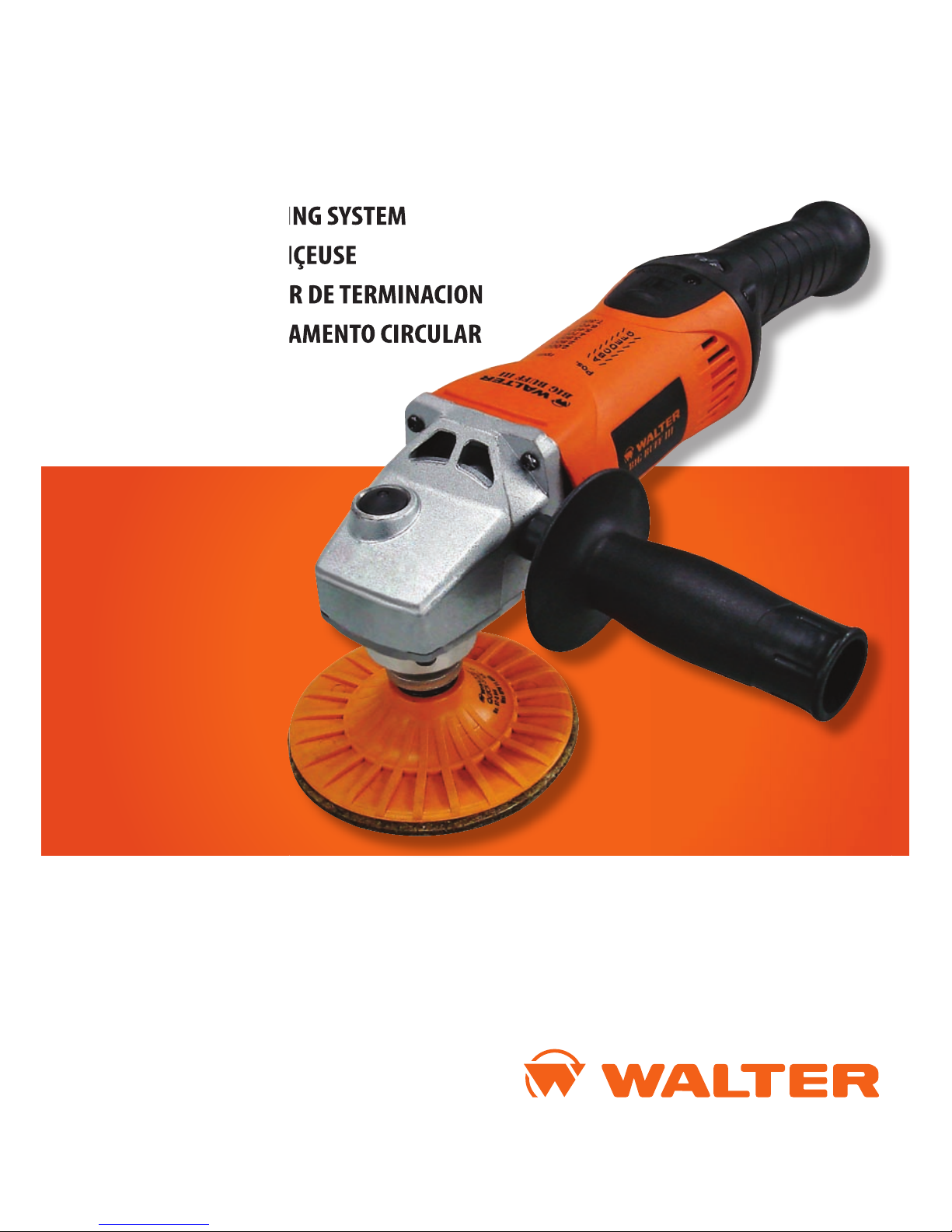

Walter BIG BUFF III, 6265 C User Manual

USER GUIDE

GUIDE DE L’UTILISATEUR

MANUAL DEL USUARIO

MANUAL DO PROPRIETÁRIO

BIG BUFF III

(6265 C)

CIRCULAR FINISHING SYSTEM

POLISSEUSE / PONÇEUSE

SISTEMA CIRCULAR DE TERMINACION

SISTEMA DE ACABAMENTO CIRCULAR

BIG BUFF III

CIRCULAR FINISHING SYSTEM

(Model 6265 C)

ENGLISH

E N GLI S H

BIG BUFF III

CIRCULAR FINISHING SYSTEM

(Model 6265 C)

1

Thank you for purchasing the BIG BUFF III

CIRCULAR FINISHING SYSTEM (Model 6265 C)

This operating instruction booklet has been designed to give

you all the information on the BIG BUFF III.

To ensure perfect functioning of your circular finishing

system, carefully read these instructions before using the

tool. Familiarize yourself with this tool's operation, its

particular features, applications and limitations. You will

also find useful tips on safety and maintenance.

TITLES PAGES

General Safety Rules ...................................................................................2

Introduction .................................................................................................8

Voltage .........................................................................................................

9

Extension cord .............................................................................................9

Technical Data .............................................................................................

