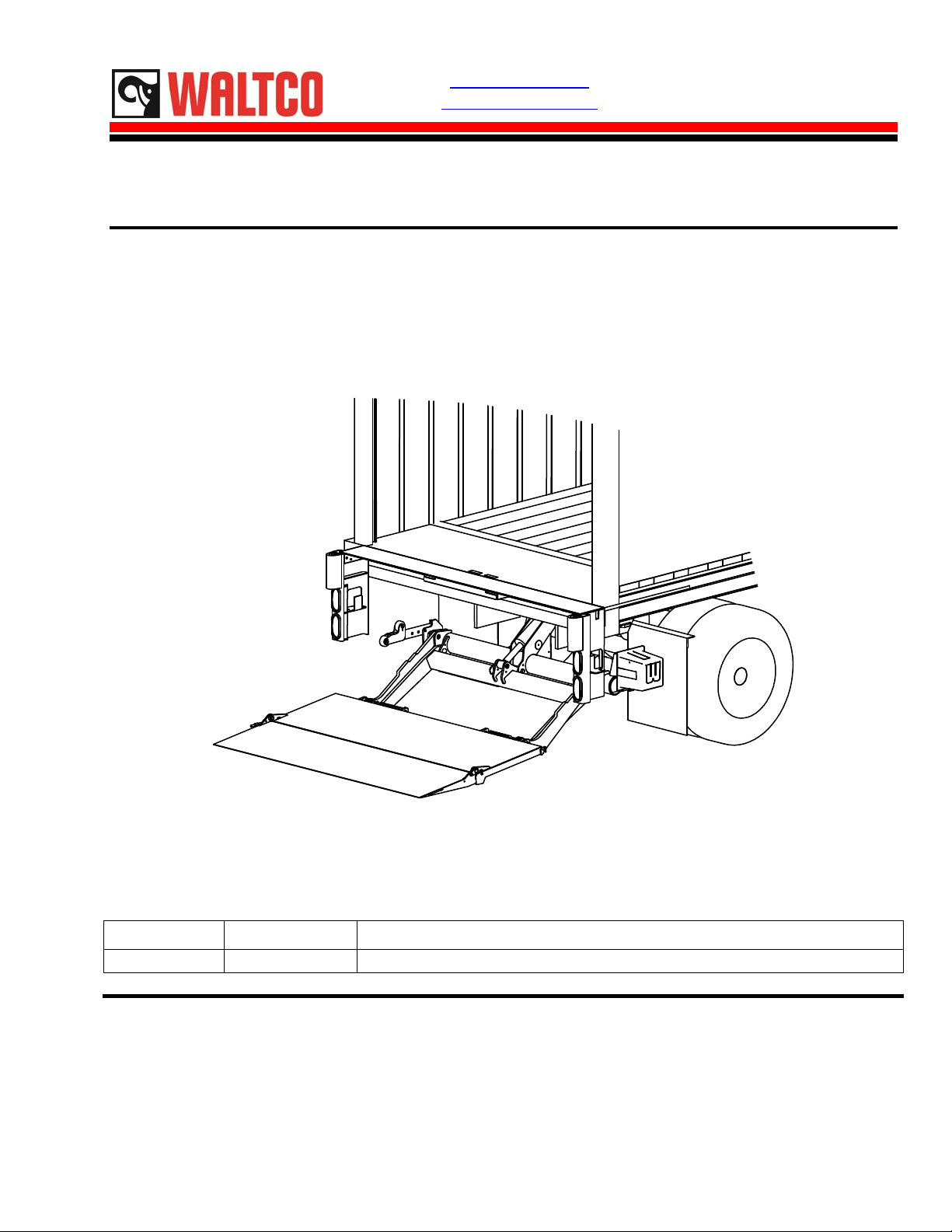

Waltco EM25, EM33 User Manual

www.waltco.com Phone: 800.211.3074

sales@waltco.com Fax: 800.211.3075

Owner’s Manual

EM25, EM33

2500, 3300 lb. Capacity Flipaway Liftgates

ast Change

L

Date Page(s) Description

4-2016 17 P17 – Added bleeding instructions

GR02693

Waltco Lift Corp. Waltco Lift Corp. Waltco Lift Inc.

Corporate Office United State United States Canada

285 Northeast Ave. 620 S Hambledon Ave. 90 North Queen St.

Tallmadge, OH 44278 City of Industry, CA 91744 Etobicoke, ON M8Z 2C5

P: 330.633.9191 P: 626.964.0990 P: 888.343.4550

F: 330.633.1418 F: 626.964.0149

EO:7915 Rev 13

4-2016 80126402

Table of Contents

I

mproper operation and maintenance of this liftgate could result in severe

Page 2

personal injury or death.

