Page 1

USER GUIDE

GUIDE DE L’UTILISATEUR

MANUAL DEL USUARIO

MANUAL DO PROPRIETÁRIO

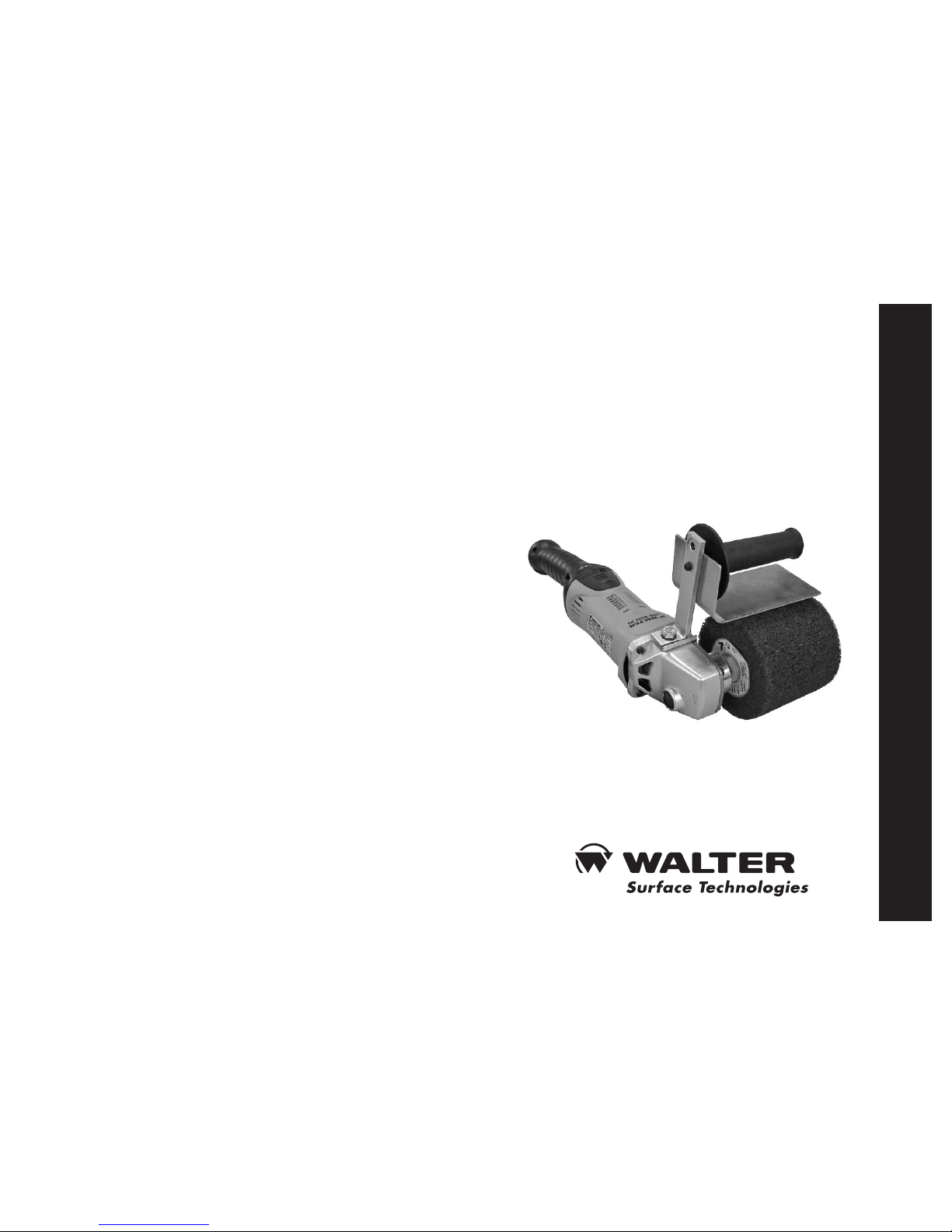

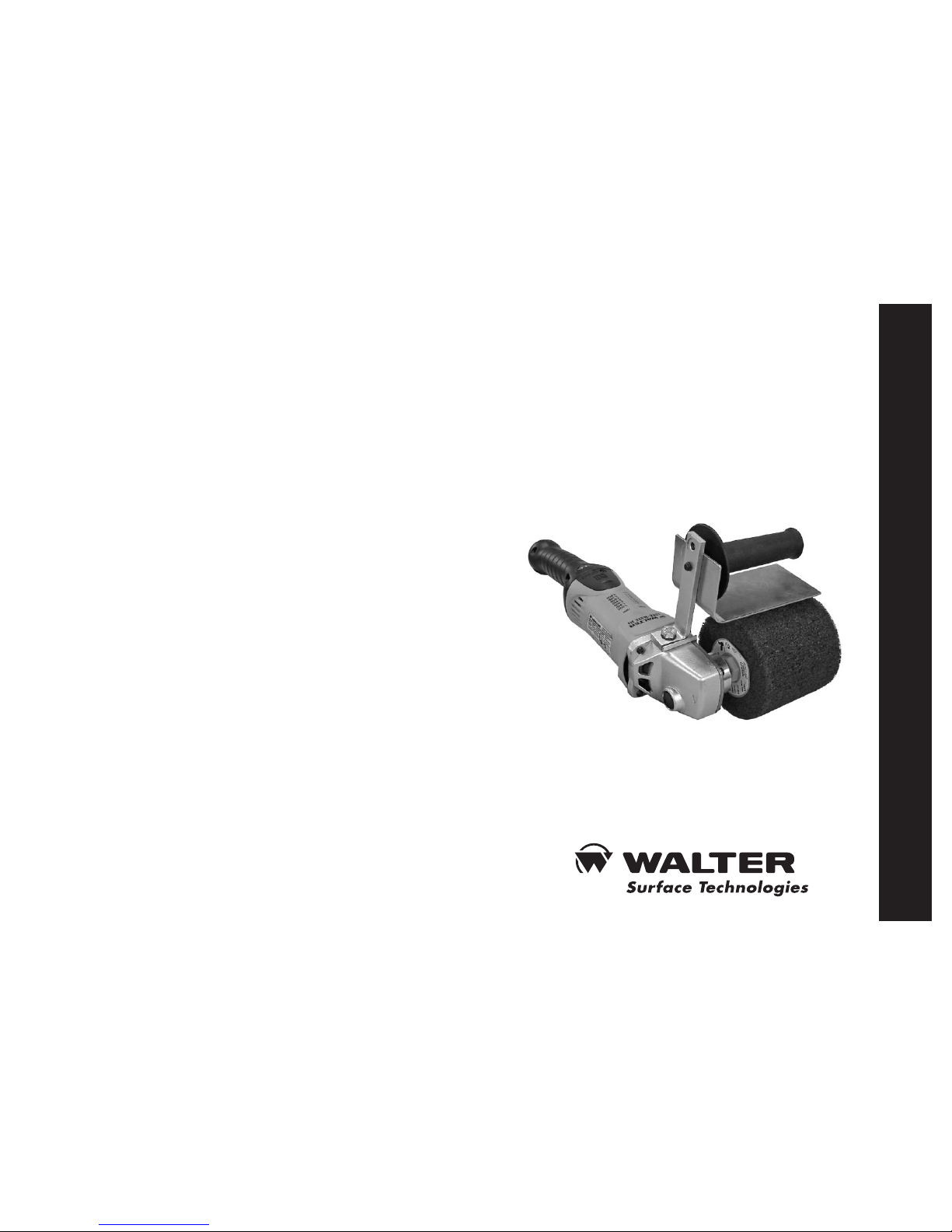

LINE-MATE III

(6268 C)

LINE FINISHING SYSTEM

SYSTÈME DE FINITION LIGNÉE

SISTEMA DE TERMINACION LINEAL

SISTEMA DE ACABAMENTO CIRCULAR

Page 2

LINE-MATE III

LINE FINISHING SYSTEM

(Model 6268 C)

ENGLISH

Page 3

1

Thank you for purchasing the LINE-MATE III

LINE FINISHING SYSTEM (Model 6268 C)

This operating instruction booklet has been designed to give you

all the information on the LINE-MATE III.

To ensure perfect functioning of your Line finishing system,

carefully read these instructions before using the tool.

Familiarize yourself with this tool’s operation, its particular

features, applications and limitations. You will also find useful

tips on safety and maintenance.

TITLES PAGES

Safety instructions ...................................................................................... 2

Introduction ................................................................................................ 8

Voltage .........................................................................................................

8

Extension cord ............................................................................................ 8

Technical Data ............................................................................................

9

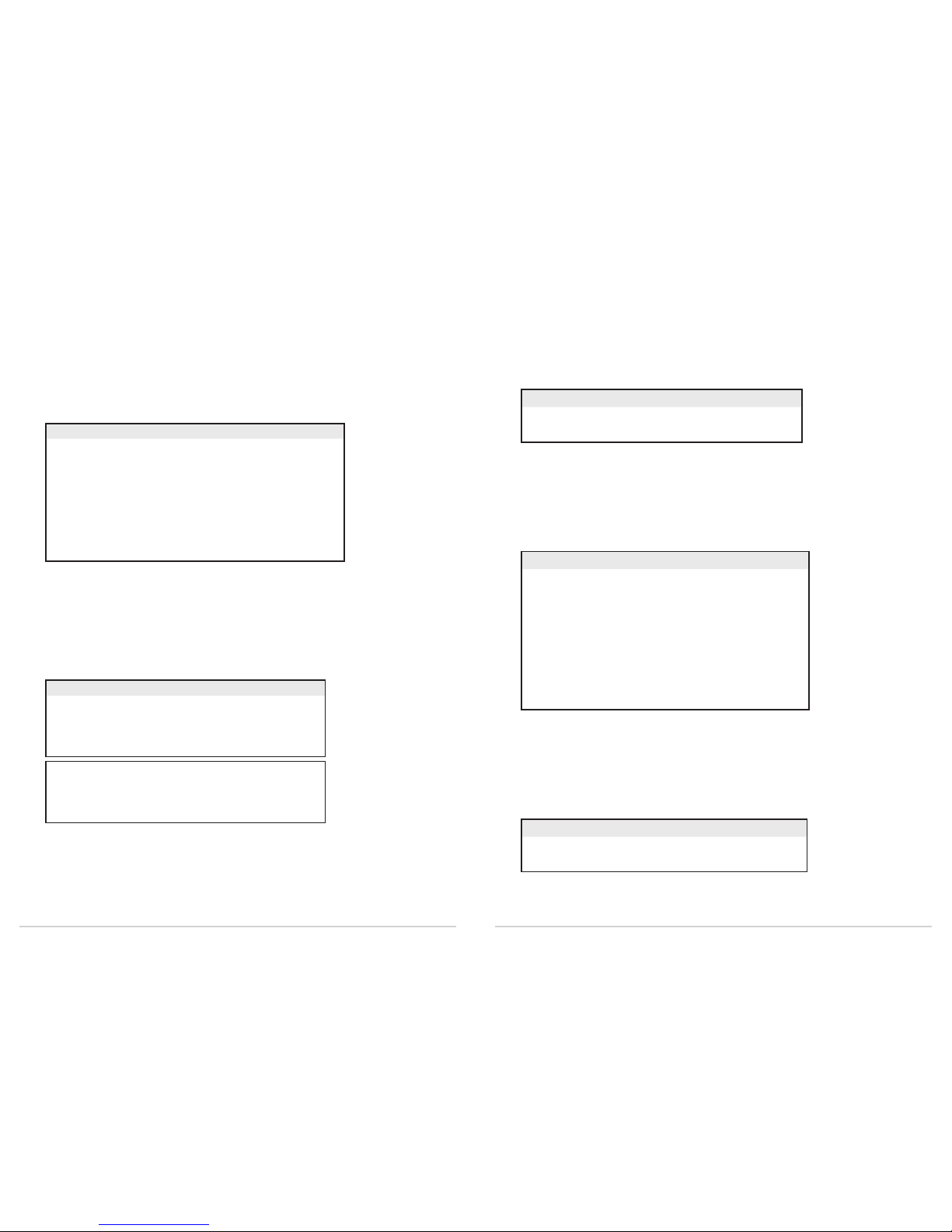

Model illustration ....................................................................................... 10

Side handle & safety guard ......................................................................... 10

Spindle lock ................................................................................................ 10

Switch ......................................................................................................... 10

Dialspeed TM selector ................................................................................... 11

Dialspeed TM settings .................................................................................... 11

Dynamax TM Electronics .............................................................................. 11

Operation .................................................................................................... 12

Line finishing accessories ...........................................................................