9

Model illustration ........................................................................................10

Side handle ..................................................................................................10

Spindle lock .................................................................................................10

Switch ..........................................................................................................10

Dialspeed TM selector .................................................................................11

Dialspeed TM settings .................................................................................11

Dynamax TM Electronics ............................................................................11

Operation .....................................................................................................12

High Productivity Abrasives ........................................................................

12

Carbon Brushes ............................................................................................15

Preventive Maintenance ..............................................................................15

Warranty Policy ...........................................................................................

16

WALTER Sales and Service ........................................................................

17

2

3

General safety rules

Every WALTER power tool is produced in accordance with applicable

standards governing the manufacture, performance and safety of power

tools.

WARNING – To reduce the risk of injury, user must read instruction manual.

Read all instructions. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury. The term “power tool”in

all of the warnings listed below refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit

. Cluttered or dark areas invite

accidents.

b) Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust

. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in

any way.

Do not use any adapter plugs with earthed (grounded) power

tools.

Unmodified plugs and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling

or unplugging the power tool. Keep cord away from heat, oil,

sharp edges or moving parts

. Damaged or entangled cords increase

the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord

suitable for outdoor use

. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in

serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety

equipment such as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position

before plugging in. Carrying power tools with your finger on the

switch or plugging in power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before turning the power

tool on.

A wrench or a key left attached to a rotating part of the power tool

may result in personal injury.

e) Do not over-reach. Keep proper footing and balance at all

times. This enables better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

used. Use of these devices can reduce dust-related hazards.

4

5

Operation of this power tool

a) This power tool is intended to function as a sander, wire brush,

or polisher. Read all safety warnings, instructions, illustrations

and specifications provided with this power tool. Failure to follow

all instructions listed below may result in electric shock, fire and/or

serious injury.

b) Operations such as grinding or cutting-off are not recommended

to be performed with this power tool. Operations for which the

power tool was not designed may create a hazard and cause personal

injury.

c) Do not use accessories which are not specifically designed

and recommended by Walter. Just because the accessory can be

attached to your power tool, it does not assure safe operation.

d) The rated speed of the accessory must be at least equal to the

maximum speed marked on the power tool. Accessories running

faster than their RATED SPEED can break and fly apart.

e) The outside diameter and the thickness of your accessory must

be within the capacity rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded or controlled.

f) The arbour size of wheels, flanges, backing pads or any other

accessory must properly fit the spindle of the power tool.

Accessories with arbour holes that do not match the mounting

hardware of the power tool will run out of balance, vibrate

excessively and may cause loss of control.

g) Do not use a damaged accessory. Before each use inspect the

accessory such as abrasive wheels for chips and cracks, backing

pad for cracks, tear or excess wear, wire brush for loose or

cracked wires. If power tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After inspecting and

installing an accessory, position yourself and bystanders away

from the plane of the rotating accessory and run the power tool

at maximum no-load speed for one minute. Damaged accessories

will normally break apart during this test time.

h) Wear personal protective equipment. Depending on application,

use face shield, safety goggles or safety glasses. As appropriate,

wear dust mask, hearing protectors, gloves and workshop apron

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer

at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and

off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments,

changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are dangerous

in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits etc., in accordance

with these instructions and in the manner intended for the

particular type of power tool, taking into account the working

conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a

hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair person using

only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

6

7

Further safety instructions for all operations

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel,

backing pad, brush or any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction opposite of the

accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the work

piece, the edge of the wheel that is entering into the pinch point can dig

into the surface of the material causing the wheel to climb out or kick out.

The wheel may either jump toward or away from the operator, depending

on direction of the wheel’s movement at the point of pinching. Abrasive

wheels may also break under these conditions. Kickback is the result of

power tool misuse and/or incorrect operating procedures or conditions and

can be avoided by taking proper precautions as given below.

a) Maintain a firm grip on the power tool and position your

body and arm to allow you to resist kickback forces. Always

use auxiliary handle, if provided, for maximum control over

kickback or torque reaction during start-up. The operator can

control torque reactions or kickback forces, if proper precautions are

taken.

b) Never place your hand near the rotating accessory. Accessory

may kickback over your hand.

c) Do not position your body in the area where power tool will

move if kickback occurs. Kickback will propel the tool in direction

opposite to the wheel’s movement at the point of snagging.

d) Use special care when working corners, sharp edges etc. Avoid

bouncing and snagging the accessory. Corners, sharp edges or

bouncing have a tendency to snag the rotating accessory and cause

loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed saw

blade.

Such blades create frequent kickback and loss of control.

capable of stopping small abrasive or work piece fragments. The

eye protection must be capable of stopping flying debris generated by

various operations. The dust mask or respirator must be capable of

filtrating particles generated by your operation. Prolonged exposure

to high intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from work area.