Read and understand the contents of this manual and all warning and operation

decals before operating and/or performing maintenance on this liftgate.

Introduction ..................................................................................................................... 3

Safety Information ........................................................................................................... 4

Warranty ......................................................................................................................... 6

Liftgate Terminology ....................................................................................................... 7

Operation Instructions .................................................................................................... 10

Preventive Maintenance ................................................................................................ 11

Placement of Decals ...................................................................................................... 18

Lubrication Instructions .................................................................................................. 19

Schematics .................................................................................................................... 20

How to Order Parts ........................................................................................................ 24

INTRODUCTION

Page 3

If anyone observes improper installation, improper operation, or damage, they should immediately

contact a qualified person for assistance and correction. We strongly urge anyone that has any

questions or doubts as to the installation, condition, use, operation, maintenance or repair of the liftgate

to contact us at Waltco where we have qualified personnel that will be happy to assist you. Telephone

numbers and addresses of these locations are listed in the Owner’s Manual and Installation

Instructions.

INSTALLATION

Waltco

installation and operation of the liftgate, along with the equipment on which the liftgate is being

installed. Waltco’s installation instructions are not intended to give rationale for all the instructions that

are given; however, it is the intent of these instructions to give the installer both the operations and

what we believe to be the most desirable sequence of implementing these operations. These

instructions can in no way expand into an area where they will replace a qualified person, or clear

thinking and a basic knowledge that must be possessed by the installer.

It has been our experience that a knowledgeable journeyman following these instructions and

observing the operation of the liftgate will have a sufficient comprehension of the liftgate to enable this

person to troubleshoot and correct all normal problems that may be encountered.

Failure to follow the installation instructions, adjustments and mounting dimensions may result in

improper and unsafe operation of the liftgate. Unauthorized alterations of the liftgate can cause an

undesirable and dangerous condition.

OWNER’S MANUAL

The Waltco Owner’s Manual is intended to act as a guide for operation and routine maintenance but

is no way intended to encourage usage or repair of the liftgate by those who are not qualified to do so.

liftgates should only be installed by those with sufficient basic skills to understand the

The contents of the owner’s manual include, but are not limited to general operation instructions,

routine lubrication, parts lists, and an outline of things that should be checked but may not be obvious

to those not technically qualified. This manual assumes the liftgate is properly installed, undamaged

and operates correctly. Improper installation, improper operation, or damage should be immediately

corrected by a qualified person.

INSPECTION

As par

t of the regular inspection of a liftgate and after damage or suspicion of an overload, inspect

for wear or structural damage and make necessary repairs or replacements. Check all structural

components and their attachment to the liftgate for cracked welds, loose fasteners, wear and part

deformation. Check cylinder and hose for leaks. Inspections and repairs should be made by a qualified

mechanic.

REPLACEMENT PARTS

Use only Waltco original equipment replacement parts. Components of other liftgate manufacturers

may outwardly appear to be the same but are not interchangeable with Waltco products. Waltco

components are specifically designed for safety requirements, reliability and compatibility with our

products. Refer to your Waltco parts manual when ordering parts. NOTE: When ordering, give model

and serial number of liftgate.

DECALS

important that every vehicle that has a WALTCO Liftgate have legible DECALS clearly posted on

It is

the vehicle and an OWNER’S MANUAL in the vehicle at all times as a guide for proper operation and

maintenance.

Additional DECALS and OWNER’S MANUALS can be obtained from WALTCO LIFT CORP.

80101388 Rev 03 EO 7820

Chapter 1 Safety Information

Page 4

WARNING

Read, understand, and follow all of the warning listed below.

Failure to follow these warning could result in severe personal injury or death.

• Read and understand the Owner’s Manual, all decals and warning on liftgate before operating liftgate.

• Do not operate liftgate without a thorough knowledge and understanding of the operation of the liftgate.

• Liftgate hazards can result in crushing or falling.

• This liftgate is designed for loading and unloading of cargo. If personnel are required to ride liftgate, observe

and familiarize yourself with the liftgate operation, decals and manuals. Ensure stable footing at all times.

• Do not ride liftgate with unstable loads.

• Wheeled loads must be properly retained from rolling.

• Tall, high center of gravity loads must be retained from falling over.

• Never overload liftgate:

Load platform as close to the vehicle, and towards the middle of the platform as possible. Refer to owner’s

manual and capacity decal of liftgate for maximum load and load placement.