12

Drums ......................................................................................................... 13

Pipe Finishing Abrasives ............................................................................

16

Carbon brushes ........................................................................................... 17

Preventive maintenance .............................................................................. 17

Warranty policy ..........................................................................................

18

WALTER Sales and Service .......................................................................

19

Page 4

2

3

General safety rules

Every WALTER power tool is produced in accordance with applicable

standards governing the manufacture, performance and safety of power

tools.

WARNING – To reduce the risk of injury, user

must read instruction manual.

Read all instructions. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury. The term “power tool”�in

all of the warnings listed below refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

b) Do not operate power tools in explosive atmospheres, such as in

the presence of flammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in

any way.

Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp

edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord

suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired

or under the influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in serious

personal injury.

b) Use safety equipment. Always wear eye protection. Safety

equipment such as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position

before plugging in. Carrying power tools with your finger on the

switch or plugging in power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before turning the power tool

on. A wrench or a key left attached to a rotating part of the power

tool may result in personal injury.

e) Do not over-reach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your

hair, clothing and gloves away from moving parts. Loose clothes,

jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used.

Use of these devices can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your

application.

The correct power tool will do the job better and safer at the rate for

which it was designed.

Page 5

4

5

below may result in electric shock, fire and/or serious injury.

b) Operations such as grinding or cutting-off are not recommended to

be performed with this power tool. Operations for which the power

tool was not designed may create a hazard and cause personal injury.

c) Do not use accessories which are not specifically designed and

recommended by Walter. Just because the accessory can be attached

to your power tool, it does not assure safe operation.

d) The rated speed of the accessory must be at least equal to the

maximum speed marked on the power tool. Accessories running

faster than their RATED SPEED can break and fly apart.

e) The outside diameter and the thickness of your accessory must

be within the capacity rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded or controlled.

f) The arbour size of wheels, flanges, backing pads or any other

accessory must properly fit the spindle of the power tool. Accessories

with arbour holes that do not match the mounting hardware of the

power tool will run out of balance, vibrate excessively and may cause

loss of control.

g) Do not use a damaged accessory. Before each use inspect the

accessory such as abrasive wheels for chips and cracks, backing

pad for cracks, tear or excess wear, wire brush for loose or cracked

wires. If power tool or accessory is dropped, inspect for damage or

install an undamaged accessory. After inspecting and installing an

accessory, position yourself and bystanders away from the plane of

the rotating accessory and run the power tool at maximum no-load

speed for one minute. Damaged accessories will normally break

apart during this test time.

h) Wear personal protective equipment. Depending on application, use

face shield, safety goggles or safety glasses. As appropriate, wear

dust mask, hearing protectors, gloves and workshop apron capable of

stopping small abrasive or work piece fragments. The eye protection

must be capable of stopping flying debris generated by various

operations. The dust mask or respirator must be capable of filtrating

particles generated by your operation. Prolonged exposure to high

intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from work area. Anyone

b) Do not use the power tool if the switch does not turn it on and

off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack

from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to

operate the power tool. Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits etc., in accordance with

these instructions and in the manner intended for the particular type

of power tool, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair person using

only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

Operation of this power tool

a) This power tool is intended to function as a sander, wire brush, or

polisher.

Read all safety warnings, instructions, illustrations and specifications

provided with this power tool. Failure to follow all instructions listed

Page 6

6

7

into the surface of the material causing the wheel to climb out or kick out.

The wheel may either jump toward or away from the operator, depending

on direction of the wheel’s movement at the point of pinching. Abrasive

wheels may also break under these conditions. Kickback is the result of

power tool misuse and/or incorrect operating procedures or conditions and

can be avoided by taking proper precautions as given below.

a) Maintain a firm grip on the power tool and position your body and

arm to allow you to resist kickback forces. Always use auxiliary

handle, if provided, for maximum control over kickback or torque

reaction during start-up. The operator can control torque reactions or

kickback forces, if proper precautions are taken.

b) Never place your hand near the rotating accessory. Accessory may

kickback over your hand.

c) Do not position your body in the area where power tool will move if

kickback occurs. Kickback will propel the tool in direction opposite

to the wheel’s movement at the point of snagging.

d) Use special care when working corners, sharp edges etc. Avoid

bouncing and snagging the accessory. Corners, sharp edges or

bouncing have a tendency to snag the rotating accessory and cause

loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed saw blade.

Such blades create frequent kickback and loss of control.

Safety Warnings Specific for Sanding Operations:

a) Do not use excessively oversized sanding disc paper. Follow

manufacturers recommendations, when selecting sanding paper.

Larger sanding paper extending beyond the sanding pad presents

a laceration hazard and may cause snagging, tearing of the disc or

kickback.

Safety Warnings Specific for Polishing Operations:

a) Do not allow any loose portion of the polishing bonnet or its

attachment strings to spin freely. Tuck away or trim any loose

attachment strings. Loose and spinning attachment strings can

entangle your fingers or snag on the work piece.

entering the work area must wear personal protective equipment.

Fragments of work piece or of a broken accessory may fly away and

cause injury beyond immediate area of operation.

j) Hold power tool by insulated gripping surfaces only, when

performing an operation where the cutting accessory may contact

hidden wiring or its own cord. Cutting accessory contacting a

“live”�wire may make exposed metal parts of the power tool “live”�

and shock the operator.

k) Position the cord clear of the spinning accessory. If you lose control,

the cord may be cut or snagged and your hand or arm may be pulled

into the spinning accessory.

l) Never lay the power tool down until the accessory has come to a

complete stop. The spinning accessory may grab the surface and pull

the power tool out of your control.

m) Do not run the power tool while carrying it at your side. Accidental

contact with the spinning accessory could snag your clothing, pulling

the accessory into your body.

n) Regularly clean the power tool’s air vents. The motor’s fan will draw

the dust inside the housing and excessive accumulation of powdered

metal may cause electrical hazards.

o) Do not operate the power tool near flammable materials. Sparks

could ignite these materials.

p) Do not use accessories that require liquid coolants. Using water or

other liquid coolants may result in electrocution or shock.

Further safety instructions for all operations

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel,

backing pad, brush or any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction opposite of the

accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the work

piece, the edge of the wheel that is entering into the pinch point can dig

Page 7

8

9

TECHNICAL DATA

MODEL 6268 C

Voltage .........................120 V AC; 60 Hz

Amperage .....................12

No-load speed ..............POS.A POS.B POS.C POS.D POS.E POS.F POS.G

.....................................1,000 1,400 2,000 2,400 2,800 3,300 3,800

Spindle Thread .............5/8“ -11 NC

Weight ..........................2,87 kg - 6lb. 5oz

MODEL 6268 C

Voltage .........................220 - 240 V AC; 50 - 60 Hz

Amperage .....................7,2

No-load speed ..............POS.A POS.B POS.C POS.D POS.E POS.F POS.G

.....................................1,000 1,400 2,000 2,400 2,800 3,300 3,800

Spindle Thread .............M14

Weight ..........................2,87kg - 6lb. 5oz

INTRODUCTION

Your WALTER power tool is precision built to meet the highest industrial

standards. For maximum performance and longest tool life, follow the

operating instructions and service procedures outlined in this manual.

This tool is CSA certified.

This tool is double insulated, it does not have to be grounded.

It may be safely operated from a grounded or ungrounded

receptacle. It is supplied with a 2-conductor power cord and a

polarized plug (one blade wider than the other). The plug will

fit only one way into a polarized outlet. If the plug does not fit,

have the outlet replaced by a qualified electrician. If an extension

cord is necessary, only one that is polarized must be used. Do

not change the plug in any way.

In order to maintain the safety features of the double insulation, the

housing must not be drilled to affix nameplates or the like. Self-adhesive

labels may be used for this purpose.

VOLTAGE

Before connecting the tool, make sure that the voltage shown on the rating

plate is the same as the power source.

Operating the tool on a voltage other than specified on its rating plate, may

result in personal injury to the user and damage to the unit.