Anyone entering the work area must wear personal protective

equipment. Fragments of work piece or of a broken accessory may

fly away and cause injury beyond immediate area of operation.

j) Hold power tool by insulated gripping surfaces only, when

performing an operation where the cutting accessory may

contact hidden wiring or its own cord. Cutting accessory

contacting a “live”wire may make exposed metal parts of the power

tool “live” and shock the operator.

k) Position the cord clear of the spinning accessory. If you lose

control, the cord may be cut or snagged and your hand or arm may

be pulled into the spinning accessory.

l) Never lay the power tool down until the accessory has come to

a complete stop. The spinning accessory may grab the surface and

pull the power tool out of your control.

m) Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could snag your

clothing, pulling the accessory into your body.

n) Regularly clean the power tool’s air vents. The motor’s fan will

draw the dust inside the housing and excessive accumulation of

powdered metal may cause electrical hazards.

o) Do not operate the power tool near flammable materials. Sparks

could ignite these materials.

p) Do not use accessories that require liquid coolants. Using water

or other liquid coolants may result in electrocution or shock.

8

9

VOLTAGE

Before connecting the tool, make sure that the voltage shown on the rating

plate is the same as the power source.

Operating the tool on a voltage other than specified on its rating plate, may

result in personal injury to the user and damage to the unit.

EXTENSION CORD

When an extension cord is required, use one that is sufficient for the power

requirement of the tool. Extension cords of inadequate wire size cause a

serious drop in voltage, loss of power and possible motor damage. To limit

line voltage drop to a safe level, refer to the following table:

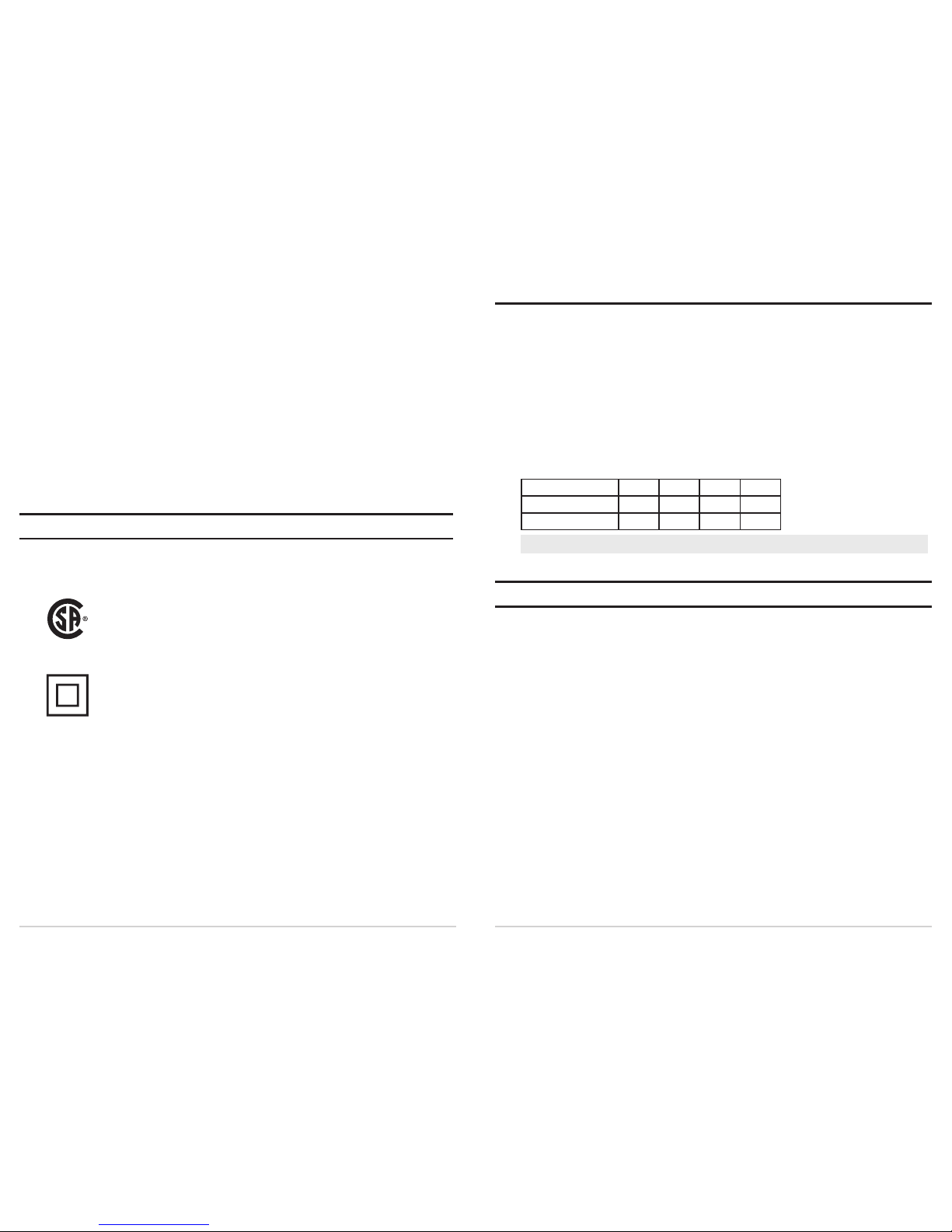

Length in meters 8 15 23 30

Length in feet 25 50 75 100

Wire size AWG

14 14 12 10

NOTE: Extension cords that are used outdoors must be approved for outdoor use.