• Keep hands and feet clear of all potential pinch points.

• Never use liftgate if it makes any unusual noise, has unusual vibration, raises or lowers unevenly, or fails to

operate smoothly.

• Never use liftgate if it shows any signs of structural damage such as cracked welds, bent or distorted

members.

• Do not attempt any repairs unless you are qualified to do so. Care should be taken when work is performed

on a disabled liftgate located near moving traffic. When possible the vehicle should be moved away from

traffic areas for repair. Precautionary measures should be taken to ensure personal safety including those

recommended in Federal Motor Vehicle Safety Standards 571.125.

• When welding to liftgate, or liftgate components, take all necessary safety precautions, including using

respiratory protection and other pertinent personal protective gear when welding harmful materials.

• All protective covers, guards, and safety devices must be in place and access doors closed before operating

liftgate.

• Do not allow anyone to stand in, or near area, in which Platform will open and close before opening or closing

Platform.

• Do not allow anyone to stand near the Platform where a falling load could land on them.

• Platform is always to be properly stored and secured for transit. See the Owner’s Manual for details.

• Take care to retain cargo during transit for liftgate Platforms which function as the tailgate or door of the cargo

area. Small objects can fall through the space between the vehicle and the folded Platform.

• A Lock-Out device or Shut-Off Switch should always be used to prevent unauthorized use of liftgate.

• For liftgates with Runners, never use liftgate if Runners do not travel freely and smoothly.

• For liftgates with Roller Lifting Chain, the Chain should be replaced every (5) five years or 15,000 cycles,

whichever comes first. Replace only with Waltco approved Roller Chain.

• Never transfer loads which exceed lifting capacity on or over any part of the Platform unless the liftgate is

equipped with a special reinforced Platform and Platform Support Bars for use when the Platform is used as

loading ramp (dock board). Refer to the “Using Platform as a loading ramp” Chapter in the Operation

Instructions of the BZ/RZ series Owner’s Manual.

• For liftgates equipped with Trailer Hitches, never exceed the rated capacity of the hitch. Do not exceed the

vehicle’s weight rating. Refer to the vehicle’s Owner’s Manual.

• Vehicle must comply with all state and federal standards.

• Follow the “Maintenance Guide” chapter in the Owner’s Manual.

80101253 Rev 04 EO 6309JJ

Chapter 1 Safety Information

Page 5

Liftgates with Tilt Function

• Proper use of the Control Switches is of extreme importance.

• Improper use of Tilt Switch could cause load to fall from the Platform or damage the liftgate.

• Platform should be in a generally horizontal position when raising or lowering with a load.

• In any tilt position, the Platform may vary from level while raising or lowering the Platform.

Liftgates equipped with spring operated Cam Closer

• Replace Cam Release Spring every five (5) years or 15,000 cycles, whichever comes first.

RGL-Series Liftgates

• Make certain Platform Brake mechanisms are operating properly.

• The Runners are always to remain powered up against the Upstops Pins when in transit.

• Inspect Cables every three (3) months or 750 cycles, whichever comes first. Cables must be replaced if they

show signs of wear, distortion, kinking or if any broken wires are visible

• Replace cables every five (5) years or 10,000 cycles, whichever comes first.

This is the safety alert symbol. This manual uses this symbol to alert you to potential personal injury

hazards.

Obey all safety messages that follow this symbol to avoid personal injury or death.

SIGNAL WORDS

WARNING

Indicates a potentially hazardous situation, which if not

avoided, could result in death or serious injury.

Black letters on an orange background

CAUTION

Indicates a potentially hazardous situation, which if not

avoided, may result in minor or moderate injury. May

also be used to alert against unsafe practices.

Black letters on a yellow background.

NOTICE

Indicates a potentially hazardous situation, which if not

avoided, may result in property damage.

WARNING

CAUTION

NOTICE

80101253 Rev 04 EO 6309JJ

WALTCO warrants its products free of defects in materials and workmanship.

Waltco Lift Corp

Page 6

WALTCO

will replace components found defective during the warranty period. Labor will be

reimbursed according to our flat rate labor schedule at the prevailing shop rate.

Contact our Sales or Warranty departments for the warranty period of your model or for

information regarding our flat rate labor schedule.

WALTCO Warranty Claim Procedure

For consideration, all claims must be received within 30 days of repair and include the following

inform

Replacement warranty parts can be obtained by contacting Waltco’s Parts Department.

Parts must be returned for inspection when requested.