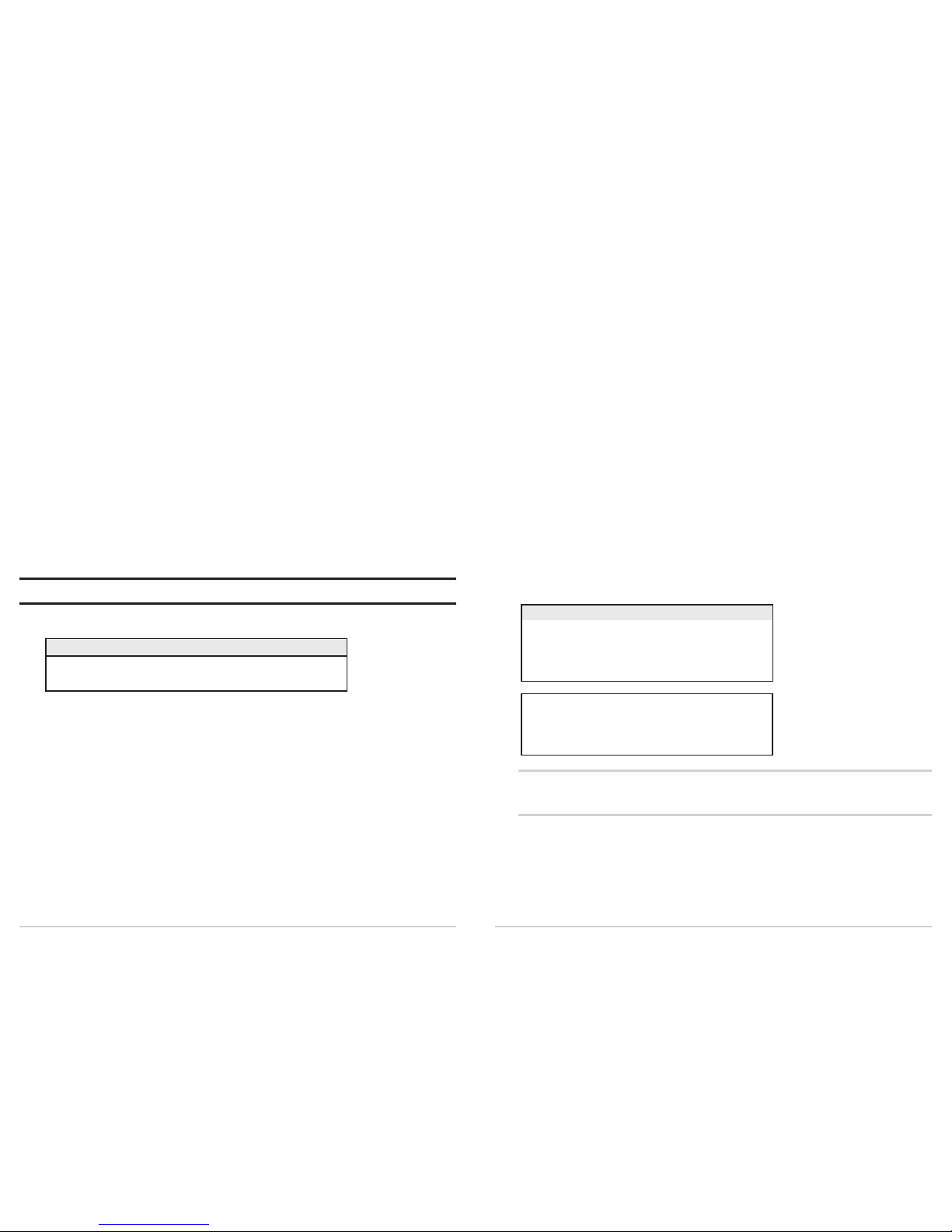

EXTENSION CORD

When an extension cord is required, use one that is sufficient for the power

requirement of the tool. Extension cords of inadequate wire size cause a

serious drop in voltage, loss of power and possible motor damage. To limit

line voltage drop to a safe level, refer to the following table:

Length in meters 8 15 23 30

Length in feet 25 50 75 100

Wire size AWG 14 14 12 10

NOTE: Extension cords that are used outdoors must be approved for outdoor use.

Page 8

10

11

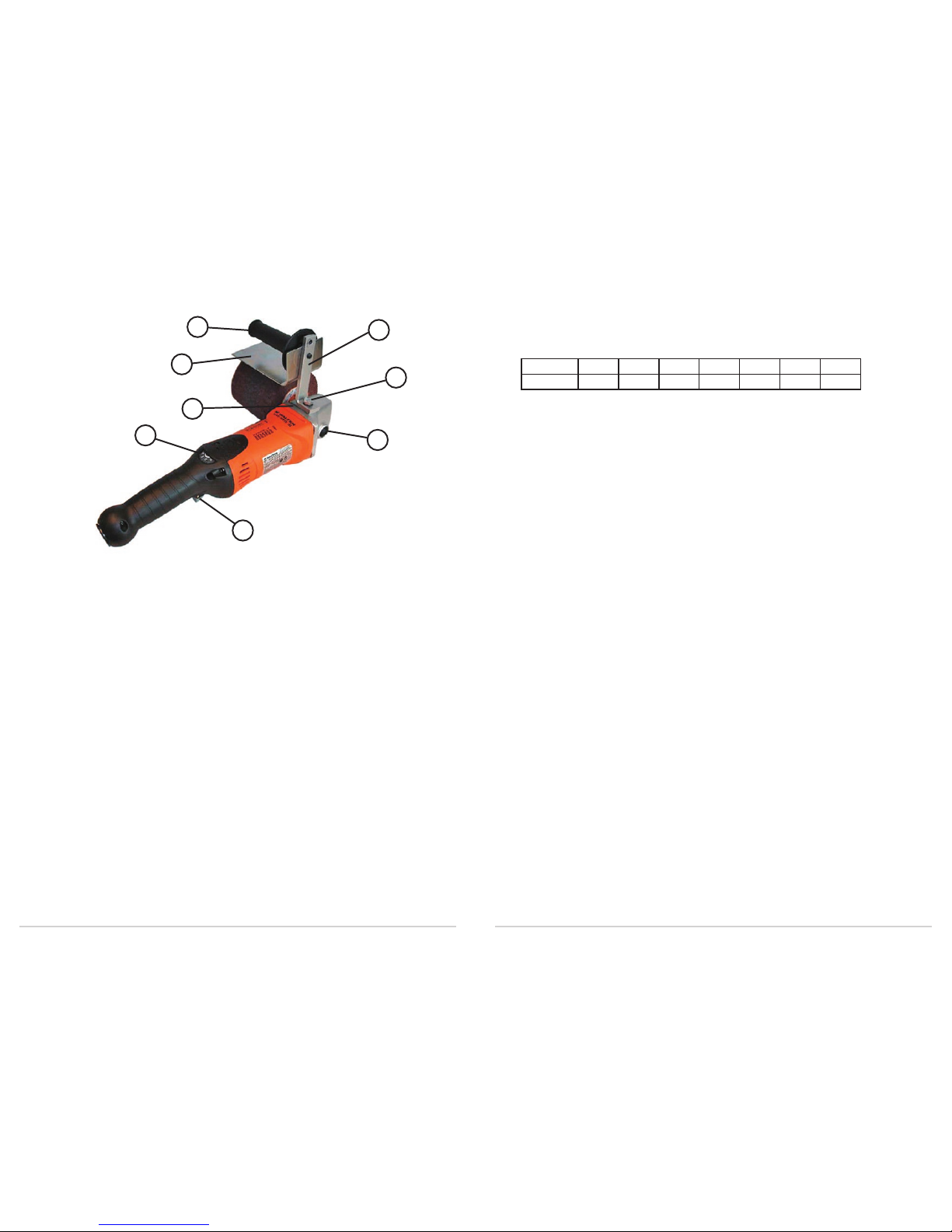

DIALSPEED™ SELECTOR

Select the required speed by rotating speed selector (8). Positions A-G

roughly equal the following no load revolutions per minute:

Pos. A B C D E F G

RPM

1,000 1,400 2,000 2,400 2,800 3,300 3,800

DIALSPEED™ SETTINGS

Set speed selector (8) to position D and adjust either up or down until you

have found a speed that meets your surface finishing requirements.

The correct setting will depend on:

a) Type of material being worked c) Amount of pressure being

applied

b) Abrasive accessory being used d) Surface finish required

DYNAMAX

™ ELECTRONICS

The built-in electronic feedback circuit continuously monitors the load on

the motor and adjusts power as required to maintain a virtually constant

speed.

Should the machine be subjected to overload for an extended period, for

example when being run at a lower speed setting, the rotation speed will be

decreased electronically to protect the motor, . The machine will not stop

completely, it will continue to run slowly to allow the motor to cool. After

a brief period, by switching the machine off and on again, it can then be

used again at the rated load.

When used for extended periods, it is quite normal for the machine to

become warm. The thermal overload protection described above will

auto-activate whenever necessary. With practice, the user will feel to what

extent the machine can be loaded at each speed setting for continuous

uninterrupted operation.

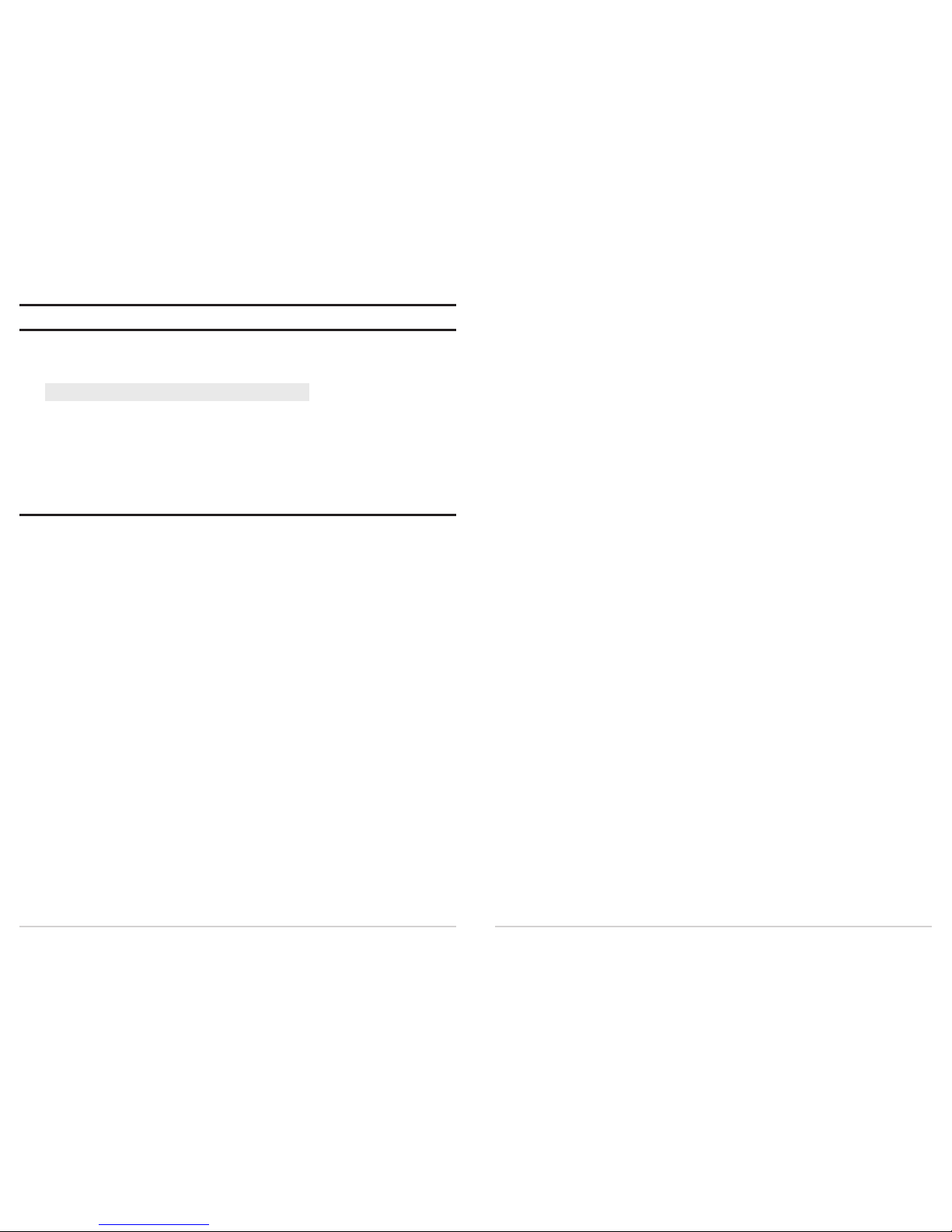

3

6

7

5

4

1

8

2

SIDE HANDLE AND SAFETY GUARD

Mount stabilizer (1) and handle bracket (2) to gear housing and secure

properly with bolt (3). Mount hand guard (4) and screw-in handle (5). For

reasons of safety and for better control, the hand guard and side handle

must always be used.

