Walter Surfox 103 User Manual

User's Guide

60-C 780

TABLE OF CONTENTS

Page

I - Introduction

...........................................................................................................................................................

3

II -

Safety instructions

...............................................................................................................................................

4,5

III - Equipment controls

............................................................................................................................................

6

A) Control panel pictograms

..........................................................................................................................

6

B) Front and back view of the machine

.........................................................................................................

7

C) Wand control buttons

.................................................................................................................................

8

IV - Control

panel

......................................................................................................................................................

9

A) Main power switch

....................................................................................................................................

9

B) Solution pump switch

................................................................................................................................

9

C)

Indicator light

............................................................................................................................................

9

D) Accessory outlet

........................................................................................................................................

9

V - Start-up pro

cedure

...............................................................................................................................................

A) What is included in the box

......................................................................................................................

B) Filling the reservoir

...................................................................................................................................

C) Mounting a cleaning pad

...........................................................................................................................

D) Plugging in the power cord

.......................................................................................................................

E)

Plugging in the ground clamp

...................................................................................................................

VI - Using the hand wan

d to clean and passivate

.....................................................................................................

A

)

S

electing the proper pumpin

g mode

.........................................................................................................

B)

Cleaning and passivating

...........................................................................................................................

C) Neutralizing

...............................................................................................................................................

VII - Using the Mini Wan

d (optional) to clean and passivate

..................................................................................

A) Manual pumping mode

.............................................................................................................................

B) Cleaning and passivating

...........................................................................................................................

C) Neutralizing

...............................................................................................................................................

D) List of supplies and part numbers

.............................................................................................................

3

VIII - Using the Marking Wand (optional)

................................................................................................................

A) Procedure for marking

...............................................................................................................................

B) Marking Wand supplies and part numbers

................................................................................................

IX - Neutralizing

........................................................................................................................................................

Page

X - Accessories

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A) Cleaning tips

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B) Cleaning pads

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C) Cleaning boots

D) PTFE clamp rings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

E) Surfox-T solution

20

XI - Safety features

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

A) Sparks

on the tip/work piece

21

B) Interna

l temperature

21

C) Welds that cannot be cleaned

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

XII - Technical data

22

XIII - Wa

rranty and service

23

A) War

ranty policy

23

B) Where to get service

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

2

INTRODUCTION

Congratulations on purchasing the finest electrochemical weld cleaning and passivation equipment available today.

WALTER's SURFOX

weld cleaning equipment quickly, easily and cost effectively removes the heat tint created

during TIG welding while completely passivating the stainless steel surface.

Be

fore starting

owner's manual completely as we take you step-by-step through the

intenance procedures of your new SURFOX

TM

equipment. Your new SURFOX

TM

machine

has been built with extra d

urability to stand up to the hea

vy demands of industrial use. However, like any piece of

electrical equipment, care and safety shou

ld always be taken when using and ma

intaining this valuable investment.

With proper care and maintenance your SURFOX

TM

equipment will provide years of dependable service.

To learn more about the other Walter products

In Canada:

www.jwalter.ca

www.jwalter.ca

In USA:

www.jwalterinc.com

www.jwalterinc.com

In Mexico:

mex.walter.com

OPERATION

The Surfox machine works by an electrochemical process to clean and passivate the welds on stainless steel.

clean the welds. The process takes only a few seconds without damaging or scratching the surface of your part.

YOUR SURFOX

TM

MACHINE CAN CLEAN:

o TIG welds

o Plasma welds

o Laser welds

o Spot welds

o MIG welds (with Pulse technology)

BASICS OF PASSIVATION:

o Cleaning of the welds not only for aesthetic purposes but most importantly for passivation.

o Passivation is the treatment of stainless steel surfaces to remove contaminants and promote the

formation of the passive film layer.

o This passive film layer will assure the corrosion resistance of stainless steel.

o If passivation is not done properly, the stainless steel

and heat affected areas

may

start to rust.

