages CA/CC pour l’appareil SURFOX 38

E) Les soudures qui ne peuvent pas être nettoyées 38

12 Données techniques 39

13 Garantie et service 39

A) Politique de garantie 39

B) Réparation et service 39

SURFOX 204 Manuel de l’utilisateur 21

Introduction

1

Introduction

Félicitations! Vous avez acheté le meilleur équipement de

nettoyage de soudures et de passivation électrochimique

sur le marché. L’équipement de nettoyage de soudures

SURFOX

la teinte de chaleur sur les zones affectées rapidement,

facilement et de manière rentable, tout en permettant une

passivation totale de la surface en acier inoxydable.

Notre nouvelle génération d’appareils SURFOX est équipée

de panneaux convertisseurs à régulation automatique qui

surveillent l’intensité du courant et le règlent automatique-

ment de manière optimale an d’assurer une efcacité de

nettoyage maximum sans perte de productivité.

Avant de commencer vos travaux, nous vous demandons

de lire ce manuel du propriétaire SURFOX en entier; nous

vous guiderons, étape par étape, du démarrage aux procédures de maintenance, en passant par la mise en œuvre de

votre nouvel équipement SURFOX. Votre nouvel appareil

SURFOX possède une durabilité accrue pour résister aux

exigences élevées d’une utilisation industrielle. Toutefois,

comme c’est le cas pour toute pièce d’équipement électrique, son utilisation exige des soins et la sécurité nécessaires à la protection de cet important investissement.

En y apportant les soins et l’entretien appropriés, vous

pourrez compter sur votre équipement SURFOX pendant

des années.

Pour obtenir des informations sur les autres produits

WALTER, visitez notre site Web : www.walter.com

MC

fabriqué par WALTER permet de supprimer

Opérations

L’appareil SURFOX utilise un procédé électrochimique

pour nettoyer et passiver les soudures faites sur l’acier

inoxy dable. Les solutions électrolytiques utilisées par les

appareils SURFOX sont à base d’acide phosphorique. Elles

sont approuvées par l’industrie alimentaire et sont activées

par un courant électrique pour nettoyer les soudures. Le

traitement ne prend que quelques secondes et ne provoque

aucun dommage ou égratignure à la surface des pièces

nettoyées.

Votre appareil SURFOX peut nettoyer :

u les soudures TIG;

u les soudures plasma;

u les soudures laser;

u les soudures par points;

u les soudures MIG (utilisant la technologie à impulsion).

Rudiments de la passivation :

u Le nettoyage des soudures se fait non seulement à des

ns esthétiques, mais surtout pour les besoins de

passivation.

u La passivation est un traitement des surfaces en acier

inoxydable qui élimine les contaminants et favorise la

formation d’une couche de protection en oxyde de

chrome épaisse et durable.

22

u Cette « couche passive » permet une meilleure résistance

de l’acier inoxydable à la corrosion.

u Si la passivation n’est pas correctement réalisée, l’acier

inoxydable et les zones touchées par la chaleur peuvent

commencer à rouiller.

Directives de sécurité

Directives de sécurité

2

Les appareils de nettoyage de soudure WALTER sont produits

conformément aux normes en vigueur pour la fabrication, le rendement et la sécurité des produits industriels.

AVERTISSEMENT : Lorsque vous utilisez ces appareils, vous

devez toujours prendre des précautions pour réduire les risques

d’incendie, de décharges électriques et de blessures personnelles.

Avant d’utiliser cet appareil, lisez attentivement toutes les

consignes de fonctionnement et de sécurité; assurez-vous de

conserver ce manuel pour pouvoir vous y référer dans le futur.

1. Lisez ce manuel du propriétaire pour vous familiariser avec le

fonctionnement de cet appareil, ses particularités, son champ

d’application et ses limites.

2. Cet appareil est muni d’un cordon d’alimentation à 3 con-

ducteurs et de prises électriques enchables doubles avec

terre (3 ches); il doit être branché à une prise adéquate avec

mise à la terre.

3. Prévoyez un dégagement minimum de 8 pouces autour

de l’appareil an de maintenir les ouvertures de ventilation

libres de toute obstruction. Un débit d’air libre à travers les

ouvertures de ventilation est nécessaire pour empêcher la

surchauffe de l’appareil.

4. Gardez la zone de travail propre et bien éclairée. Un envi ronnement encombré peut provoquer des accidents. Enlevez

tout matériel qui pourrait s’enammer au contact d’étincelles.