SPINDLE LOCK

To mount or remove drums and other accessories, disconnect the machine

from the power supply. Depress the locking button (6) located on top

of gear housing, while rotating the spindle by hand until the locking

mechanism is engaged. With the spindle in locked position, properly secure

the accessory being utilized. Never depress the locking button while the

tool is turned on.

SWITCH

To start, push locking switch (7) forward, locking it in the ON position.

To stop, press up on the long part of the switch, returning it to the OFF

position.

Page 9

12

13

Mounting Drum Belts

First, deflate bladder and check for a directional arrow on the inside of

the drum belt and match it with the arrow located on the outside flange of

the pneumatic drum. Slip on the selected drum belt and center it over the

drum. To secure belt, inflate bladder by applying air source to valve stem.

Inflate until drum belt feels snug, without over-inflating.

NOTE: a) Do not inflate bladder above 15 psi.

b)

When using shop air, be sure to use an approved blow-

gun

equipped with a safety nozzle.

COOLCUT

™ Drum Belts

These belts are made with premium zirconium and aluminum oxide

abrasive grains that are resin bonded to a heavy-duty cotton cloth. The

result is a cool aggressive rate of cut. Excellent for creating or restoring

line finishes, matching mill finishes and levelling small welds. These belts

are well suited as a starting point for further surface refinement.

Width Length Grit Order No.

3 1/2" 15 1/2" 40 07-F 364

3 1/2" 15 1/2" 60 07-F 366

3 1/2" 15 1/2" 80 07-F 368

3 1/2" 15 1/2" 120 07-F 371

5 3/8” 11 5/8" 40 07-F 504

5 3/8” 11 5/8" 60 07-F 506

5 3/8” 11 5/8" 80 07-F 508

5 3/8” 11 5/8" 120 07-F 511

NOTE: Prior to mounting the drum belt, verify that the directional arrow on the

inside of the drum belt matches the arrow located on the outside flange of the

pneumatic drum.

OPERATION

Please be sure to read and observe the “SAFETY INSTRUCTIONS” at

the beginning of this manual.

Always use the recommended safety guards when working with this power

tool.

Use only WALTER accessories with a maximum diameter of 7” and a

maximum safe operating speed of at least 4,500 RPM.

The use of any accessories and tooling other than those recommended may

be hazardous. Inspect all accessories and tooling before using. Do not use

any that may be damaged.

Screw all mounted accessories onto spindle and secure firmly with a

spanner.

For maximum performance and best efficiency, apply a steady and even

pressure. Do not use excessive force. Always wear eye protection.

LINE FINISHING ACCESSORIES

PNEUMATIC DRUMS

Width Dia. Arbor Max. RPM Order No.

5 3/8" 3 1/2" 5/8"-11 3,800 07-F 051

3 1/2" 5" 5/8"-11 3,800 07-F 037

Replacement rubber bladder assemblies

5 3/8" x 3 1/2" (for drum 07-F 051) 07-F 095

3 1/2" x 5" (for drum 07-F 037) 07-F 093

Replacement valve for all drums 07-F 010

The pneumatic drums will accept either COOLCUT™ or BLENDEX™ Drum

Belts.

The inflatable bladder conforms to the work piece for a more positive

surface contact.

Mounting Pneumatic Drums

Screw drum onto spindle and secure firmly. Once secured in place, the

pneumatic drum is ready to accept either COOLCUT ™ or BLENDEX™

drum belts.

Page 10

14

15

TWO-IN-ONE™ Drums

These drums combine 2 finishing steps into 1. Primarily designed for fine

finishing, they produce consistent results on both ferrous and non-ferrous

metals. The coated abrasive cloth cuts aggressively while the interleaved

BLENDEX™ flaps give the surface a satin finish.

Dia. Width Arbor Grit Order No.

4 1/4” 2” 5/8”-11 80 07-K 422

4 1/4” 4” 5/8”-11 80 07-K 442

BLENDEX™ Drums

These drums are designed to produce a wide range of decorative finishes

used for polishing, burnishing light blending and deburring, removing

shallow scratches and brightening. These non-woven flaps conform to flat

or curved work pieces giving consistent quality finishes, suitable for use on

all ferrous and non-ferrous metals.

Dia. Width Arbor Grit Order No.

4 1/4” 2” 5/8”-11 Coarse 07-M 422

4 1/4” 2” 5/8”-11 Medium 07-M- 423

4 1/4” 2” 5/8”-11 Fine 07-M 424

3 1/2” 2” 5/8”-11 Super Fine 07-M 425

4 1/4” 4” 5/8”-11 Coarse 07-M 442

4 1/4” 4” 5/8”-11 Medium 07-M 443

4 1/4” 4” 5/8”-11 Fine 07-M 444

4 1/4” 4” 5/8”-11 Super Fine 07-M 445

FX™ Drums

Designed for tough cleaning applications, these drums will strip paint with

ease, remove rust and scale, and clean-up a variety of surfaces. The open

web-like construction assures cool operations that resist loading for greater

productivity. These drums can replace wire brushes and sand blasting

operations.

Dia. Width Arbor Grit Order No.

4 1/4” 2” 5/8”-11 Coarse 07-L 420

4 1/4” 4” 5/8”-11 Coarse 07-L 440

BLENDEX™ Drum Belts

These surface conditioning drum belts will quickly clean, refine and

condition large metal surfaces. They will produce a wide range of finishes

such as polishing, buffing, matching mill satin, burnishing and also

eliminating scratches.

They produce a consistent and uniform brushed finish on stainless steel,

steel, aluminum and other non-ferrous metals.

Width Length Grit/Color Order No.

3 1/2” 15 1/2” Coarse - Tan 07-H 362

3 1/2” 15 1/2” Medium - Maroon 07-H 363

3 1/2” 15 1/2” Fine - Blue 07-H 364

3 1/2” 15 1/2” Super Fine - Grey 07-H 365

5 3/8” 11 5/8" Coarse - Tan 07-H 502

5 3/8” 11 5/8" Medium - Maroon 07-H 503

5 3/8” 11 5/8" Fine - Blue 07-H 504

5 3/8” 11 5/8" Super Fine - Grey 07-H 505

COOLCUT™ Flap Drums

These drums are recommended where light metal removal and graining is

required. They remove light casting/forging lines, small weld seams and

are excellent for components with contours. They are as effective as the

first step of the final finishing process.

Dia. Width Arbor Grit Order No.

4 1/4” 2” 5/8”-11 40 07-J 424

4 1/4” 2” 5/8”-11 60 07-J 426

4 1/4” 2” 5/8”-11 80 07-J 428

4 1/4” 2” 5/8”-11 120 07-J 432

4 1/4” 4” 5/8”-11 40 07-J 444

4 1/4” 4” 5/8”-11 60 07-J 446

4 1/4” 4” 5/8”-11 80 07-J 448

4 1/4” 4” 5/8”-11 120 07-J 452

Page 11

16

17

Buffing Drums

Heavy cotton drums used with polishing pastes.

Ideal for enhancing and brightening existing finishes, taking out stains in

metals and bringing outa new lustre in work surfaces.

Optimal working speed 1700-2200 RPM.

Dia. Width Arbor Grit Order No.

4 3/4” 2” 5/8”-11 Multi-ply cotton 07-T 425

PIPE FINISHING ABRASIVES

BLENDEX™ Strip Belts

Quick and efficient method to produce in-line finishes on small diameter

tubing and pipes made of steel, stainless steel and aluminum.

- Produce new sheen and lustre in tarnished pipe work.

- Ideal for enhancing and brightening existing finishes, taking out

stains in metals and bringing out a new lustre in work surfaces.

Width Length Grit/Color Order No.

1 3/16” 25” Coarse - Tan 07-H 242

1 3/16” 25” Medium - Maroon 07-H 243

1 3/16” 25” Fine - Blue 07-H 244

1 3/16” 25” Super Fine - Grey 07-H 245

Belt Drive Rollers

For use with BLENDEX™ Conditioning Strip Belts. This belt drive roller

is made of resistant polyurethane. The ribbed design ensures positive drive

of belts. The large stainless steel side plates prevent belts from slipping

off.

CARBON BRUSHES

When the carbon brushes are worn down, the Auto-Stop feature will

automatically turn the machine off in order not to damage the motor. The

brushes must then be replaced.

Use only genuine WALTER carbon brushes. These brushes are specially

made for this tool. They will maintain their high performance standard and

ensure maximum life of the motor.

To check or replace carbon brushes:

1. Disconnect the tool from power supply.

2. Unscrew and remove carbon brush service window.

3. Carbon brushes may be pulled from their holders after lifting spring

and detaching the connector.

4. Replace brushes if necessary. Always replace them in pairs.

5. Check that the new brushes move freely in their holders. To help seat

the carbon brushes properly after they have been installed, use the

power tool without applying a heavy load for at least 30 minutes.

However, when the carbon brushes require replacement, it is recommended

that the tool be sent to a WALTER Factory Service Center or a WALTER

Authorized Service Center. Apart from changing the brushes, your power

tool will be cleaned, inspected and lubricated as required.

PREVENTIVE MAINTENANCE

Your WALTER power tool should be properly maintained to insure

continued high performance.

Use low-pressure compressed air to blow out dust from the motor through

the vent openings.

Clean dust and dirt deposits from the exterior of the tool. Clean the power

cord to prevent deterioration from oil and grease and check for possible

damage to cord or plug.

NOTE: Damaged cord sets must be replaced. Refer to Spare Parts List for

the ordering number.

Page 12

18

19

WARRANTY POLICY

All WALTER power tools and accessories are inspected and tested before

shipping and are guaranteed to be free from any defect in material and

faulty workmanship. Should any malfunction occur within one (1) year

from the date of original purchase, return the complete tool prepaid with

proof of purchase, to the nearest WALTER Factory or Authorized Service

Center. If an examination shows that the malfunction was caused by

defective material or faulty workmanship, WALTER will repair (or at our

option, replace) without charge. This warranty does not apply when normal

maintenance is required, repairs or replacements have been made or were

attempted by anyone other than WALTER authorized service personnel,

and does not cover any damage caused by accidents, modifications, use of

improper accessories, abuse or misuse, which also includes overloading

the tool beyond its rated capacity as well as its continued use after partial

failure. No other warranty, written or verbal is authorized.

In no event shall WALTER be liable for any indirect, incidental or

consequential damages from the sale of the product. This disclaimer

applies both during and after the term of this warranty.

This warranty gives you specific rights. The provisions contained in this

warranty are not intended to limit, modify, take away from, disclaim or

exclude any warranties set forth in any Provincial or State legislation.

To the extent required by law, the provisions in any Provincial, State or

Federal legislation with respect to warranties take precedence over the

provisions in this warranty.