TECHNICAL DATA

MODEL 6265 C

Voltage .........................120 V AC; 60 Hz

Amperage .....................12

No-load speed ..............POS.A POS.B POS.C POS.D POS.E POS.F POS.G

.....................................2,000 2,800 3,800 4,700 5,400 6,400 7,300

Spindle Thread ............. 5/8“ -11 NC

Weight .........................2,66kg - 5lb. 14oz

MODEL 6265 C

Voltage .........................220 - 240 V AC; 50 - 60 Hz

Amperage .....................7,2

No-load speed ..............POS.A POS.B POS.C POS.D POS.E POS.F POS.G

.....................................2,000 2,800 3,800 4,700 5,400 6,400 7,300

Spindle Thread ............. M14

Weight ..........................2,66kg - 5lb. 14oz

Safety Warnings Specific for Sanding Operations:

a) Do not use excessively oversized sanding disc paper. Follow

manufacturers recommendations, when selecting sanding paper.

Larger sanding paper extending beyond the sanding pad presents

a laceration hazard and may cause snagging, tearing of the disc or

kickback.

Safety Warnings Specific for Polishing Operations:

a) Do not allow any loose portion of the polishing bonnet or its

attachment strings to spin freely. Tuck away or trim any loose

attachment strings. Loose and spinning attachment strings can

entangle your fingers or snag on the work piece.

INTRODUCTION

Your WALTER power tool is precision built to meet the highest industrial

standards. For maximum performance and longest tool life, follow the

operating instructions and service procedures outlined in this manual.

This tool is CSA certified.

This tool is double insulated, it does not have to be grounded.

It may be safely operated from a grounded or ungrounded

receptacle. It is supplied with a 2-conductor power cord and

a polarized plug (one blade wider than the other). The plug

will fit only one way into a polarized outlet. If the plug does

not fit, have the outlet replaced by a qualified electrician. If an

extension cord is necessary, only one that is polarized must be

used. Do not change the plug in any way.

In order to maintain the safety features of the double insulation, the

housing must not be drilled to affix nameplates or the like. Self-adhesive

labels may be used for this purpose.

10

11

DIALSPEED™ SELECTOR

Select the required speed by rotating speed selector (4). Positions A-G

roughly equal the following no load revolutions per minute:

Pos. A B C D E F G

RPM 2,000 2,800 3,800 4,700 5,400 6,400 7,300

DIALSPEED™ SETTINGS

Set speed selector (4) to position D, and adjust either up or down until you

have found a speed that meets your surface finishing requirements.

The correct setting will depend on:

a) Type of material being worked

c) Amount of pressure being applied

b) Abrasive accessory being used

d) Surface finish required

DYNAMAX™ ELECTRONICS

The built-in electronic feedback circuit continuously monitors the load on

the motor and adjusts power as required to maintain a virtually constant

speed.

Should the machine be subjected to overload for an extended period, for

example when being run at a lower speed setting, the rotation speed will

be decreased electronically to protect the motor. Rather than stopping

completely, the machine will continue to run slowly to allow the motor to

cool. After a brief period, by switching the machine off and on again, it can

then be used again at the rated load.

When used for extended periods, it is quite normal for the machine to

become quite warm, with the thermal overload protection, as described

above, cutting in whenever necessary. With practice, the user will feel to

what extent the machine can be loaded at each speed setting for continuous

uninterrupted operation.)