N’utilisez pas cet outil lorsque des liquides inammables ou

des gaz sont présents dans l’environnement. Gardez les

poignées propres, sèches et sans souillure de solution

nettoyante, d’huile ou de graisses. N’utilisez pas cet appareil

sous la pluie et dans des endroits humides ou mouillés.

5. Gardez les enfants et les autres personnes à une distance

sécuritaire des travaux. Veillez à ce que personne ne soit placé

en dessous de vous lorsque vous travaillez en hauteur. Ne

laissez personne sans formation adéquate utiliser cet appareil.

6. Portez toujours des vêtements appropriés et l’équipement de

sécurité nécessaire lorsque vous travaillez, des gants de

protection certiés pour résister aux produits chimiques par

exemple, des combinaisons ou chaussures de sécurité, etc.

7. Portez toujours des lunettes de protection approuvées.

8. Pendant le processus de nettoyage, la buse de la baguette et

la pièce de travail peuvent atteindre des températures extrême ment élevées; assurez-vous que ces pièces refroidissent avant

de les mettre en contact avec une surface cutanée.

9. Évitez d’inhaler des fumées; n’utilisez l’appareil que dans un

environnement bien ventilé. Utilisez un masque ltrant au

besoin.

10. Toute décharge électrique peut être dangereuse.

11. Si vous éprouvez des problèmes d’ordre électrique,

n’utilisez pas l’appareil avant qu’une personne qualiée ait

vérié l’équipement.

12. N’utilisez jamais l’appareil lorsque le couvercle de protection

est retiré.

13. Restez vigilant en tout temps lorsque vous utilisez cet

appareil. Prenez garde à ce que vous faites. Utilisez votre bon

sens. N’utilisez pas l’appareil lorsque vous êtes fatigué. Ne

laissez jamais l’appareil en marche sans surveillance.

14. Assurez-vous que l’appareil est à l’arrêt (position OFF) avant

de le brancher ou lors d’un déplacement an d’éviter un

démarrage intempestif.

15. Tenez la baguette fermement. Ne travaillez pas à bout de bras

an de maintenir un bon équilibre en tout temps.

16. Avant l’utilisation, toutes les pièces devraient être examinées

soigneusement pour vous assurer que l’appareil fonctionne

correctement et remplisse sa fonction.

17. Les pièces endommagées ou défectueuses doivent être

réparées ou remplacées par un Centre de services de fabrica tion WALTER ou un centre de service agréé par WALTER.

18. N’utilisez pas l’appareil s’il est impossible de faire passer

l’interrupteur de l’arrêt à la mise en marche ou le contraire (ON

et OFF).

19. N’utilisez que les accessoires recommandés pour ce système.

Faites toujours une vérication des accessoires avant de com-

mencer le travail et ne les utilisez pas s’ils sont endommagés.

20. ATTENTION : Les solutions électrolytiques de nettoyage

SURFOX de WALTER contiennent de l’acide phosphorique

pouvant causer des brûlures lorsqu’elles ne sont pas

manipulées correctement. Évitez tout contact avec la peau.

Premiers soins : laver la zone affectée avec de l’eau.

Contact avec les yeux : rincez à l’eau pendant 15 minutes

en soulevant les paupières de temps en temps. Appelez un

médecin au besoin. Ingestion : NE PAS PROVOQUER le

vomissement. Rincez votre bouche, buvez beaucoup d’eau

et recherchez une aide médicale. Reportez-vous aux ches

techniques de sécurité (FDS) des produits WALTER pour

obtenir des informations de sécurité exhaustives.

21. N’utilisez que les solutions électrolytiques de nettoyage de

soudures SURFOX de WALTER avec cet appareil; ne les

mélangez JAMAIS avec d’autres solutions.

22. Entreposez la solution dans son contenant original et dans

un endroit sûr se trouvant hors de portée des enfants et des

personnes non qualiées. Gardez le contenu du récipient

propre. Ne réutilisez jamais les solutions électrolytiques de

nettoyage SURFOX.

23. Ne touchez pas la buse de la baguette ou la pièce de travail

lorsque vous utilisez l’appareil ou immédiatement après l’avoir

utilisé; ils peuvent être extrêmement chauds et pourraient vous

causer de graves brûlures.