Exclusions:

Waltco’s warranty does not include reimbursement for service calls, vehicle rental, towing, travel

time, fabrication of parts available from WALTCO, damage from misuse or abuse, negligence,

accidents, alteration, loss of income or overtime expense, oil, or normal wear.

ation:

• Liftgate Serial Number

• Description of problem and corrective actions

• Itemization of the labor charge to include the number of hours and labor rate

Diagnosis and troubleshooting time are included in the flat rate labor times.

Warranty and technical information is available from WALTCO’s toll free customer service lines

from 8:00 a.m. to 5:00 p.m. EST.

285 Northeast Ave, Box 354, Tallmadge, OH 44278

1-800-211-3074, 330-633-9191

Please visit our websites: http://www.waltco.com or http://www.hiab.com

We're behind you all the way!

EO:7714 Rev 01

5-2015 80101667

Chapter 2 Liftgate Terminology

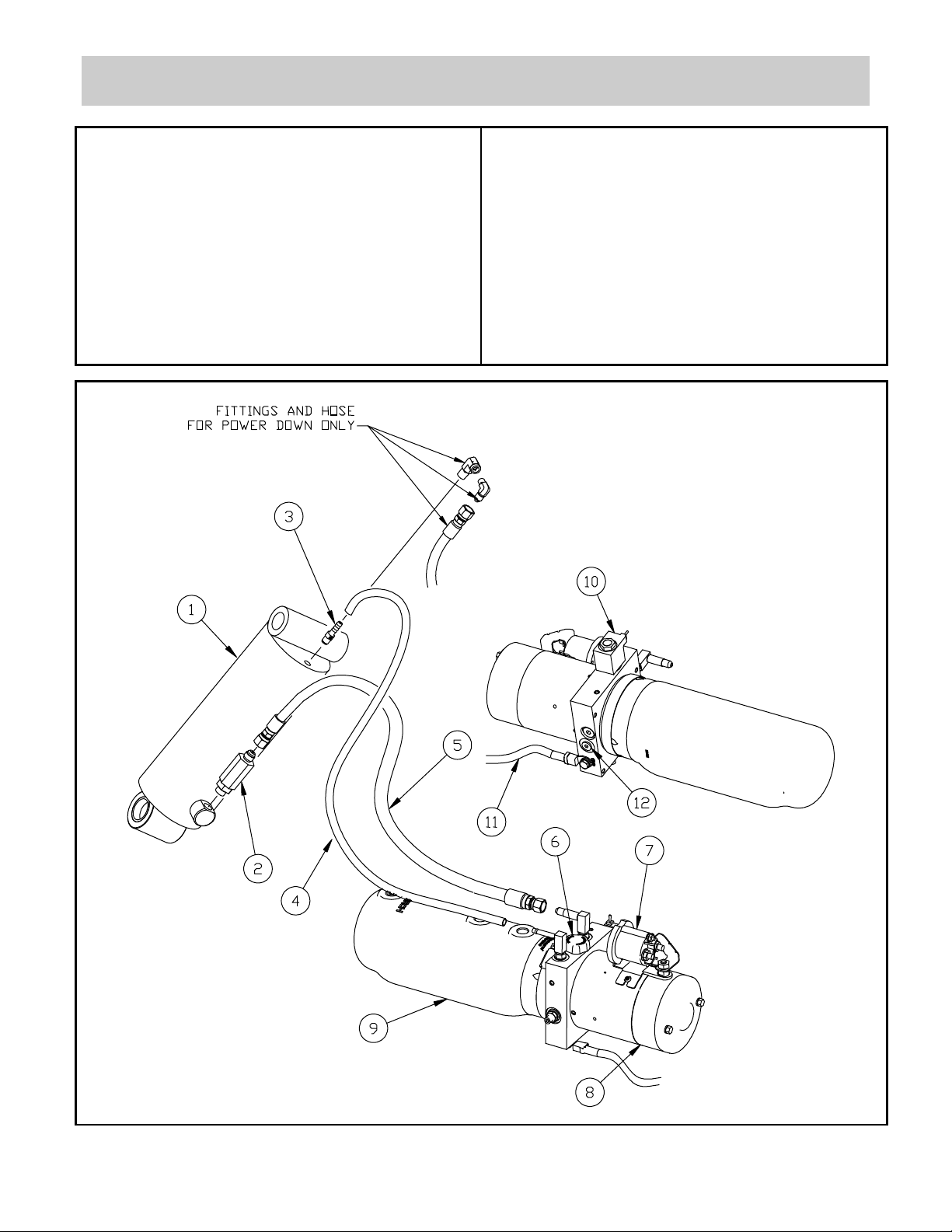

GR02636

Page 7

1. Hydraulic Cylinder

2. Flow Control Valve

3. Return Line Barbed Fitting (Gravity Down)

4. Return Line (Gravity Down)

5. Raise Hose Assembly

6. Breather Cap

7. Pump Unit Starter Solenoid

8. Motor

9. Reservoir

10. Lowering Valve Coil

11. Ground Cable

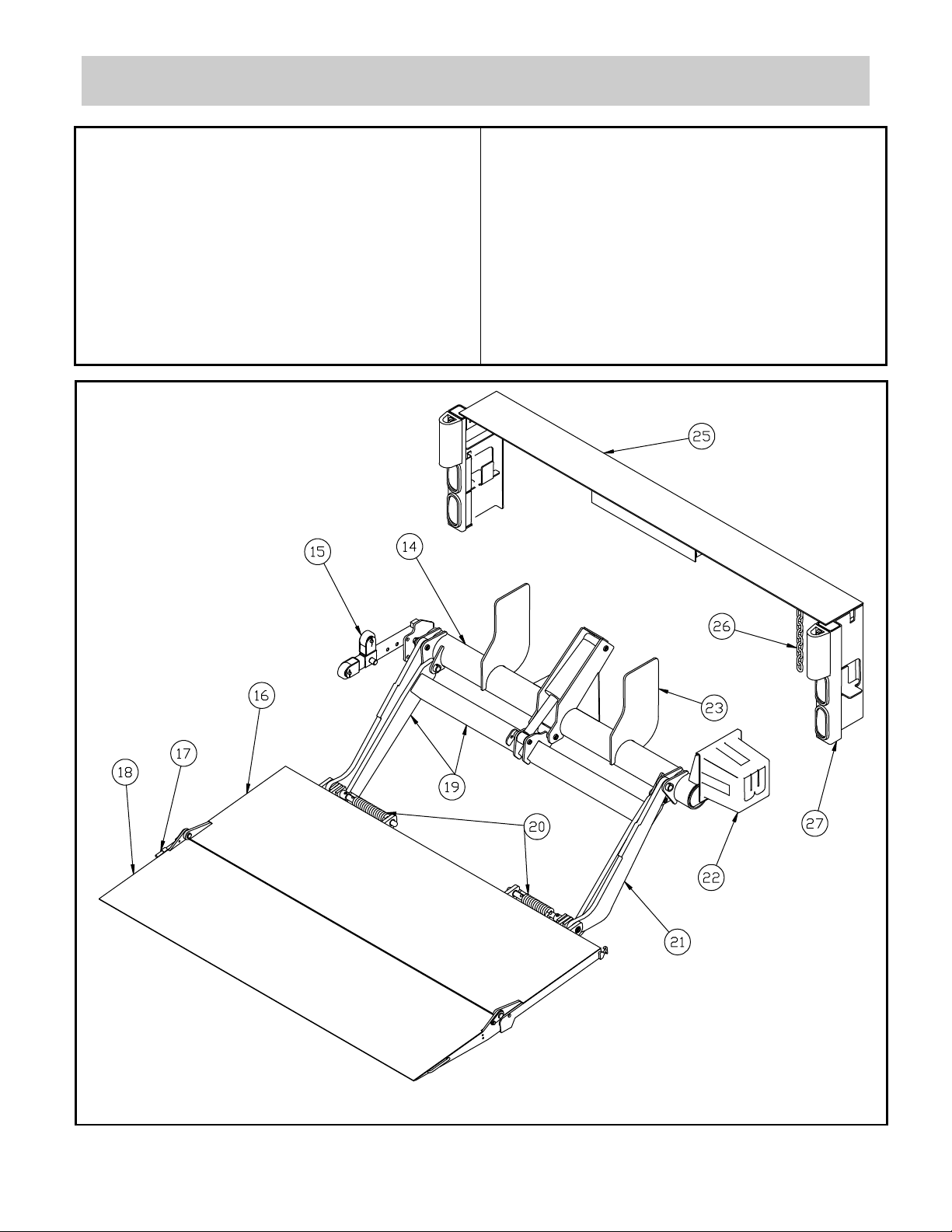

Chapter 2 Liftgate Terminology

GR0

2637

Page 8

14. Mount Tube Assembly

15. Parting Bar Assembly

16. Deck Assembly

17. Torsion Bar

18. Deck Extension Assembly

19. Lift Arm Assembly

20. Folding Assist Springs

21. Parallel Arm

22. Pump Cover

23. Mount Plate

24. Spec Tag (see following page)

25. Bed Extension

26. Transit Chain

27. Dock Bumper

Loading...

Loading...