WALTER SALES AND SERVICE

CANADA

MONTREAL:

5977 Trans Canada Highway

Pointe-Claire QC H9R 1C1

Tel.: (514) 630-2801

Fax: (514) 630-2825

TORONTO:

151 Superior Blvd., Unit 12

Mississauga ON L5T 2L1

Tel.: (905) 795-8555

Fax: (905) 795-8558

VANCOUVER:

1-1595 Cliveden Avenue

Delta BC V3M 6M2

Tel.: (604) 540-4777

Fax: (604) 540-4778

U.S.A.

WINDSOR:

J. Walter Inc.

810 Day Hill Road

Windsor CT 06095-1704

Tel: (860) 298 1100

Fax: (860) 274 4435

BRAZIL

SAO PAULO

Walter Indústria e Comércio Ltda.

Rua Marco Gianini, 426

Butantã, São Paulo, SP

CEP: 05550-000

Tel.: (5511) 3783.9500

Fax: (5511) 3783.9501

ARGENTINA

BUENOS AIRES

Walter S.A.

Dardo Rocha 1032/34

B1754FCD) San Justo

Tel.: (54-11)4441-1889/1648

Fax: (54-11)4441-0258

MEXICO

JALISCO

Walter

Boulevard La Carreta No. 835

PARQUE INDUSTRIAL

BELENES NORTE

CP 45145 Zapopan

Tel.: (52) 33 11 99 15 15

Fax: (52) 01 800 087 51 19

In Canada call toll free 1-888-JWALTER and in the U.S.A. 1-866-JWALTER for the location of

an Authorized Service Center closest to you or visit our web site: www.walter.com.

Page 13

LINE-MATE III

SYSTÈME DE FINITION LIGNÉE

(Modèle 6268 C)

FRANÇAIS

Page 14

1

Nous vous remercions d’avoir choisi le LINE-MATE III

SYSTÈME DE FINITION LIGNÉE (Modèle 6268C)

Plus vous serez familiarisé avec le Line-Mate III, mieux

vous pourrez exploiter cet appareil.

C’est pourquoi nous vous prions de lire attentivement

ce mode d’emploi avant de mettre le l’outil en service.

Vous y trouverez des indications importantes pour une

utilisation sans problème, ainsi que des informations

importantes relatives à la sécurité et à la maintenance

du Line-Mate III.

TITRES PAGE

Directives de sécurité .................................................................................. 2

Introduction ................................................................................................ 9

Voltage .........................................................................................................

9

Rallonge électrique ..................................................................................... 10

Caractéristiques Techniques .......................................................................

10

Illustration du modèle ................................................................................. 11

Poignée latérale ........................................................................................... 11

Dispositif de blocage de l’arbre .................................................................. 11

Interrupteur ................................................................................................. 11

Sélecteur de vitesses Dialspeed MC ...........................................................

12

Réglage Dialspeed MC ...............................................................................

12

Électronique Dynamax MC .........................................................................

12

Fonctionnement .......................................................................................... 13

Accessoires pour la finition lignée ..............................................................

13

Tambours ....................................................................................................

15

Abrasifs pour la finition de tuyaux .............................................................

17

Entretien préventif ...................................................................................... 18

Politique de garantie ................................................................................... 19

Ventes et service WALTER .........................................................................

20

Page 15

2

3

Consignes de sécurité générales

Les outils électriques Walter sont fabriqués selon les normes établies

régissant la fabrication, le fonctionnement et la sécurité des outils

électriques.

MISE EN GARDE : Afin de réduire le risque de blessures,

l’utilisateur doit lire attentivement le mode d’emploi.

Veuillez lire toutes les instructions. Il est important de suivre les

instructions énumérées afin de réduire le risque de chocs électriques,

d’incendie et/ou de blessures graves. Le terme « outil électrique » dans

toutes les mises en garde énumérées fait référence à votre outil électrique

avec ou sans fil (muni d’une pile).

CONSERVEZ CES INSTRUCTIONS

1) Sécurité dans votre zone de travail

a) Gardez votre zone de travail propre et bien éclairée. Un milieu

de travail en désordre ou mal éclairé peut devenir une source

d’accidents.

b) Ne pas utiliser l’outil électrique dans des atmosphères explosives, par

exemple en présence de liquide inflammable, de gaz ou de poussière.

L’outil électrique en fonction crée des étincelles et pourrait enflammer

la poussière ou les vapeurs.

c) Éloigner les enfants et les passants lors de l’utilisation d’un outil

électrique. Les distractions peuvent vous faire perdre le contrôle.

2) Sécurité en électricité

a) La fiche de l’outil électrique doit correspondre à la prise de courant.

Ne jamais modifier la fiche d’aucune façon. N’utilisez pas de

raccords de fiches avec des outils électriques mis à la terre. Les

fiches originales et les prises correspondantes réduiront le risque de

chocs électriques.

b) Évitez tout contact avec les surfaces mises à la terre, tels les tuyaux,

les radiateurs, les cuisinières et les réfrigérateurs. Le risque de chocs

électriques augmente si votre corps est relié à la terre.

c) Ne pas utiliser l’outil électrique sous la pluie ou dans des endroits

humides. L’infiltration d’eau dans l’outil augmente le risque de chocs

électriques.

d) N’abusez pas du cordon électrique. Ne transportez jamais l’outil en

le tenant par le cordon électrique et ne le débranchez pas en tirant sur

le cordon.Tenir le cordon loin de la chaleur, de l’huile et des pièces

tranchantes ou en mouvement. Un cordon endommagé ou enchevêtré

augmente le risque de chocs électriques.

e) Lorsque vous utilisez l’outil en plein air, assurez-vous d’avoir une

rallonge conçue pour une utilisation extérieure, réduisant ainsi le

risque de chocs électriques.

3) Sécurité personnelle

a) Soyez vigilant en tout temps lorsque vous manipulez un outil

électrique et faites preuve de bons sens. N’utilisez pas l’outil lorsque

vous êtes fatigué ou sous l’influence de l’alcool, de drogues ou

de médicaments. Un seul moment d’inattention dans l’utilisation

d’outils électriques peut entraîner des blessures graves.

b) Utilisation de matériel de sécurité – Il est important de toujours

porter des lunettes de sécurité. Le matériel de sécurité, y compris

un masque, des chaussures de sécurité antidérapantes, un casque de

sécurité et des tampons pour oreilles, évite les blessures.

c) Évitez un démarrage involontaire. Assurez-vous que l’interrupteur

est à la position « OFF » avant de le brancher. Le fait de transporter

l’outil avec votre doigt sur l’interrupteur ou de brancher l’outil

lorsque l’interrupteur est à « ON » peut provoquer des accidents.

d) Avant d’actionner l’outil électrique, assurez-vous de retirer toutes

les clés et les outils de réglage. Une clé attachée aux pièces en

mouvement d’un outil électrique peut provoquer des blessures.

e) Ne travaillez pas à bout de bras. Gardez un bon équilibre en tout

temps. Cela permet un meilleur contrôle de l’outil électrique dans

des situations imprévues.

f) Portez des vêtements appropriés. Évitez de porter des bijoux et des

vêtements amples lorsque vous travaillez avec des outils électriques.

Gardez vos cheveux, vos vêtements et vos gants loin des pièces en

mouvement. Les vêtements amples, les bijoux ou les cheveux longs

peuvent s’entremêler dans les pièces en mouvement.

Page 16

4

5

g) Si des dispositifs de connexion sont fournis pour l’extraction et la

collecte de poussière, assurez-vous de bien les raccorder et de les

utiliser correctement. L’utilisation de ces dispositifs peut réduire les

risques engendrés par la poussière.

4) Utilisation et entretien de l’outil

a) Ne pas forcer l’outil au-delà de sa capacité. Utilisez l’outil approprié

pour l’application requise. L’utilisation du bon outil, conçu pour

l’application désirée, donnera de meilleurs résultats et sera plus

sécuritaire.

b) Ne pas utiliser l’outil lorsqu’il est impossible de positionner

l’interrupteur à « ON » ou à « OFF ». Tout outil électrique qui ne

peut être contrôlé à l’aide de l’interrupteur n’est pas sécuritaire;

celui-ci doit être réparé.

c) Débranchez la fiche de la source électrique et/ou enlevez la batterie

de l’outil avant de faire des ajustements, de changer d’accessoires ou

lorsque vous le ranger. Cette mesure de sécurité prévient le risque

d’un démarrage accidentel de l’outil.

d) Remisez vos outils électriques hors de la portée des enfants et

empêchez quiconque n’est pas familier avec les instructions et le

fonctionnement de l’outil de l’utiliser. Il est dangereux de laisser des

outils électriques dans les mains d’utilisateurs inexpérimentés.

e) Faites l’entretien des outils électriques. Vérifiez l’alignement,

l’état des pièces mobiles, le bris de pièces et toute autre condition

qui pourrait influencer le bon fonctionnement de l’outil. Si celuici est endommagé, assurez-vous de le réparer avant de l’utiliser.

Plusieurs accidents sont attribuables au manque d’entretien des outils

électriques.

f) Gardez les outils de coupe bien affûtés et propres. Le bon entretien

de votre outil de coupe sera moins susceptible de se coincer et plus

facile à manœuvrer.

g) Utilisez l’outil électrique, les accessoires et forets selon ces

instructions et de la façon prévue pour le type particulier d’outil

électrique, tenant compte des conditions de travail et du travail à

accomplir. L’utilisation de l’outil électrique pour des applications

autre que celles qui lui sont destinées pourrait entraîner un danger.

5) Entretien

a) Assurez-vous que l’entretien de votre outil électrique soit effectué

par un technicien qualifié qui utilise des pièces de remplacement

originales. Cela assurera un fonctionnement sécuritaire de l’outil.