24. Ne maltraitez pas le cordon d’alimentation. Ne tirez jamais

cet appareil en utilisant le cordon et ne tirez pas brusquement

sur celui-ci pour débrancher l’appareil. Gardez le cordon

électrique loin de la chaleur, de l’huile et des rebords tran chants. Inspectez régulièrement le cordon et, s’il est endom magé, faites-le remplacer par un Centre de services de fabrica tion WALTER ou un centre de service agréé par WALTER.

25. Lorsqu’il n’est pas utilisé, il faut mettre l’appareil en arrêt (OFF)

et débrancher le cordon électrique ainsi que le boyau pour l’air

(s’il est branché). L’appareil doit également demeurer débran ché pour le remplacement de tampons de nettoyage ou

d’autres accessoires ainsi que pendant les périodes d’entretien

et de réparation.

26. Entreposez l’équipement dans un endroit sûr et sec se

trouvant hors de portée des enfants et des personnes qui ne

possèdent pas la formation appropriée.

SURFOX 204 Manuel de l’utilisateur 23

Directives de sécurité

Commandes de l’équipement

2

Tension électrique

Avant de brancher cet appareil, vériez que l’intensité du courant (ampérage) indiqué sur la plaque signalétique est la même

que sur le bloc d’alimentation.

L’utilisation de cet appareil avec une intensité de courant

différente de celle afchée sur la plaque signalétique pourrait

provoquer des blessures à l’utilisateur et des dommages à

l’appareil.

Entretien préventif

Après une utilisation, donnez à la buse le temps de refroidir,

puis enlevez le tampon de nettoyage. Faites une neutralisation

avec le SURFOX-N, puis rincez le tampon de nettoyage et la

buse de la baguette avec de l’eau; laissez sécher. Nettoyez la

poussière et les dépôts qui se sont formés sur la partie extérieure de l’appareil. Gardez les ouvertures de ventilation libres

de toute obstruction. Nettoyez le cordon d’alimentation pour

prévenir sa détérioration et cherchez d’éventuels dommages

qui auraient pu survenir au cordon ou à la che d’alimentation.

Remarque : Les cordons électriques endommagés doivent

être remplacés immédiatement par du personnel qualié

uniquement. Reportez-vous à la liste des pièces de rechange

pour obtenir le numéro de commande.

Transport

Avant de transporter l’appareil, assurez-vous que le réservoir de la solution de nettoyage et sa conduite d’alimentation

sont complètement vides et que tous les raccordements sont

débranchés. L’appareil doit être emballé soigneusement dans

un contenant approprié et doit être convenablement protégé.

WALTER ne pourra être tenu responsable des dommages

résultant d’une fuite de solution de nettoyage ou d’une manipulation brusque.

Entreposage

Si vous devez entreposer l’appareil, peu importe la durée de

l’entreposage, le réservoir de la solution de nettoyage et sa

conduite d’alimentation doivent être complètement vidés; le

tampon de nettoyage enlevé (neutralisé, rincé et laissé de

côté); la buse doit être neutralisée, rincée et séchée. Entreposez l’appareil dans un endroit sec et sécuritaire pour éviter

les dommages qui pourraient survenir, particulièrement aux

composantes électroniques.

3

Commandes de l’équipement

A) Pictogrammes du panneau de commande

Sortie pour la mini-baguette ou

baguette de marquage

Indicateur de mise en

marche (ON) de l’appareil

Mode pompage manuel Mode pompage automatique

Indicateur de mise en marche pour

la buse de la baguette

Indicateur de bas niveau

de la solution

Élimination des déchets

Éliminez les déchets résiduels en conformité avec les réglementations environnementales en vigueur (fédérales, provin-

ciales, territoriales ou locales). Consultez les ches techniques

de santé-sécurité du matériel de WALTER qui traitent des

solutions électrolytiques de nettoyage SURFOX.

Cordon de rallonge

Lorsque l’ajout d’un cordon de rallonge est nécessaire, utilisez

la taille 14 (AWG) pour les cordons ayant une longueur maximum de 50 pieds (15 mètres) et la taille 12 (AWG) pour les

cordons de 50 à 100 pieds (15 à 30 mètres).

24

Sélecteur de la

baguette de marquage

Sélecteur d’embout large

Sélecteur de la

mini-baguette

Sélecteur de la baguette

de nettoyage ou polissage

Sélecteur d’ampérage

Loading...

Loading...