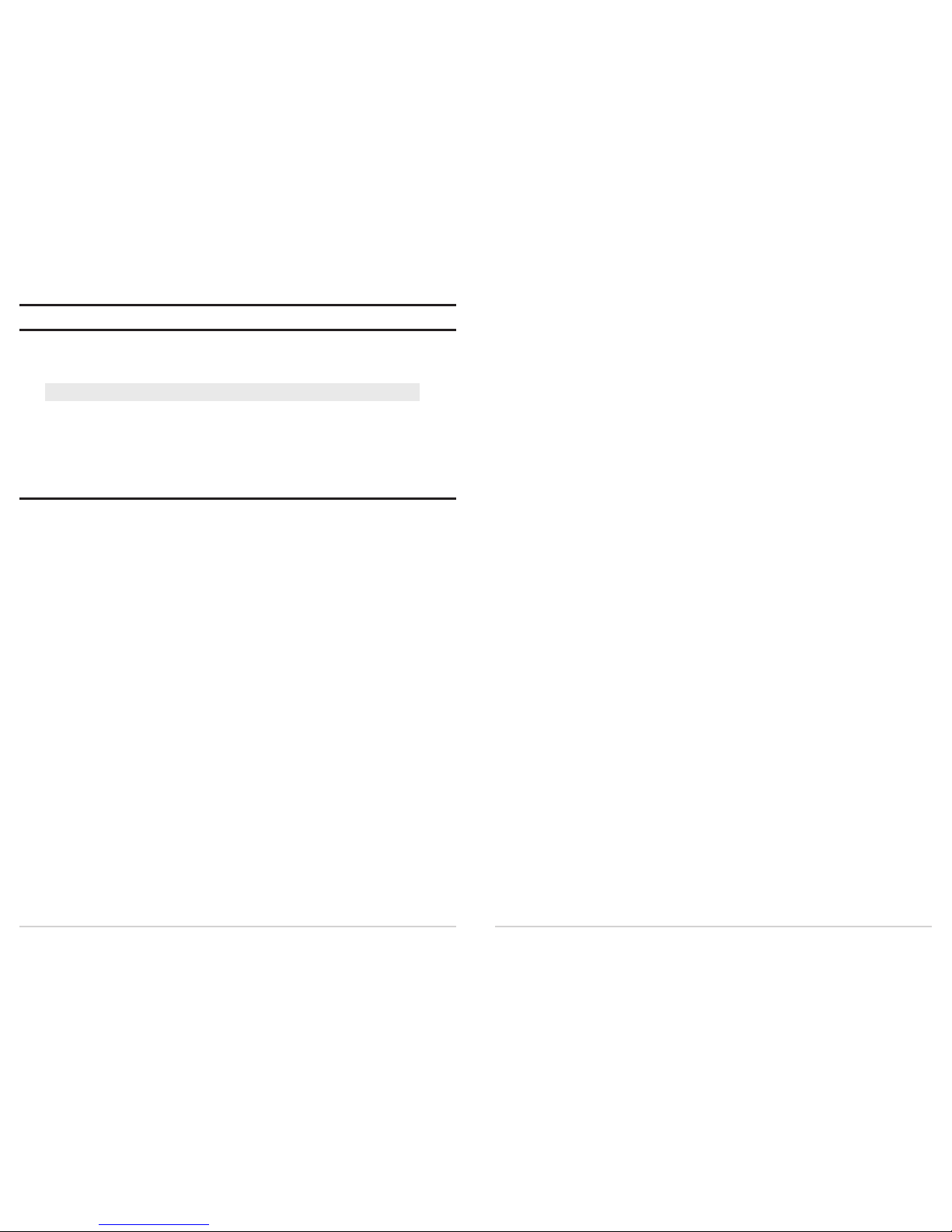

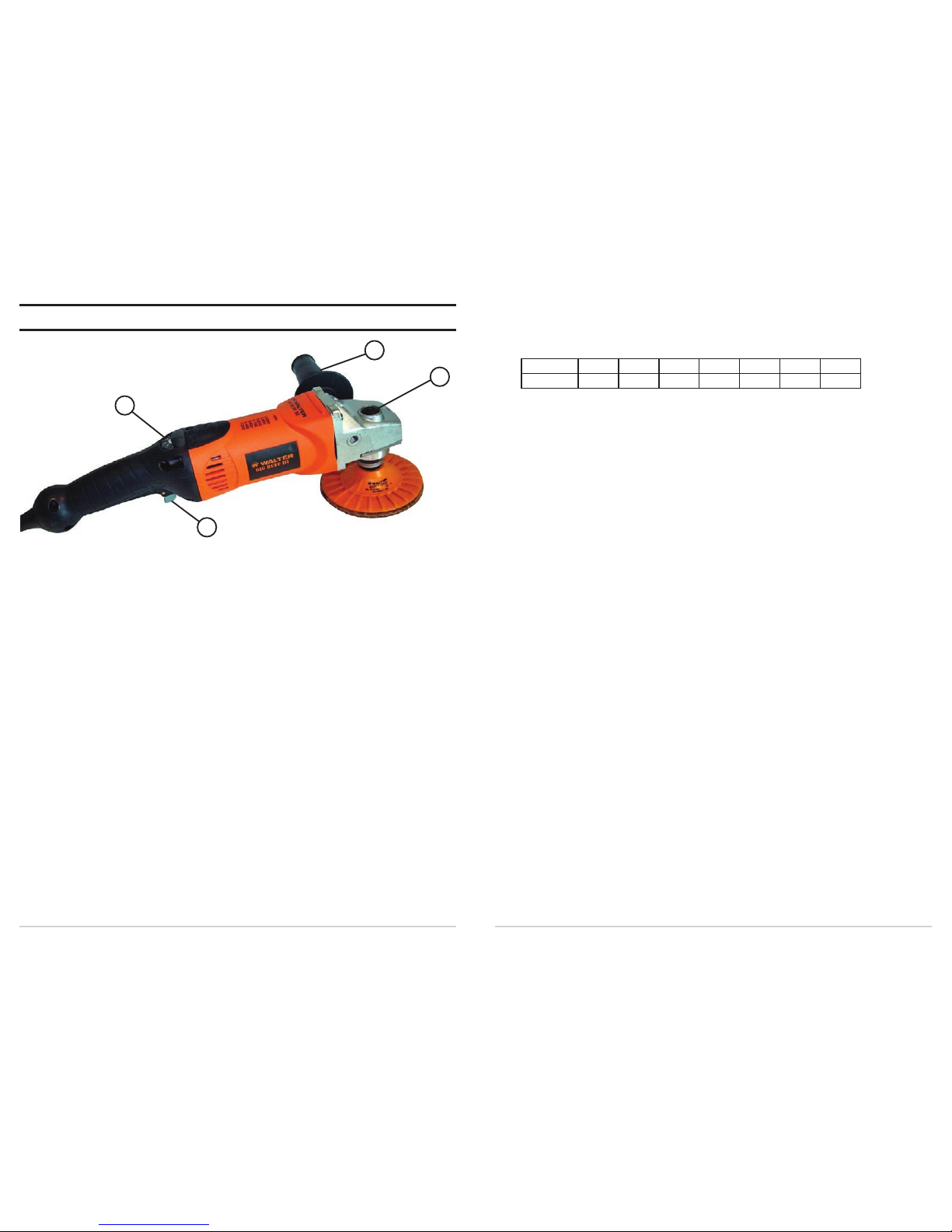

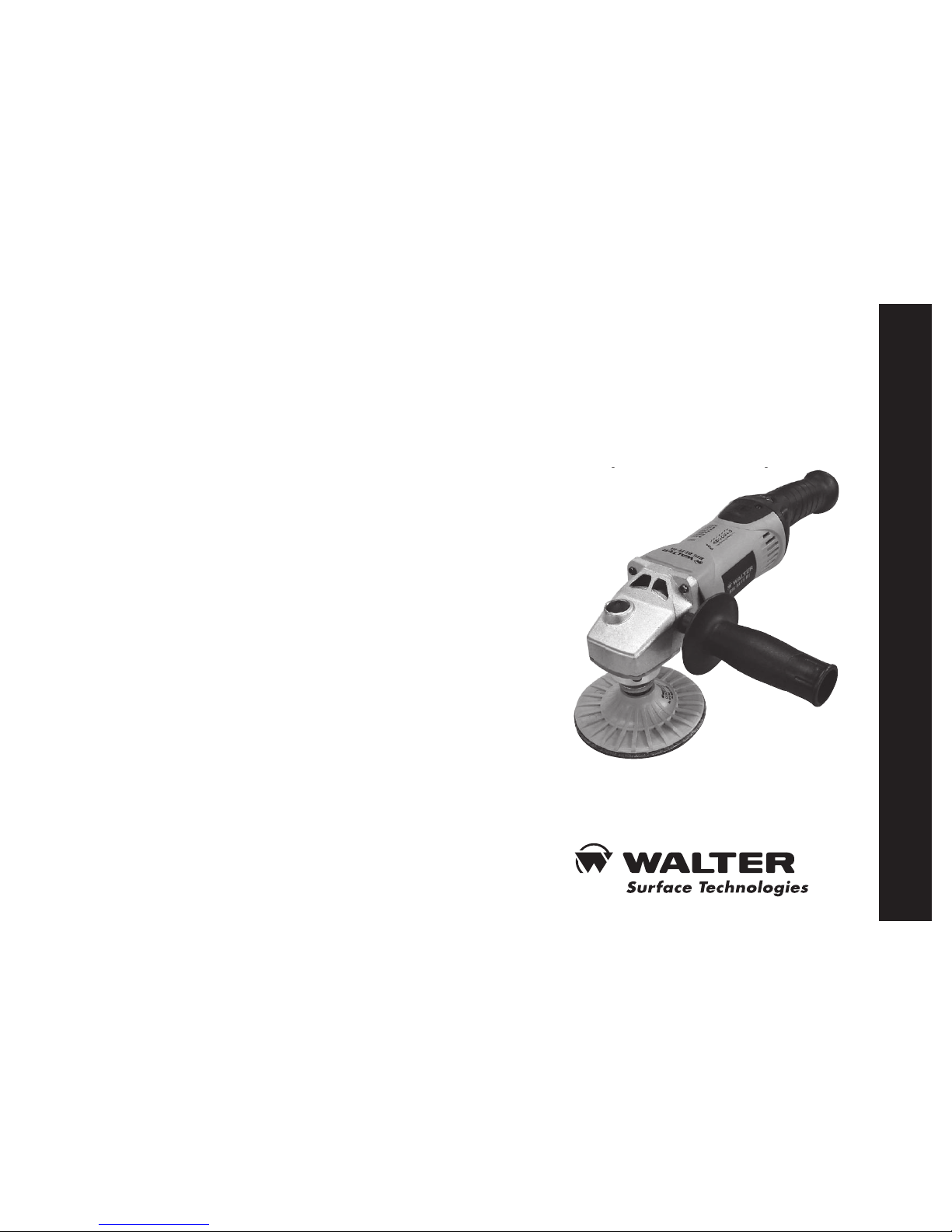

MODEL ILLUSTRATION

3

2

4

1

SIDE HANDLE

Side handle (1) may be mounted on either side of the gear housing for

greater convenience in both right and left hand operation. For reasons of

safety and better control, the side handle must always be used.

SPINDLE LOCK

To mount or remove abrasive wheels and accessories, disconnect the

machine from the power supply. Depress spindle lock button (2), while

rotating the spindle by hand until the locking mechanism is engaged. With

the spindle in a locked position, use the appropriate pin key or open-end

spanner for the accessory being utilized. Never depress the locking button

while the tool is turned on.

SWITCH

To start, push locking switch (3) forward, locking it in the ON position.

To stop, press up on the long part of the switch, returning it to the OFF

position.