3

I - INTRODUCTION

II - SAFETY INSTRUCTIONS

WALTER

weld cleaning machines are produced in accordance with applicable standards governing the

manufacture, performance and safety of industrial products.

WARNING:

When using these machines, basic safety precautions should always be observed to reduce the risk

of fire, electrical shocks and personal injuries.

Before using this machine, read all Safety and Operating Instructions carefully and save this owner's

manual for future reference.

and limitations.

2. This unit is equipped with a 3-conductor power cord and 3-prong electrical plug, it must be connected to a

correspondingly grounded receptacle.

3. Allow a minimum of 8" clearance around the unit to keep all air openings clear of any obstruction. Free

airflow through the vent openings is required to prevent the unit from overheating.

4. Keep work area clean and well lit. A cluttered environment invites accidents. Remove any material that may be

ignited by sparks. Do not use this tool when flammable liquids or gases are present. Keep handles clean, dry

and free from cleaning solution, oil and grease. Do not use in rain, damp or wet locations.

5. Keep children and other persons at a safe distance from the work. Make sure no one is under you when

working in high places. Do not let unqualified persons handle this machine.

6. When working, always wear appropriate clothing and safety gear, such as suitable and safety approved

working gloves, ear plugs, safety shoes, etc.

7. Always wear approved safety goggles.

before coming in contact with exposed skin.

9.

Avoid inhalation of fumes, use only in well ventilated areas. Use a respirator, if necessary.

equipment.

the tool when you are tired. Never leave it running unattended.

void unintentional

starting.

perform its intended function.

Center or a

WALTER

Authorized Service Center.

do not use if damaged.

20.

CAUTION: WALTER

Surfox-T weld cleaning solution contains phosphoric acid and may cause burns when

not handled properly. Avoid skin contact.

First aid:

Wash affected area with water.

Eye contact:

Flush with water for 15 minutes lifting eyelids occasionally. Contact physician if necessary.

Ingestion:

DO NOT induce vomiting. Rinse mouth, drink plenty of water and get medical attention.

Refer to WALTER MSDS #S-01E for complete safety data information.

21. Use only

WALTER

Surfox-T weld cleaning solution with this unit and NEVER mix it with any other products.

22. Store solution in its original container and in a safe place, out of the reach of children and other unqualified

persons. Keep container contents clean.

Do not

reuse Surfox-T solution.

4

II - SAFETY INSTRUCTIONS

23. Do not touch the wand tip or work piece while working or immediately after use, they may be extremely

hot and could cause serious burns.

24. Do not abuse the power cord. Never pull or lift this unit by its cord or yank to disconnect it from the

receptacle. Keep the cord away from heat, oil and sharp edges. Inspect the cord periodically, if damaged,

have it replaced by a WALTER Factory Service Center or a WALTER Authorized Service Center.

25. When not in use, switch OFF and unplug the electrical cord and air hose. It must also remain unplugged when

replacing cleaning pads and other accessories, while performing maintenance and before servicing.

26. Store the unit in a dry safe place, out of the reach of children and other unqualified persons.

VOLTAGE

Before connecting this unit, check that the voltage shown on the rating plate is the same as that of the power

source.

Operating this unit on a voltage other than specified on its rating plate may result in personal in

jury to the

user and

damage the unit.

PREVENTIVE MAINTENANCE

After use, allow the tip to cool and remove the cleaning pad. Rinse the cleaning pad and wand tip with water

and dry. Clean dust and dirt deposits from the exterior of the unit. Keep all airflow vent openings free of any

obstructions. Clean the power cord to prevent deterioration and check for possible damage to cord and plug.

Note:

Damaged cords must be replaced immediately by qualified personnel only. Refer to Spare Parts List for

the ordering number.

TRANSPORTATION

Before transporting the machine, make sure the cleaning solution reservoir and supply line are completely empty

and all connecting lines disconnected. The machine must be carefully packed in a suitable container and properly

protected.

WALTER

will not be held responsible for any damages resulting from leaked cleaning solution or

rough handling.