Utilisation de l’outil électrique

a) Cet outil est destiné à servir de sableuse ou de polisseuse; il est

muni d’une brosse d’acier. Veuillez lire les mises en garde, le mode

d’emploi, les particularités et les schémas fournis avec cet outil

électrique. Il est important de suivre les instructions énumérées plus

bas afin de réduire le risque de chocs électriques, d’incendie et/ou de

blessures graves.

b) Il n’est pas recommandé d’utiliser cet outil pour meuler, tronçonner

ou effectuer des travaux de ce genre. Les travaux ne convenant pas à

l’outil peuvent entraîner un risque de danger et de blessures.

c) Ne pas utiliser les accessoires qui ne sont pas précisément conçus

et recommandés par Walter. Sachez que même si un accessoire

peut être raccordé à votre outil électrique, ceci n’assure pas

nécessairement sa sécurité d’utilisation.

d) La vitesse approuvée de l’accessoire doit correspondre au moins à

la vitesse maximale indiquée sur l’outil. Utiliser l’accessoire à une

vitesse supérieure à celle APPROUVÉE peut provoquer le bris et

l’éclatement de l’accessoire.

e) L’épaisseur et le diamètre extérieur de l’accessoire doivent figurer

dans l`indice de capacité de votre outil électrique. Les accessoires

de taille inappropriée ne peuvent être convenablement surveillés ou

contrôlés.

f) La dimension de l`arbre, de la bride, des tampons de soutien ou de

tout accessoire doit s’ajuster adéquatement au mandrin de l’outil

électrique. Les accessoires dont les trous de fixation de l’arbre ne

correspondent pas aux pièces de montage de l’outil électrique seront

en déséquilibre, présenteront une vibration excessive et pourront

entraîner une perte de contrôle.

g) Ne pas utiliser un accessoire endommagé. Avant chaque utilisation,

vérifiez l’état des accessoires, notamment les meules abrasives

Page 17

6

7

pour repérer les ébréchures et les fissures, les tampons de soutien

pour repérer des déchirures ou une usure excessive et les brosses

métalliques pour repérer des fils brisés ou endommagés. Si l’outil

ou l’accessoire est échappé, vérifier la présence de dommages ou

installer un nouvel accessoire. Suite à cette inspection et l’installation

du nouvel accessoire, tenez-vous (et les passants) hors de portée du

rabot de l’accessoire rotatif et mettez le moteur de l’outil en marche

à la position maximale « à vide » pendant une minute. En général, un

accessoire endommagé se brisera durant cette période d’essai.

h) Portez un équipement de protection. Selon l’application, utilisez une

visière ou des lunettes de sécurité. Utilisez un masque anti-poussière,

des protecteurs auditifs, des gants et un tablier d’atelier afin de

vous protéger de petites pièces abrasives or fragments. Les lunettes

de sécurité doivent couvrir suffisamment les yeux pour éviter

l’infiltration de débris générés par diverses applications de l’outil.

Le masque anti-poussières doit pouvoir filtrer les particules générées

lors de vos travaux exécutés avec l’outil. Une exposition prolongée

au bruit très intense peut entraîner une perte auditive.

i) Gardez les passants à une distance sécuritaire de votre zone de

travail. Toute personne qui accède à la zone de travail doit porter un

équipement de protection. Des fragments de pièces ou d’accessoire

brisé peuvent voler en éclats et causer des blessures au-delà de la

zone immédiate des travaux.

j) Toujours tenir l’outil électrique par la poignée et/ou le boîtier isolés

durant les travaux alors que l’accessoire de coupe peut entrer en

contact avec son propre cordon d’alimentation ou atteindre des fils

électriques dissimulés. Un accessoire tranchant qui touche un fil

électrique pourrait ainsi exposer les parties métalliques, ce qui risque

de donner un choc électrique à l’utilisateur.

k) Placez le cordon d’alimentation hors de la portée de l’accessoire

rotatif. Si vous perdrez le contrôle, le cordon peut être coupé ou

se détacher et entraîner votre main ou votre bras dans l’accessoire

rotatif.

l) Ne jamais déposer l’outil avant qu’il soit entièrement arrêté.

L’accessoire rotatif pourrait saisir la surface et ainsi causer la perte

de contrôle.

m) Ne jamais transporter l’outil lorsqu’il est en marche. L’accessoire

rotatif qui entrerait en contact accidentellement à vos vêtements

pourrait causer des blessures.

n) Nettoyez régulièrement le dispositif de ventilation de l’outil

électrique. Le ventilateur du moteur laissera de la poussière s’infiltrer

dans l’enveloppe. L’accumulation excessive de poussière métallique

peut alors causer des risques d’origine électrique.

o) Ne pas utiliser l’outil à proximité de matières inflammables. Des

étincelles pourraient enflammer ces matières.

p) Ne pas utiliser d’accessoires qui nécessitent un liquide de

refroidissement. Utiliser de l’eau ou d’autres liquides de

refroidissement pourrait provoquer l’électrocution ou un choc

électrique.

Autres directives de sécurité pour toutes les applications

Les rebonds et les mises en garde

L’effet de rebond est une réaction soudaine provoquée par le coincement

ou l’accrochage d’une meule en rotation, du tampon de soutien ou de tout

autre accessoire. Le coincement ou l’accrochage cause un freinage rapide

qui incite l’outil à se diriger dans la direction opposée de la rotation.

Par exemple, lorsqu’une meule abrasive s’accroche ou se coince dans

la pièce, le rebord de la meule qui pénètre la surface du matériel fait

remonter ou rebondir la meule. Il est possible que la meule rebondisse vers

l’utilisateur ou s’en éloigne, selon la direction du mouvement de la meule

au point de coincement. Les meules abrasives peuvent aussi de briser dans

ces conditions. Le rebond est le résultat d’une mauvaise utilisation de

l’outil électrique et/ou des procédures inappropriées ou du mauvais état

de fonctionnement. Cela peut être évité en prenant les bonnes précautions

indiquées plus bas.

a) Tenez l’outil fermement et placez votre corps et votre bras de

manière à pouvoir résister aux forces de rebond. Utiliser toujours la

poignée auxiliaire, si disponible, afin d’exercer un contrôle maximal

du rebond ou de la réaction de couple au démarrage. L’opérateur peut

contrôler les réactions de couple ou les forces du rebond, s’il prend

les mesures appropriées.

Page 18

8

9

b) Ne placez jamais votre main près de l’accessoire rotatif. L’accessoire

peut rebondir sur votre main.

c) Ne placez pas votre corps dans la zone où l’outil électrique se

déplacera s’il survient un rebond. Le rebond propulsera l’outil en

direction opposée au mouvement de la meule au point d’accrochage.

d) Soyez vigilants lorsque vous travaillez les coins, les bords coupants,

etc. Évitez de faire rebondir et d’accrocher l’accessoire. Les coins,

les bords coupants ou le rebond ont tendance à accrocher l’accessoire

rotatif et provoquer une perte de contrôle ou un rebond.

e) N’attachez pas de lame de sculpture sur bois à chaîne ou de lame de

scie à dents. Ce genre de lames occasionnent souvent un rebond et

une perte de contrôle.

Mises en garde de sécurité particulières aux travaux de sablage :

a) N’utilisez pas du papier abrasif trop grand. Respectez les

recommandations du fabricant dans votre choix de papier abrasif.

Du papier abrasif trop grand qui dépasse le patin ponceur présente

un risque de lacération et peut occasionner l’accrochage et le

déchirement du disque ou un effet de rebond.

Mises en garde de sécurité particulières aux travaux de polissage :

a) Ne laissez aucune pièce lâche du couvercle de polissage ou ses

cordes de fixation tourner librement. Rentrez ou coupez toute corde

de fixation lâche. Les cordes de fixation lâches et en rotation peuvent

s’entremêler à vos doigts ou s’accrocher à la pièce.

INTRODUCTION

Votre outil WALTER est fabriqué avec précision selon les normes

industrielles les plus élevées. Pour un rendement optimal et une plus

longue durée de vie, veuillez suivre les directives de mise en marche et

d’entretien décrites dans ce manuel.

Cet outil est certifié CSA.

Cet outil est doublement isolé, il ne doit pas être mis à la terre.

Il peut être raccordé sans risque à une prise de courant mise à la

terre ou non mise à la terre. Il est fourni avec un câble à deux

(2) conducteurs et une fiche polarisée (une lame plus large que

l’autre). La fiche entrera dans une seule direction dans une prise

de courant polarisée. Si la fiche ne convient pas, faites remplacer

la prise de courant par un électricien qualifié. Si une rallonge

électrique est nécessaire, vous devez en utiliser une qui soit

polarisée. Ne changez en aucune façon la prise de courant.

Afin de maintenir les avantages sécuritaires de la double isolation,

le boîtier du moteur ne doit pas être perforé pour y fixer des plaques

d’identification. Utilisez plutôt des étiquettes auto-adhésives.

VOLTAGE

Avant de brancher l’outil, veuillez vous assurer que le voltage inscrit sur la

plaque de l’outil est le même que celui de la source électrique.

L’utilisation de l’outil à un voltage autre que celui spécifié pourrait causer

des blessures et endommager l’outil.

Page 19

10

11

RALLONGE ÉLECTRIQUE

Lorsqu’une rallonge électrique est requise, utilisez un câble ayant un

diamètre suffisant pour accommoder les besoins en courant de votre outil.

Des rallonges électriques ayant une grosseur de fil insuffisante causent

une perte de voltage importante ainsi qu’une perte d’énergie et peuvent

endommager le moteur.

Afin de limiter la perte de voltage à un niveau modéré, veuillez consulter la

table suivante.

Longueur en mètres 8 15 23 30

Longueur en pieds 25 50 75 100

Grosseur de fil AWG 14 14 12 10

NOTE :

Toutes les rallonges utilisées à l’extérieur doivent être approuvées pour un usage

extérieur.

CARACTÉRISTIQUES TECHNIQUES

MODEL 6268 C

Tension ......................... 120 V AC; 60 Hz

Ampéres ....................... 12

Vitesse de rotation .......POS.A POS.B POS.C POS.D POS.E POS.F POS.G

.....................................1,000 1,400 2,000 2,400 2,800 3,300 3,800

Filet d‘arbre .................5/8“ -11 NC

Poids ............................2,87kg - 6lb. 5oz

MODEL 6268 C

Tension ......................... 220 - 240 V AC; 50 - 60 Hz

Ampéres ....................... 7,2

Vitesse de rotation .......POS.A POS.B POS.C POS.D POS.E POS.F POS.G

.....................................1,000 1,400 2,000 2,400 2,800 3,300 3,800

Filet d‘arbre .................M14

Poids

.................................

2,87kg - 6lb. 5oz

3

6

7

5

4

1

8

2

POIGNÉE LATÉRALE & PROTÈGE-MAIN

Montez le stabilisateur (1) et le support de la poignée (2) sur le boîtier

d’engrenages et fixez correctement avec le boulon (3). Montez le protègemain (4) et vissez la poignée (5). Pour des raisons de sécurité et un

meilleur contrôle, le protège-main et la poignée latérale doivent toujours

être utilisés.

DISPOSITIF DE BLOCAGE DE L’ARBRE

Pour monter ou enlever les tambours et autres accessoires, débranchez

l’unité de la prise électrique. Enfoncez le dispositif de blocage de l’arbre

situé sur le dessus du boîtier d’engrenages (6) , tout en faisant pivoter

l’arbre à la main jusqu’à ce que le mécanisme de blocage soit engagé.

Avec l’arbre dans une position de blocage, sécurisez correctement

l’accessoire utilisé. Ne jamais enfoncer le bouton de blocage si l’outil est

activé

INTERRUPTEUR

Pour mettre en marche, poussez la glissière (7) vers l’avant, la verrouillant

à la position “ON”. Pour arrêter, pressez vers l’arrière, retournant à la

position “OFF”.

Page 20

12

13

SÉLECTEUR DE VITESSES DIALSPEED

MC

Sélectionnez la vitesse requise en pivotant le sélecteur de vitesses (8). Les

positions A-G équivalent environ aux révolutions par minute suivantes:

Pos. A B C D E F G

RPM

1,000 1,400 2,000 2,400 2,800 3,300 3,800

RÉGLAGE DIALSPEED

MC

Mettre le sélecteur de vitesse à ( 8) position D et ajustez vers le haut ou

vers le bas jusqu’à ce que vous ayez atteint la vitesse qui rencontre vos

exigences de finition de surfaces.