12

13

BLENDEX

Surface Conditioning Discs

-Grid line conditioning

4 1/2” 5”

-Cleaning and deburring

Coarse tan

07-R 452 Coarse tan 07-R 452

-Oxidation removal Medium Medium 07-R 452

-Paint dulling and stripping

maroon

07-R 453 maroon 07-R 452

Fine blue

07-R 454

-Hiding imperfections

-Produce textured finishes

6” 7”

Coarse tan

07-R 602

Coarse tan

07-R 702

Medium Medium

maroon

07-R 603

maroon

07-R 703

Fine blue

07-R 604

Fine blue

07-R 704

POLISHING DISCS

-Upgrade #4 finish

4 1/2”

Felt Disc 07-T 450

-Produce food grade finish

6”

Felt Disc 07-T 600

-Reflective surface finishing

7”

Felt Disc 07-T 700

-Restore mill-buffed finishes

4 1/2”

High Polish Disc 07-T 454

-Polish to a mirror finish

6”

High Polish Disc 07-T 604

7”

High Polish Disc 07-T 704

Blue = White polishing Paste

No Animal fat 07-T 901 approx. 600 g

Content Blue Mirror Finishing Paste

07-T 905 approx. 650 g

OPERATION

Please be sure to read and observe, the “SAFETY INSTRUCTIONS” at

the beginning of this manual. Use only those WALTER accessories with

maximum dimensions of 6” in diameter and a maximum safe operating

speed of at least 8,800 R.P.M.

The use of any accessories other than those recommended may be

hazardous. Inspect all accessories before using. Do not use any that may

be damaged. Screw all mounted accessories into spindle and secure firmly

with a spanner.

For maximum performance and best efficiency, apply a steady and even

pressure.

Do not use excessive force. Always wear eye protection when working

with this power tool.

HIGH PRODUCTIVITY ABRASIVES

BACKING PADS INTERFACE PADS

Patented design with a unique centering

Ideal to work on curved surfaces

Pin which guarantees a centered fit every

the interface pad will help to achieve

time for a vibration-free performance. a higher quality finish

Dia. M14x2.0 5/8” -11

4 1/2”

07-Q 049

4” 07-Q 042 07-Q 044

6”

07-Q 064

4 1/2” 07-Q 047 07-Q 049

7”

07-Q 074

5” - 07-Q054

6” 07-Q 062 07-Q 064

7” - 07-Q074

FLAP DISCS

-Weld removal

4 1/2” 6”

- Blending in welds Grit 40 07-Q 454 Grit 40 07-Q 604

-Blending uneven edges Grit 60 07-Q 456 Grit 60 07-Q 606

-Breaking edges Grit 80 07-Q 458 Grit 80 07-Q 608

-Light scale removal Grit 120 07-Q 462 Grit 120 07-Q 612

-Removing corrosion

14

15

SAFETY INSTRUCTIONS

-Do not exceed rated maximum RPM.

-Wear eye, face and body protection.

-Use in properly ventilated areas.

-Keep contact surface of backing pad clean.

-Maintain working and of 2 to 5 with the work piece for best results.

-Store the QUICK-STEP flap discs in an area with 50% humidity at 21° C

( 70° F).

CARBON BRUSHES

When the carbon brushes are worn down, the Auto-Stop feature will

automatically turn the machine off in order not to damage the motor.

The brushes must then be replaced. Use only genuine WALTER carbon

brushes. These brushes are specially made for this tool; they will maintain

its high performance standard and ensure maximum life of the motor.

To check or replace carbon brushes:

1. Disconnect the tool from power supply.

2. Remove motor housing cover.

3. Carbon brushes may be pulled from their holders after lifting spring and

detaching the connector.

4. Replace brushes if necessary. Always replace them in pairs.

5. Check that the new brushes move freely in their holders. To help seat the

carbon brushes properly after they have been installed, use the power

tool without applying a heavy load for at least 30 minutes.

However, when the carbon brushes require replacement, it is recommended

that the tool be sent to a WALTER Factory Service Center or a WALTER

Authorized Service Center. Apart from changing the brushes, your power

tool will be cleaned, inspected and lubricated as required. If new parts are

necessary, only genuine WALTER replacement parts will be used.

PREVENTIVE MAINTENANCE

Your WALTER

power tool should be properly maintained to insure

continued high performance. Use low pressure compressed air to blow

out dust from the motor through the vent openings. Clean dust and dirt

deposits from the exterior of the tool. Clean the power cord to prevent

deterioration from oil and grease and check for possible damage.

Note: Damaged cord sets must be replaced. Refer

to Spare Parts List for the ordering number.

FX

Surface Cleaning Discs

-Clean without gouging

-Strip paint and coatings

-Remove rust and scale

-Remove adhesive labels

4 ½” 07-X 845 Use only with 4” diameter backing pads

6” 07-X 860 Use only with 4 ½ diameter backing pads

* Can replace wire brushes Max RPM ; 4,500

* Open web structure which resists loading Optimal RPM ; 2, 000 to 3, 000

QUICK-STEP

Trial Pack

The answer to all your finishing needs, from weld blending to a mirror #8

finish.

Includes: 1 backing pad, 1 flap disc ( grit 10),9 Blendex discs (1 extra

coarse, 2 coarse),3 medium (2 fine and 1 super fine), 1 felt disc, 1 high

polish disc, 1 mini white paste and 1 mini blue paste.