If the machine is to be stored for any length of time, the cleaning solution reservoir and supply line must be

emptied, cleaning pad removed (rinsed and left off) and the tip rinsed and dried. Store in a dry safe place to avoid

damage, especially to the electronic components.

WASTE DISPOSAL

Dispose of residual waste in compliance with Federal, Provincial, State and local environmental regulations.

Refer to WALTER Material Safety Data Sheet for Surfox-T #S-01E.

EXTENSION CORD

When an extension cord is needed, use wire size 14 (AWG) for up to 50 feet (15 meters) and size 12 (AWG) for 50

to 100 feet (15 to 30 meters).

II - SAFETY INSTRUCTIONS

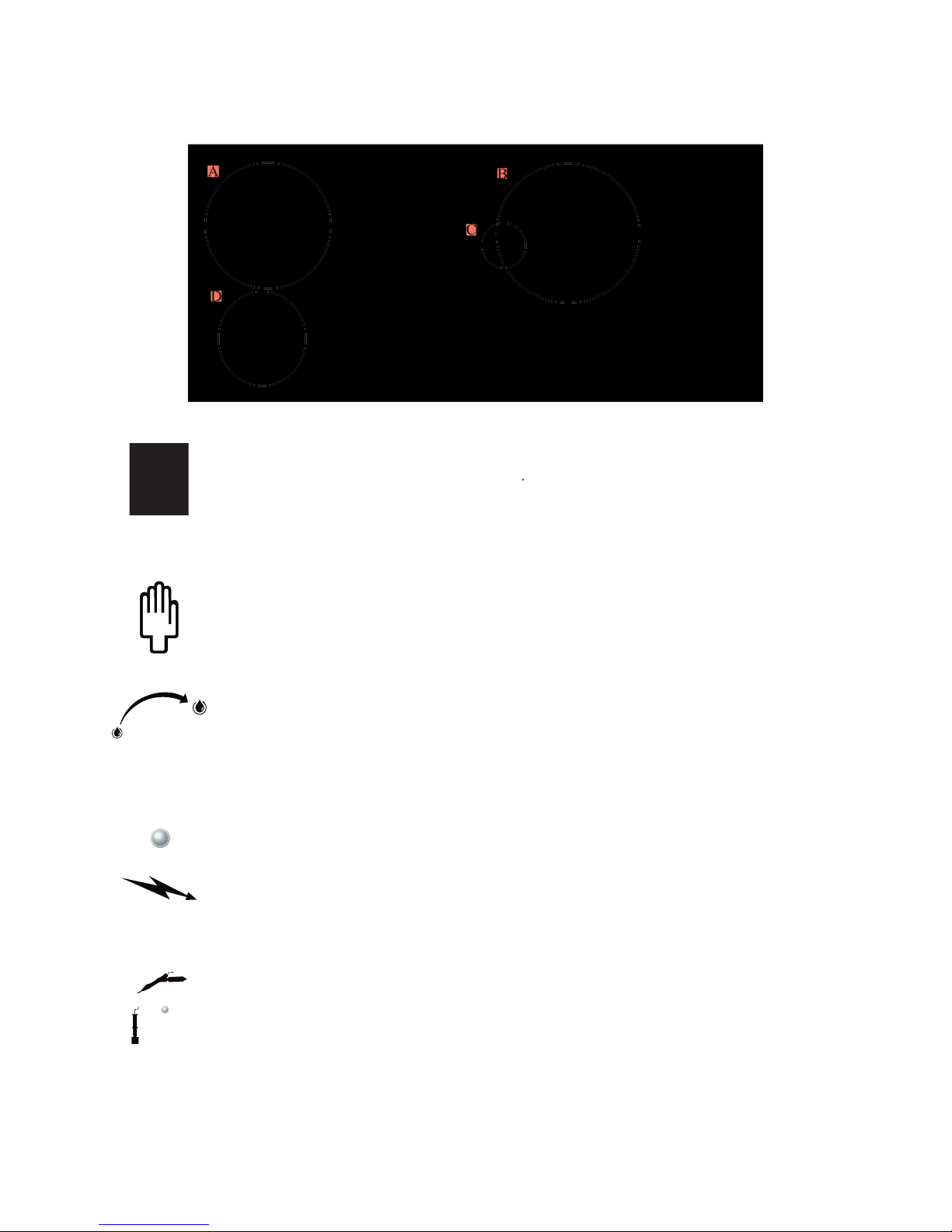

A) CONTROL PANEL PICTOGRAMS

Outlet for Mini Wand or Marking Wand

Indicator for wand tip power ON

Manual pumping mode Automatic pumping mode

III - EQUIPMENT CONTROLS

III - EQUIPMENT CONTROLS

7

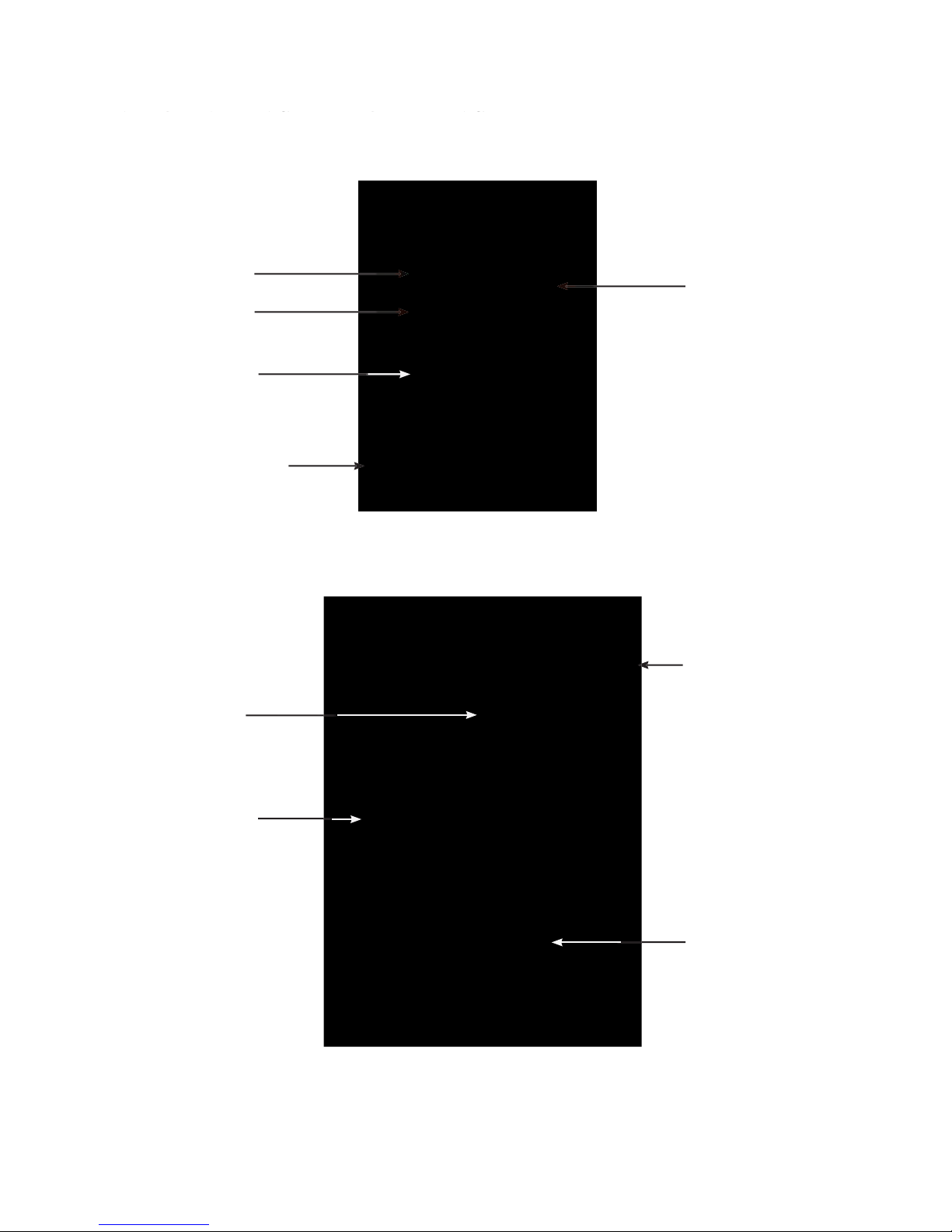

Cleaning pad