Le bon réglage dépendra de: a) Type de matériau

b) Accessoire abrasif utilisé

c) Quantité de pression

d) Finition requise

ÉLECTRONIQUES DYNAMAX

MC

Cet outil est muni d’un circuit d’alimentation électronique. La charge du

moteur ainsi que l’alimentation en énergie requise sont continuellement

contrôlées afin de maintenir une vitesse quasi constante.

Si la machine est soumise à une forte pression durant une période

prolongée, par exemple, lorsque l’appareil fonctionne à basse vitesse,

la rotation du moteur sera électroniquement diminué afin de protéger

le moteur. Plutôt que d’arrêter complètement, le moteur continuera son

fonctionnement à une vitesse réduite afin de refroidir ( protection de

surcharge thermique). Après un court moment, mettez l’appareil hors

tension pour ensuite le redémarrer. Suivant ces étapes, l’appareil peut être

utilisé de nouveau à une charge nominale.

Lorsque l’appareil est utilisé pendant de longues périodes, il est tout à

fait normal qu’il devienne chaud. La fonction de protection de surcharge

thermique, tel que décrit ci-dessus, s’activera automatiquement lorsque

nécessaire. À l’usage, l’utilisateur saura reconnaître à quelle vitesse et avec

quel pression l’outil performera le mieux pour un fonctionnement continu

et sans interruption.

FONCTIONNEMENT

Veuillez bien lire et suivre les “DIRECTIVES DE SÉCURITÉ’’ décrites

au début de ce manuel.

Toujours utiliser les protège-meules recommandés quand vous travaillez

avec cet outil électrique.

Utilisez seulement des accessoires WALTER ayant un diamètre maximal de

7” et une vitesse de fonctionnement sécuritaire maximale d’au moins 4,500

RPM.

Inspectez tous les accessoires et outillage avant l’utilisation. Ne pas utiliser

ceux qui pourraient être endommagés.

Vissez tous les accessoires montés sur l’arbre et fixez fermement avec une

clé à ergot.

Pour une performance et une efficacité optimales, maintenez une pression

uniforme et constante. Évitez de trop forcer. Utilisez toujours des lunettes

de protection.

ACCESSOIRES POUR FINITION LIGNÉE

TAMBOURS PNEUMATIQUES

Largeur Dia. Arbre RPM Max. N° de comm.

5 3/8" 3 1/2" 5/8"-11 3,800 07-F 051

3 1/2" 5" 5/8"-11 3,800 07-F 037

Ensemble de rechange de gaines en caoutchouc:

5 3/8" x 3 1/2" (pour tambours 07-F 051) 07-F 095

3 1/2" x 5" (pour tambours 07-F 037) 07-F 093

Soupape de rechange pour tous les tambours 07-F 010

Le tambour pneumatique acceptera les courroies de tambours COOLCUT MC

ou BLENDEX MC. La gaine gonflable s’adapte à la pièce à travailler pour un

meilleur contact à la surface.

Page 21

14

15

Montage des tambours pneumatiques

Vissez le tambour sur l’arbre et fixez fermement. Une foix fixé, le tambour

pneumatique est prêt pour les courroies de tambours COOLCUT MC ou

BLENDEX MC.

Montage des courroies de tambours

Premièrement, dégonflez la gaine et trouvez la flèche directionnelle à

l’intérieur de la courroie et alignez-la avec celle située à l’extérieur de

la rondelle du tambour pneumatique. Glissez la courroie sélectionnée

et centrez-la sur le tambour. Pour fixer la courroie, gonflez la gaine en

appliquant une source d’air dans la tige de la soupape. Gonflez jusqu’à ce

que la courroie soit bien ajustée, mais ne pas trop gonfler.

NOTE: a) Ne pas gonfler la gaine au-dessus de 15 psi.

b) Assurez-vous d’utiliser une pompe approuvé et équipé

d’unembout de sûreté.

Courroies de tambours COOLCUT

MC

Ces courroies sont fabriquées avec des grains de la meilleure qualité

d’abrasifs de zirconium et d’oxyde d’aluminium qui sont agglomérés sur

un matériau coton très résistant, lequel donne comme résultat un taux

de coupes agressif et froid. Excellent pour créer ou restaurer des finis

lignés, finis procédés en usine et mettre à niveau les petites soudures.

Ces courroies sont bien appropriées comme point de départ pour une

amélioration de surfaces.

Largeur Longueur Grain N° de comm.

3 1/2" 15 1/2" 40 07-F 364

3 1/2" 15 1/2" 60 07-F 366

3 1/2" 15 1/2" 80 07-F 368

3 1/2" 15 1/2" 120 07-F 371

5 3/8” 11 5/8" 40 07-F 504

5 3/8” 11 5/8" 60 07-F 506

5 3/8” 11 5/8" 80 07-F 508

5 3/8” 11 5/8" 120 07-F 511

NOTE: Avant de monter la courroie, vérifiez que la flèche directionnelle à l’intérieur

de la courroie du tambour est alignée avec celle de la rondelle extérieure du

tambour pneumatique.

Courroies de tambours BLENDEX

MC

Ces courroies de conditionnement de surfaces nettoient rapidement,

améliorent et conditionnent de grandes surfaces métalliques. Elles

permettent de réaliser tant des travaux de rectification, de conditionnement

de surfaces que de polissage pour des finis décoratifs.

Elles produisent un fini brossé conforme et uniforme sur l’acier

inoxydable, l’acier, l’aluminium et autres métaux non-ferreux.

Largeur Longueur Grain/Couleur N° de comm.

3 1/2” 15 1/2”

Grossier - Beige

07-H 362

3 1/2” 15 1/2”

Moyen - Marron

07-H 363

3 1/2” 15 1/2”

Fin - Bleu

07-H 364

3 1/2” 15 1/2”

Super Fin - Gris

07-H 365

5 3/8” 11 5/8"

Grossier - Beige

07-H 502

5 3/8” 11 5/8"

Moyen - Marron

07-H 503

5 3/8” 11 5/8"

Fin - Bleu

07-H 504

5 3/8” 11 5/8"

Super Fin - Gris

07-H 505

TAMBOURS

Tambours à feuillets abrasifs COOLCUT

MC

Ces tambours sont recommandés quand un enlèvement de métal léger

et de grainage est nécessaire. Ils enlèvent les lignes légères des pièces

de fonte ou forgées, petits joints de soudures et, sont excellents pour les

composantes à contour. Ils sont efficaces en tant que première étape dans le

procédé d’une finition satinée.

Dia. Largeur Arbre Grain N° de comm.

4 1/4” 2” 5/8”-11 40 07-J 424

4 1/4” 2” 5/8”-11 60 07-J 426

4 1/4” 2” 5/8”-11 80 07-J 428

4 1/4” 2” 5/8”-11 120 07-J 432

4 1/4” 4” 5/8”-11 40 07-J 444

4 1/4” 4” 5/8”-11 60 07-J 446

4 1/4” 4” 5/8”-11 80 07-J 448

4 1/4” 4” 5/8”-11 120 07-J 452

Page 22

16

17

Tambours TWO-IN-ONE

MC

Ces tambours combinent 2 étapes de finition en une seule. Principalement

conçus pour la finition fine, ils produisent des résultats constants sur les

métaux ferreux et non-ferreux. L’abrasif sur toile coupe agressivement

tandis que les feuillets intercalés BLENDEX MC donnent à la surface un fini

satiné.

Dia. Largeur Arbre Grain N° de comm.

4 1/4” 2” 5/8”-11 80 07-K 422

4 1/4” 4” 5/8”-11 80 07-K 442

Tambours BLENDEX

MC

Ces tambours sont conçus pour produire une grande variété de finis décoratifs et

utilisés pour polir, brunir la finition légère et ébavurer, enlever les égratignures peu

profondes et éclaircir. Les feuillets non-tissés s’adaptent aux pièces à travailler

plates ou courbées, donnant des finis de qualité constants, appropriés pour

l’utilisation sur tous les métaux ferreux et non-ferreux.

Dia. Largeur Arbre Grain N° de comm.

4 1/4” 2” 5/8”-11 Grossier 07-M 422

4 1/4” 2” 5/8”-11 Moyen 07-M- 423

4 1/4” 2” 5/8”-11 Fin 07-M 424

3 1/2” 2” 5/8”-11 Super Fin 07-M 425

4 1/4” 4” 5/8”-11 Grossier 07-M 442

4 1/4” 4” 5/8”-11 Moyen 07-M 443

4 1/4” 4” 5/8”-11 Fin 07-M 444

4 1/4” 4” 5/8”-11 Super Fin 07-M 445

Tambours FX

MC

Conçus pour les gros travaux de nettoyage, ces tambours décapent de la peinture

avec facilité, enlèvent rouille et écailles, et nettoient une variété de surfaces. La

structure à mailles ouvertes assure le refroidissement nécessaire pour résister à

l’encrassement pour une plus grande productivité. Ces tambours peuvent remplacer

les brosses métalliques et les opérations de nettoyage aux grains de sable.

Dia. Largeur Arbre Grain N° de comm.

4 1/4” 2” 5/8”-11 Grossier 07-L 420

4 1/4” 4” 5/8”-11 Grossier 07-L 440

Tambours de polissage

Tambours en coton robuste utilisés avec les pâtes à polir.

Conviennent particulièrement pour accentuer et lustrer les finis existants,

en enlevant les taches sur le métal et en redonnant une nouvelle brillance

aux surfaces usinées.

Vitesse de travail optimale: 1700 - 2200 RPM.

Dia. Largeur Arbre Grain N° de comm.

4 3/4” 2” 5/8”-11 Coton Multi-pli 07-T 425

ABRASIFS POUR LA FINITION DE TUYAUX

Courroies BLENDEX

MC

Méthode rapide et efficace pour produire des finis intégrés sur des

tuyaux de petits diamètres et conduits faits d’acier, d’acier inoxydable et

d’aluminium.

- Donner un nouvel éclat aux pièces ternies.

- Idéal pour rehausser et éclaircir les finis existants, enlever les taches

sur les métaux et apporter un nouveau lustre aux surfaces de travail.

Largeur Longueur Grain/Couleur N° de comm.

1 3/16” 25” Grossier - Beige 07-H 242

1 3/16” 25” Moyen - Marron 07-H 243

1 3/16” 25” Fin - Bleu 07-H 244

1 3/16” 25” Super Fin - Gris 07-H 245

Rouleaux d’entraînement

Pour l’utilisation avec les courroies de conditionnement

BLENDEX MC.

Ce rouleau est fabriqué de polyuréthane résistant. La conception nervurée

assure un entraînement positif des courroies. Les grands côtés en acier

inoxydable préviennent le glissement des courroies.

BALAIS DE CARBONE

Quand les brosses de carbone sont usées à la marque de référence blanche,

la fonction auto-stop est automatique activé et la machine arrête pour ne

Page 23

18

19

pas endommager le moteur. Les brosses peuvent ensuite être remplacées.