4 ½” M14x 2.0 07-Q952

4 ½” 5/8” – 11 07-Q 953

MOUNTING INSTRUCTION

The WALTER QUICK-STEP is a patented, fully integrated surface

finishing system for use on portable angle grinders/sanders.

-Use only specially designed WALTER QUICK STEP discs on QUICK-

STEP backing pads for safety performance.

-To mount disc on pad, center disc over pin and press firmly onto pad.

-Make sure that you apply pressure around the center of the disc so that the

center hole is firmly pushed over the centering pin of the pad.

-Slight torquing of disc against pad before starting will increase initial

adherence.

16

17

WARRANTY POLICY

All WALTER power tools and accessories are inspected and tested before

shipping and are guaranteed to be free from any defect in material and

faulty workmanship. Should any malfunction occur within one year from

the date of original purchase, return the complete tool prepaid, with proof

of purchase, to the nearest WALTER Factory or Authorized Service Center.

If an examination shows that the malfunction was caused by defective

material or faulty workmanship, WALTER will repair (or at our option,

replace) without charge. This warranty does not apply when; normal

maintenance is required, repairs or replacements have been made or were

attempted by anyone other than WALTER authorized service personnel,

and does not cover any damage caused by accidents, modifications, use of

improper accessories, abuse or misuse, which also includes overloading

the tool beyond its rated capacity as well as its continued use after partial

failure. No other warranty, written or verbal, is authorized.

In no event shall WALTER be liable for any indirect, incidental or

consequential damages from the sale of the product. This disclaimer

applies both during and after the term of this warranty.

This warranty gives you specific rights. The provisions contained in this

warranty are not intended to limit, modify, take away from, disclaim or

exclude any warranties set forth in any provincial legislation. To the extent

required by law, the provisions in any provincial, or federal legislation with

respect to warranties take precedence over the provisions in this warranty.

WALTER SALES AND SERVICE

CANADA

MONTREAL:

5977 Trans Canada Highway

Pointe-Claire QC H9R 1C1

Tel.: (514) 630-2801

Fax: (514) 630-2825

TORONTO:

151 Superior Blvd., Unit 12

Mississauga ON L5T 2L1

Tel.: (905) 795-8555

Fax: (905) 795-8558

VANCOUVER:

1-1595 Cliveden Avenue

Delta BC V3M 6M2

Tel.: (604) 540-4777

Fax: (604) 540-4778

U.S.A.

WINDSOR:

J. Walter Inc.

810 Day Hill Road

Windsor CT 06095-1704

Tel: (860) 298 1100

Fax: (860) 274 4435

BRAZIL

SAO PAULO

Walter Indústria e Comércio Ltda.

Rua Marco Gianini, 426

Butantã, São Paulo, SP

CEP: 05550-000

Tel.: (5511) 3783.9500

Fax: (5511) 3783.9501

ARGENTINA

BUENOS AIRES

Walter S.A.

Dardo Rocha 1032/34

B1754FCD) San Justo

Tel.: (54-11)4441-1889/1648

Fax: (54-11)4441-0258

MEXICO

JALISCO

Walter

Boulevard La Carreta No. 835

PARQUE INDUSTRIAL

BELENES NORTE

CP 45145 Zapopan

Tel.: (52) 33 11 99 15 15

Fax: (52) 01 800 087 51 19

In Canada call toll free 1-888-JWALTER and in the U.S.A. 1-866-JWALTER for the location

of an Authorized Service Center closest to you or visit our web site: www.walter.com.

BIG BUFF III

POLISSEUSE/PONÇEUSE

(Modèle 6265 C)

FRANÇAIS

E N G L I S H

BIG BUFF III

CIRCULAR FINISHING SYSTEM

(Model 6265 C)

1

Nous vous remercions d’avoir choisi le BIG BUFF III

POLISSEUSE/PONÇEUSE 6” (Modèle 6265 C)

Plus vous serez familiarisé avec le Big Buff III, mieux vous

pourrez exploiter cet appareil.

C’est pourquoi nous vous prions de lire attentivement ce

mode d’emploi avant de mettre le l’outil en service. Vous

y trouverez des indications importantes pour une utilisation

sans problème, ainsi que des informations importantes

relatives à la sécurité et à la maintenance du Big Buff III.

TITRES PAGE

Directives de sécurité .................................................................................. 2

Introduction ................................................................................................ 9

Voltage .........................................................................................................

9

Rallonge électrique ..................................................................................... 9

Caractéristiques Techniques ........................................................................

10

Illustration du modèle ................................................................................. 10

Poignée latérale ........................................................................................... 11

Dispositif de blocage de l’arbre .................................................................. 11

Interrupteur ................................................................................................. 11

Sélecteur de vitesses Dialspeed MC ........................................................... 11

Réglage Dialspeed MC ............................................................................... 11

Électronique Dynamax MC .........................................................................

12

Fonctionnement .......................................................................................... 12

Abrasifs haute productivité ......................................................................... 13

Balais de carbone ........................................................................................ 16

Entretien préventif ...................................................................................... 16

Politique de garantie ................................................................................... 17

Ventes et service WALTER .........................................................................

18

Loading...

Loading...