mounting unit

reservoir

Wand holder

ON/OFF button

Accessory outlet

Ground connector

Control panel

III -

EQUIPMENT CONTROLS

Power cord

Hand Wand hose

(electrical and solution

B

) FRONT AND BACK VIEW OF THE MACHINE

C

) WAND CONTROL BUTTONS

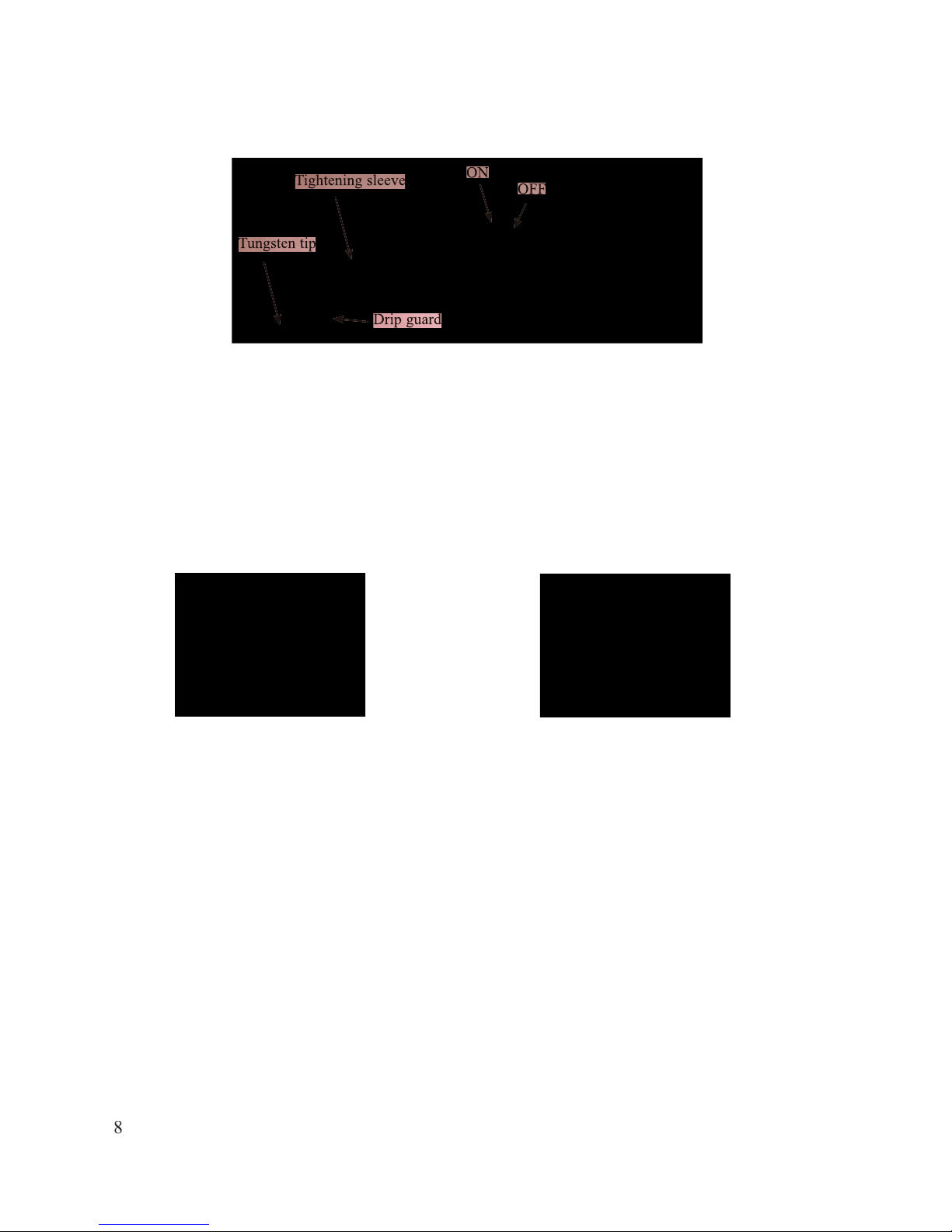

The ON butt

on is used to give power to the Tungsten tip. When the pumping mode is set to manual,

press the

ON button to activate the pump.

Press and keep the button pressed to get continuous flow of liquid.

How

ever, if the pumping mode is set to automatic, press the ON button once to activate the pump. To stop the

pump, press the OFF button. When finished working with the machine (in either mode) make sure to press

the

OFF button.

Once the ON button is pressed, there will be continuous power at the tip until the OFF button is pressed.

The Surfox 103 features a pivoting wand tip (tungsten tip). Simply loosen the plastic tightening sleeve and