Utilisez seulement les brosses de carbone originales WALTER. Ces brosses

sont spécialement conçues pour cet outil. Elles maintiendront la norme de

rendement élevé et assureront une durée de vie maximale du moteur.

Vérifiez ou remplacez les brosses de carbone comme suit:

1. Débranchez l’outil de la prise électrique.

2. Enlevez le couvercle du boîtier du moteur.

3. Les brosses de carbone peuvent être enlevées de leurs supports après

avoir soulevé le ressort et détaché le connecteur.

4. Remplacez les brosses si nécessaire. Toujours remplacer les brosses

en paire.

5. Vérifiez que les nouvelles brosses bougent librement dans leurs

supports. Pour s’assurer que les brosses sont bien en lace après

l’installation, utilisez l’outil électrique en appliquant une lourde

charge pour au moins 30 minutes.

Quand les brosses doivent être remplacées, il est recommandé que l’outil

soit envoyé à un centre de service autorisé WALTER. À part le changement

de brosses, votre outil électrique sera nettoyé, inspecté et lubrifié si

nécessaire.

ENTRETIEN PRÉVENTIF

Votre outil WALTER doit être convenablement entretenu afin demaintenir

une performance optimale.

Utilisez de l’air comprimé à basse pression pour dégager la poussière du

moteur à travers les trous d’aération.

Après usage, enlevez la poussière ainsi que les dépôts de toutes les autres

matières se trouvant sur la partie extérieure de l’outil. Essuyez le câble afin

de prévenir la détérioration due à l’huile et la graisse et vérifiez le câble et

la fiche afin de vous assurer qu’ils sont en bon état.

NOTE: Les fils électriques endommagés doivent être remplacés. Veuillez

vous référer à la liste des pièces de rechange pour le numéro de commande.

POLITIQUE DE GARANTIE

Tous les outils électriques et accessoires WALTER sont vérifiés et

inspectés avant chaque expédition et sont garantis exempts de toutes

défectuosités de matériel ou de fabrication. Si un appareil fait défaut dans

la première année suivant l’achat initial, il doit être retourné port payé

avec preuve d’achat au Centre de Service Autorisé WALTER le plus près.

Si une vérification révèle une défectuosité de matériel ou de fabrication,

WALTER le réparera (ou selon notre décision, l’échangera) sans frais.

Cette garantie ne s’applique pas si un entretien normal est requis, que des

réparations ou des remplacements ont été tentés par d’autres techniciens

que ceux autorisés par WALTER, et ne couvre pas les dommages causés

par les accidents, les modifications, l’utilisation d’accessoires inadéquats,

l’abus ou la mauvaise utilisation, ce qui inclus faire fonctionner l’outil

au-dessus de sa capacité, ainsi que l’utilisation après avoir endommagé

partiellement l’outil. Aucune autre garantie, tant écrite que verbale, n’est

autorisée.

WALTER ne sera, en aucun cas, tenu responsable pour tous dommages

indirects, incidents ou conséquents à la vente du produit. Ce désistement

s’applique durant et après l’échéance des termes de la garantie.

Cette garantie vous confère des droits spécifiques. Les conditions

contenues dans cette garantie ne visent pas à limiter, modifier, retirer,

nier ou exclure toute garantie établie par les législations Provinciales

ou Fédérales. Dans la mesure prescrite, les dispositions de toutes lois

Provinciales ou Fédérales ont priorité sur les conditions de la présente

garantie.

Page 24

20

21

VENTES ET SERVICE WALTER

CANADA

MONTREAL:

5977 Trans Canada Highway

Pointe-Claire QC H9R 1C1

Tel.: (514) 630-2801

Fax: (514) 630-2825

TORONTO:

151 Superior Blvd., Unit 12

Mississauga ON L5T 2L1

Tel.: (905) 795-8555

Fax: (905) 795-8558

VANCOUVER:

1-1595 Cliveden Avenue

Delta BC V3M 6M2

Tel.: (604) 540-4777

Fax: (604) 540-4778

U.S.A.

WINDSOR:

J. Walter Inc.

810 Day Hill Road

Windsor CT 06095-1704

Tel: (860) 298 1100

Fax: (860) 274 4435

BRAZIL

SAO PAULO

Walter Indústria e Comércio Ltda.

Rua Marco Gianini, 426

Butantã, São Paulo, SP

CEP: 05550-000

Tel.: (5511) 3783.9500

Fax: (5511) 3783.9501

ARGENTINA

BUENOS AIRES

Walter S.A.

Dardo Rocha 1032/34

B1754FCD) San Justo

Tel.: (54-11)4441-1889/1648

Fax: (54-11)4441-0258

MEXICO

JALISCO

Walter

Boulevard La Carreta No. 835

PARQUE INDUSTRIAL

BELENES NORTE

CP 45145 Zapopan

Tel.: (52) 33 11 99 15 15

Fax: (52) 01 800 087 51 19

Au Canada, pour communiquer avec le centre de service autorisé Walter le plus près de chez vous,

appelez SANS FRAIS au 1-888-JWALTER (1-888-592-5837) ou consultez notre

site internet: www.walter.com

Page 25

LINE-MATE III

SISTEMA DE TERMINACION

LINEAL

ESPAÑOL

Page 26

1

TITULOS PAG.

Instrucciones de Seguridad ......................................................................... 2

Introducción ................................................................................................ 8

Voltaje ..........................................................................................................

9

Prolongador ................................................................................................ 9

Datos Técnicos ............................................................................................

10

Ilustración del Modelo ................................................................................ 11

Empuñadura & dispositivo de seguridad .................................................... 11

Dispositivo de bloqueo del eje .................................................................... 11

Puesta en Marcha ........................................................................................ 12

Selector de Velocidades Dialspeed

TM

.......................................................... 12

Calibrador de Velocidades ..........................................................................

12

Circuito Electrónico Dynamax TM ................................................................ 12

Instrucciones de Manejo ............................................................................. 13

Accesorios de terminación lineal ................................................................ 13

Cilindros ..................................................................................................... 15

Abrasivos de Terminación ..........................................................................

17

Mantenimiento Preventivo ......................................................................... 18

Garantía ...................................................................................................... 19

Ventas y Servicio WALTER

....................................................................... 20

Gracias por comprar LINE-MATE III

SISTEMA DE TERMINACION LINEAL (Modelo 6268 C)

Este manual de instrucciones ha sido

diseñado para ofrecerle toda la información

sobre el funcionamiento de la máquina

LINE-MATE III.

Para garantizar el funcionamiento perfecto de su Sistema

de acabado lineal, lea atentamente estas instrucciones

antes de utilizar la herramienta. Familiarícese con el

funcionamiento de esta herramienta, sus características

particulares, aplicaciones y limitaciones. También

encontrará consejos útiles en materia de seguridad y

mantenimiento.

Page 27

2

3

agua que ingresa a una herramienta eléctrica incrementa el riesgo de

descarga eléctrica.

d) No abuse del cable. Nunca utilice el cable para transportar la

herramienta eléctrica, tirando o desconectando la herramienta

eléctrica. Mantenga el cable lejos del calor, aceite, bordes afilados o

piezas móviles.

Cables enredados o dañados aumentan el riesgo de descarga

eléctrica.

e) Cuando utilice una herramienta eléctrica al aire libre, utilice un cable

de extensión adecuado para uso al exterior. La utilización de un cable

de extensión adecuado para uso al exterior reduce los riesgos de

descarga eléctrica.

3) Seguridad Personal

a) Manténgase alerta, vea lo que está haciendo y utilice el sentido

común cuando opere una herramienta eléctrica. No utilice la

herramienta mientras esté cansado o bajo influencia de drogas,

alcohol o medicación. Un momento de falta de atención durante el

manejo de herramientas eléctricas puede resultar en serios daños

personales.

b) Utilice equipo de seguridad. Siempre utilice protección ocular.

Equipo de seguridad como máscara para polvo, calzado de seguridad

anti deslizante, cazco, o protección auditiva adecuada, utilizados en

las condiciones apropiadas para reducir riesgos personales.

c) Evite el encendido accidental. Asegúrese que el interruptor esté en

posición de apagado. Transportar las herramientas eléctricas con

el dedo en el interruptor o conectar las herramientas eléctricas que

tienen el interruptor encendido invita a accidentes.

d) Retire cualquier llave de ajuste antes de encender la herramienta

eléctrica. Una llave que se deje en la máquina cuando se encienda

puede causar serias lesiones personales.

e) Mantenga los pies en equilibrio y buen balance todo el tiempo. Esto

permite un mejor control de la herramienta eléctrica en situaciones

inesperadas.

f) Vístase adecuadamente. No utilice ropa suelta o joyas. Mantenga su

cabeza, ropa y guantes lejos de las partes móviles. Ropa suelta, joyas

o el cabello largo pueden ser atrapados en las partes móviles.

Instrucciones de seguridad generales

Todas las herramientas eléctricas WALTER son fabricadas bajo normas que

rigen la manufactura, rendimiento y seguridad de este tipo de herramienta.

ADVERTENCIA – Para reducir el riesgo de lesiones, el usuario debe

leer el manual de instrucciones.

Lea todas las instrucciones. El no seguir todas las instrucciones que figuran

a continuación puede dar lugar a una descarga eléctrica, incendio y/o serios

daños.

El término “herramienta eléctrica” �en todas las advertencias que figuran a

continuación se refieren a las herramientas eléctricas que se alimentan de la

red eléctrica (cable) o las que funcionan con batería (sin cable).

CONSERVE ESTAS INSTRUCCIONES

1) Seguridad del área de trabajo

a) GMantenga el área de trabajo limpia y bien iluminada. Las áreas

oscuras invitan a los accidentes.

b) No utilice herramientas eléctricas en atmósferas explosivas, como en

presencia de líquidos inflamables, gases o polvo. Las herramientas

eléctricas producen chispas que pueden encender polvo o humos.

c) Mantenga a los niños o transeuntes a distancia de la herramienta

eléctrica mientras esté funcionando. Las distracciones pueden causar

la pérdida del control.

2) Seguridad eléctrica

a) a) La potencia de la herramienta eléctrica debe coincidir con la

potencia del toma corriente. Nunca modifique el enchufe de ninguna

manera. No utilice ningún adaptador para enchufar la herramienta a

tierra. Los enchufes no modificados y la correspondiente de salidas

de electricidad reducirán la probabilidad de descarga eléctrica.

b) Evite el contacto con cualquier cuerpo a tierra o superficies a

tierra como tuberías radiadores o refrigeradores. Hay incremento de

riesgo de descarga eléctrica si su cuerpo está a tierra.

c) No exponga las herramientas eléctricas a la lluvia o humedad. El

Page 28

4

5

5) Servicio Técnico

a) Haga que su herramienta eléctrica sea reparada por una persona

calificada utilizando solamente piezas originales. De este modo se

garantizará que la seguridad de la herramienta eléctrica se mantenga.

Funcionamiento eléctrico

a) Esta herramienta eléctrica está destinada a funcionar como una

máquina lijadora, con cepillo de alambre, o pulidora.

Lea todas las advertencias de seguridad, instrucciones, ilustraciones