turn the tip for hard to reach places, then re-tighten the sleeve (do not over-tighten).

EQUIPMENT CONTROLS

Tungsten tip

ON

OFF

Tightening sleeve

Drip guard

IV - CONTROL PANEL

) MAIN POWER SWITCH

Turns the main power to the unit

ON

and

OFF

) SOLUTION PUMP SWITCH

Manual pumping mode.

Choose the manual pumping mode to control the amount of solution

pumping to the tip. Hold the Hand Wand ON button down to pump solution to the tip. Release

the ON button to stop the pumping cycle. Always use enough solution to keep the cleaning pad

wet. Too little solution will reduce the cleaning pad life.

Automatic pumping mode.

To start the automatic pumping mode, press the ON button on the

wand. Once it is activated, it will automatically pump the liquid. The quantity of liquid can be

selected from less to more. Pumping will continue in this mode until the OFF button is pressed.

C

) INDICATOR LIGHT

Hand Wand power

ON in

dicator.

The yellow light goes ON when the Hand Wand ON button

is pressed and there is power to the tip. Power to the tip is OFF when the Hand Wand OFF

button is pressed.

) ACCESSORY OUTLET

Outlet for optional Mini Wand or Marking Wand.

The Marking Wand is used to permanently

etch your company name, logo, part number or other desired information onto any metal surface.

The Mini Wand is used to access hard to reach areas for cleaning and passivating, which are too

small for the Hand Wand.

9

IV -

A

C

V - START-UP P

ROCEDURE

A) WHAT IS INCLUDED IN THE BOX

1- Surf

chine

2- Hand Wand and connecting hose

3

- Ground clamp

4- Accessory kit contai

ning:

- 3 cleaning pads

- 1 PTFE clamping ring

- 1 cleaning boot

- 1 x 2.5mm hexagonal key for changing

Tungsten cleaning tips

B) FILLING THE RESERVOIR:

Fill the reservoir in the back of the machine with Surfox-T solution. The reservoir holds 1.9L of Surfox-T

solution.

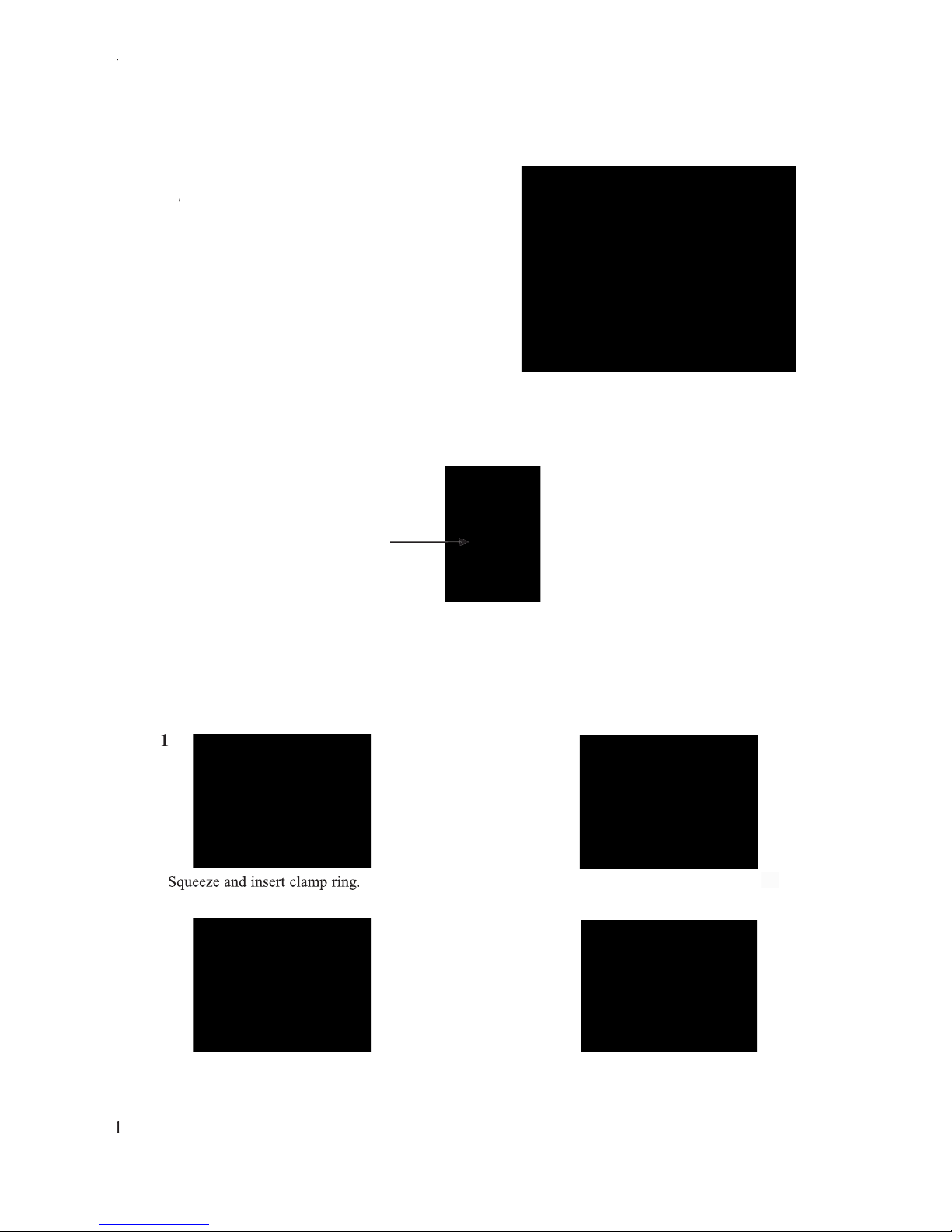

C) MOUNTING A CLEANING PAD

0

Insert cleaning pad with symbol

facing up.

Firmly press-in Tungsten tip.

Remove tip with installed pad

and retaining ring.

3

Reservoir

START-UP PRO

) PLUGGING IN THE POWER CORD

When an ext

ension cord is needed, use w

ire size 14 (AWG) for up to 50 feet (1

5 meters) and size 12 (AWG)

for 50 to 100 feet (15 to 30 meters).

E

) PLUGGING IN THE GROUND CLAMP

Plug the ground clamp at the

front of the unit. Attach the clamp to the work piece being cleaned. The cleaning

and passivating process will not work if the part is not properly grounded.

START-UP PROC

EDURE

Ground clamp

Loading...

Loading...